Control system for stabilized soil mixing station

A control system and mixing station technology, applied in roads, road repairs, roads, etc., can solve problems such as large starting current of belt scales, poor system dynamic response, and poor real-time performance of the system, so as to overcome the problem of easy jamming and skip flow , Reduce the waste rate of start-up, and reduce the effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention proposes a control system for a stabilized soil mixing plant.

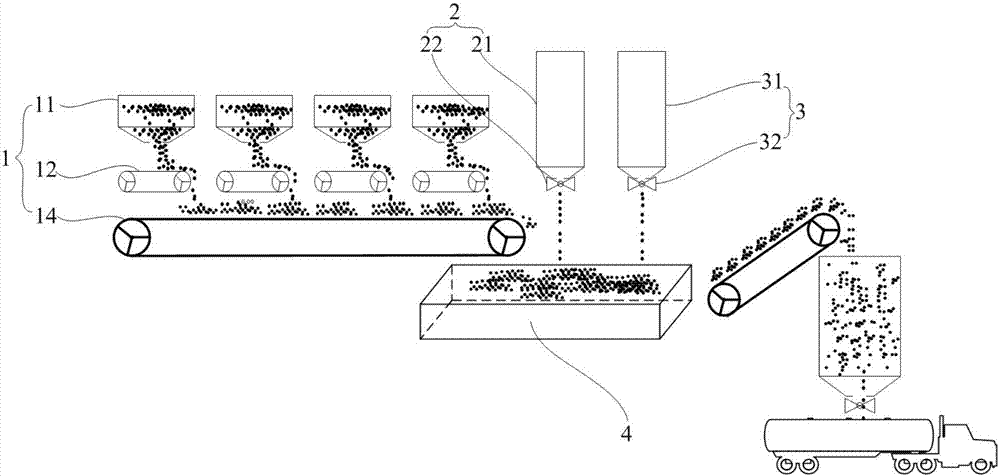

[0024] refer to figure 1 , figure 1 It is a schematic diagram of the structure of the stabilized soil mixing plant.

[0025] Such as figure 1 As shown, the stabilized soil mixing plant includes: an aggregate supply module 1, a stabilizer supply module 2, a clean water supply module 3, a mixer 4, an inclined belt and a finished product storage tank.

[0026] Wherein, aggregates include slag, lime, sand and stones, and the aggregate supply module 1 includes four batching hoppers 11 , four belt scales 12 , four first drive motors 13 and flat belts 14 . The four batching hoppers 11 are respectively used for loading slag, lime, sand and stones. Four belt scales 12 are in one-to-one correspondence with four batching hoppers 11, and each batching hopper 11 is respectively located below the outlet of its corresponding batching hopper 11, and is positioned at the top of the flat belt 14, to transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com