Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about "Drop hammers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

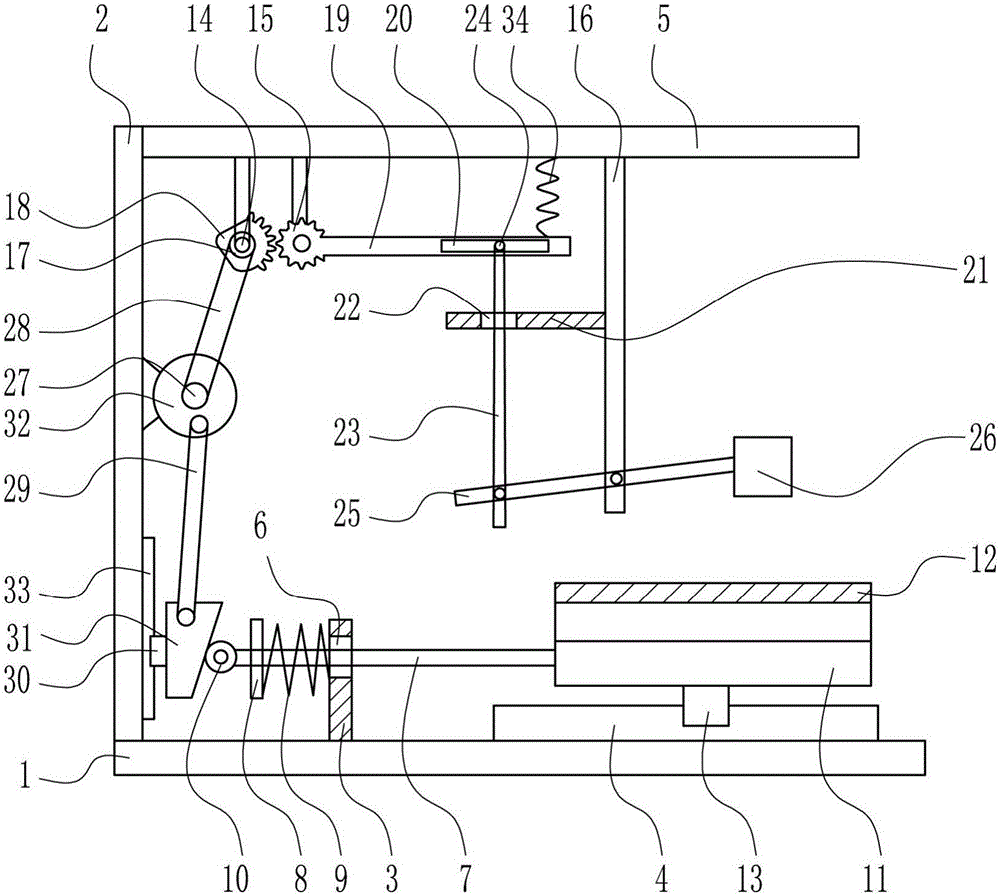

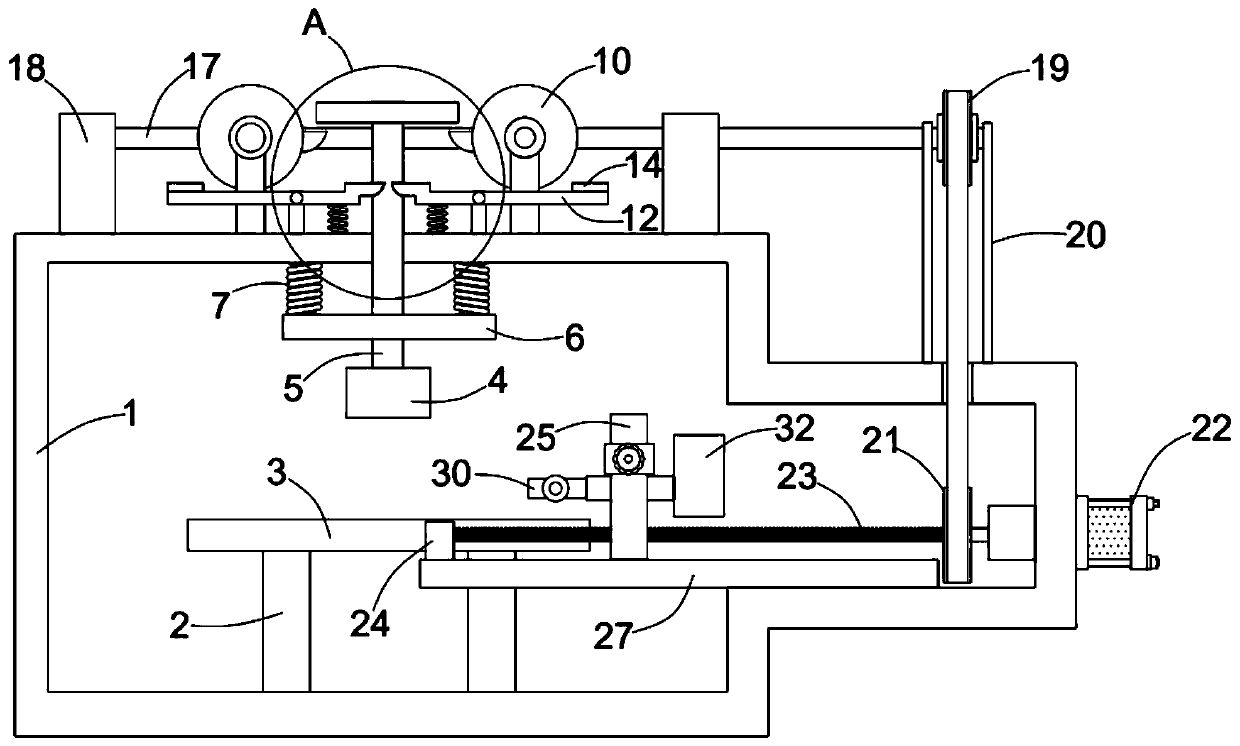

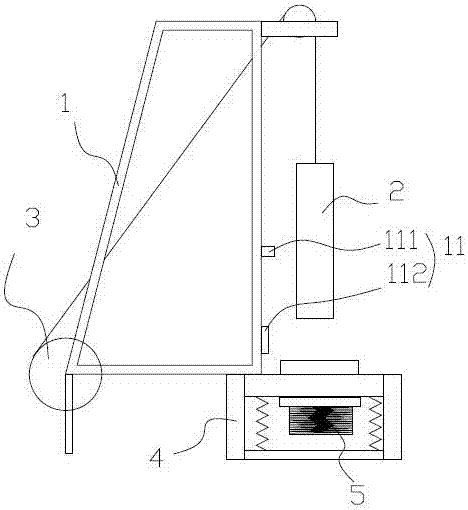

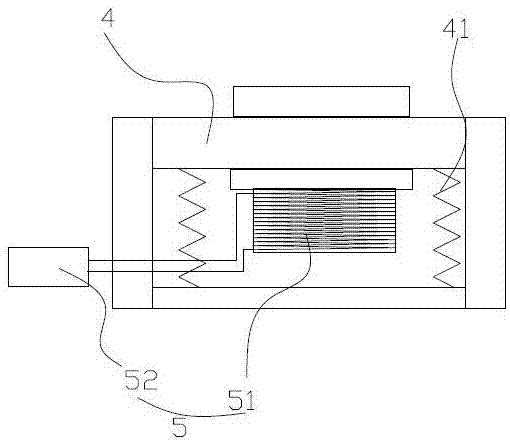

Rapid iron sheet forging device for hardware

ActiveCN106111865AOptimizing Forging PerformanceImprove stabilityDrop hammersHammer drivesMaterials sciencePulley

The invention relates to an iron sheet forging device, and particularly relates to a rapid iron sheet forging device for hardware. The invention aims to solve the technical problem of providing the rapid iron sheet forging device for hardware, which has the advantages of good forging effect, simplicity in operation and high stability. In order to solve the technical problem, the invention provides the rapid iron sheet forging device for hardware. The rapid iron sheet forging device comprises a bottom plate, a left side plate, a first guide rod, a first sliding rail, a top plate, a push rod, a fixed stop block, a carbon fire box, an electromagnet, a first sliding block, a motor, a gear, a vertical plate, a transverse plate, a second guide rod, a lifting rod, a rolling shaft, a first connecting rod, a hammer, a second belt pulley and the like, wherein the left side plate, the first guide rod and the first sliding rail are arranged on the bottom plate in sequence from left to right, and the top plate and the like are arranged on the right side of the left side plate in sequence from top to bottom. The invention provides the rapid iron sheet forging device for hardware, the effects of good forging effect and high stability are achieved by utilizing a water tank and an inclined plate, and the rapid iron sheet forging device is operated only by controlling the motor.

