Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Easy to cool and form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

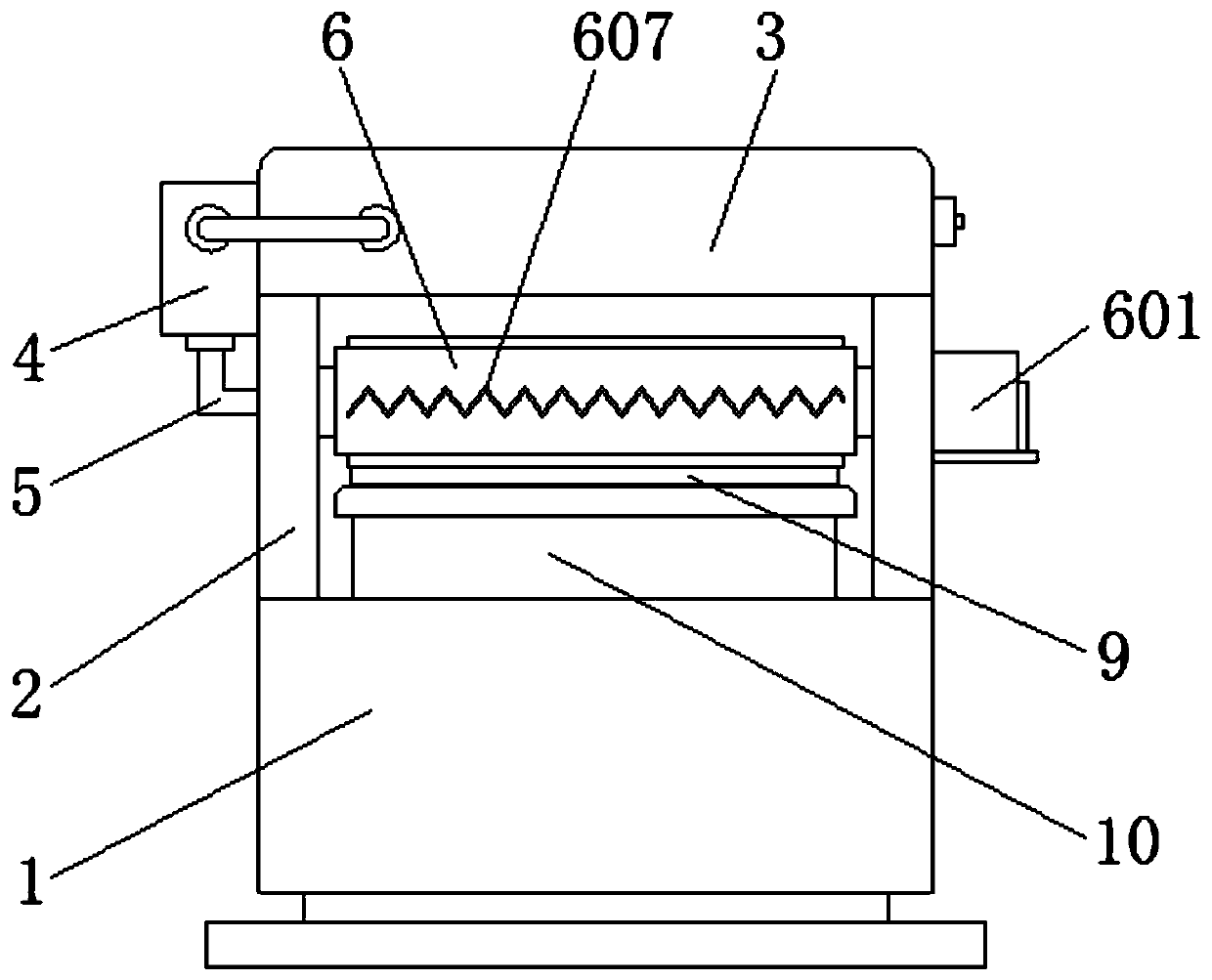

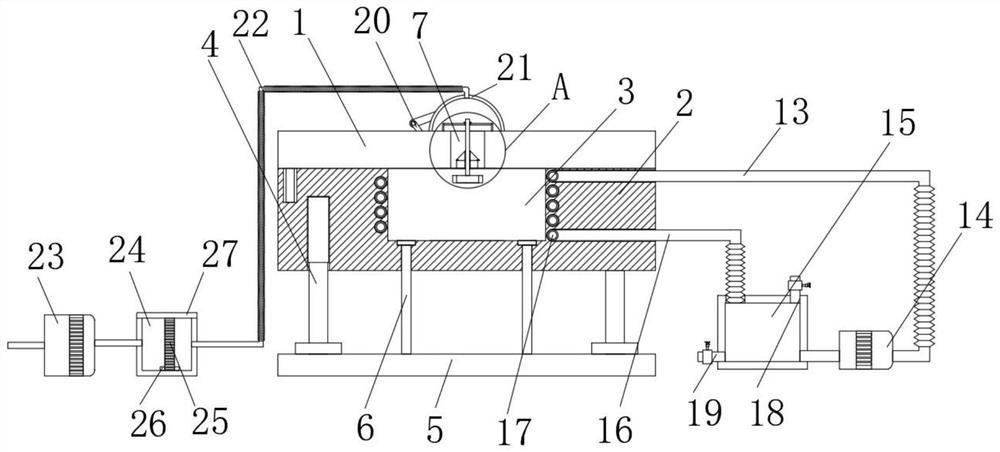

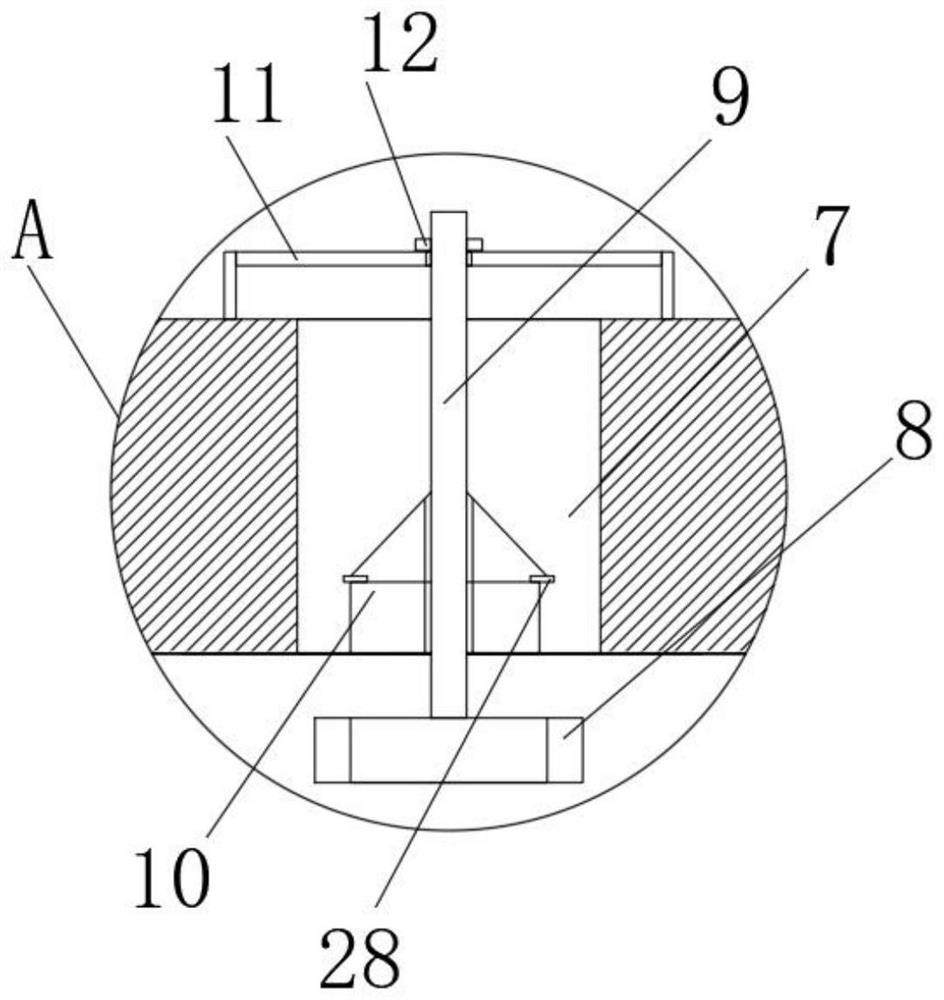

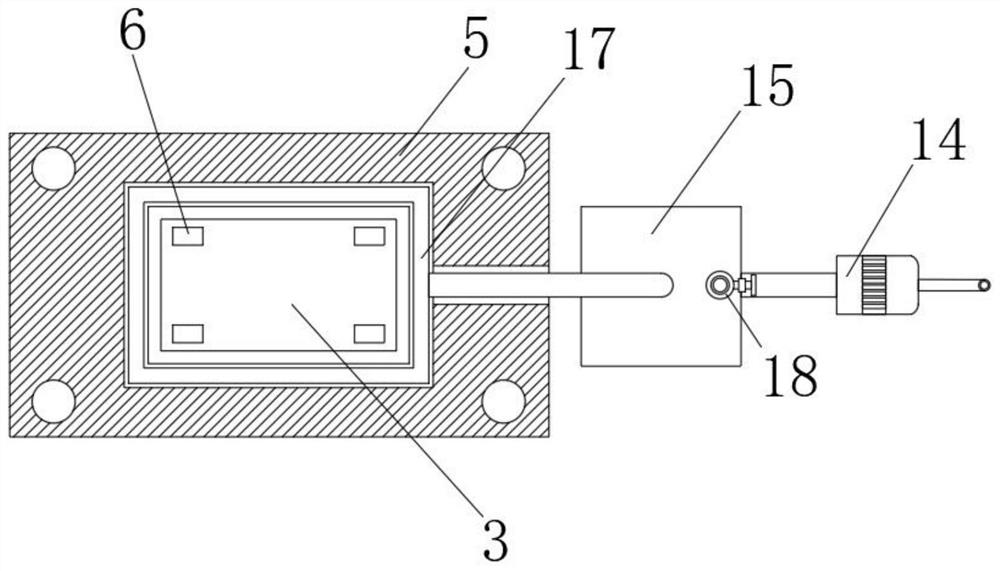

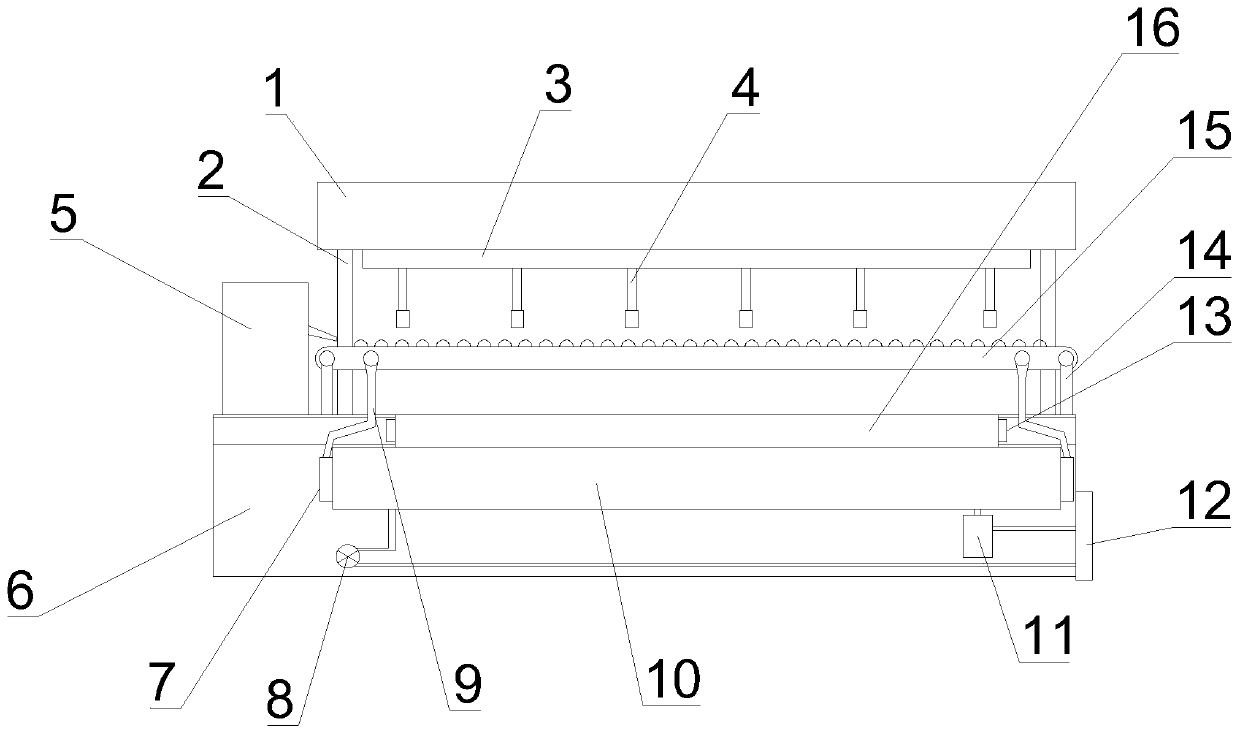

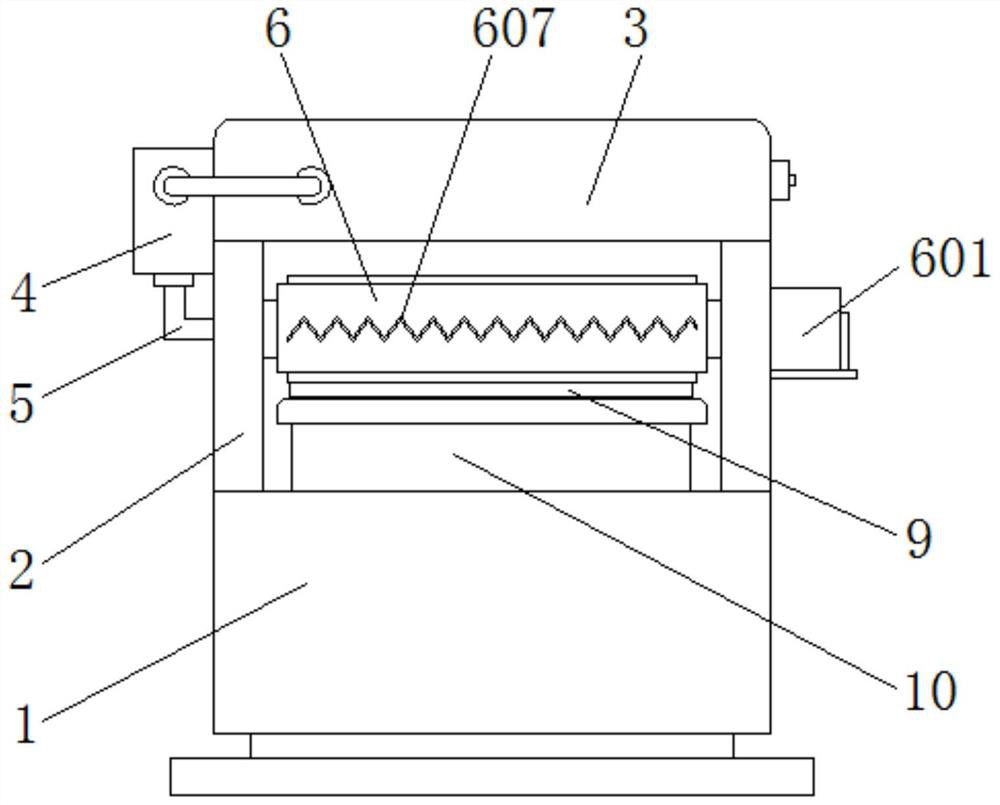

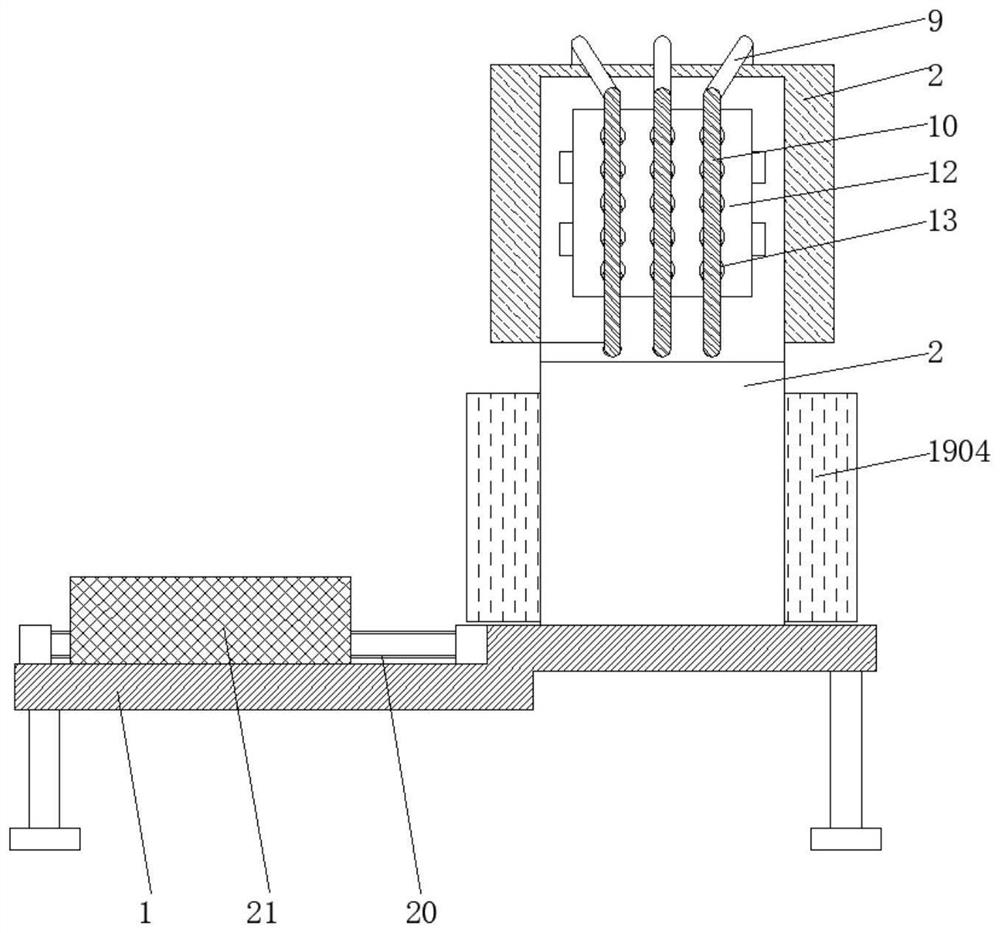

Electric kettle handle machining device

The invention relates to a handle processing device for an electric kettle, comprising a motor, a heating sheet, a control box, a stirring fan blade, a temperature sensor, a receiving water tank, a support base, a booster pump, a first half module, a second half module and a box One side of the top of the support base is equipped with a support frame, and the top of the support base inside the support frame is equipped with a receiving water tank, and a connecting cross bar is evenly installed horizontally between the top ends of the support frame, and the connecting cross bar A slide rail is arranged at the middle position of the bottom end of the rod. The invention is equipped with a motor, a stirring shaft, a stirring blade, a heating plate and a temperature sensor. When in use, the liquid enters the box, and then the heating plate is heated through the control box, so that the liquid is fully dissolved, and the motor is started to drive the stirring shaft. Stir the liquid together with the stirring fan to make it uniform, which is convenient for later cooling and forming.

Owner:潘统谟

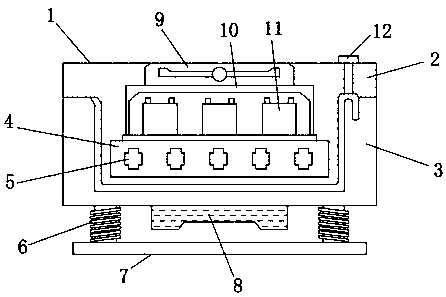

Injection mold for refrigerator drawer

PendingCN110406026AEfficient cooling and heat dissipationImprove cooling effectDomestic articlesCooling effectSemiconductor

The invention discloses an injection mold for a refrigerator drawer. The injection mold comprises a mold main body, an upper mold body and a lower mold body, wherein the mold main body is composed ofthe upper mold body and the lower mold body, the upper mold body is positioned above the lower mold body, a heat dissipation pipeline is arranged inside the mold main body, a cavity is fixedly connected to the upper part of the heat dissipation pipeline, a semiconductor refrigerator is arranged inside the cavity, a heat dissipation fan is inlaid at the upper part of the cavity, and an injection molding opening is formed in one end of the upper part of the mold main body. According to the mold, by arranging an ice crystal, a graphene heat conduction layer, a semiconductor refrigerator and the heat dissipation fan, the upper mold body is effectively cooled, the cooling effect of the mold main body is improved, cooling forming of the refrigerator drawer is facilitated, the forming uniformityof the mold main body is effectively improved by arranging a vibration motor and a vibration spring, bubble grooves and the like are avoided, the formed refrigerator drawer can be slowly pushed out ofthe mold by arranging a hydraulic rod and a sliding block, and the lower mold body can be conveniently separated from the refrigerator drawer.

