Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Beat evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

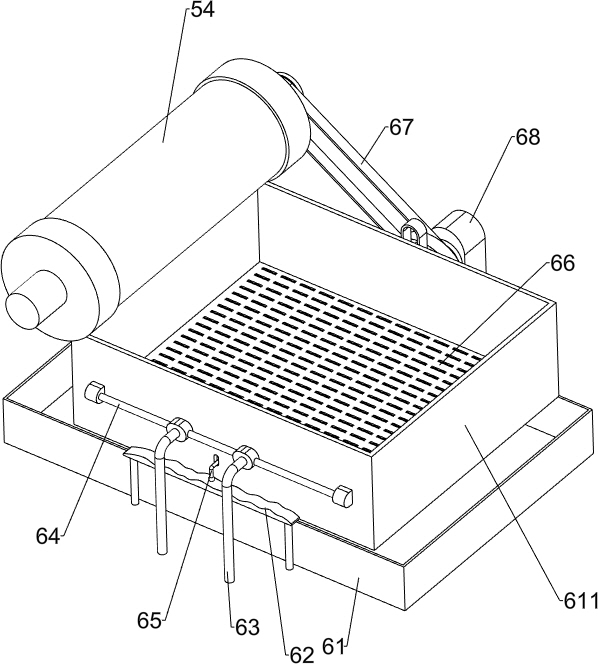

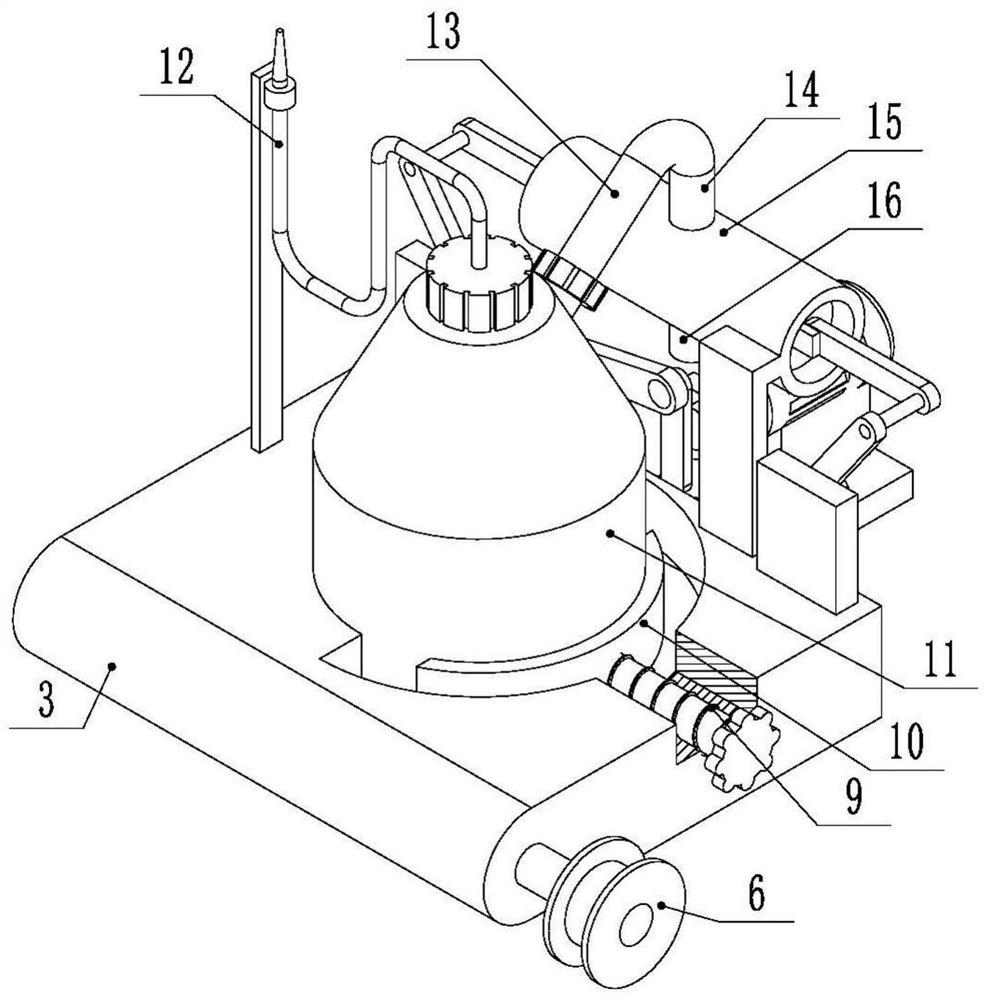

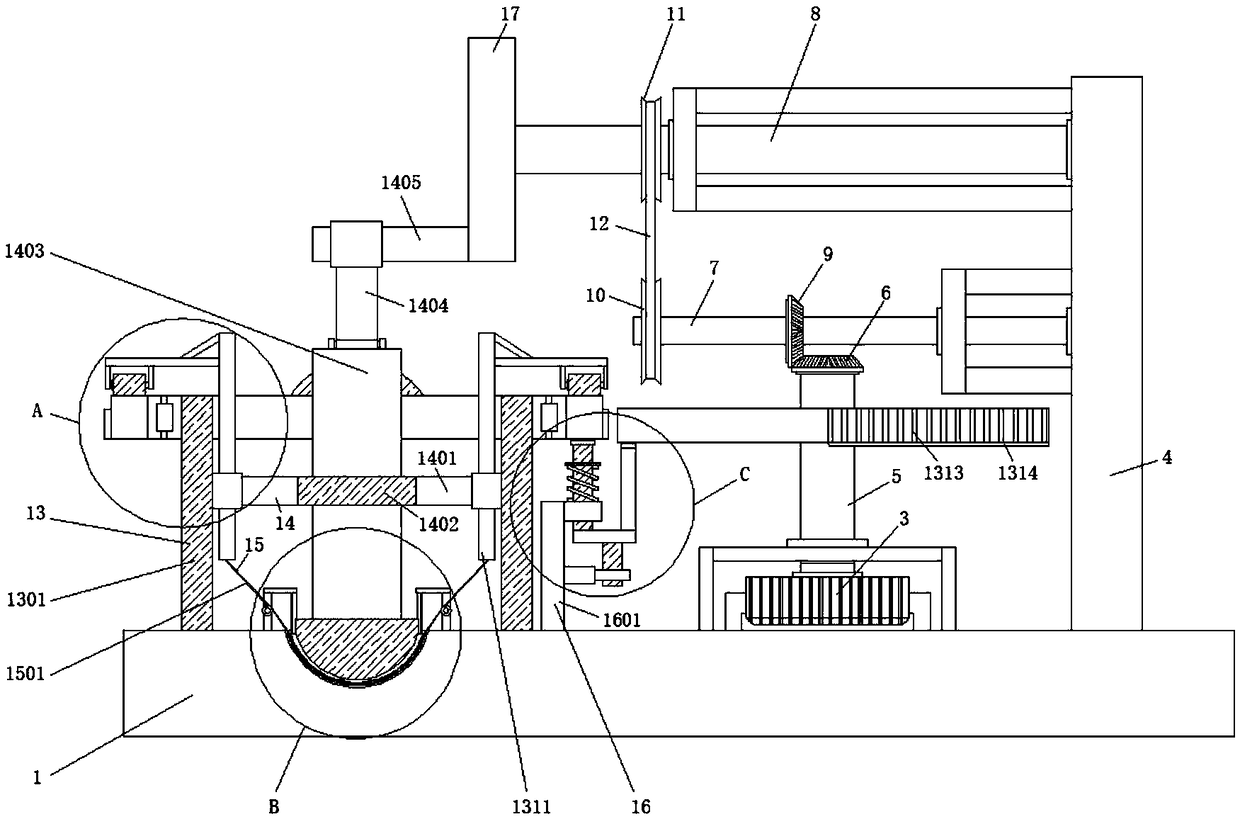

Automatic meat paste hammering machine

InactiveCN104068094AHighlight substantiveHighlight substantive featuresMeat processingEngineeringRaw meat