Owner:CN PRECISION CASING (SHENZHEN) CO LTD

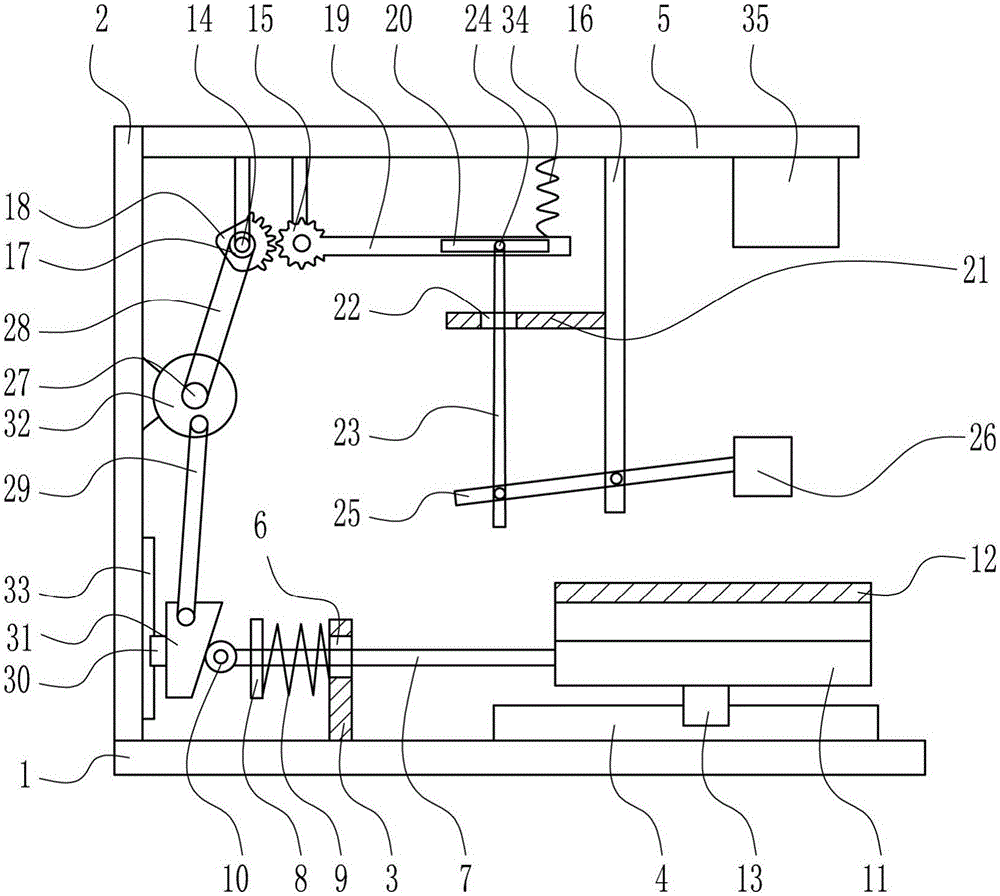

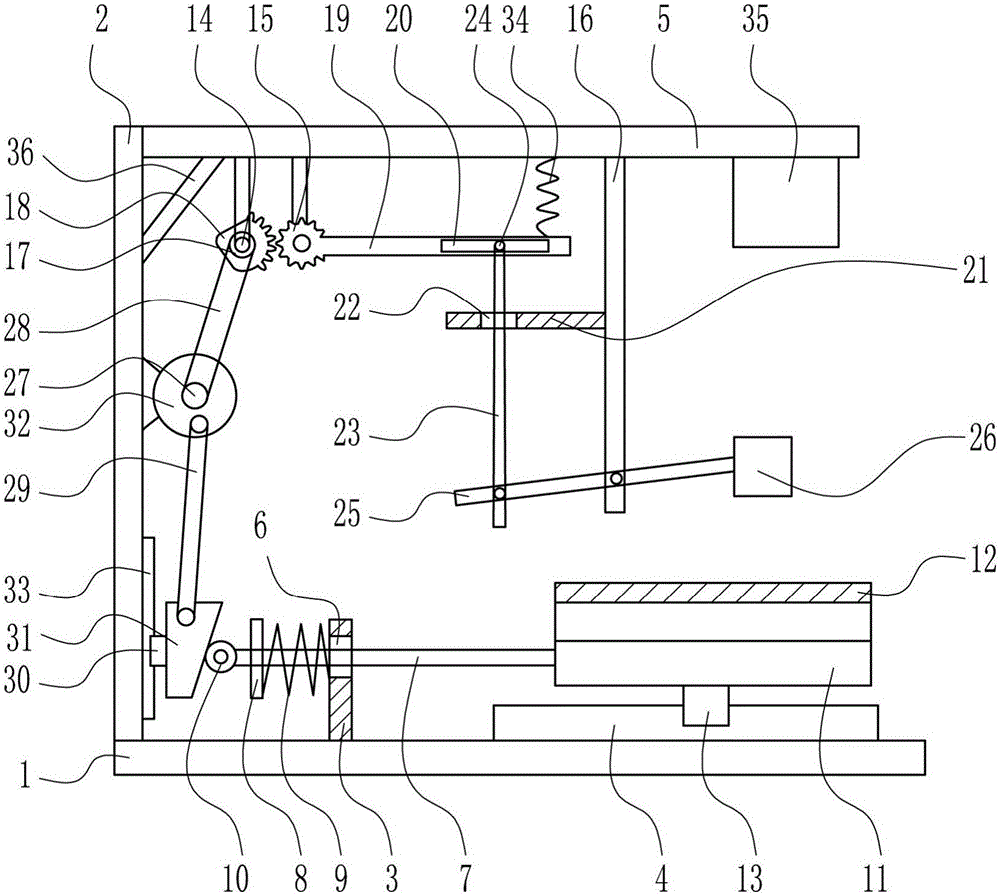

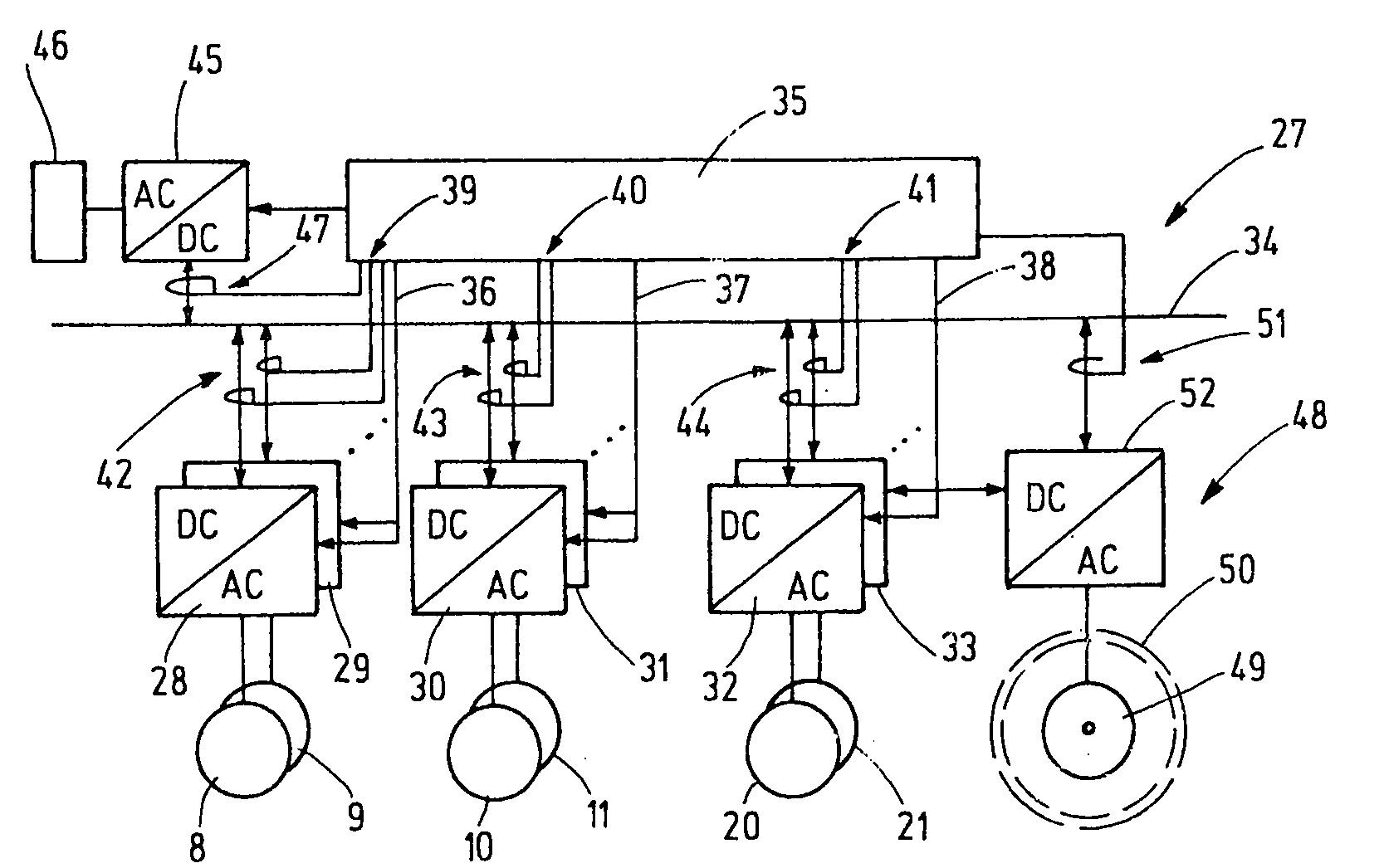

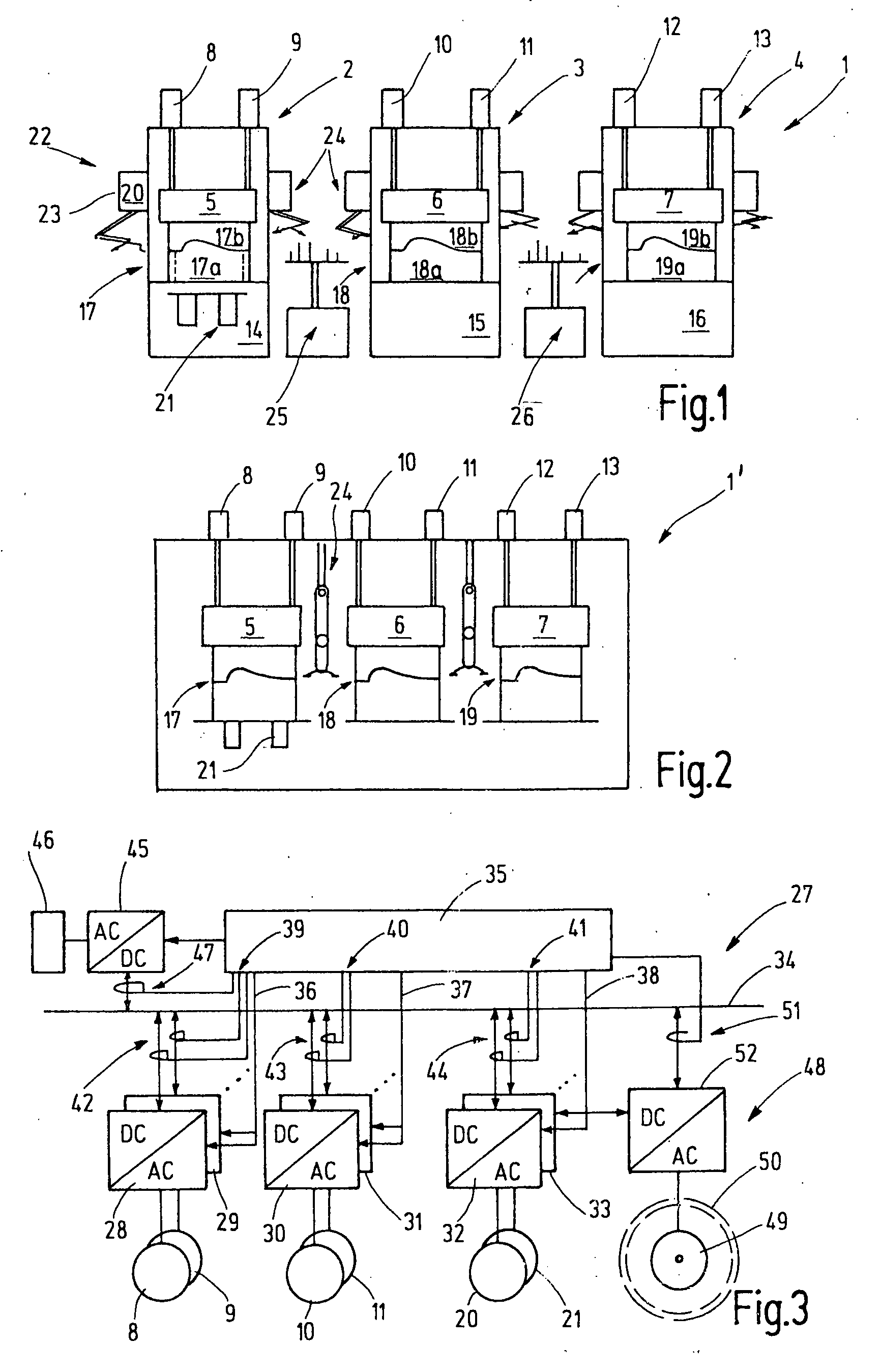

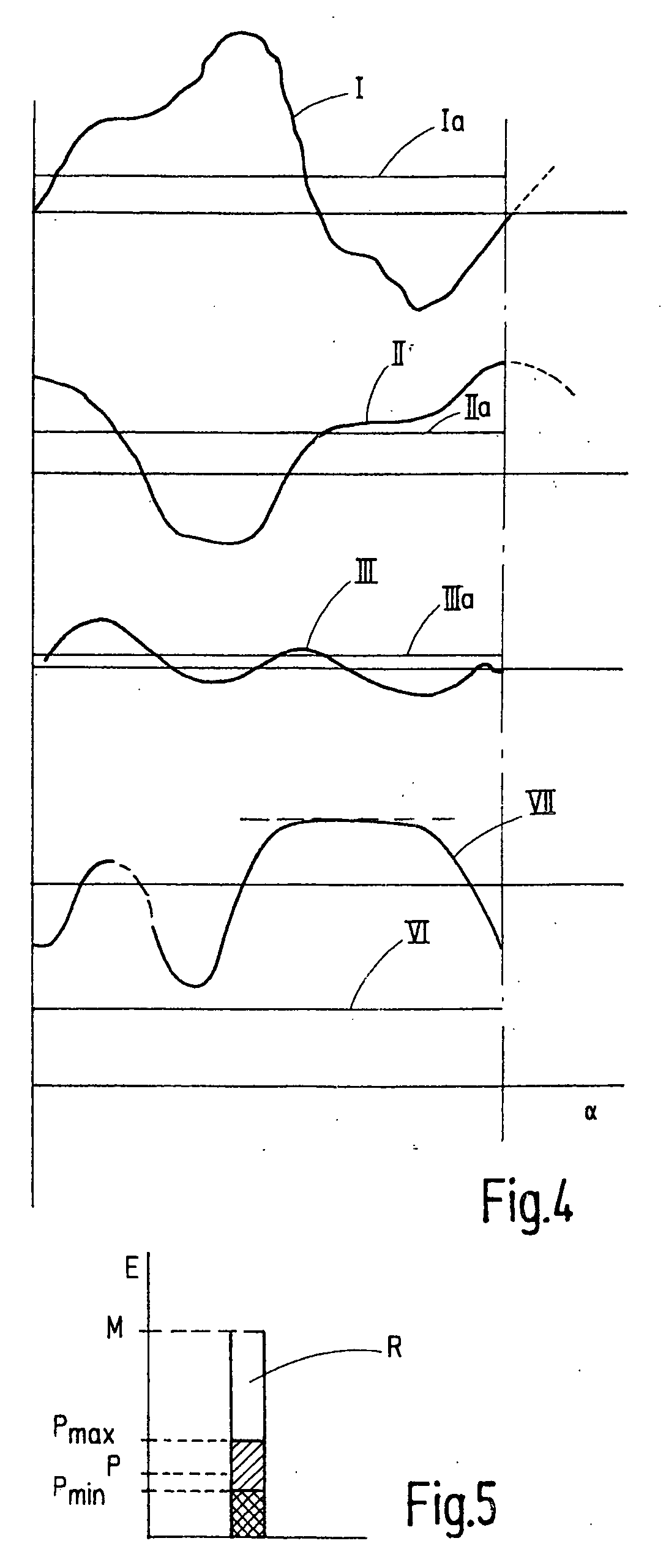

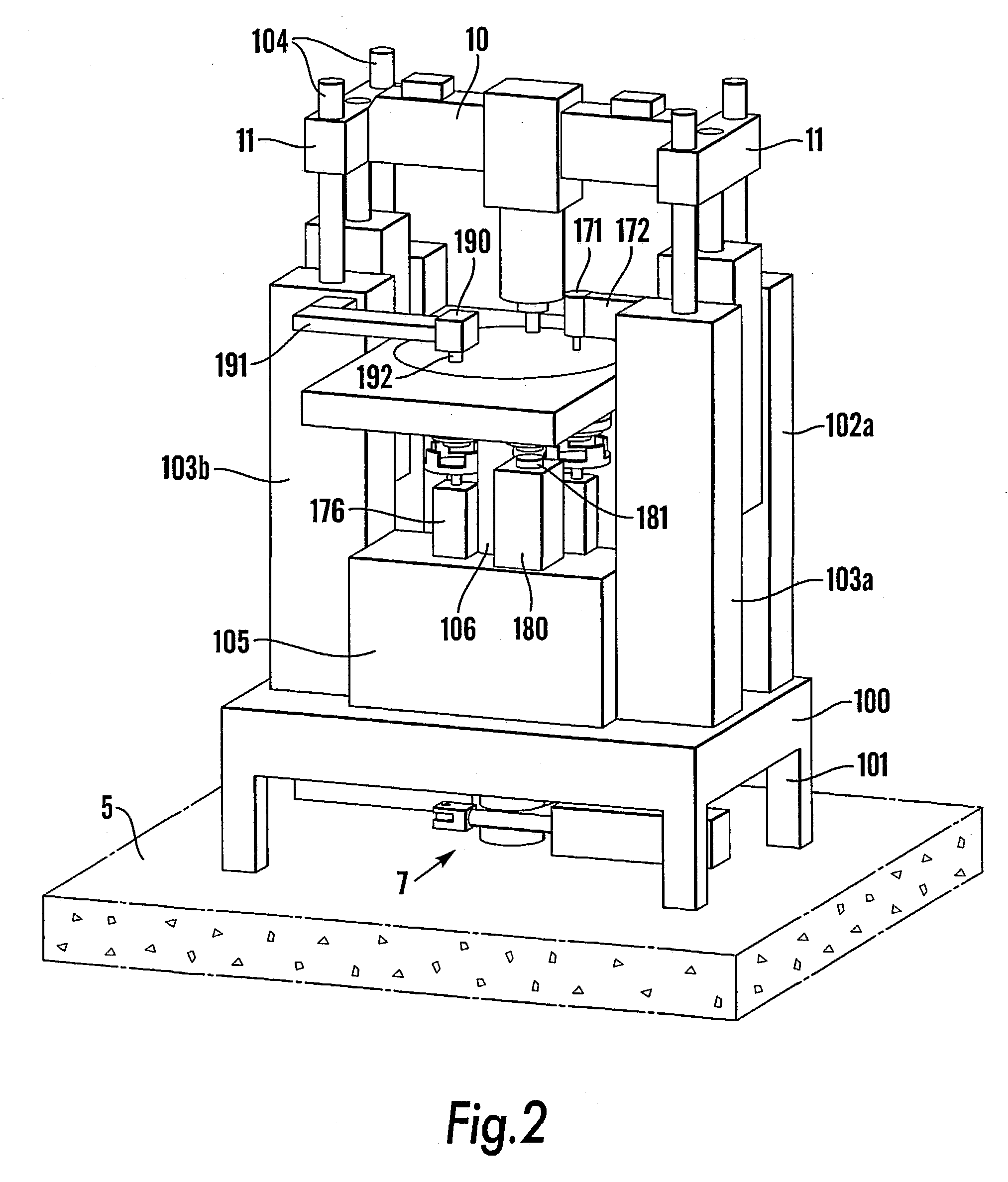

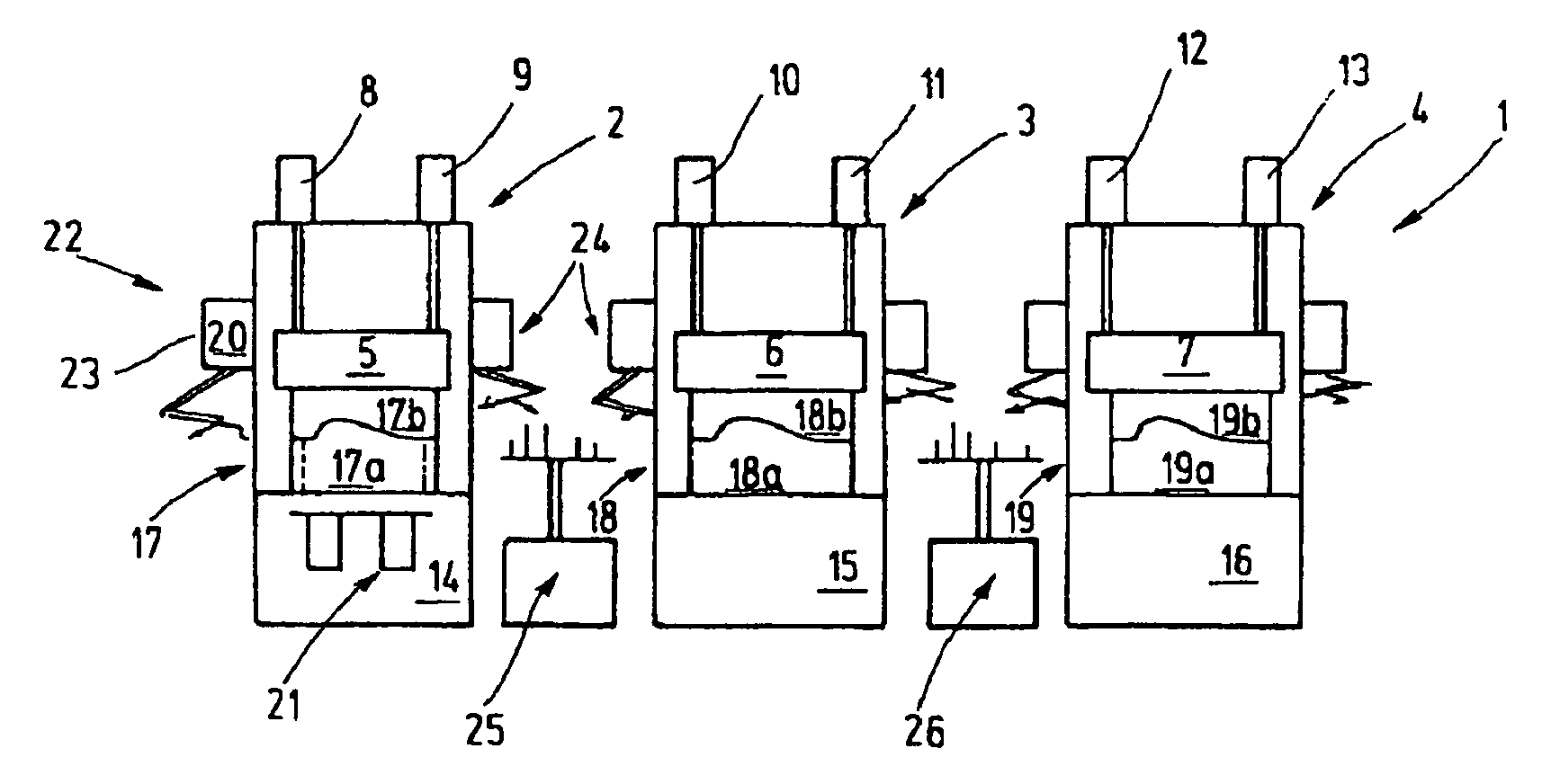

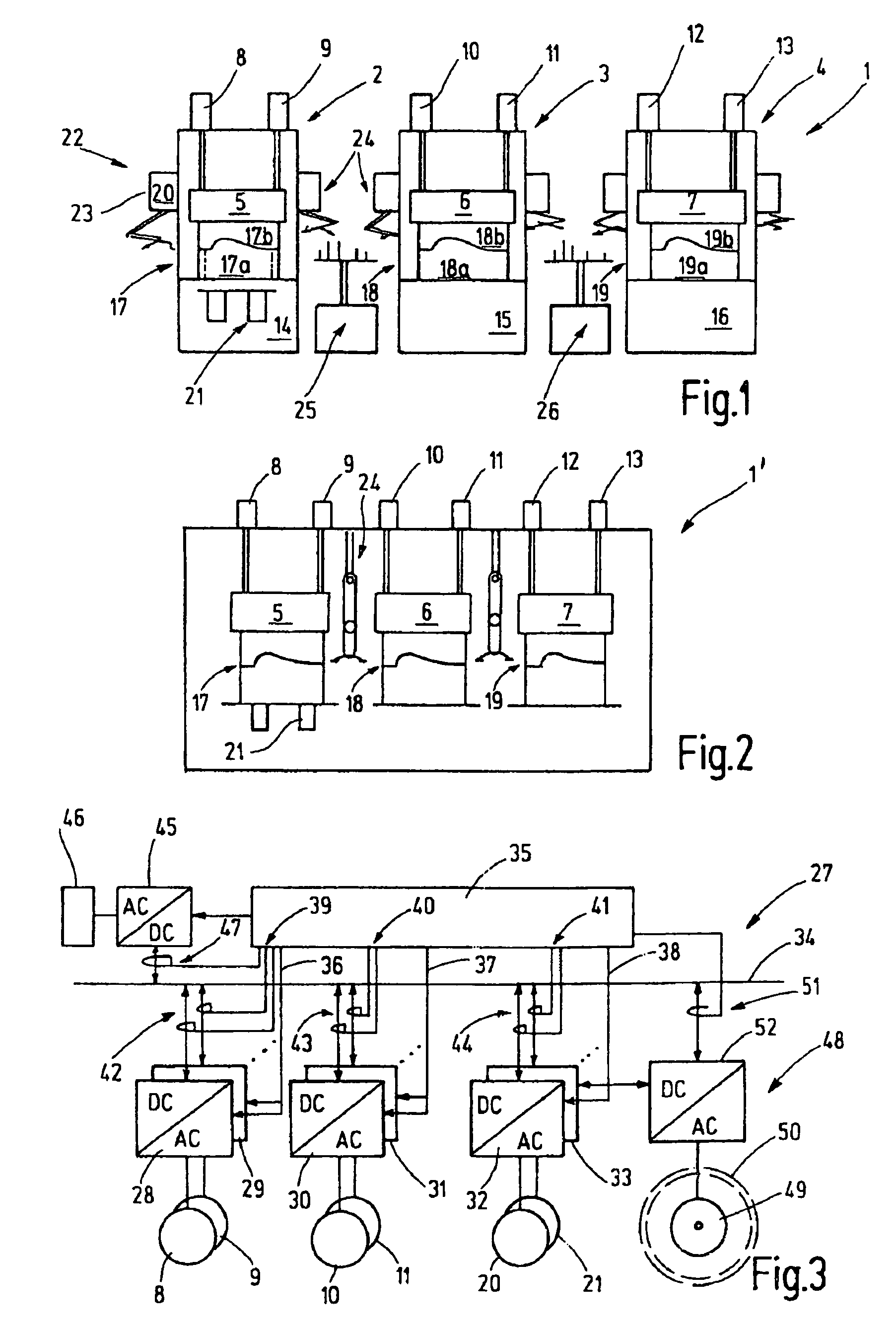

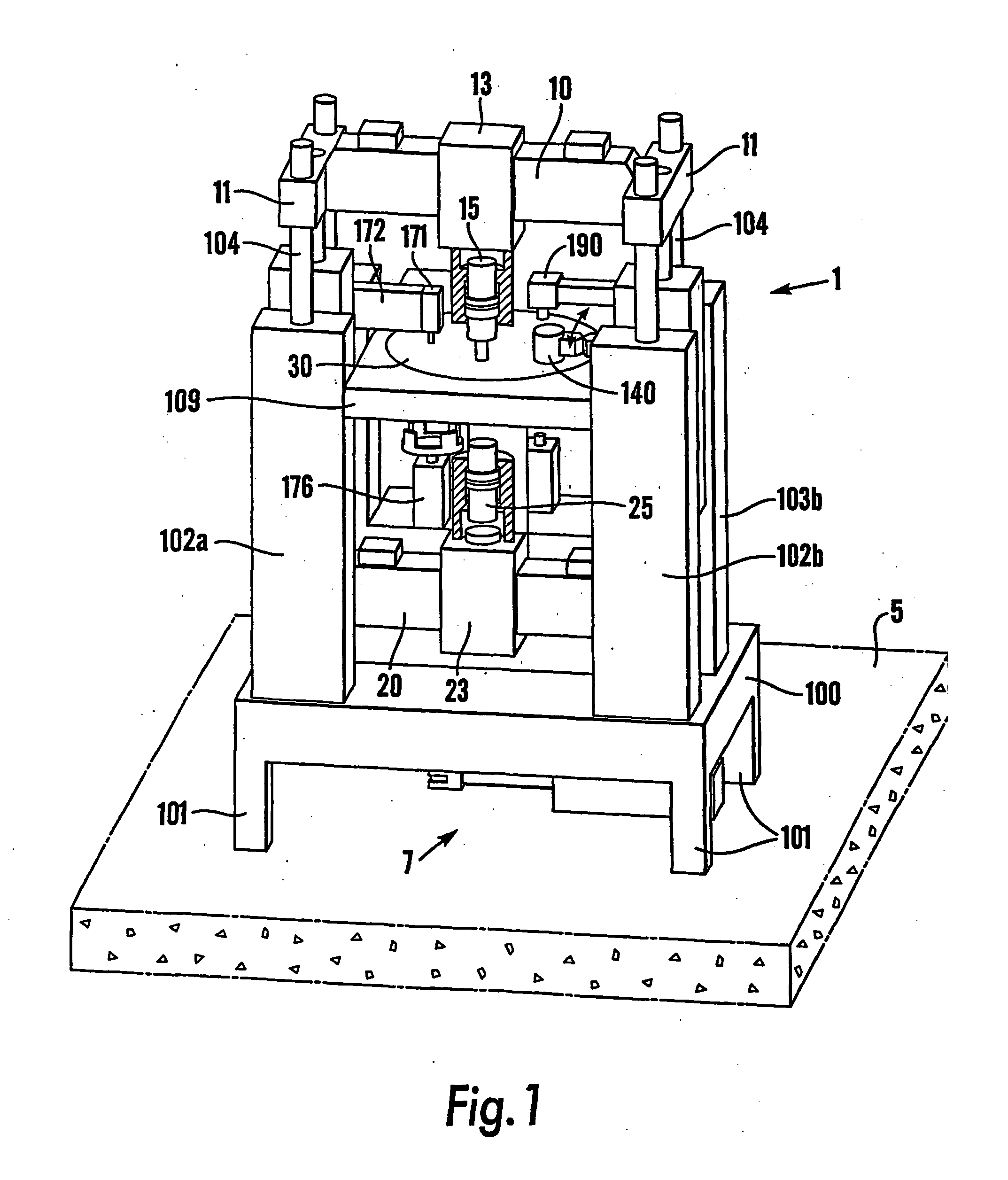

Servo-press with energy management

InactiveUS20080016940A1Arrangement be smallLow costDrop hammersMetal-working feeding devicesServo pressEnergy management system

In a press installation including a number of presses with servo-drives for operating the presses and auxiliary equipment such as workpiece handling devices wherein an energy management system is provided including a DC voltage intermediate circuit connected to a power supply grid via an AC / DC converter and to the servo-drives via servo-converters, a fly-wheel storage device is connected to the intermediate circuit for supplying energy thereto and recapturing energy therefrom under the control of a control arrangement which controls the flow of power between the intermediate circuit, the servo-drives, the fly-wheel storage device and the power supply grid.

Owner:SCHULER PRESSEN GMBH & CO KG

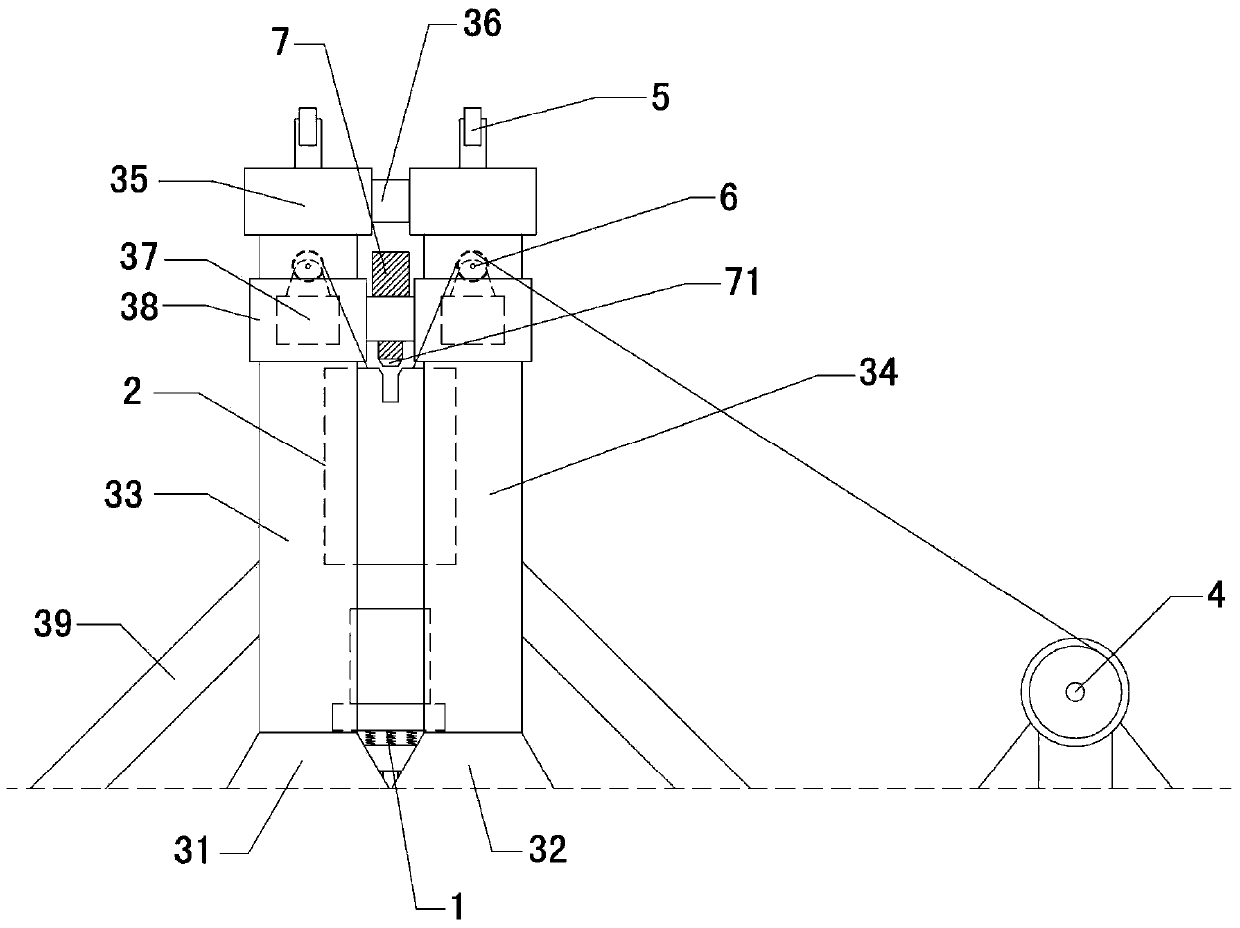

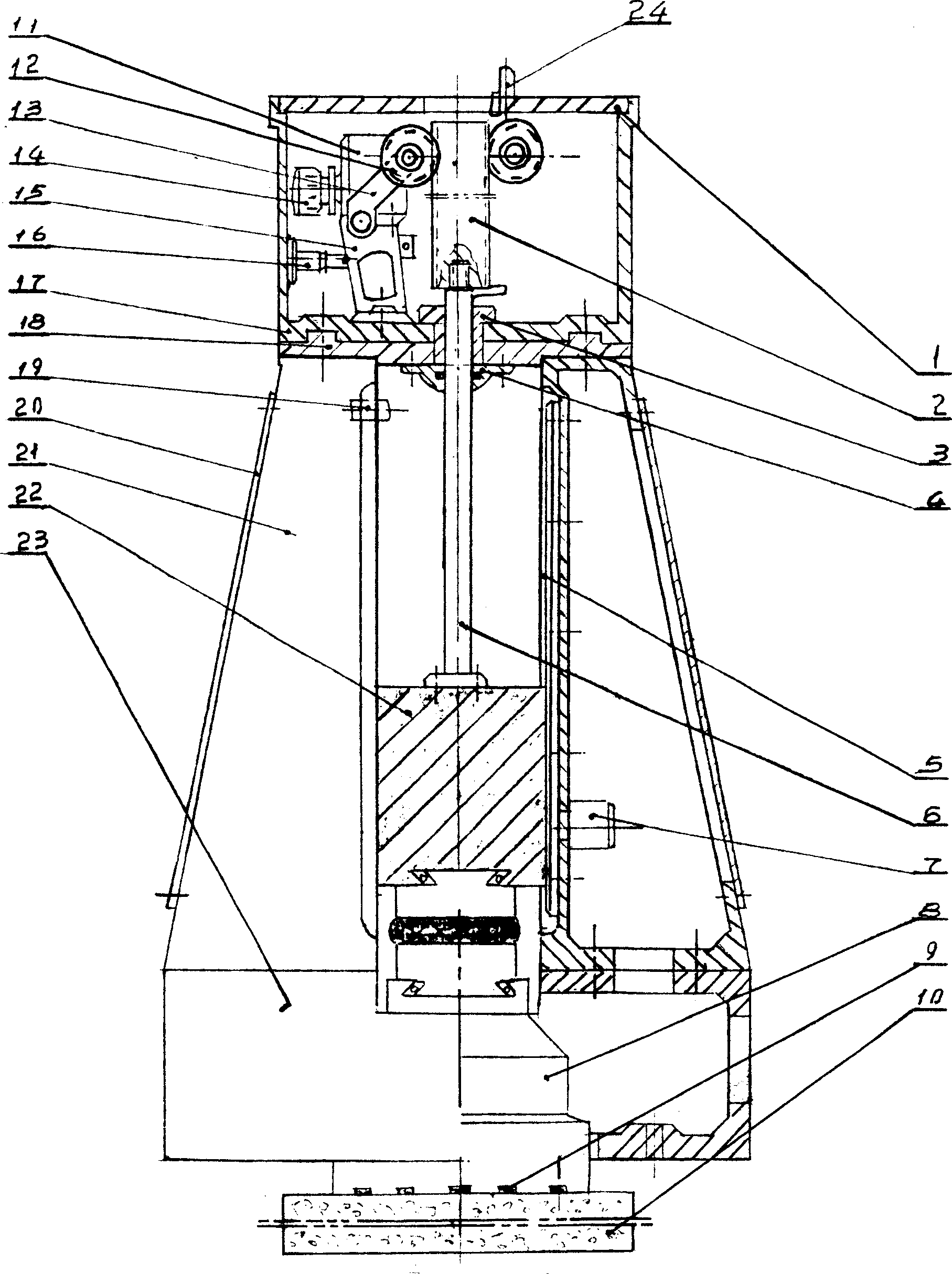

Method, impact machine, and equipment included in an impact machine

InactiveUS6871524B2High strengthReasonably preparedDrop hammersPower hammersHigh velocityMaterials science

The invention relates to a method for the manufacture of an annular article, which substantially consists of metal, ceramic material, and / or polymer. A cavity in a die is filled with a formable working material, which shall form said article. A tubular, upper punch (17) is introduced into the upper mouth of a hole in a die (34), so that a closed mould cavity is formed. The upper punch and a lower punch (27) are simultaneously struck towards one another at such a high velocity that the working material is plasticized and flows out and fills the mould cavity, and thereafter the upper punch is removed. Then, a mandrel (35) in the lower punch is driven out of the annular body by means of a mandrel expulsor (170), which is pressed against the mandrel from above, and thereafter the annular body is from below pushed out of the die by mean of the lower punch. The invention also relates to an equipment for the carrying out of the method.

