Hot pressing and cooling forming device for VR helmet manufacturing

A technology of cooling molding and VR helmets, applied in applications, household components, household appliances, etc., can solve the problems of insufficient cooling structure, failure to replace the cleaning structure, and no shockproof buffer structure, etc., to achieve easy installation and disassembly , easy to replace, and maintain the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

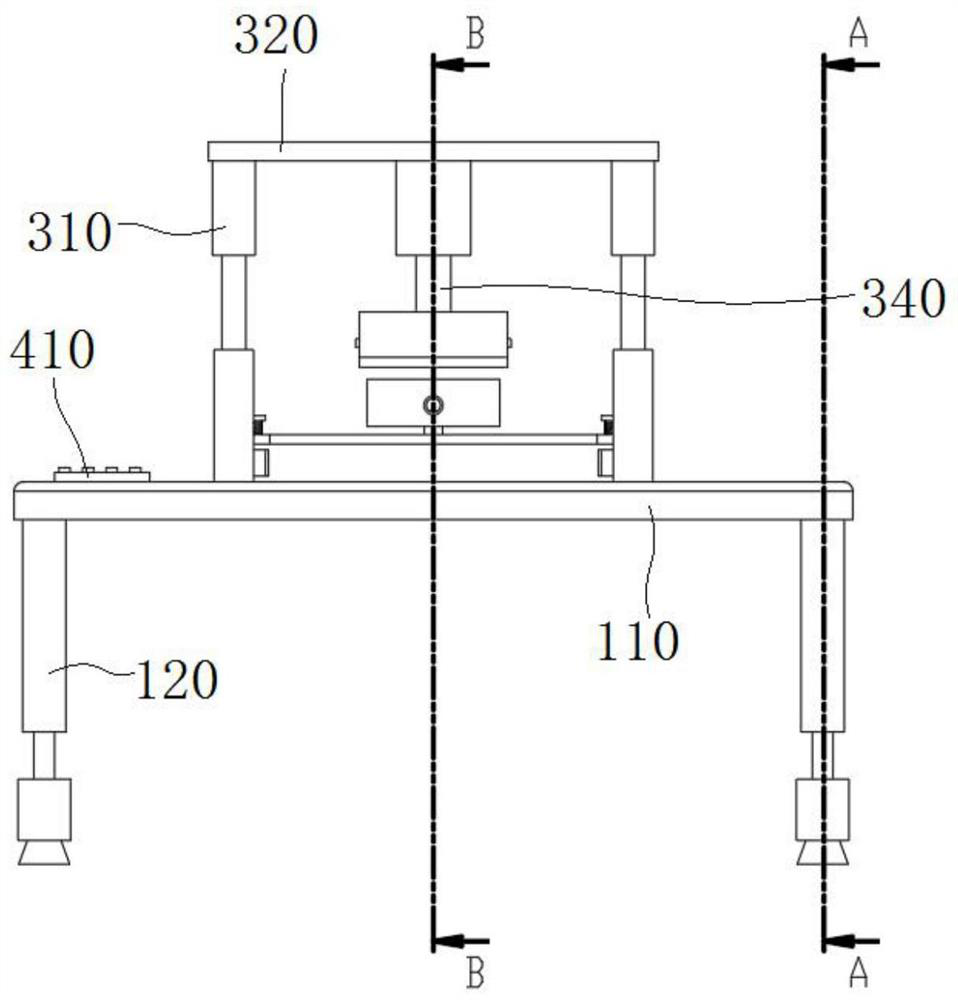

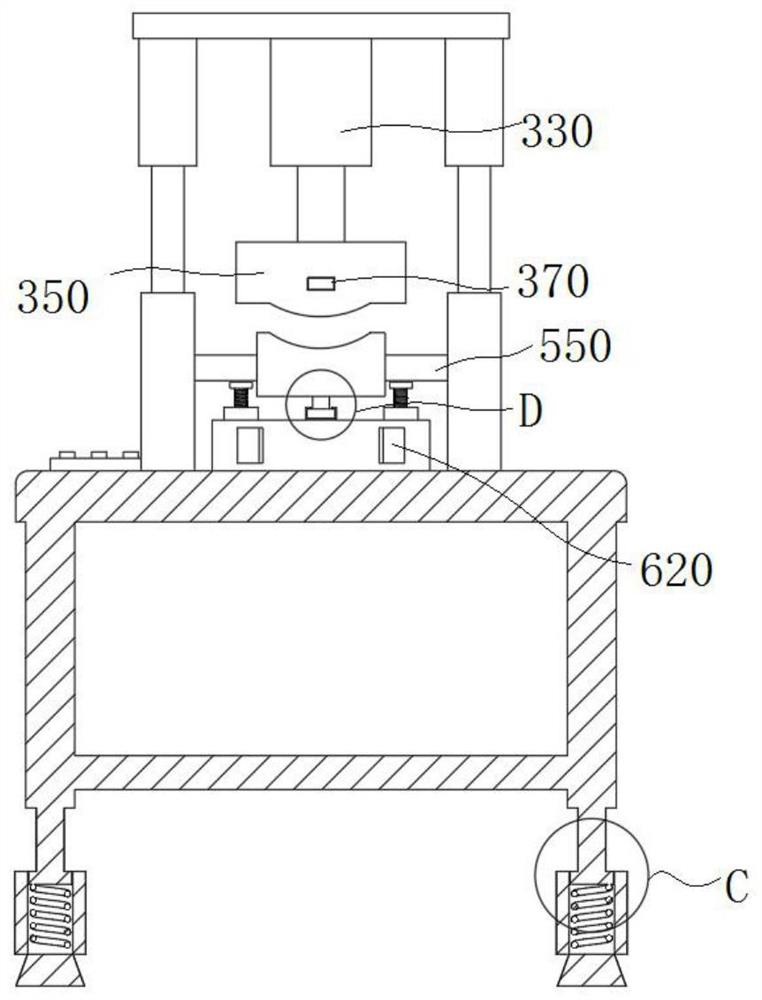

[0032] see Figure 1-7As shown, the present invention is a hot pressing and cooling molding device for VR helmet manufacturing, including a load-bearing structure 100, an installation structure 200, a main structure 300, a control structure 400, a cooling structure 500, a force unloading structure 600, and a buffer structure 700. The feature is that: the carrying structure 100 includes a carrying table 110 and supporting columns 120, the upper surfaces of several supporting columns 120 are welded to the lower surface of the carrying table 110, the mounting structure 200 includes a mounting plate 210, a mounting track 220, a slider 230 and a connecting column 240, The mounting plate 210 is arranged on the upper surface of the bearing table 110, the lower surface of the mounting rail 220 is connected to the upper surface of the mounting plate 210, the upper surface of the mounting rail 220 is provided with a first chute, the slider 230 is slidably matched with the first chute, an...

Embodiment 2

[0041] see Figure 1-7 As shown, the present invention is a hot pressing and cooling molding device for VR helmet manufacturing. Its use method is as follows: when personnel are using it, the installation rail 220 cooperates with the slider 230, and the slider 230 is connected to the fixed mold 360 through the connecting column 240. Installing the fixed mold 360 can be relatively easy to install and disassemble. It is not only convenient to clean the fixed mold 360, but also convenient to replace the fixed mold 360, so as to achieve the purpose of manufacturing different types of helmets, and put the production materials into the fixed mold 360 In the process, through the button 430 and the control panel 410, the hydraulic cylinder 330 and the heating pipe 370 are opened, and the heated movable mold 350 cooperates with the telescopic column 340 to carry out hot pressing. After the hot pressing is completed, the cooling water enters the cooling cavity through the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com