Owner:合肥高科科技股份有限公司

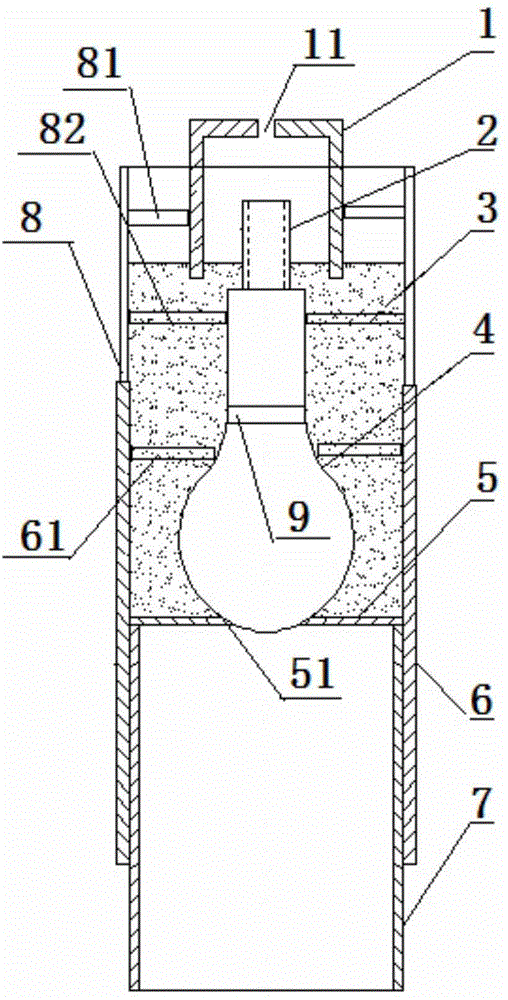

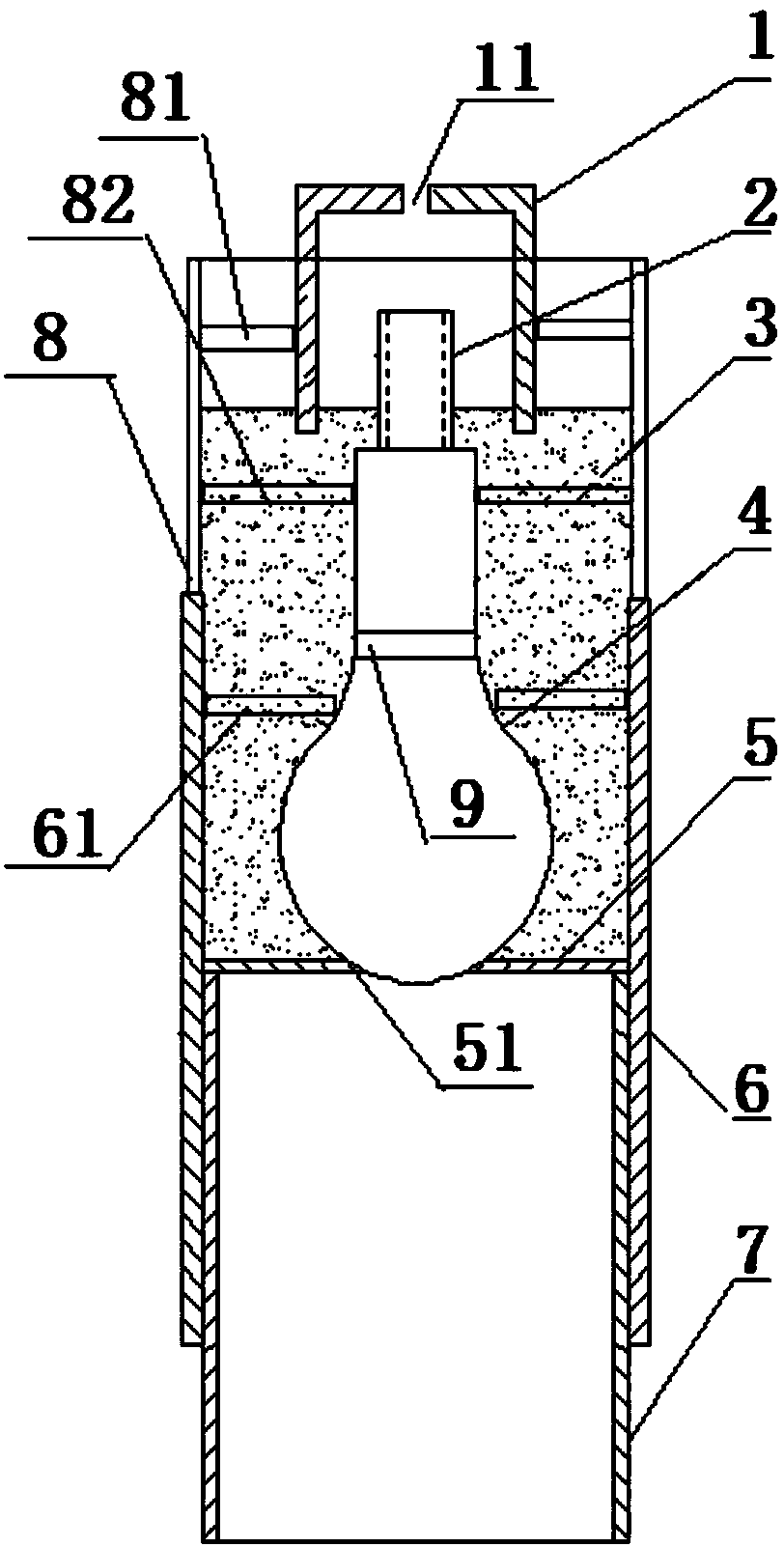

Tool for manufacturing molten steel sampler and method for manufacturing molten steel sampler by adopting tool

The invention belongs to the technical field of tools for manufacturing molten steel samplers and discloses a tool for manufacturing a molten steel sampler and a method for manufacturing the molten steel sampler by adopting the tool. The tool comprises a metal cap, a quartz tube, precoated sand, a sample box, a base plate, an outer protective casing pipe, an inner protective casing pipe and a metal sleeve, wherein the outer diameter of the inner protective casing pipe is equal to the inner diameter of the outer protective casing pipe, and the lower half part of the outer protective casing pipe is sleeved with the inner protective casing pipe; the base plate covers the upper end surface of the inner protective casing pipe; the sample box adopts a flat structure and is formed by buckling two symmetrical half box bodies; the quartz tube is seamlessly inserted into a handle of the sample box; the inner diameter of the metal casing pipe is equal to that of the outer protective casing pipe, and the metal casing pipe is arranged on the upper end surface of the outer protective casing pipe; a gap between a cavity formed by the metal casing pipe, the outer protective casing pipe and the base plate and the sample box is filled with the procoated sand, and a filling surface is lower than the pipe orifice of the metal casing pipe; the open end of the metal cap is inserted into the precoated sand, and the sealed end of the quartz tube covers the top of the quartz tube. By means of the molten steel sampler manufactured by adopting the tool, sampling can be quickly performed, the sample box is easy to take out, and the manufacturing cost is low.

Owner:马鞍山市东江冶金材料有限公司

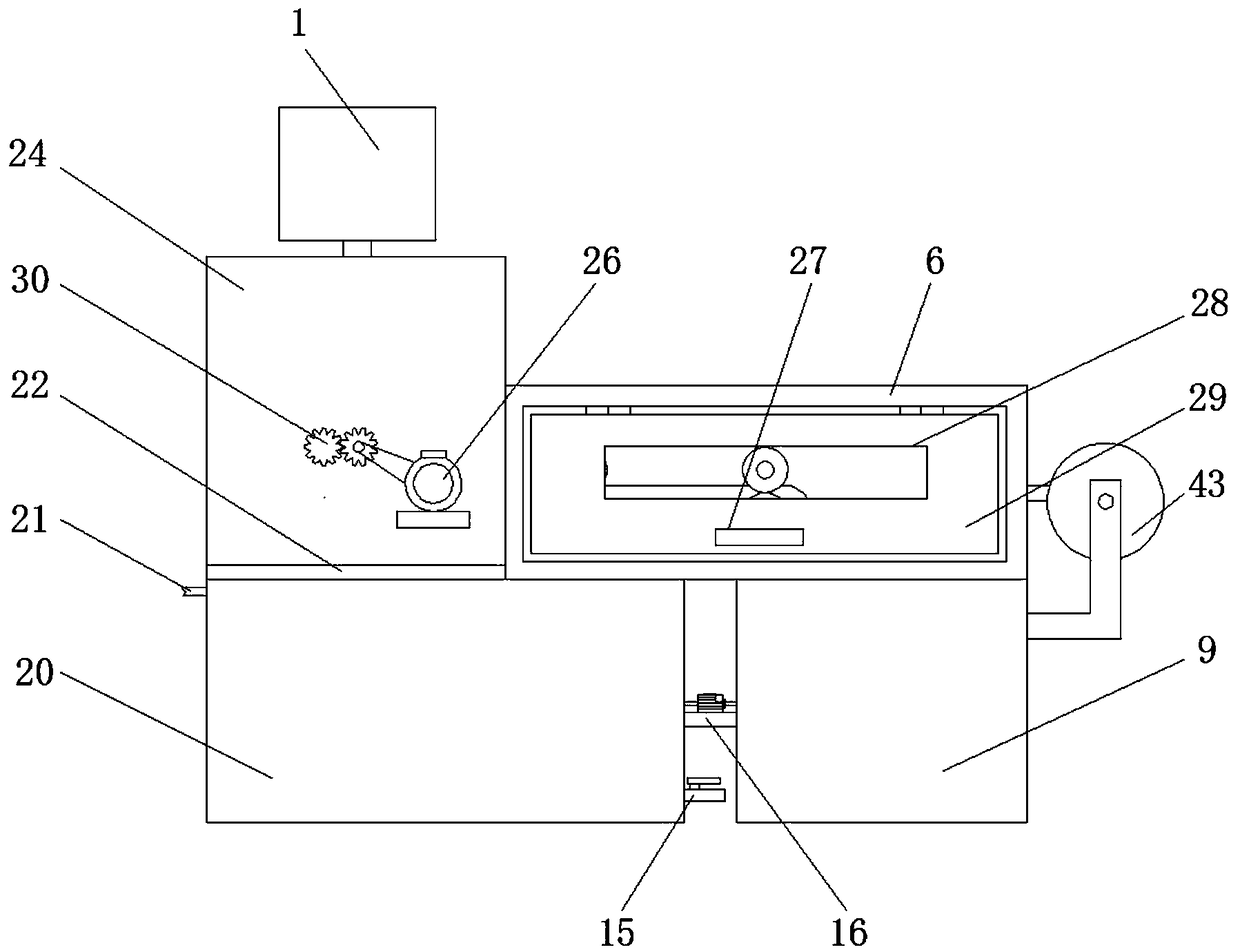

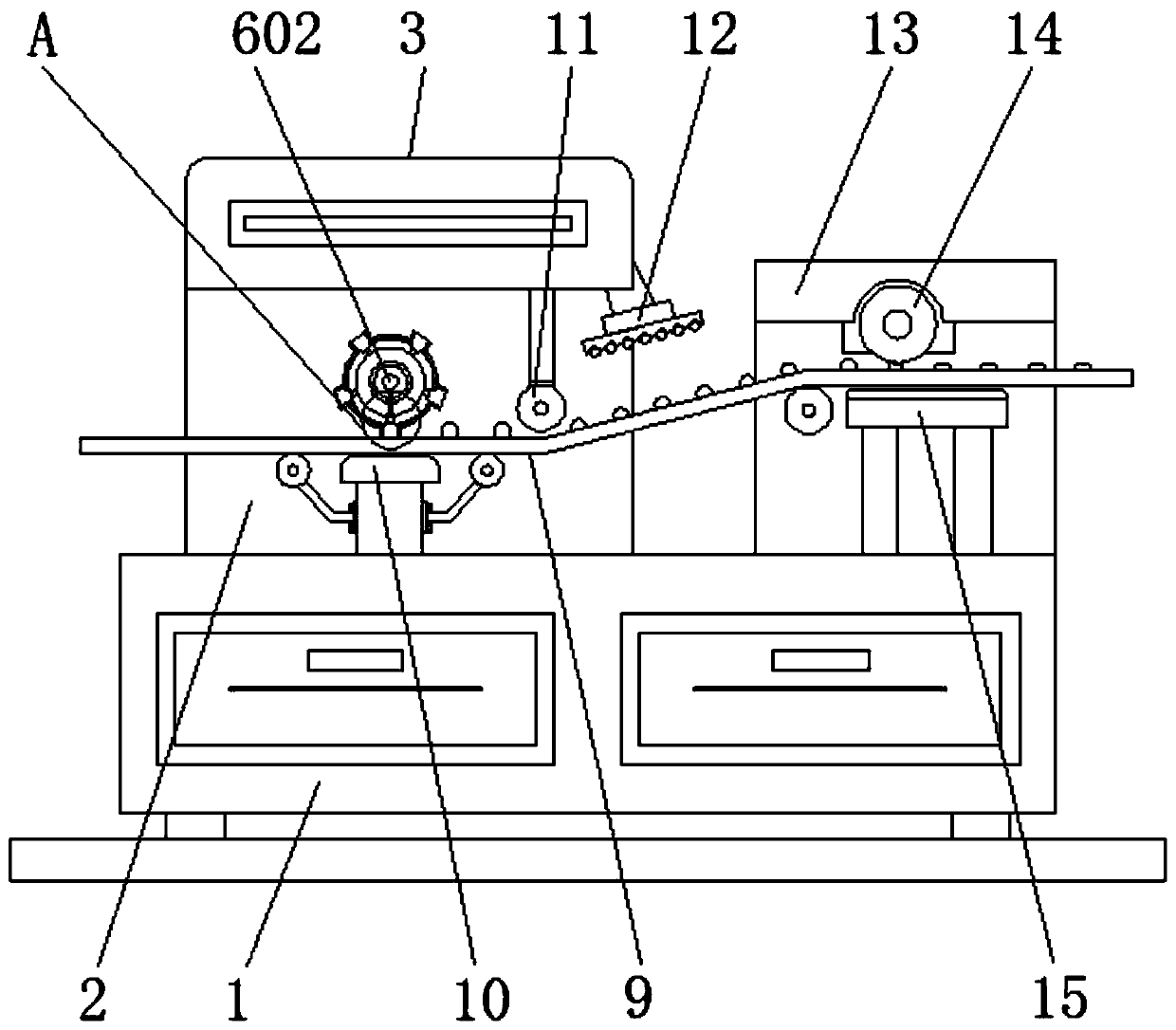

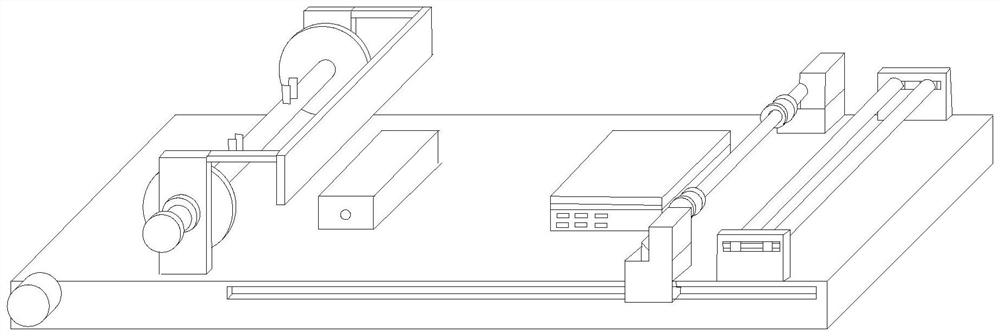

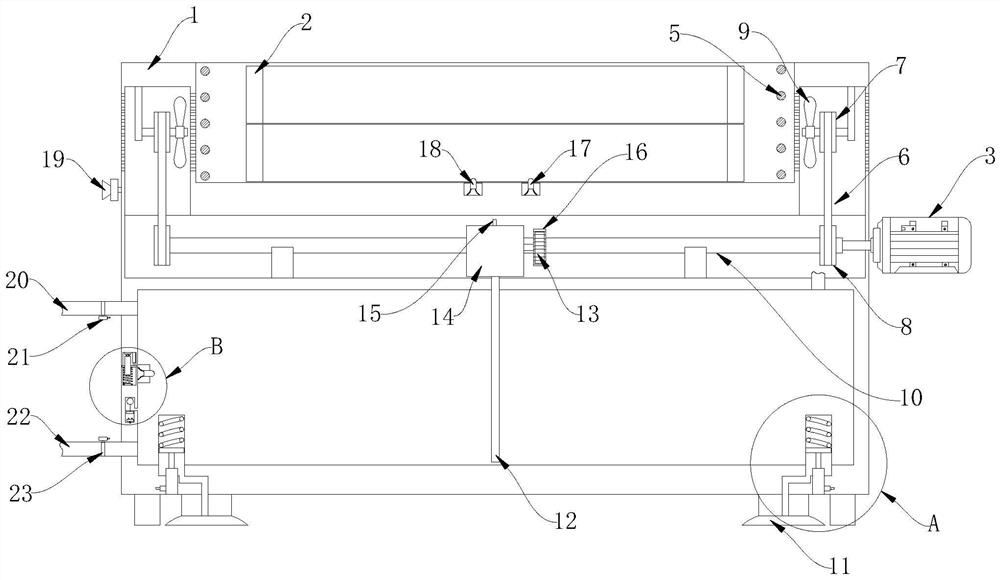

Efficient 3D printing consumable drawing device

The invention discloses an efficient 3D printing consumable drawing device. The efficient 3D printing consumable drawing device comprises an extruding machine, a paraffin removing tank, a water cooling tank, a shell and a paraffin applying bucket; a supporting plate is arranged at one end of the top of the water cooling tank, and the shell is welded to the top of the supporting plate; the paraffinremoving tank is connected to one side of the water cooling tank; and a fixing plate is welded between the paraffin removing tank and the water cooling tank, a first water pump is fixed to the top ofthe fixing plate, and a water inlet pipe is connected to the input end of the first water pump. According to the efficient 3D printing consumable drawing device, scraper blades matched with first guiding wheels are welded to the two sides of the interior of the shell in an oblique downward mode, a collecting tank is arranged under the scraper blades, a heating water chamber is arranged in the side wall of the shell, therefore, excess liquid paraffin remaining on the outer surfaces of extruded wires on the first guiding wheels can be conveniently scraped by the scraper blades, the scraped excess liquid paraffin is guided into the collecting tank to be cyclically utilized through the flow guiding property of the oblique scraper blades, and the internal temperature of the shell can be kept at a certain temperature through the heating water chamber, so that the paraffin keeps the liquid state.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

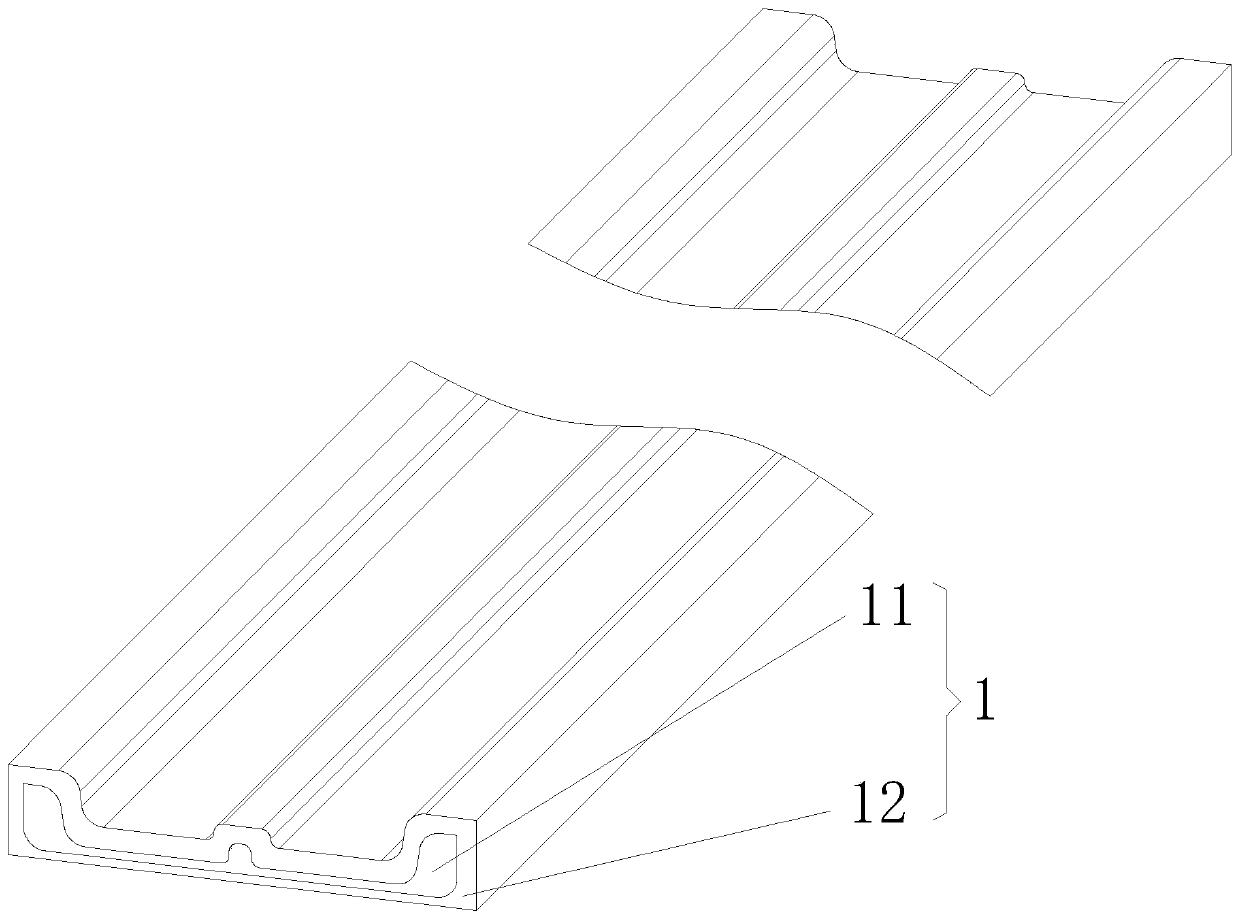

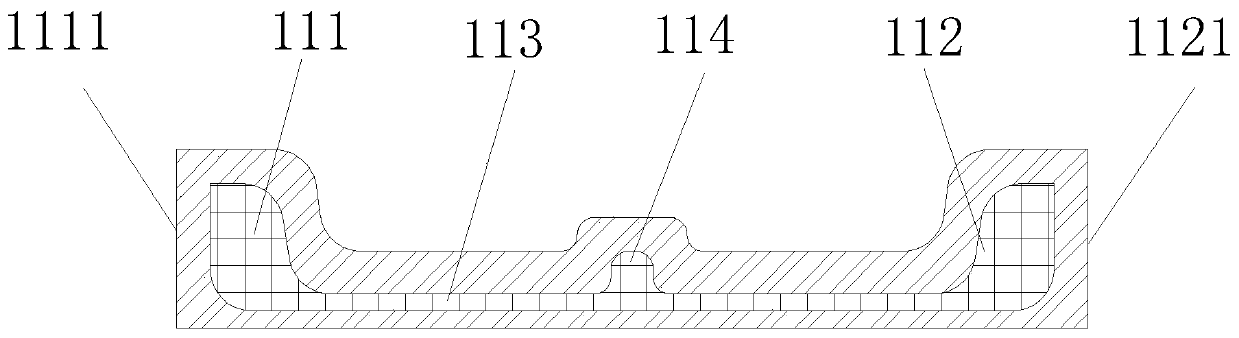

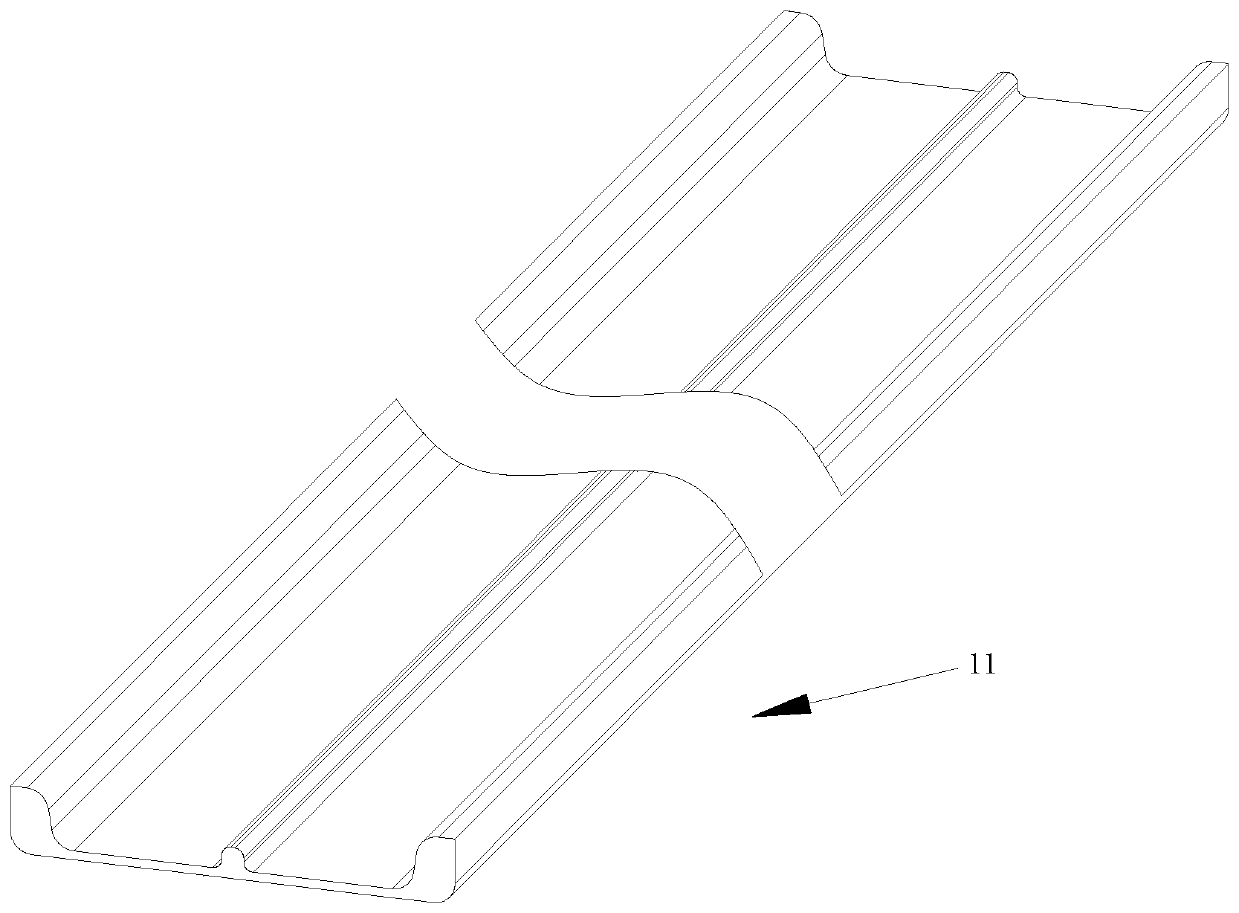

Hot winding solid corrugated pipe, sectional material thereof and manufacturing method thereof

PendingCN110588032AEasy to cool and formIncrease production speedRigid pipesTubular articlesSolid wallShock resistance

The invention relates to a hot winding solid corrugated pipe, and a sectional material and manufacturing method thereof. The sectional material of the hot winding solid corrugated pipe comprises a first sectional material and a second sectional material; the first sectional material comprises a supporting rib and a first hot coating layer; the first sectional material comprises a connecting strip,a first half wave crest strip and a second half wave crest strip; the second sectional material comprises a buckle plate and a second hot coating layer; a buckling groove is formed in the middle partof the second sectional material; and the shape and size of the buckling groove are matched with the shape and size of the outer wall of a small wave crest structure formed by splicing the first halfwave crest strip and the second half wave crest strip. The sectional material adopts the first sectional material and the second sectional material which are solid wall structures, and the sectionalmaterial can facilitate the cooling forming of a pipe, the production speed of the pipe is increased and the welding quality of the pipe can be improved. The solid corrugated pipe is of a solid wall structure, and is high in ring stiffness, good in impact resistance and destruction resistance, and excellent in ring flexibility. The manufacturing method of the corrugated pipe adopts hot winding tocompound all units together, the welding strength is high and the residual stress problem basically does not exist.