Owner:MORPHIC TECH

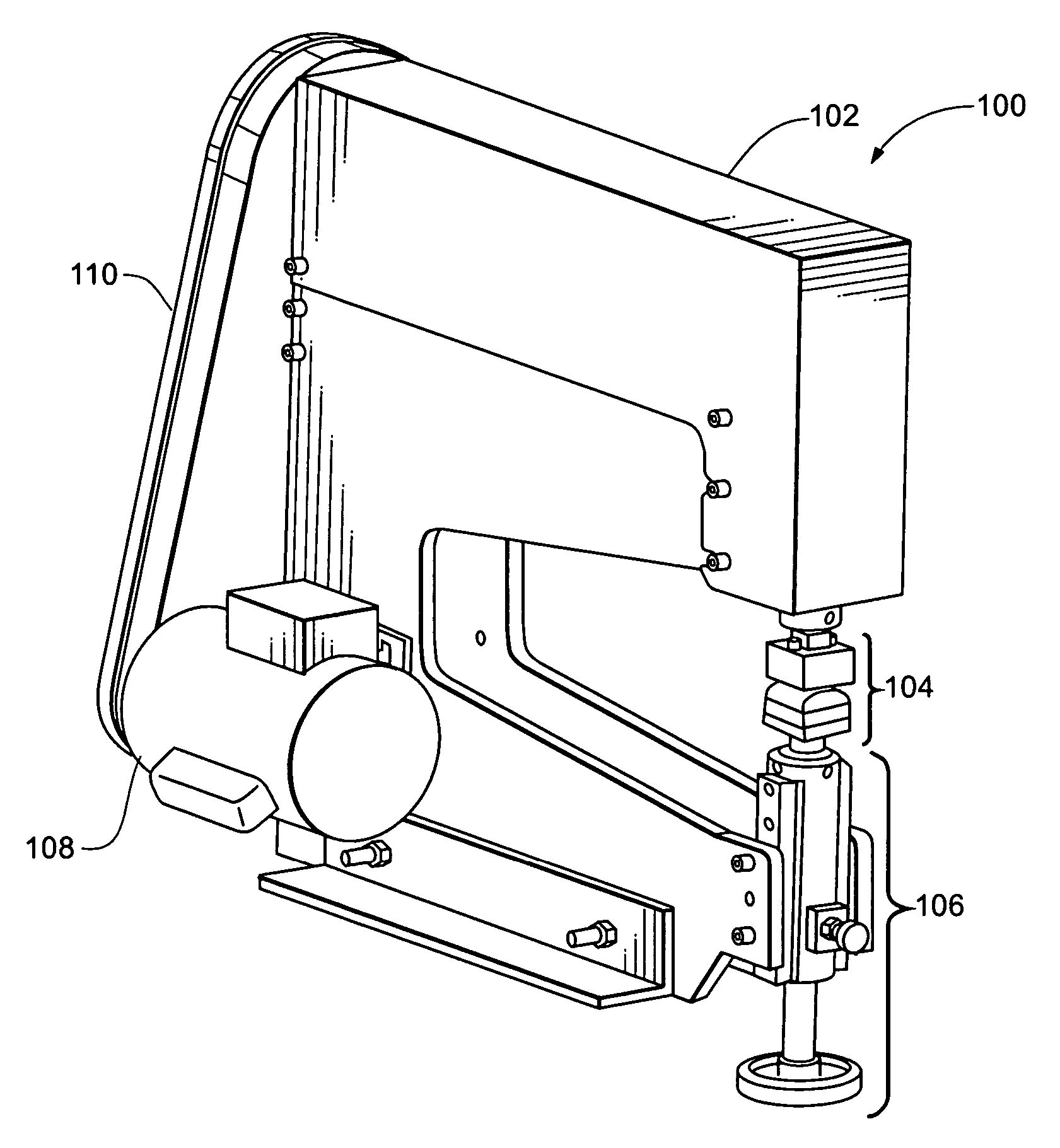

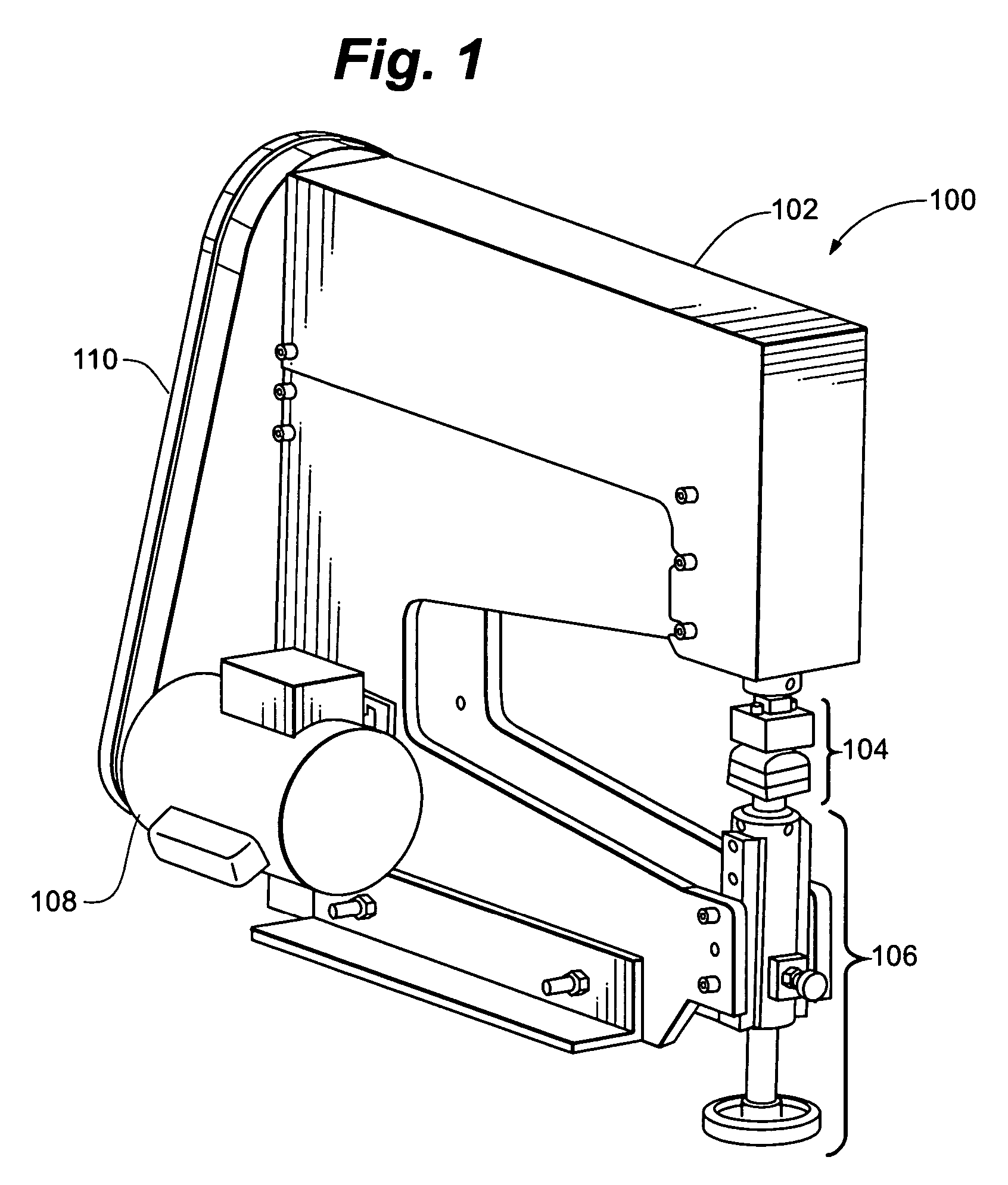

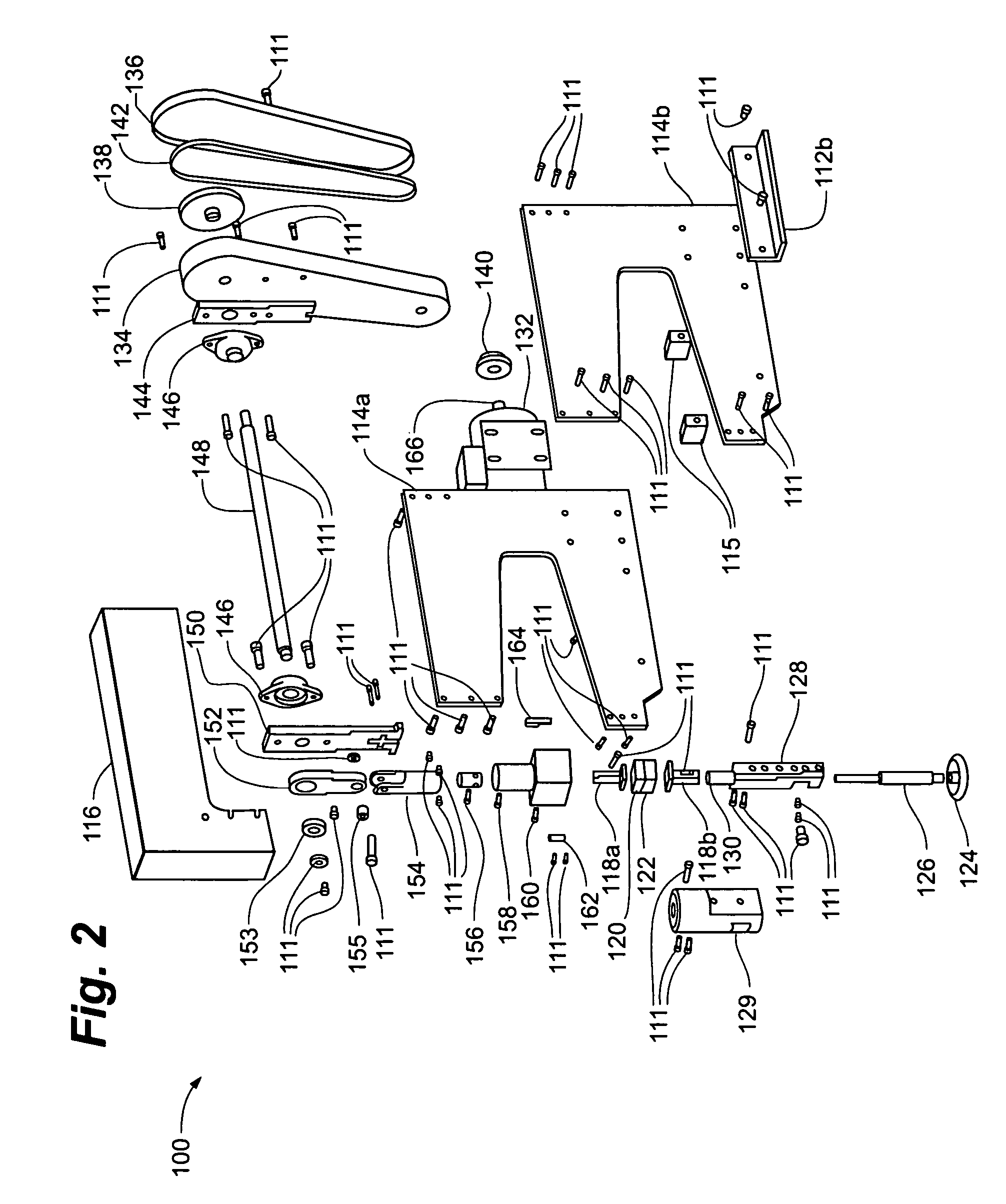

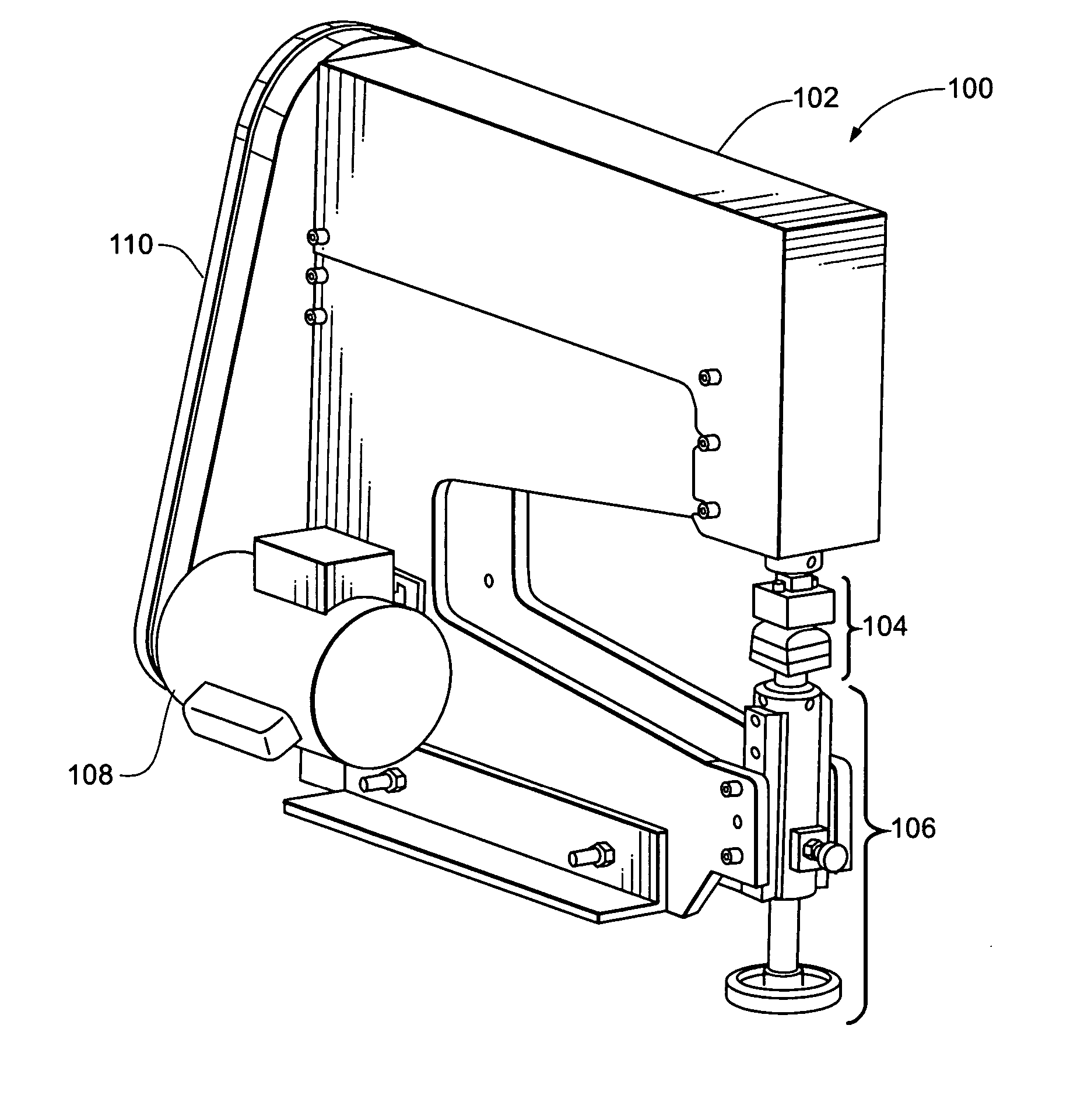

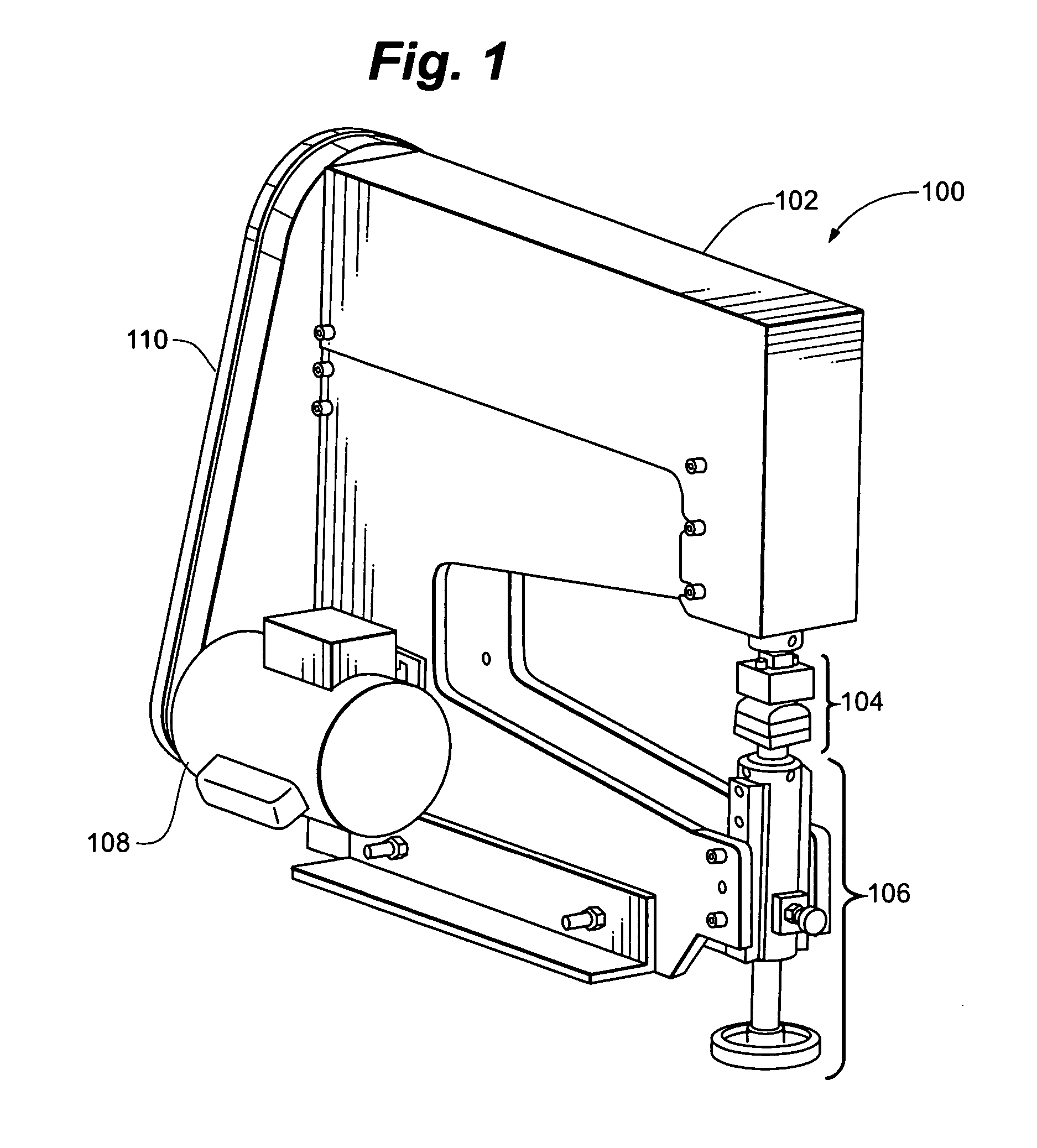

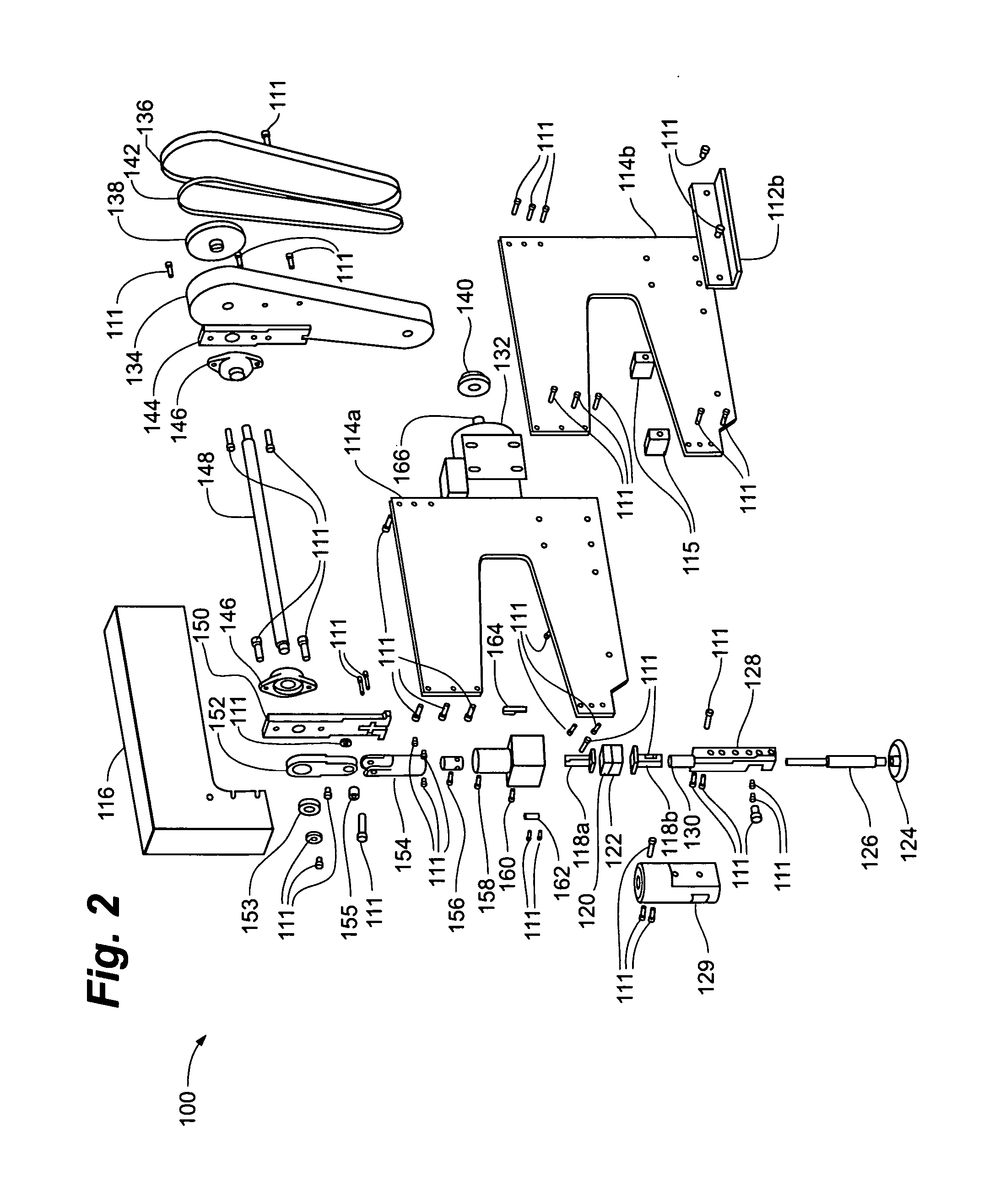

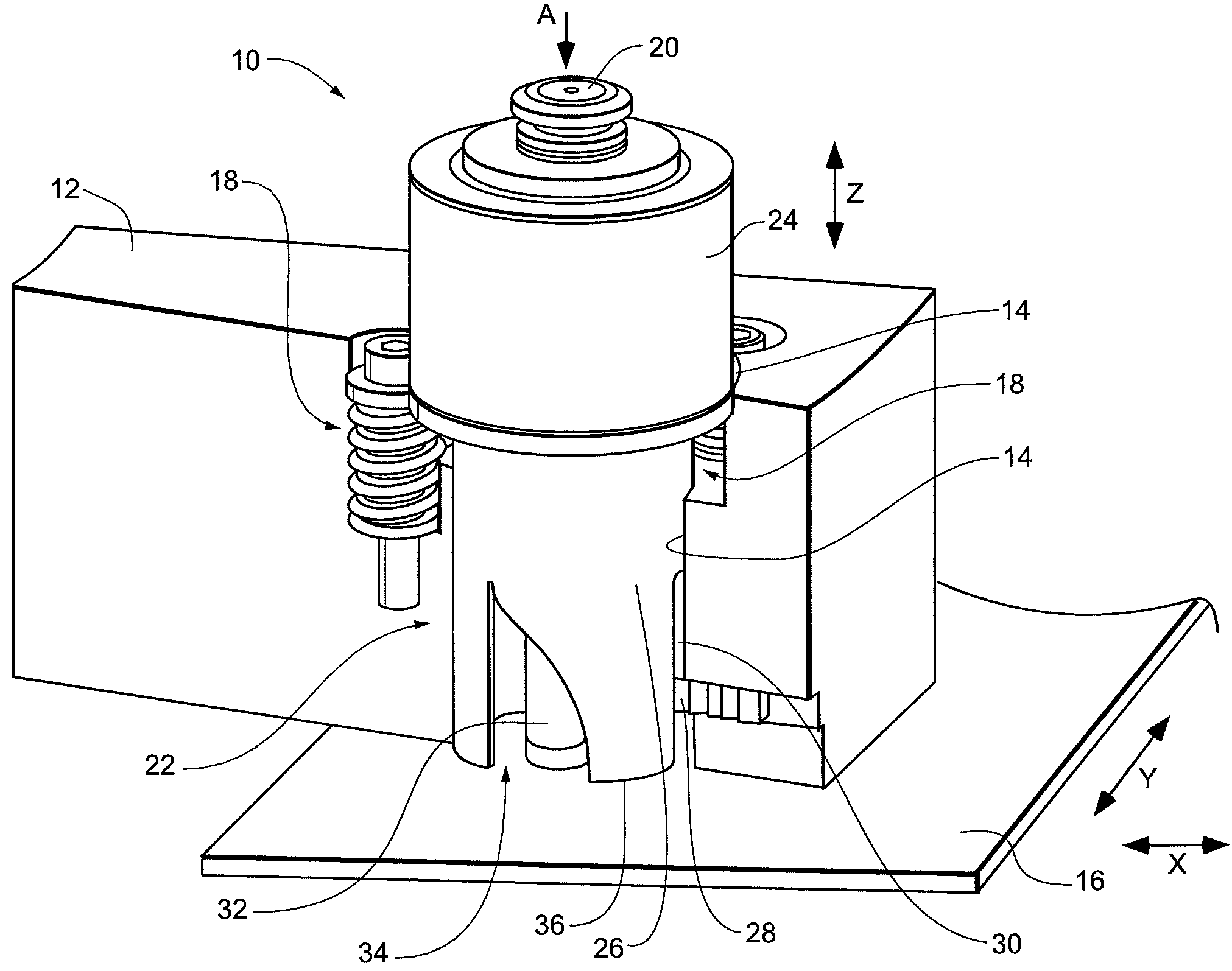

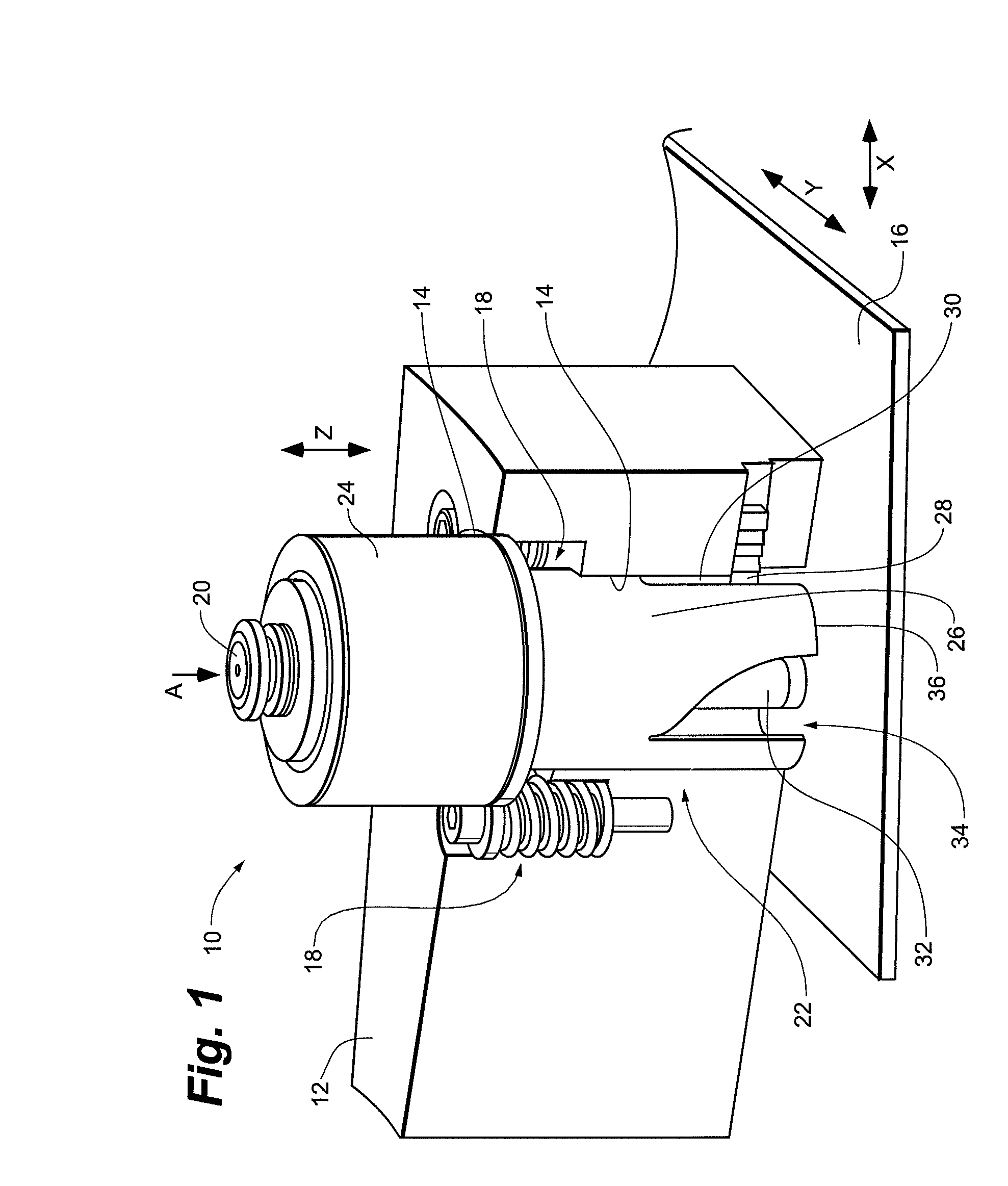

Metal shaping apparatus

A power hammer assembly providing forming capabilities while remaining economical with respect to performance, vibration, footprint size and acquisition costs. The power hammer assembly can provide for a single stroke speed and / or a single set stroke with respect to the striking of die assemblies against a piece of metal. The power hammer assembly can provide for a large throat area and / or a larger die gap for ease of use. The power hammer assembly can include adjustment features allowing for the use of die sets of varying configurations such as, for example, shank size, shank length or alternatively, die sets fabricated for use with other machinery. In addition, the power hammer assembly can include a belt transmission assembly designed to slip in the event of die interference during set-up or operation so as to avoid damaging the power hammer assembly.

Owner:JSJ CORP

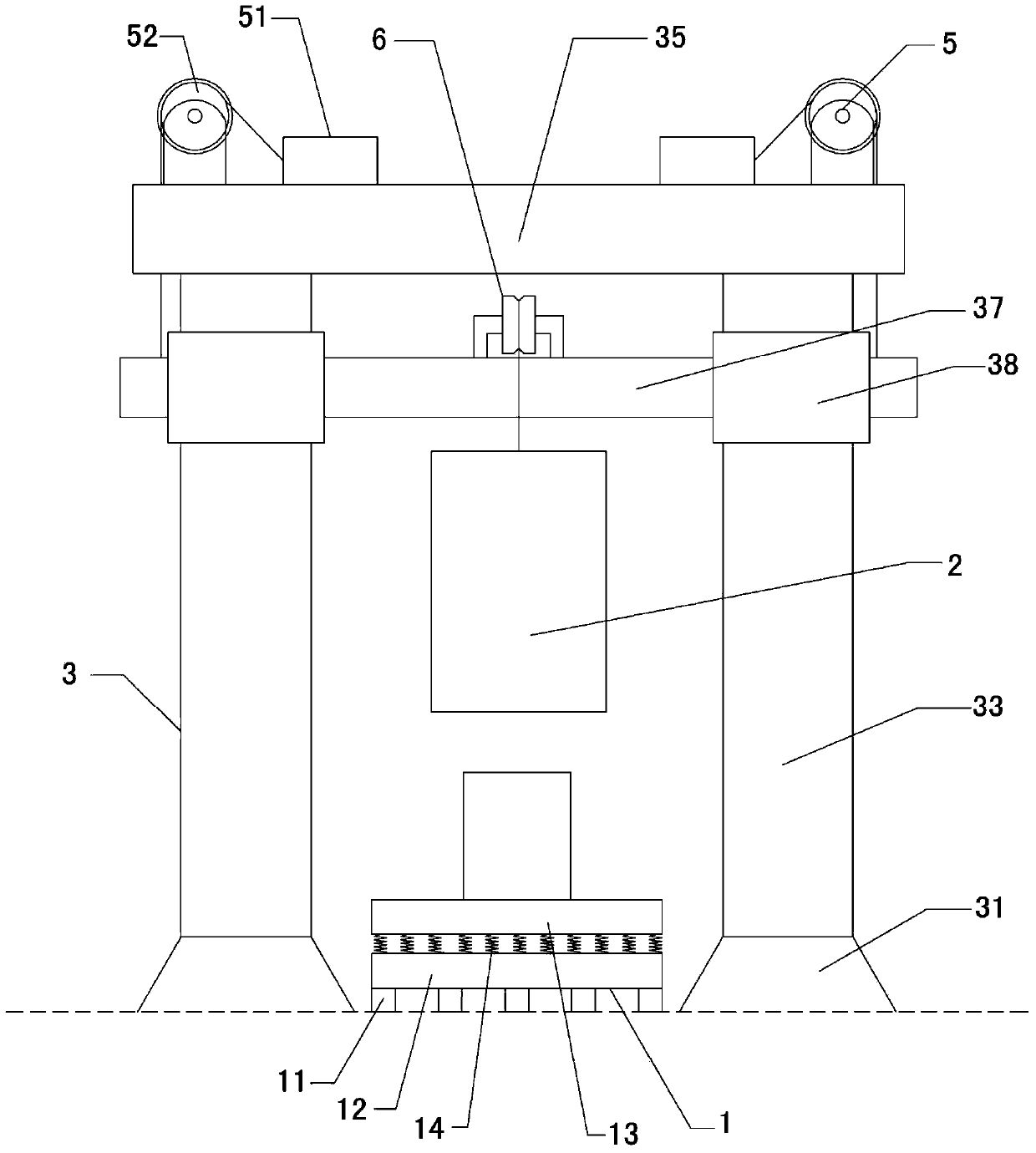

Novel suspension arm hammer

The invention relates to a novel suspension arm hammer which is used for forging large-size metal blank materials. Forging intensity is high. The novel suspension arm hammer comprises a workbench, a hammer body, a suspension arm frame and a stretching motor. The suspension arm frame comprises a front base, a back base, front stand columns, back stand columns, a horizontal beam, a connecting column and a lifting table. The front base and the back base are arranged on the two sides of the workbench side by side. The front stand columns and the back stand columns are vertically fixed on the front base and the back base. Horizontal beams are fixed between the tops of the front stand columns and between the tops of the back stand columns. Connecting columns are fixed between the horizontal beams. The two sides of the lifting table slide on the front stand column and the back stand column relatively. A suspension device for lifting table lifting is arranged on the horizontal beams. A pulley block is arranged in the middle of the lifting table. The stretching motor is arranged at the far end of the back side of the workbench. The stretching motor hangs the hammer body at the bottom of the lifting table through a cable which is wound on the pulley block. A high-pressure gas sprayer is arranged at the bottom of the lifting table. An air chamber matched with the high-pressure gas sprayer in an inserting mode is arranged at the top of the hammer body.

