Tool for manufacturing molten steel sampler and method for manufacturing molten steel sampler by adopting tool

A sampler and tooling technology, applied in the field of tools for making molten steel samplers, can solve the problems of skewed heating of sample boxes and metal caps, long sampling time, slow forming, etc., and achieves low manufacturing cost, reduced sampling cost, and uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

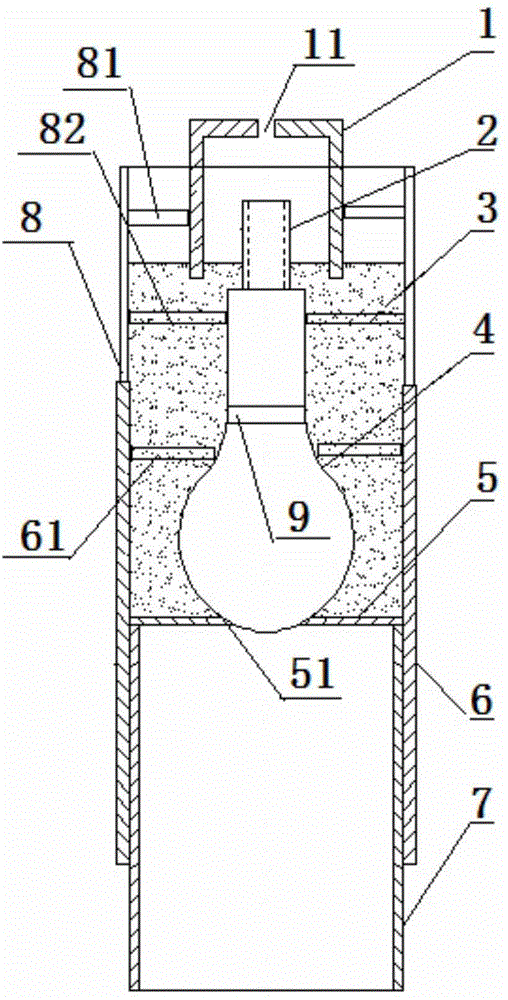

[0043] A kind of frock for making molten steel sampler of the present embodiment comprises metal cap 1, quartz tube 2, coated sand 3, sample box 4, backing plate 5, outer sheath pipe 6 and inner sheath pipe 7, also includes metal Casing tube 8; wherein: the outer diameter of the inner sheath tube 7 is the same as the inner diameter of the outer sheath tube 6, both of which are made of kraft paper, and the inner sheath tube 7 is set on the lower half of the outer sheath tube 6; the backing plate 5 is circular , is also made of paper, covering the upper end surface of the inner sheath tube 7; the sample box 4 is a flat structure in the shape of a "ping-pong racket", which is formed by buckling two symmetrical halves, and stands upside down vertically on the center of the backing plate 5 The place is made of iron; the quartz tube 2 is seamlessly inserted into the inside of the round handle of the sample box 4 "table tennis racket"; the metal sleeve 8 is made of iron in this embodi...

Embodiment 2

[0056] A kind of frock for making the molten steel sampler of the present embodiment has solved the problem of the embodiment 1 through the efforts of the inventor and a series of tests.

[0057] A kind of frock of making molten steel sampler of the present embodiment, its basic structure is the same as embodiment 1, and the improvement is: as figure 1 As shown, the positioning hole 51 of the sample box 4 is set at the center of the backing plate 5, and the positioning ring A81 of the metal cap 1 and the positioning ring B82 of the sample box 4 are respectively arranged in the metal sleeve 8 along the inner wall; the inner diameter of the positioning ring A81 and the metal The outer diameter of cap 1 is identical, and is fixedly connected together with the top of metal cap 1, and location ring A81 is mesh shape, and the inner diameter of location ring B82 is identical with the outer diameter of " table tennis racket " circular handle of sample box 4, also It is mesh-shaped, an...

Embodiment 3

[0069] A kind of tooling of making molten steel sampler of the present embodiment, its basic structure is the same as embodiment 2, and difference is: the material of metal cap 1 is iron; There are 2 reinforcing ribs 61, left and right symmetrically arranged; The vertical distance from the filling surface to the upper end surface of the outer sheath pipe 6 is 2 / 3 of the height of the entire coated sand 3; the metal casing 8 is made of iron; there is no aluminum wire in the "table tennis racket" circular handle of the sample box 4.

[0070] A kind of frock of making molten steel sampler of the present embodiment, the basic steps of the method for making molten steel sampler with it are the same as embodiment 2, and difference is:

[0071] E. Heating: Turn the tooling frame into the oven and heat it. The temperature of the oven is controlled at 360°C, and the heating time is gradual: 50 minutes; when the temperature rises to 360°C, stop heating;

[0072] F. Cooling: After transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com