Owner:萍乡市大地新材料科技有限公司

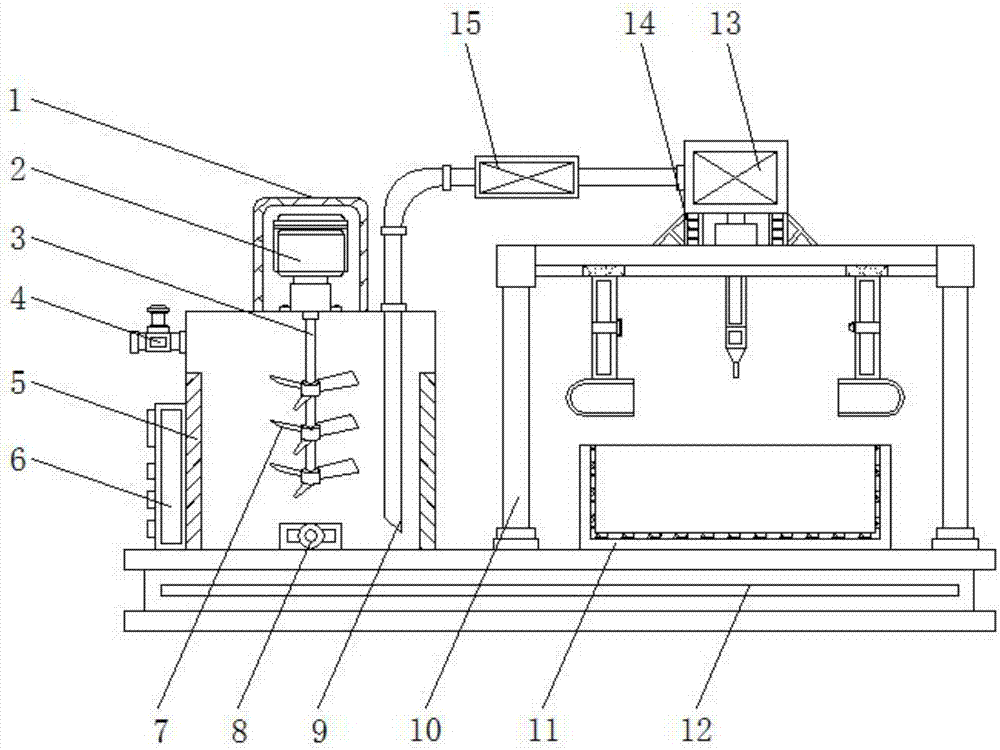

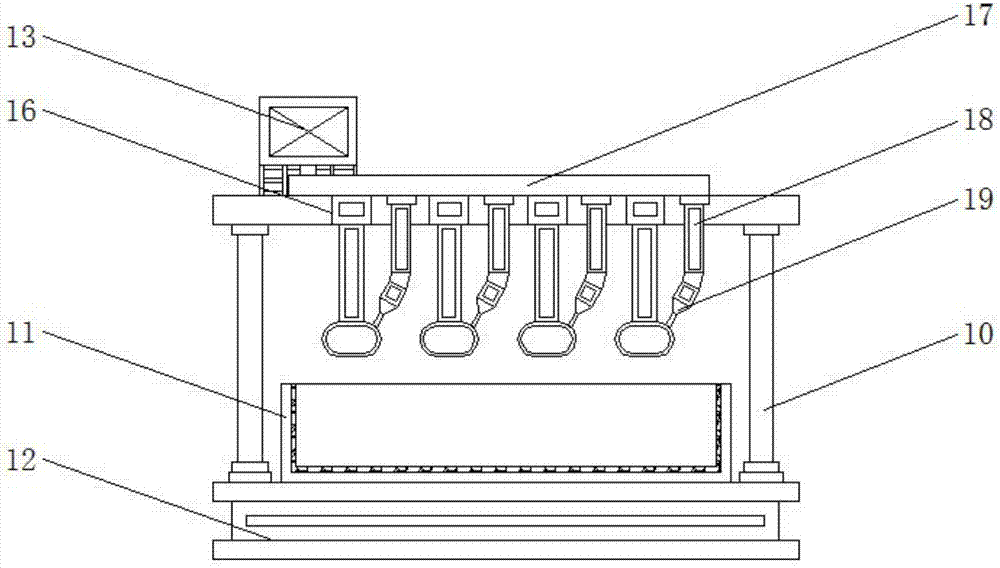

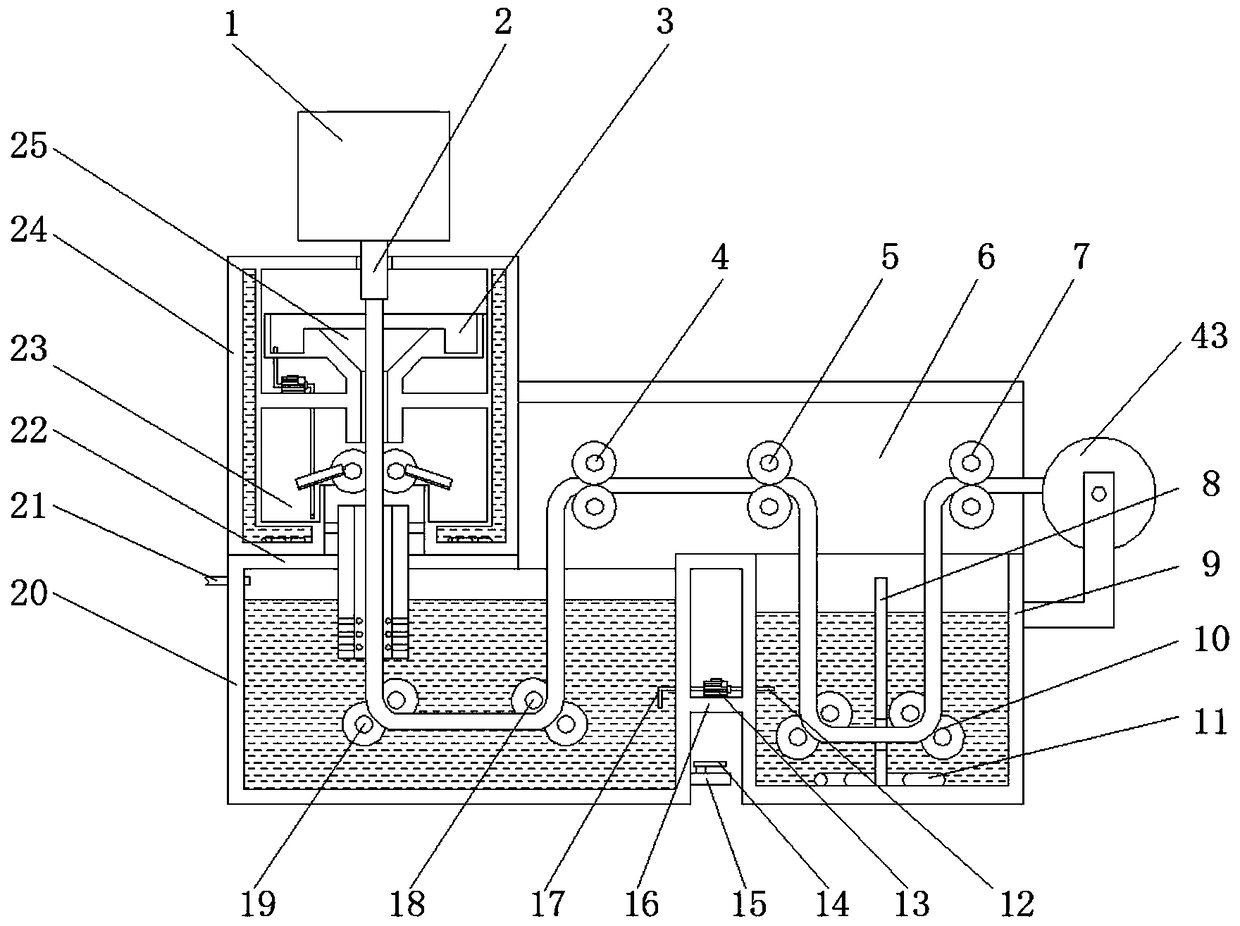

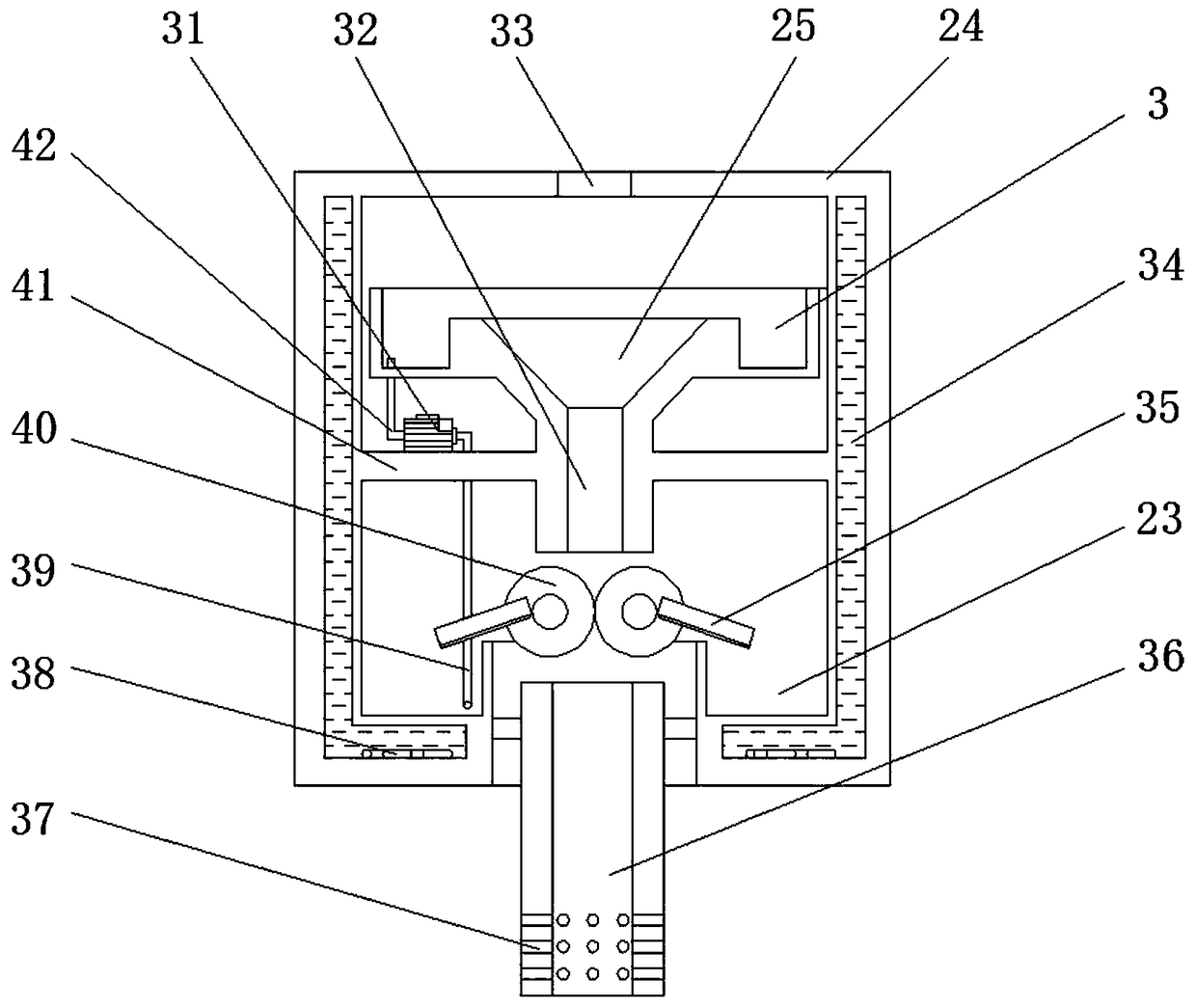

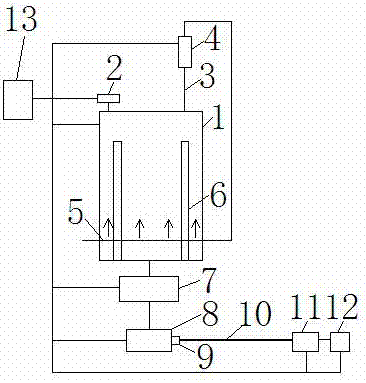

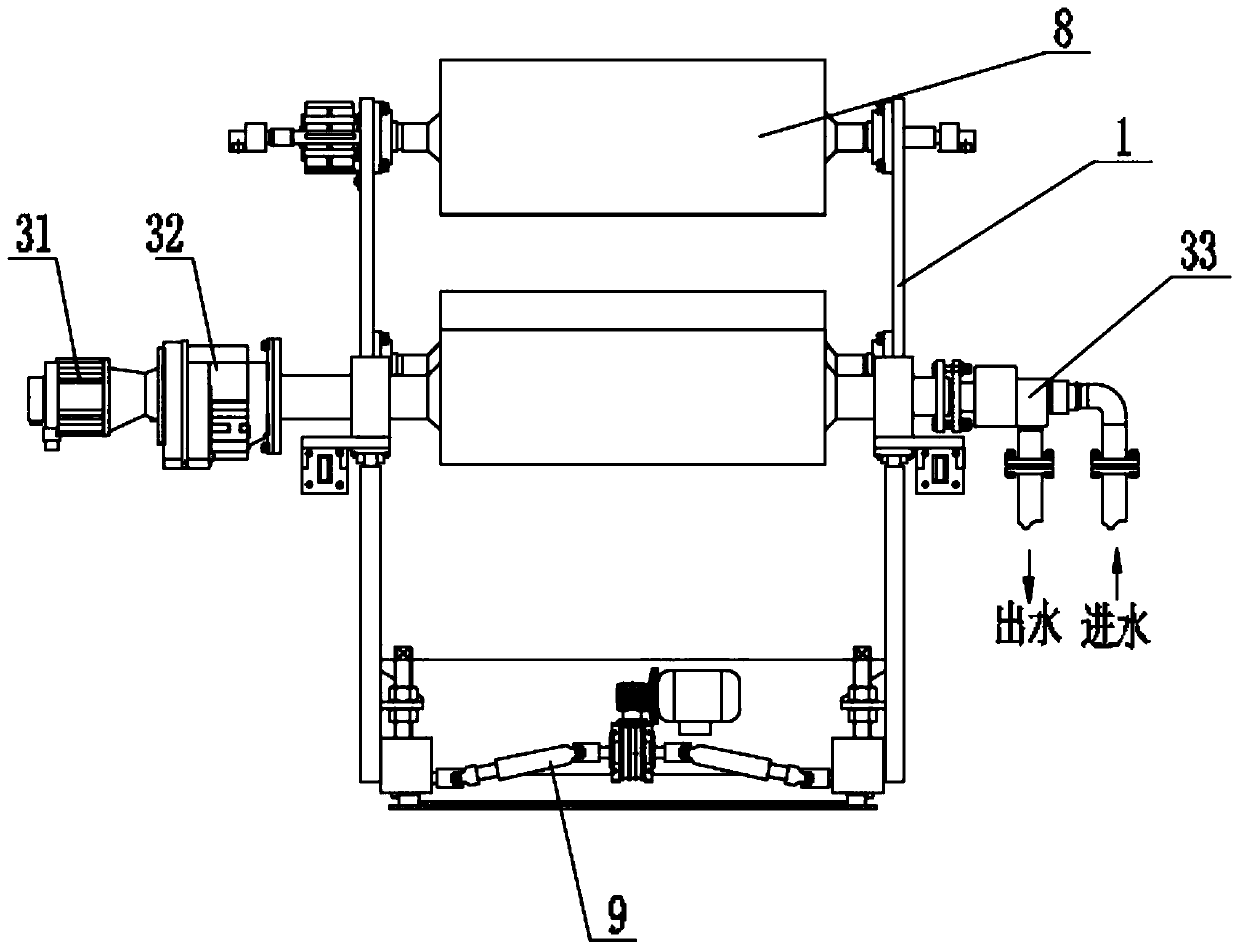

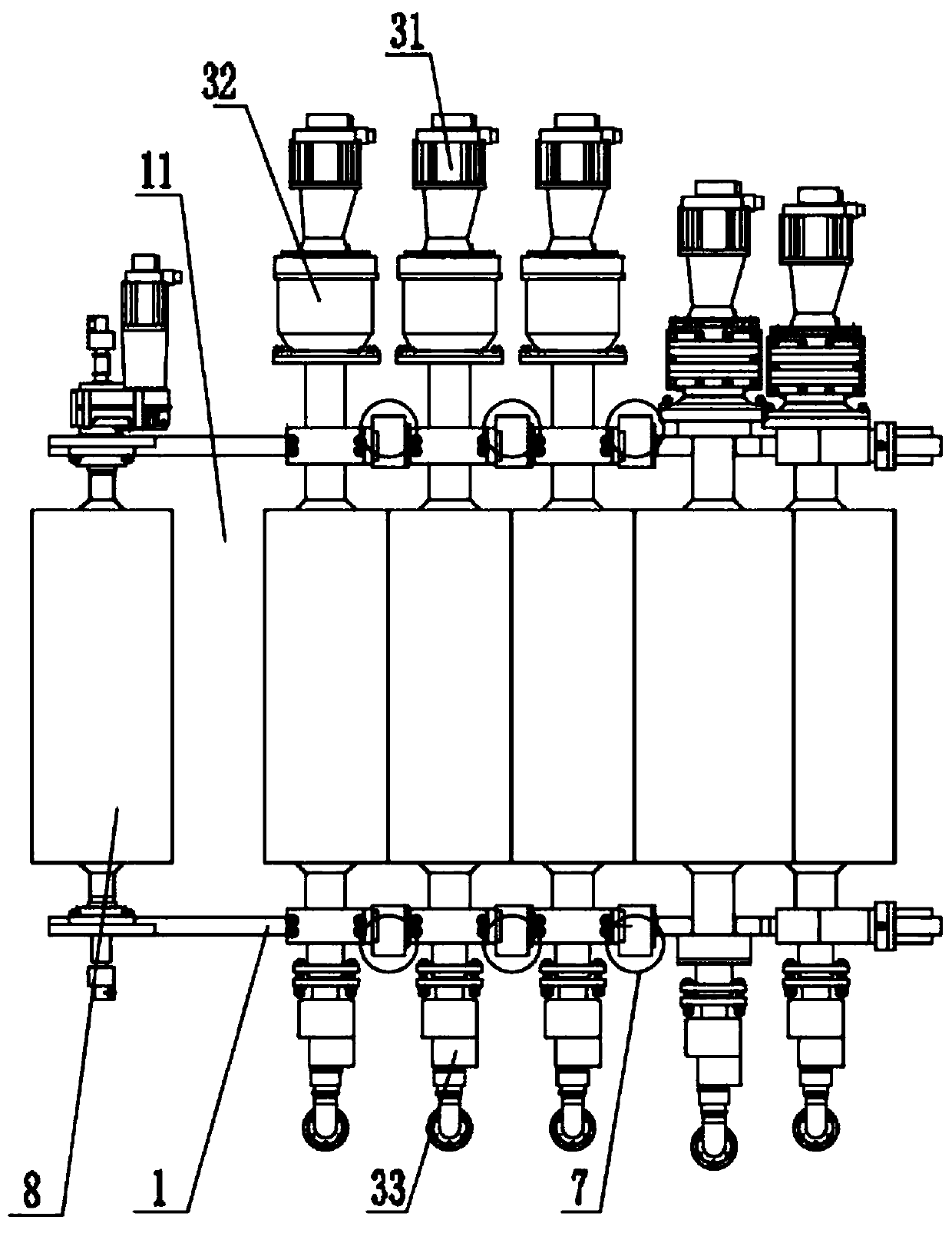

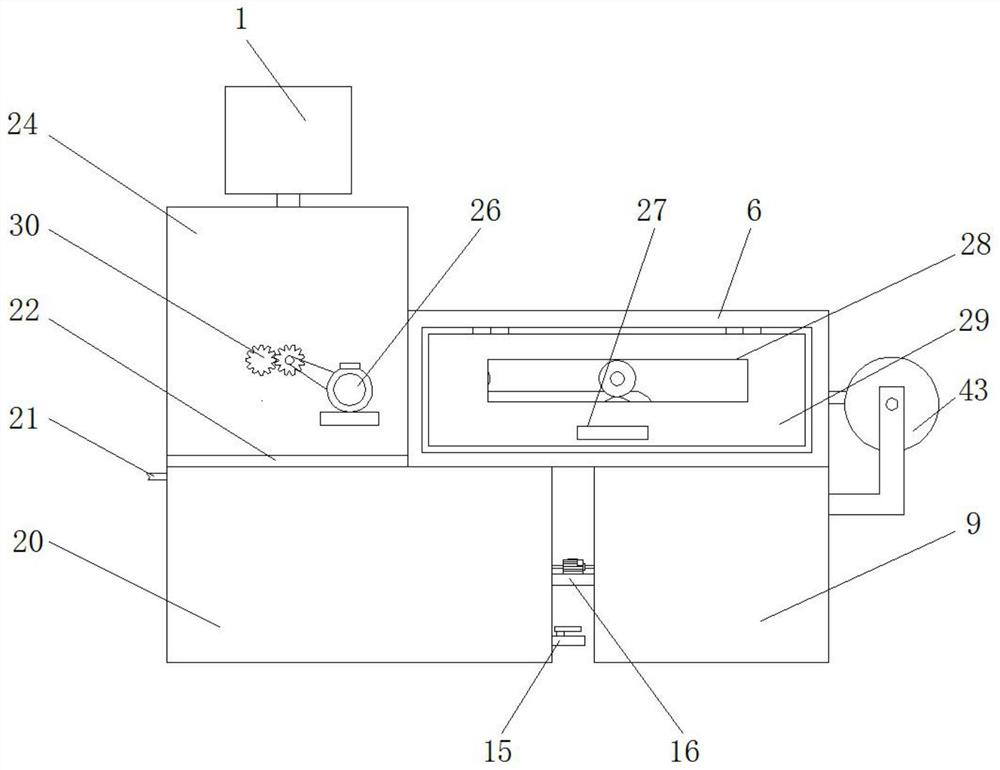

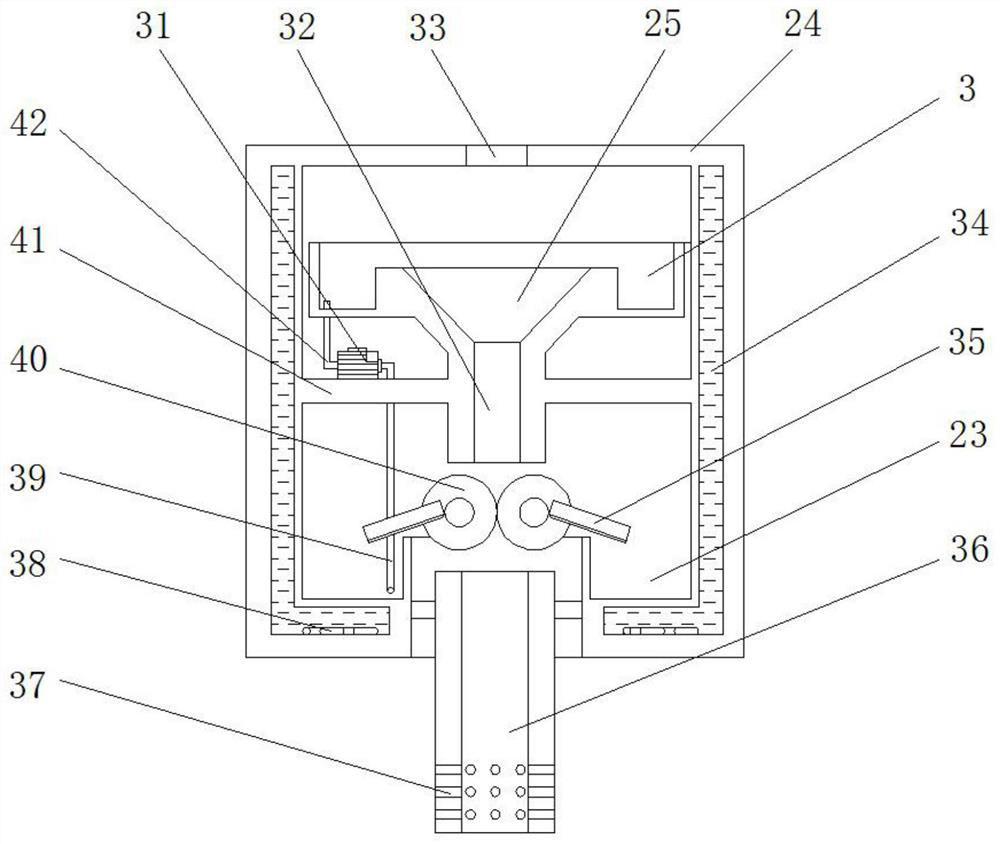

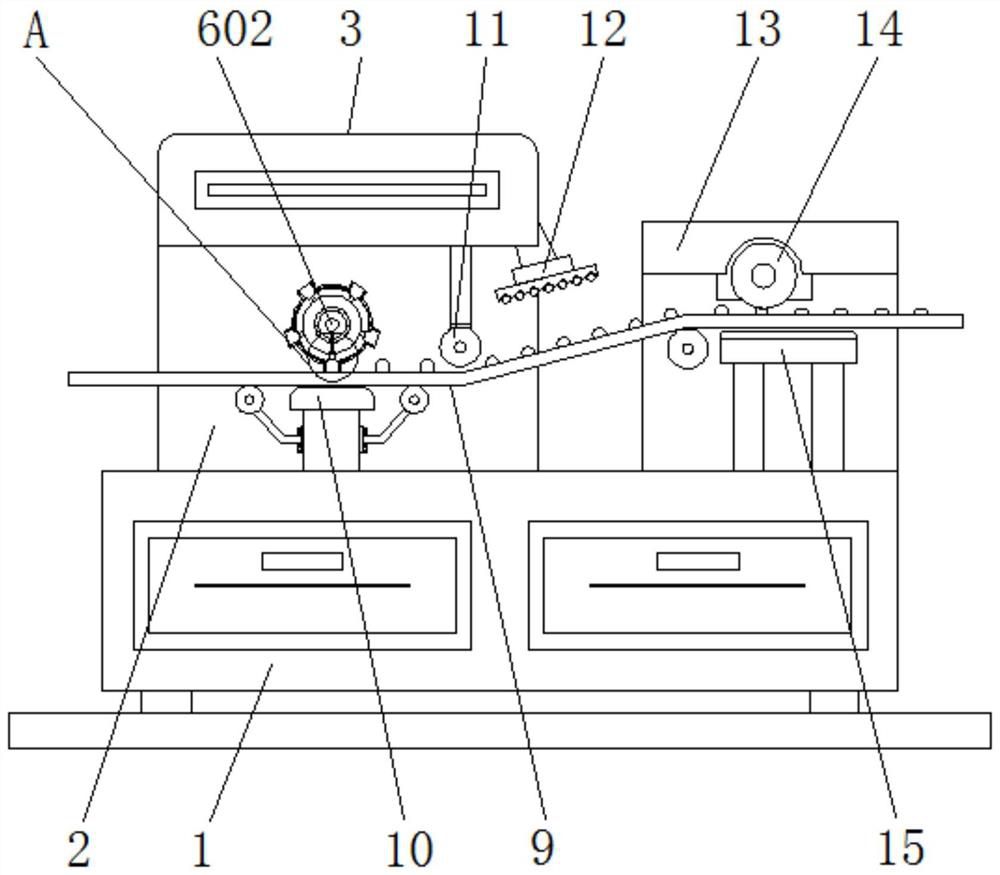

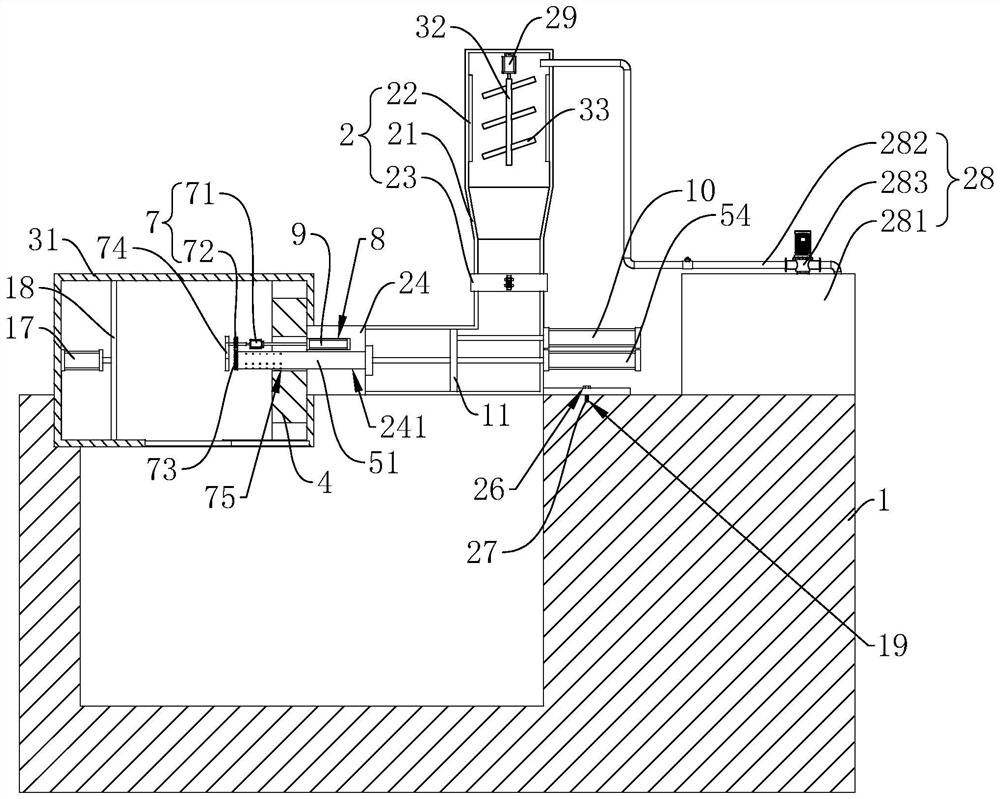

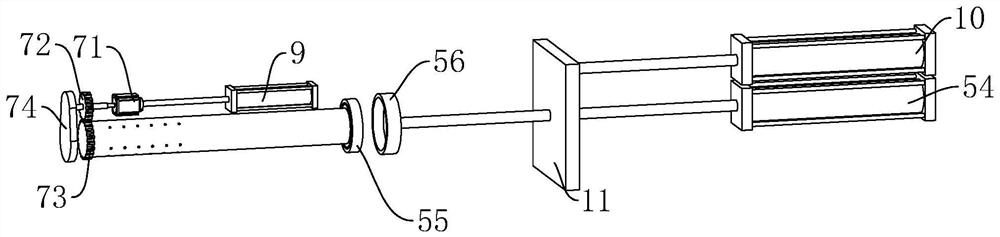

Automatic production system for hot melt adhesive

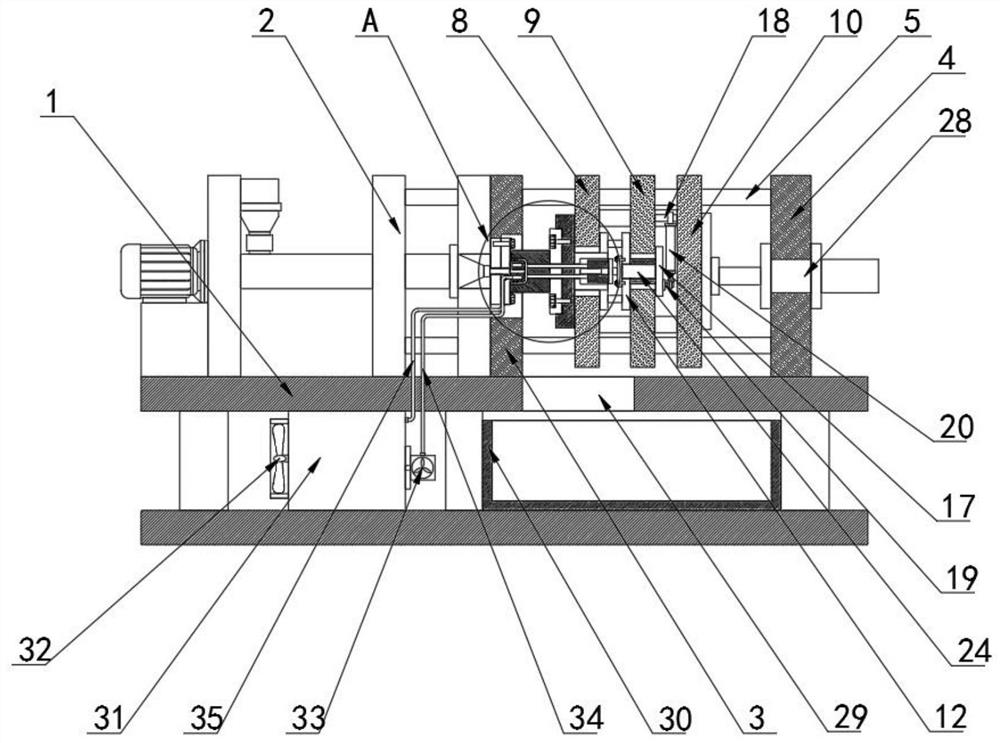

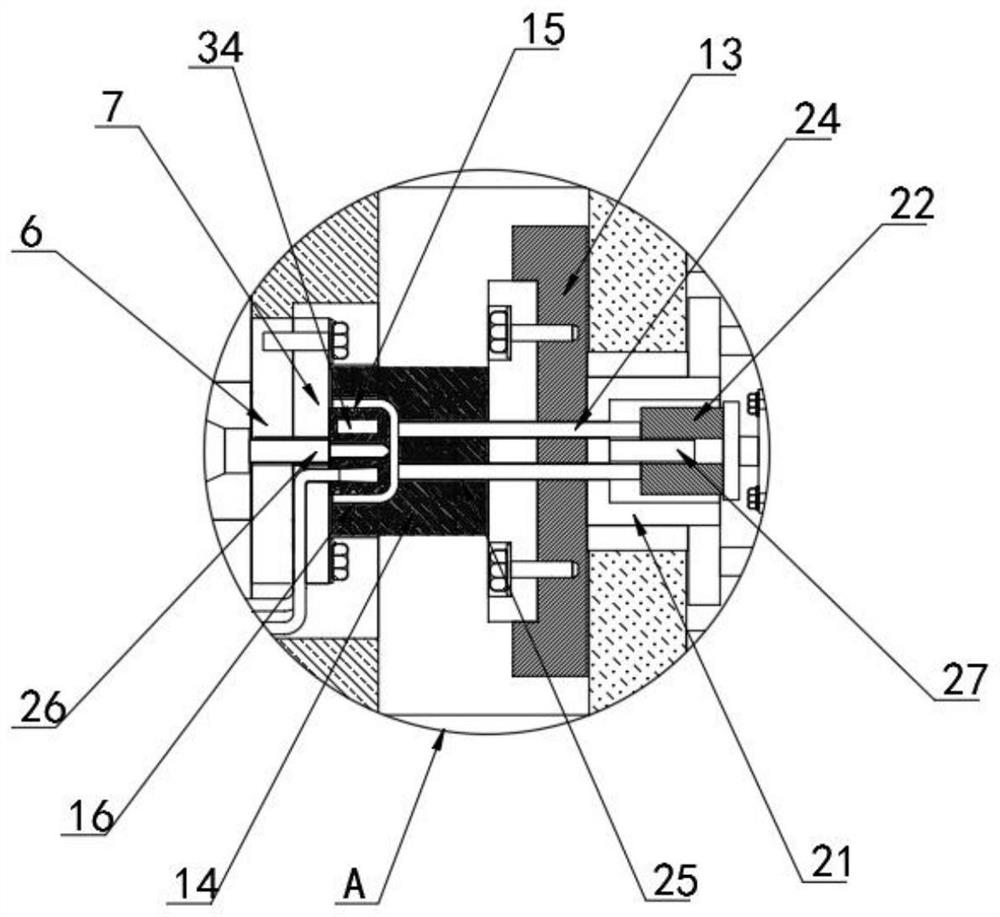

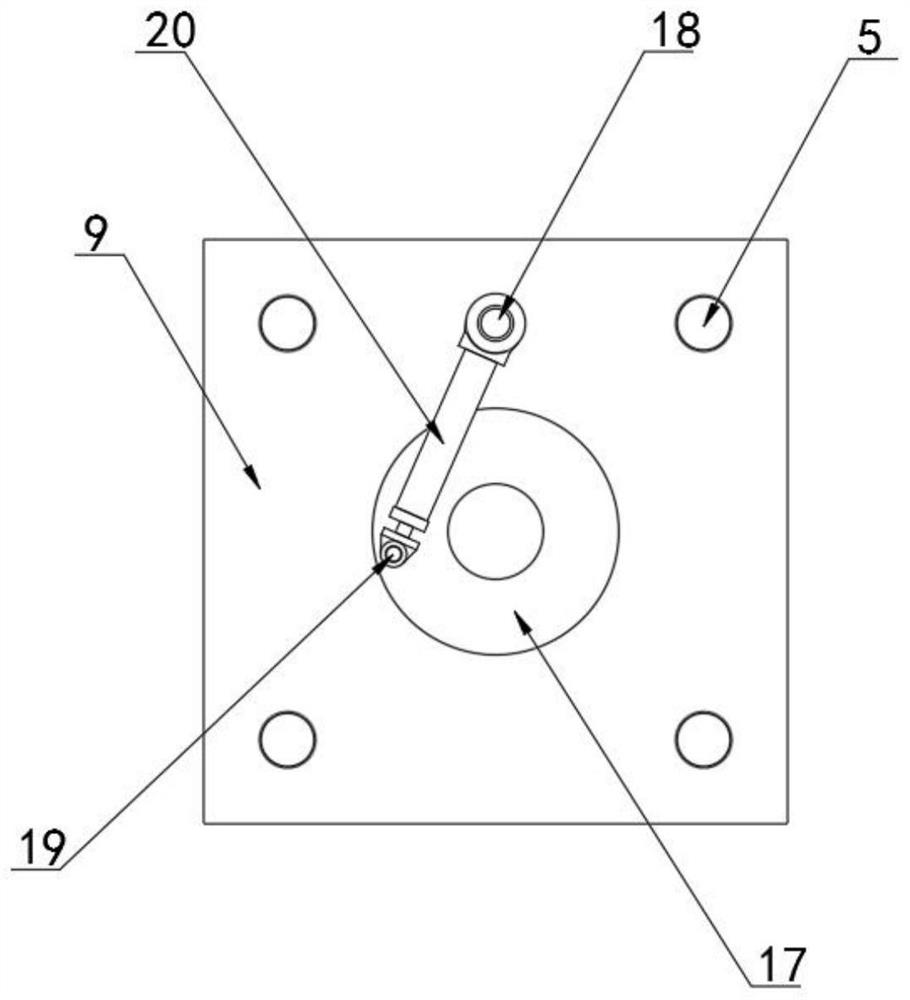

InactiveCN107442049AEasy to cool and formAchieve recyclingProcess control/regulationInert gas productionProcess engineeringHot-melt adhesive

The invention relates to an automatic production system for a hot melt adhesive. The automatic production system comprises a reaction device body, wherein an automatic material proportioning device is arranged on the top of the reaction device body; an air outlet pipeline is arranged near the automatic material proportioning device; a filter device is arranged on the air outlet pipeline; an inert gas coil pipe is arranged at the lower part inside the reaction device; a heating device is arranged at the bottom inside the reaction device body; a discharge filter is arranged below the reaction device body; the discharge filter is connected with a constant temperature mixer; an adhesive outlet is formed in one end of the constant temperature mixer, and is connected with a cooling pipeline; the cooling pipeline is connected with a cutter; the cutter is connected with a dryer; and the reaction device body, the automatic material proportioning device, the filter device, the discharge filter, the constant temperature mixer, the cutter and the dryer are all connected with an automatic controller. The system is uniform in stirring, accurate to control, excellent in cooling forming and automatic in operation.

Owner:江苏光辉粘合科技有限公司

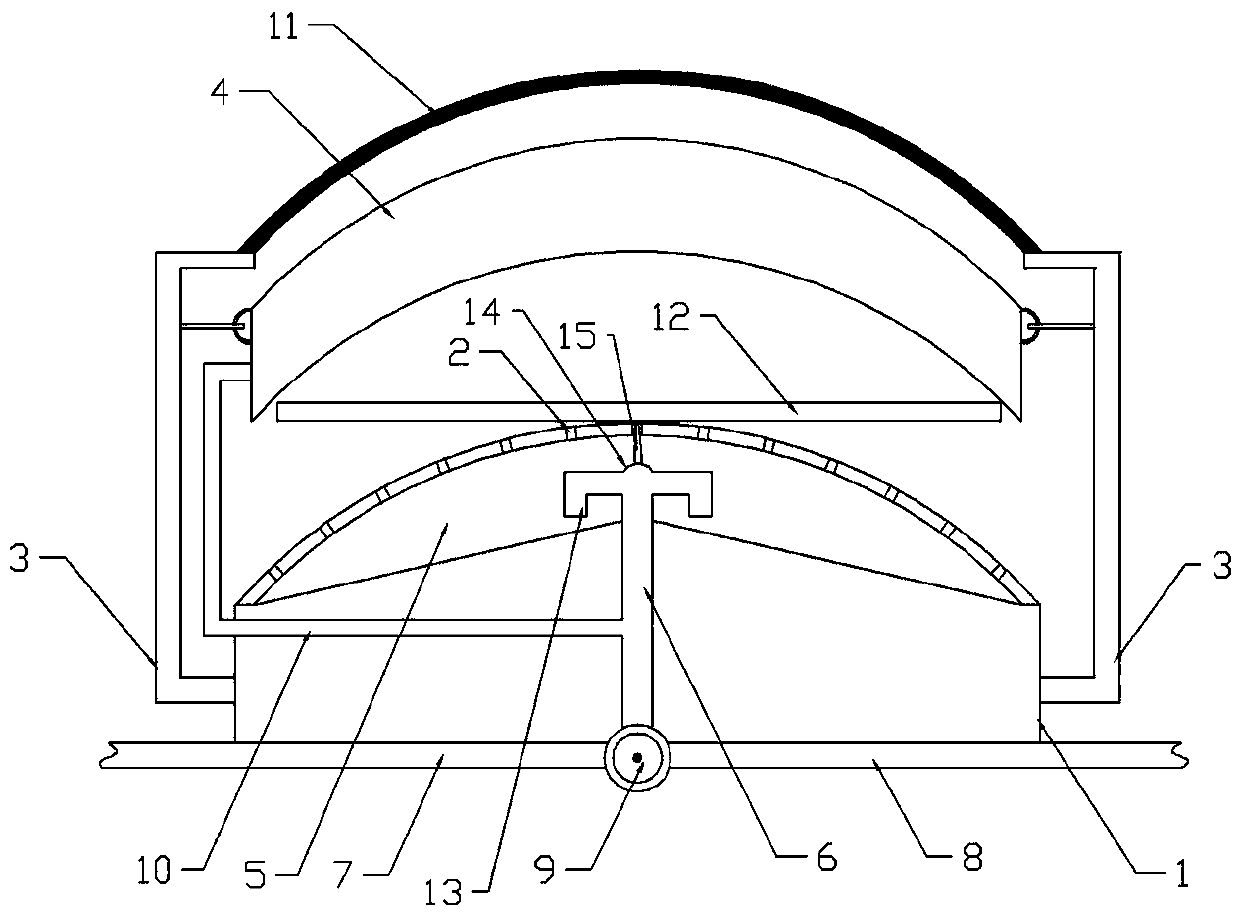

Method for bending forming of windshield