Owner:邯郸市车夫轴承有限公司

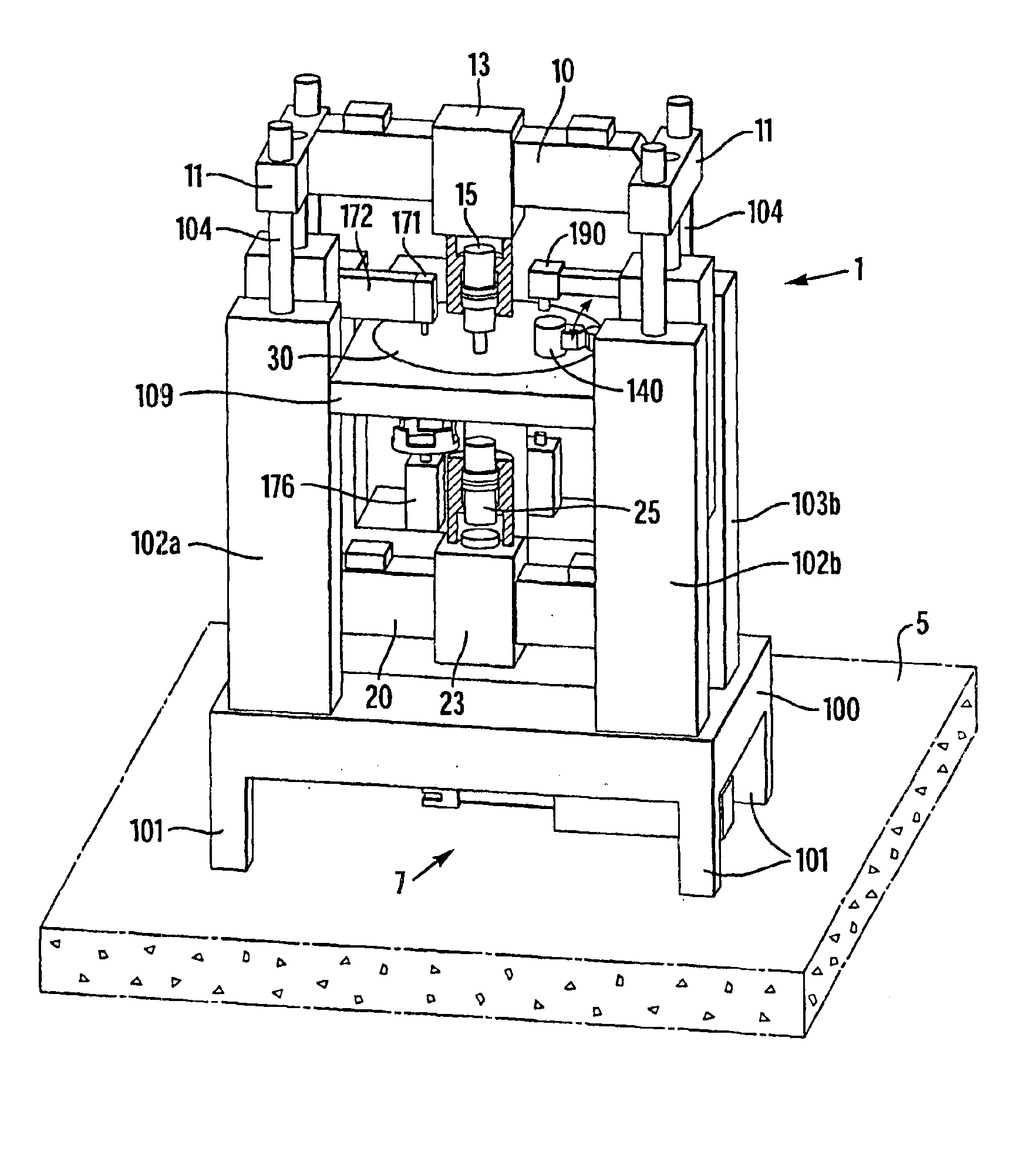

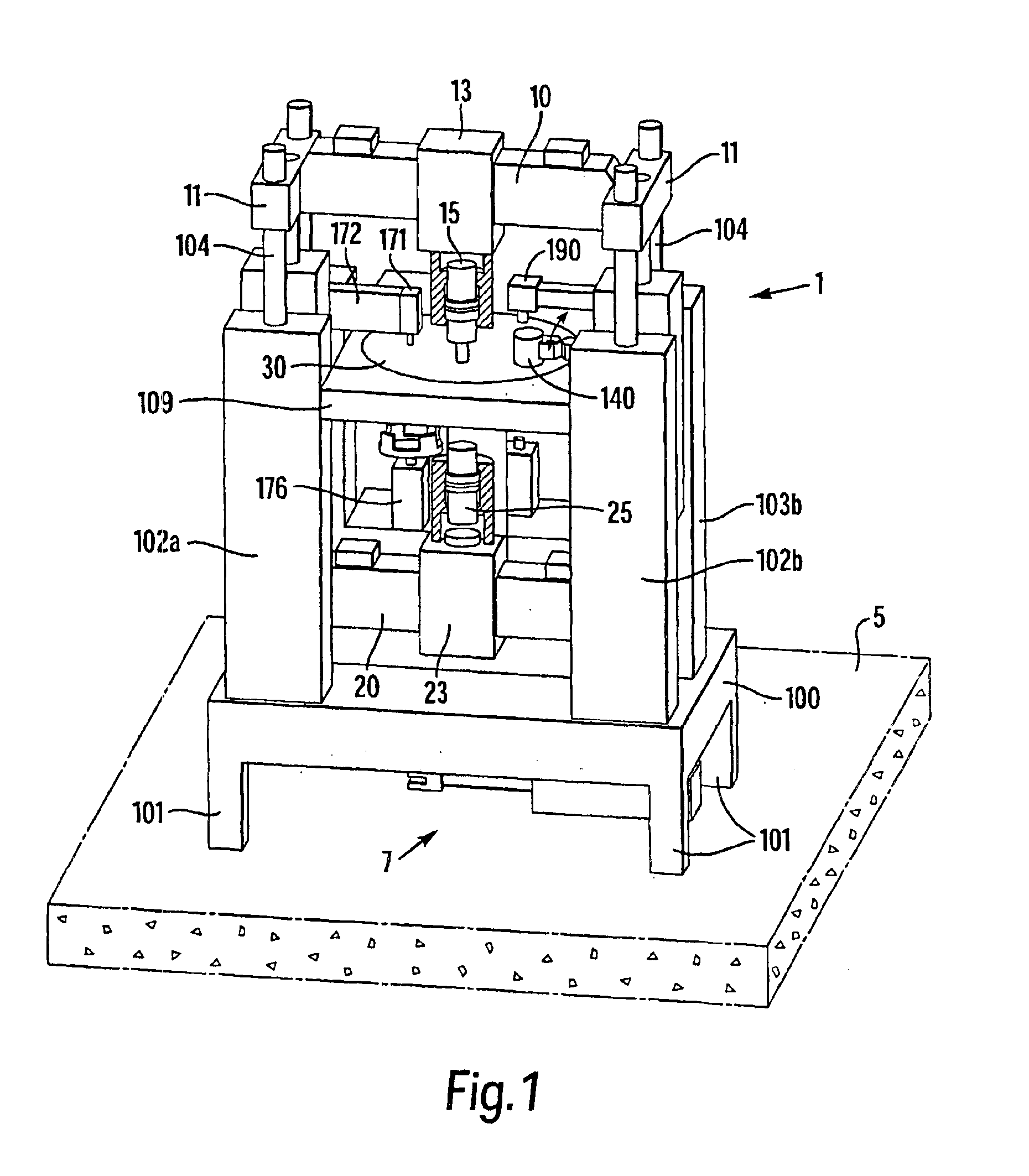

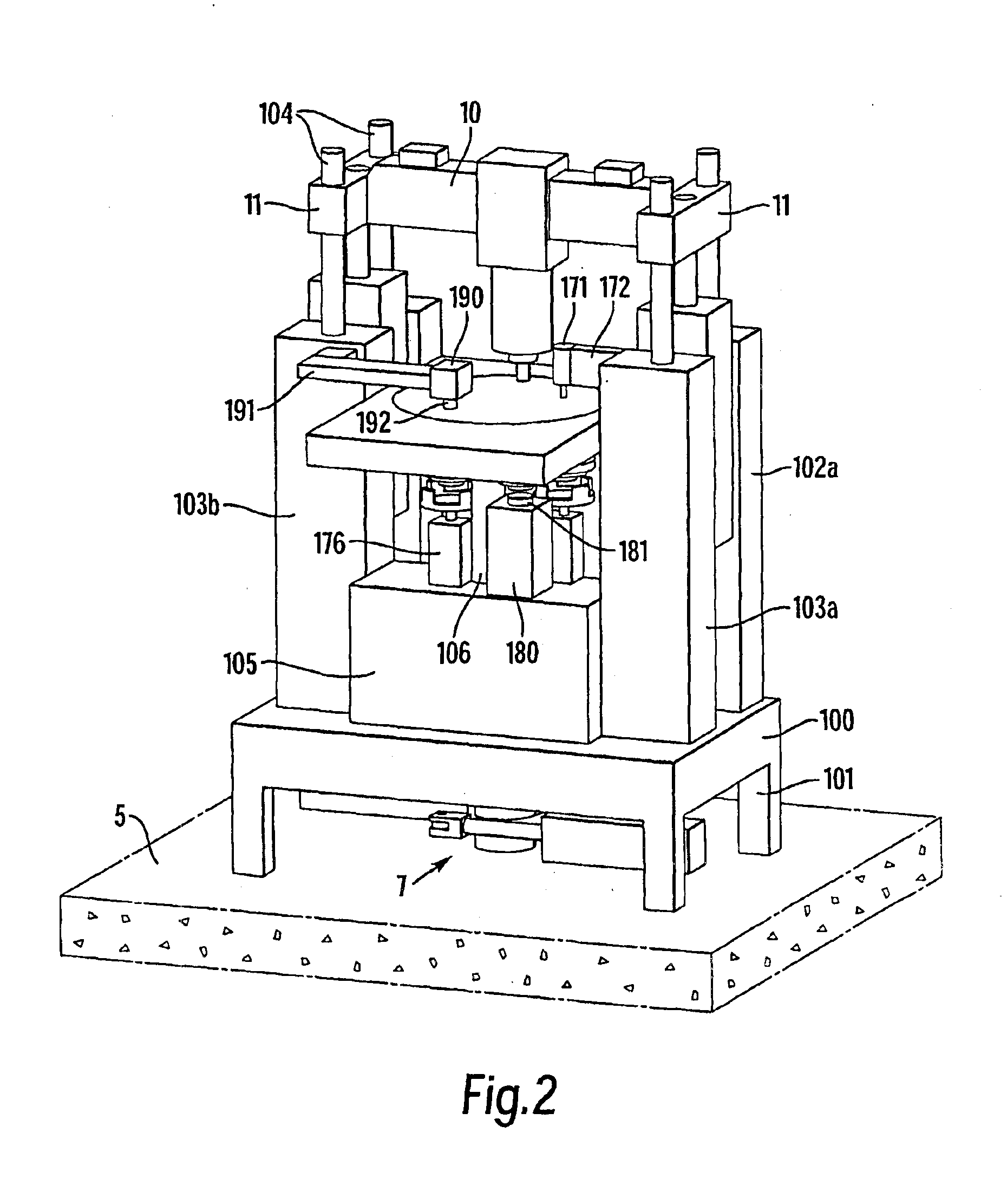

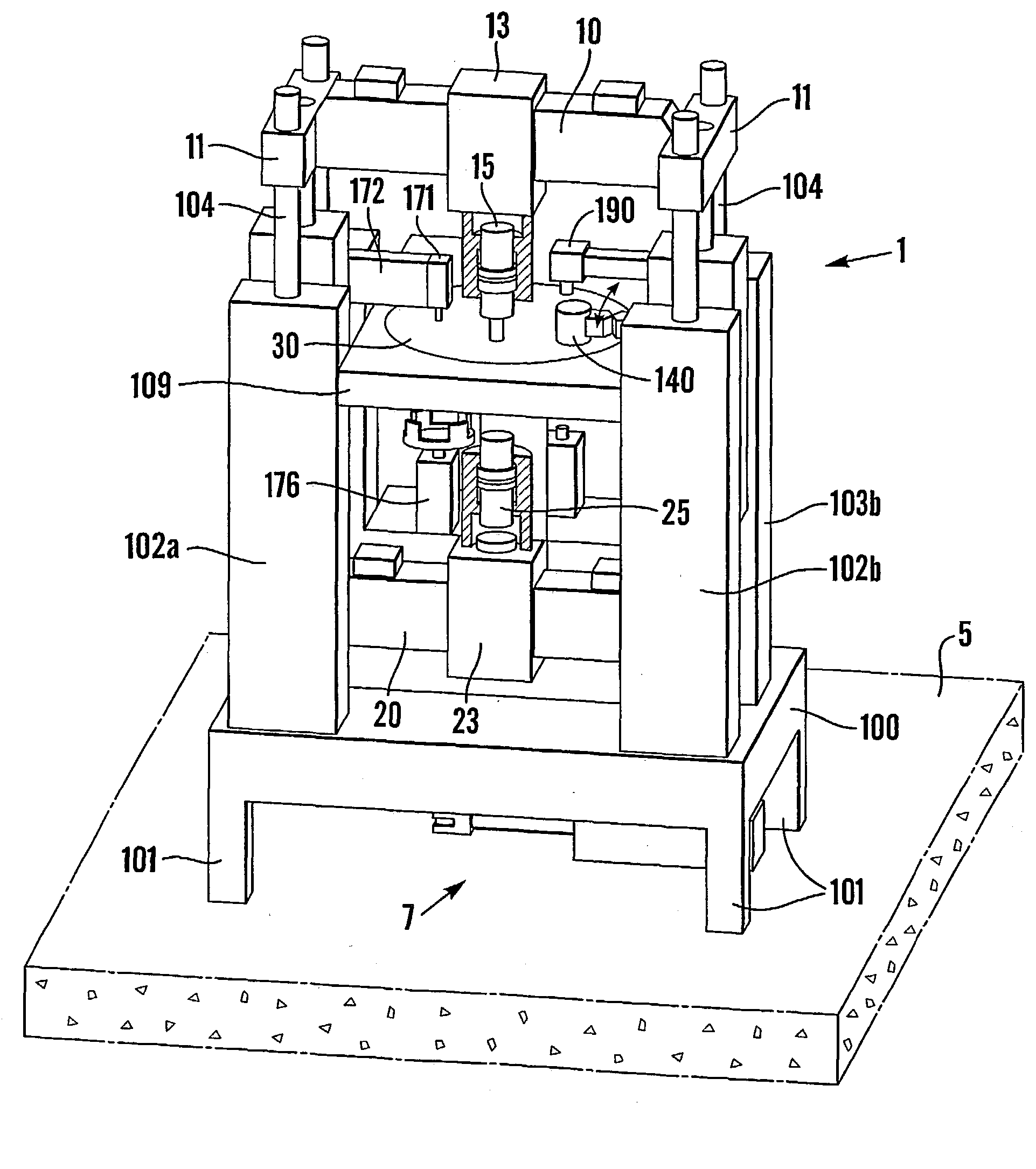

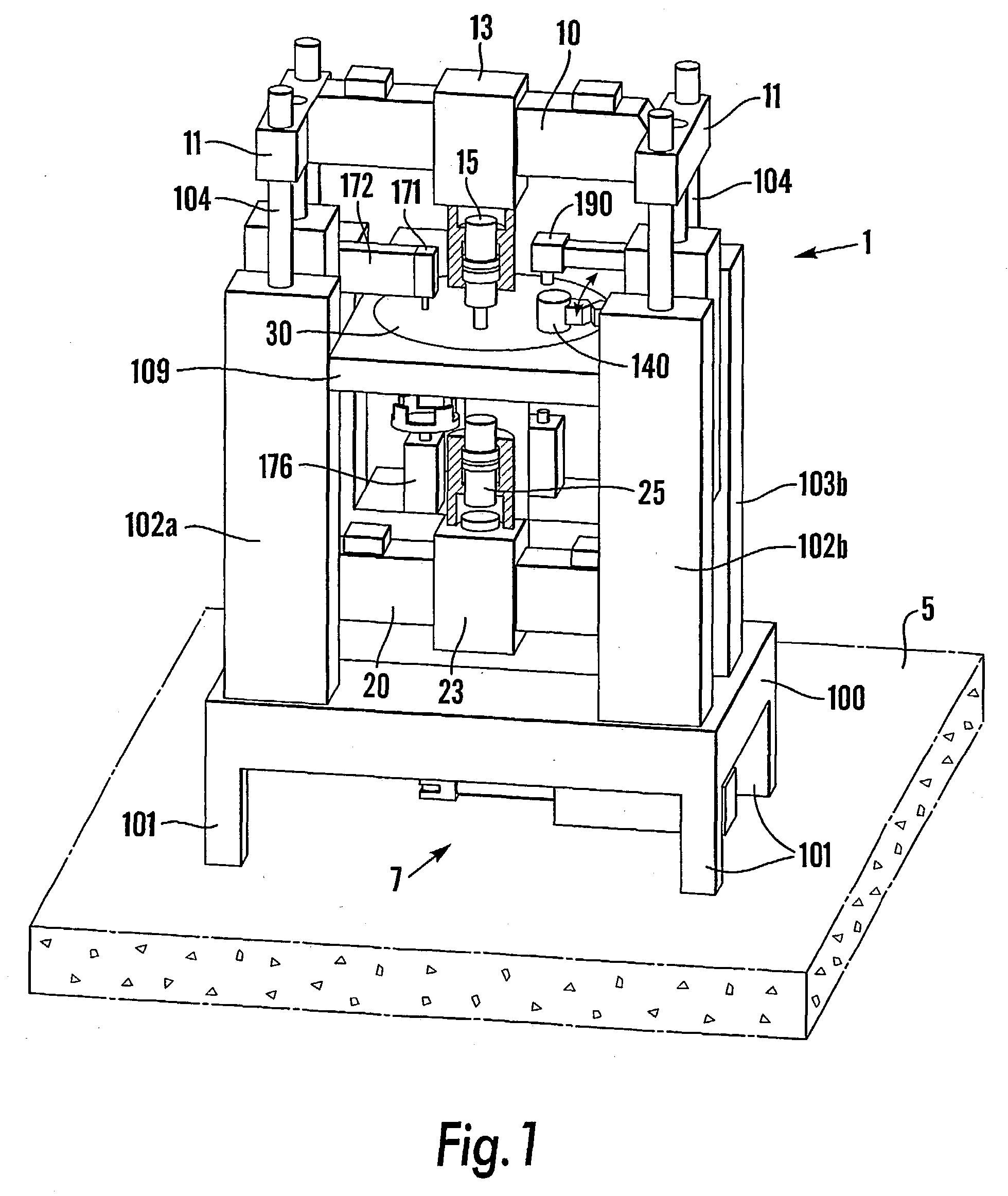

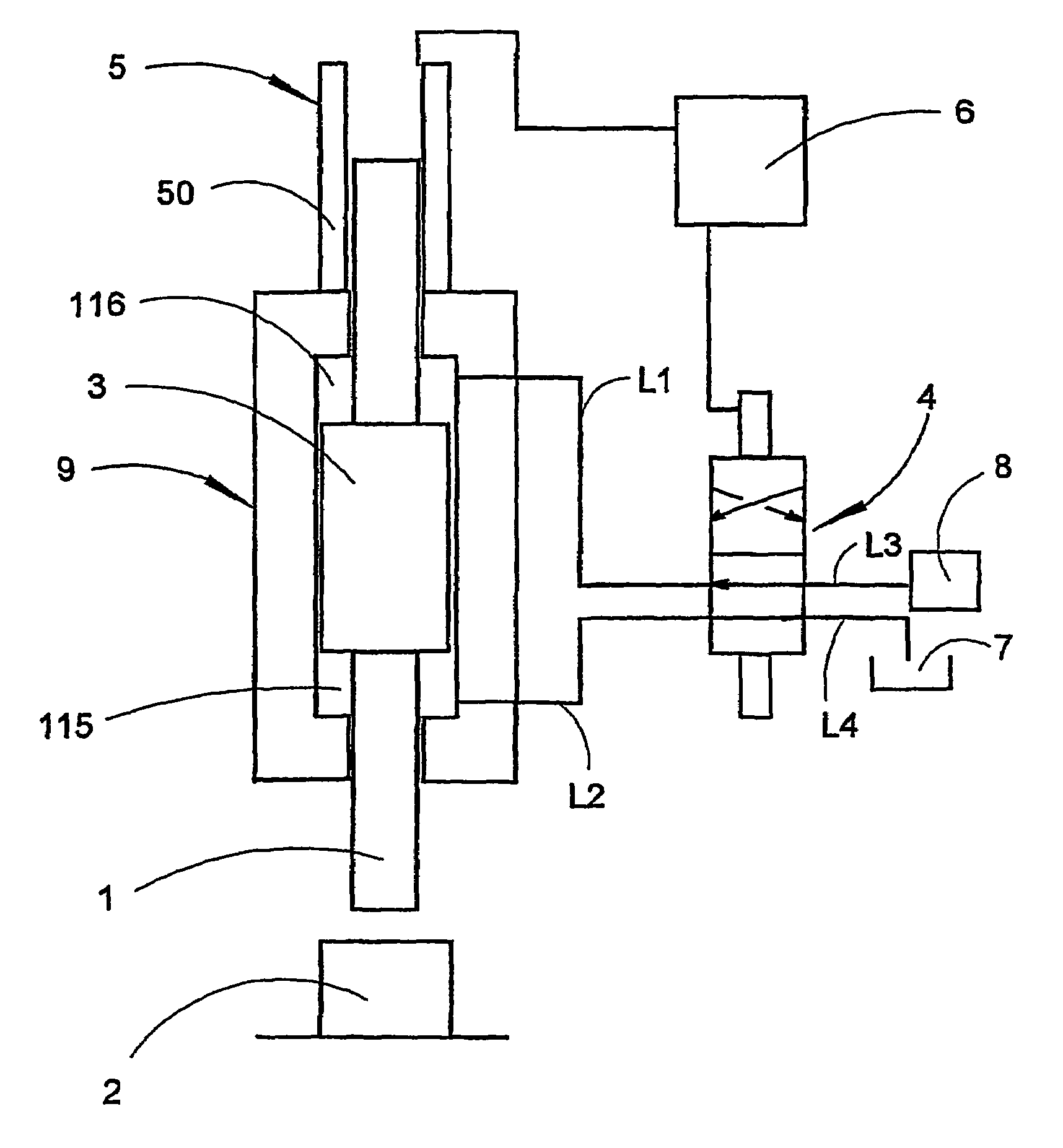

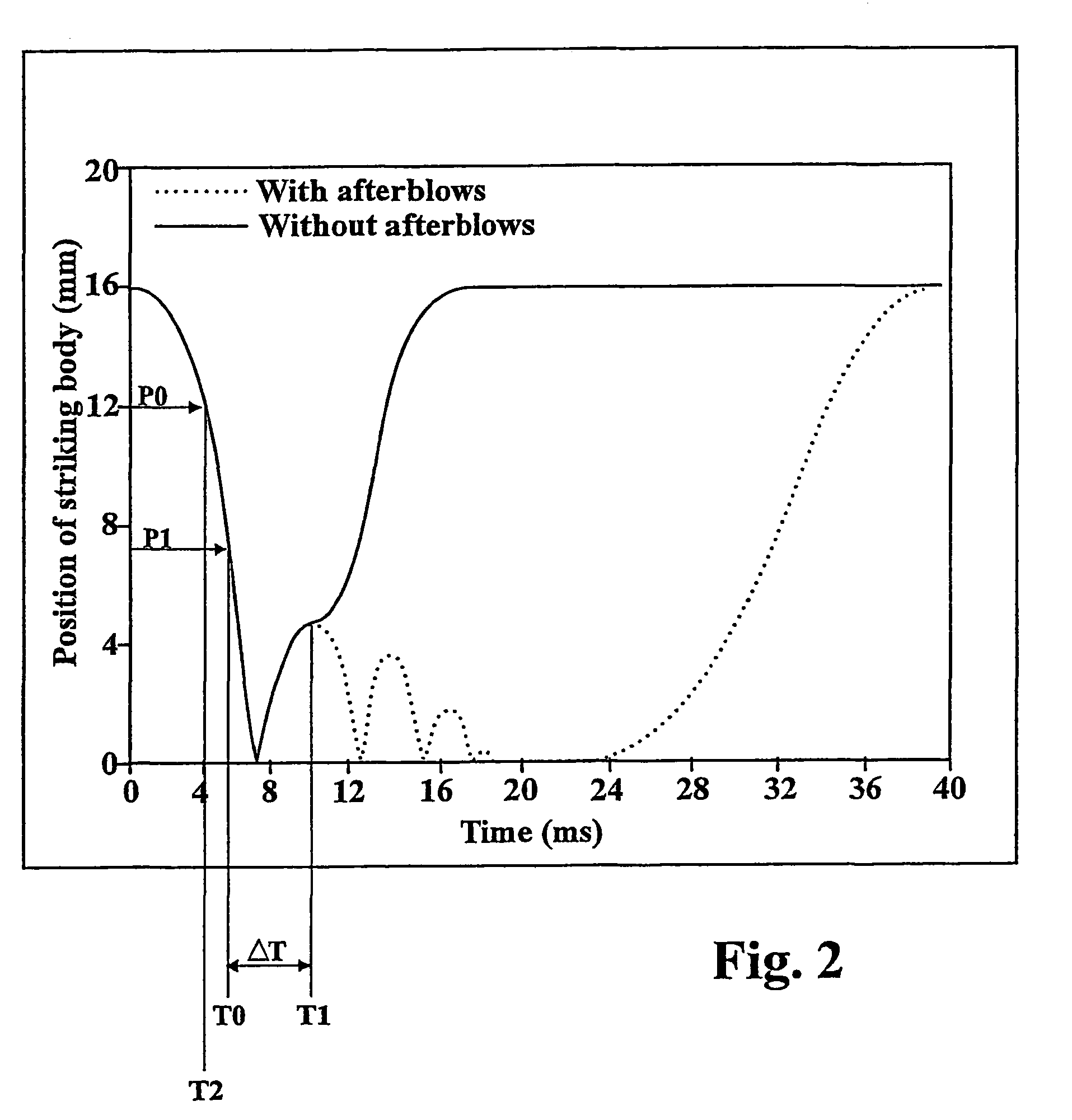

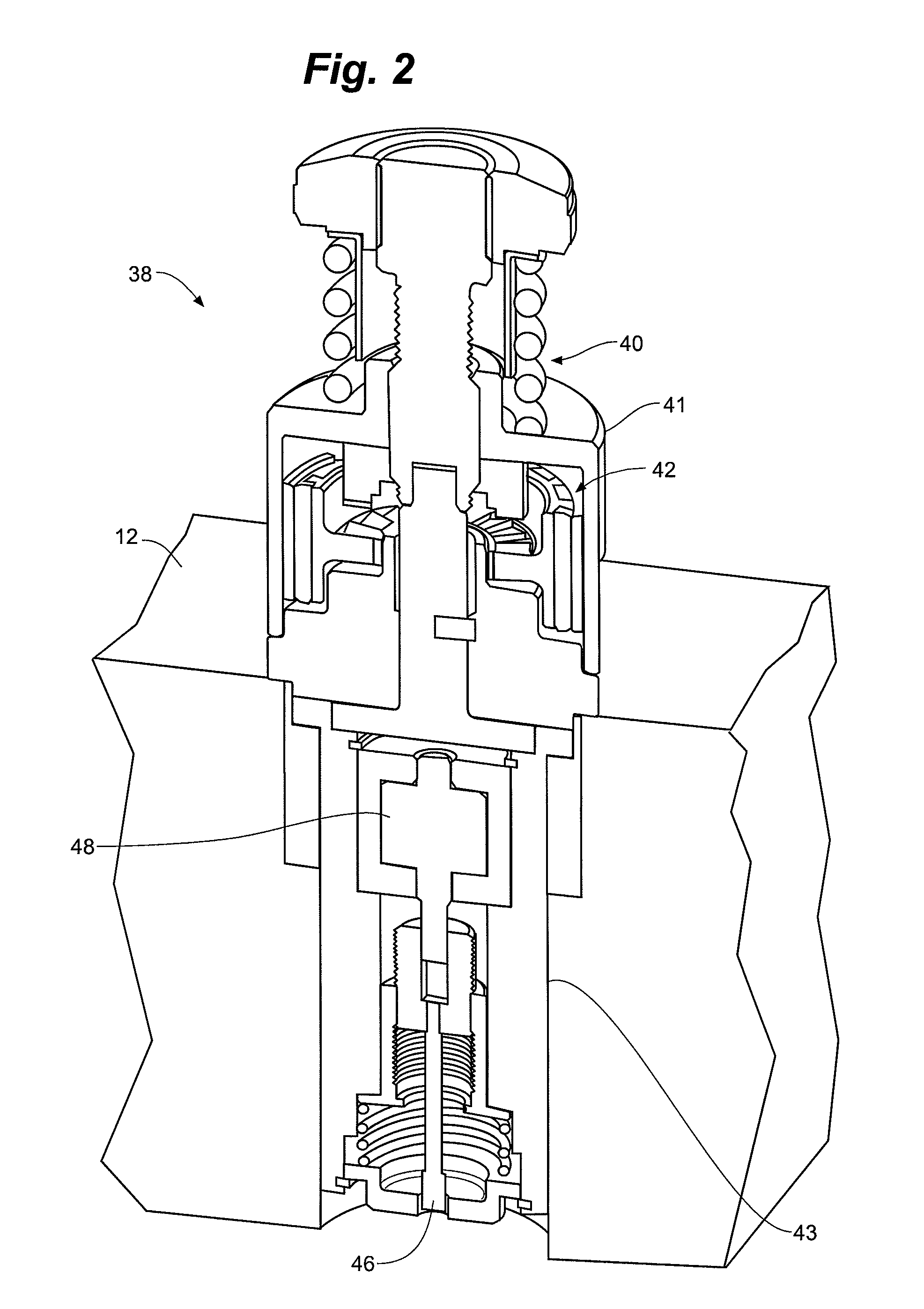

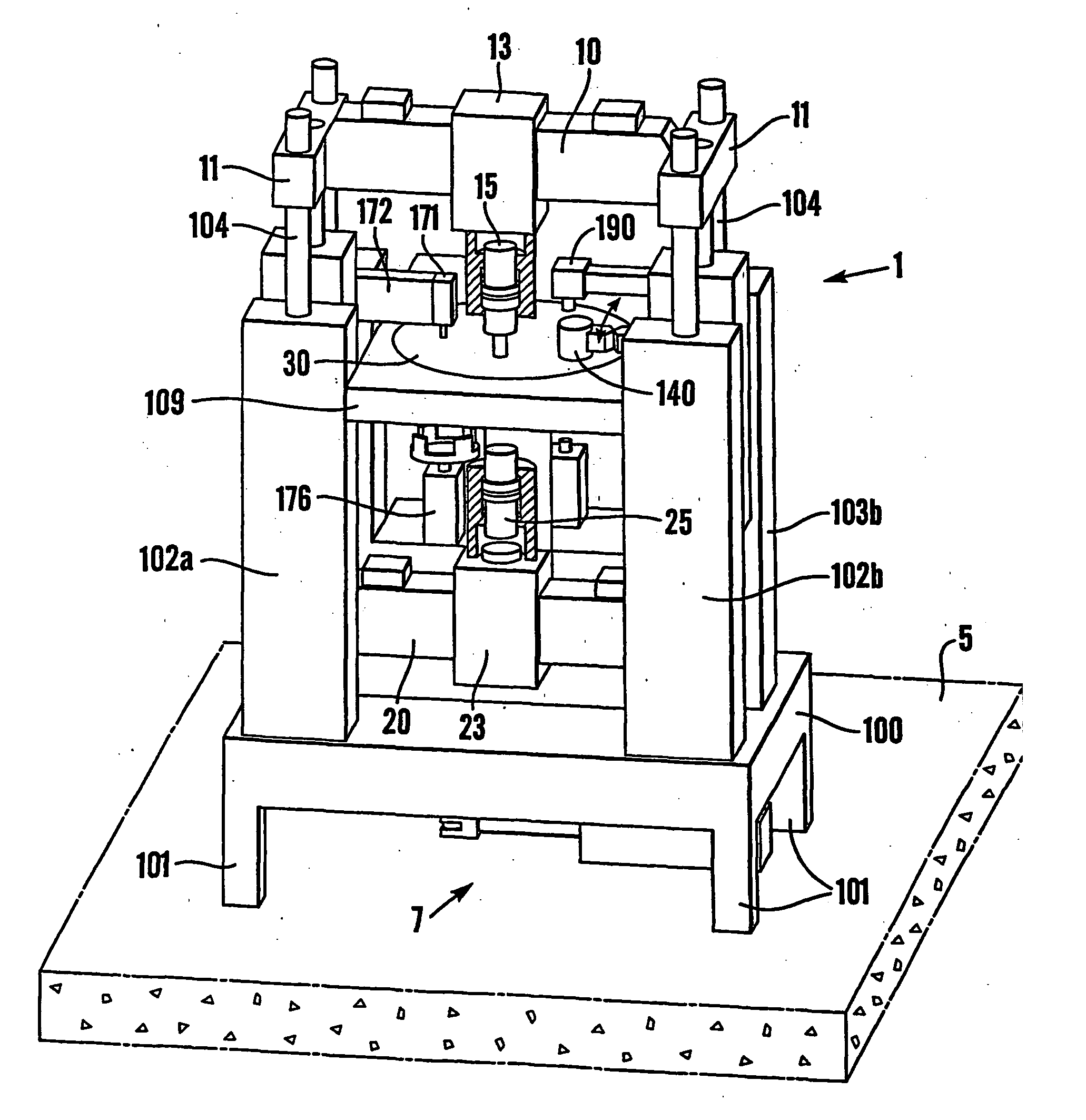

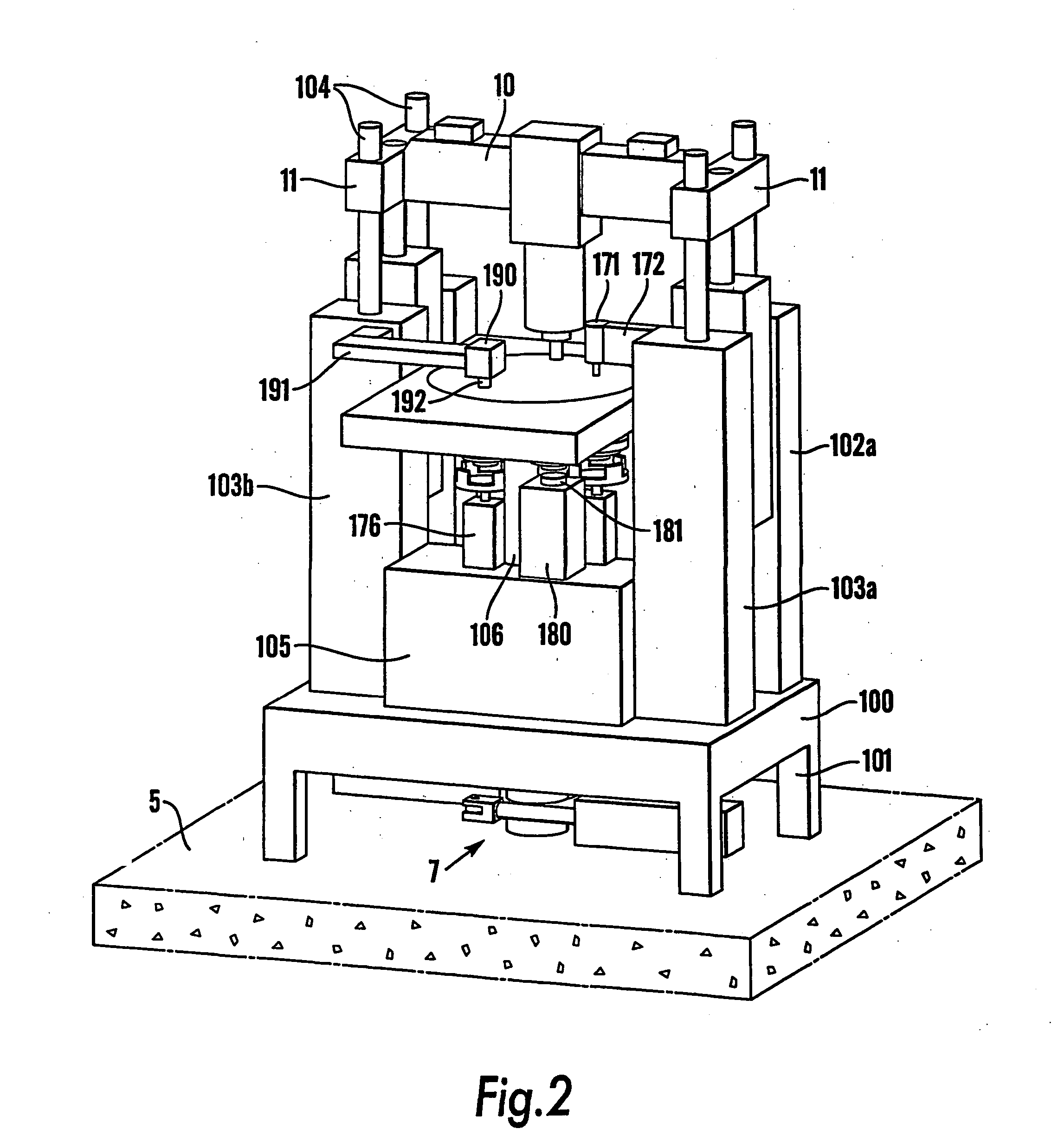

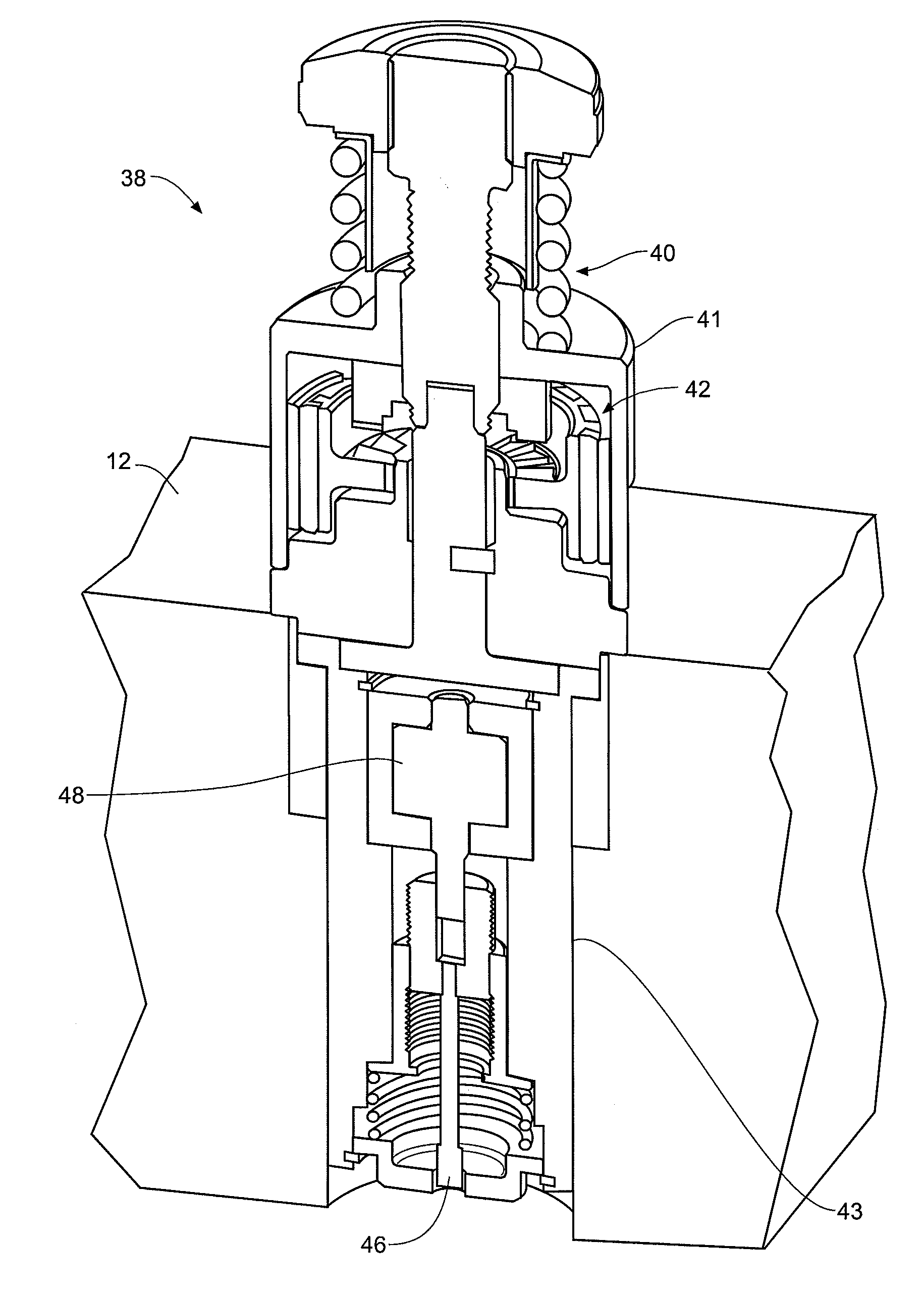

Impact machine and a method of forming a body

The invention concerns an impact machine for forming a body with desired shape of a formable working material through impact action in a forming operation, said impact machine comprising a machine stand (6), an upper unit which comprises either a lower impact unit (3), which comprises a counter-impact device, or a stationary anvil, and a central unit between the upper and the lower units. The central unit (4) comprises one or more carriers (30), each of which containing and carrying one or a plurality of identically equal tool units (32), each of which comprising a die (34) with a mould cavity (46) for the working material (90) intended to be formed, said carriers including at least one carrier which is stationary during the forming operation and which contains at least one such tool unit, and that motion devices (7) are provided for indexing the carrier or carriers in a horizontal plane for positioning the tool units in different function stations (I-V), comprising a forming station (II) and at least one more station.

