Sizing table for vacuum and quick sizing

A technology of fast vacuum and calibrating table, applied in the field of calibrating table, can solve the problems of water ring vacuum pump efficiency drop, accelerate water flow in the calibrating section, and unfavorable profile molding, so as to reduce the waste rate of starting up, avoid loud noise, and facilitate installation reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

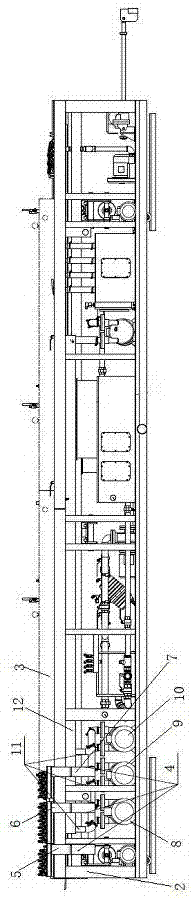

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

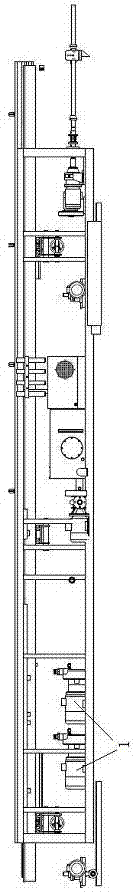

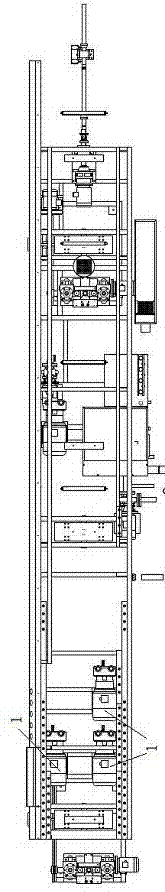

[0026] like image 3 , Figure 4 , Figure 5 and Image 6 Shown, a kind of shaping platform of vacuum rapid shaping comprises frame 2, and described frame 2 is provided with the shaping vacuum section that is used for cooling profile, and described shaping vacuum section is connected shaping mold 3, and described shaping vacuum section includes Four sizing vacuum cabinets, the first sizing vacuum cabinet 15 from left to right is the first sizing vacuum section, the second sizing vacuum cabinet 16 and the third sizing vacuum cabinet 17 are the second sizing vacuum section, the fourth The sizing vacuum cabinet 18 is the third sizing vacuum section, and they are connected to three exhaust passages 4 arranged on one side of the frame through pipelines.

[0027] Three exhaust channels 4 are respectively the first exhaust channel 5, the second e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com