ActiveCN107673589AEasy to bendPromote softeningGlass reforming apparatusProcess efficiencyEngineering

The invention relates to a method for bending forming of a windshield and belongs to the technical field of reforming primary glass. The method comprises the following processing steps: step one, carrying out pretreatment processing on glass; step two, preparing glass bending forming equipment; step three: introducing hot gas for softening the glass; step four, continuously introducing the hot gas, using an air bag to act on the glass, and enabling the glass to be bent and laminated on a bending die; step five, introducing cold gas and carrying out cooling forming treatment on the glass. According to the technical scheme, the problem that the windshield is low in processing efficiency of bending forming in the prior art is effectively solved; the method has the advantages of good glass bending effect, convenience for glass forming, high practicality and high processing efficiency.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

Novel geotextile production process

ActiveCN111549447AAchieve the effect of equidistant operationGood positioning functionRoadwaysSynthetic resin layered productsSoil scienceEngineering

The invention discloses a novel geotextile production process, and belongs to the production field of novel geotextile. Compared with a traditional process, positioning and extruding striped hot meltrubber are added to the geotextile outer surface in the novel geotextile production process and soil carrying capacity of the geotextile is convenient to increase, so that the geotextile processed bythe equipment has a good positioning function. Deviation and relative sliding at the appropriate location are prevented from happening, and the normal construction of the geotextile is ensured. Compared with common production process, the novel geotextile production process is added with anti-ultraviolet fiber. The inner material of the anti-ultraviolet fiber is acrylic, and the acrylic has a goodanti-ultraviolet aging effect, is laid on the upper surface of the geotextile through extrusion molding, and is subjected to waterproof spraying to achieve a good waterproof effect.