Owner:MORPHIC TECH

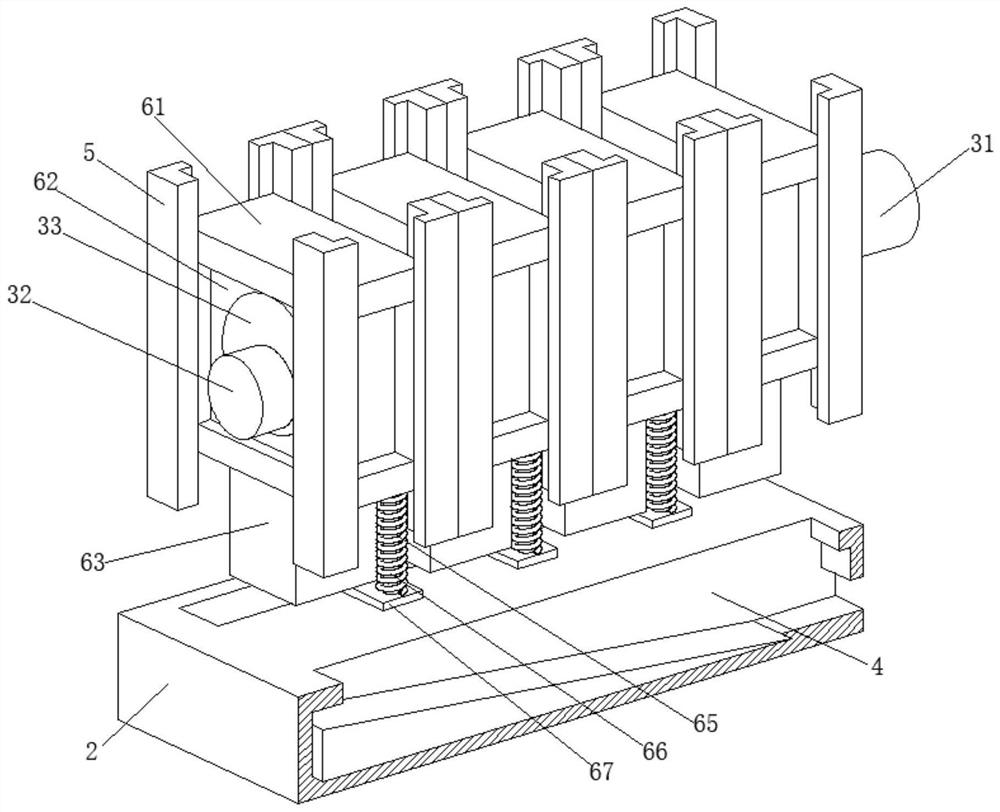

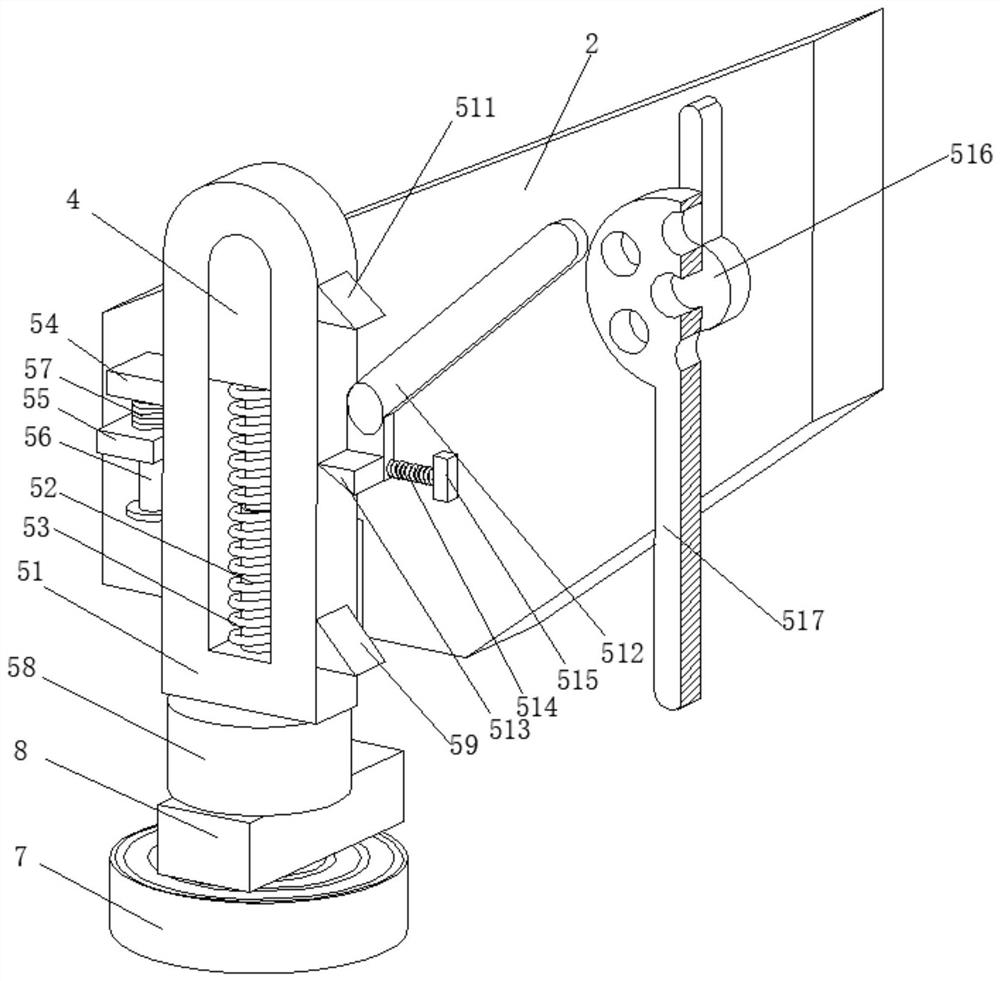

Beating device convenient to use and applied to machining of mechanical parts

The invention relates to a beating device, in particular to a convenient beating device for processing mechanical parts. The technical problem to be solved by the invention is that the movement of the hammer head is unstable. In order to solve the above technical problems, the present invention provides a convenient beating device for processing mechanical parts, which includes a base, vertical plates are fixedly connected to both sides of the top of the base, and the opposite sides of the two vertical plates are opened There is a chute, the top and bottom of the inner wall of the chute are connected by a slide bar, a slide block is slidably connected in the chute and sleeved on the slide bar, and a slide block is sleeved on the slide bar and located above the slide block A return spring, the two ends of the return spring are respectively fixedly connected to the top of the inner wall of the chute and the top of the slider. In the present invention, through the improvement of the hammer head, when the hammer head moves, the slider can slide on the sliding rod inserted in the chute through two connecting rods, and at this time, the stability of the hammer head when moving can be improved.

Owner:绍兴市积成包装机械有限公司

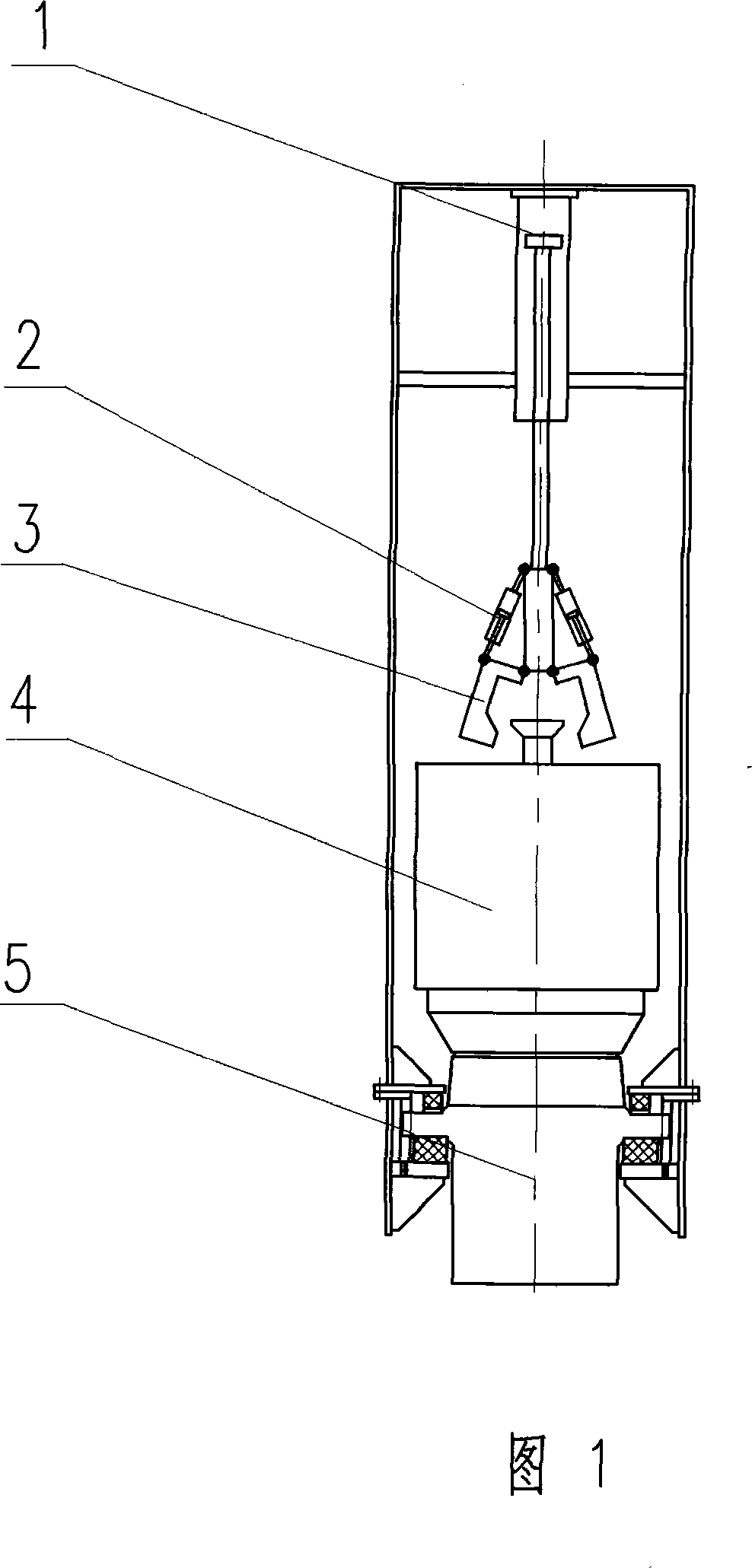

Dropping grabbing tamping hammer

The invention relates to a hammer ram used frequently in forging and construction field. The hammer core is lifted to a certain height by an oil cylinder or other lifting device then falling freely. When it falls, it separates with lifting oil cylinder or other lifting device.

Owner:张立新

Energy-saving type automatic forging device for metal part

ActiveCN105855445AAchieve the effect of automatic forgingWon't fall offDrop hammersHammer drivesEngineeringMechanical engineering

The invention relates to an energy-saving type automatic forging device for a metal part. The energy-saving type automatic forging device for the metal part comprises a rectangular furnace body, an orifice, a lateral cavity and an opening, wherein a striking hammer is placed at the lower end of the orifice, and a T-shaped head is arranged at the upper end of the striking hammer. A lifting plate is installed on the orifice in a sliding mode and fixedly provided with upper fixing pins and lower fixing pins. The upper fixing pins are hinged to upper control plates. The lower fixing pins are hinged to lower clamping plates, and a clamping portion is arranged at the lower end of each lower clamping plate. A reset spring is arranged between the two lower clamping plates. The energy-saving type automatic forging device for the metal part can achieve the effect of automatically forging the metal part by automatically grasping, lifting and releasing the striking hammer. In addition, the energy-saving type automatic forging device for the metal part has the effects of saving energy and protecting the environment while guaranteeing the forging efficiency and quality.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

Metal shaping apparatus

A power hammer assembly providing forming capabilities while remaining economical with respect to performance, vibration, footprint size and acquisition costs. The power hammer assembly can provide for a single stroke speed and / or a single set stroke with respect to the striking of die assemblies against a piece of metal. The power hammer assembly can provide for a large throat area and / or a larger die gap for ease of use. The power hammer assembly can include adjustment features allowing for the use of die sets of varying configurations such as, for example, shank size, shank length or alternatively, die sets fabricated for use with other machinery. In addition, the power hammer assembly can include a belt transmission assembly designed to slip in the event of die interference during set-up or operation so as to avoid damaging the power hammer assembly.

Owner:JSJ CORP

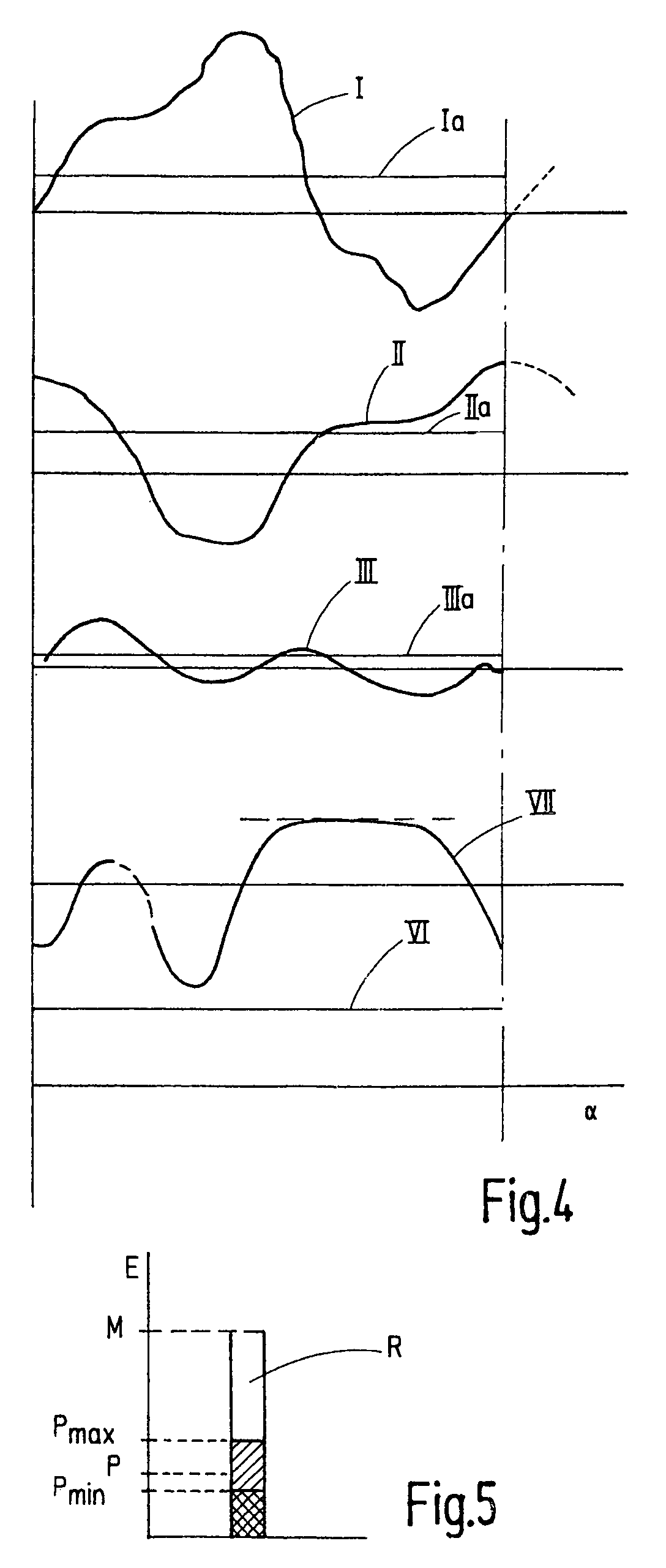

Servo-press with energy management

InactiveUS7752878B2Reduce resistance lossMinimize power variationDrop hammersMetal-working feeding devicesPower gridEngineering

In a press installation including a number of presses with servo-drives for operating the presses and auxiliary equipment such as workpiece handling devices wherein an energy management system is provided including a DC voltage intermediate circuit connected to a power supply grid via an AC / DC converter and to the servo-drives via servo-converters, a fly-wheel storage device is connected to the intermediate circuit for supplying energy thereto and recapturing energy therefrom under the control of a control arrangement which controls the flow of power between the intermediate circuit, the servo-drives, the fly-wheel storage device and the power supply grid.

Owner:SCHULER PRESSEN GMBH & CO KG

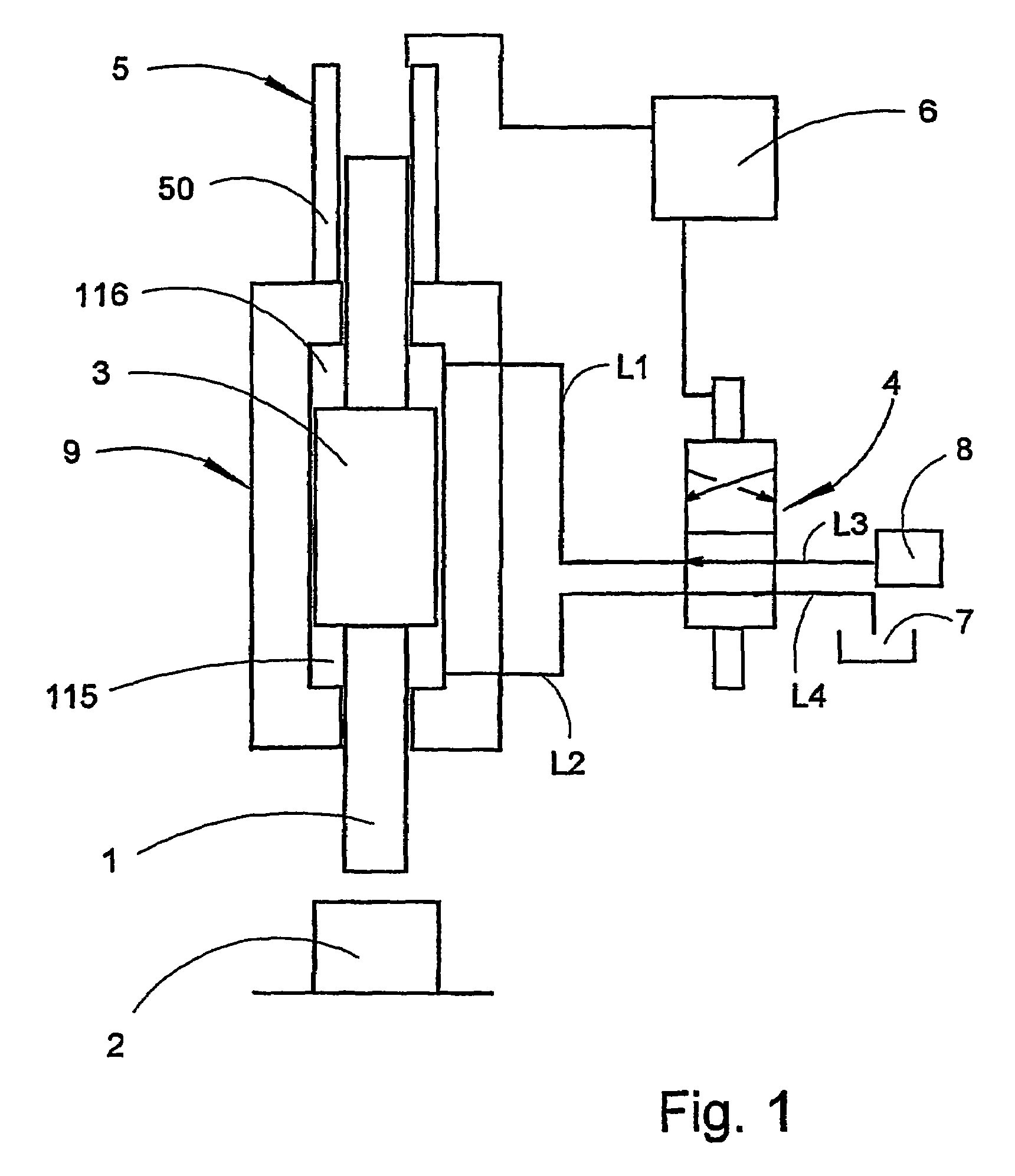

Method employing high kinetic energy for working of material

InactiveUS7104190B2Increase kinetic energyQuality improvementDrop hammersPower hammersEngineeringMaterials processing

The present invention relates to a method for material working utilizing high kinetic energy, in which a stamp or striking body transfers, by delivering a blow, high kinetic energy to a material body that is to be worked, after which a rebound of the stamp occurs. In an embodiment of the method, a measure is taken in conjunction with said blow delivered, which measure prevents said stamp from delivering an afterblow with an appreciable kinetic energy content, for the purpose of avoiding negative effects as a consequence of afterblows.

Owner:CELL IMPACT +1

Hot steel part forging workbench

The invention discloses a hot steel part forging workbench. Ends, away from a framework, of forging table supporting legs are fixedly equipped with a forging table; a forging hammer is movably mountedon the upper part of the forging table; a tilting plate is in matched connection to a pair of left and right tilting blocks; the tilting blocks are fixedly mounted on rotary discs at left and right sides of a forging connecting rod separately; one end, away from an extruding slot, of a tiling rod is fixedly equipped with a lower pressure plate; a gear connecting rod is movably mounted on connecting rod bases at the two ends of the framework; a drive shaft of a forging motor is fixedly equipped with a horizontal-moving lead screw; a horizontal-moving base is movably arranged on the horizontal-moving lead screw in a sleeving mode; the bottom of the horizontal-moving base is fixedly equipped with a slide block; and a lifting frame is arranged on the horizontal-moving base in the sleeving mode. According to the hot steel part forging workbench disclosed by the invention, after an iron hammer is lifted to certain height, the iron hammer hammers the steel part through driving of a spring, so that hammering force is relatively strong; and in a hammering process, the hammed part is moved, so that the hot steel part forging workbench can uniformly hammer iron sheet surfaces of different length, and therefore, the steel part can be effectively forged.