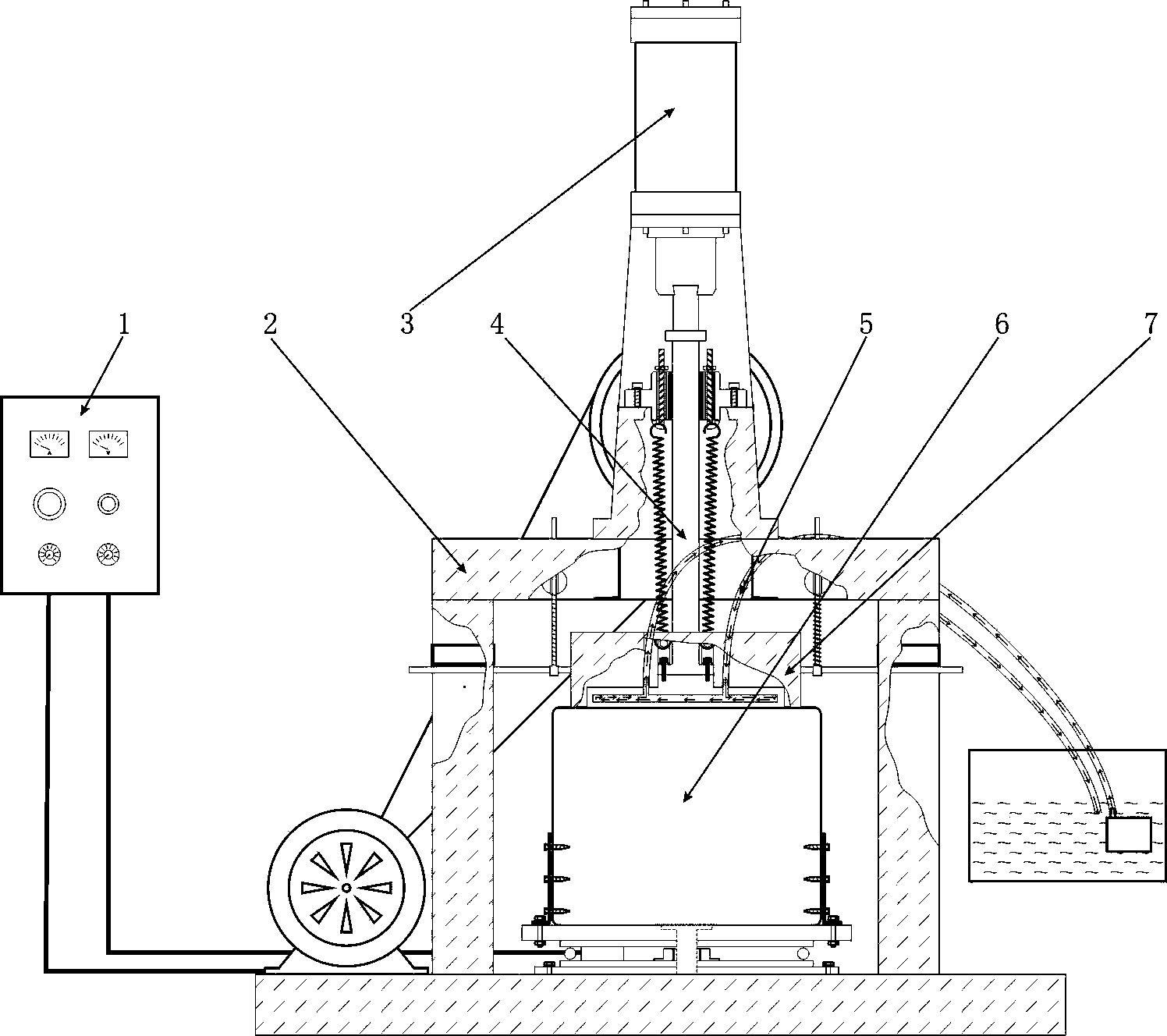

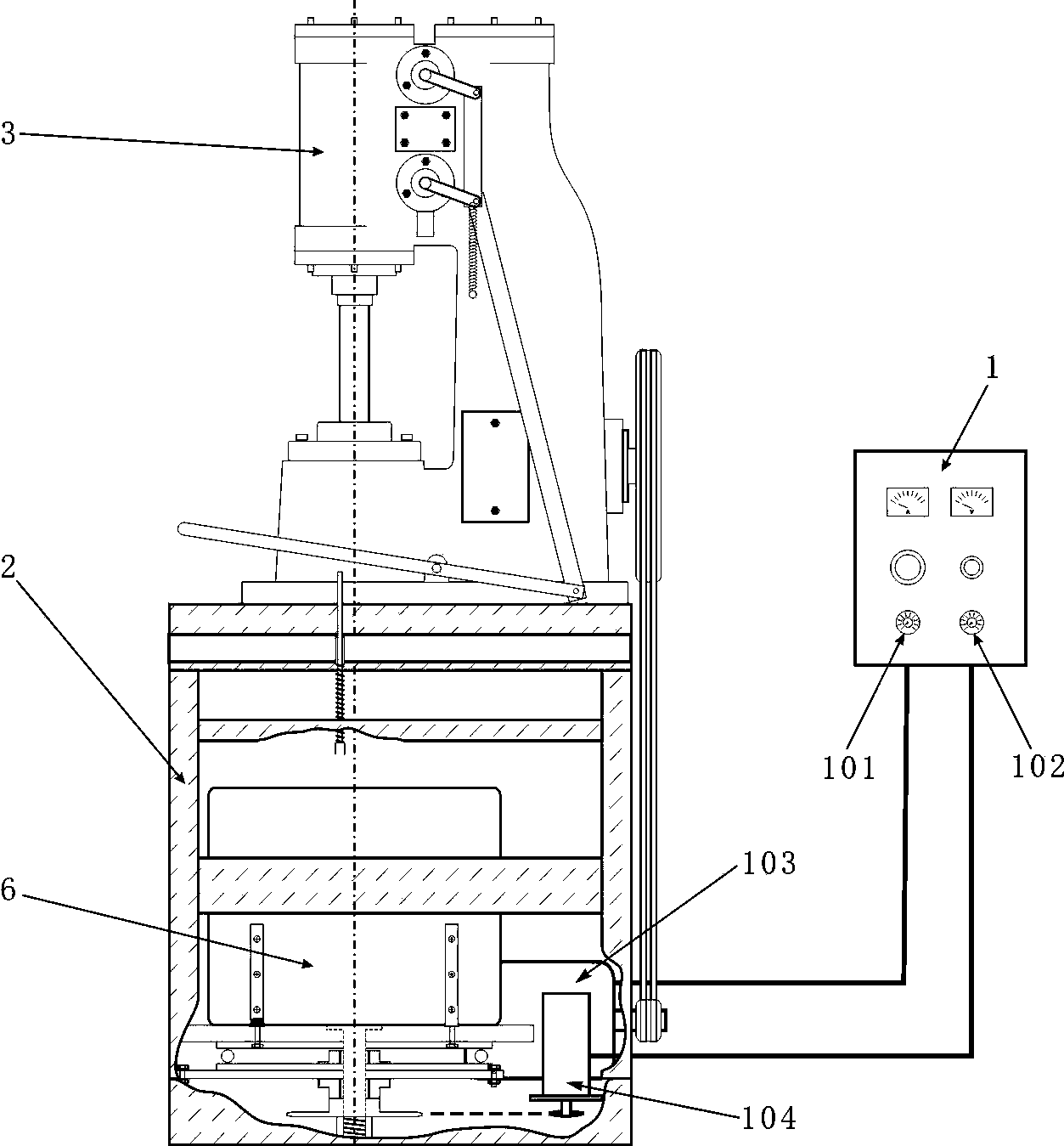

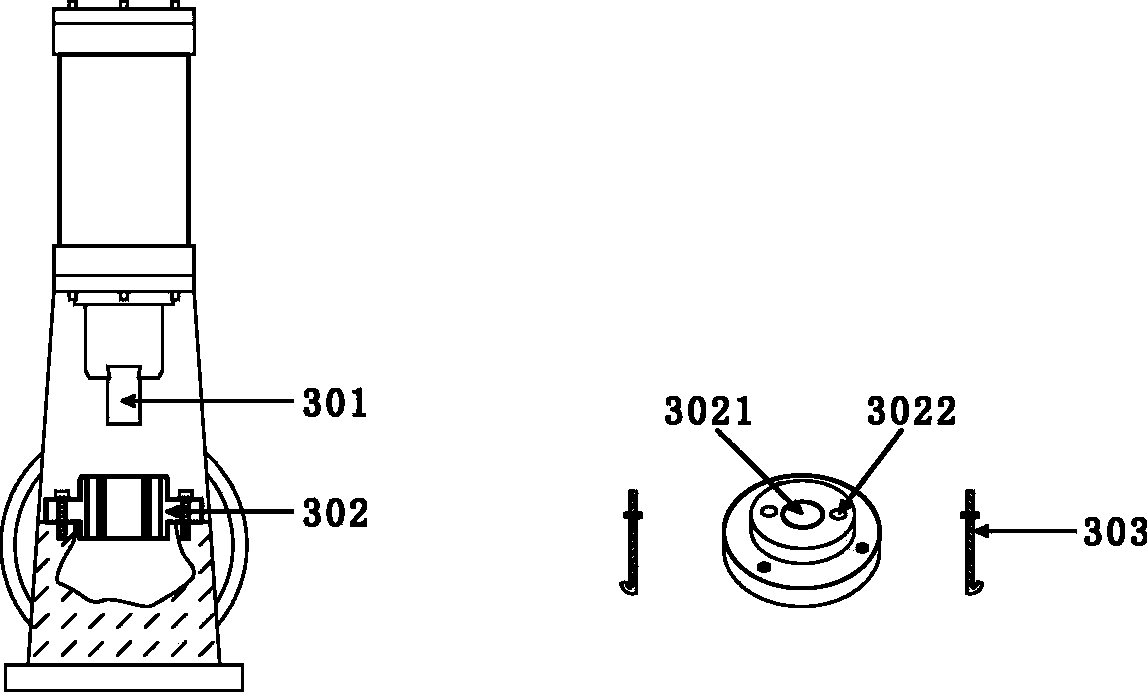

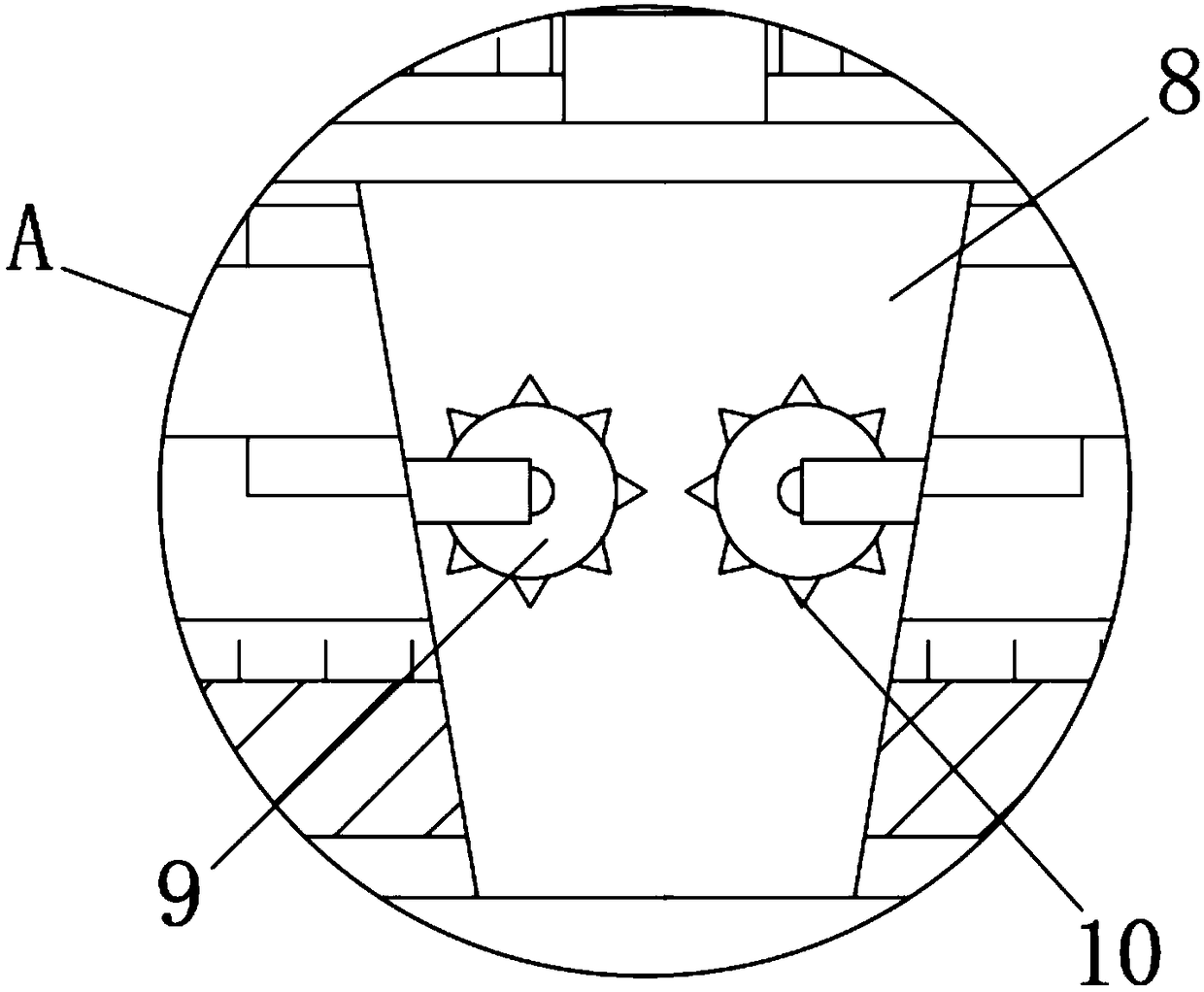

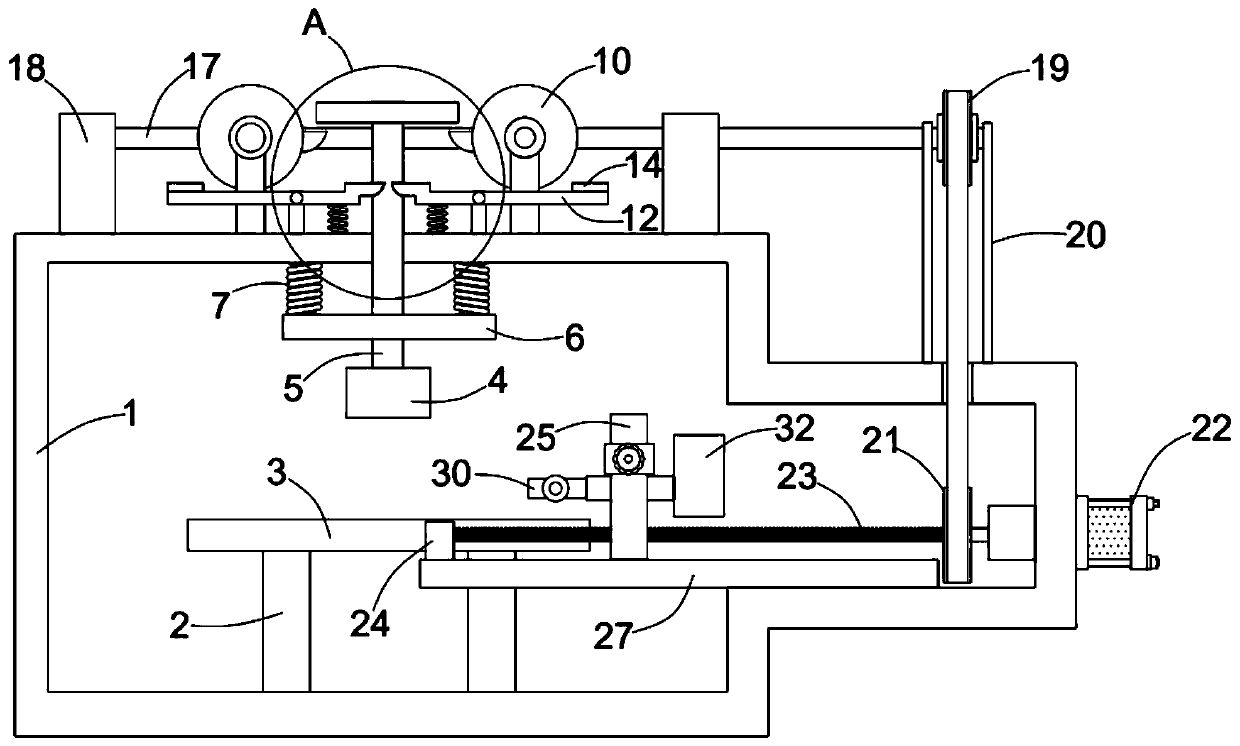

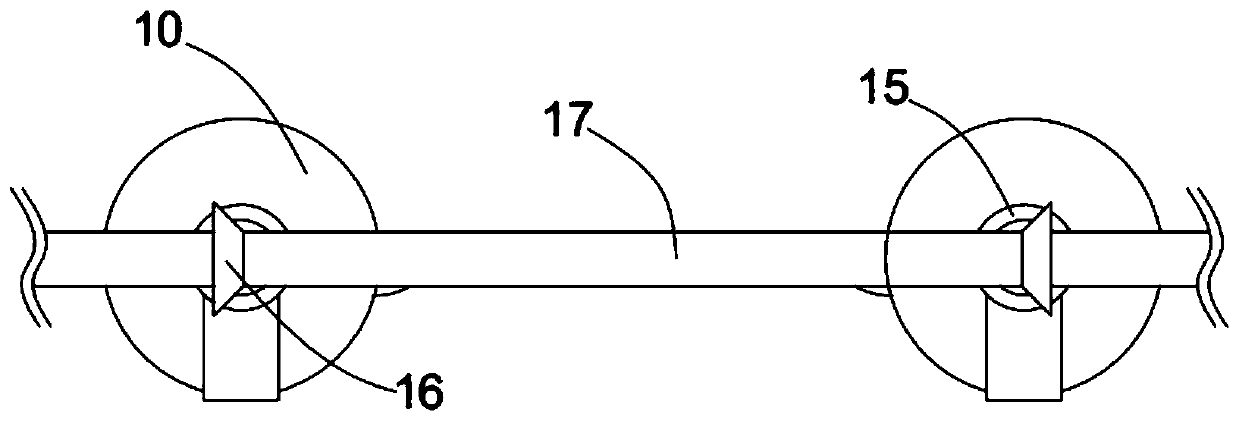

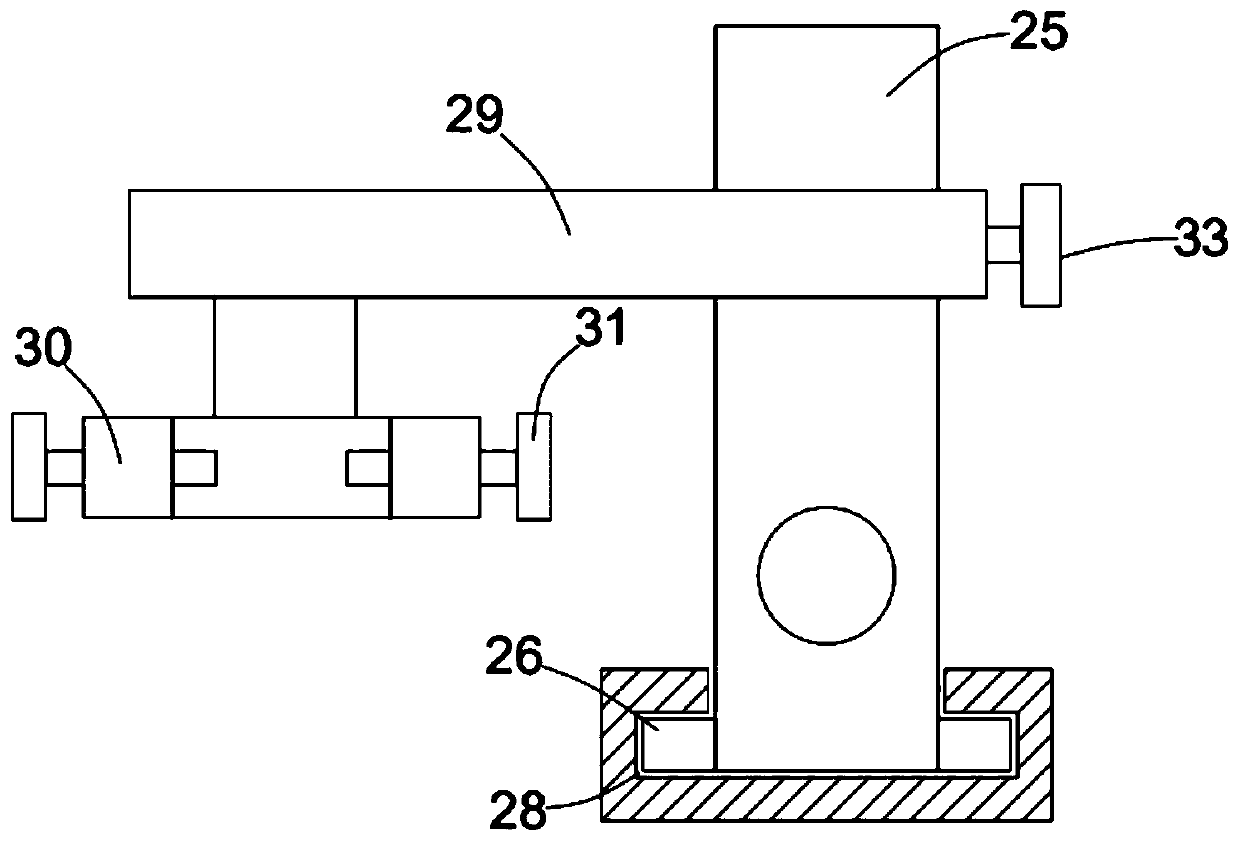

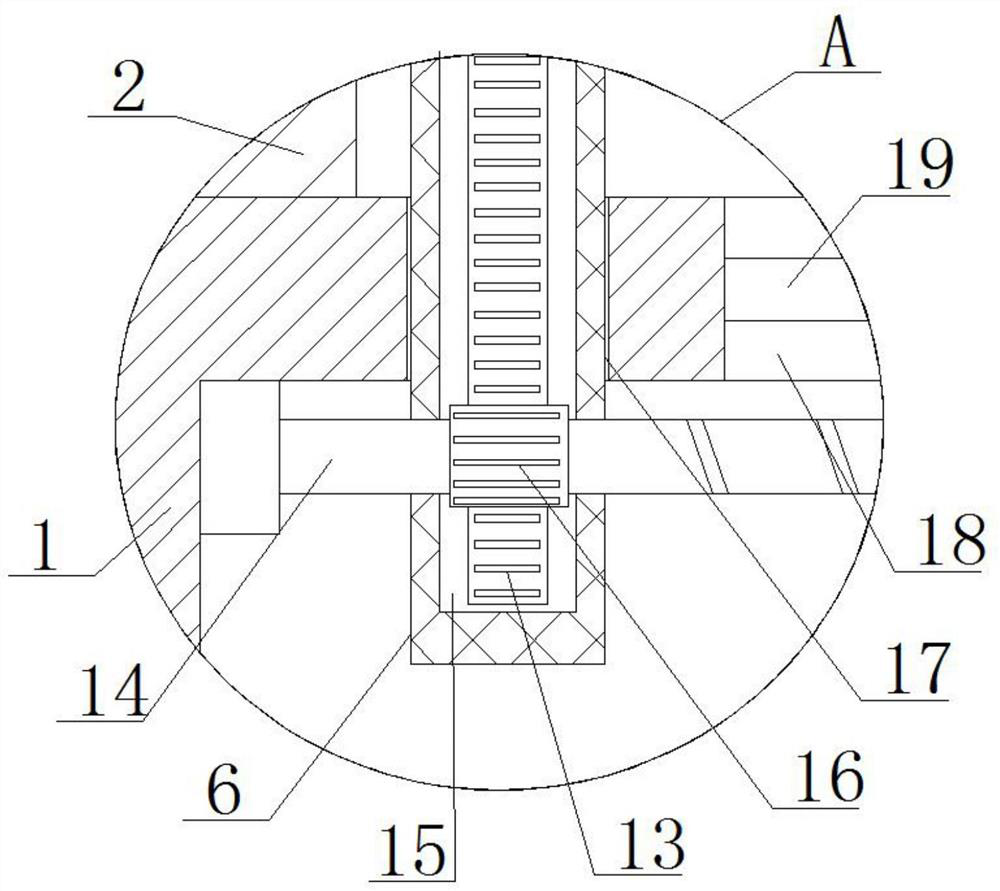

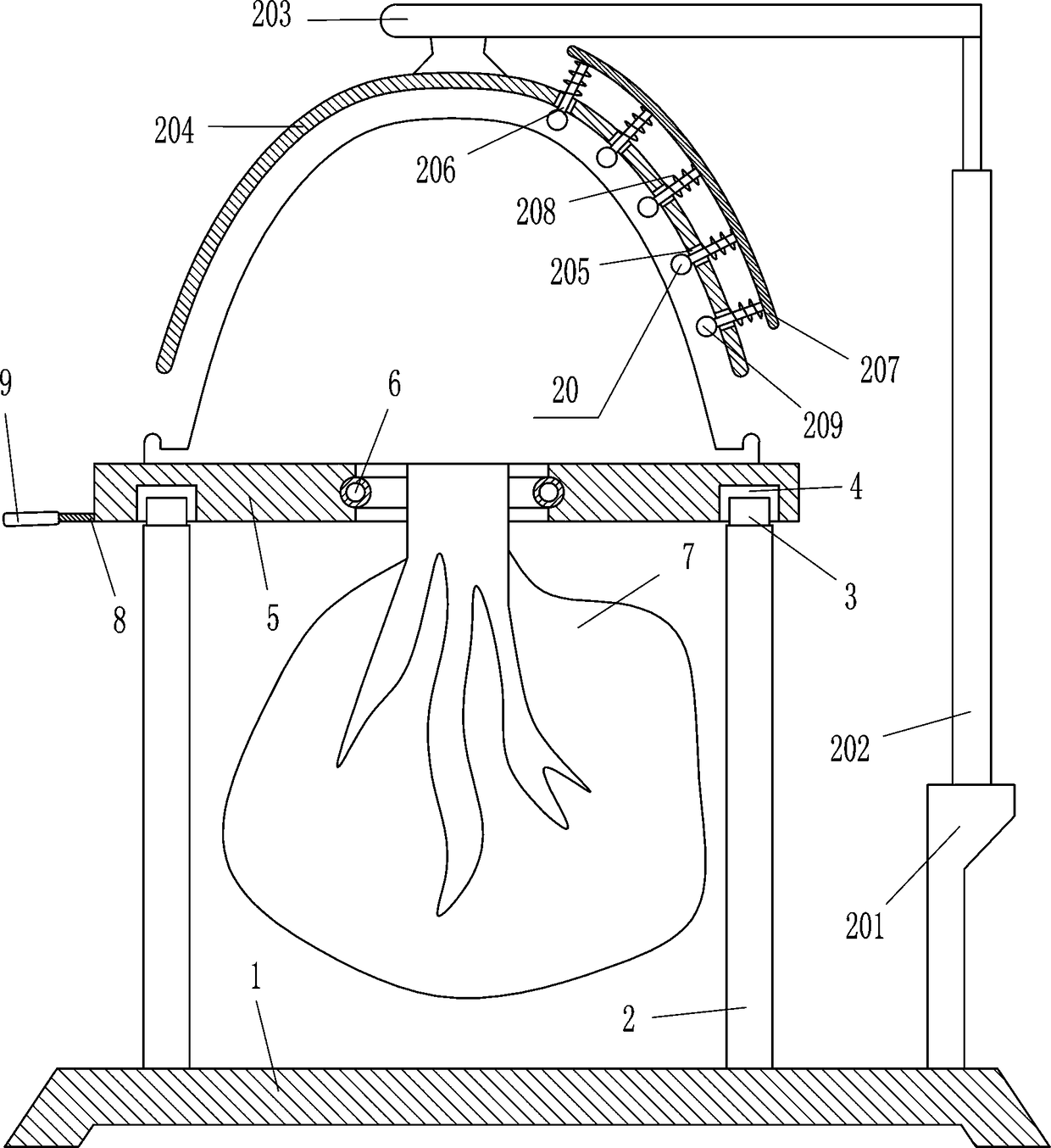

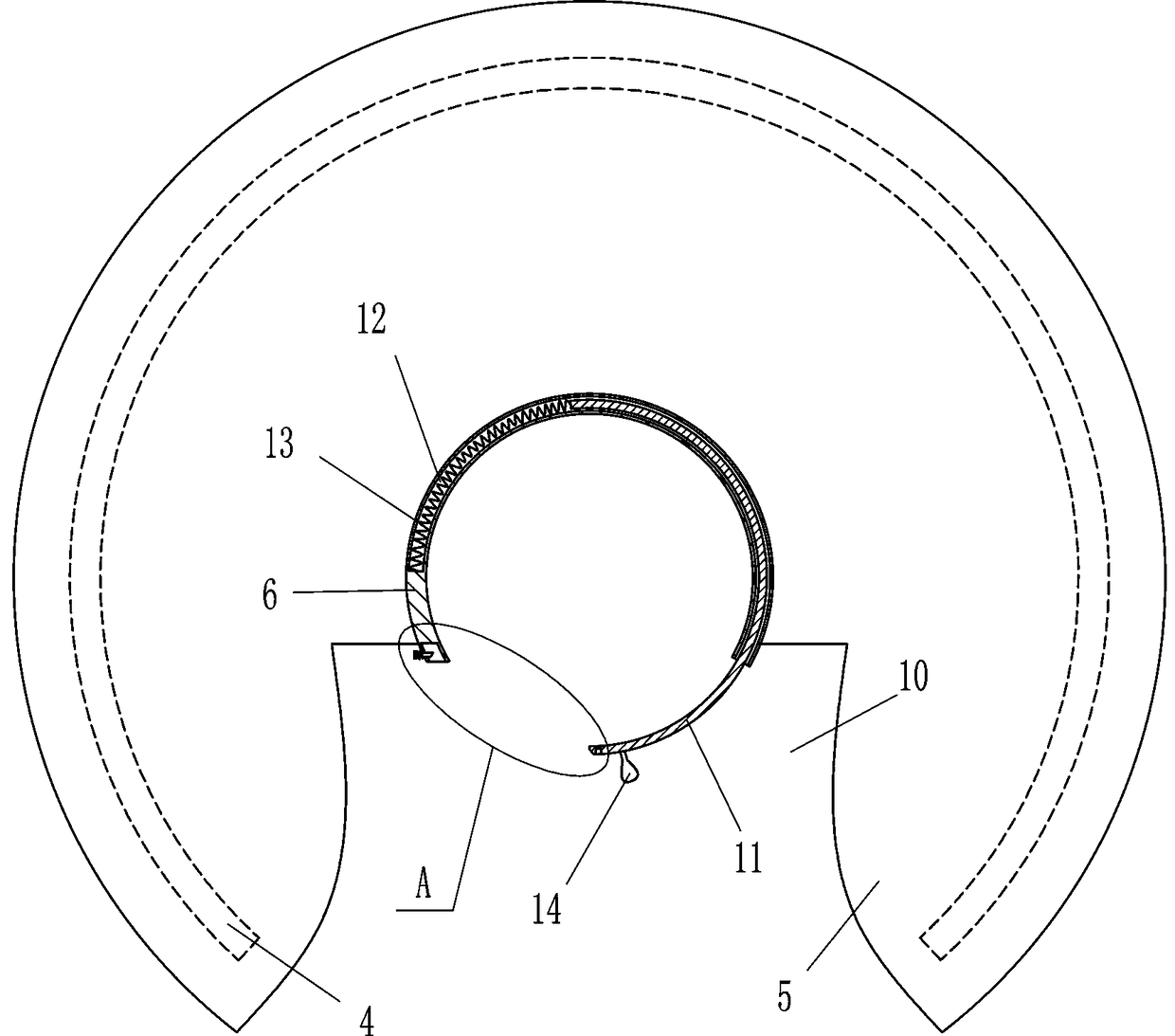

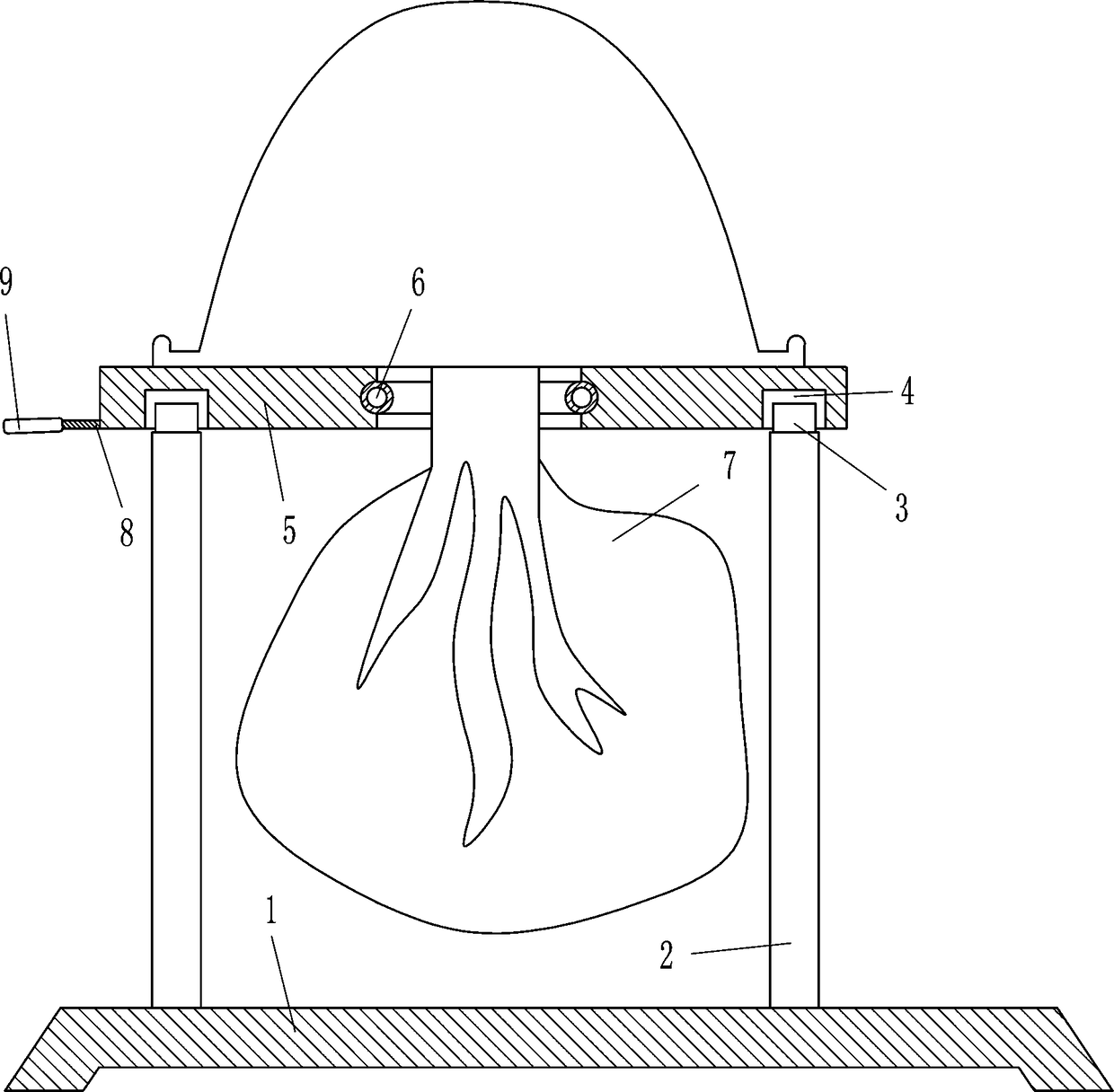

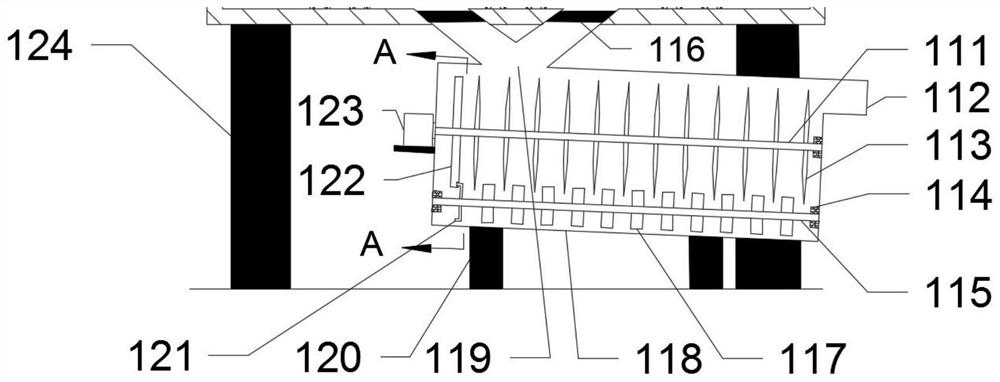

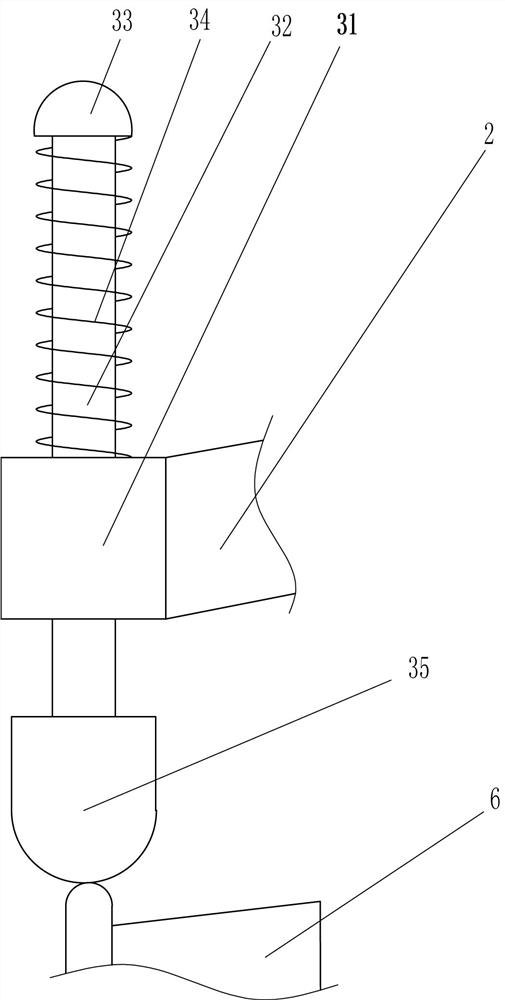

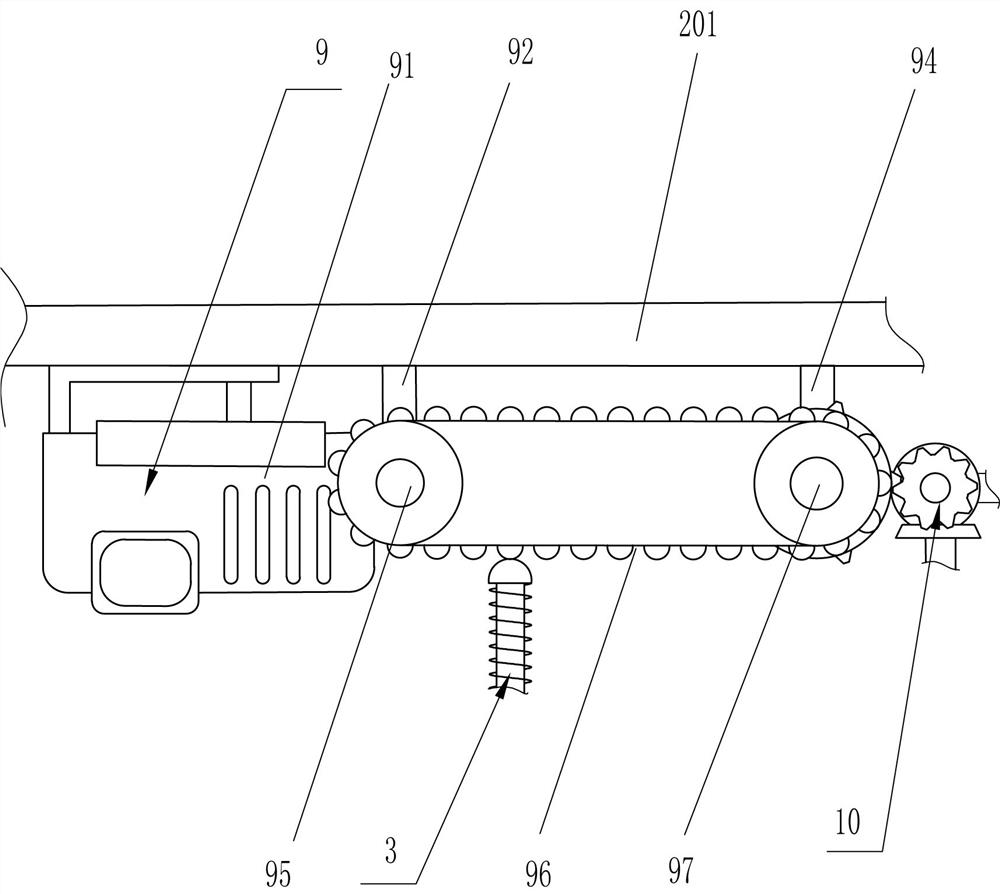

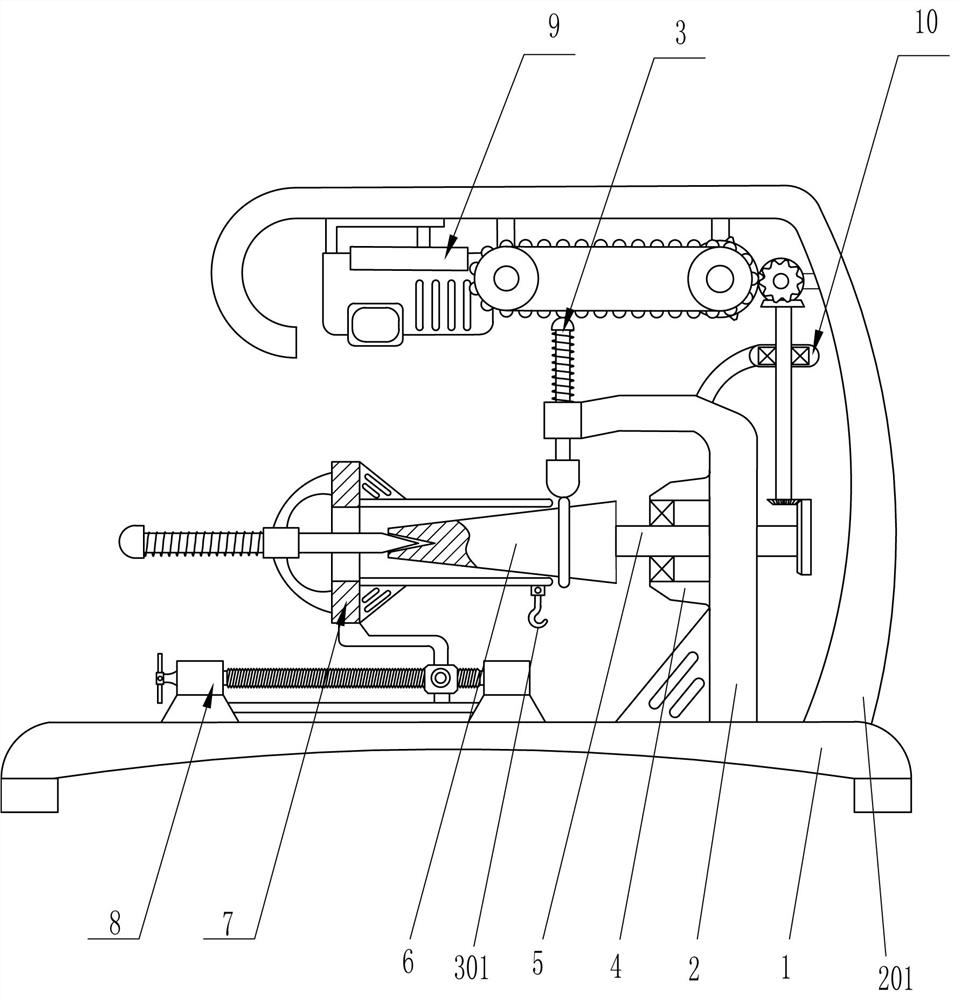

The invention discloses an automatic meat paste hammering machine, and relates to a machine automatically hammering massive raw meat into meat paste. The machine overcomes the defects that the fitness of square iron bars and an anvil face cannot be mastered well, the fineness, the elasticity and the like of the meat paste are not stable, the meat paste is easily deteriorated after hammering heating, and the physical energy is consumed when the massive raw meat is manually hammered into the meat paste with the two square iron bars in the current local characteristic technology of manual meat ball hammering. The machine is characterized in that a hammering area is formed by hammering a rotating anvil face arranged below in a fixed direction with a rectangular hammering bar in an extending hammering device of an air hammer; a used baffle device turns over the massive raw meat to the hammering area during rotation of the anvil face and avoids overflow; a coolant circulation cooling loop in the rectangular hammering bar reduces a heating state of the massive raw meat or the meat paste on the anvil face in a hammering process and improves the quality of a finished product until the massive raw meat is completely and uniformly hammered into the finished meat paste; and the characteristics of fine and elastic hammered meat paste and the like are shown better.