Owner:扬州华诚土工材料有限公司

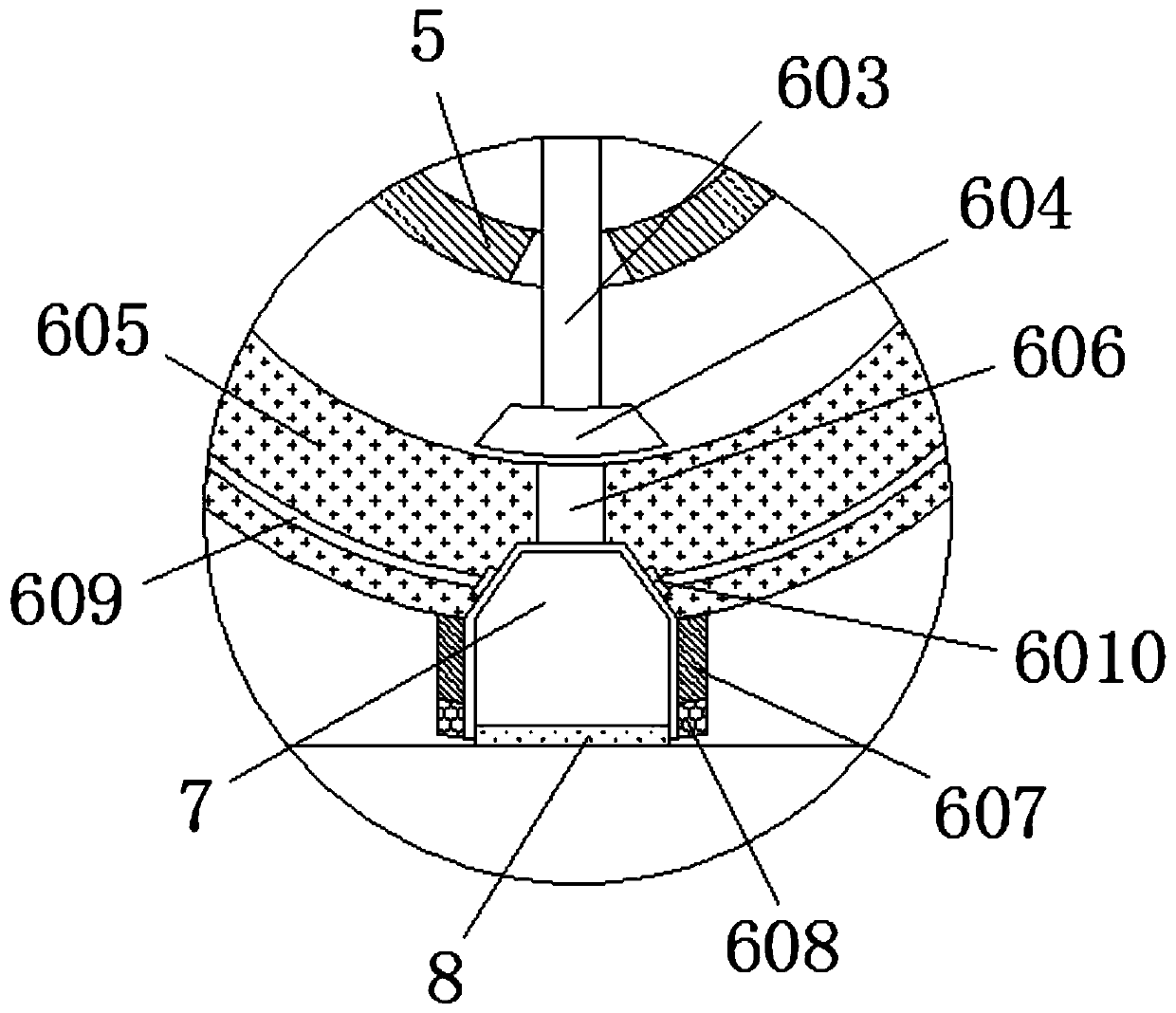

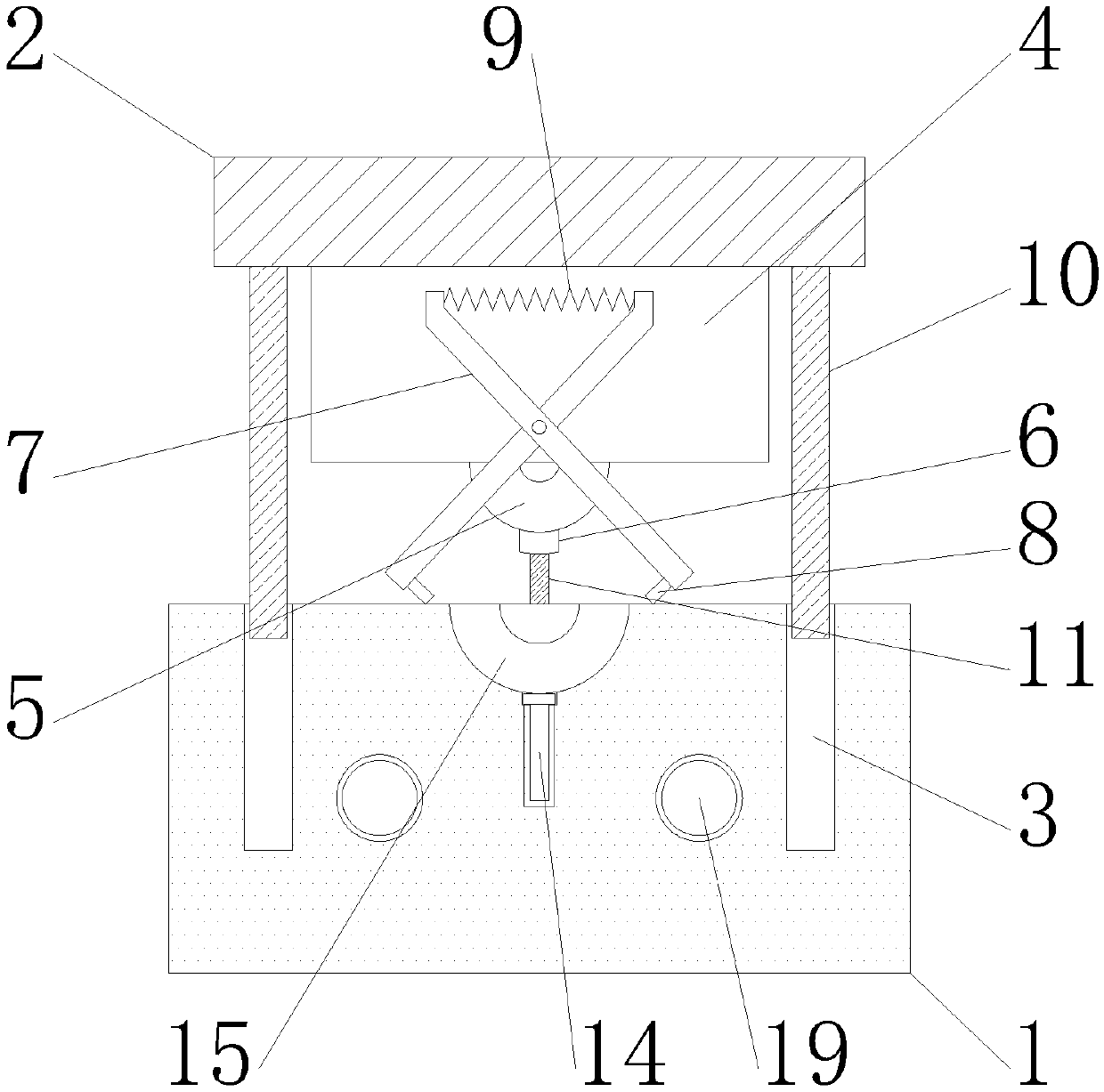

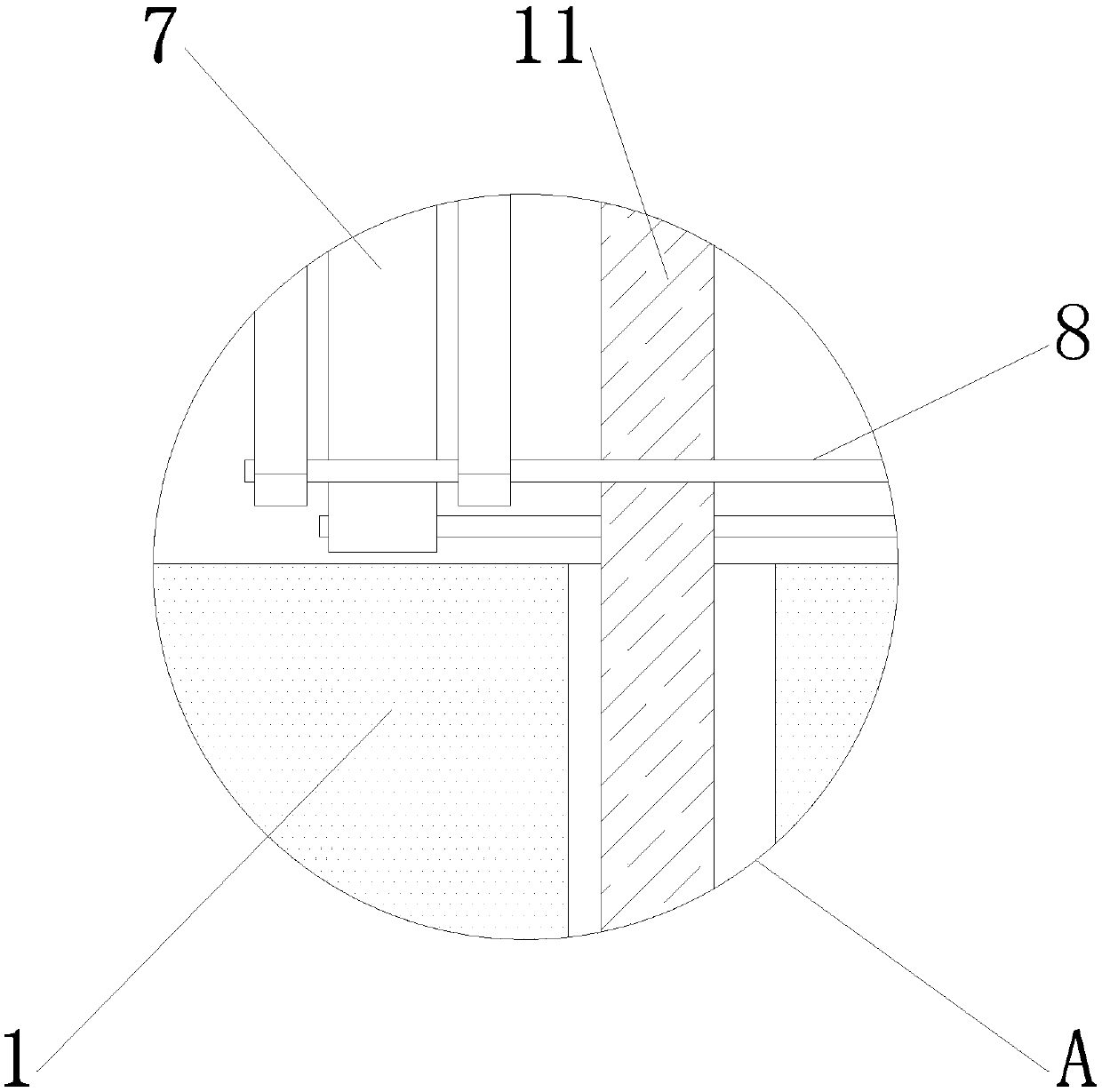

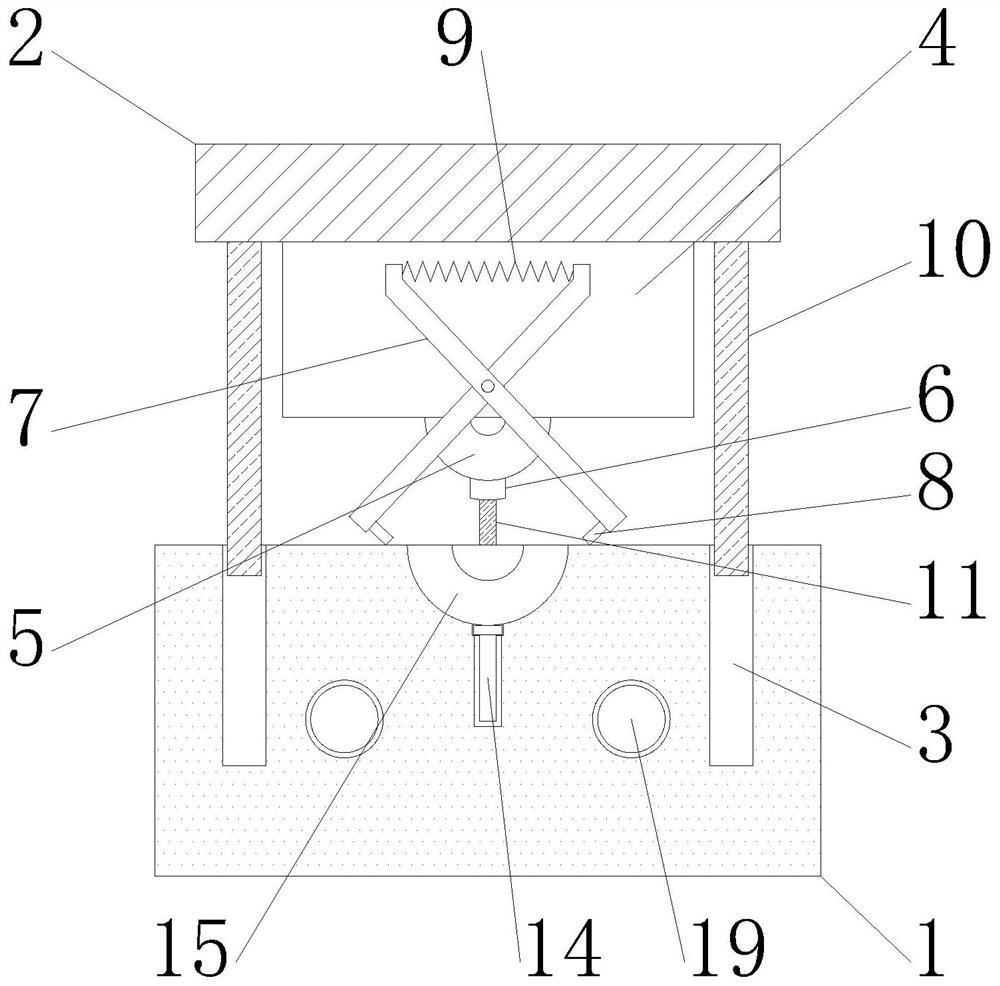

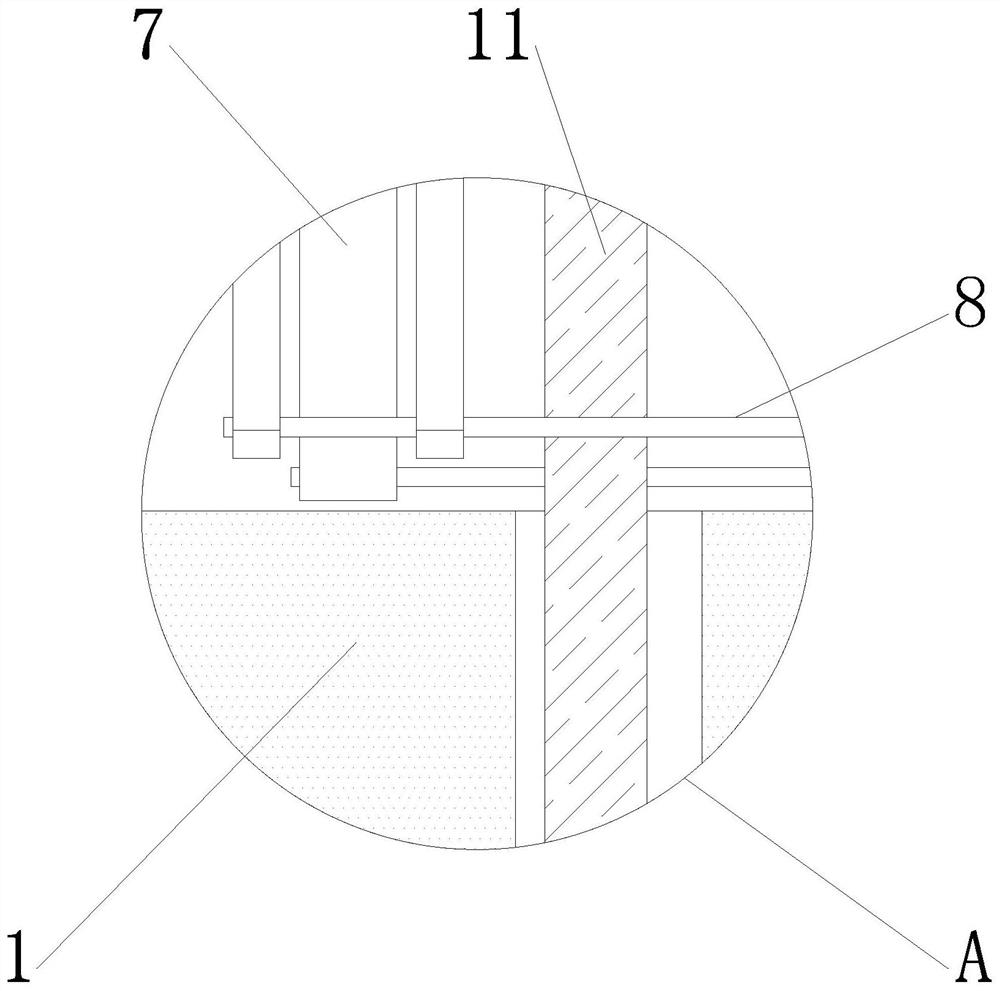

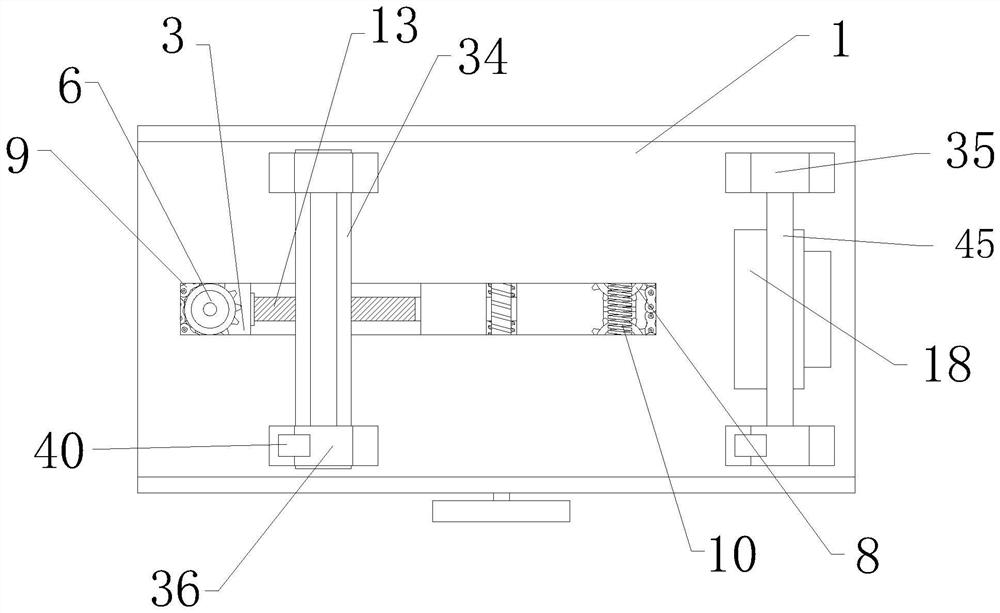

Rapid-formed die casting device for die of metal anti-vibration engine precision accessory

The invention discloses a rapidly-formed die casting device for a die of a metal anti-vibration engine precision accessory in the technical field of engine precision accessories. The rapidly-formed die casting device comprises a base, an upper ventilation opening is formed in the upper part of the side wall of the base, a lower ventilation opening is formed in the lower part of the side wall of the base, a cavity is formed in the inner wall of the base, the top of the cavity communicates with the base, an inclined liquid inlet cavity is formed in the top of the base, the top of the inclined liquid inlet cavity is communicates with a liquid feeding port, and the top end of the liquid feeding port penetrates through the base. When a guide rod moves up and down, an eccentric wheel rotates through a movable rod, then through a rolling wheel, a the piston plate can intermittently squeeze water in a water tank into a cooling pipe, and therefore, for one thing, the water does not need to be supplied through a water pump, and vibration can be avoided from a vibration source in the prior art again; and for another thing, the contact time of water flow and the cavity can be prolonged, more heat in the cavity can be conveniently taken away, and rapid cooling forming of molten metal is facilitated.

Owner:郝杰

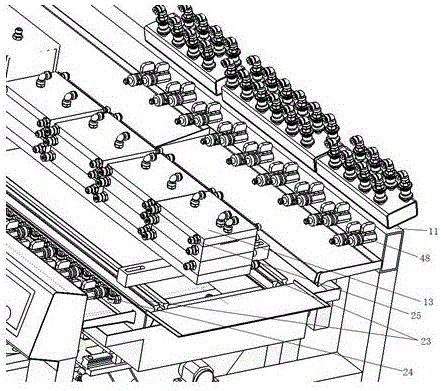

Sizing table for vacuum and quick sizing

The invention discloses a sizing table for vacuum and quick sizing. The sizing table comprises a stander, wherein a sizing vacuum section for cooling a profile is arranged on the stander and is connected with a sizing mold; the sizing vacuum section comprises three sections which includes a first sizing vacuum section, a second sizing vacuum section and a third sizing vacuum section in sequence from left to right and are connected with three exhaust channels arranged on one side of the stander through pipelines in a one-to-one correspondence manner; the three exhaust channels are respectively a first exhaust channel, a second exhaust channel and a third exhaust channel; the first exhaust channel is connected with a variable-frequency vacuum pump; the second exhaust channel and the third exhaust channel are respectively connected with a water ring type vacuum pump. According to the sizing table for vacuum and quick sizing, negative pressure required for the profile can be generated at the highest speed, and the starting-up rejection rate is reduced; the energy consumption of the vacuum pump can be reduced.