Owner:ANHUI RUIDA MACHINERY

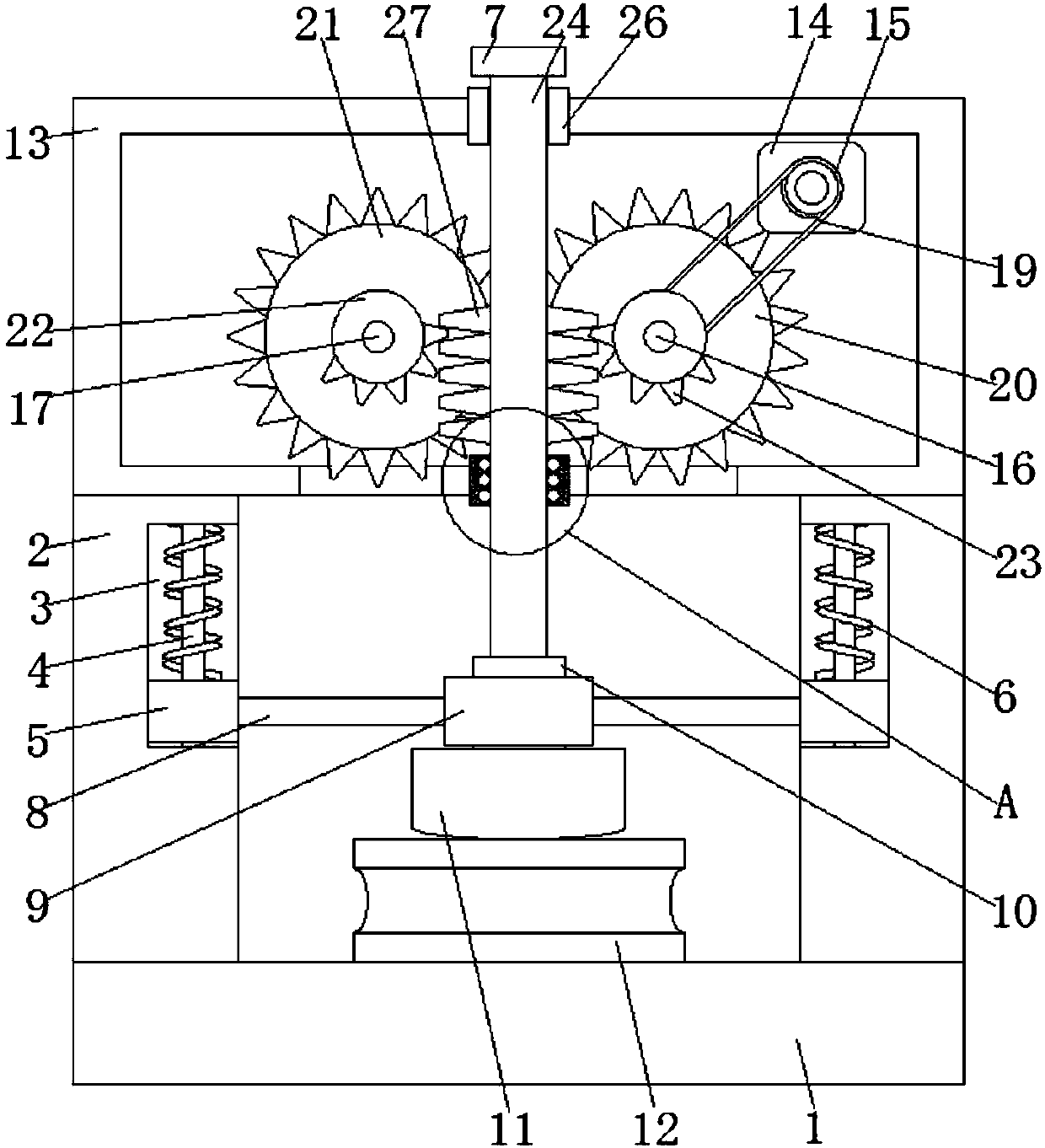

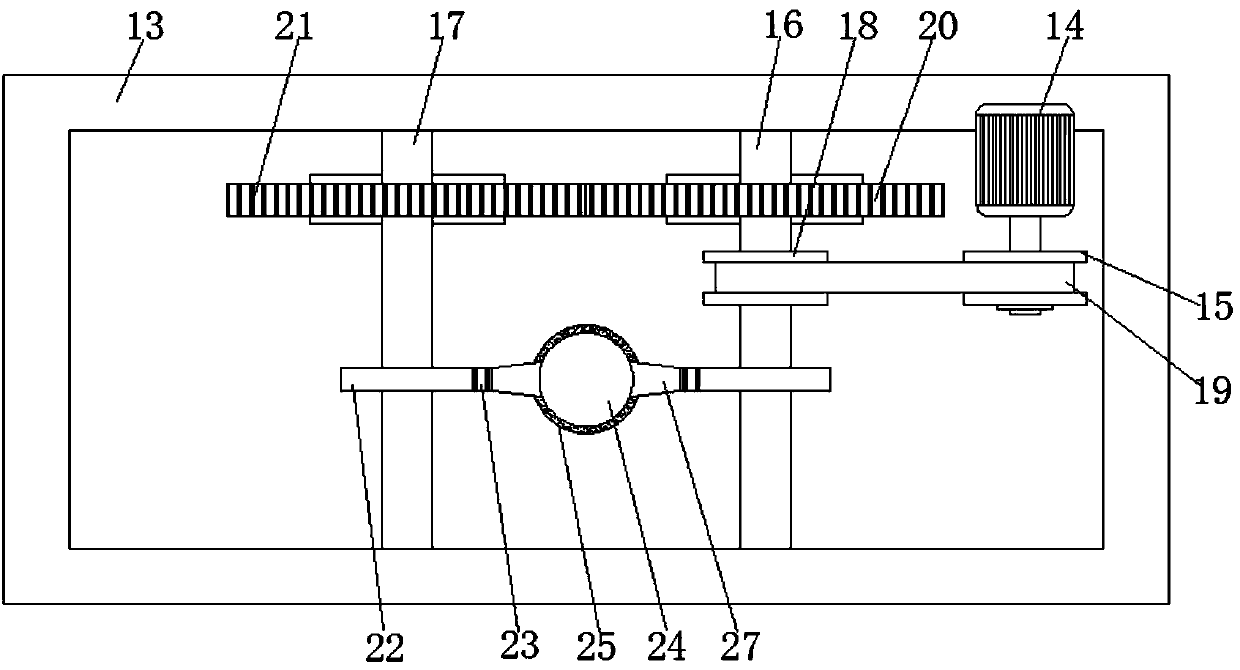

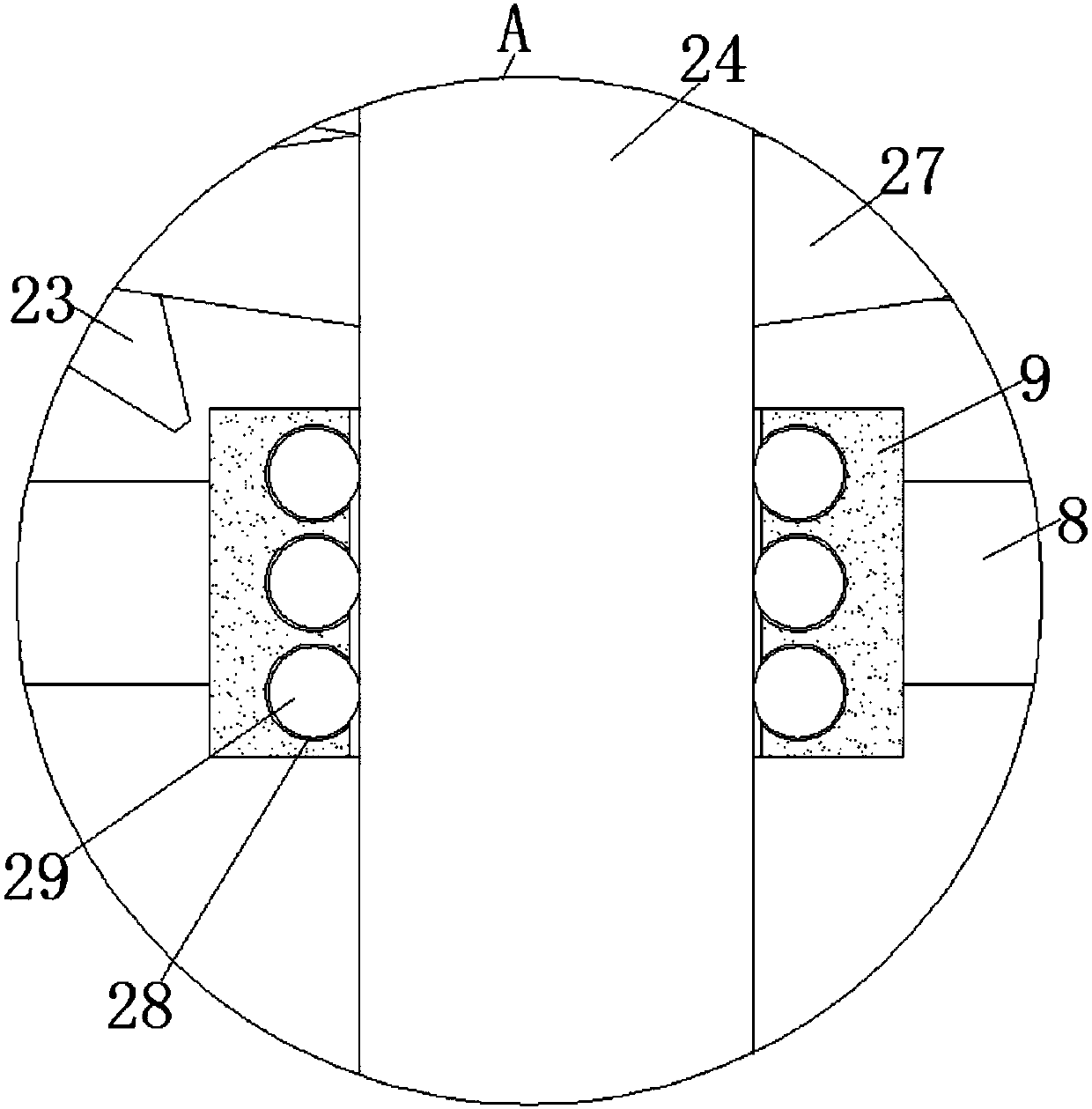

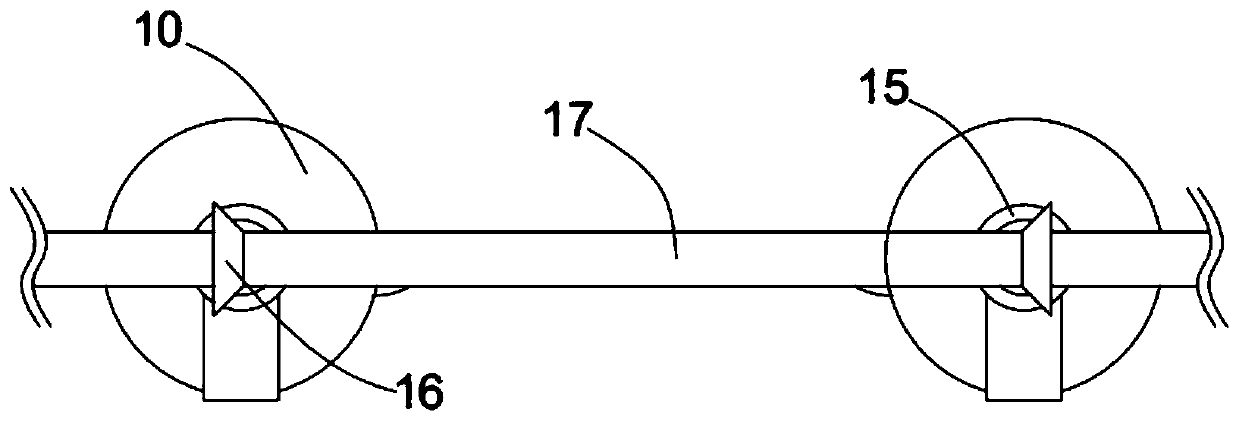

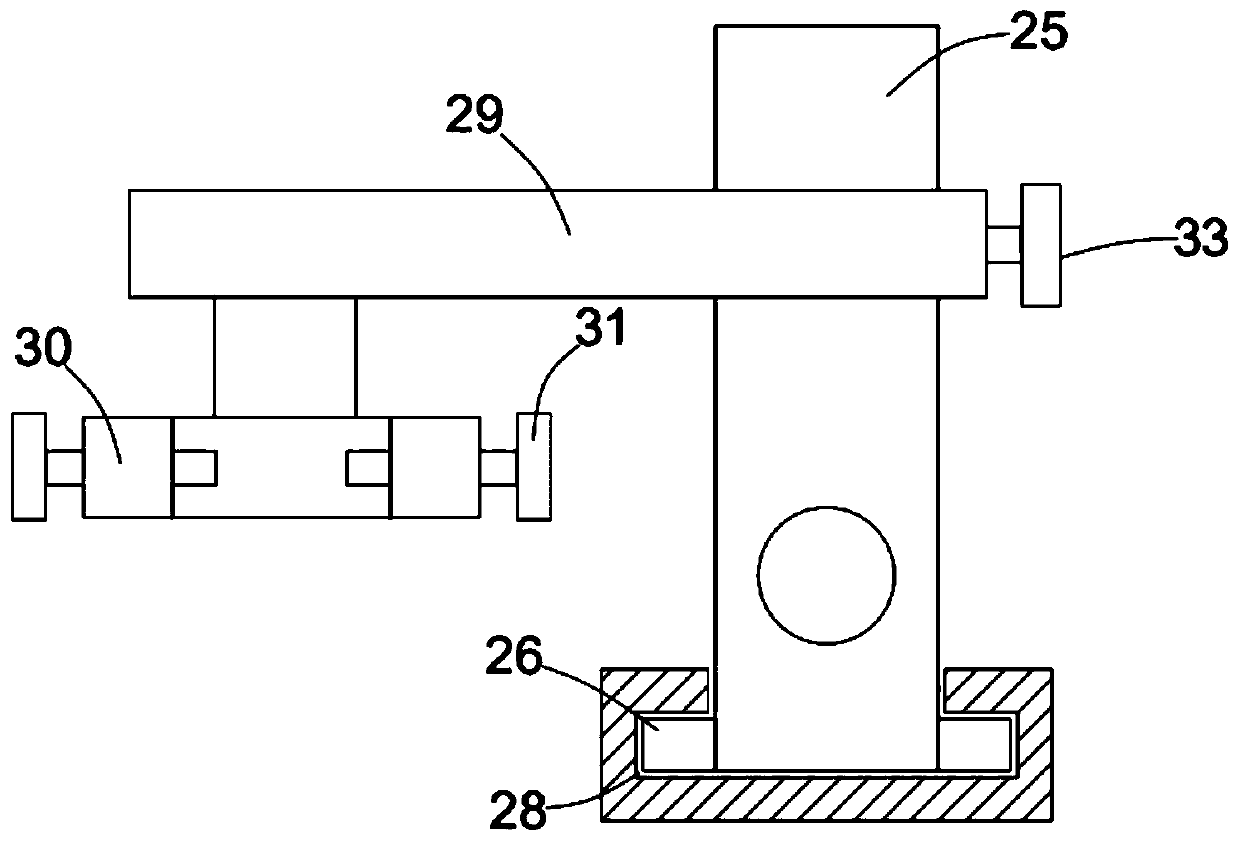

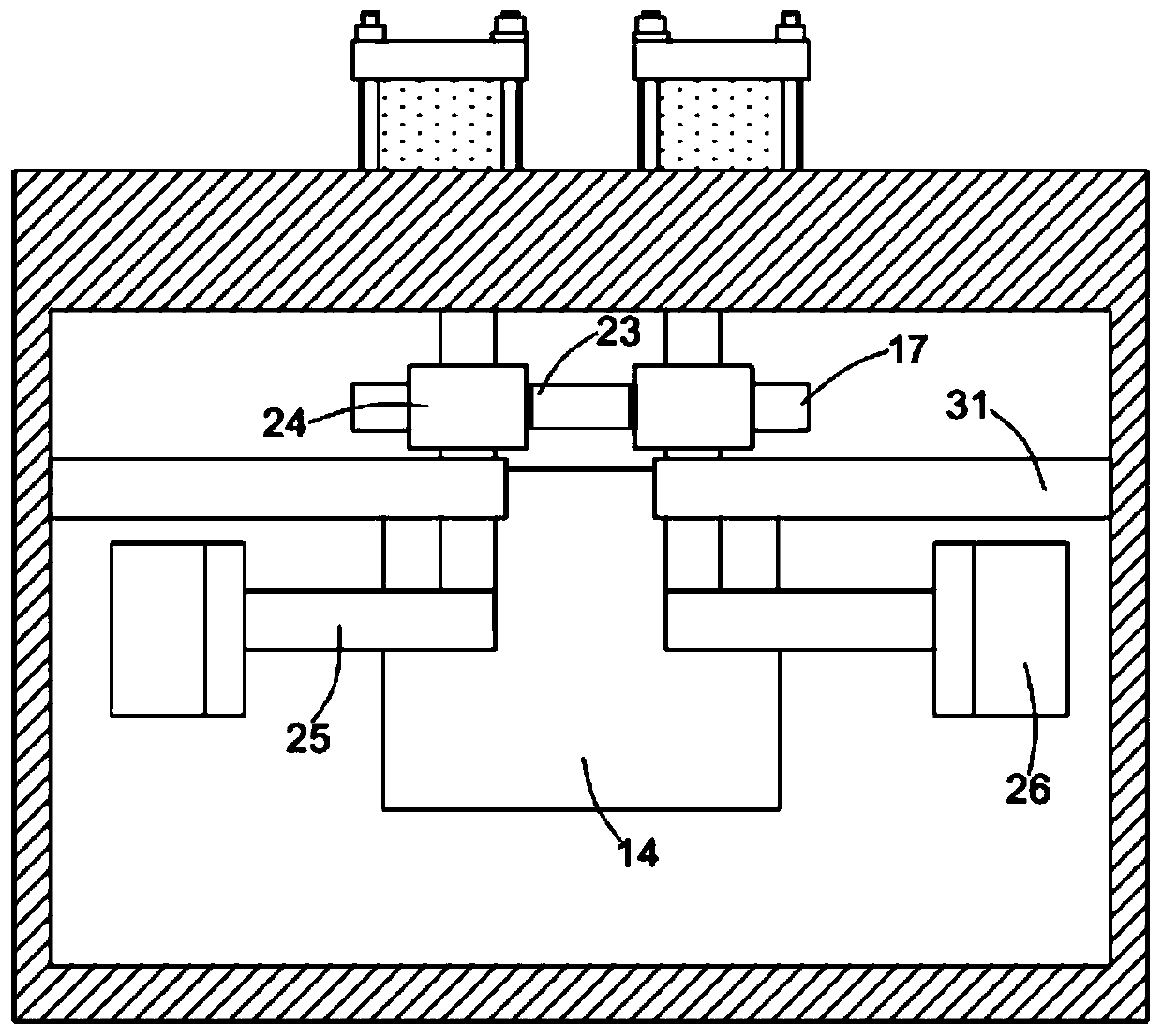

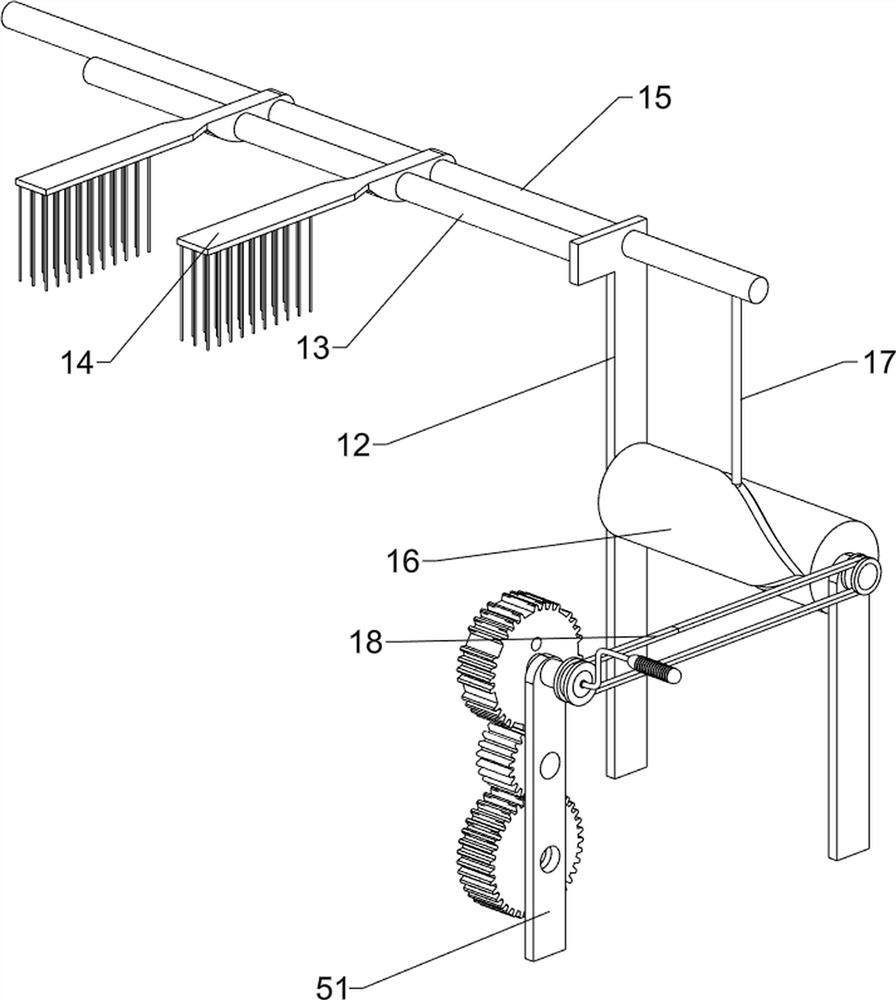

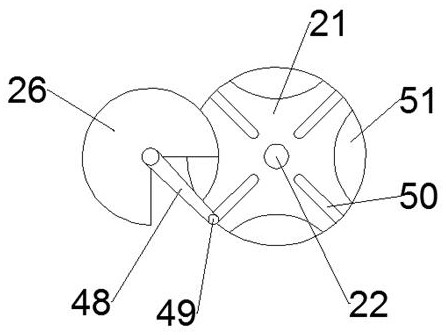

Dual-face rapid forging device of iron sheets

ActiveCN109894560AGuaranteed stabilityImprove forging efficiencyDrop hammersHammer drivesDrive wheelEngineering

The invention discloses a dual-face rapid forging device of iron sheets. The dual-face rapid forging device comprises a box. A pair of forging motors is fixedly mounted on the box. Connecting rods arefixedly connected with lifting screws. Each lifting screw is movably sleeved with a lifting seat. Forging table connecting plates on the two sides are fixedly connected with a forging table. A firstdual-face rack is movably mounted between driven wheels of a ratchet mechanism. The end, away from the first dual-face rack, of a rack connecting rod is fixedly connected with a second dual-face rack.Cooperation gears are movably mounted at the two ends of the second dual-face rack. A forging rod is fixedly mounted on the axle of each cooperation gear. The end, away from the corresponding cooperation gear, of each forging rod is fixedly connected with a forging hammer. According to the dual-face rapid forging device, the two faces of each iron sheet can be beaten at the same time, the beatenportions can be moved in the beating process, the device can evenly beat the surfaces of the iron sheets of different lengths, the stability of the iron sheets in the forging process can be guaranteed, the forging efficiency is high, and the forging effect is good.

Owner:ANHUI RUIDA MACHINERY

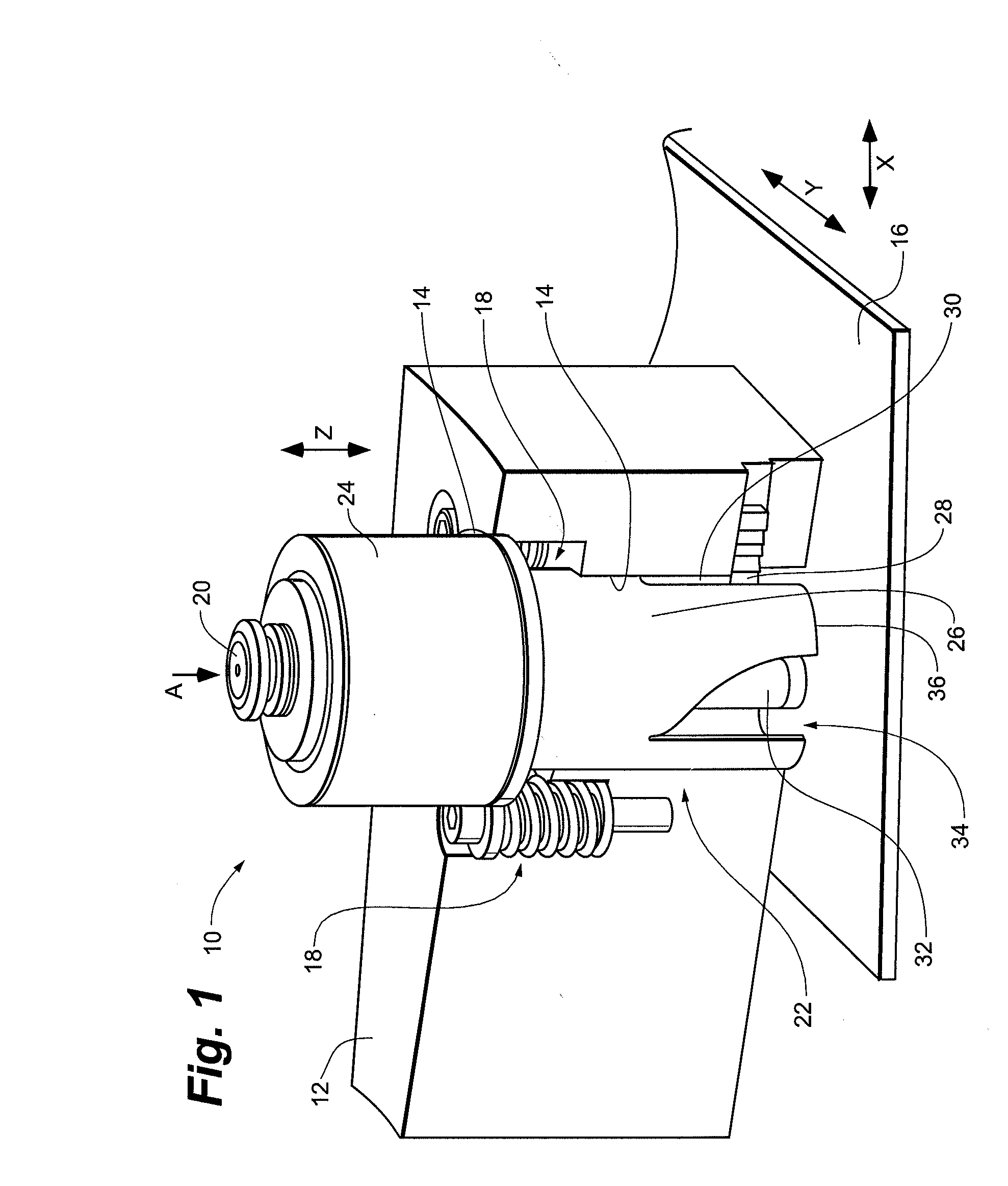

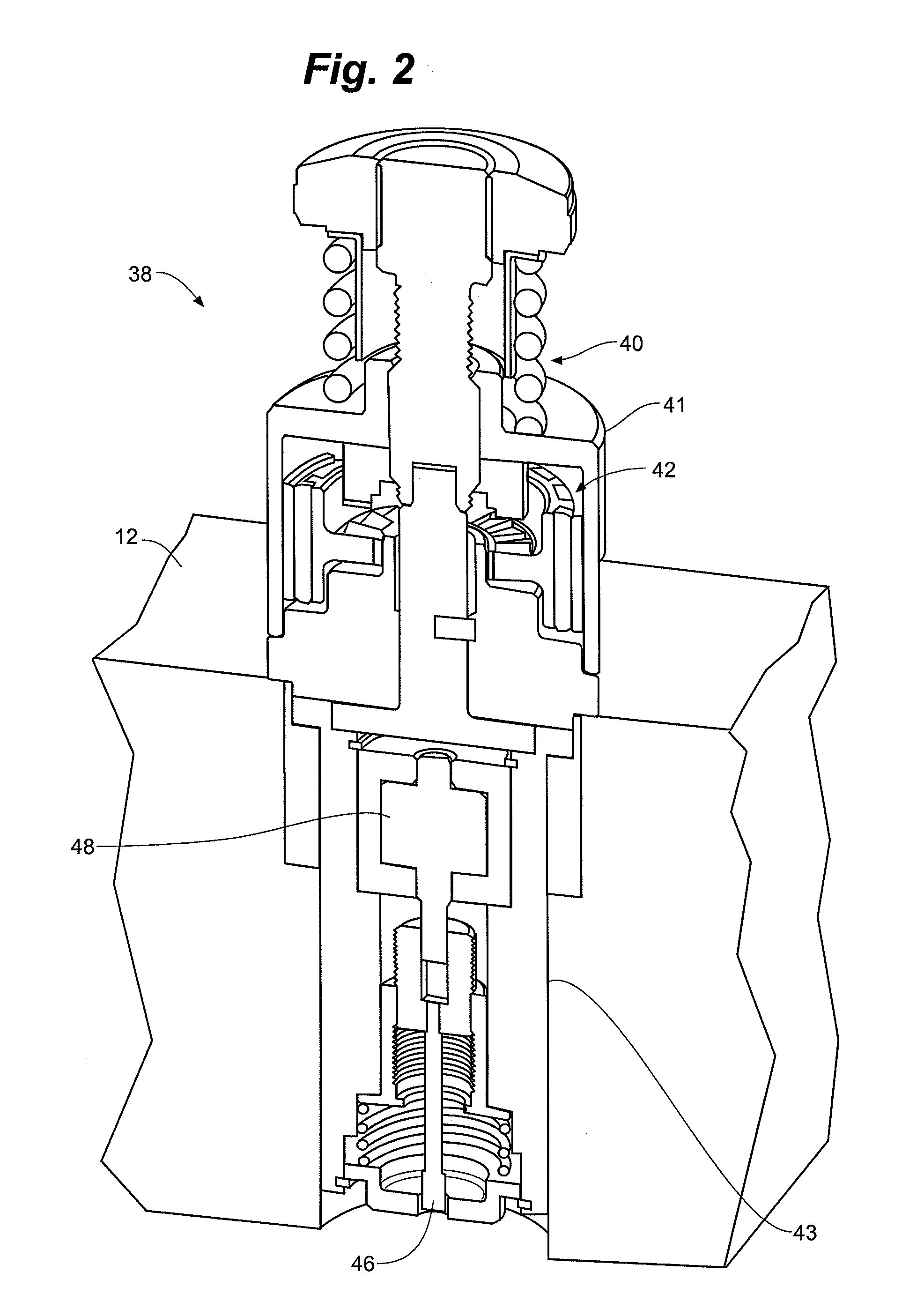

Live tooling systems for machine tools

In conventional ram-driven presses, the downward stroke of the ram into a tool causes acceleration of the tool, thereby facilitating an operation on a workpiece by the tip of the tool. While the ram stroke is found to impart sufficient dynamic energy to the tool to facilitate the necessitated operation by the tool tip, there are other more efficient, and in turn, more effective, means and methods of actuating the tool tip, with such means and methods being facilitated from energy derived from the tool's acceleration or from energy from other external sources.

Owner:WILSON TOOL INT

Forging equipment and forging method

InactiveCN107570648ALower lifting heightIncrease the intensity of forgingDrop hammersHammer drivesDrive motorEngineering

The invention relates to forging equipment. The forging equipment comprises a forging frame, a forging hammer moving up and down along the forging frame, and a driving motor for driving the forging hammer to move; a forging cutting board and an electromagnetic device are arranged at the bottom of the forging frame corresponding to the forging hammer; the electromagnetic device comprises an electromagnetic coil and a driving circuit; the electromagnetic coil is arranged at the bottom of the forging cutting board and fixedly connected with the forging cutting board; and the driving circuit controls the electrifying state of the electromagnetic coil. In addition, the invention further relates to a forging method; specifically, the forging hammer freely drops down after being lifted to reach aspecific height; and when the forging hammer drops down, the electromagnetic device is controlled to conduct to generate magnetic force so as to improve the forging strength. The forging equipment has the following beneficial effects: (1) the electromagnetic device magnetizes the forging cutting board and a contacted mold, so that the forging strength is improved, the lifting height of the forging hammer is greatly reduced, and the energy consumption is effectively reduced; and (2) the electromagnetic device fixes the forging mold to effectively prevent the technical problem of displacement of the mold in the forging process.

Owner:龙门县南华新金属科技有限公司

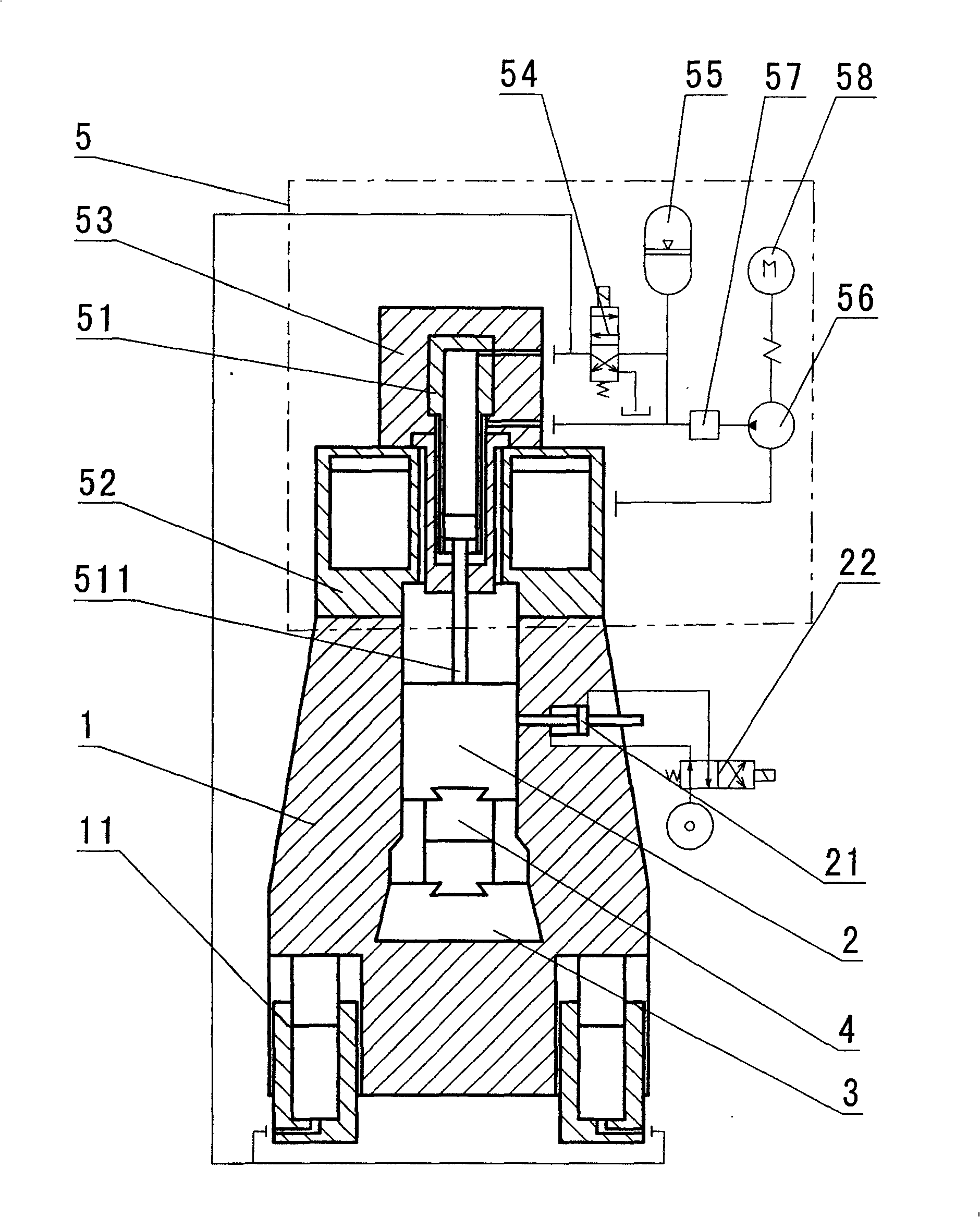

Lower ram micromotion full-hydraulic counterblow hammer

InactiveCN101254519AImprove transmission efficiencyHigh precisionDrop hammersHammer drivesHydraulic cylinderAutomatic control

The invention discloses a full hydraulic counterblow hammer with a micro-displacement lower hammer head, which comprises a lower hammer head, an upper hammer head, a die holder, a die and a program-controlled full hydraulic power head. The invention is characterized in that balancing hydraulic cylinders are arranged at two bottom sides of the lower hammer head to achieve the micro-displacement of the lower hammer head, and the program-controlled full hydraulic power head drives the upper hammer head to move. The upper and the lower hammer heads hit to each other in a way of non-uniform velocity and unequal travel based on full hydraulic drive and hydraulic linkage. Both the movement velocity and travel of the lower hammer head are smaller than those of the upper hammer head. The counterblow hammer has the advantages of micro-displacement of the lower hammer head, full hydraulic drive, automatic control of hydraulic linkage and high reliability.