Owner:黄裕原

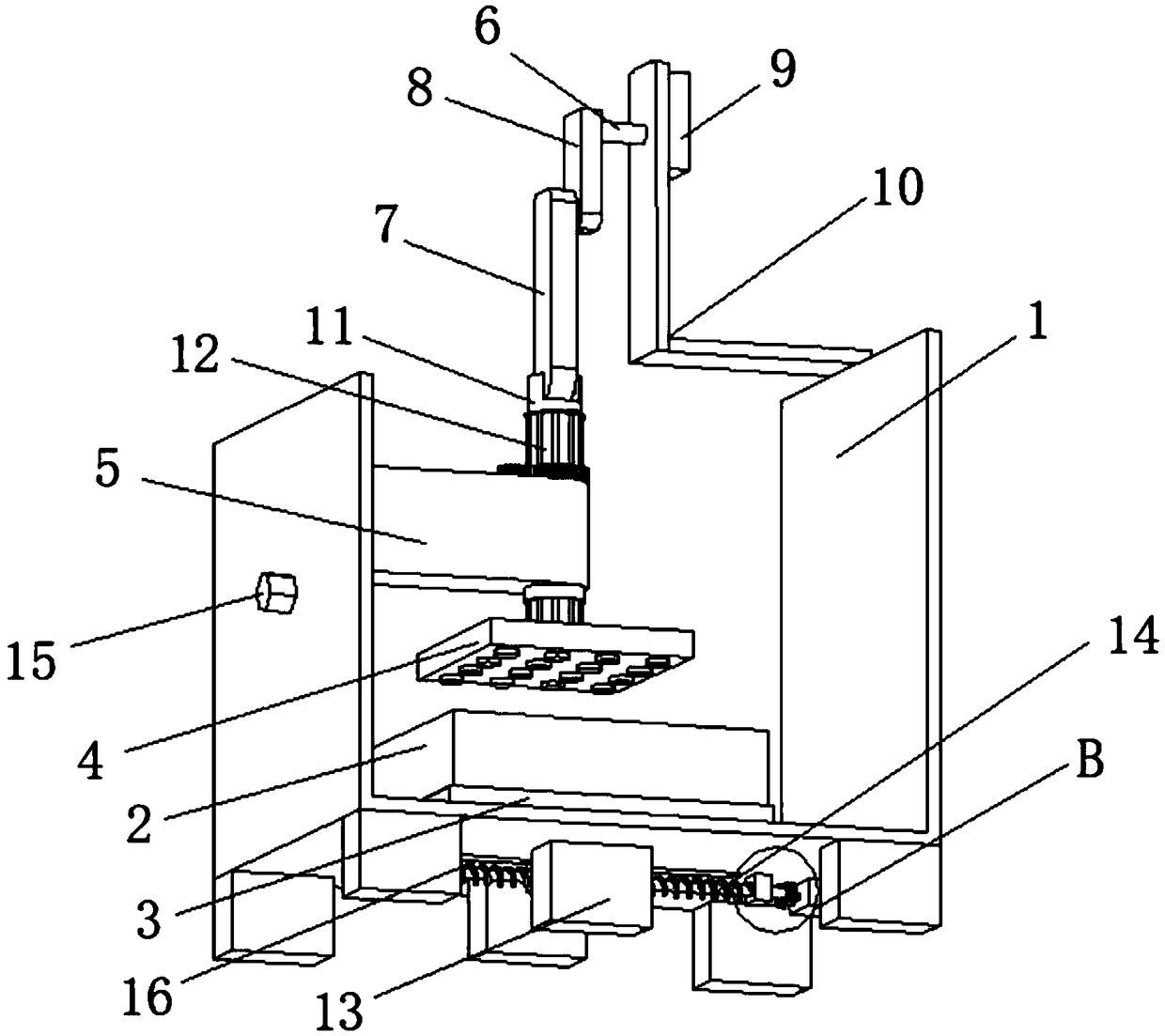

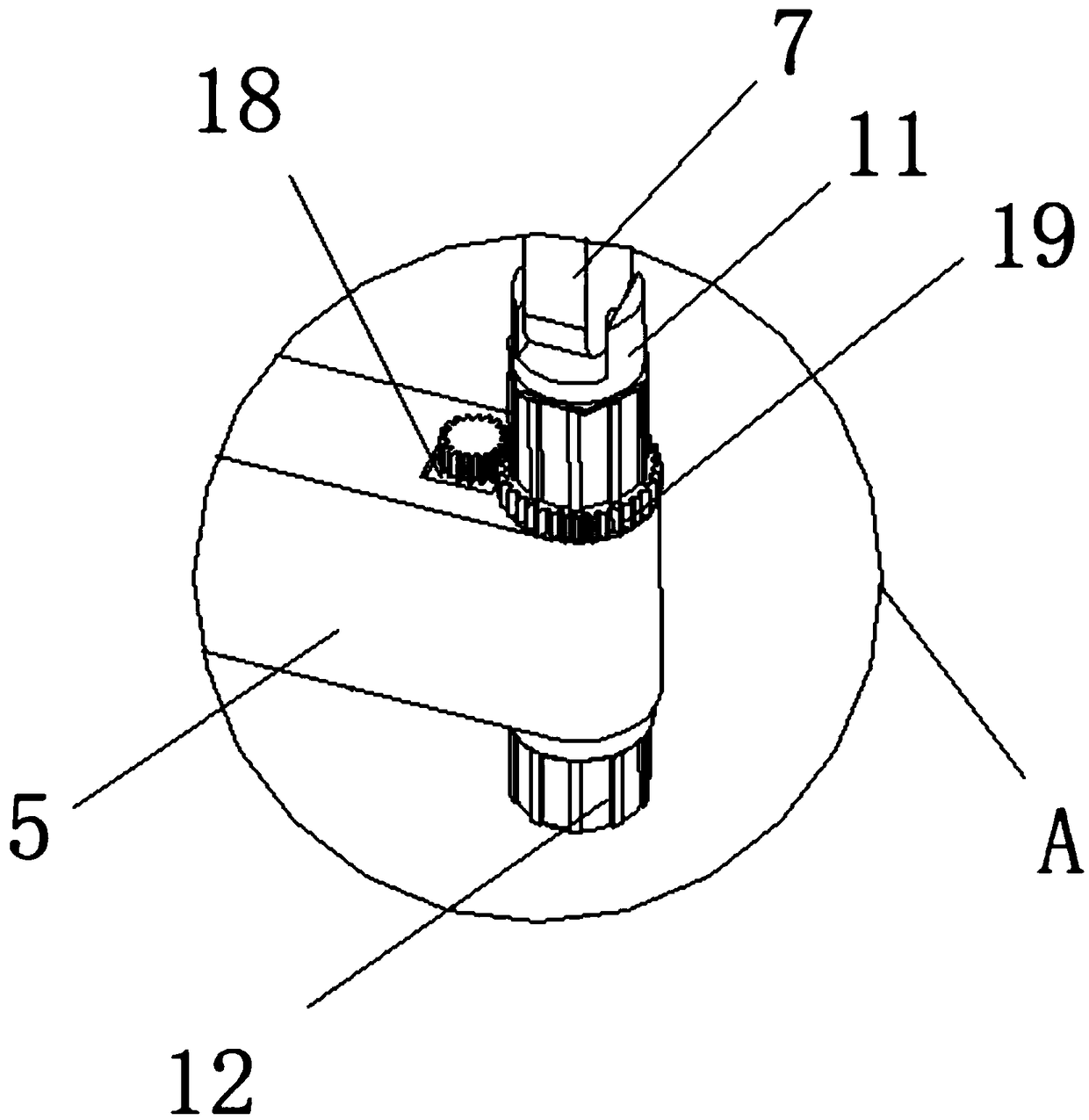

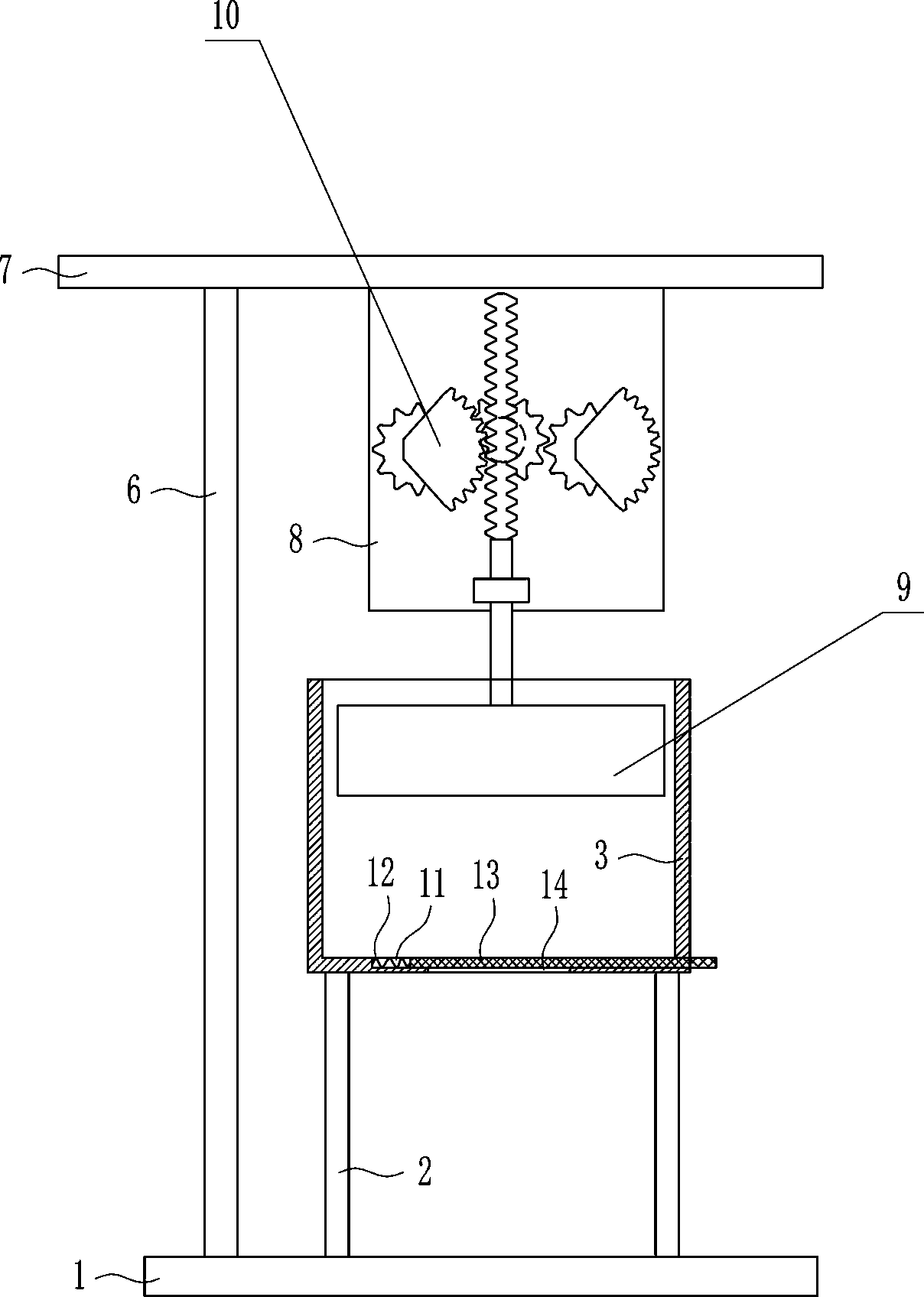

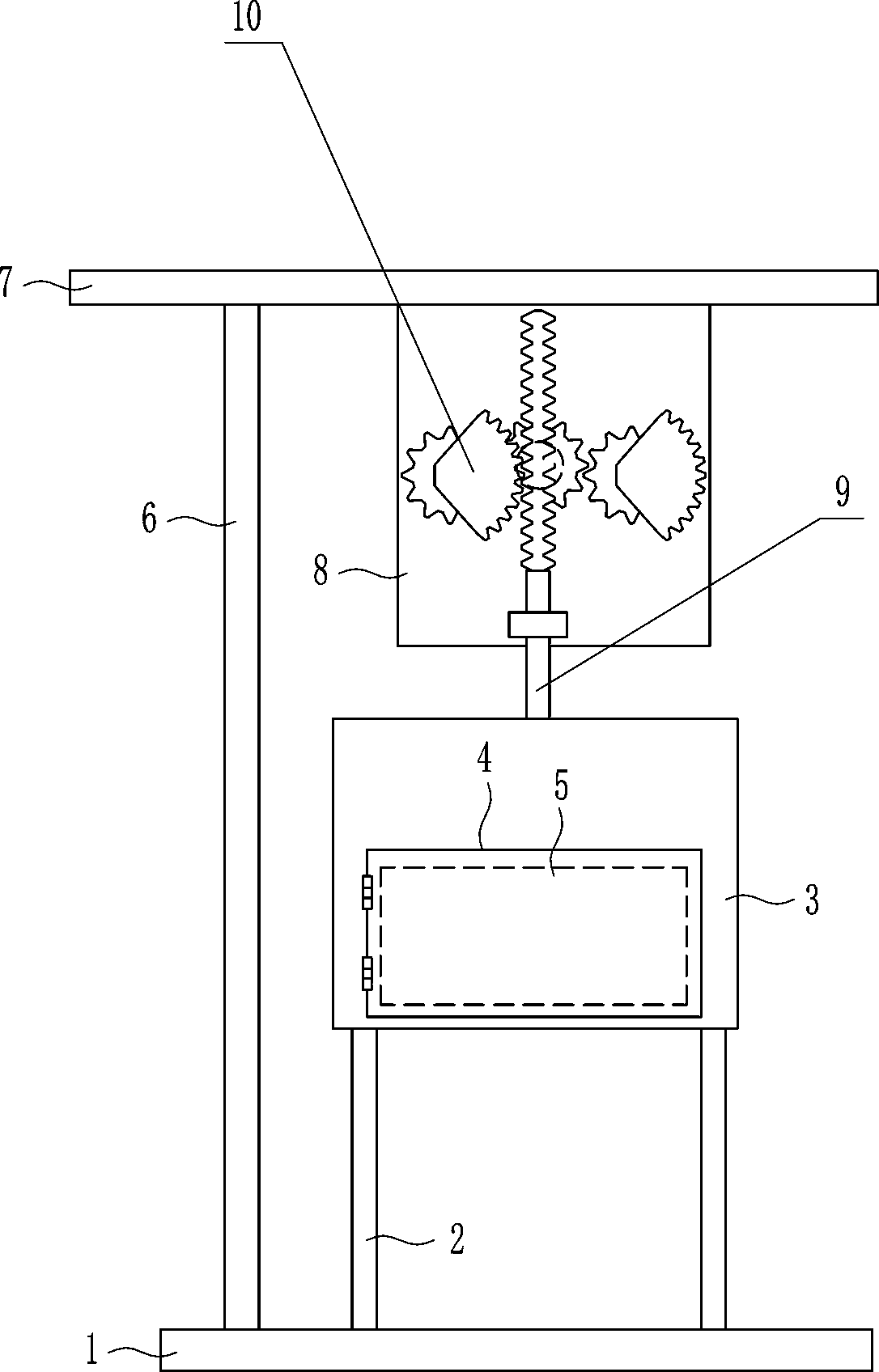

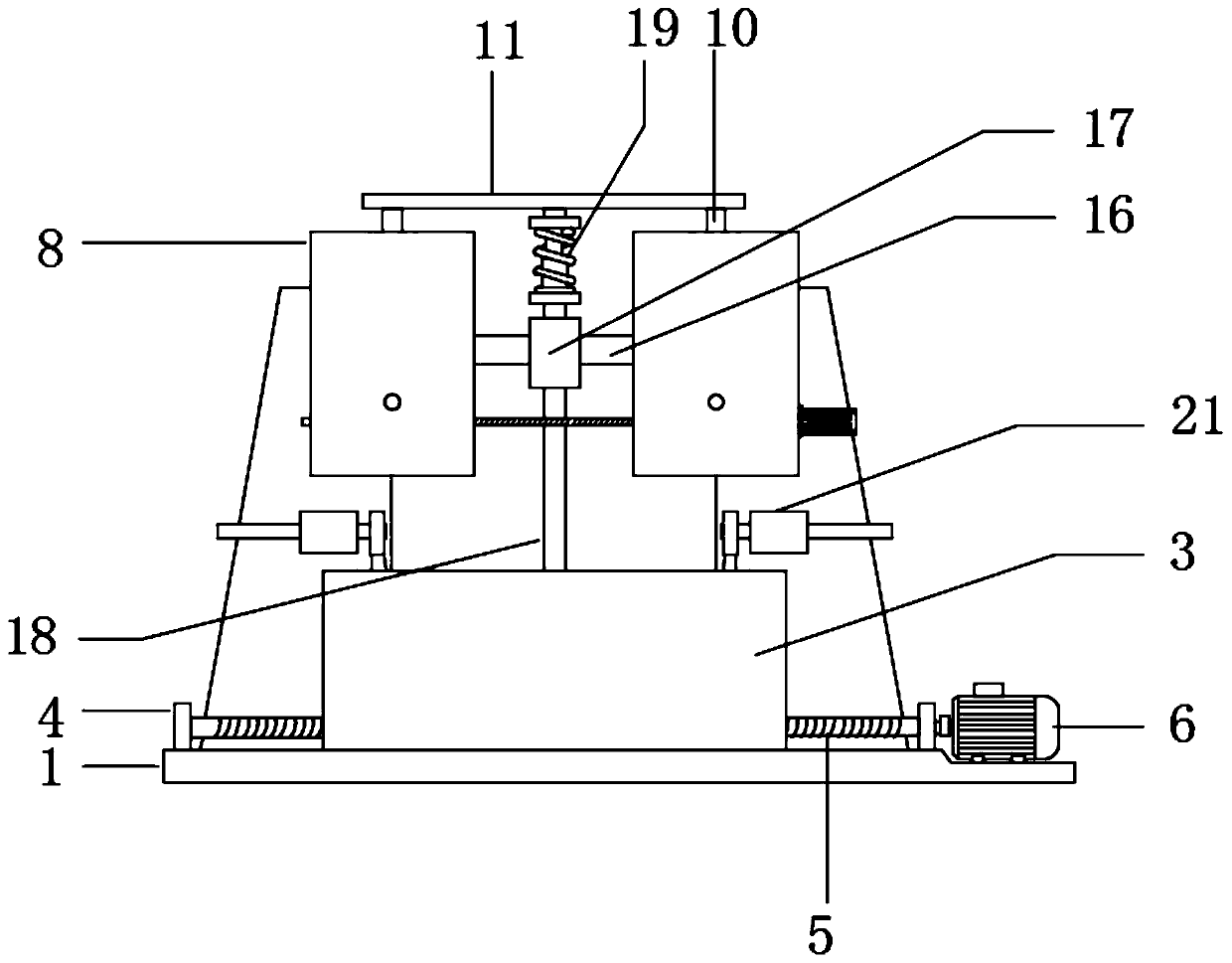

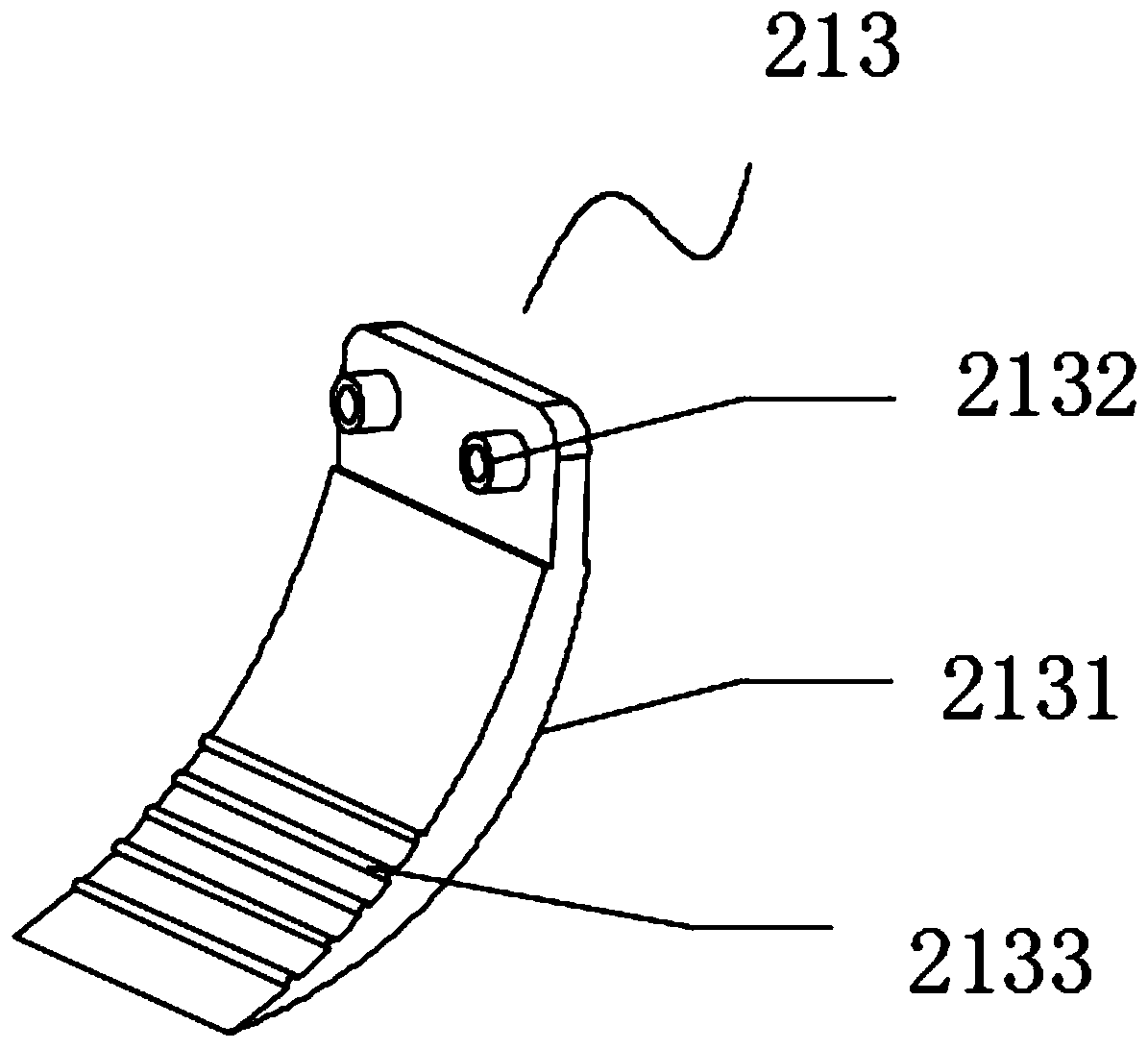

Hammering apparatus used for meat products

The invention discloses hammering apparatus used for meat products. The hammering apparatus used for the meat products comprises a work box; a through slot is transversely arranged at an inner bottomof the work box; a slider at the bottom of a limit box is in sliding connection with the interior of the through slot; a placement box is placed at an inner bottom of the limit box; the bottom of theslider of the limit box penetrates through the through slot, and is connected with an upper surface of a nut fixing block; screw rod fixing blocks are respectively arranged at left and right ends of the bottom of the work box; the right side of the left screw rod fixing block is connected with the left end of a screw rod via a bearing; the left side of the right screw rod fixing block is connectedwith the right end of the screw rod via a bearing; the middle side of the screw rod is in threaded connection with a screw hole of the nut fixing block; and a screw rod gear is arranged on an extended part of the right end of the screw rod. The hammering apparatus used for the meat products is simple in operation, high in practicability and capable of performing all-around uniform hammering on meat placed thereon; moreover, the hammering apparatus used for the meat products is further arranged with a shock absorber, so that excessive big shake is prevented.

