Method for bending forming of windshield

A bending forming and windshield technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of low windshield processing efficiency, etc., and achieve good glass bending effect, strong practicability, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

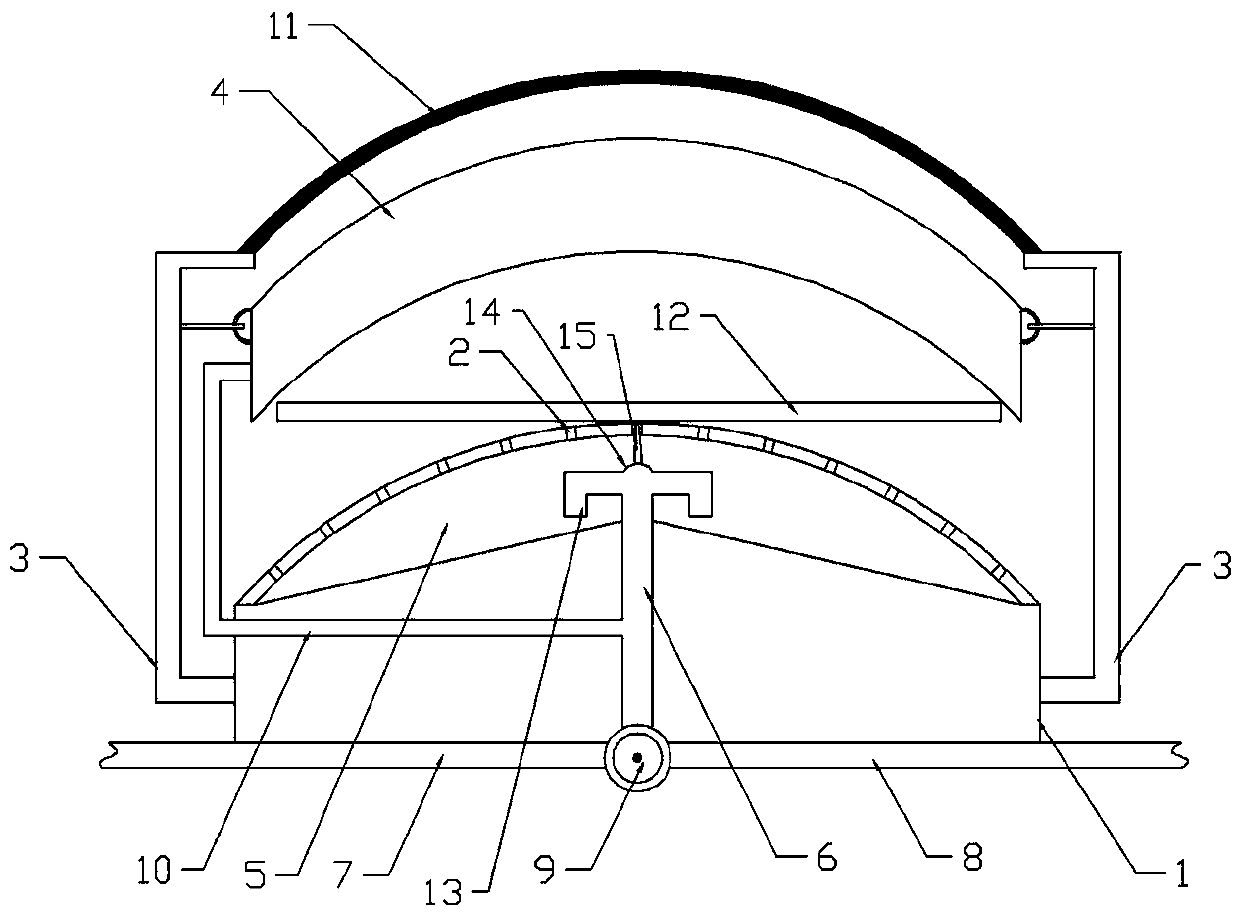

[0020] The reference signs in the accompanying drawings of the description include: bending mold 1, vent hole 2, strut 3, air bag 4, vent chamber 5, first branch pipe 6, second branch pipe 7, third branch pipe 8, valve 9, air pipe 10, Support plate 11, glass 12, M-shaped air duct 13, flexible graphite film 14, marker pen 15.

[0021] The embodiment is basically as figure 1 Shown: a method for bending and forming a windshield of the present invention, comprising the following processing steps:

[0022] Step 1: Perform pretreatment on the windshield 12 raw material to be bent and formed, that is, cut it into required size.

[0023] Step 2: Prepare glass bending and forming equipment, including a hollow bending mold 1, the curved surface of the bending mold 1 is the working surface, a number of air holes 2 are provided on the curved surface of the bending mold 1, and two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com