Owner:张长龙

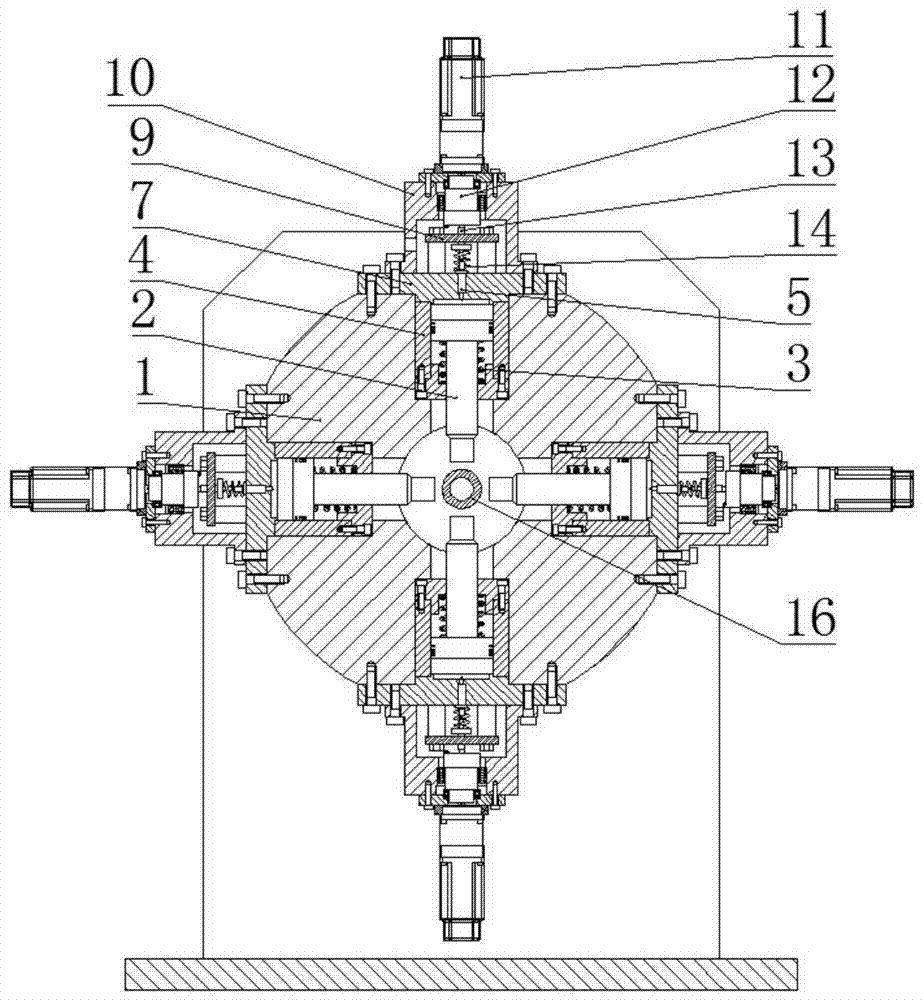

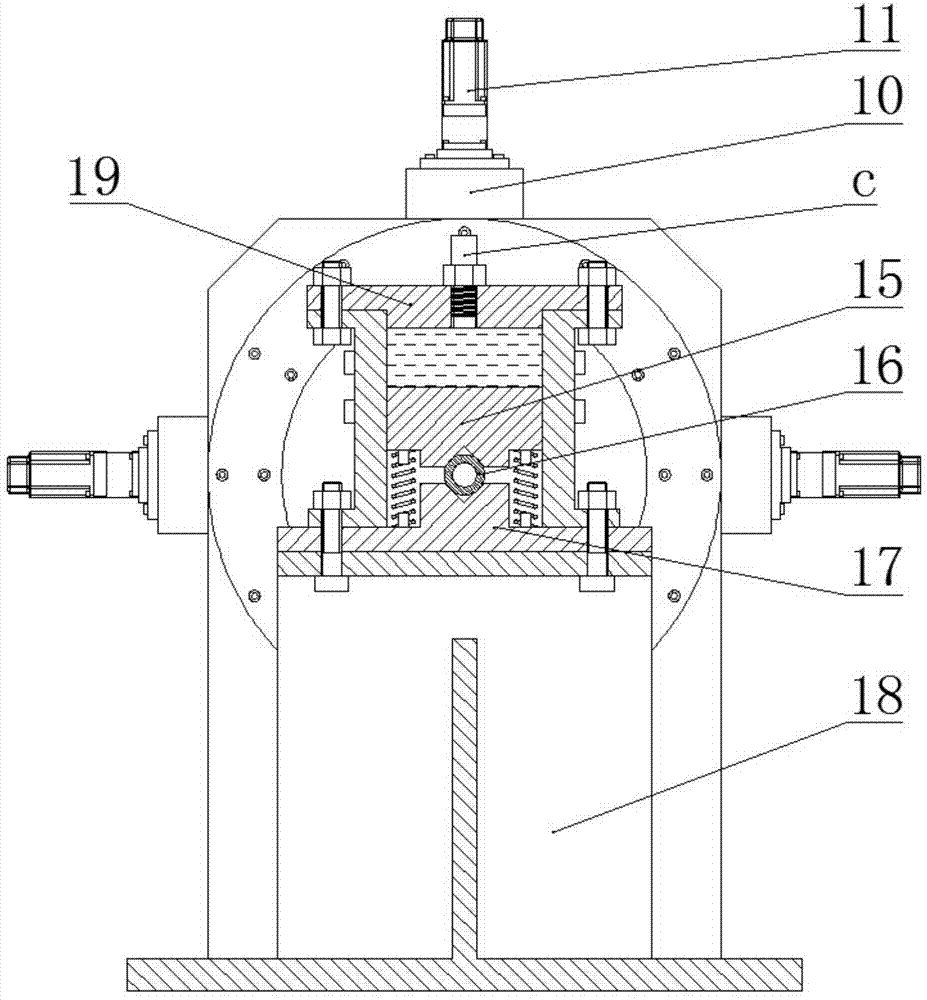

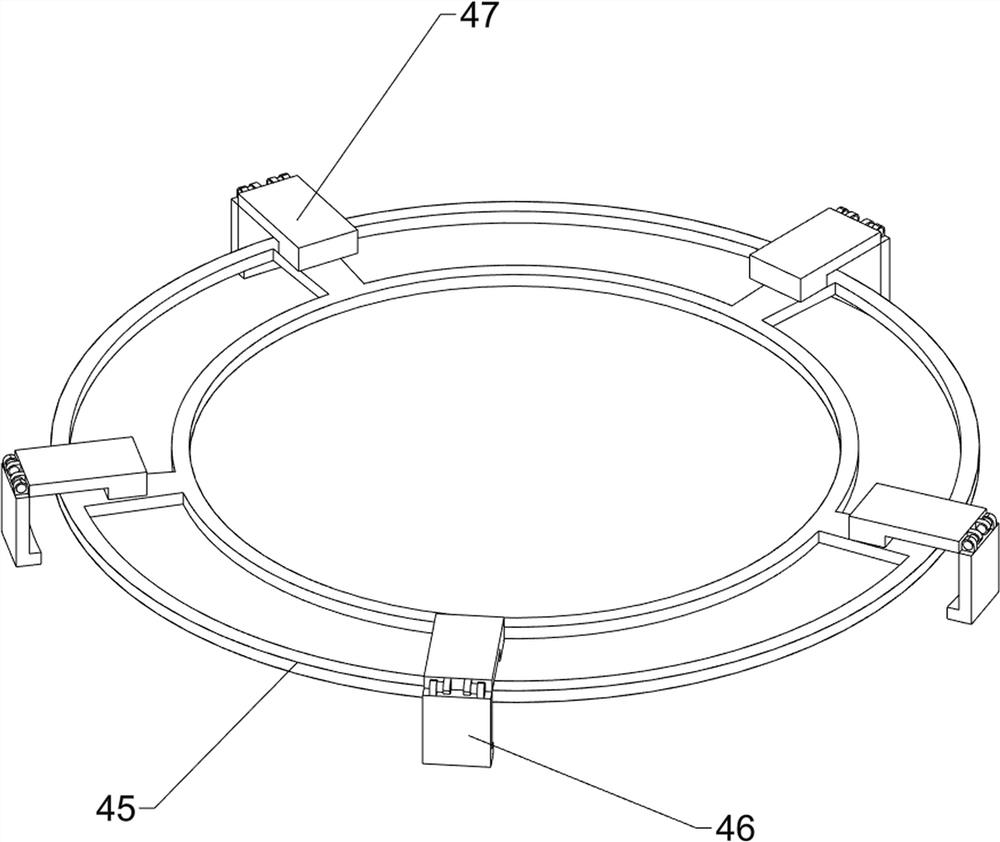

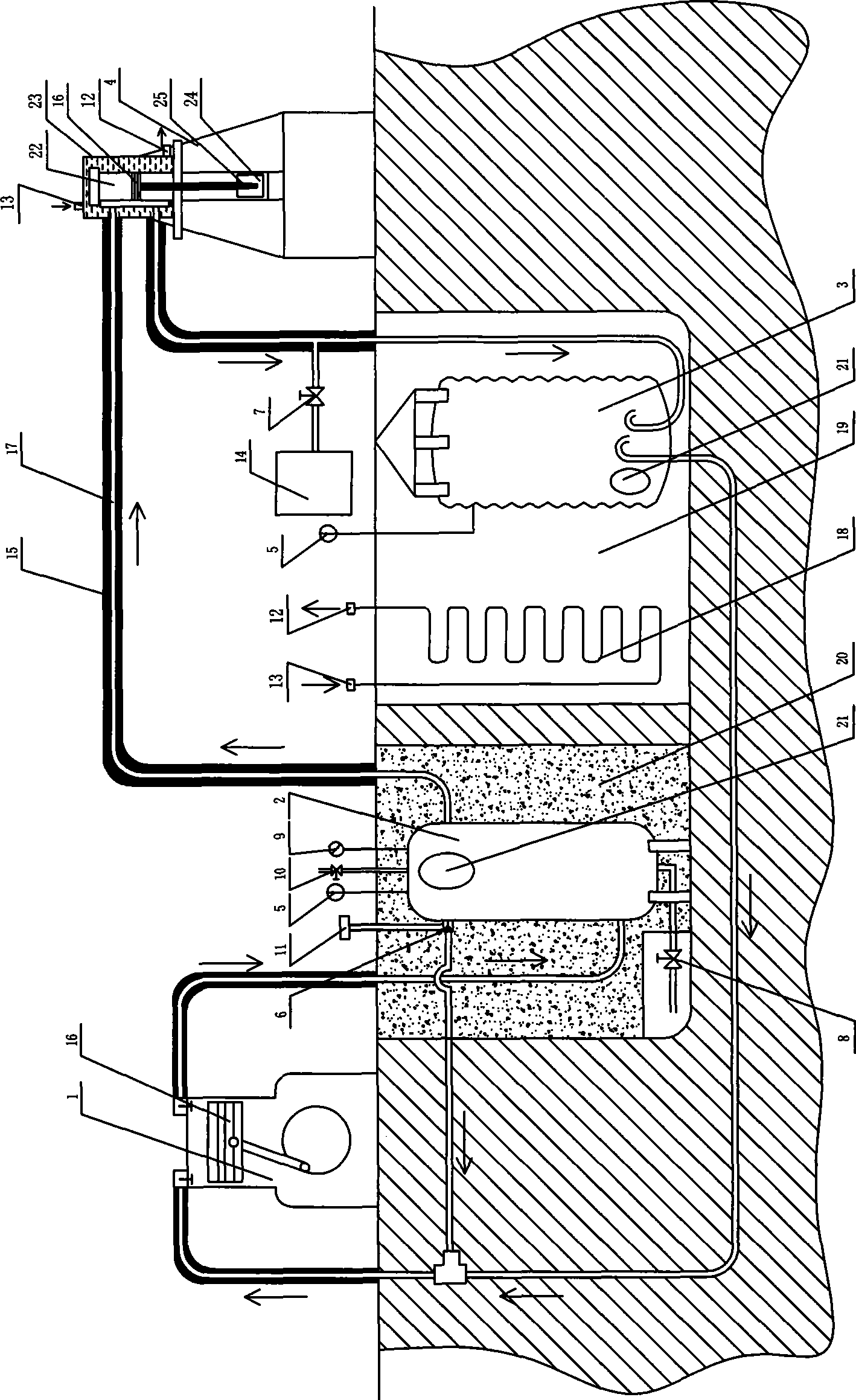

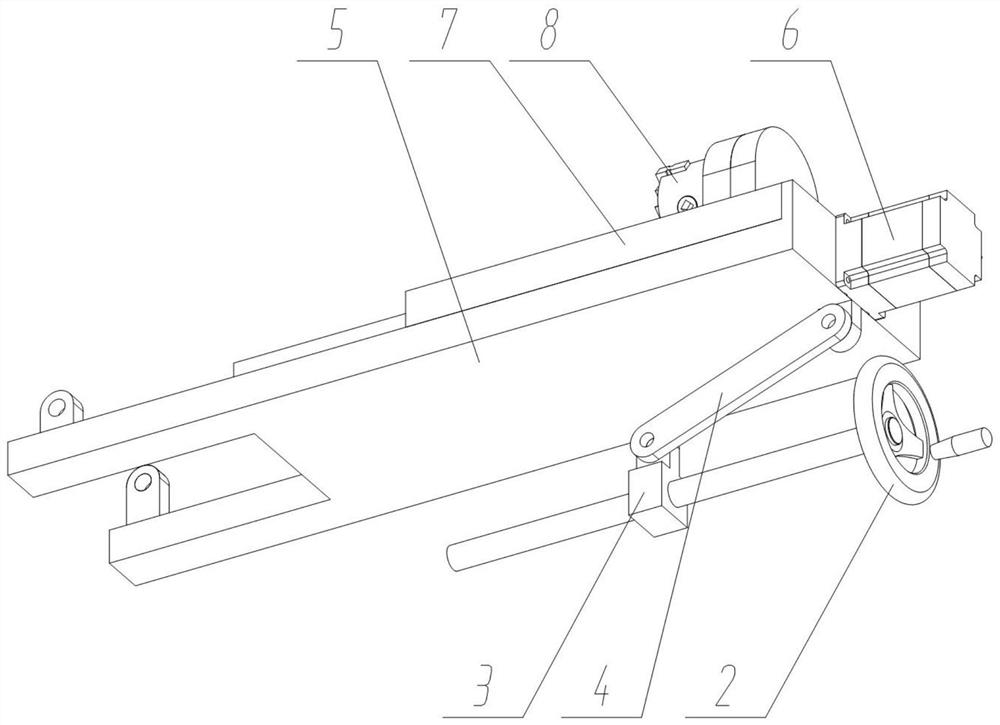

Radial asymmetric feeding device driven by liquefied natural gas

ActiveCN104493034ASimple structureReduce pollutionDrop hammersHammer drivesCombustionMaterial consumption

A radial asymmetric feeding device driven by the liquefied natural gas comprises a device body and a gas configuring mechanism and a material clamping mechanism which match with the device body. A feeding mechanism is composed of four sets of same striking and forging mechanisms distributed along the device body in the radial direction, feeding hammers are driven by the high pressure gas produced by liquefied natural gas combustion to apply the radial offset radial force to a bar or tube, the hammers of the four sets of striking and forging mechanisms strike the bar or tube sequentially to cause fatigue break of the bar or tube, and the feeding process is completed. The expansion gas produced by liquefied natural gas combustion is utilized to drive the feeding hammers to move so as to feed, so that pollution is reduced; on the basis of the low stress fatigue feeding method, the method of utilizing the explosion expansion of the liquefied natural gas combustion is adopted to drive the hammers and implement the precision feeding of metal bars and tubes; the device has the advantages of high producing efficiency, and less material consumption.

Owner:XI AN JIAOTONG UNIV

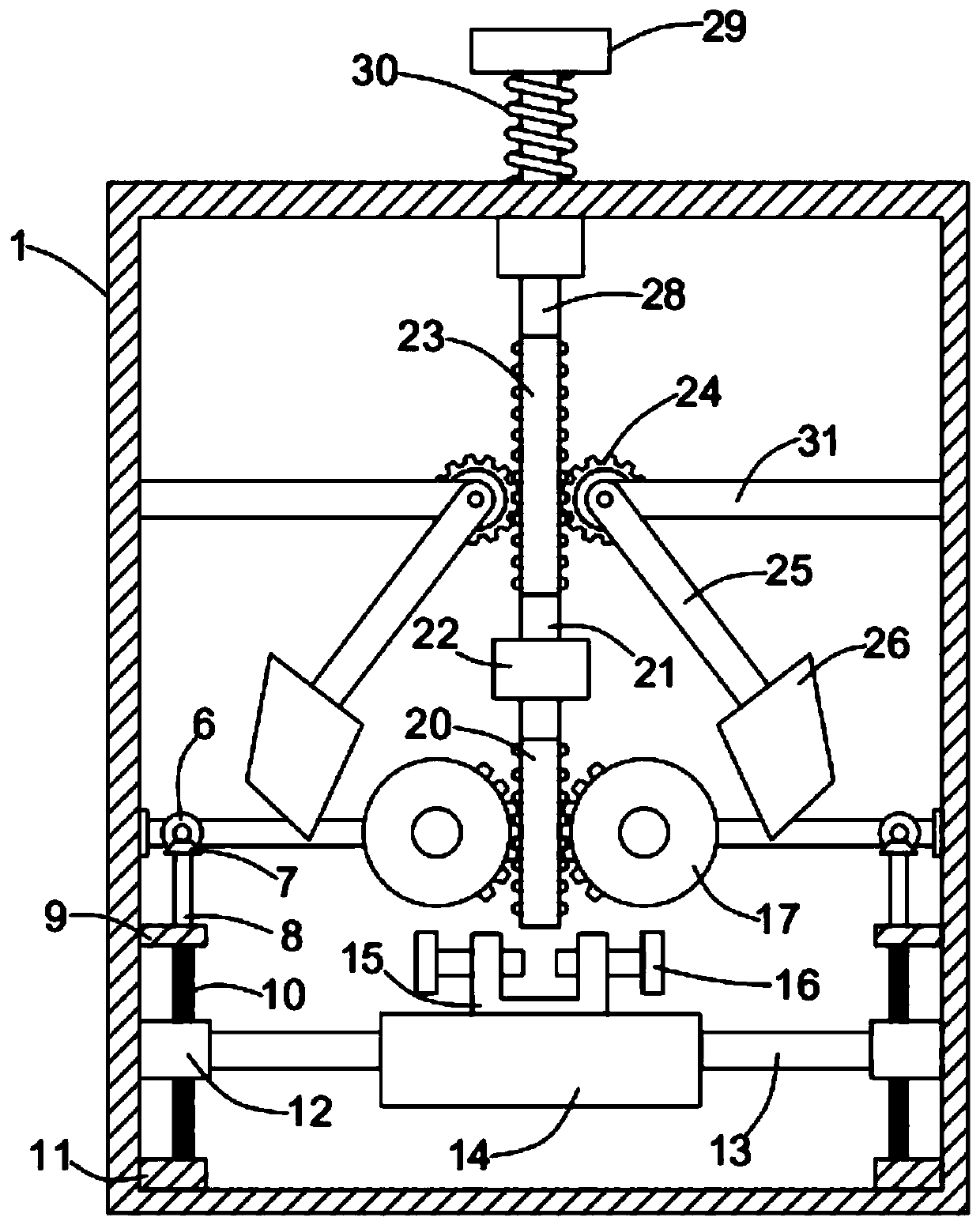

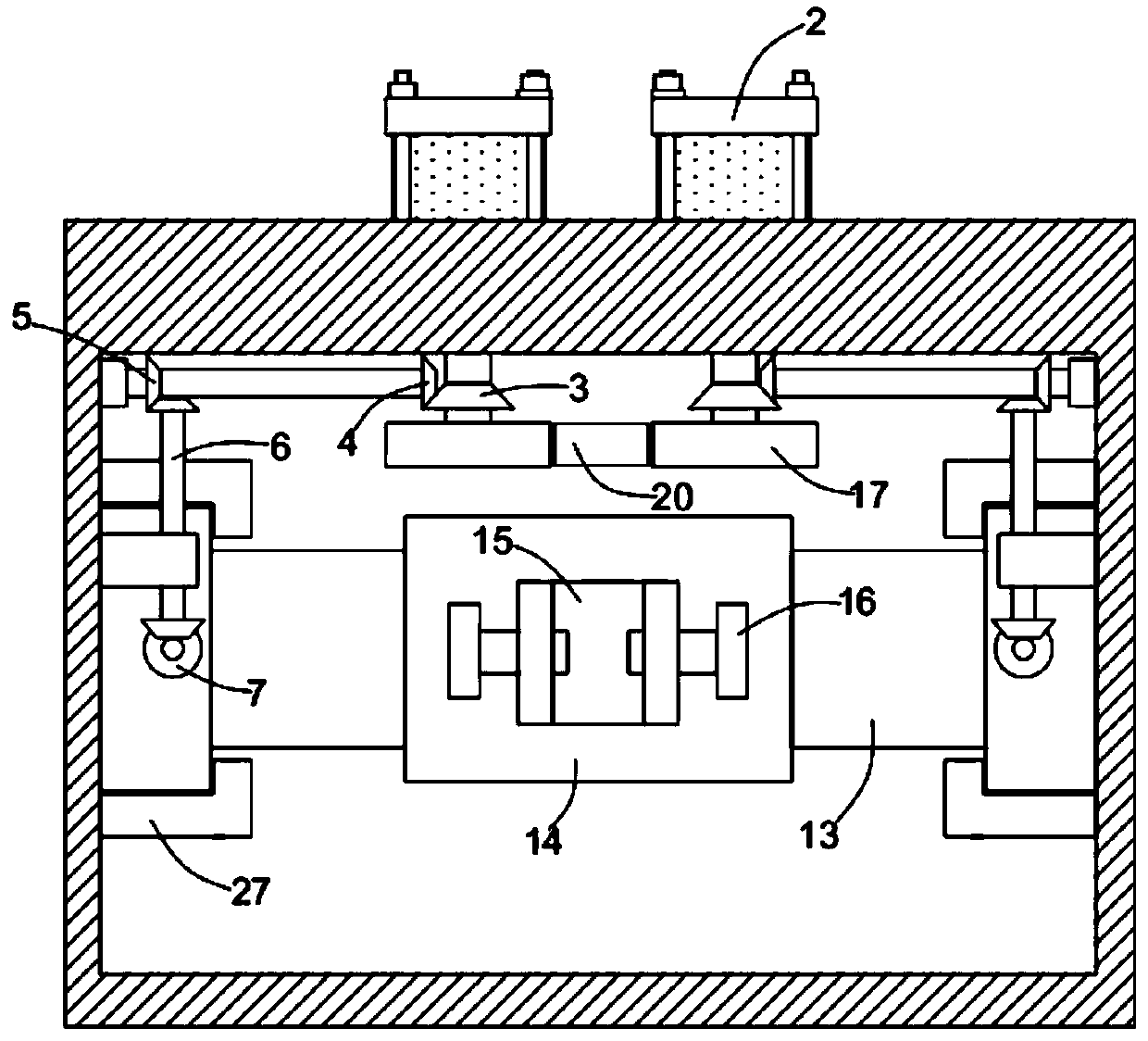

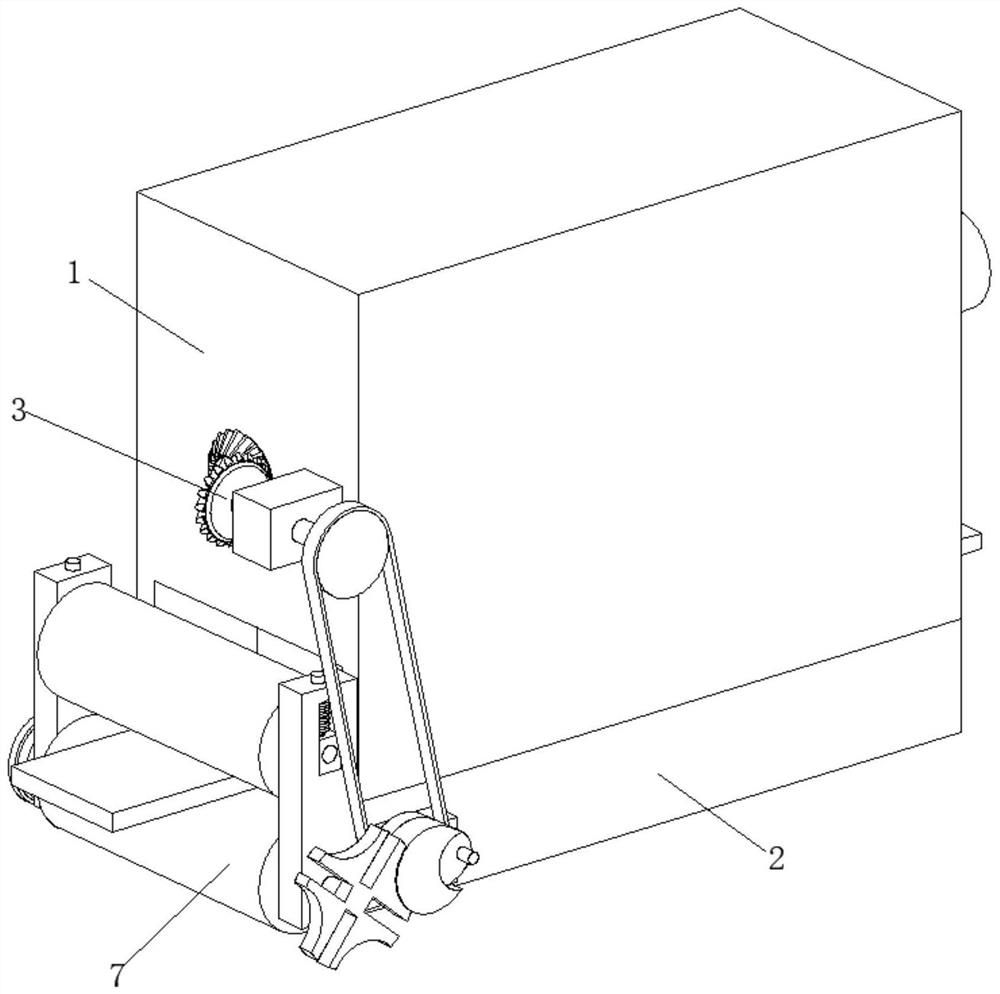

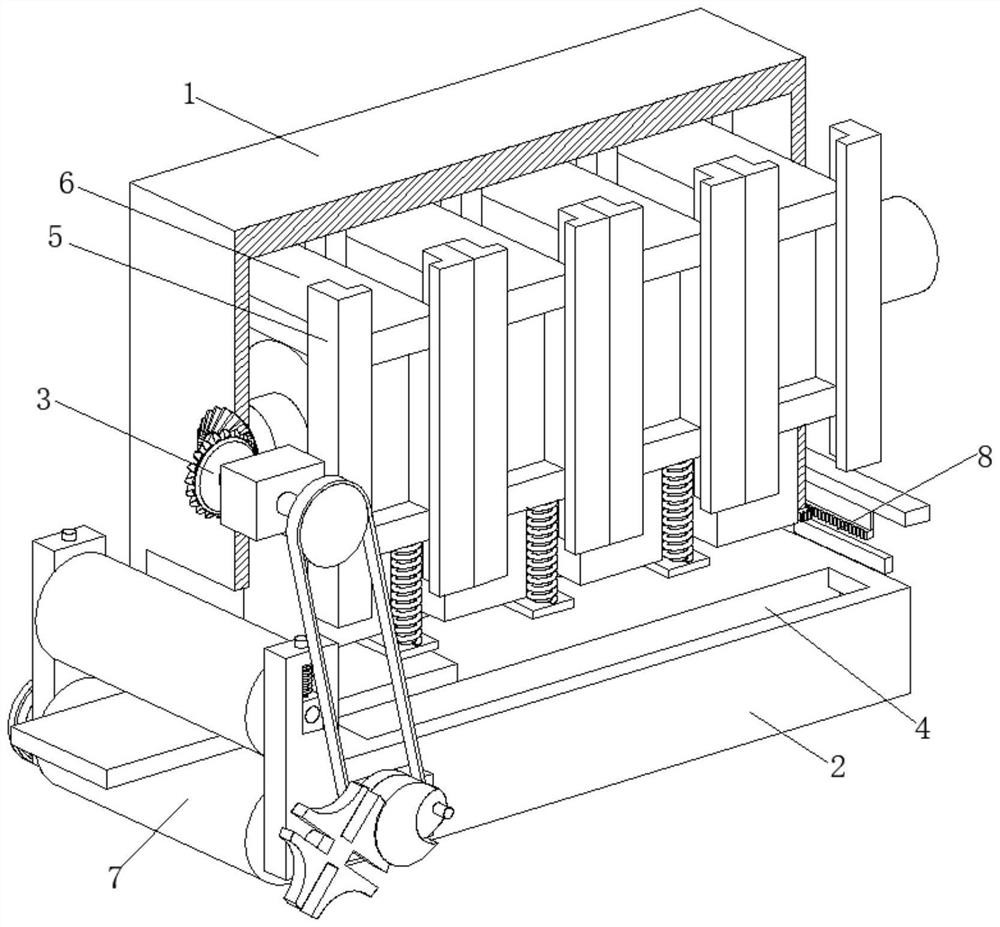

Continuous forging device with automatic cleaning function

ActiveCN112719183AShorten forging timeImprove work efficiencyDrop hammersHammer drivesEngineeringWorkbench

The invention relates to the technical field of forging equipment, and discloses a continuous forging device with an automatic cleaning function. The device comprises a box body, a workbench is welded at the bottom of the box body, a transmission mechanism is arranged at the front part of the box body, two discharge grooves are formed in the top of the workbench, and a plurality of limiting columns are welded on the inner wall of the box body. A forging mechanism is arranged on the surfaces of the limiting columns, a feeding mechanism is arranged at the front part of the workbench, and a cleaning mechanism is arranged at the rear part of the box body. According to the continuous forging device, through cooperative work of the transmission mechanism and the forging mechanism, a steel plate can be continuously forged, so that the situation that forging equipment is replaced after forging is conducted once is avoided, the stroke of the forging equipment is adjusted, forging time can be greatly shortened, the working efficiency is improved, the practicability is greatly improved, the cleaning mechanism can clean the finally forged steel plate, manual cleaning by workers is not needed, and the labor intensity of the workers is reduced.