Owner:GUANGDONG LIANSU MACHINERY MFG

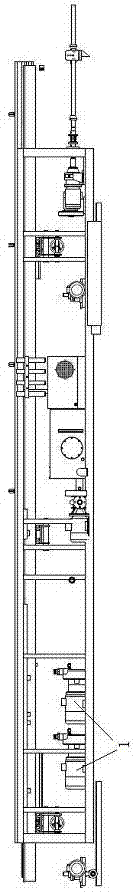

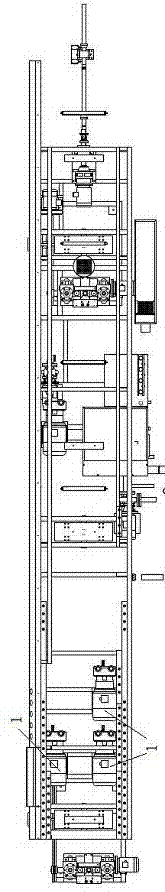

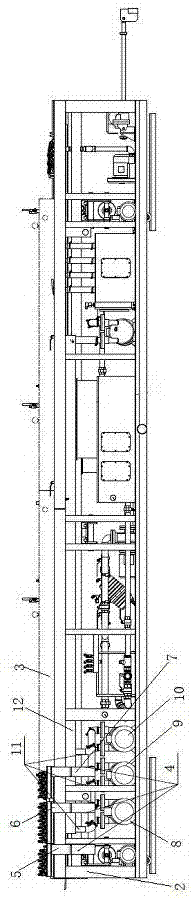

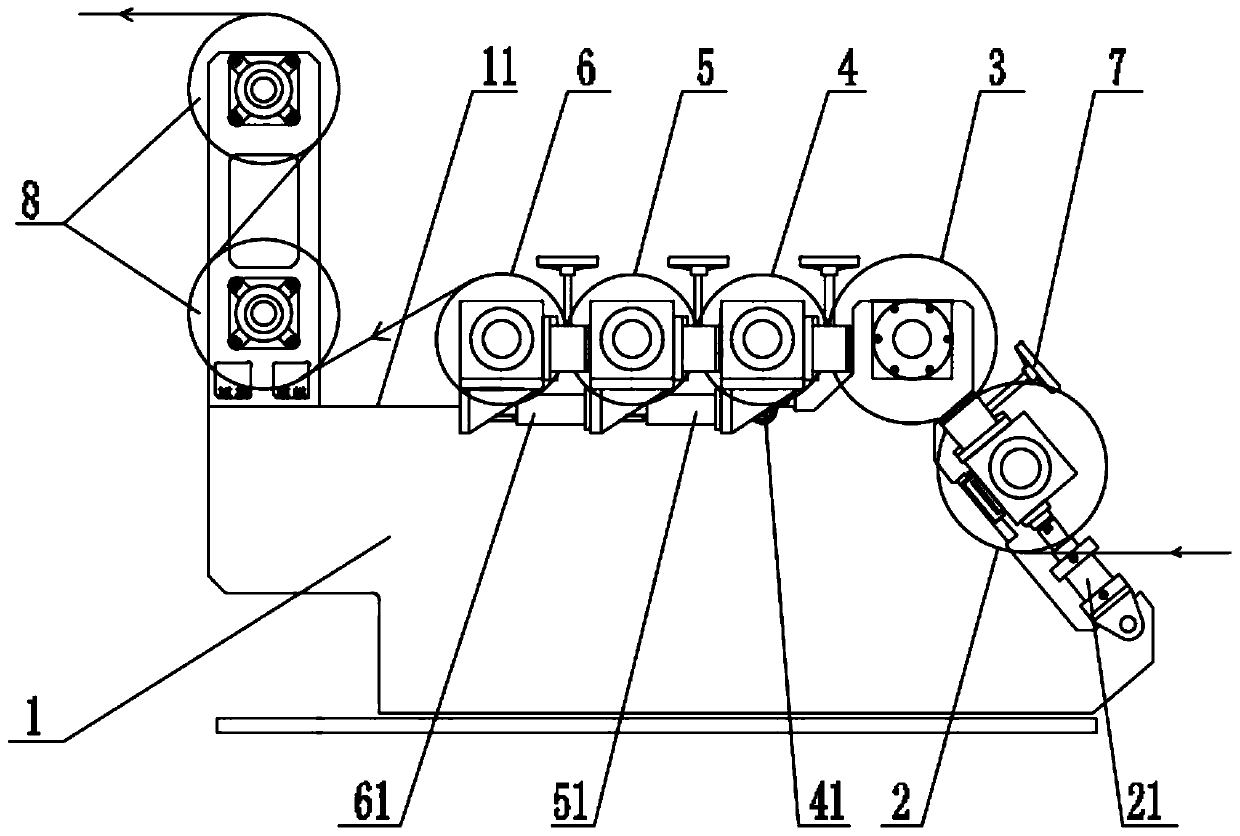

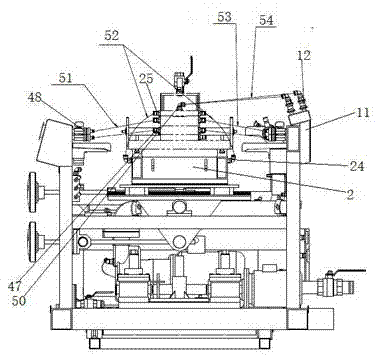

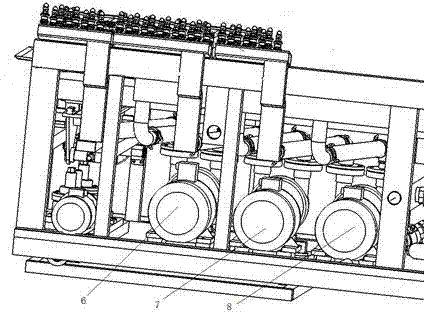

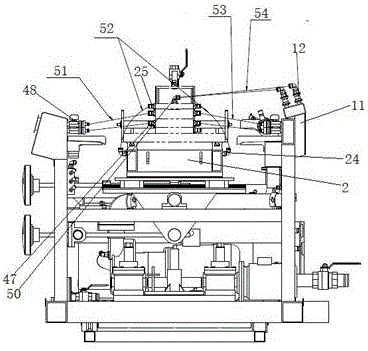

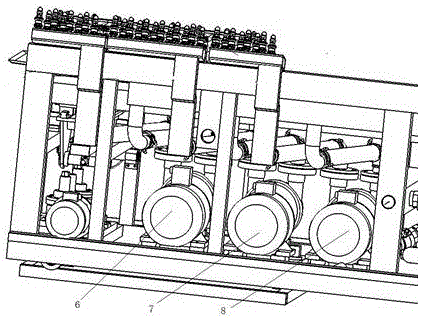

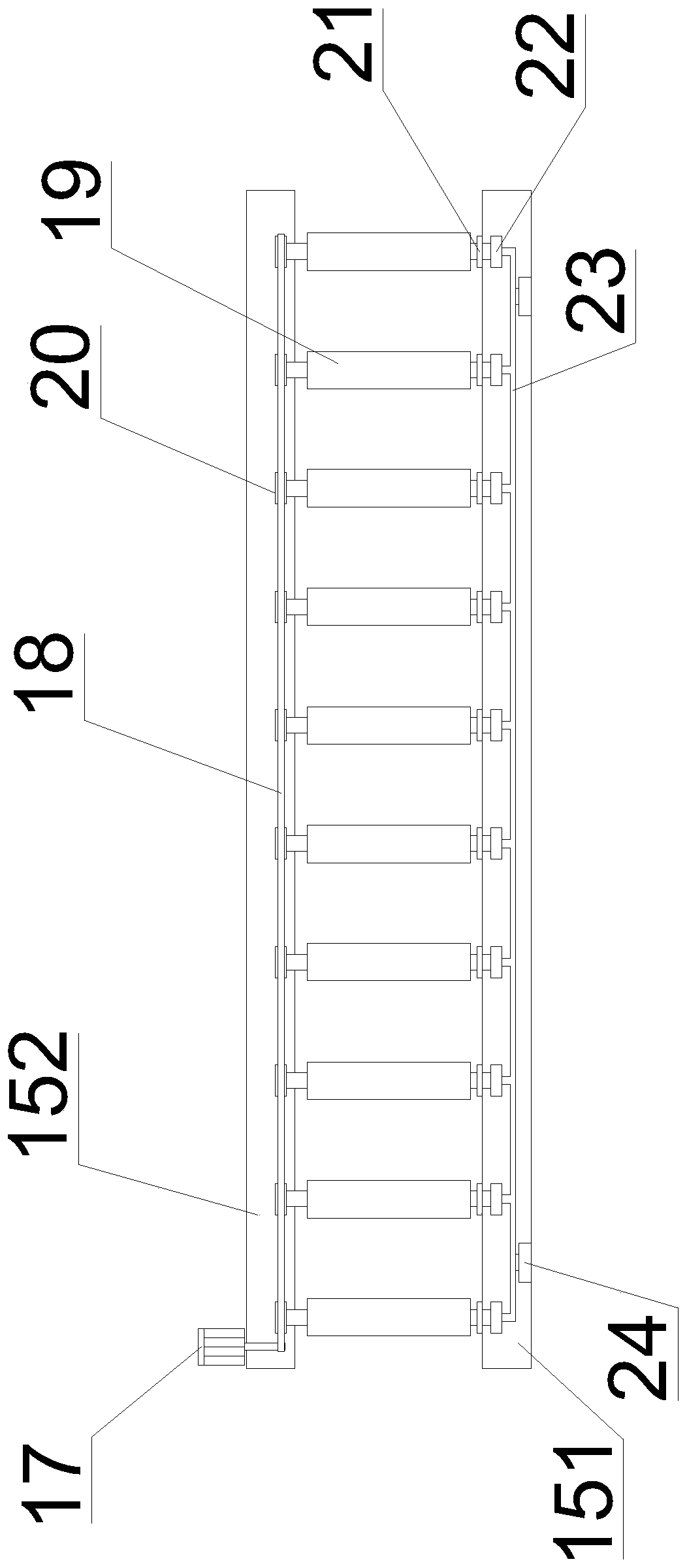

Multi-roller continuous plastic sheet calender

PendingCN111152395AIncrease the number ofIncrease contact areaFlat articlesStructural engineeringIndustrial engineering

The invention relates to a multi-roller continuous plastic sheet calender. The multi-roller continuous plastic sheet calender comprises machine frame walls and a roller assembly; the roller assembly comprises inclined surface conveying rollers and horizontal conveying rollers; the inclined surface conveying rollers are installed on the feeding end inclined surfaces of the machine frame walls and comprise at least two rollers; the horizontal conveying rollers are horizontally installed at the tops of the machine frame walls and comprise at least three rollers, and roller interval adjusting devices are arranged between the rollers; and electric walking devices are installed at the bottoms of the machine frame walls. According to the multi-roller continuous plastic sheet calender, the multiple rollers are continuously arranged, the roller quantity is increased, the contact area between the rollers and a sheet is effectively increased, the time for the rollers to make contact with the sheet is prolonged, thus, the sheet can be cooled and formed better, meanwhile, the inner stress of the sheet is reduced, the surface quality of the sheet is improved, and the multi-roller continuous plastic sheet calender is suitable for high-output production of plastic sheets.

Owner:南京光瑞挤出装备有限公司

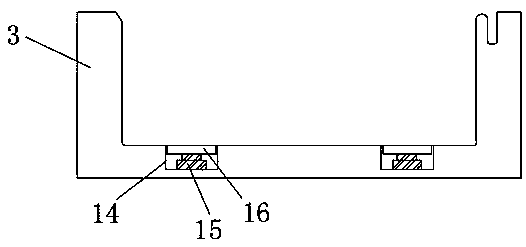

Window section material sizing platform

The invention discloses a window section material sizing platform. The window section material sizing platform comprises a rack, a supporting platform, a sizing vacuum section, a sizing mold section, a vortex pump for pumping vortex of the sizing mold section, and a plurality of vacuum pumps for vacuumizing the sizing vacuum section, wherein the supporting platform is arranged in the middle of the rack; the sizing vacuum section and the sizing mold section are mounted on the supporting platform; one side of the rack is provided with a vacuumizing device which is connected with the sizing vacuum section by a pipeline; the vacuum pumps and the vortex pump are connected with a water collection device for recycling water and reducing noises; the water collection device is connected with the rack by a heat exchange device and water is led into the rack; and the water is supplied to the sizing vacuum section and the sizing mold section through the rack to form the circulating utilization of the water. The window section material sizing platform can be used for rapidly cooling and molding a section material and water resources are circularly utilized; and the whole structure layout is reasonable, and energy conservation and environmental friendliness are realized.

Owner:GUANGDONG LIANSU MACHINERY MFG

Casting device for surgical equipment

PendingCN113751670AAchieve vibrationRealize the vibration mechanism to realize the vibration of the connected componentsFoundry mouldsFoundry coresReoperative surgeryMechanical engineering

The invention relates to a casting device for surgical equipment. The casting device comprises a base, a connecting mechanism and a feeding mechanism. The connecting mechanism comprises a connecting assembly and a sealing assembly, the feeding mechanism comprises a feeding pipe and an extrusion assembly. The casting device for the surgical equipment realizes manufacturing of a main body through the connecting mechanism and the feeding mechanism, and therefore the product quality is improved. The connecting assembly is vibrated through a vibration mechanism, so that flowing of bubbles in air is accelerated, heat dissipation of liquid in a fixing plate can be achieved by increasing flowing of the air, and therefore the liquid can be better cooled and formed, and the working efficiency is improved. Cross flow of air in the fixing plate is achieved through a cross flow mechanism, vibration of the connecting assembly is better achieved through a vibration ball, the vibration effect is improved, linkage of multiple mechanisms is achieved through the same driving source, and the use practicability is improved.

Owner:广州菲曜互联网医院有限公司

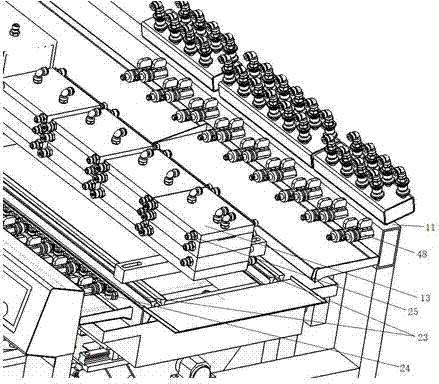

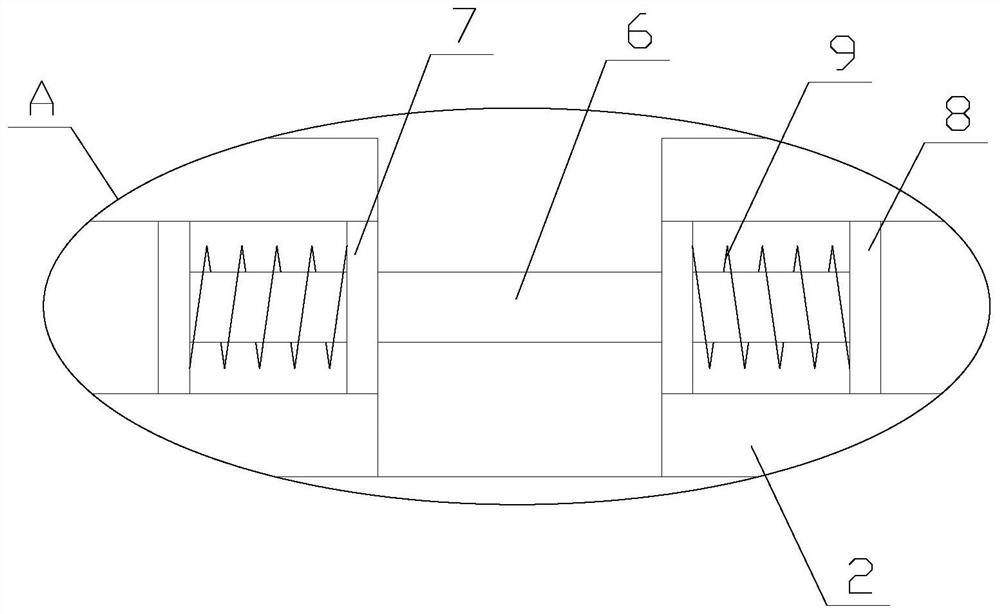

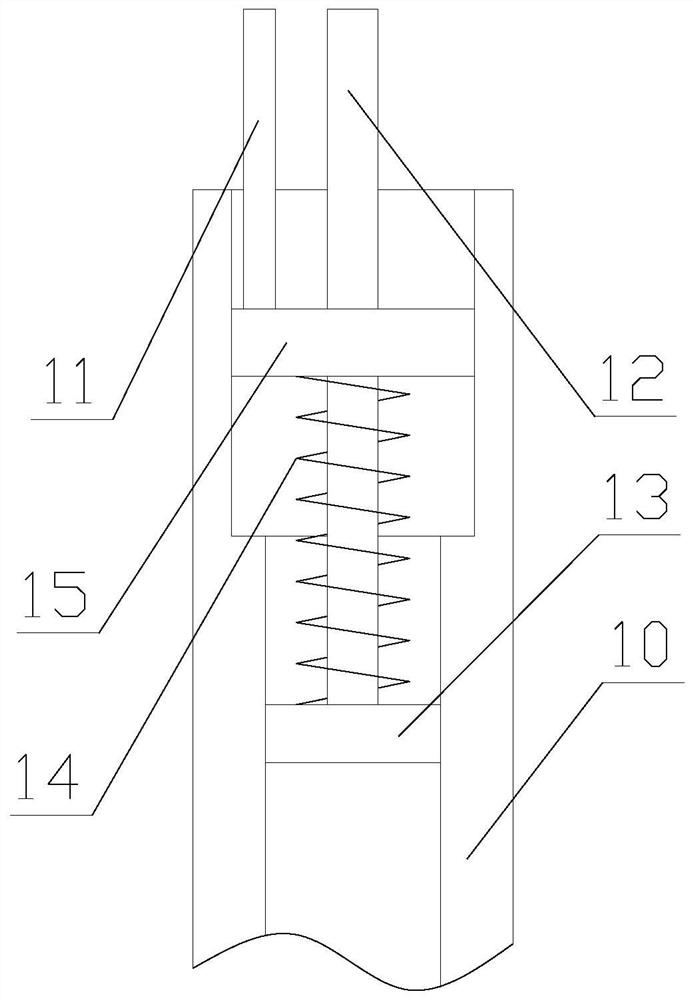

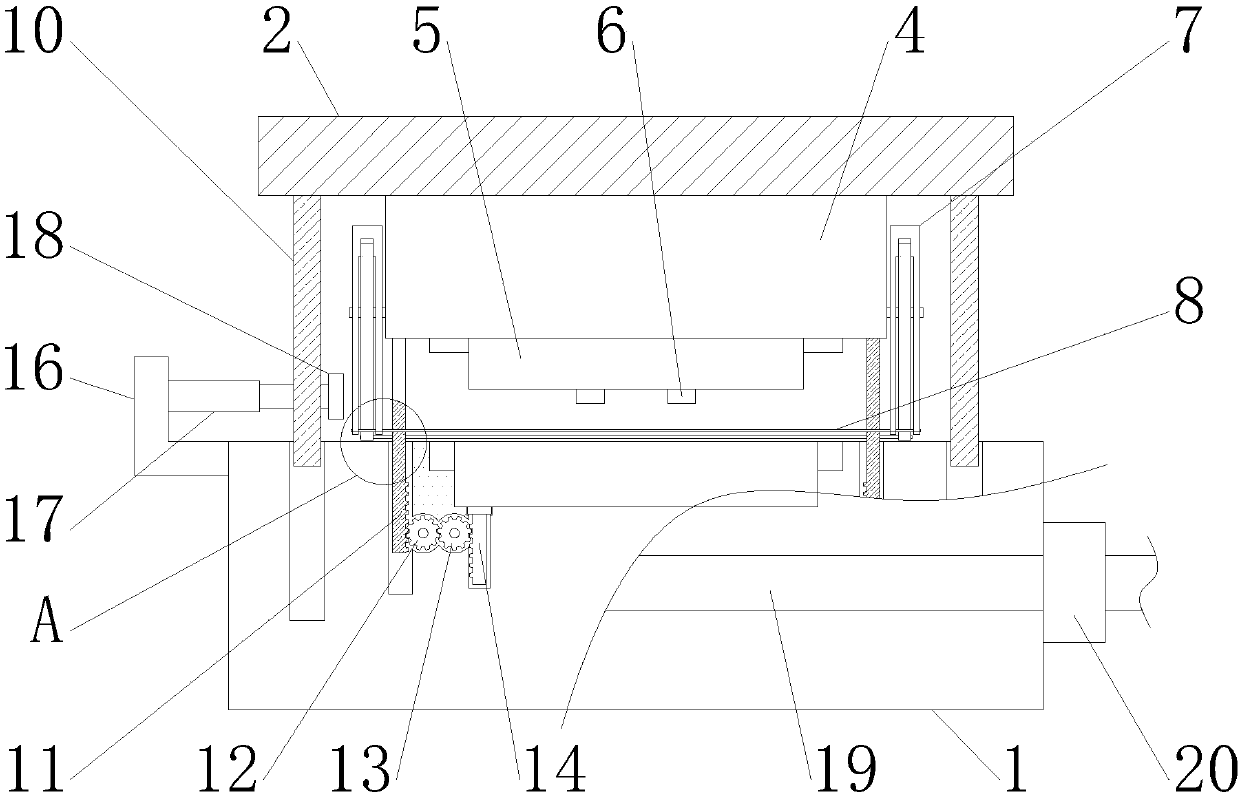

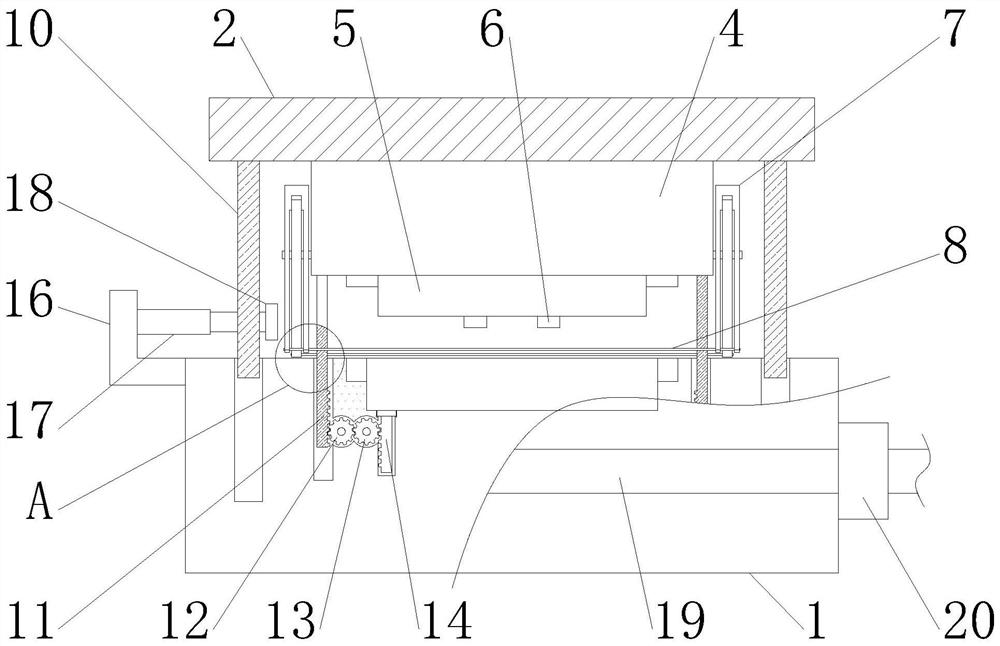

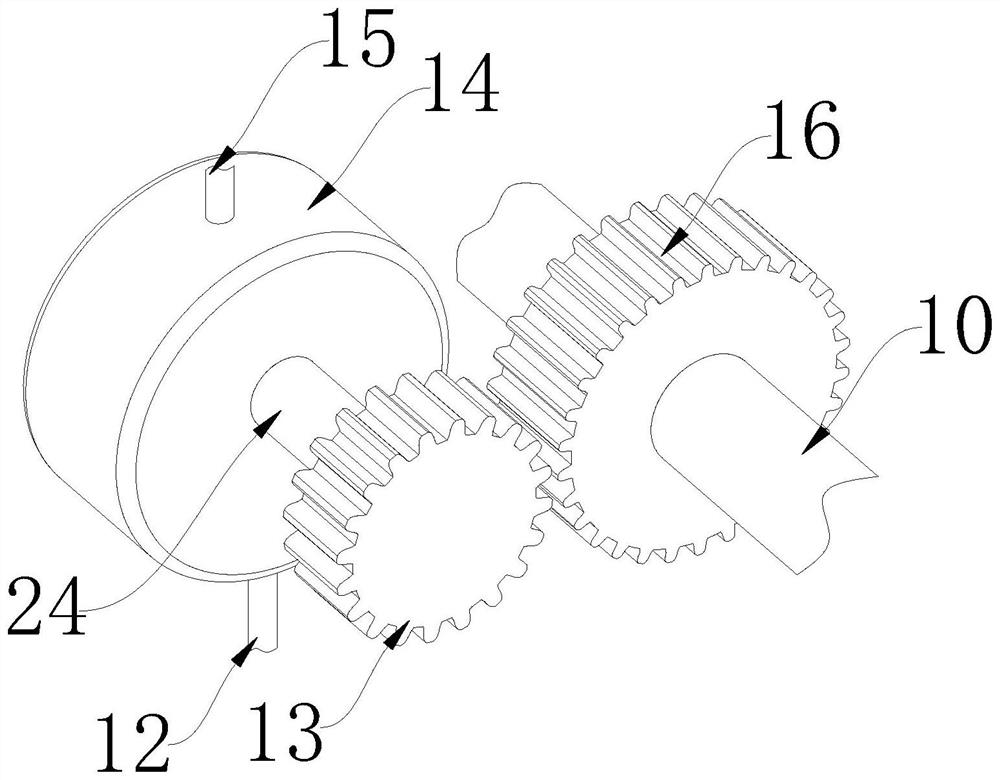

Manufacturing device of communication cable joint protection box

The invention belongs to the technical field of communication and particularly relates to a manufacturing device of a communication cable joint protection box which comprises a main body, a top plate,a groove, a pressing plate, a male mold, a fixed shaft, a rotating rod, a supporting rod, a spring, a limiting rod, a toothed rod, a first gear, a second gear, a top rod, a female mold, a fixed plate, an electric push rod, a push plate, a water pipe and a water pump. After a cavity is formed by pressing the female mold and the male mold, injection molding is carried out, so that the manufacturingof the protection box is facilitated, the protection box is conveniently taken out from the mold while the top plate moves, the operation convenience is improved, the operation difficulty is reduced,and the ejection of the protection box is facilitated. The manufacturing device of the communication cable joint protection box conveniently supports the protection box through movement of the supporting rod, facilitates blanking of the protection box through movement of the push plate, facilitates blanking of the protection box, decreases operation procedures, improves working efficiency and improves integration degree.