Owner:阜阳市三原食品股份有限公司

Fish meat stuffing making device for fish balls

The invention discloses a fish meat stuffing making device for fish balls, the fish meat stuffing making device comprises a base, a mounting cover is fixedly connected to the upper side of the base, atransmission cover is fixedly connected to the top of the mounting cover, a feeding box is fixedly connected to the inner top of the mounting cover, the top of the feeding box is connected with a feeding hopper, the lower end of the feeding hopper penetrates through the mounting cover and the top of the feeding box and extends downwards in sequence, a crushing mechanism is arranged in the feedinghopper, and a discharging pipe is connected to the bottom of the feeding box. The fish meat stuffing making device has the advantages that a screw rod can be driven to rotate by arranging of a transmission mechanism, the screw rod rotates to drive a lifting rod to move, the lifting rod moves to drive a rotating plate to rotate, and the rotating plate rotates to drive a beating roller to repeatedly beating fish meat stuffing, so that the fish meat stuffing is finer; a push rod can be driven to move by arranging of a rotating mechanism, the push rod moves to drive a squeezing plate to move, andthe squeezing plate moves to drive the fish meat stuffing to be extruded, so that the fish meat stuffing is more uniform to be hammered.

Owner:张兵

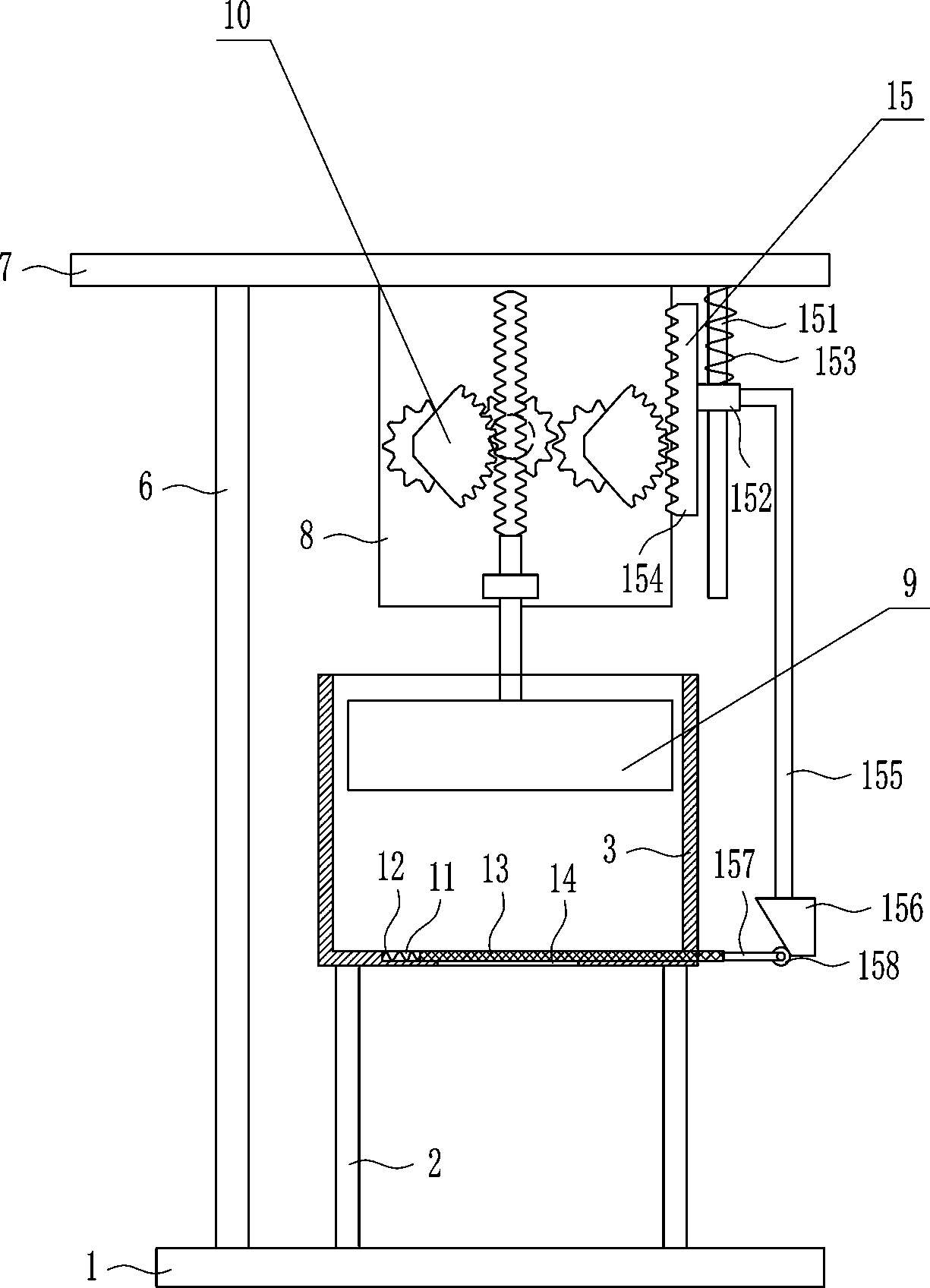

Hot steel part forging workbench

The invention discloses a hot steel part forging workbench. Ends, away from a framework, of forging table supporting legs are fixedly equipped with a forging table; a forging hammer is movably mountedon the upper part of the forging table; a tilting plate is in matched connection to a pair of left and right tilting blocks; the tilting blocks are fixedly mounted on rotary discs at left and right sides of a forging connecting rod separately; one end, away from an extruding slot, of a tiling rod is fixedly equipped with a lower pressure plate; a gear connecting rod is movably mounted on connecting rod bases at the two ends of the framework; a drive shaft of a forging motor is fixedly equipped with a horizontal-moving lead screw; a horizontal-moving base is movably arranged on the horizontal-moving lead screw in a sleeving mode; the bottom of the horizontal-moving base is fixedly equipped with a slide block; and a lifting frame is arranged on the horizontal-moving base in the sleeving mode. According to the hot steel part forging workbench disclosed by the invention, after an iron hammer is lifted to certain height, the iron hammer hammers the steel part through driving of a spring, so that hammering force is relatively strong; and in a hammering process, the hammed part is moved, so that the hot steel part forging workbench can uniformly hammer iron sheet surfaces of different length, and therefore, the steel part can be effectively forged.

Owner:ANHUI RUIDA MACHINERY

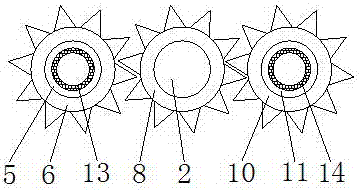

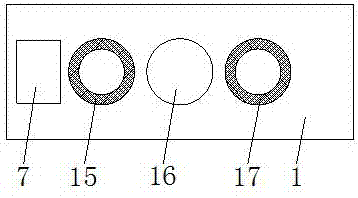

Flapping type sunflower seed taking-out device

The invention relates to a taking-out device, in particular to a flapping type sunflower seed taking-out device. The flapping type sunflower seed taking-out device can automatically flap sunflowers, is uniform in flapping and can also automatically separate sunflower seeds from the sunflowers. The flapping type sunflower seed taking-out device comprises a mounting seat, first brackets, a flappingmechanism and a transmission mechanism. The mounting seat is mounted at one side of the top of a base, the first brackets are arranged on the periphery of the top of the base, the flapping mechanism is arranged at the position, close to one side of the mounting seat, of the top of the base, and the transmission mechanism is connected between the first brackets. The sunflowers can be beaten intermittently through cooperation of a full gear and a rack rod, meanwhile, the sunflowers can be transmitted intermittently through an arranged roller and an arranged belt, flapping is more uniform, a screening frame drives a through hole block to move left and right, under cooperation of a special-shaped rod and a convex block, the convex block can be driven to shake up and down, the sunflower seeds and the sunflowers are automatically separated, and the working efficiency is high.

Owner:合肥市航拯工业设计有限公司

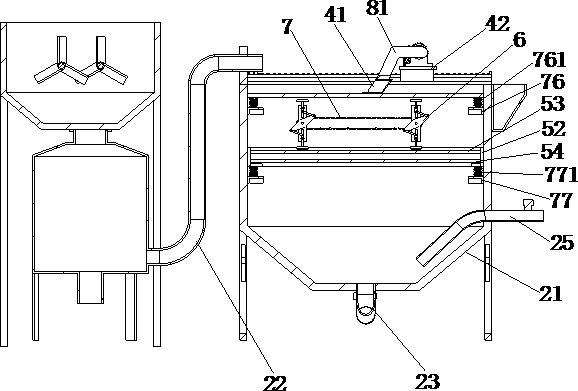

Dye raw material extraction equipment for garment production

InactiveCN107638898ABeat evenlyImprove work efficiencySievingScreeningEngineeringUltimate tensile strength

The invention relates to raw material extraction equipment, particularly to dye raw material extraction equipment for garment production. The invention aims at providing dye raw material extraction equipment for garment production which is capable of reducing labor intensity, improving extraction rate and dye production efficiency. In order to achieve the aim, the invention provides the dye raw material extraction equipment for garment production which comprises a base, supporting rods, a box, a box door, a supporting plate and the like; the middle of the top of the base is vertically connected with the two supporting rods through bolts, the box is connected between the top ends of the two supporting rods, a first opening is formed in the lower part of the front side surface of the box, and the front side surface of the box, at the left side of the first opening, is connected with the box door through hinges. According to the dye raw material extraction equipment, a driving device candrive a thumping device to thump plants, so that the plants can be quickly mashed, and the effects of reducing labor intensity, improving extraction rate and dye production efficiency are realized.

Owner:晋江诺研机械设计有限公司

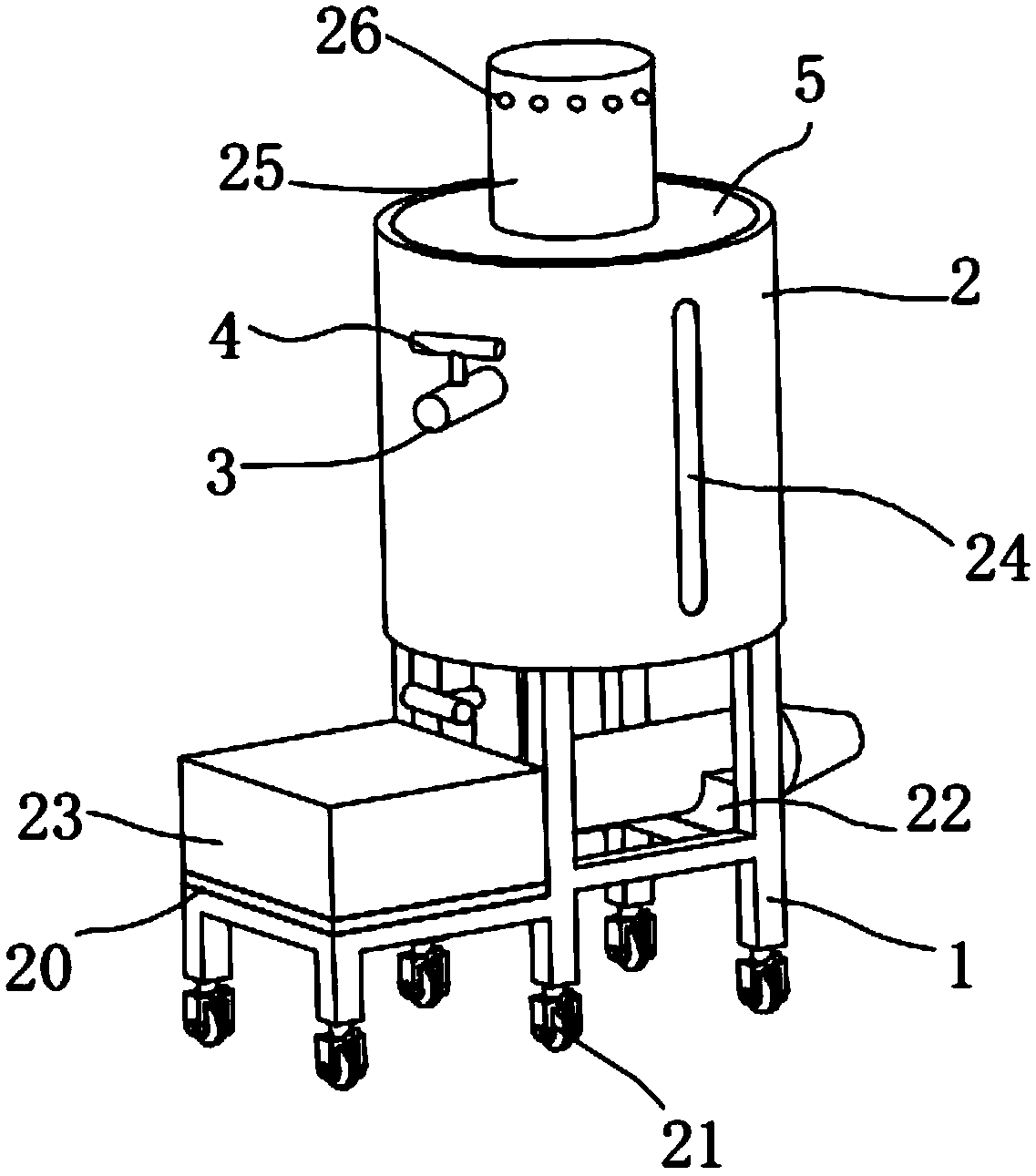

Lung clearing and sputum excretion device for respiratory medicine department

InactiveCN113209395AConvenient expectoration operationImprove functionalityVibration massageSuction devicesSurgeryBiology

The invention relates to a lung clearing and sputum excretion device for the respiratory medicine department, which effectively solves the problems that a conventional lung clearing and sputum excretion device for the respiratory medicine department is single in sputum excretion mode, suction of sputum of a patient is slow in efficiency in the suction process, the comfort of the patient is poor, the labor amount of family members of the patient is increased invisibly when the family members beat the backs all the time, when the patient coughs out sputum, there is no place to store the sputum, pollution can be caused due to random spitting the sputum, an unsealed garbage can is used for collecting the sputum in the prior art, so that peculiar smell is easy to spill out, and the garbage can is not easy to clean. The lung clearing and sputum excretion device comprises a bed body, wherein a negative pressure plate capable of being overturned up and down is rotationally connected to the middle of the right side of the bed body; and a detachable collecting bottle is slidably connected to the upper end of the negative pressure plate, a detachable sputum suction pipe is in threaded connection to the upper end of the collecting bottle, a detachable exhaust pipe is in threaded connection to the right end of the collecting bottle, the left end of the rear part of an air cylinder is fixedly connected with the negative pressure plate, and two pistons capable of moving inwards or outwards at the same time are slidably connected into the air cylinder.

Owner:PEOPLES HOSPITAL OF HENAN PROV

Beating device of toilet paper machine

InactiveCN108755225ARealize reciprocating up and down movementShake evenlyRotating receptacle mixersTransportation and packagingReciprocating motionPulp and paper industry

The invention discloses a beating device of a toilet paper machine. The beating device comprises a base, a plurality of supporting legs are fixedly installed on the bottom side of the base, the top side of the base is fixedly provided with a plurality of supporting columns, and one sides of the supporting columns are fixedly provided with a same installation base. A first motor cavity is formed inthe installation base, a first motor is fixedly installed in the first motor cavity, a cavity is formed in the installation base, a communication hole is formed in the inner wall on the side, close to the cavity, of the first motor cavity, and the communication hole is communicated with the cavity. A rotary shaft is rotationally installed in the communication hole, the end, close to the first motor cavity, of the rotary shaft extends into the first motor cavity and is fixedly connected with an output shaft of the first motor, and the other end of the rotary shaft extends into the cavity and is fixedly provided with a cam. By means of the beating device, a stirring barrel can be rotated, pulp in the stirring barrel can be uniformly shaken, while stirring is conducted, the stirring barrel can do reciprocating motion up and down, the pulp in the stirring barrel is stirred and beaten at different depths, beating is uniform, the structure is simple, and operation is simple.

