Electric kettle handle machining device

A processing device and electric kettle technology, which is applied in the field of processing devices for electric kettle handles, can solve problems such as insufficient temperature control, abnormal smell of the handle, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

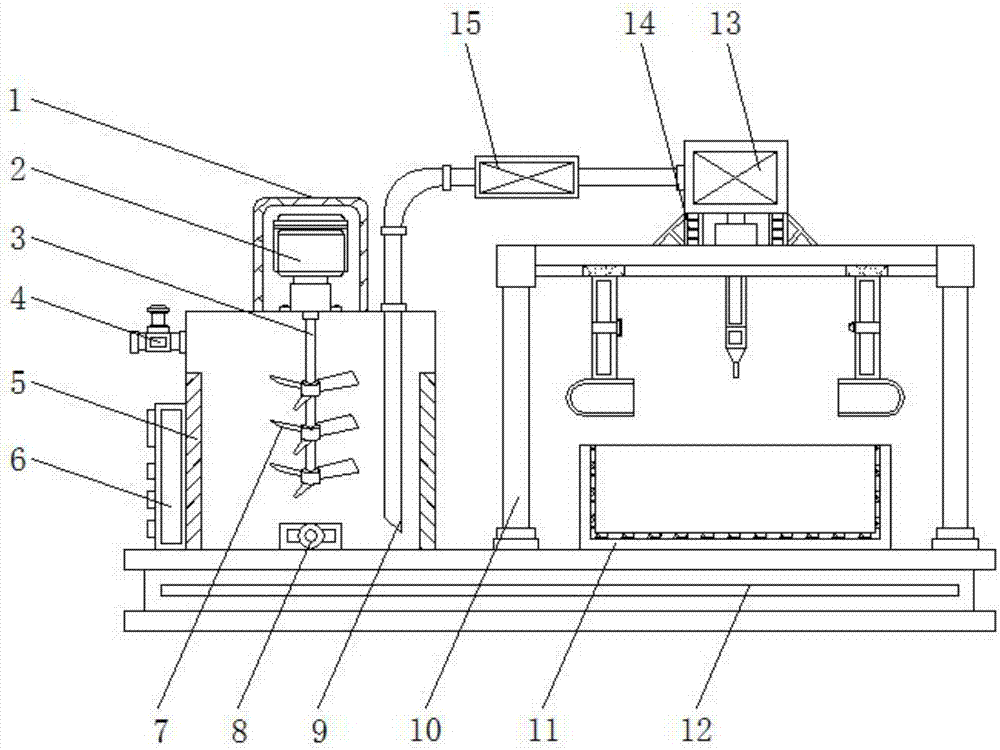

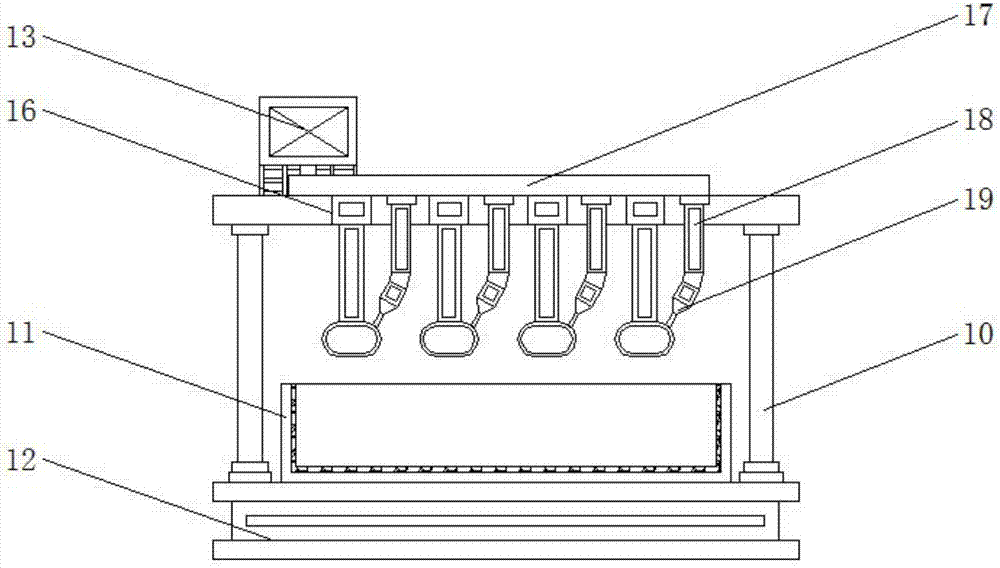

[0019] Such as Figure 1 to Figure 4 As shown, an electric kettle handle processing device includes a motor 2, a heating plate 5, a control box 6, a stirring blade 7, a temperature sensor 8, a receiving tank 11, a support base 12, a booster pump 13, a first half Module 23, the second half module 24 and casing 28, a support frame 10 is installed on one side of the support base 12 top, and the top of the support base 12 inside the support frame 10 is equipped with a receiving tank 11, the inner wall of the receiving tank 11 An activated carbon adsorption layer is installed to facilitate the adsorption and removal of the peculiar smell of the forming mold. A connecting cross bar 16 is evenly installed horizontally between the top ends of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com