Owner:固安县朔程燃气有限公司

A high-efficiency 3D printing filament drawing device

The invention discloses an efficient 3D printing consumable drawing device. The efficient 3D printing consumable drawing device comprises an extruding machine, a paraffin removing tank, a water cooling tank, a shell and a paraffin applying bucket; a supporting plate is arranged at one end of the top of the water cooling tank, and the shell is welded to the top of the supporting plate; the paraffinremoving tank is connected to one side of the water cooling tank; and a fixing plate is welded between the paraffin removing tank and the water cooling tank, a first water pump is fixed to the top ofthe fixing plate, and a water inlet pipe is connected to the input end of the first water pump. According to the efficient 3D printing consumable drawing device, scraper blades matched with first guiding wheels are welded to the two sides of the interior of the shell in an oblique downward mode, a collecting tank is arranged under the scraper blades, a heating water chamber is arranged in the side wall of the shell, therefore, excess liquid paraffin remaining on the outer surfaces of extruded wires on the first guiding wheels can be conveniently scraped by the scraper blades, the scraped excess liquid paraffin is guided into the collecting tank to be cyclically utilized through the flow guiding property of the oblique scraper blades, and the internal temperature of the shell can be kept at a certain temperature through the heating water chamber, so that the paraffin keeps the liquid state.

Owner:ANHUI POLYTECHNIC UNIV

A preparation device for communication cable joint protection box

The invention belongs to the technical field of communication, and specifically relates to a preparation device for a protection box of a communication cable joint, which includes a main body, a top plate, a groove, a pressing plate, a punch, a fixed shaft, a rotating rod, a supporting rod, a spring, a limit rod, Gear rod, first gear, second gear, ejector rod, die, fixed plate, electric push rod, push plate, water pipe and water pump. The invention forms a cavity by pressing the concave mold and the convex mold and then performs injection molding, which facilitates the preparation of the protective box, and facilitates the removal of the protective box from the mold while the top plate moves, which improves the convenience of operation and reduces the difficulty of operation. It is conducive to the ejection of the protection box; the preparation device of the communication cable joint protection box facilitates the support of the protection box through the movement of the support rod, and facilitates the unloading of the protection box and the unloading of the protection box through the movement of the push plate. materials, reducing the operating procedures, improving work efficiency, and improving the degree of integration.

Owner:固安县朔程燃气有限公司

A window profile shaping platform

The invention discloses a window section material sizing platform. The window section material sizing platform comprises a rack, a supporting platform, a sizing vacuum section, a sizing mold section, a vortex pump for pumping vortex of the sizing mold section, and a plurality of vacuum pumps for vacuumizing the sizing vacuum section, wherein the supporting platform is arranged in the middle of the rack; the sizing vacuum section and the sizing mold section are mounted on the supporting platform; one side of the rack is provided with a vacuumizing device which is connected with the sizing vacuum section by a pipeline; the vacuum pumps and the vortex pump are connected with a water collection device for recycling water and reducing noises; the water collection device is connected with the rack by a heat exchange device and water is led into the rack; and the water is supplied to the sizing vacuum section and the sizing mold section through the rack to form the circulating utilization of the water. The window section material sizing platform can be used for rapidly cooling and molding a section material and water resources are circularly utilized; and the whole structure layout is reasonable, and energy conservation and environmental friendliness are realized.

Owner:GUANGDONG LIANSU MACHINERY MFG

A method of bending and forming a windshield

The invention relates to a method for bending forming of a windshield and belongs to the technical field of reforming primary glass. The method comprises the following processing steps: step one, carrying out pretreatment processing on glass; step two, preparing glass bending forming equipment; step three: introducing hot gas for softening the glass; step four, continuously introducing the hot gas, using an air bag to act on the glass, and enabling the glass to be bent and laminated on a bending die; step five, introducing cold gas and carrying out cooling forming treatment on the glass. According to the technical scheme, the problem that the windshield is low in processing efficiency of bending forming in the prior art is effectively solved; the method has the advantages of good glass bending effect, convenience for glass forming, high practicality and high processing efficiency.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

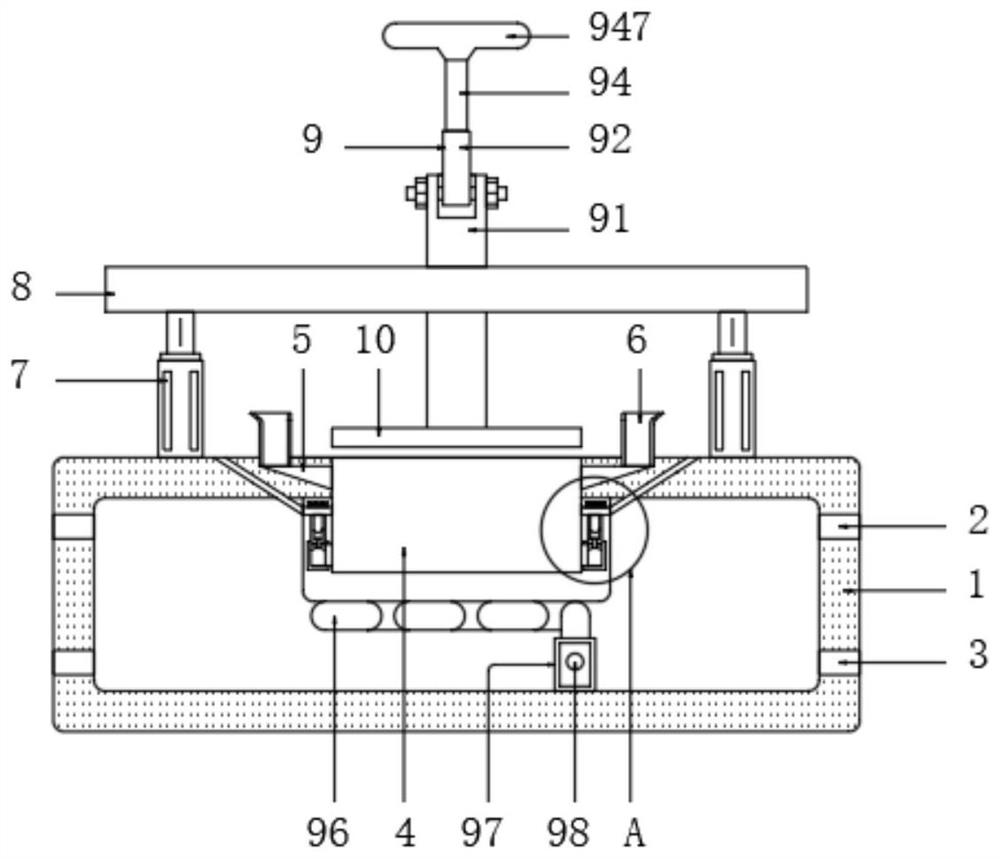

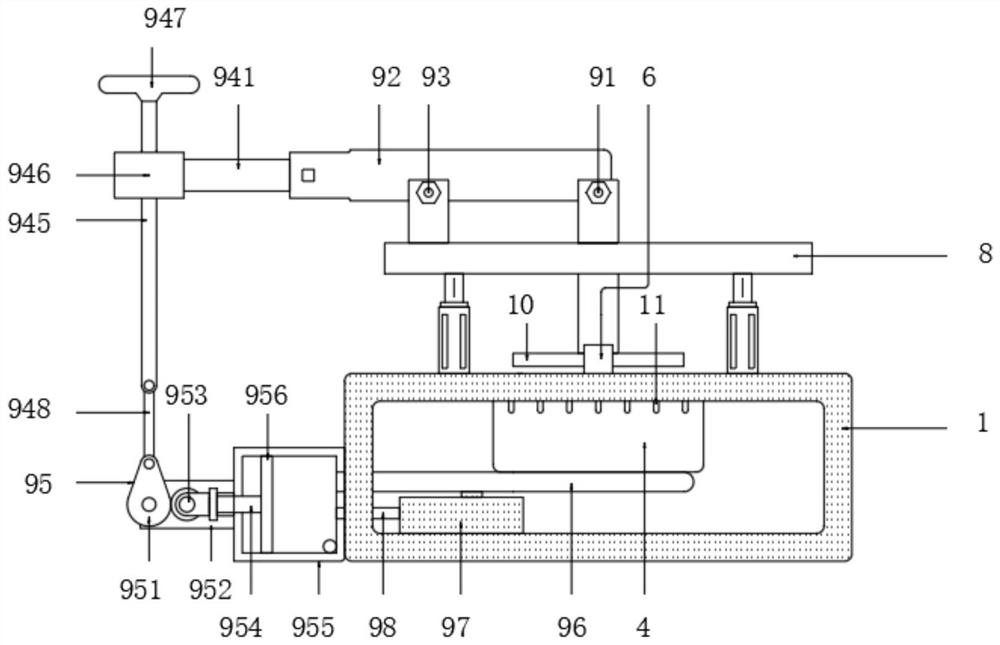

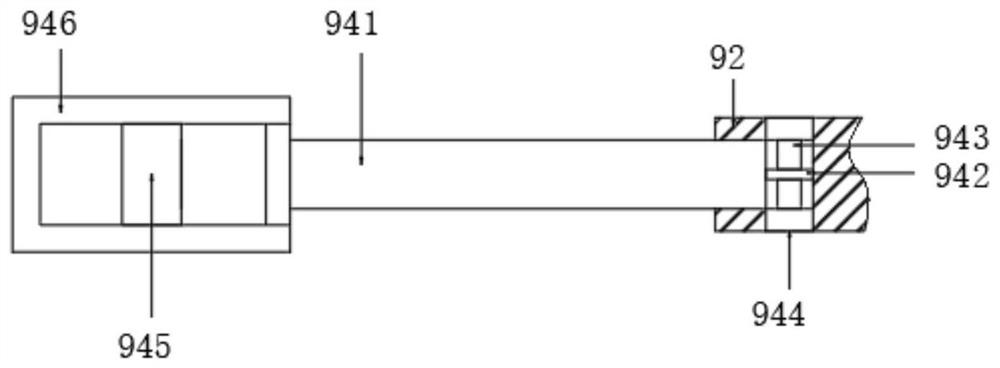

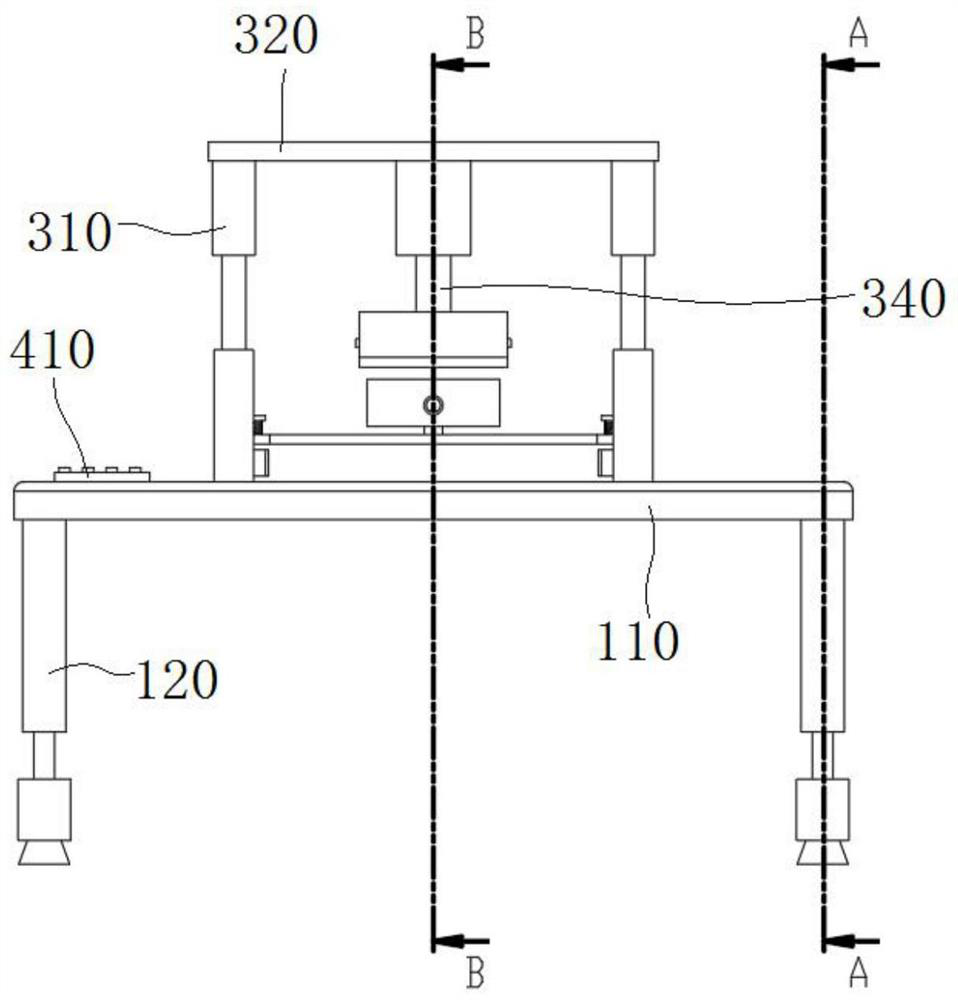

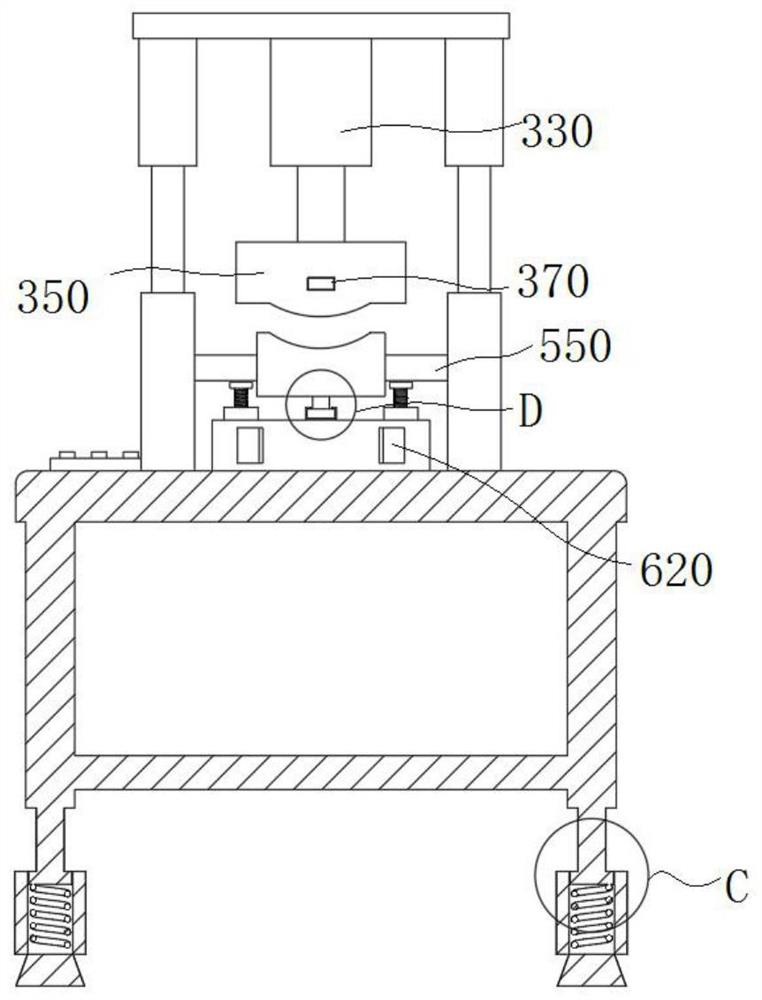

Hot pressing and cooling forming device for VR helmet manufacturing

InactiveCN112720983AReduce vibrationImprove accuracyDomestic articlesVibration suppression adjustmentsMechanical engineeringPhysics

The invention discloses a hot pressing and cooling forming device for VR helmet manufacturing, and relates to the technical field of VR helmet manufacturing. The device comprises a bearing structure, a mounting structure, a main body structure, a control structure, a cooling structure, a force unloading structure and a buffer structure, and is characterized in that the bearing structure comprises a bearing table and supporting columns, the upper surfaces of the multiple supporting columns are welded to the lower surface of the bearing table, the mounting structure comprises a mounting plate, a mounting rail, a sliding block and a connecting column, the mounting plate is arranged on the upper surface of the bearing table, and the lower surface of the mounting rail is connected with the upper surface of the mounting plate. By arranging buffer springs, when pressure and vibration force exist, connecting rods are matched with pressing blocks to extrude the buffer springs, the buffer springs can emit elastic force opposite to the pressure and vibration force in direction, the vibration force is reduced, and the workbench and the manufacturing accuracy are protected.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Tooling for making molten steel sampler and method for making molten steel sampler

ActiveCN104897435BAccurately reflect the actual situationReduce manufacturing costWithdrawing sample devicesMolten steelQuartz

The invention belongs to the technical field of tools for manufacturing molten steel samplers and discloses a tool for manufacturing a molten steel sampler and a method for manufacturing the molten steel sampler by adopting the tool. The tool comprises a metal cap, a quartz tube, precoated sand, a sample box, a base plate, an outer protective casing pipe, an inner protective casing pipe and a metal sleeve, wherein the outer diameter of the inner protective casing pipe is equal to the inner diameter of the outer protective casing pipe, and the lower half part of the outer protective casing pipe is sleeved with the inner protective casing pipe; the base plate covers the upper end surface of the inner protective casing pipe; the sample box adopts a flat structure and is formed by buckling two symmetrical half box bodies; the quartz tube is seamlessly inserted into a handle of the sample box; the inner diameter of the metal casing pipe is equal to that of the outer protective casing pipe, and the metal casing pipe is arranged on the upper end surface of the outer protective casing pipe; a gap between a cavity formed by the metal casing pipe, the outer protective casing pipe and the base plate and the sample box is filled with the procoated sand, and a filling surface is lower than the pipe orifice of the metal casing pipe; the open end of the metal cap is inserted into the precoated sand, and the sealed end of the quartz tube covers the top of the quartz tube. By means of the molten steel sampler manufactured by adopting the tool, sampling can be quickly performed, the sample box is easy to take out, and the manufacturing cost is low.

Owner:马鞍山市东江冶金材料有限公司

Environment-friendly and energy-saving casting mold

InactiveCN111906255ASpeed up coolingEasy to plug inFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to the technical field of molds, and particularly discloses an environment-friendly and energy-saving casting mold. The mold comprises an upper mold base. A lower die base is movably connected to the bottom surface of the upper mold base, a mold cavity is formed in the middle of the top surface of the lower mold base, and air cylinders are fixedly connected to the four corners of the bottom surface of the lower mold base respectively. The output ends of the bottom surfaces of the air cylinders are fixedly connected with an ejector plate. Ejector rods are fixedly connectedto the left side and the right side of the middle of the top surface of the ejector plate respectively. According to the environment-friendly and energy-saving casting mold, a sprue gate is formed inthe upper mold base to play a role in pouring raw materials, the upper mold base and the lower mold base are assembled to facilitate cooling and formation of the raw materials, a vertical rod is arranged in the sprue gate, a floating block on the vertical rod is used in cooperation, then the sprue gate can be conveniently blocked by the floating block, the effect of closing the sprue gate is achieved, it is avoided that raw materials accumulate inside the sprue gate, and waste of the raw materials is avoided.