Owner:郭文英

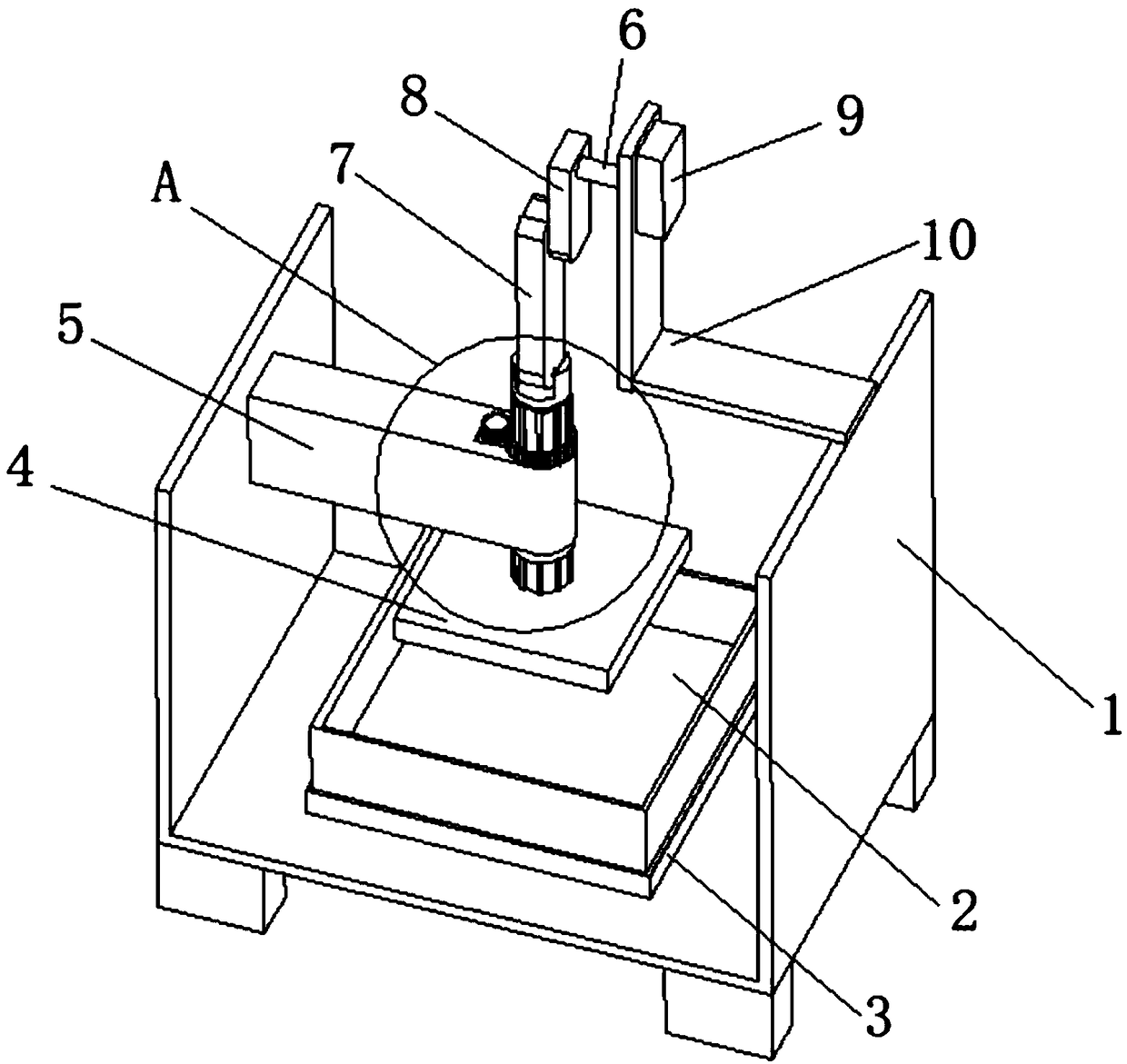

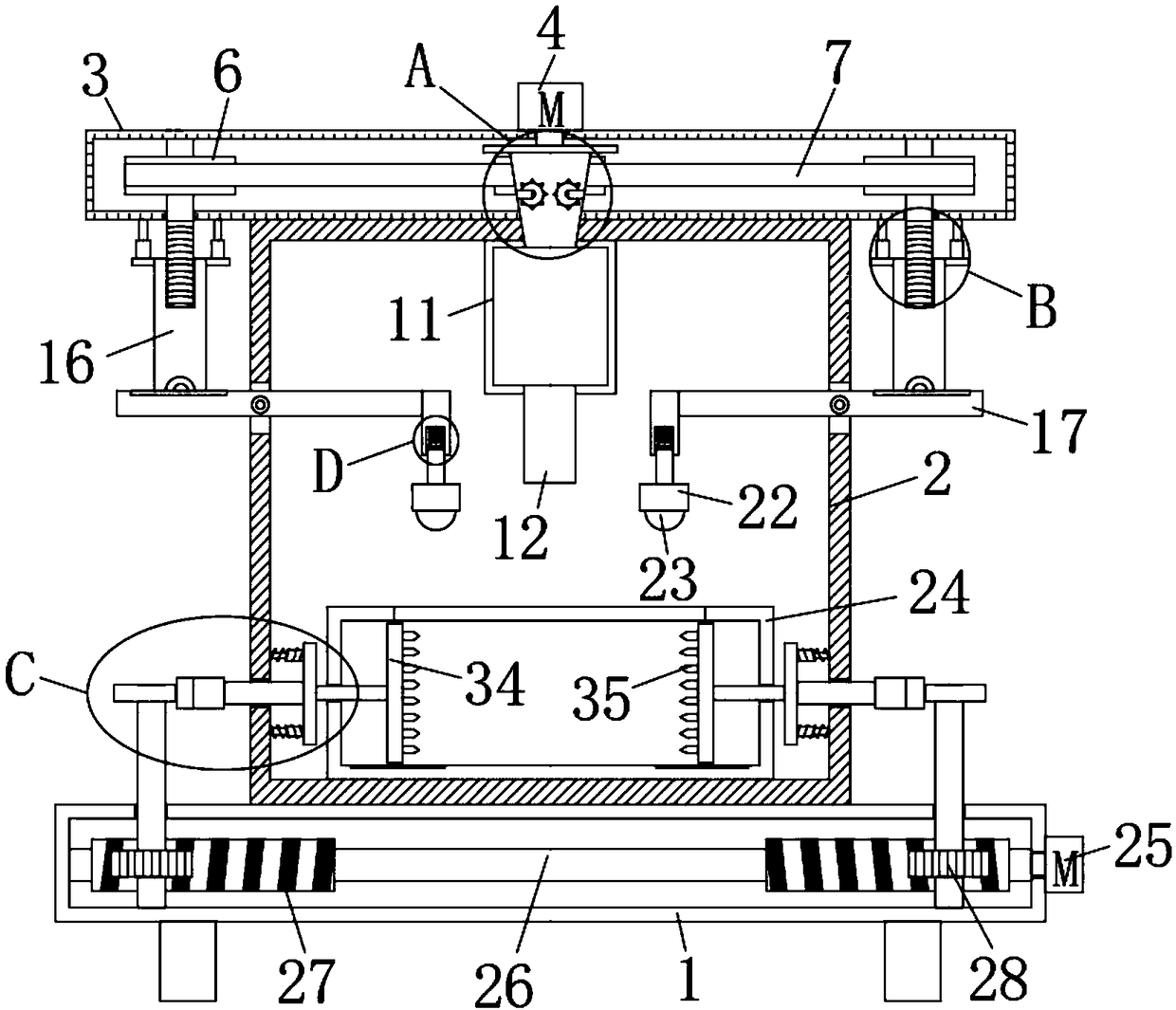

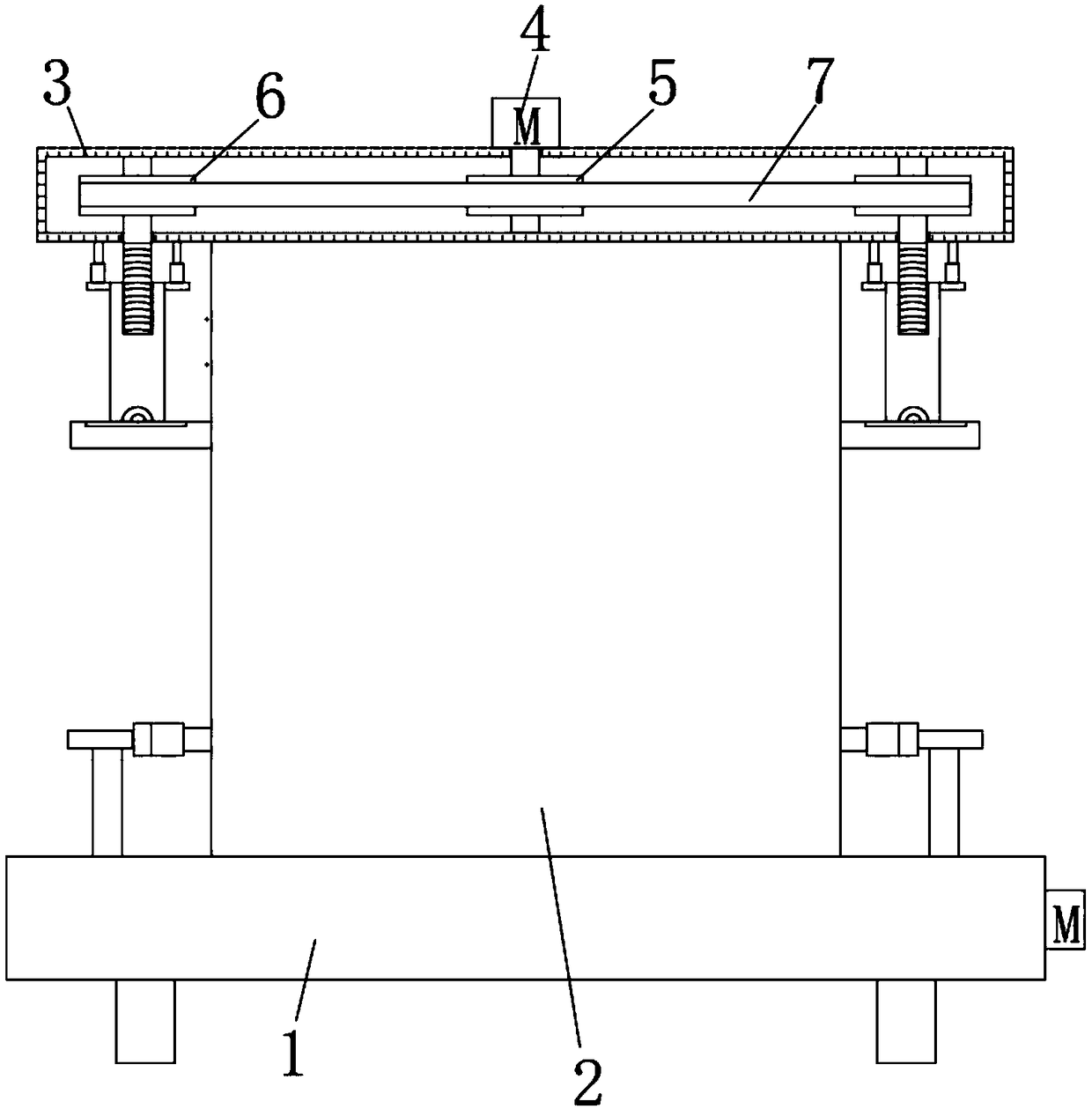

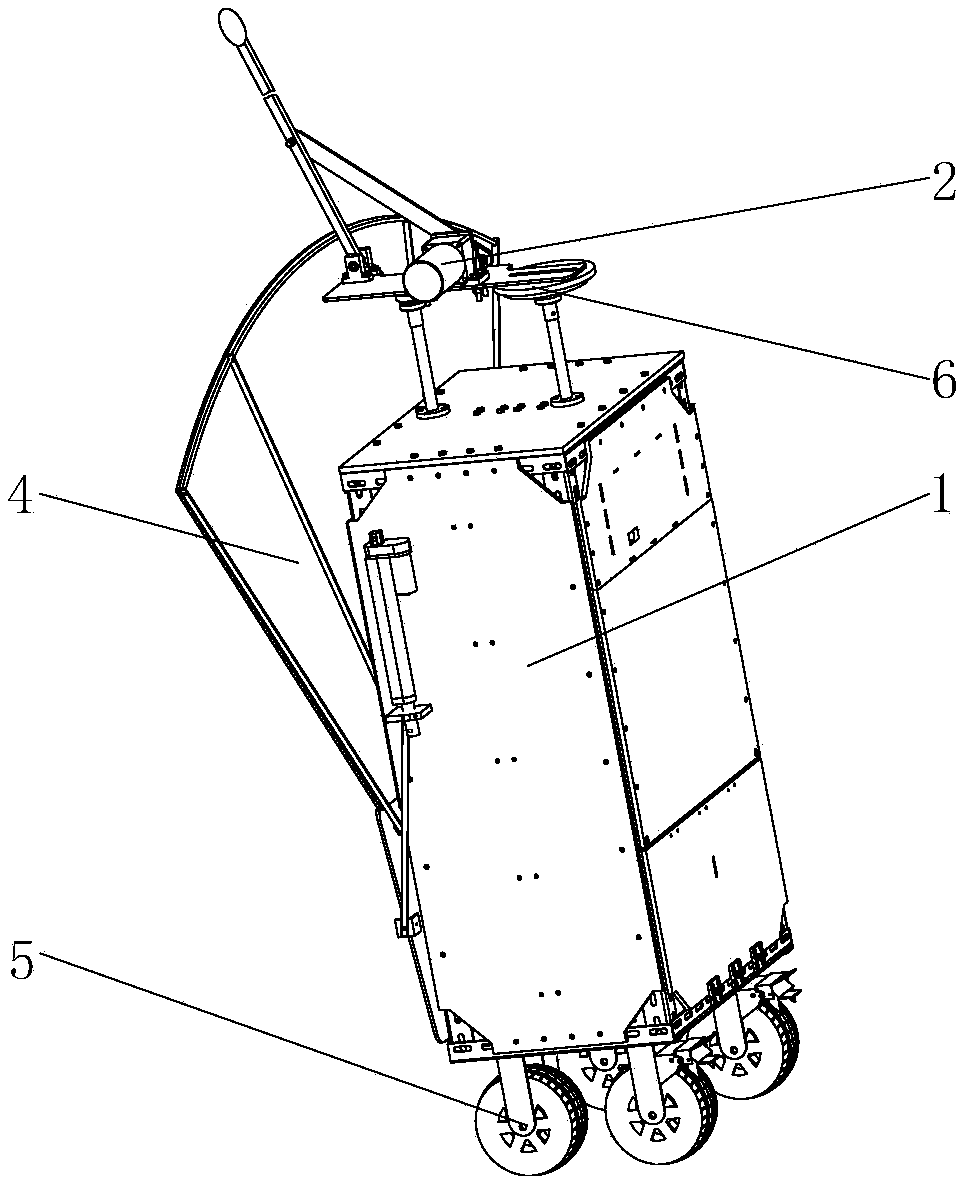

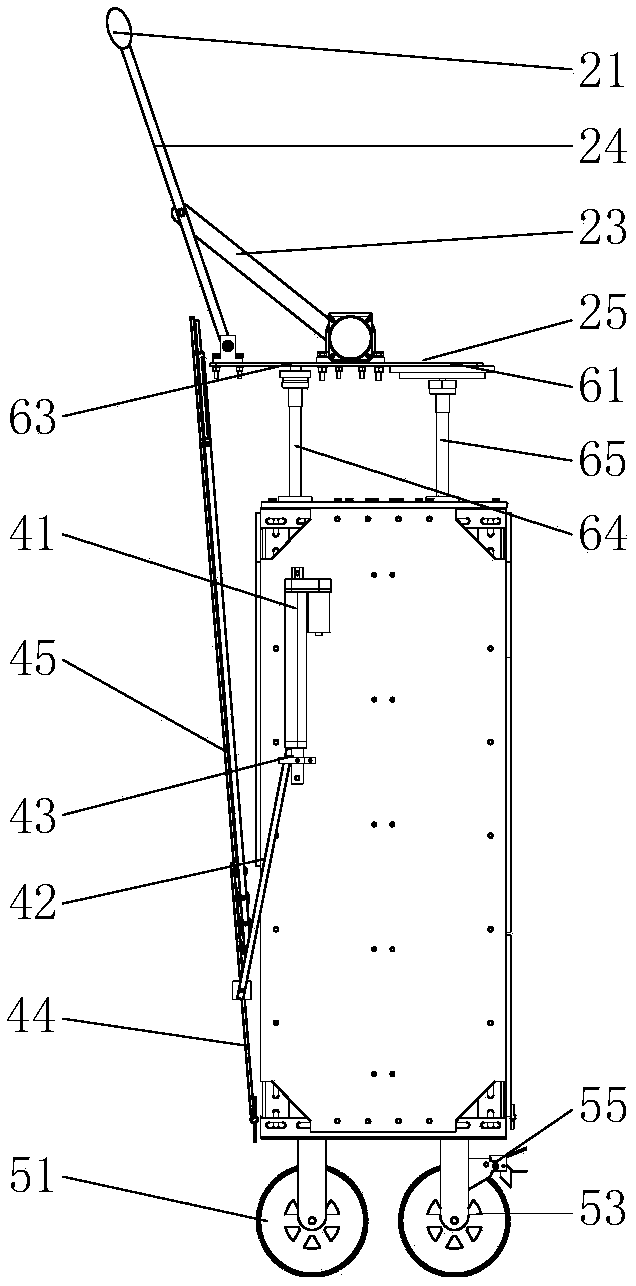

Multi-degree-of-freedom imitating manual beating and collecting jujube device

PendingCN108575312ABeat evenlyImprove beating efficiencyPicking devicesRenewable energy machinesMulti degree of freedomZiziphus jujuba

Owner:周逸伦

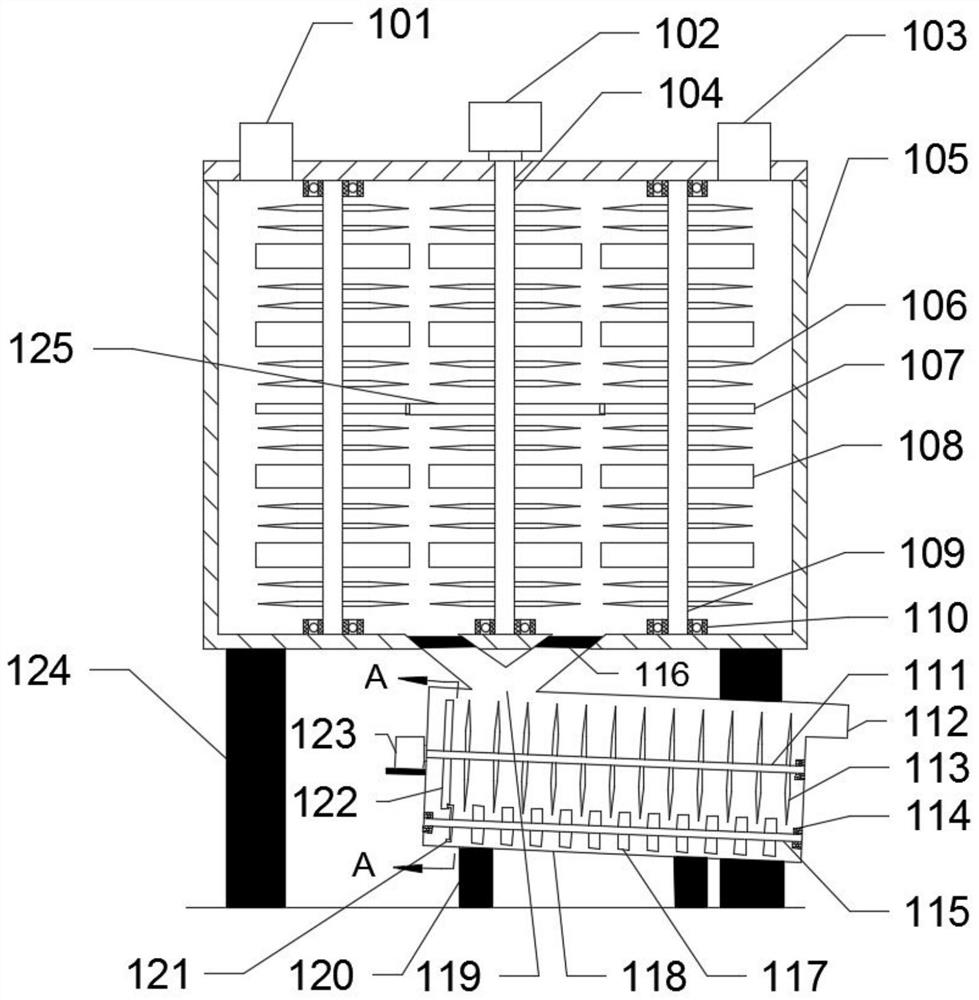

Papermaking beating machine

The invention discloses a papermaking beating machine. The papermaking beating machine comprises a beating machine body, the lower part of the outer side face of the beating machine body is provided with a discharge opening, the top of the beating machine body is provided with a feed inlet and a through hole separately, the top of the beating machine body is further provided with a motor, the output end of the motor is movably connected to a first rotation shaft, one end of the first rotation shaft penetrates through the through hole and extends to the inside of the beating machine body, the inner bottom wall of the beating machine body is fixedly connected to a cylindrical placing block, the inner top wall of the beating machine body is provided with a first clamping groove and a second clamping groove separately, the inside of the beating machine body is provided with a first gear, a second gear, a third gear, a second rotation shaft and a third rotation shaft, and the inner wall of the first gear is fixedly connected to the outer surface of the second rotation shaft. The papermaking beating machine makes beating more even and more thorough, makes the beating speed higher, and saves time and labor, the beating speed is effectively guaranteed, the beating effect is better, and the working efficiency is high.

Owner:保定达亿纸业有限公司

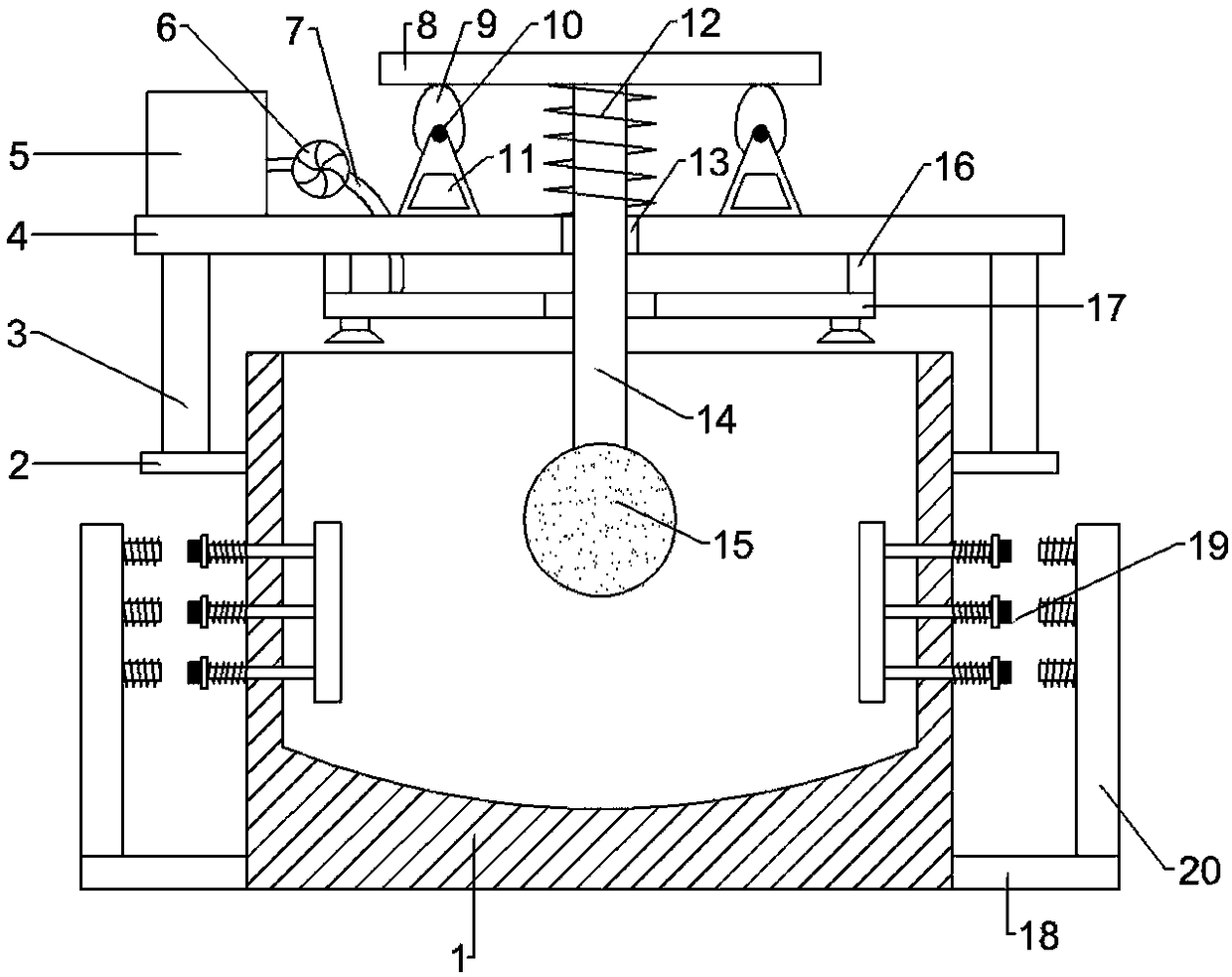

Hydraulic forging device

InactiveCN111633173AImprove processing qualitySimple structureForging hammersForging/hammering/pressing machinesEngineeringForge

The invention belongs to the technical field of forging devices, and particularly relates to a hydraulic forging device. Aiming to solve the problems that an existing forging mode is uneven in force application in different directions and cannot achieve effective synchronization, so that a workpiece is unevenly deformed, and forge piece machining quality is affected, the following scheme is provided. The device comprises a fixing box, a placing seat is arranged at the top of the fixing box, a placing groove is formed in the top of the placing seat, a forge piece is placed in the placing groove, two welding rods are fixedly arranged at the top of the fixing box, the same ejector rod is fixedly arranged at the tops of the two welding rods, a hydraulic pushing rod is fixedly connected to thebottom of the ejector rod, a connecting rod is fixedly connected to an output shaft of the hydraulic pushing rod, and the bottom of the connecting rod is fixedly connected with a top forging head. According to the device, the structure is simple, the operation is convenient, multi-direction beating can be carried out, and meanwhile, the forge piece can be driven to rotate, so that the force application is uniform, and the forge piece machining quality is improved.

Owner:孙敏

Garden potted plant soil changing device

ActiveCN108966934AEven strengthEasy to change soilCultivating equipmentsFlower-pot fillingElectric machineryEngineering

The invention relates to a soil changing device, in particular to a garden potted plant soil changing device and provides a garden potted plant soil changing device which is uniform in potted plant knocking force and capable of preventing influences on subsequent use due to potted plant damages. The technical scheme includes that the garden potted plant soil changing device comprises a bottom plate, supporting rods, an annular slider, a circular plate, semicircular plates, a fixing plate, a handle and the like. The supporting rods are mounted on left and right sides of the top of the bottom plate, the circular plate is arranged above the left and right supporting rods, the bottom of the circular plate is peripherally provided with an annular slide groove, and the annular slider is arrangedin the annular slide groove and is in slide fit with the annular slide groove. By a knocking device, uniformity in potted plant knocking force is achieved, and then soil in potted plants can be completely separated to make it convenient for subsequent soil changing. By action of a motor, manual knocking of the potted plants is avoided, so that time saving and labor saving are realized. By a clamping device, potted plant clamping and fixing can be realized, and influences of potted plant moving on ball knocking are prevented.

Owner:惠安权小白科技有限公司

Building construction vertical type brick attaching device facilitated to feeding

The invention relates to a building construction vertical type brick attaching device facilitated to feeding. The building construction vertical type brick attaching device comprises a base. The bottom of the base is fixedly connected with universal wheels, the tops of the universal wheels are fixedly connected with a hydraulic cylinder, a first telescopic rod is arranged on the top of the hydraulic cylinder, shearing type telescopic frames are arranged on the left and right sides of the first telescopic rod correspondingly, the top of the hydraulic telescopic rod is fixedly connected with a supporting plate, a fence is arranged at the edge of the supporting plate, the top of the supporting plate is fixedly connected with a first motor and a second motor through supporting frames correspondingly, the first motor is arranged on the left side of the second motor, the left end of the first motor is fixedly connected with a first wire spool, and the right end of the second motor is fixedlyconnected with a second wire spool. The whole building construction vertical type brick attaching device is facilitated to lifting to conduct brick attaching on walls with different heights, a secondtelescopic rod driven by an air cylinder is used for driving a compaction plate to conduct mechanical compaction on wall bricks more uniform, meanwhile feeding is convenient, and the working efficiency of brick attaching is improved.

Owner:山东港基建设集团有限公司

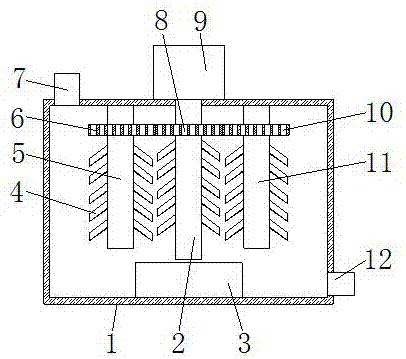

Paper making beater

InactiveCN106638097ALarge reserved spaceImprove beating effectPulp beating methodsProduction ratePulp and paper industry

The invention belongs to a paper making machinery and discloses a paper making beater. The upper portion of a machine body and the lower portion of the machine body are each provided with a beating assembly. Each beating assembly comprises a motor, a cutter shaft, cutter rests and cutter blades. An output shaft of each motor is connected with the corresponding cutter shaft, the cutter rests are uniformly distributed on the periphery of the outer wall of the corresponding cutter shaft and the cutter blades are arranged on the cutter rests. The output shaft of the motor on the upper portion of the machine body and the output shaft of the motor on the lower portion of the machine body are oppositely arranged. Two sets of cutter blade components in the machine body are axially opposite, during beating, the rotational direction of the upper cutter rests is opposite to that of the lower cutter rests, pulp and water are formed into two steams of pulp flows, crushing and beating are sufficiently conducted on materials, the beating effect is good, the pulp production rate is high and uniform beating is achieved. Because the reserved space between the beating assemblies and the machine body is large, the beating bulk is great, and the beating efficiency is improved.

Owner:ZHONGSHAN WEIKE PACKAGE PROD CO LTD

High-efficiency fruit and vegetable pulping machine

InactiveCN105341954AGuaranteed uptimeEasy to adjustJuice extractionPressure sensePulp and paper industry

The invention provides a high-efficiency fruit and vegetable pulping machine. The high-efficiency fruit and vegetable pulping machine comprises a cavity, wherein a feed opening and a liquid inlet are correspondingly formed at the two sides of the top part of the cavity; a guide hole is formed in the inner wall of the feed opening, and a V-shaped pulp outlet is formed in the bottom of the cavity; a pressure sensing valve is arranged at the bottom of the V-shaped pulp outlet; flow controllers are arranged on the outer wall of the feed opening and the outer wall of the liquid inlet and are connected with the pressure sensing valve through wires; a rotating shaft is arranged in the center of the cavity, one end of the rotating shaft extends into the bottom of the cavity, and the other end of the rotating shaft is connected with a motor; a plurality of stirring vanes are arranged on the outer wall of the rotating shaft, and stirring teeth are arranged on the surfaces of the stirring vanes. According to the high-efficiency fruit and vegetable pulping machine disclosed by the invention, the number of the stirring vanes is increased, so that the pulping is uniform and thorough and the pulping efficiency is high, and besides, the pulping machine is also provided with the flow controllers and the pressure sensing valve, so that when the pressure sensing valve senses that the pulp-out flow from the pulp outlet is too high or insufficient, the pressure sensing valve can timely feedback the information to the flow controllers; therefore, the adjustment of the feed opening and the liquid inlet can be conveniently realized so as to ensure the normal and stable running of the pulping machine.

