Novel geotextile production process

A geotextile, a new type of technology, applied in the field of production technology of new geotextiles, can solve the problems of inconvenient construction, prone to offset, local aging, etc., to achieve convenient positioning extrusion molding, ensure normal construction, and good positioning function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

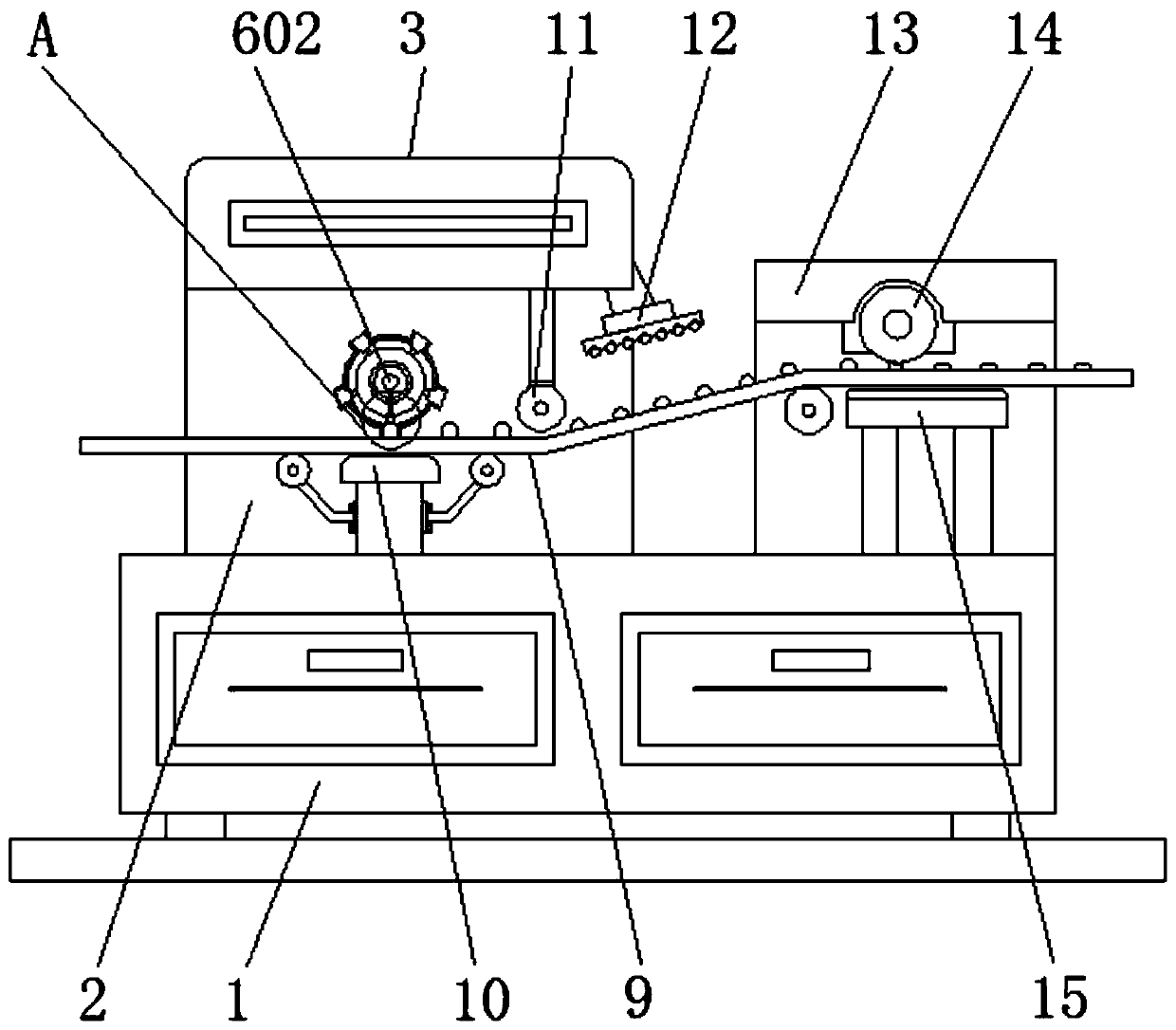

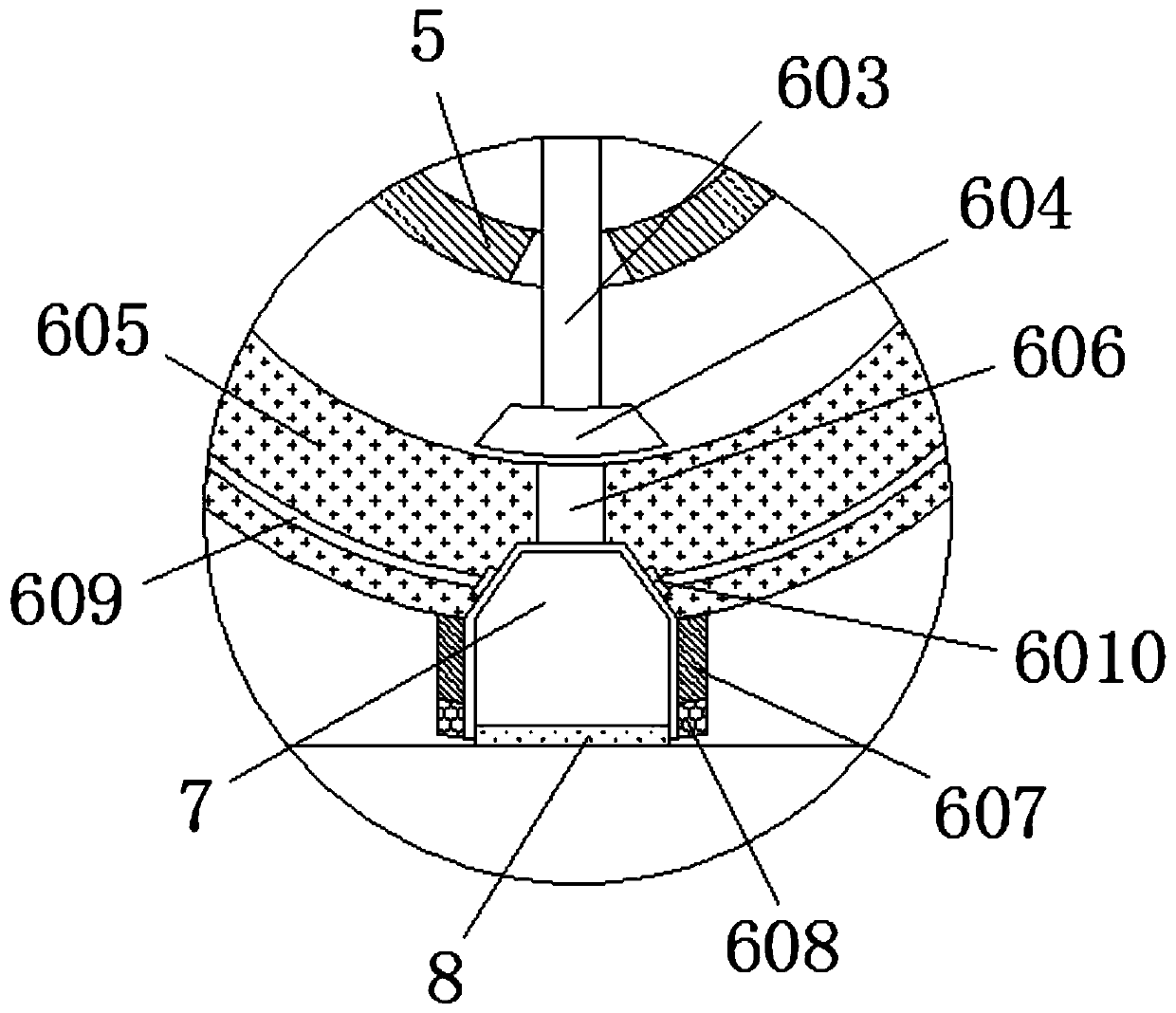

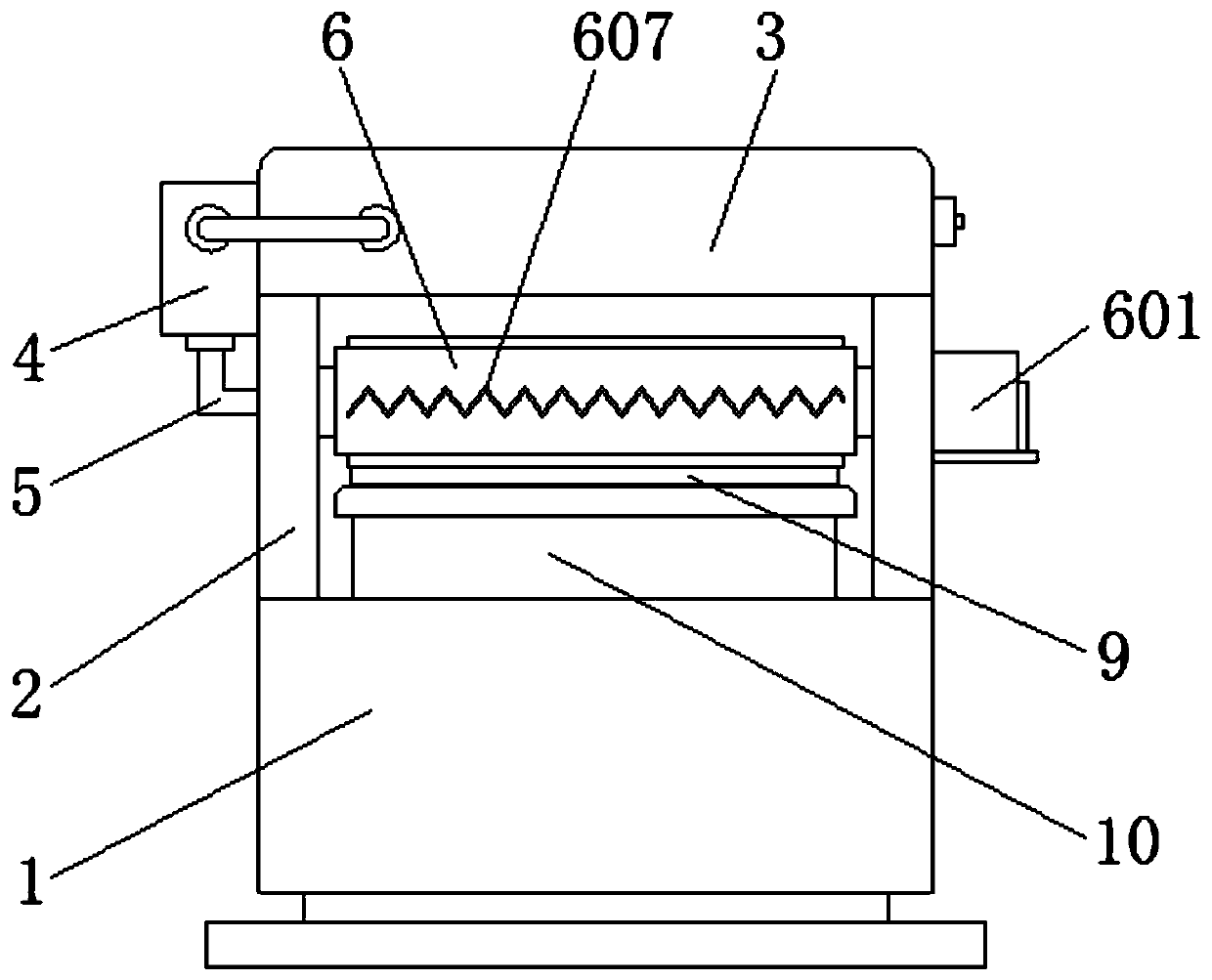

[0052] see Figure 1-8 , a new type of geotextile production process, including a processing box 1, the upper side of the processing box 1 is fixedly installed with a control box 2, the top of the control box 2 is fixedly installed with a hot melt box 3, and the rear side of the hot melt box 3 is fixedly installed There is an extracting mechanism 4, the output end of the extracting mechanism 4 is connected with an output pipe 5, and the outer side of the output pipe 5 is provided with a thermal printing mechanism 6, and the thermal printing mechanism 6 includes a driving motor 601, and the output end of the driving motor 601 is connected with a rotating shaft rod 602, The bottom of the rotating shaft rod 602 is fixedly equipped with a mounting rod 603, the bottom of the mounting rod 603 is provided with a cutting blade 604, the outer side of the cutting blade 604 is provided with a thermal printing shaft 605, and the outer end of the thermal printing shaft 605 is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com