Owner:中山市泽一照明科技有限公司

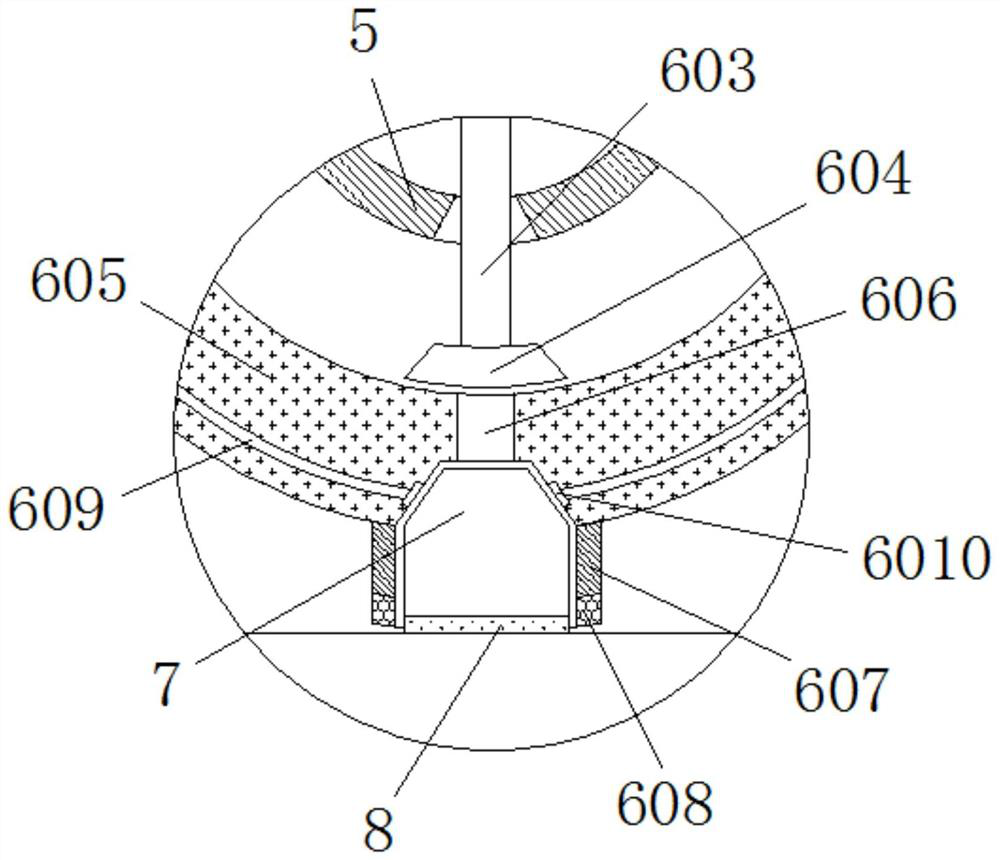

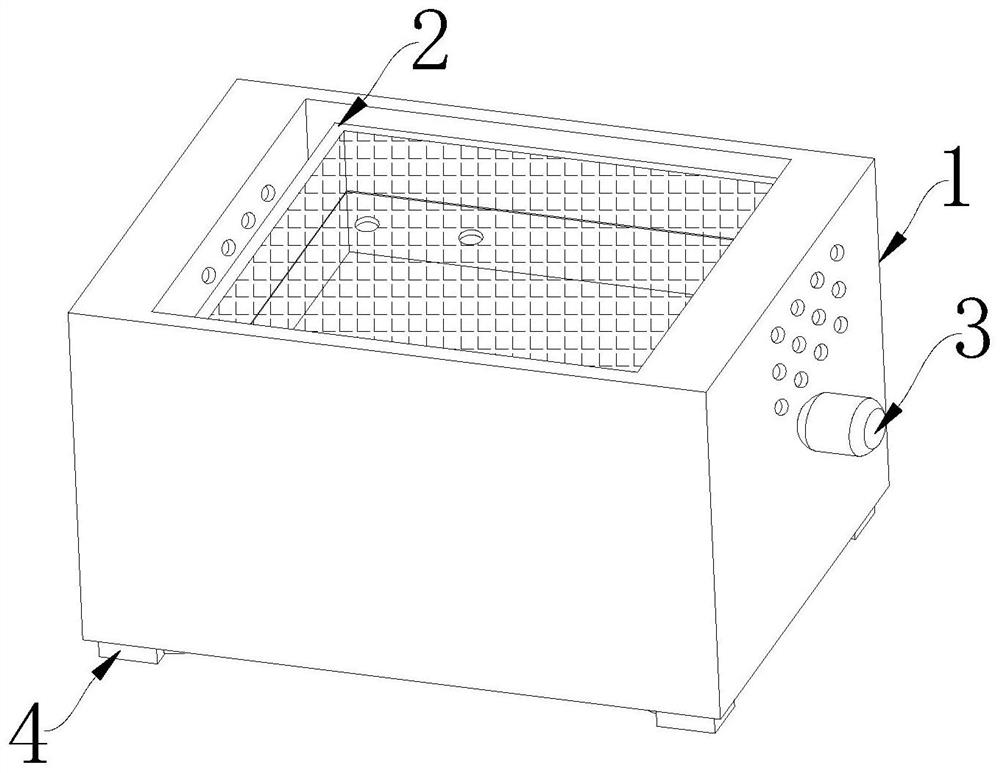

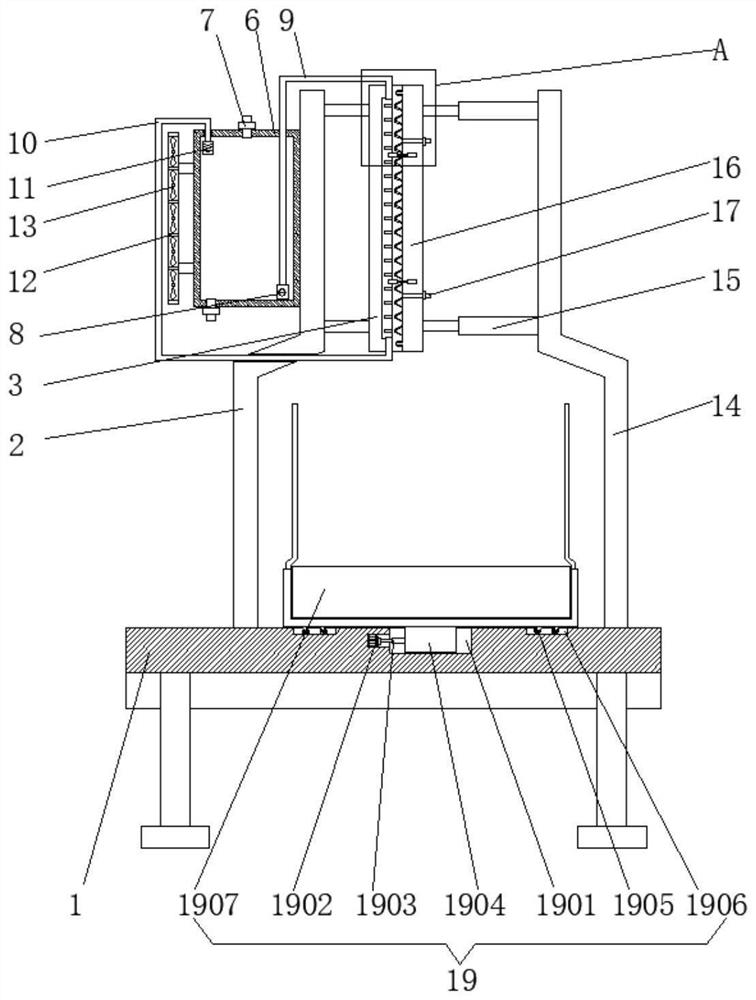

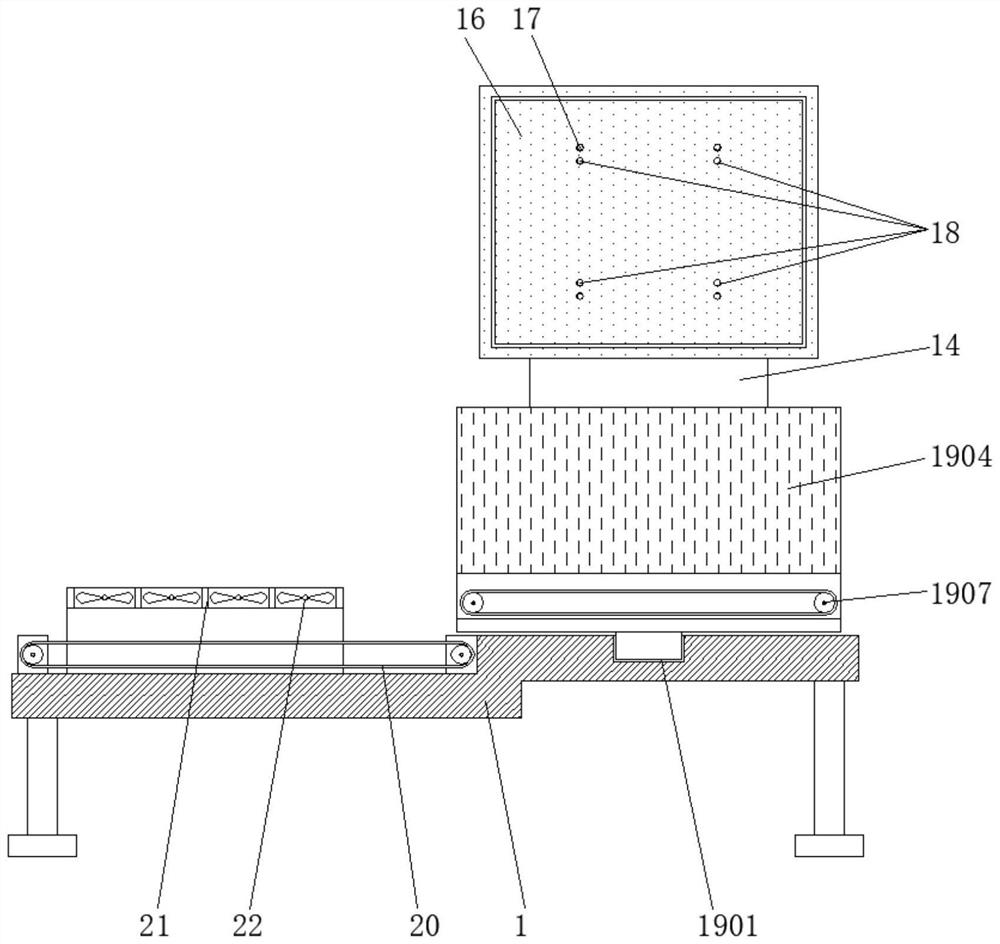

Rapid forming cooling device for producing bean paste cakes

InactiveCN110887261AContinuous heat exchange and cooling are convenientEasy to cool and formMechanical apparatusCompression machines with non-reversible cycleWater storage tankAgricultural engineering

The invention relates to a rapid forming cooling device for producing bean paste cakes. The rapid forming cooling device comprises an mounting frame, a baking device, a support table, a conveying device and a water storage tank, wherein the support table is arranged on the ground, and the water storage tank is arranged inside the support table; a support seat is arranged on the support table, andthe conveying device is arranged on the support seat; the conveying device comprises a first mounting seat and a second mounting seat; one end of a rolling roller is provided with a first transmissionshaft, and the other end of the rolling roller is provided with a second transmission shaft; a water outlet and a water supply pipe are arranged on the first mounting seat, and a plurality of mechanical seals are arranged on the first mounting seat; the baking device is arranged on one side of the conveying device, and a guide plate for conveying materials towards the conveying device is arrangedon the baking device; a plurality of support frames are arranged on the support table, and the mounting frame is arranged at the top of the support frames; and a ventilation pipe is arranged on the mounting frame, and a plurality of air outlet pipes are vertically arranged at the bottom of the ventilation pipe. According to the rapid forming cooling device for producing the bean paste cakes, through a combination mode of air cooling and water cooling, cake crusts passing through the rolling roller is rapidly cooled to form so as to facilitate subsequent further processing.

Owner:九江市金樱食品发展有限公司

A production process of geotextile

ActiveCN111549447BGood positioning functionGuarantee normal constructionRoadwaysSynthetic resin layered productsSoil scienceEngineering

The invention discloses a production process of geotextiles, which belongs to the field of production of new geotextiles. It is a production process of geotextiles, which increases the positioning and extrusion of striped hot-melt rubber on the outer surface of geotextiles in the traditional process, It is convenient to increase the soil-carrying capacity with the soil, so that the geotextile processed by this equipment has a good positioning function, which ensures that it is not easy to shift and relative sliding at the appropriate position of embedding, and ensures the normal construction of the geotextile. Compared with the common production process, anti-ultraviolet fiber is added in this process. The inner material of anti-ultraviolet fiber is acrylic fiber, which has good anti-ultraviolet aging effect, and is laid on the upper surface of geotextile by extrusion molding, and is sprayed with waterproof Under the action of water, it can achieve good waterproof effect.

Owner:扬州华诚土工材料有限公司

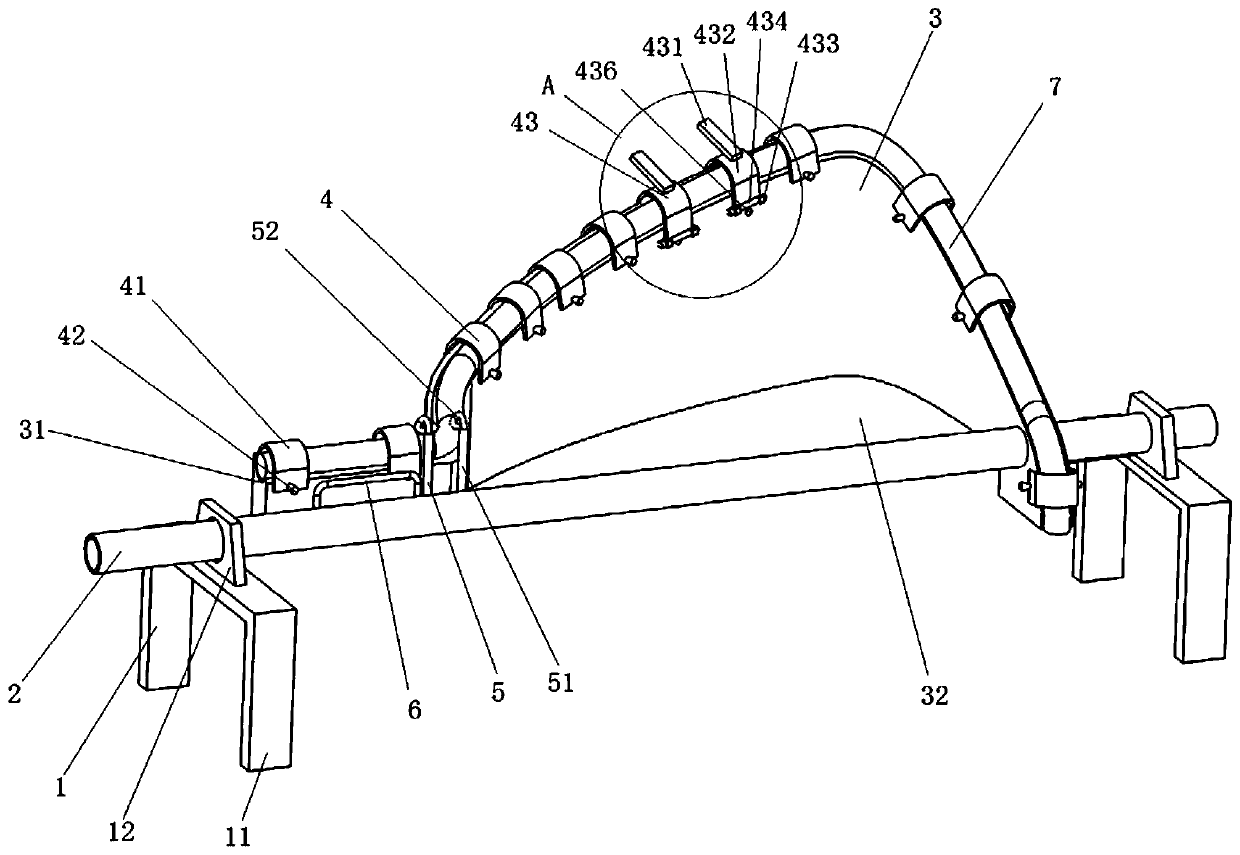

Simple laying pipe bending machine and production process

InactiveCN110743943AGuaranteed continuityPrecise positioningMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a simple laying pipe bending machine and a production process. The simple laying pipe bending machine comprises a machine frame, wherein a transverse supporting pipe and a bending support fixedly arranged on the transverse supporting pipe in an integrally-formed mode are fixedly arranged on the machine frame, a positioning channel is formed in the top end face of the bending support, a positioning device is arranged above the bending support, a limiting structure is arranged between the transverse supporting pipe and the bending support, and a prying rod is arranged onthe outer wall, located near the limiting structure, of the transverse supporting pipe. According to the machine and process, the bending support is arranged on the transverse supporting pipe in an integrally-formed mode, so that the continuity of laying pipe production is guaranteed; the positioning channel formed in the top end face of the bending support is matched with the positioning device to position a laying head pipe, and the limiting structure can limit the left and right positions of the laying pipe, so that the laying pipe can be better cooled and formed; and the machine and process are simple in structure and low in research and development cost, so that the replacement cost is greatly reduced.

Owner:河北秦合重科金属科技有限公司

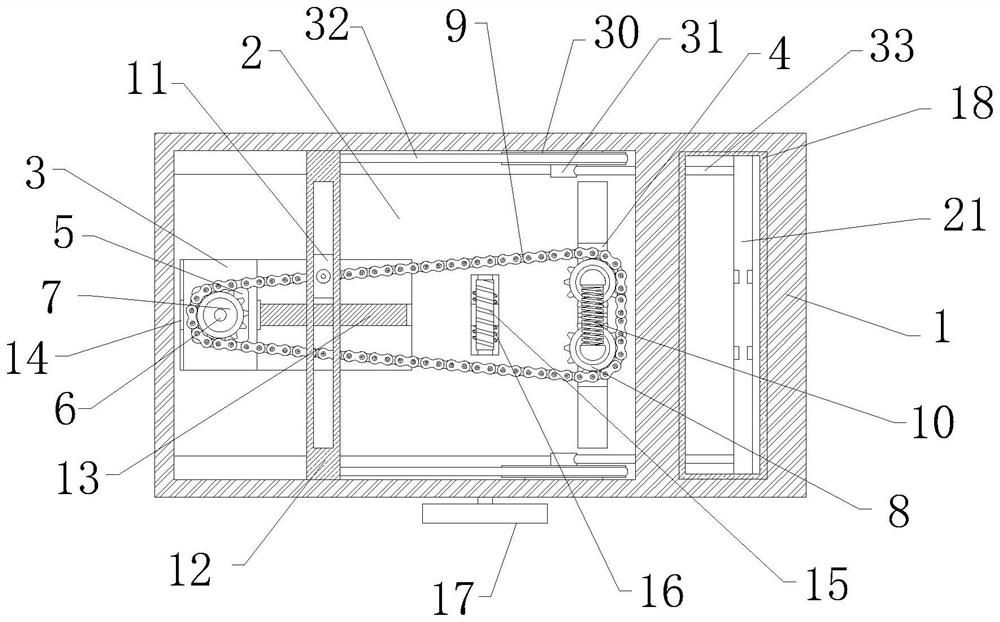

Chemical fiber drawing equipment for textile fabric production

ActiveCN114753014AControl stretch lengthAdjust stretch lengthArtificial thread manufacturing machinesFilament manufactureSpinningFiber drawing

The invention relates to the technical field of chemical fiber processing equipment, in particular to chemical fiber drawing equipment for textile fabric production, which comprises a base and a control cavity, the control cavity is arranged in the base, a control block is slidably mounted in the control cavity, and two moving blocks are slidably mounted in the control cavity and located on the right side of the control block. According to the device, the rotating disc is rotated, the threaded sleeve drives the control block to move, the moving block enables the chain to be in a tightened state all the time, and the rotating block can move along with the chain, so that the sliding frame is driven to continuously move front and back and can stay for a certain time when moving to the right end; the chemical fiber drawing and extending distance can be conveniently adjusted, the effect of controlling the chemical fiber drawing length is achieved, different chemical fiber varieties, spinning methods and product requirements are adapted, the application range of the drawing equipment is widened, workers can conveniently place chemical fibers, and the working efficiency is improved.

Owner:泗县微腾知识产权运营有限公司

Casting mold for metal prefabricated part

PendingCN114346167AGuaranteed cooling efficiencySpeed up cooling and formingFoundry mouldsFoundry coresElectromagnetic valveCold air

The invention relates to the technical field of prefabricated part machining, in particular to a casting mold for a metal prefabricated part. A groove is formed in the top wall of a device shell, a sand mold is movably installed in the groove, a pouring opening and an exhaust hole are formed in the sand mold, and four supporting columns are evenly and fixedly connected to the bottom end of the device shell; a water tank is arranged at the bottom end of the device shell, a water inlet pipe and a water outlet pipe are fixedly connected to one side wall of the device shell, the water inlet pipe and the water outlet pipe both communicate with the water tank, and a first electromagnetic valve is arranged on the water inlet pipe. Cooling is conducted through the condensation pipe, the pump core in the shell can guide cold water in the water tank into the condensation pipe and enable the cold water to flow in the condensation pipe, the cooling efficiency can be guaranteed, cooling forming of the metal prefabricated part can be accelerated, the production efficiency can be improved, circulation of cold air in the grooves can be accelerated in the rotating process of the fan blades, and the cooling effect is improved. And the cooling efficiency can be further improved.

Owner:刘佳伟

An assembled bottle cap injection molding process

ActiveCN111645268BEasy to demouldAffect opening and closing operationScrew-threads articlesDomestic articlesEngineeringWater circulation

Owner:青岛泷友制盖有限公司

Air-cooling and water-cooling integrated drain board forming die

PendingCN114193682APlay the role of air coolingThe molding effect is thoroughEngineeringRaw material

The invention discloses an air cooling and water cooling integrated drain board forming die which comprises a bearing table, a backflow pipeline, a second supporting plate and a material receiving mechanism, the second supporting plate is fixed to the other side of the upper end face of the bearing table, the material receiving mechanism is fixed to the bearing table, and a second conveying belt device is rotationally connected to the top of the bearing table. And the second bearing frame is fixed on the bearing table. According to the air-cooling and water-cooling integrated drain board forming die, water circularly flows in the water conveying pipeline, the forming speed of raw materials is increased conveniently in a water-cooling mode, after the raw materials are formed, the movable die moves rightwards, meanwhile, a second electric telescopic rod extends, the materials are conveniently ejected out, and the forming efficiency is improved. The materials fall on the first conveying belt device and move leftwards under the running action of the first conveying belt device, the materials fall on the second conveying belt device and then move leftwards under the running action of the second conveying belt device, in the process, a second cooling fan blows air downwards, and more thorough cooling forming treatment can be conveniently conducted on the materials.

Owner:建湖县盛源软基材料有限公司

Electronic plastic accessory injection molding processing equipment

The invention discloses electronic plastic accessory injection molding processing equipment, and belongs to the technical field of injection molding machines, the electronic plastic accessory injection molding processing equipment comprises a mounting seat, an injection mechanism and a mounting mechanism are arranged on the mounting seat, the injection mechanism comprises a storage frame, a heating plate, an electromagnetic valve and a discharging block, the storage frame is arranged on the mounting seat, the heating plate is arranged on the inner side wall of the storage frame, and the electromagnetic valve is arranged on the inner side wall of the storage frame. The electromagnetic valve is arranged on the material storage frame and located at the bottom of the heating plate, the mounting mechanism comprises a mounting box, a discharging block is fixedly connected with the material storage frame, a discharging port is formed in the discharging block and communicated with the interior of the material storage frame, the discharging block penetrates into the mounting box, a model block is arranged in the material storage frame and abuts against the discharging block, and the model block is arranged in the mounting box. A multi-directional injection assembly is arranged in the discharging port and used for changing the spraying direction of the raw materials. The raw material spraying device has the effects that raw materials can be sprayed out in different directions, so that the raw materials are sprayed more uniformly, and the raw materials can be better cooled and formed in the mounting box.

Owner:苏州市博力精密塑胶模具有限公司

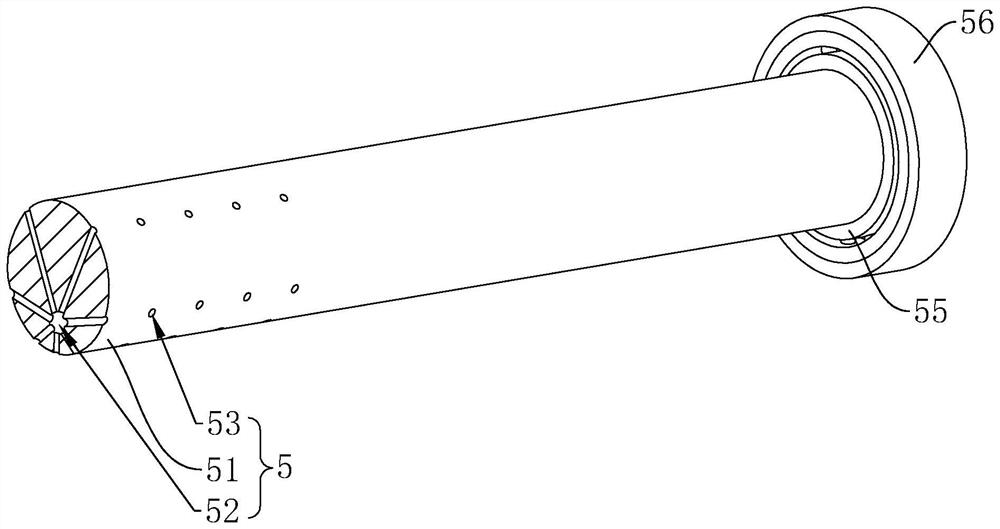

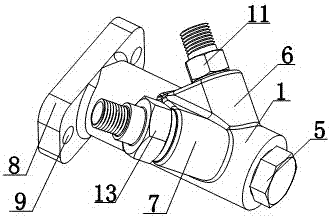

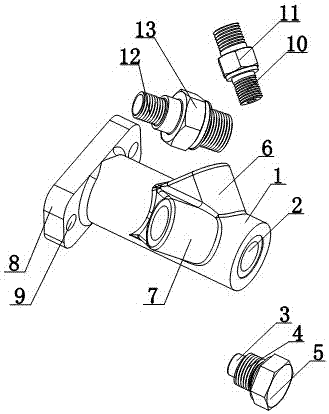

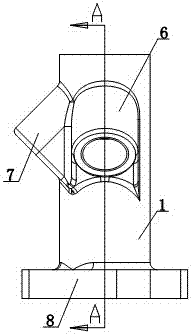

Single-inlet-double-outlet injection mold cooling liquid coupling pipe

The invention discloses a single-input and double-outlet injection mold coolant butt joint pipe, which includes an infusion tube, an infusion cavity is arranged at the axial position of the infusion tube, one end of the infusion tube is a free end, and the other end of the infusion tube is provided with a plug tube. The end of the plug tube is provided with a plug cap, which is fastened on the other end of the infusion tube; the infusion tube is provided with a first liquid outlet seat, and the first liquid outlet seat is connected with a first liquid outlet tube, and The outer surface of the liquid pipe is provided with an external thread, and a first fixing nut is provided between the first liquid outlet pipe and the first liquid outlet seat, and the first liquid outlet pipe is connected with the infusion chamber; the infusion pipe is provided with a second liquid outlet seat , the second liquid outlet seat is provided with a second liquid outlet pipe, the outer surface of the second liquid outlet pipe is provided with external threads, a second fixing nut is arranged between the second liquid outlet pipe and the infusion pipe, and the second liquid outlet pipe Connected with the infusion cavity. The invention can facilitate the delivery of the cooling liquid of the injection mold, facilitate the rapid cooling of the injection mold, and facilitate the cooling and molding of plastic parts.

Owner:朱宏洁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com