Owner:徐浩

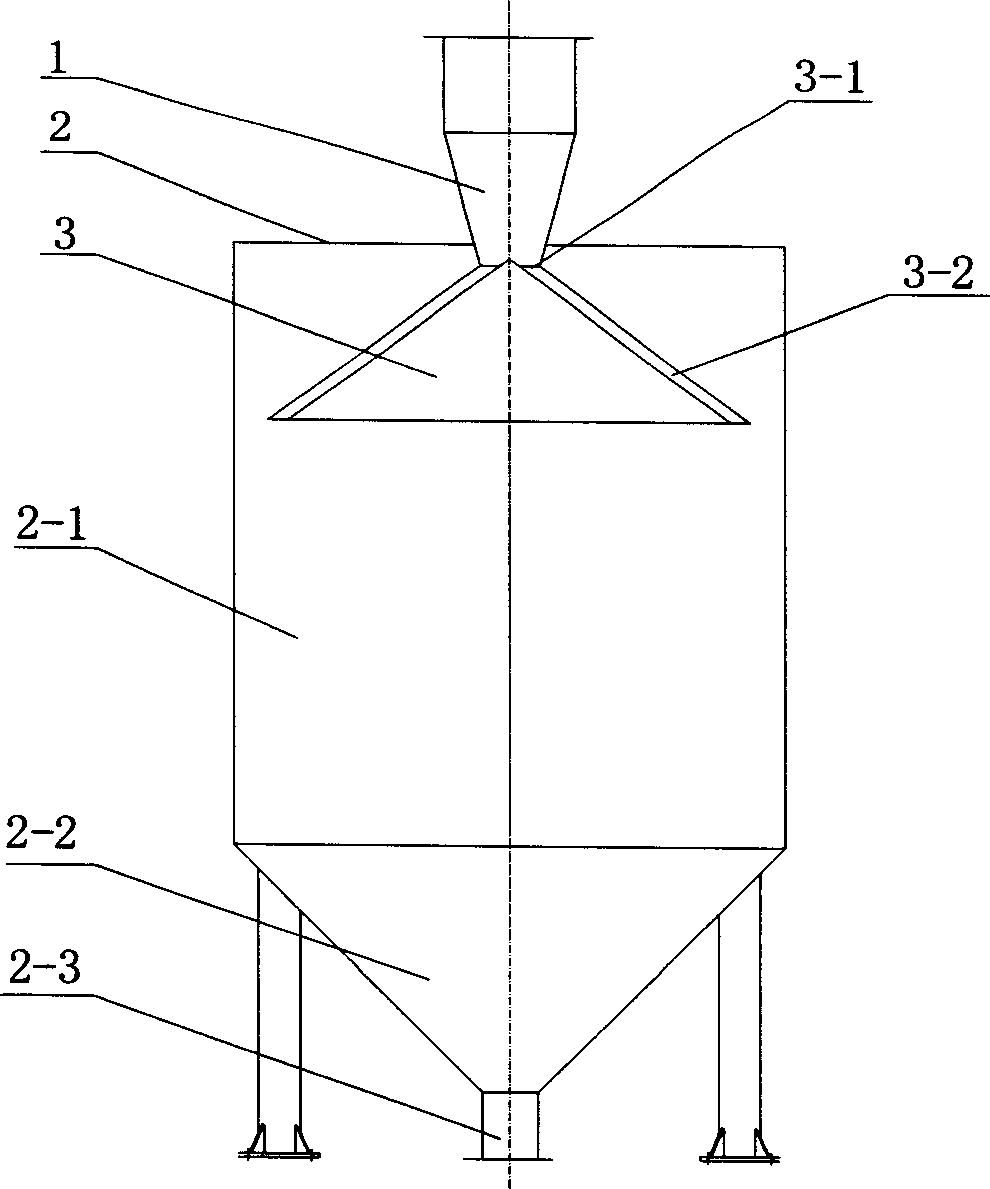

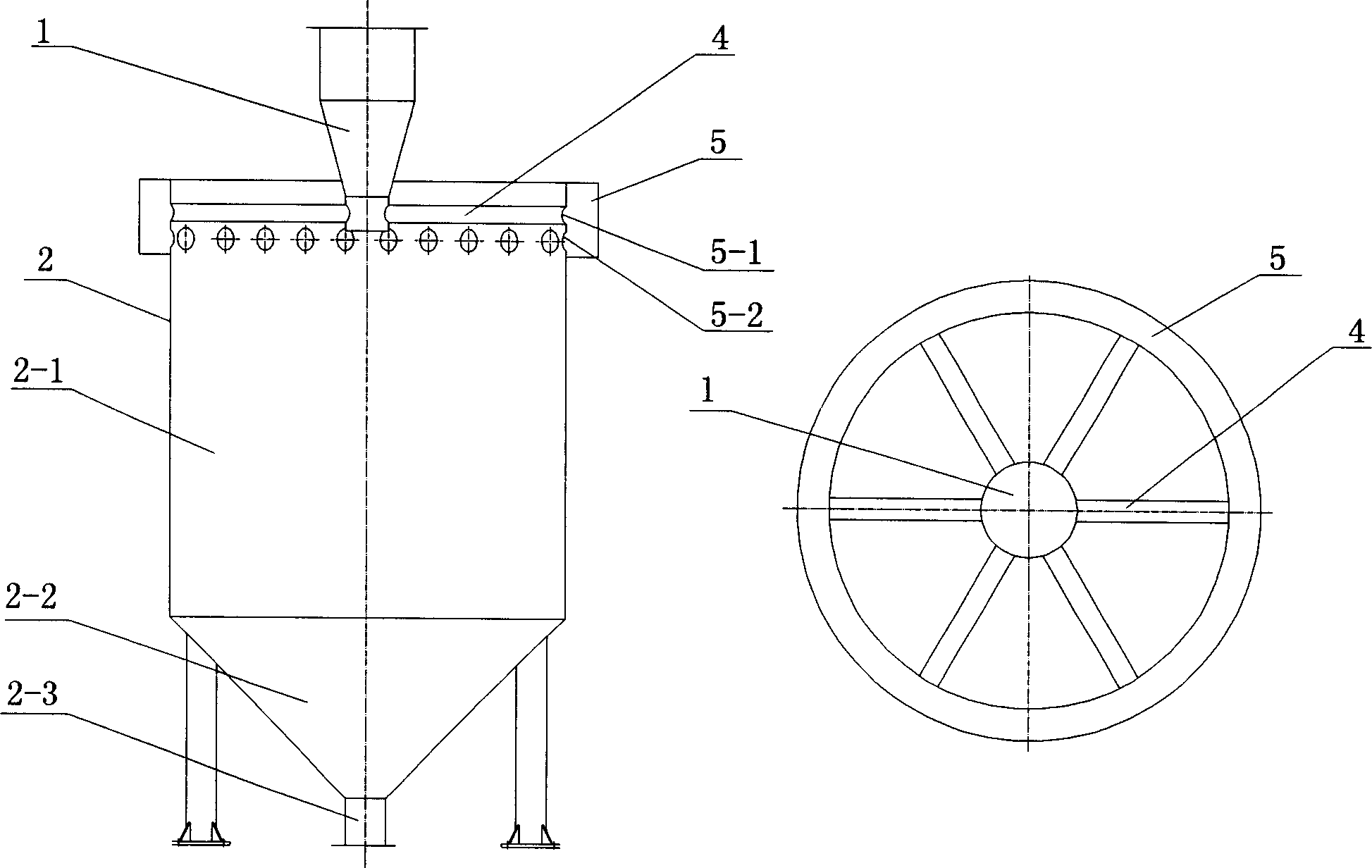

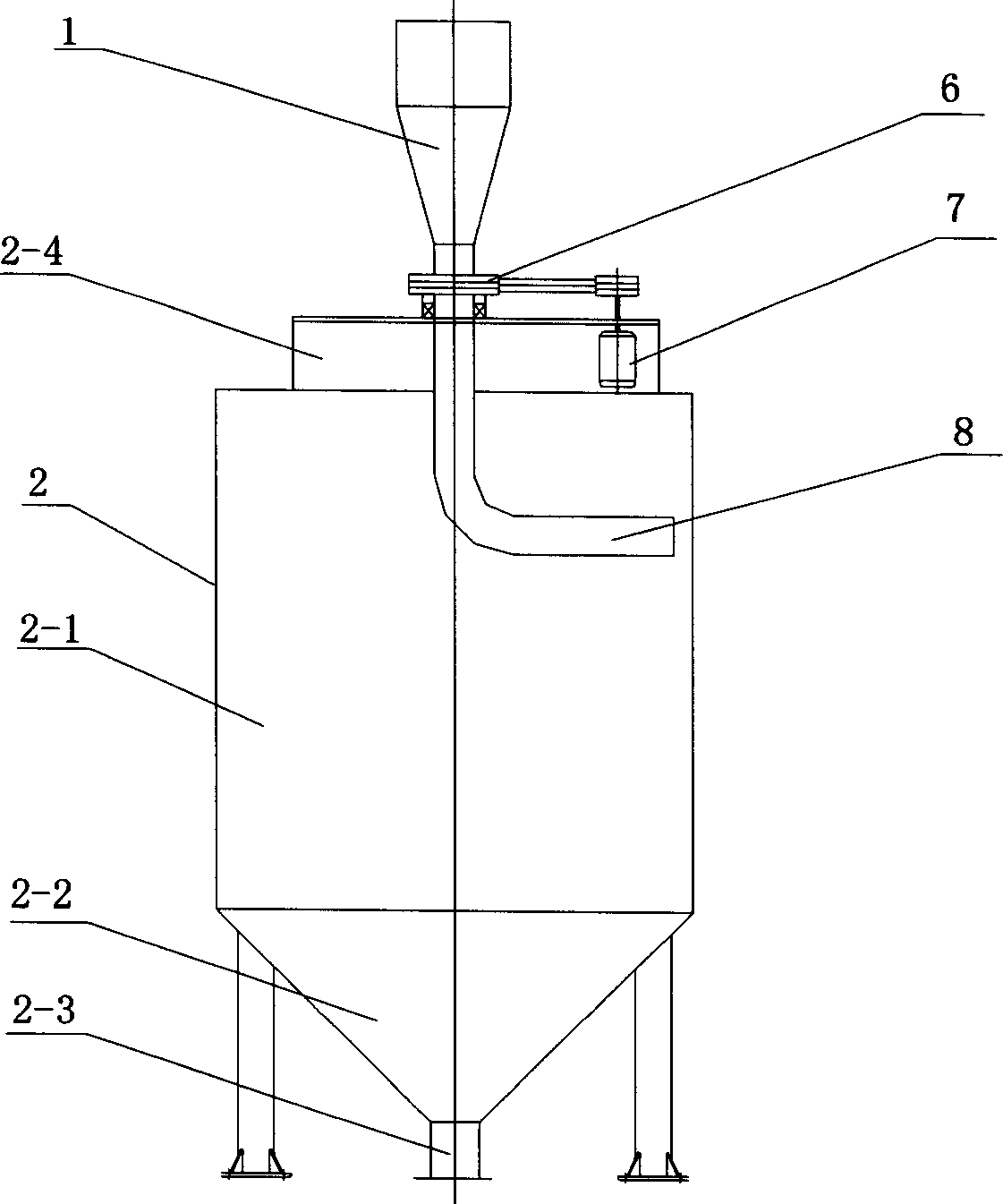

Circular beating material feeding method in papermaking and device thereof

The circulating beating material feed method in the paper-making process includes circulating tower body pulp material collecting tube, and is characterized by that it also includes pulp material dispersion member which is respectively connected with circulating tower body and pulp material collecting tube, the described dispersion member can be made into the structure of conical flow passage, radiation dispersion flow passage and electric rotating dispersion tube. Said invention can change the centralized pulp fall into dispersed pulp fall along the tower wall, at the same time the impact offalling pulp to the pulp material in the tower can reduce the retardation action of tower wall on pulp material in the tower so as to make the pulp material in the tower stably fall downward and raise the beating quality, and improve paper-making property and paper quality.

Owner:SOUTH CHINA UNIV OF TECH

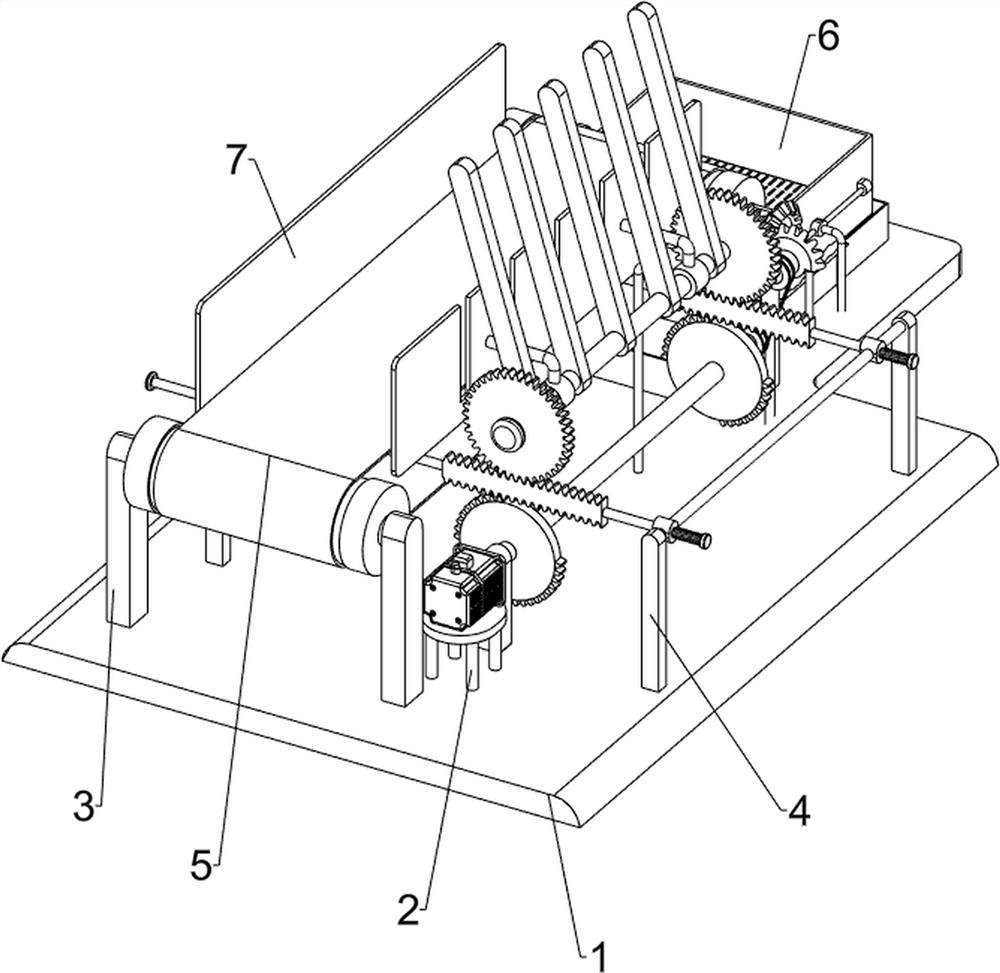

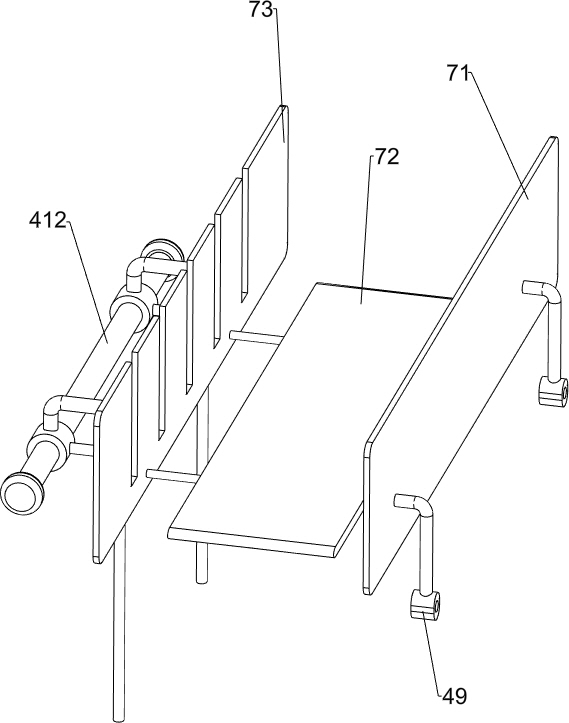

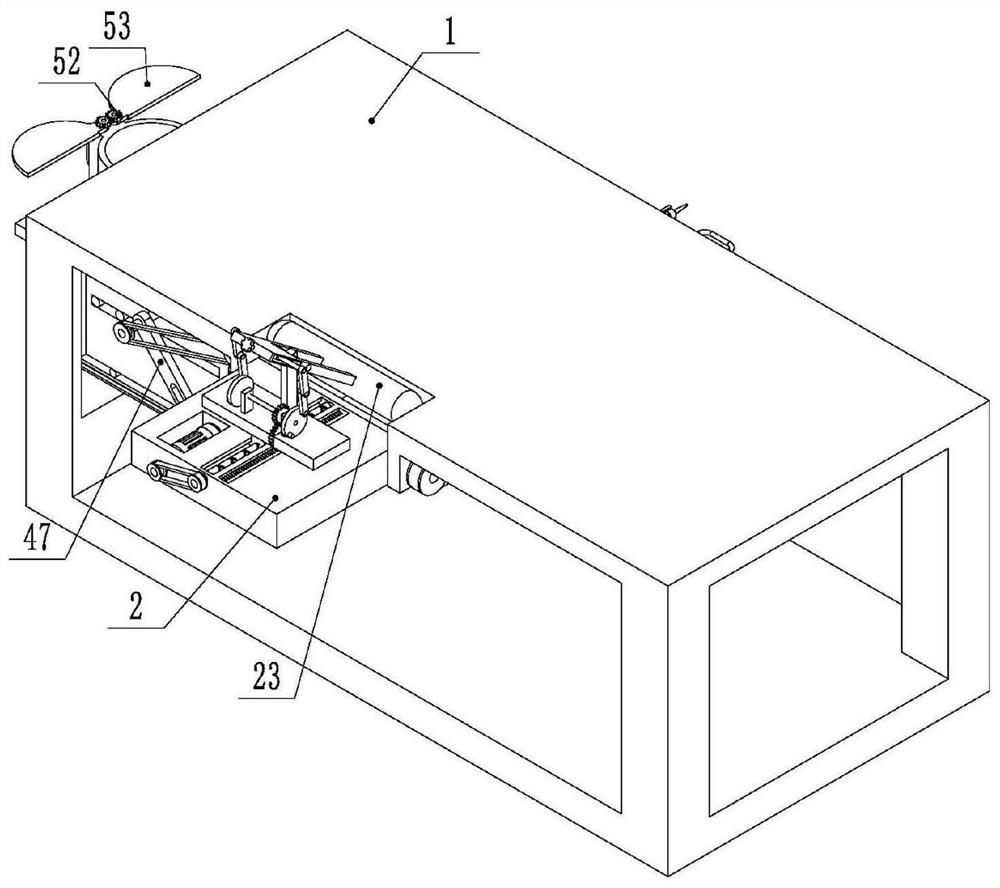

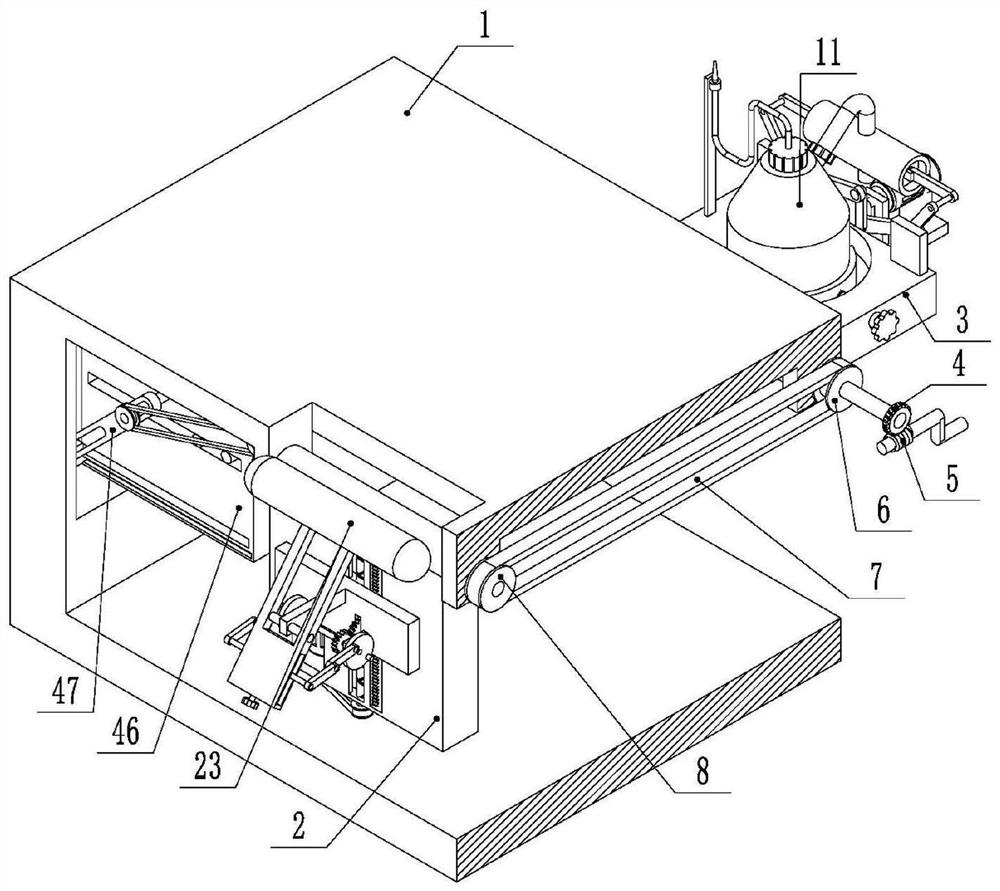

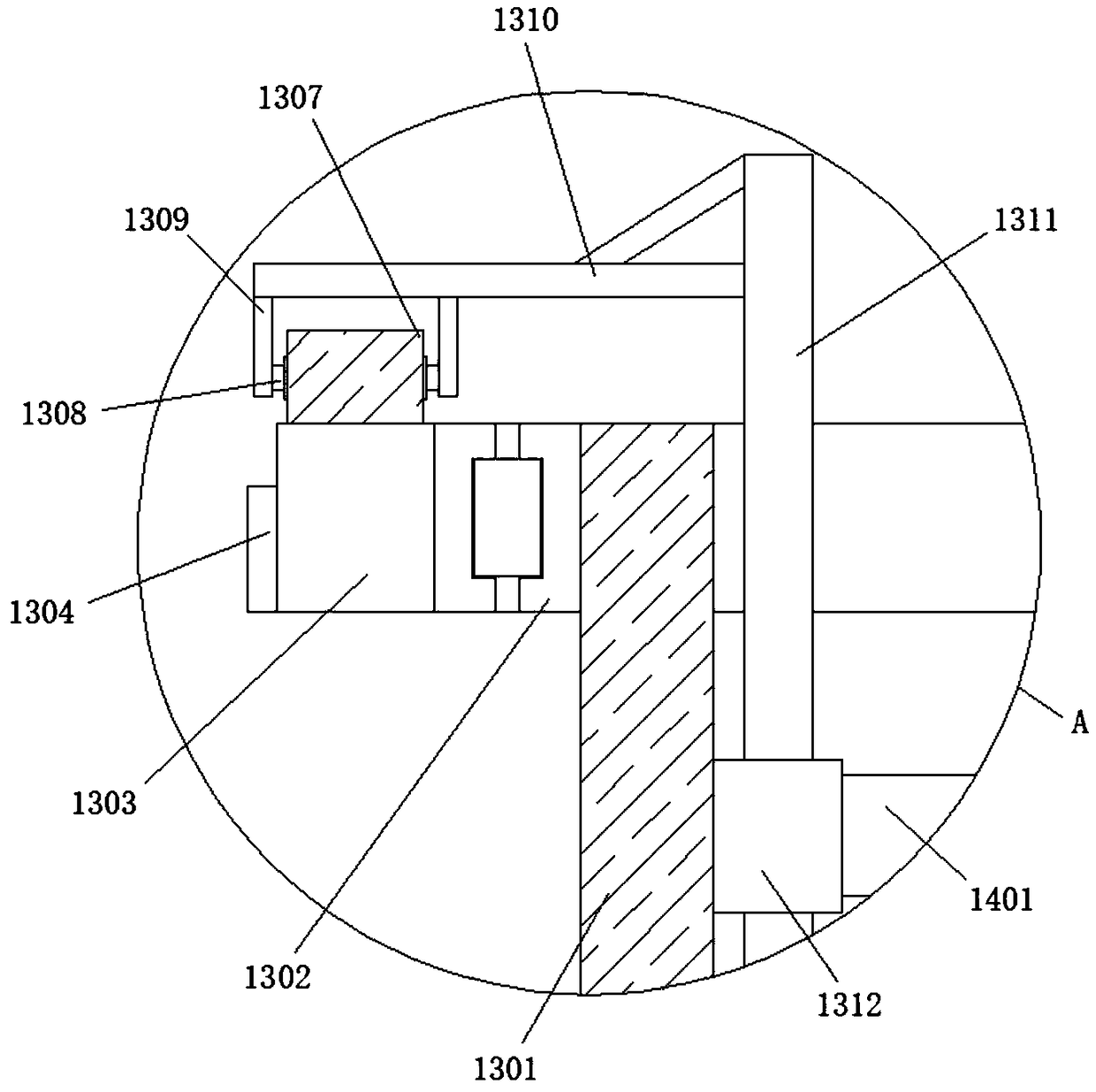

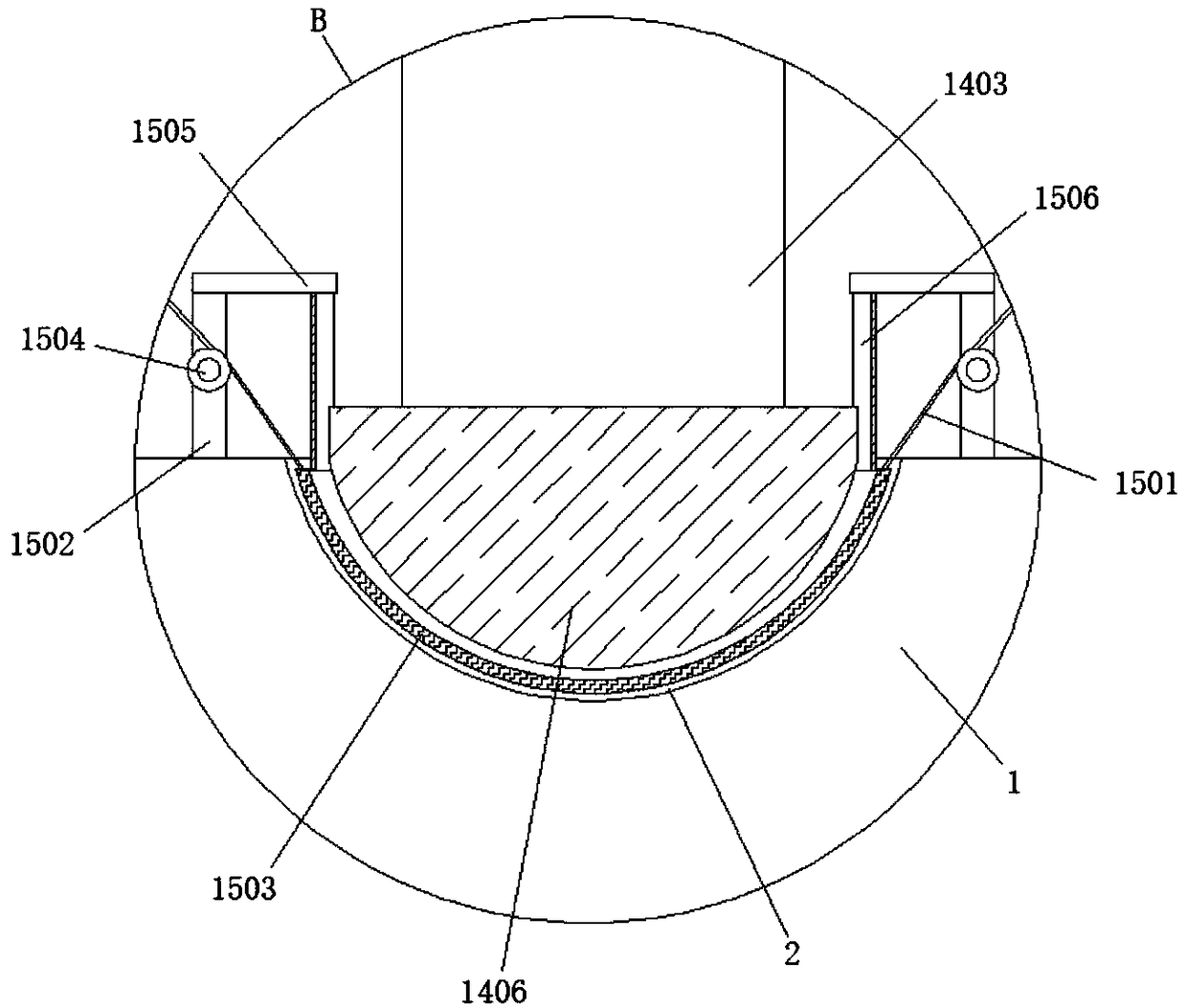

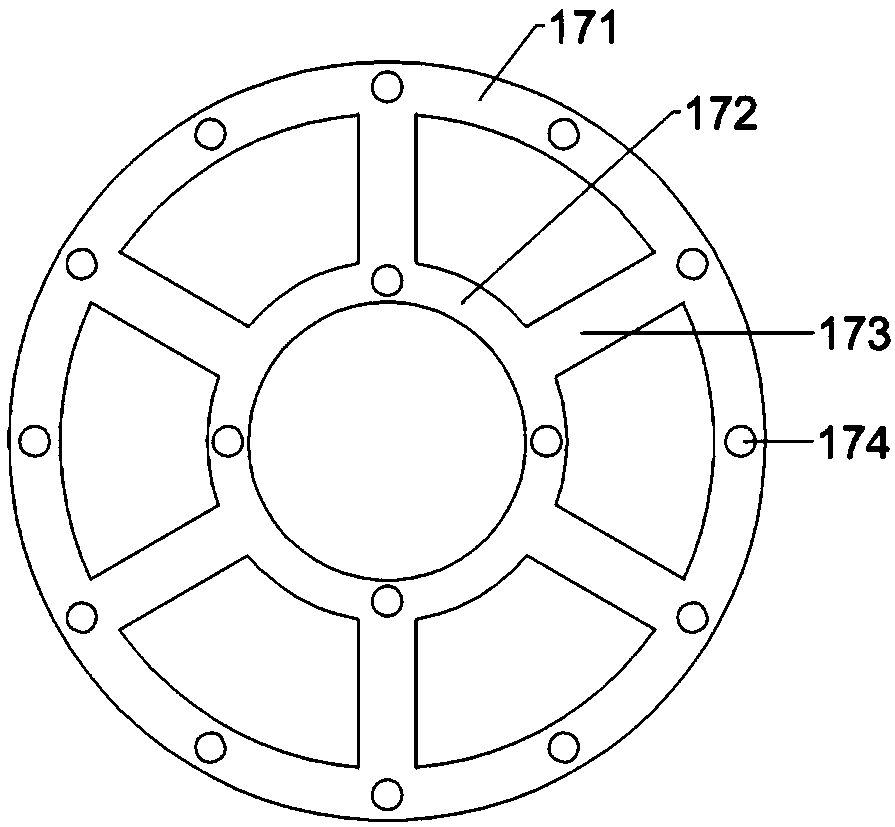

Initial stage processing device for production of special conventional snack

ActiveCN108812827AConsistent working frequencyBeat evenlyMeat processingElectric machineryDrive motor

The invention relates to the technical field of food production equipment, in particular to an initial stage processing device for production of a special conventional snack, and aims to solve the technical problems that when pork wonton wrappers are made, human resource consumption is high, and the production efficiency is low. In order to solve the technical problems, the invention provides theinitial stage processing device for production of a special conventional snack. The initial stage processing device comprises a bearing base, wherein a material placing groove is formed in the top ofthe bearing base; a driving motor and a first fixing plate are respectively and fixedly connected to the top of the bearing base from left to right; a first rotating shaft is fixedly connected to thetop of an output shaft of the driving motor; and a first helical tooth bevel gear is fixedly connected to the top of the first rotating shaft. According to the initial stage processing device for production of a special conventional snack disclosed by the invention, a wire bracing device, a meat hammering device and a meat overturning device are utilized, so that meat blanks can be automatically beaten, in the beating course, the meat blanks can be continuously overturned, and the beating of the meat blanks can be more uniform.

Owner:SHANDONG JINQIU AGRI & ANIMAL HUSBANDRY TECH

Papermaking pulping machine capable of uniformly pulping and automatically cleaning inner wall

InactiveCN109554949ABeat evenlyConvective Relative Stress IncreasePulp beating methodsElectric machineryPulp and paper industry

The invention discloses a papermaking pulping machine capable of uniformly pulping and automatically cleaning the inner wall. The papermaking pulping machine comprises a rack, wherein a pulping barrelis fixed on the upper end of the rack, a cover plate is fixed on the upper end of the pulping barrel, a first motor is fixed on the upper end of the cover plate, a rotating disc is fixed on the end portion of the output shaft of the first motor, a second motor is fixed on the upper end of the rotating disc, a first rotating shaft is fixed on the end portion of the output shaft of the second motor, a pulping mechanism is fixed on the outer circumference of the first rotating shaft, hair brush installing plates are fixed on both sides of the lower end of the rotating disc, hair brushes are fixed on the hair brush installing plates, the inner cavity of the pulping barrel is communicated to a material inlet pipeline, the bottom end of the pulping barrel is communicated to a material dischargechannel, and the lower end of the material discharge channel is communicated to a material conveying mechanism. According to the present invention, the paper pulp in the pulping barrel forms convection by using the structure, such that the pulping speed is increased, the pulping uniformity is improved, and the paper pulp quality is good; and the inner wall of the pulping barrel is cleaned by driving the hair brushes through the rotating disc so as to achieve the advantages of convenience and rapidness.

Owner:台州洪挺食品有限公司

Environment-friendly corrugated carton sewage treatment device

ActiveCN110981036AAvoid damageTroubleshoot technical issues with clearingWater/sewage treatment by centrifugal separationTreatment involving filtrationActivated carbonMicroorganism

The intention discloses an environment-friendly corrugated carton sewage treatment device, and belongs to the technical field of corrugated cartons, the environment-friendly corrugated carton sewage treatment device comprises a rotational flow sand setting device, a filter box, a paper pulp beating mechanism, a corrugated paper pulp removing mechanism and a sewage purifying mechanism, the bottom of the filter box is provided with a mud discharge funnel communicated with the interior of the filter box; a liquid outlet pipeline is arranged at the lower section of the rotational flow sand settingdevice, the sewage purifying mechanism comprises a reciprocating vibration assembly, a large particle filtering grid, a mounting frame, a microorganism filtering net and an activated carbon net, andthe reciprocating vibration assembly is arranged between the large particle filtering grid and the mounting frame. Paper pulp fibers accumulated on the large-particle filter grid and floating on sewage can be automatically fished through the corrugated paper pulp removing mechanism, and sand-water separation can be achieved through the rotational flow sand setting device; and the reciprocating vibration assembly can enable impurities blocked in filter holes of the large-particle filter grid, the microorganism filter screen and the activated carbon net to be vibrated down.

Owner:福建省群英箱聚印刷有限公司

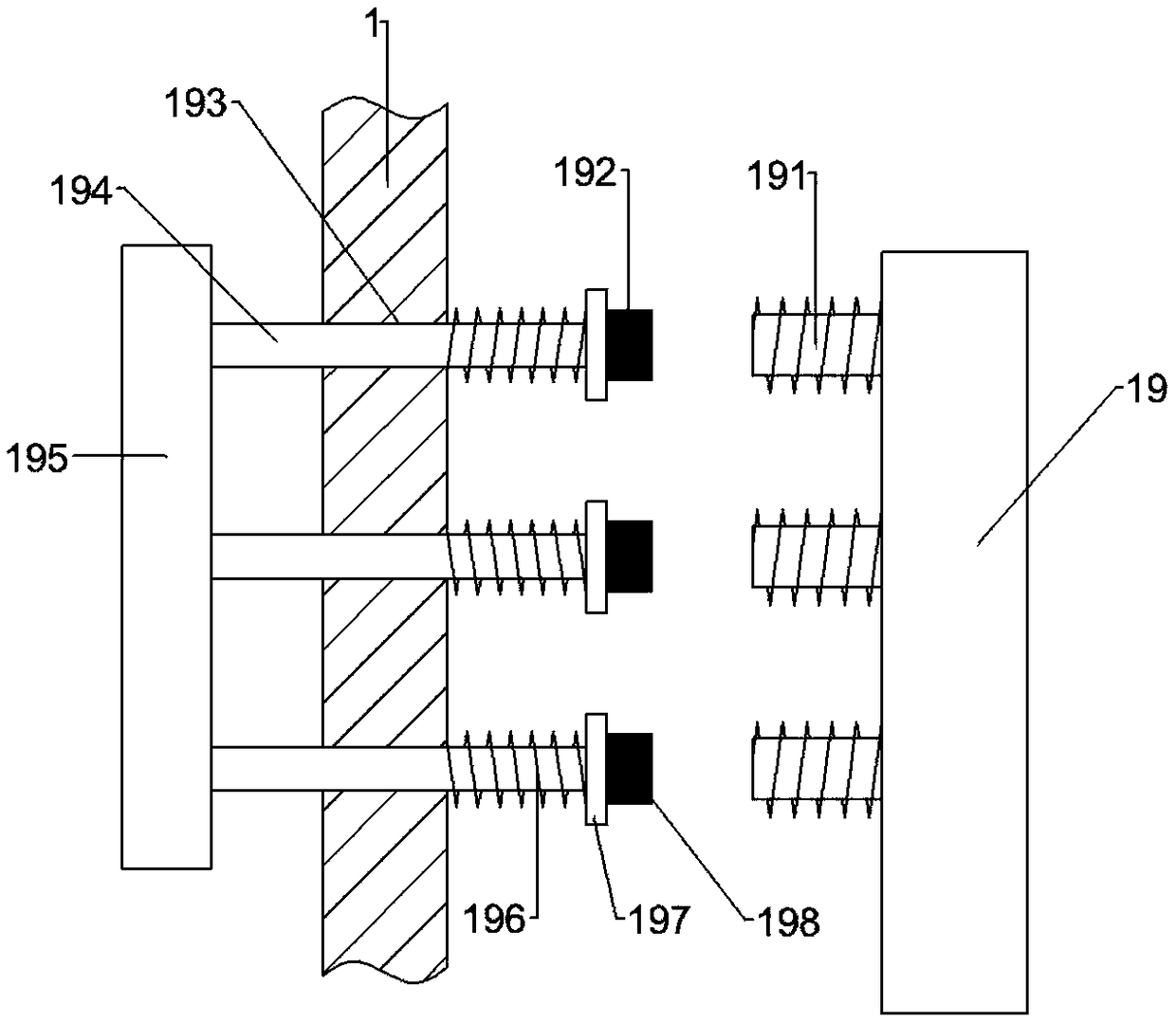

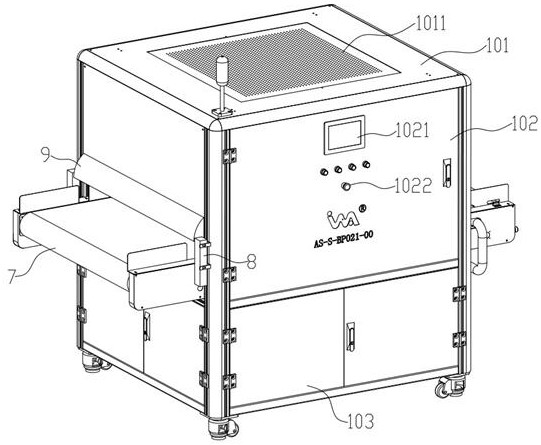

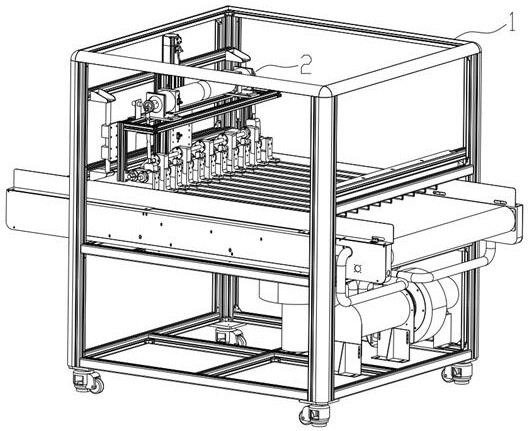

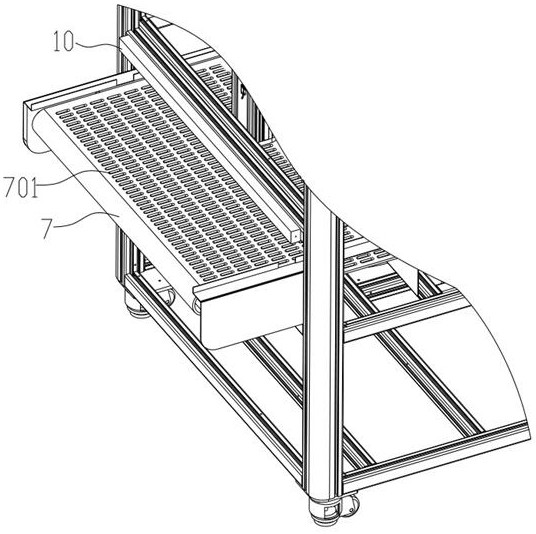

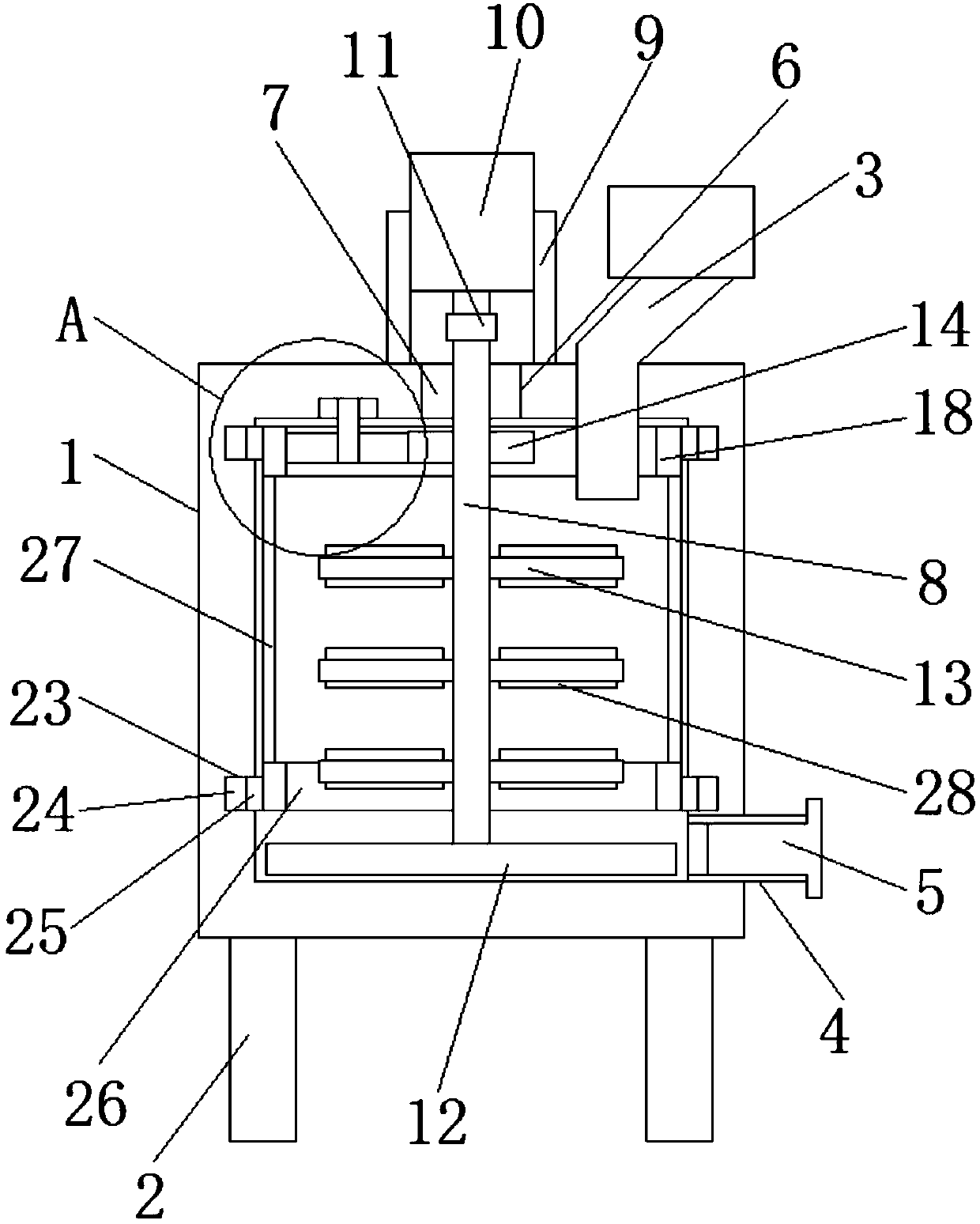

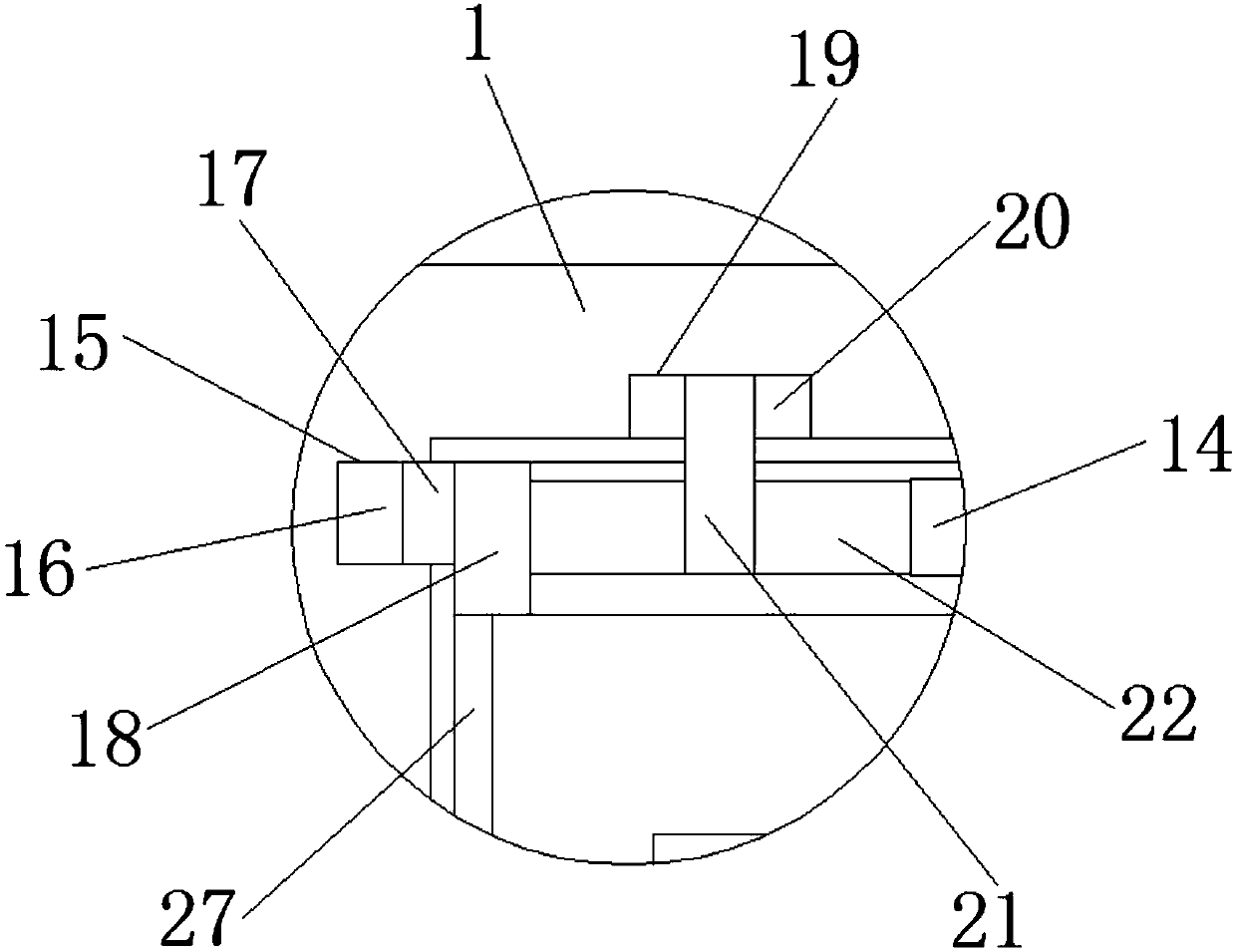

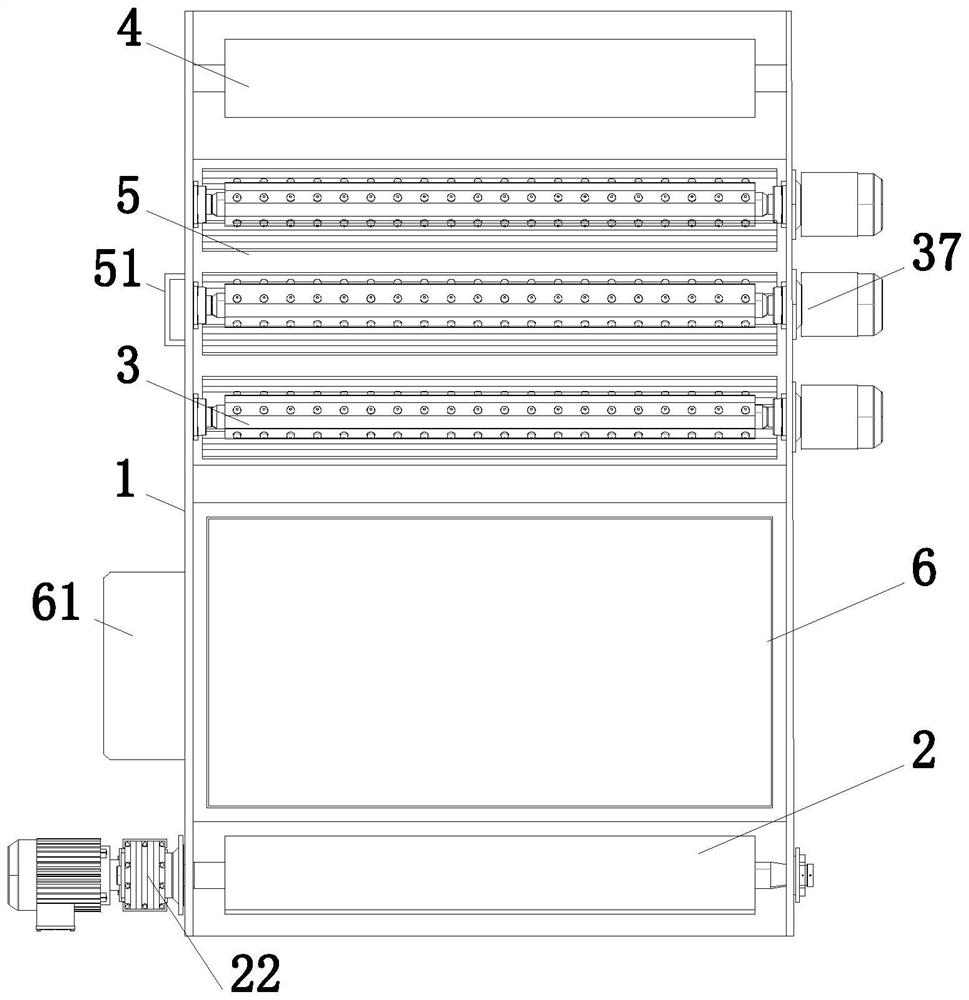

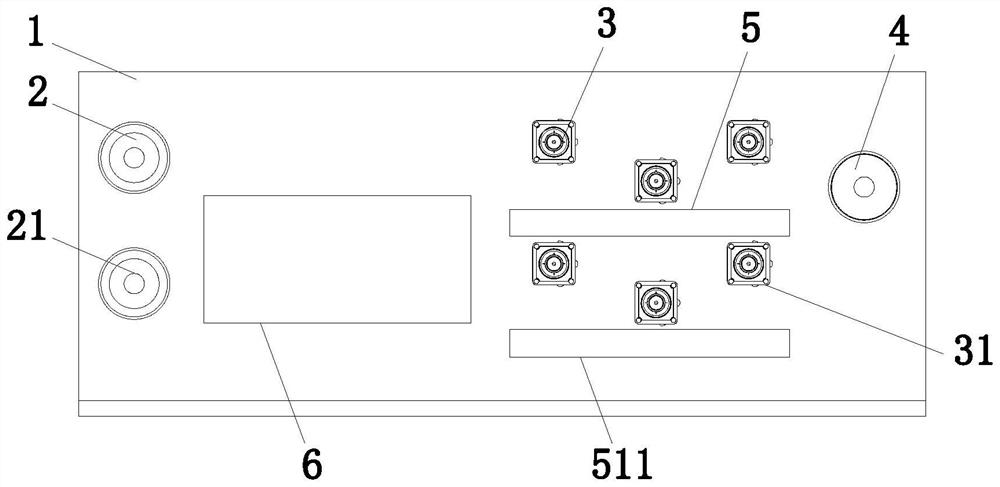

Flapping device suitable for dynamic material flapping

PendingCN113307220AIncrease productivityGood slapping effectUpholstery manufactureUpholstery auxillary devicesEngineeringConveyor belt

The invention relates to a flapping device suitable for dynamic material flapping. The device comprises a framework, a conveyor belt is arranged in the framework, a flapping rod device mounted on the framework is arranged above the conveyor belt, a flapping rod for flapping materials is arranged on the flapping rod device, and a flapping print formed on the lower end surface of the flapping rod conforms to the conveying track of the conveyor belt. When the flapping device is used for flapping, the flapping rod does not hinder material transportation or material picking and pulling; and the flapping device can also enable the materials to be flapped more uniformly and more fluffy.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

Method for treating leather leftover materials

InactiveCN108708205AEasy to sortImprove efficiencyPulp beating methodsRaw material divisionTreatment effectEngineering

The invention provides a method for treating leather leftover materials. The method solves the technical problems of complexity, excessive processes and poor treatment effects of existing methods. Themethod for treating the leather leftover materials comprises the following steps of S1, preparing the leather leftover materials, removing impurities, then conducting screening and sorting, and saving the obtained materials as standby materials; S2, placing the standby materials in S1 into a crushing mechanism of a beating system to obtain short-fiber-shaped standby materials; S3, placing the short-fiber-shaped standby materials in S2 into a cleaning liquid for soaking treatment, conducting heating to raise the temperature to 30-50 DEG C, and conducting heat preservation for 2-3 h; S4, placing the soaked standby materials in S3 into a beating barrel of the beating system, conducting grinding for 15-30 min to obtain fine-fiber-shaped initial slurry, and then placing treatment liquid into the beating barrel of the beating system to obtain finished slurry. The method has the advantage that the treatment effect is good.

Owner:海宁市丁桥镇永畅知识产权服务部

Beating device capable of achieving even beating in papermaking

The invention discloses a beating device for papermaking capable of uniform beating, comprising a barrel body, the bottom of the barrel body is fixedly equipped with outriggers, and the left side of the top wall of the barrel body is fixedly connected with the discharge end of a feeding hopper , the bottom end of the right wall of the barrel body is fixedly connected with the feed end of the discharge pipe, the discharge end of the discharge pipe is threadedly connected with a screw plug, and the middle part of the top wall of the barrel body is provided with an installation hole, A first bearing is fixedly installed inside the mounting hole. The beating device for papermaking capable of beating evenly, the bottom end of the rotating shaft penetrates the first bearing and extends to the inside of the bucket body, the bottom end of the rotating shaft is fixedly connected with the middle part of the upper surface of the scraping bar, the lower surface of the internal gear and the fixed ring The upper surface is fixedly connected by connecting rods, and the connecting rods and scraping rods can be used to stir up the pulp raw materials sticking to the inner wall of the barrel and accumulated on the bottom of the barrel, so that the raw materials can be crushed by the crushing rod and the blade to avoid the occurrence of beating In the case of uneven pulp, the problems raised in the background art are solved.

Owner:江门市新会区崖门镇众力经济发展有限公司

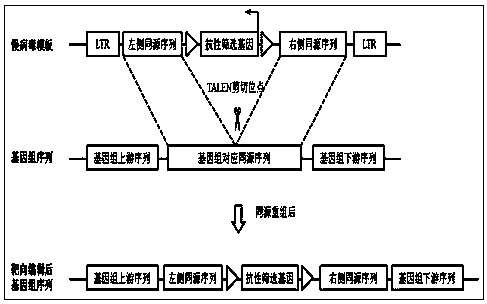

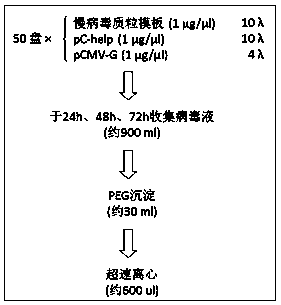

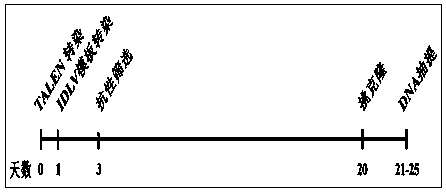

Transcription activator-like effector nuclease (TALEN) target gene editing and optimizing method taking IDLV as template

The invention provides a transcription activator-like effector Nuclease (TALEN) target gene editing and optimizing method taking IDLV as a template. A homologous recombination template is inserted into a lentiviral vector, the intracellular delivery efficiency of the homologous recombination template is improved by using efficient transduction efficiency of lentivirus, so as to improve the efficiency of a TALEN target gene editing technique. The lentivirus is packaged by using packaging plasmids with integrase defect, the lentiviral vector containing the template is not integrated into a chromosome, insertion mutation is avoided and the safety of the target gene editing technique is ensured. A complete set of TALEN target gene editing and optimizing method in which the lentivirus with integrase defect is used as an intracellular import tool of the homologous recombination template is provided. Different TALENs and homologous recombination template sequences are designed according to the research targets by the method, and efficient target editing of any gene sequence is expected to be realized.

Owner:ZHEJIANG UNIV +1

Surface treatment device used before printing and dyeing in fabric production

InactiveCN114717830ABeat evenlyEasy to solveMechanical cleaningPressure cleaningBrushMaterials science

The invention relates to the technical field of textile processing, in particular to a surface treatment device before fabric production printing and dyeing, an unwinding roller is movably mounted at the front end of the inner side surface of a supporting rack, and a winding roller is movably mounted at the position, below the unwinding roller, of the inner side surface of the supporting rack; and a thread residue treatment box is fixedly installed at the position, behind the unwinding roller, of the inner side surface of the supporting rack, and three upper pretreatment rollers are movably installed at the position, behind the thread residue treatment box, of the inner side surface of the supporting rack in a staggered mode. Through the internal structures of a twitching chassis, an upper electricity removing brush, a lower electricity removing brush and a driving mounting box, during use, static electricity is generated during friction of electrostatic cotton connected with a mounting column in a sleeving manner on the surface of a connecting sliding seat, and falling dust and attachments are adsorbed; thread ends or fluff on the surface of the fabric extend into the through holes in the surface of the shearing roller, and the shearing piece shears the thread ends or the fluff extending into the through holes when rotating.

Owner:徐州市良瑞纺织科技有限公司

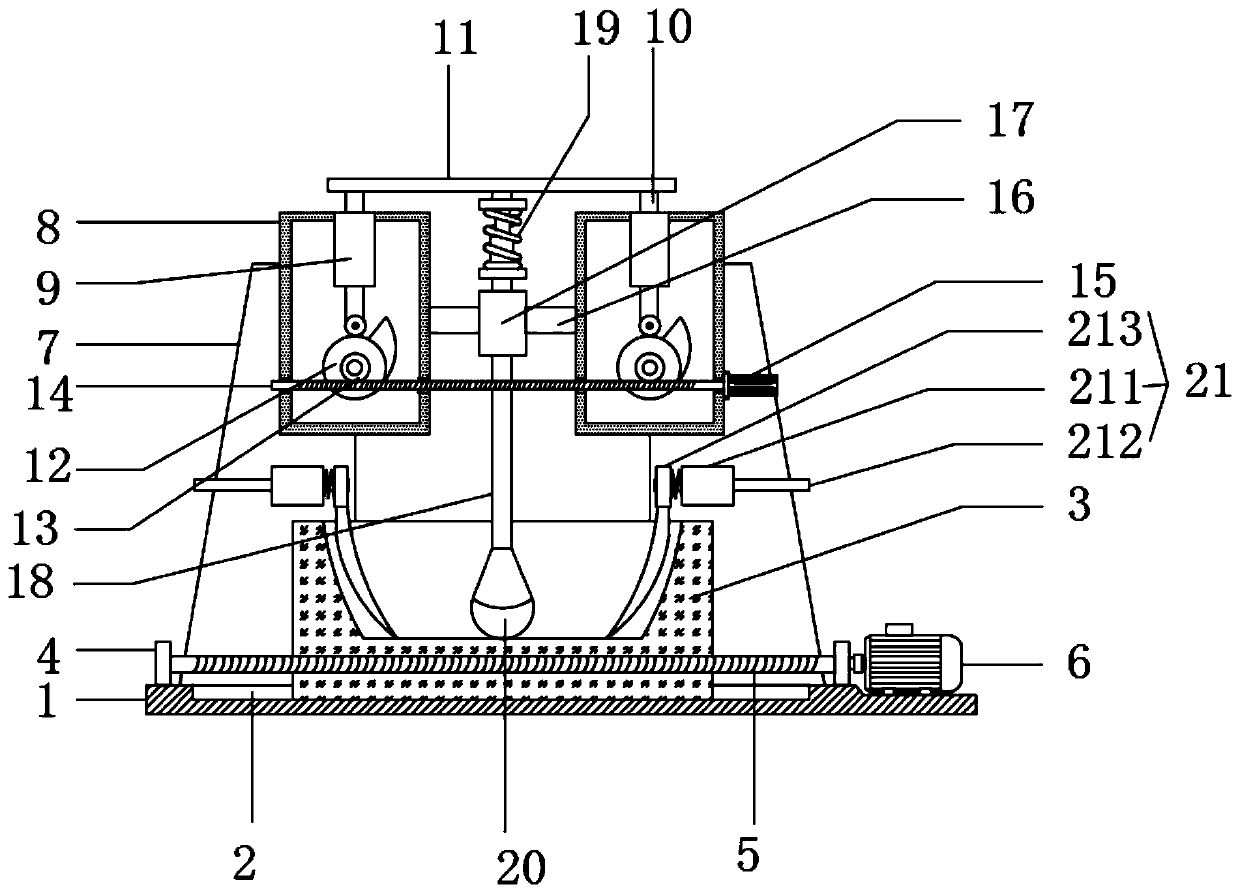

Energy-saving food processing device

PendingCN114831273AWell marinatedImprove uniformityFood processingInjection-based meat tenderisingChemistryProcess engineering

The invention relates to the technical field of food processing, in particular to an energy-saving food processing device, and provides the following scheme aiming at the problem that meat cannot be uniformly pickled when a pickling device in the prior art is used: the energy-saving food processing device comprises a base, a bracket mounted at the top of the base, and an injection mechanism and a beating mechanism which are mounted on the bracket, a workbench is mounted at the top of the base, a pickling disc is slidably connected to the workbench, and a rotating mechanism for pushing the pickling disc to reciprocate in the horizontal direction is mounted on the support; according to the device, marinade can be injected into meat, so that the meat can be better marinated, the uniformity of marinating the meat is improved, the marinade injected each time is quantitative, the phenomenon that the marinade injection amount is too large or too small is avoided, the meat can be continuously beaten in a reciprocating manner through the arranged beating mechanism, and the meat is more uniform in marinade injection amount. Therefore, the marinade and the meat can be fully fused, so that the uniformity of the marinade is further improved.

Owner:ANHUI XIAXING FOOD

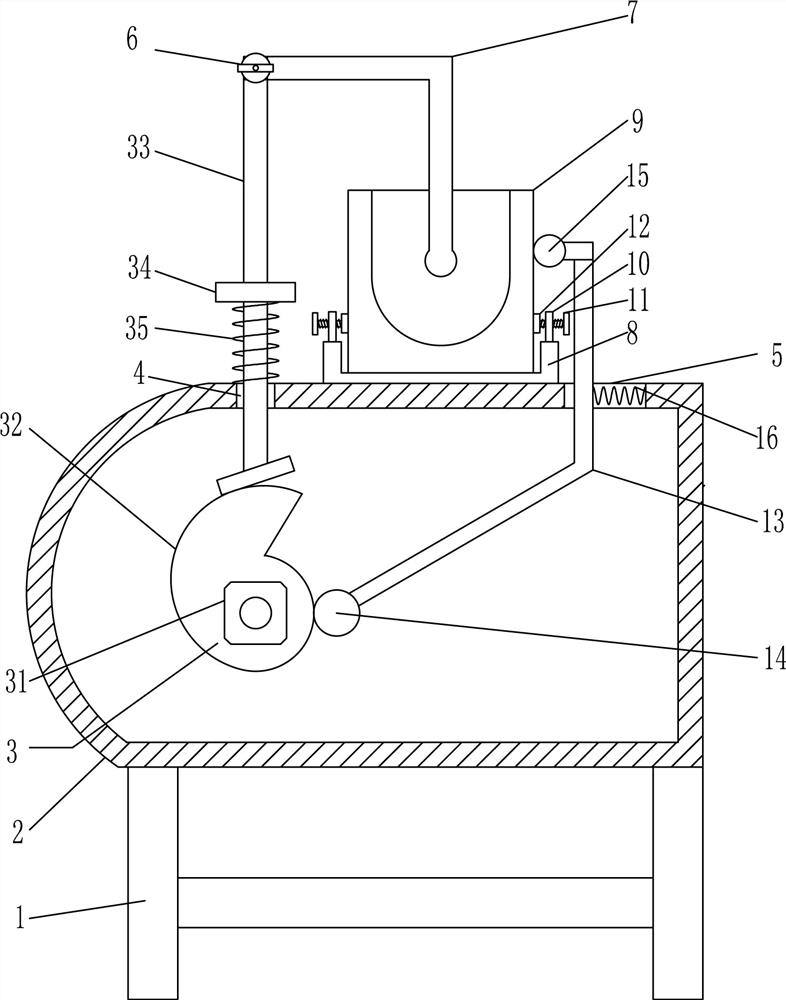

Moxa beating machine for wormwood

The invention relates to a moxa beating machine, in particular to a moxa beating machine for wormwood. The technical objective is to provide the moxa beating machine for the wormwood, and the moxa beating machine for the wormwood evenly beats the wormwood, and it is convenient for people to take out beaten moxa. The moxa beating machine for the wormwood comprises a supporting frame, a box body, alifting mechanism, and a pestle, wherein the supporting frame plays a role in supporting; the box body is arranged at the upper part of the supporting frame; the lifting mechanism is arranged on one side of the box body; and the pestle is detachably arranged at the upper part of the lifting mechanism. According to the moxa beating machine for the wormwood, the effect that the wormwood is evenly beaten, and it is convenient for the people to take out the beaten moxa is achieved, and a servo motor drives a cam to rotate, so that a lifting rod indirectly and regularly moves up and down, then thepestle is driven to regularly beat the wormwood, a moving rod drives a spherical hammer to move left and right so as to vibrate and beat a mortar, and the wormwood in the mortar is vibrated to gathertowards the middle, so that the wormwood is beaten more evenly.

Owner:邓扬招

Hammering device for food processing

The invention discloses a hammering device for food processing in the technical field of food processing. The hammering device comprises a base, wherein a slide groove is formed in the top of the base; a hammering groove block capable of leftwards and rightwards sliding is arranged on the slide groove; a groove is formed in the top of the hammering groove block; bearing seats fixedly connected onto the base are arranged at the left side and the right side of the slide groove; a screw rod is rotationally connected between the two groups of the bearing seats; the hammering groove block is penetrated and screwed by the hammering groove block; a first motor is fixedly arranged at the right side of the top of the base; and the left side output end of the first motor is connected with the rightend of the lead screw through a shaft coupler. The hammering device for food processing provided by the invention can be used for hammering raw materials in food production, and automation is realizedin the hammering process. Compared with manual auxiliary hammering, the hammering device has the advantages that the production efficiency of a factory is improved; the injury to employees can be avoided; through circulation rotation of two groups of driving wheels, a hammering head can be driven to continuously and vertically move, so that the hammering function is realized; the manual participation in the hammering process is not needed; and the expense of factories on personnel is favorably reduced.

Owner:FUZHOU JIN XIANG FOOD MACHINERY & EQUIP TECH

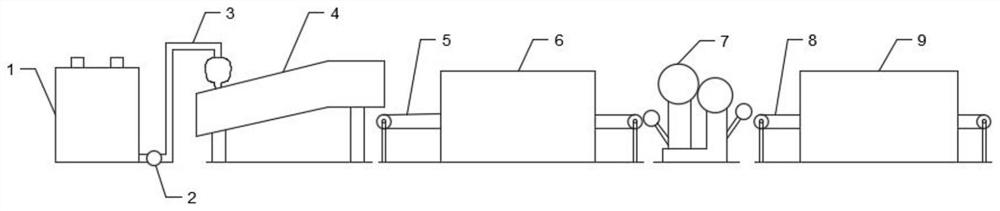

Production equipment and technology of plastic-free tableware packaging paper

ActiveCN111663362AFulfil requirementsIncrease profitabilityCoatings with pigmentsWater-repelling agents additionSocial benefitsPapermaking

The invention discloses production equipment and technology of plastic-free tableware packaging paper, and belong to the technical field of papermaking. The technology comprises the following processsteps: mixing and pulping softwood pulp, hardwood pulp and bleached bamboo pulp, blending pulp, adding auxiliary materials, making wet paper sheets, pre-drying, coating and sizing (PVA), post-drying and the like. The qualified plastic-free tableware packaging paper is manufactured by researching pulp selection, pulp proportioning, a pulping process, functional chemical additives added into pulp and the like and adopting in-machine film transfer surface sizing treatment. The one-time formed plastic-free tableware packaging paper has the advantages of being low in comprehensive cost, high in competitiveness, environmentally friendly, easy to recycle and the like, trial-produced products are put into the market to be highly evaluated by users, and economic, environmental and social benefits are quite remarkable.

Owner:湖南得凯纸业有限公司

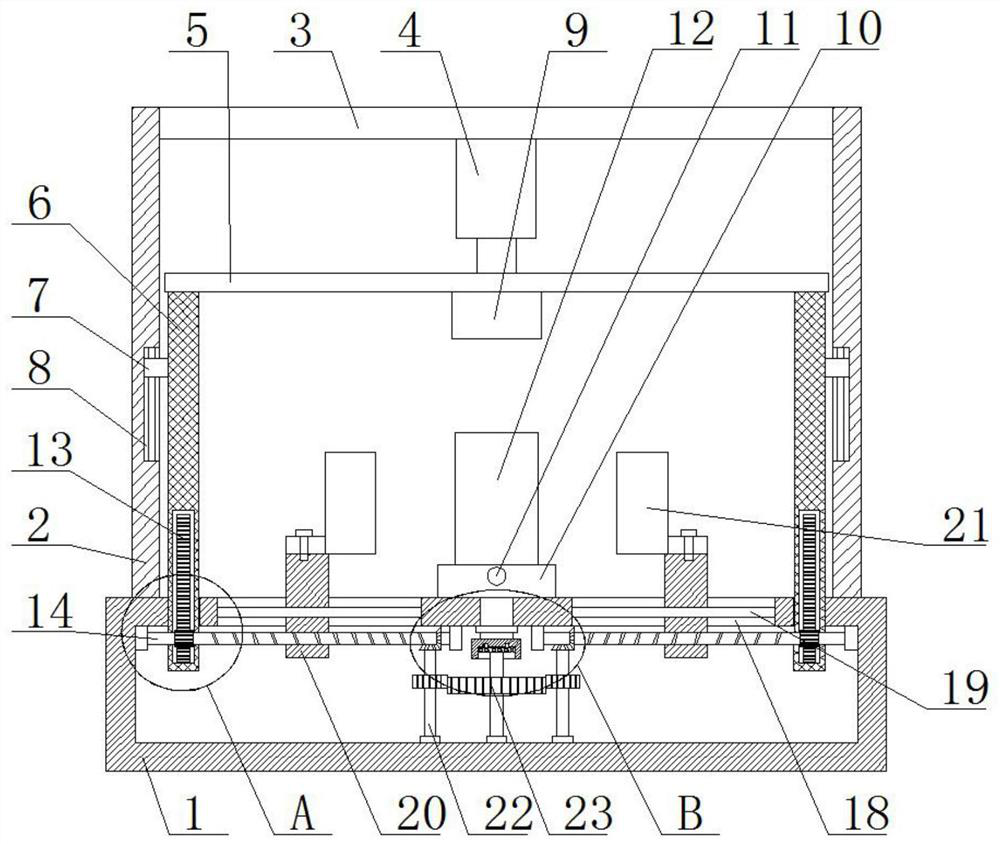

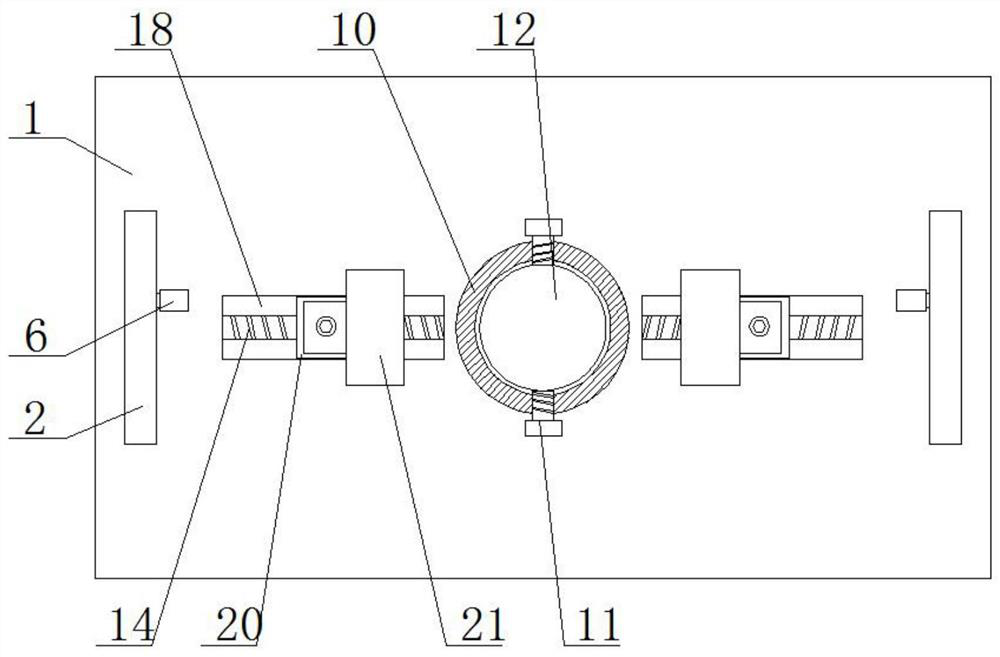

Bracelet repairing and rounding equipment

ActiveCN111602940ABeat evenlyGood round effectBraceletsWrist-watch strapsBevel gearIndustrial engineering

The invention relates to rounding equipment, in particular to bracelet repairing and rounding equipment. The technical problem to be solved is to provide the bracelet repairing and rounding equipmentwhich does not need to manually knock a bracelet, and is uniform in knocking force and high in rounding efficiency. According to the technical scheme, the bracelet repairing and rounding equipment comprises a base, a mounting frame, a supporting frame, a knocking assembly, a first bearing seat, a first rotating rod and the like; the mounting frame is connected to one side of the base, the supporting frame is connected to the base, the knocking assembly is arranged on one side of the mounting frame, and the first bearing seat is connected to the side, close to the knocking assembly, of the mounting frame. According to the invention, the bracelet is rounded through the arranged knocking block, the stabilizing rod makes contact with the bracelet, the bracelet is prevented from sliding off inthe rotating process, the bracelet is driven to automatically rotate through cooperation of the arranged first bevel gear and second bevel gear, in this way, manual rotation is not needed, time and labor are saved, and the rounding efficiency is improved.

Owner:大新珠宝(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com