Owner:山东圣利锻造有限公司

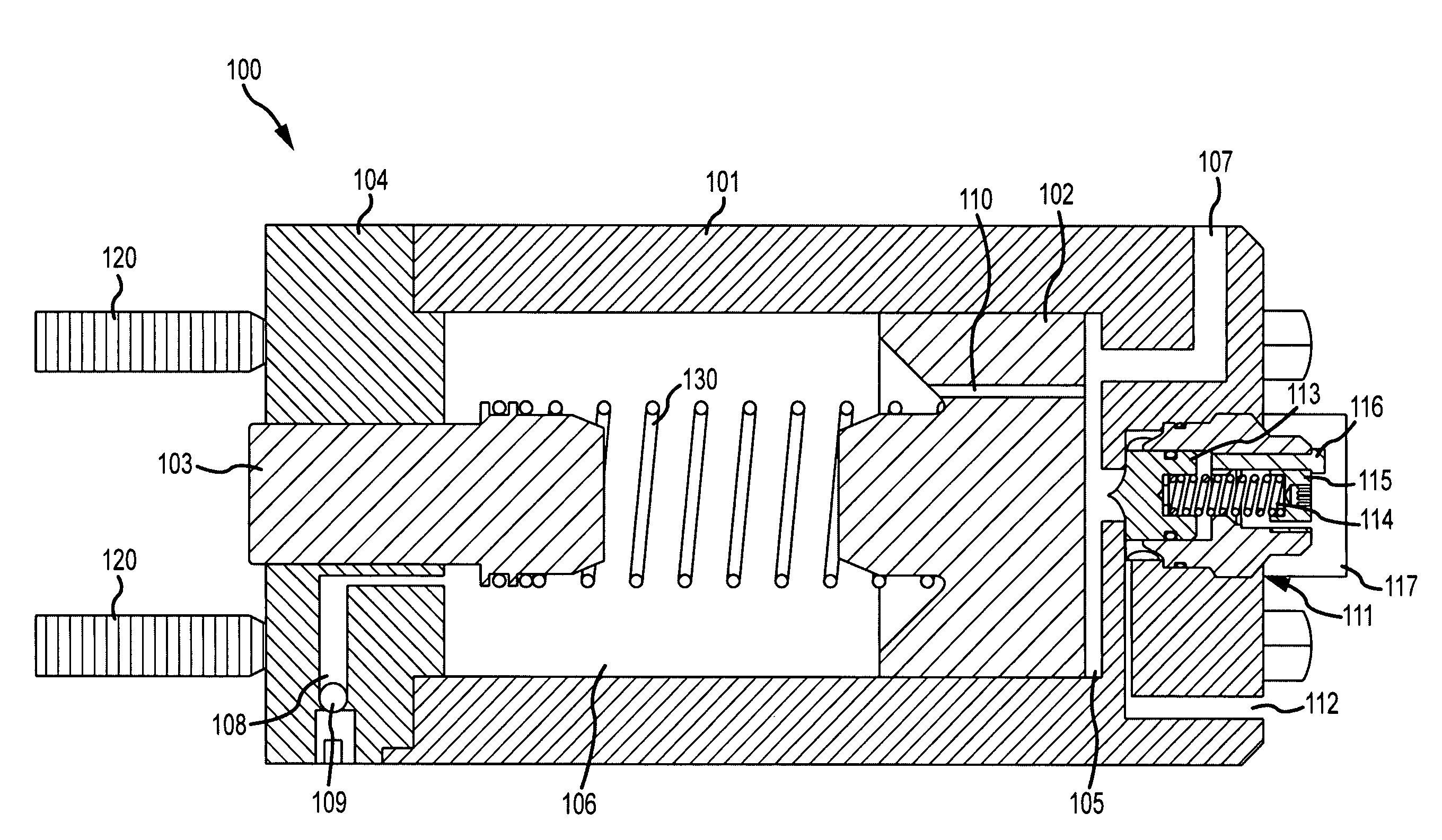

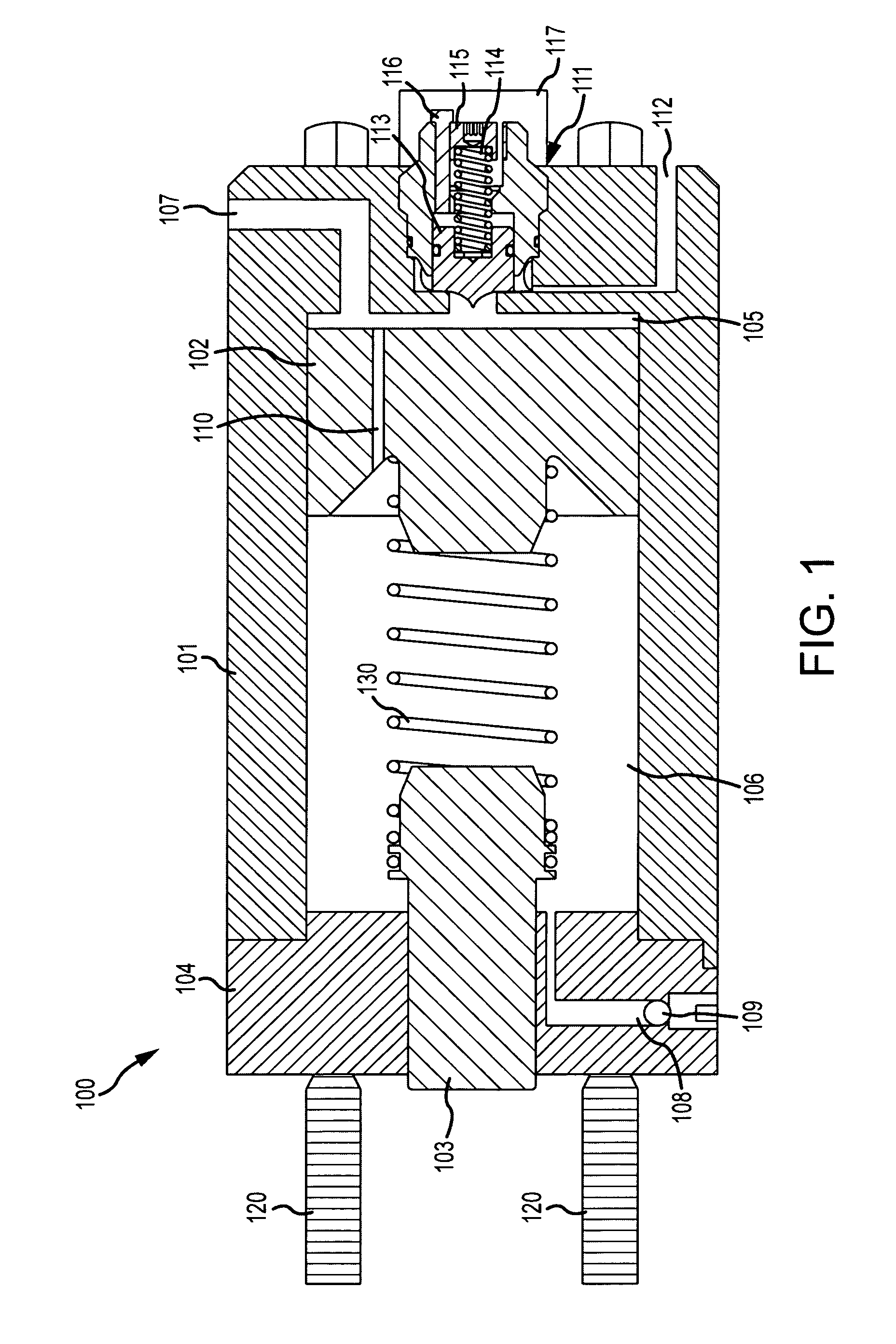

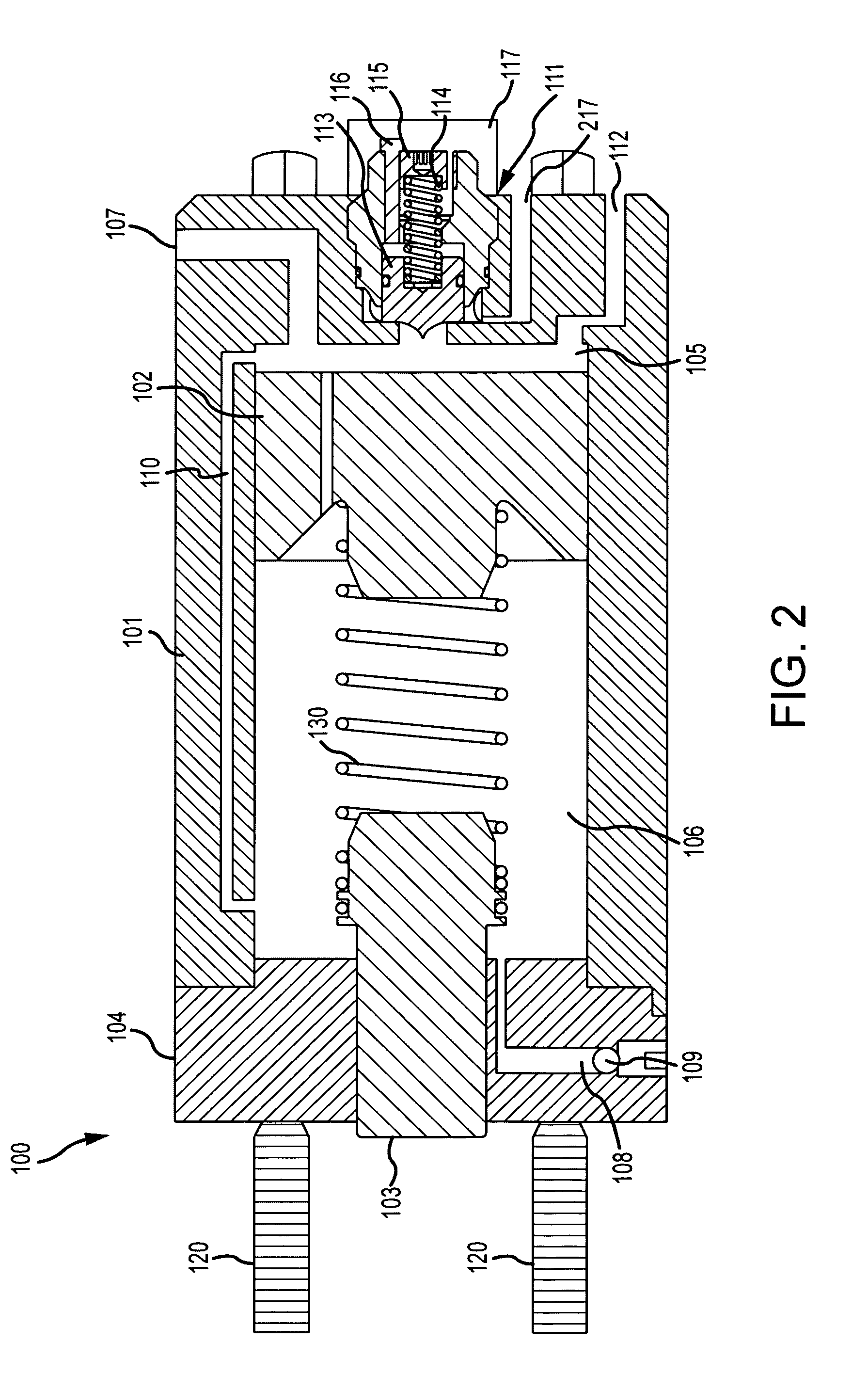

Fluid operated actuator including a bleed port

A fluid operated actuator (100) is provided. The fluid operated actuator (100) includes a cylinder body (101) and a piston (102) movable within the cylinder body (101). The piston (102) defines a first chamber (105) and a second chamber (106). The fluid operated actuator (100) can include a fluid inlet (107) formed in the first chamber (105). A bleed port (110) can be formed to provide fluid communication between the first chamber (105) and the second chamber (106).

Owner:NORGREN GMBH

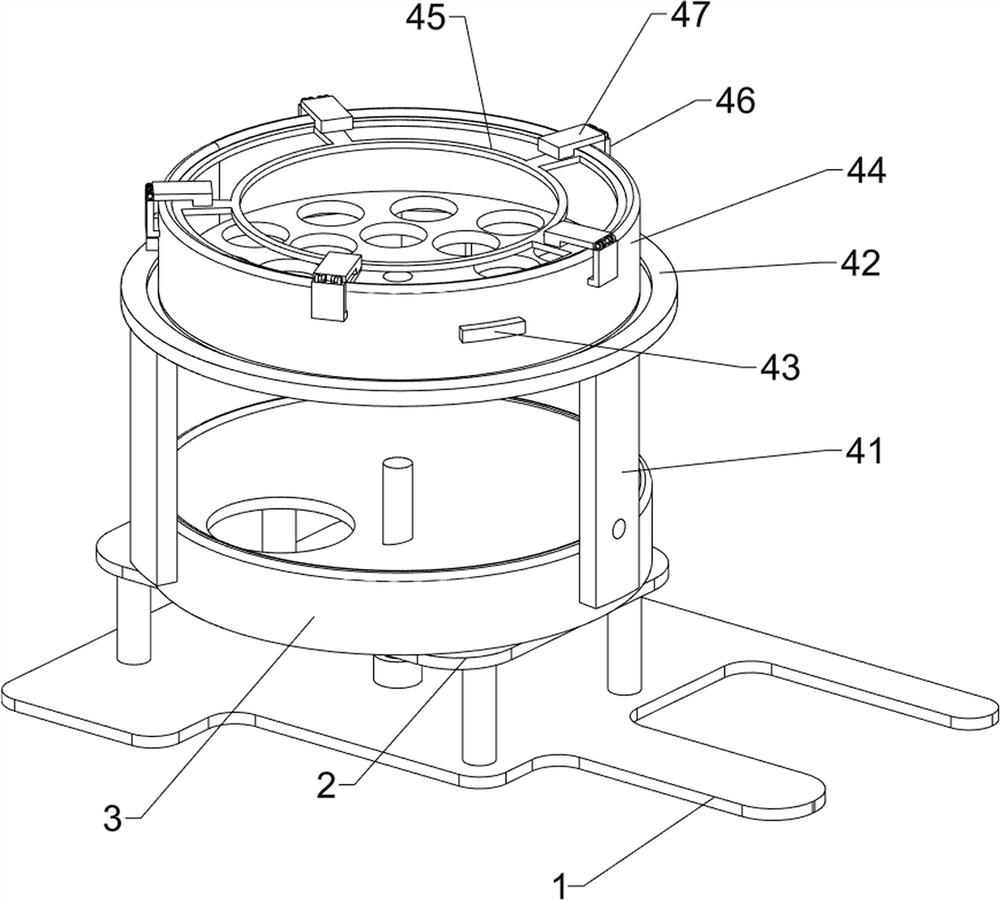

Forging device for iron pan manufacturing

InactiveCN111957866AAuto steeringEasy to operateDrop hammersForging/hammering/pressing machinesAutomatic steeringWaste management

The invention relates to a forging device, in particular to a forging device for iron pan manufacturing. The forging device for iron pan manufacturing is convenient to operate and capable of automatically turning an iron pan. According to the technical scheme, the forging device for iron pan manufacturing comprises a base, a placement table, a clamping device, and a hammering device. The placementtable is arranged at the top of the base, a waste hopper is arranged at the top of the placement table, the clamping device is arranged at the top of the base and is located over the waste hopper, and the hammering device is arranged at the position, close to the clamping device, of the top of the base. The forging device achieves the effects that operation is convenient and the iron pan can automatically be turned.

Owner:钟和平

Impact machine and a method of forming a body

InactiveUS20050189672A1Reasonably preparedConfectioneryWood working apparatusEngineeringCentral unit

The invention concerns an impact machine for forming a body with desired shape of a formable working material through impact action in a forming operation, said impact machine comprising a machine stand (6), an upper unit which comprises either a lower impact unit (3), which comprises a counter-impact device, or a stationary anvil, and a central unit between the upper and the lower units. The central unit (4) comprises one or more carriers (30), each of which containing and carrying one or a plurality of identically equal tool units (32), each of which comprising a die (34) with a mould cavity (46) for the working material (90) intended to be formed said carriers including at least one carrier which is stationary during the forming operation and which contains at least one such tool unit, and that motion devices (7) are provided for indexing the carriers in a horizontal plane for positioning the tool units in different function stations (1-V), comprising a forming station (1) and at least one more station.

Owner:CELL IMPACT

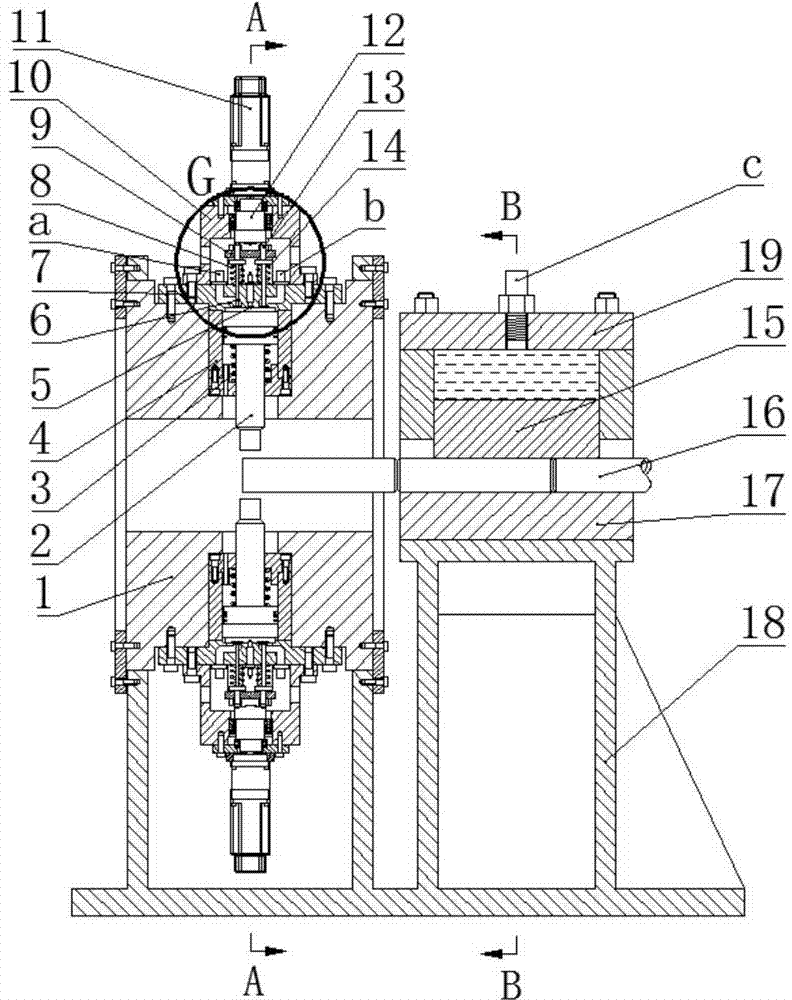

Drop-forging hammer for making toothed wheels

InactiveCN1947887ACompact structureReduce manufacturing costDrop hammersHammer drivesLow noiseGear wheel

A gear-type die forging hammer system is composed of stock, base, machine body, hammer with rod, and drive mechanism consisting of a box on machine body and such units in said box as stand, supporting frame, motor, speed reducer, clutch, gear and rack bar connected with hammer rod. It has low noise.

Owner:王国栋

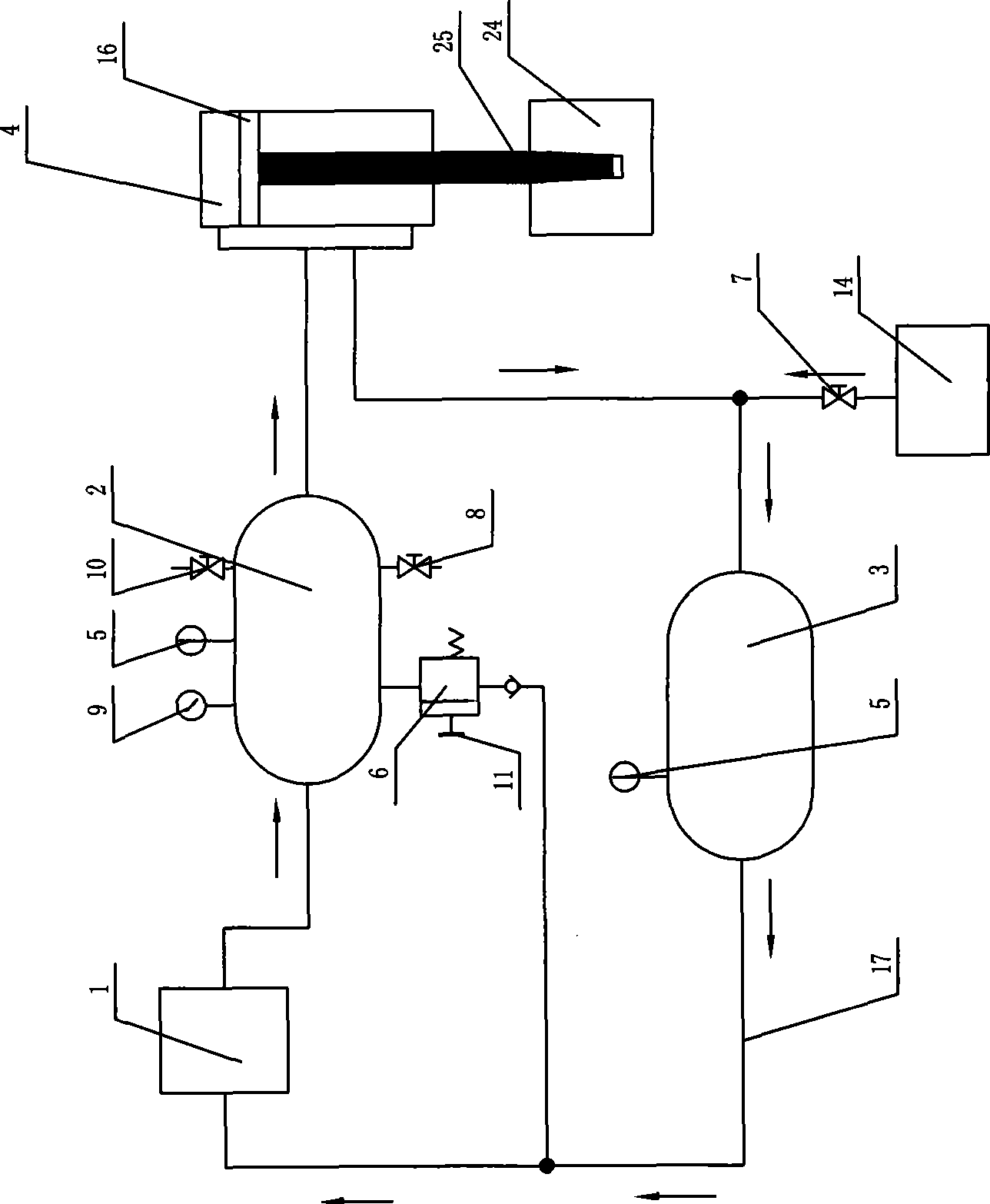

High-speed air-actuated hammer-forging device

InactiveCN101462147APrevent intrusionReasonable designDrop hammersHammer drivesAirbag deploymentPiston

The invention discloses a high-speed pneumatic forging hammer device, and belongs to forging and pressing equipment. The device structurally comprises a compressor, an air storage tank, a buffering air bag, a forging hammer and an inflator, wherein an air outlet of the buffering air bag is communicated with an air inlet of the compressor through an air delivery pipe, an air outlet of the compressor is communicated with an air inlet of the air storage tank through the air delivery pipe, an air outlet of the air storage tank is communicated with the forging hammer through the air delivery pipe, and the forging hammer is communicated with the air inlet of the buffering air bag through the air delivery pipe; the inflator is communicated with the air inlet of the buffering air bag through the air delivery pipe, and the air delivery pipe between the inflator and the air inlet of the buffering air bag is provided with an air supply valve; and the inflator is a small-sized molecular sieve type nitrogen making machine or a small-sized air dryer. The high-speed pneumatic forging hammer device adopts a closed-loop pipeline, is completely isolated with outside air, and avoids invasion of outside humid air, so as to solve the problem that a large-caliber pneumatic piston is frosted and blocked.

Owner:张国庆

Live tooling systems for machine tools

In conventional ram-driven presses, the downward stroke of the ram into a tool causes acceleration of the tool, thereby facilitating an operation on a workpiece by the tip of the tool. While the ram stroke is found to impart sufficient dynamic energy to the tool to facilitate the necessitated operation by the tool tip, there are other more efficient, and in turn, more effective, means and methods of actuating the tool tip, with such means and methods being facilitated from energy derived from the tool's acceleration or from energy from other external sources.

Owner:WILSON TOOL INT

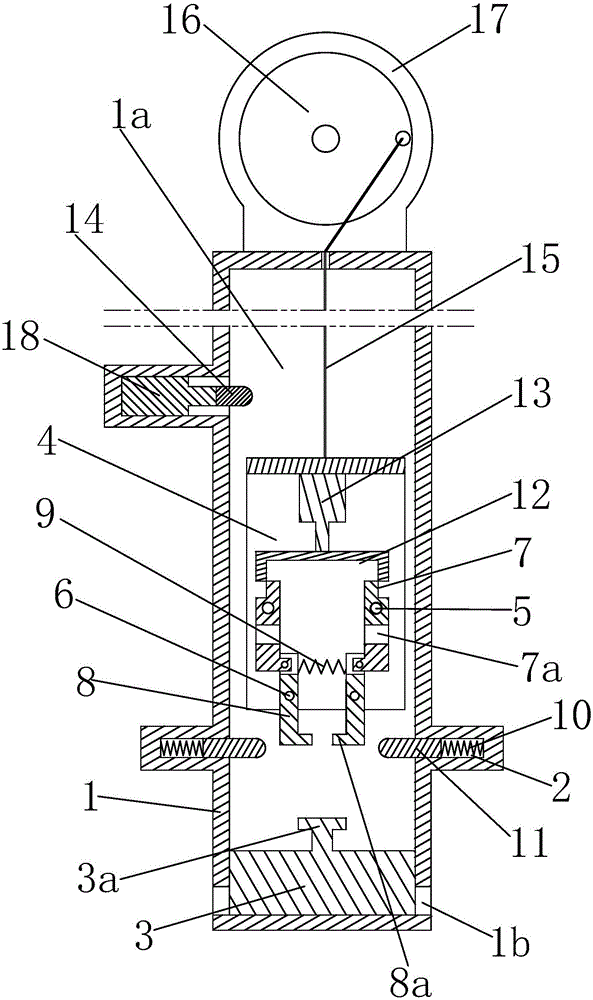

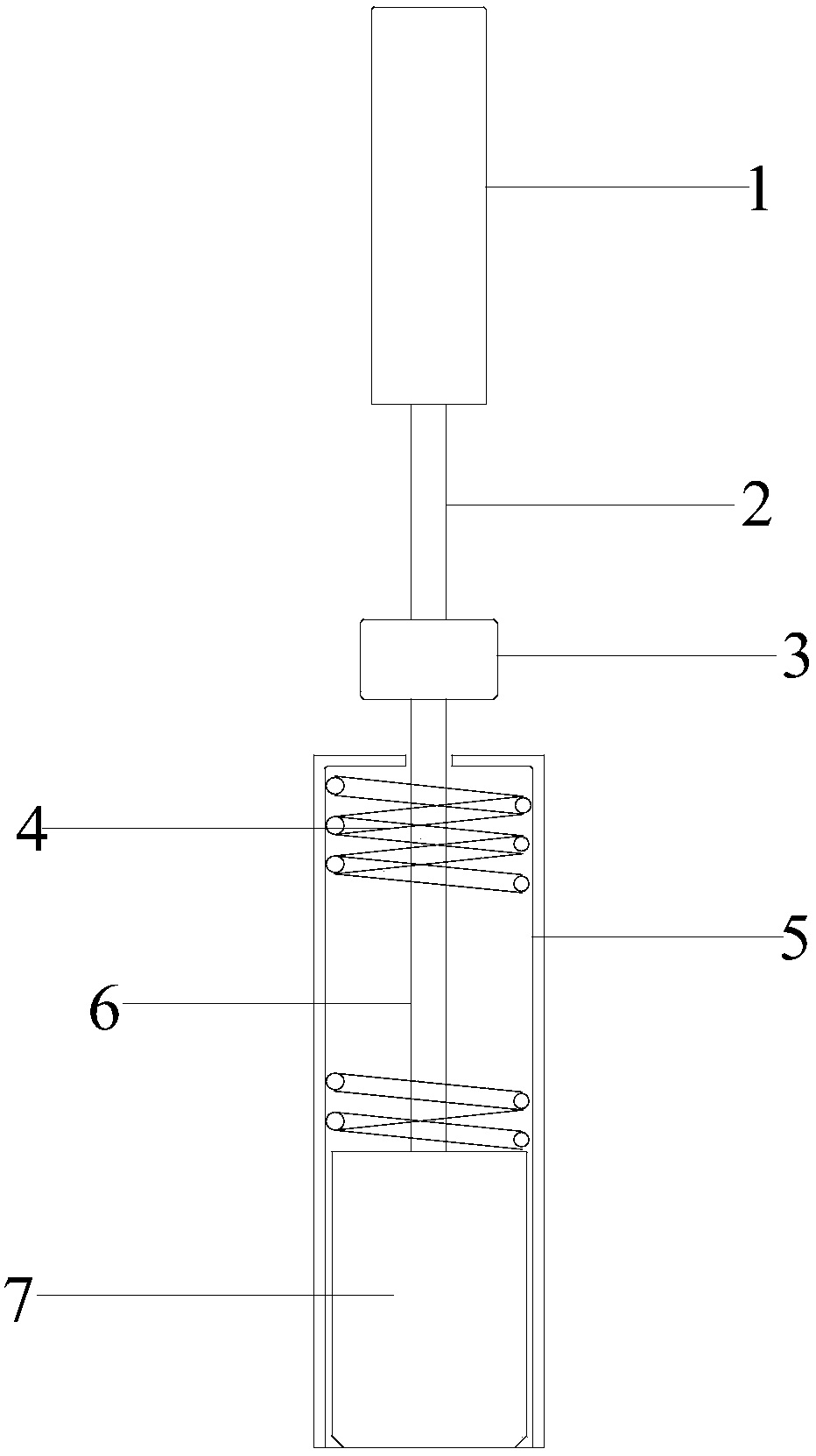

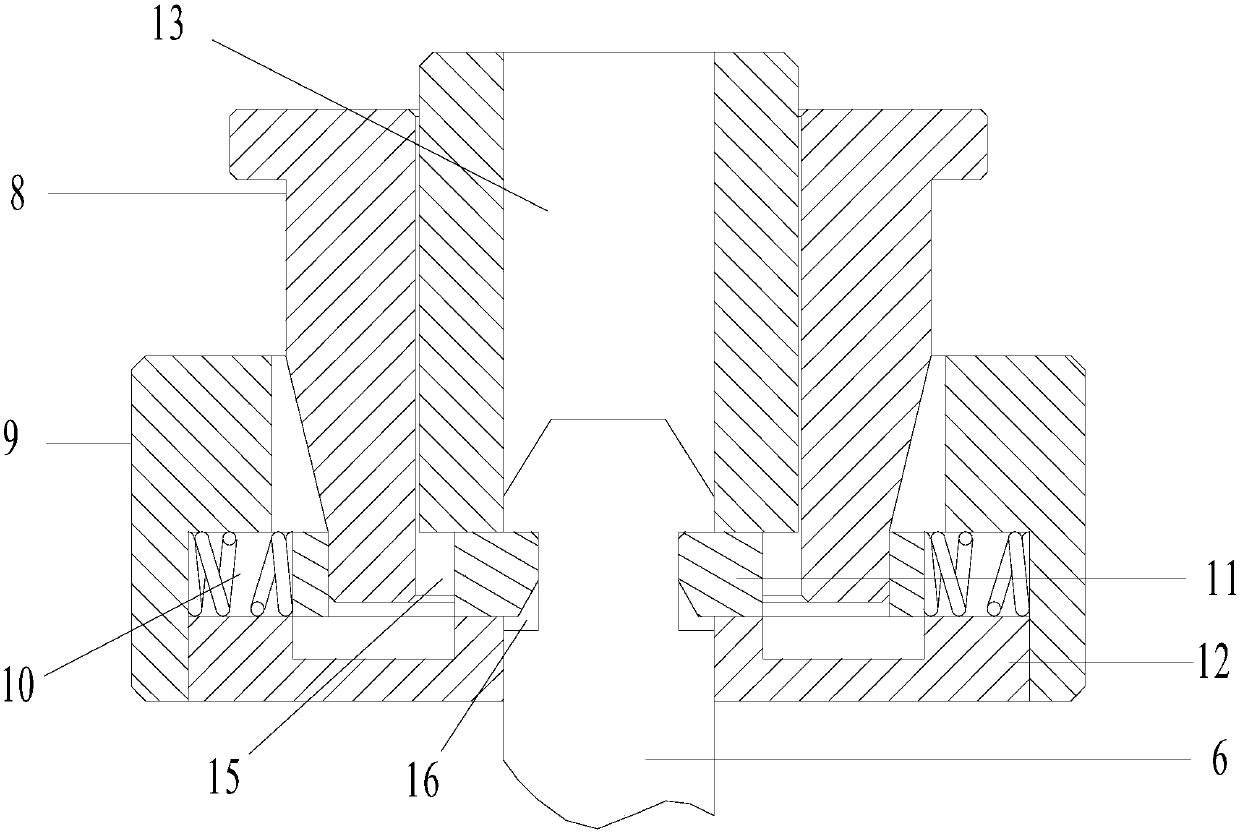

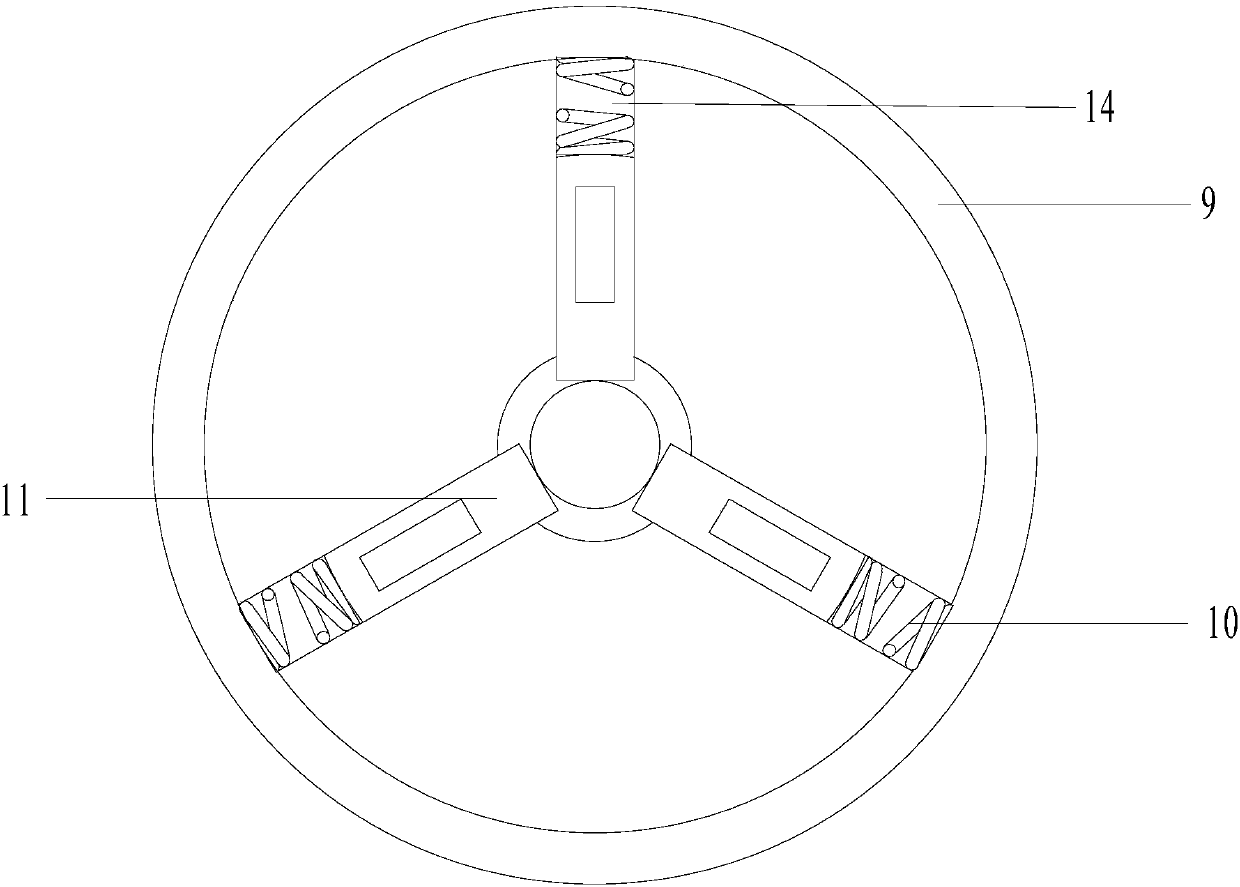

Energy storage type drop hammer quick-release impact device

The invention relates to an energy storage type drop hammer quick-release impact device, which belongs to the technical field of mining disaster prevention and control, and comprises a hydraulic cylinder, a drop hammer release device, a pull rod, a sleeve, a spring and a drop hammer. The drop hammer release device comprises a locating sleeve with a locating hole in the center; grooves are formed on the bottom part of the locating sleeve; glands are arranged on the bottom parts of the grooves; the inner ends of the grooves communicate with the locating hole; clamping jaws are arranged in the grooves; reset springs are arranged in the grooves between the clamping jaws and the locating sleeve; locating clamp slots are formed in the middle parts of the clamping jaws; the lower part of a locating body is arranged in the locating clamp slots; the outer side faces of the lower part of the locating body are provided with inclined planes; the drop hammer is arranged in the sleeve; the upper end of the pull rod penetrates through the through hole of the sleeve so as to be arranged in the locating hole of the drop hammer release device; clamping slots are formed on the upper end of the pull rod; the inner ends of the clamping jaws are arranged in the clamping slots; the lower end of the pull rod is fixedly connected with the drop hammer; the spring is arranged in the sleeve above the drop hammer; a piston rod of the hydraulic cylinder is fixedly connected with the locating sleeve of the drop hammer release device.

Owner:辽宁裕达矿业科技有限公司

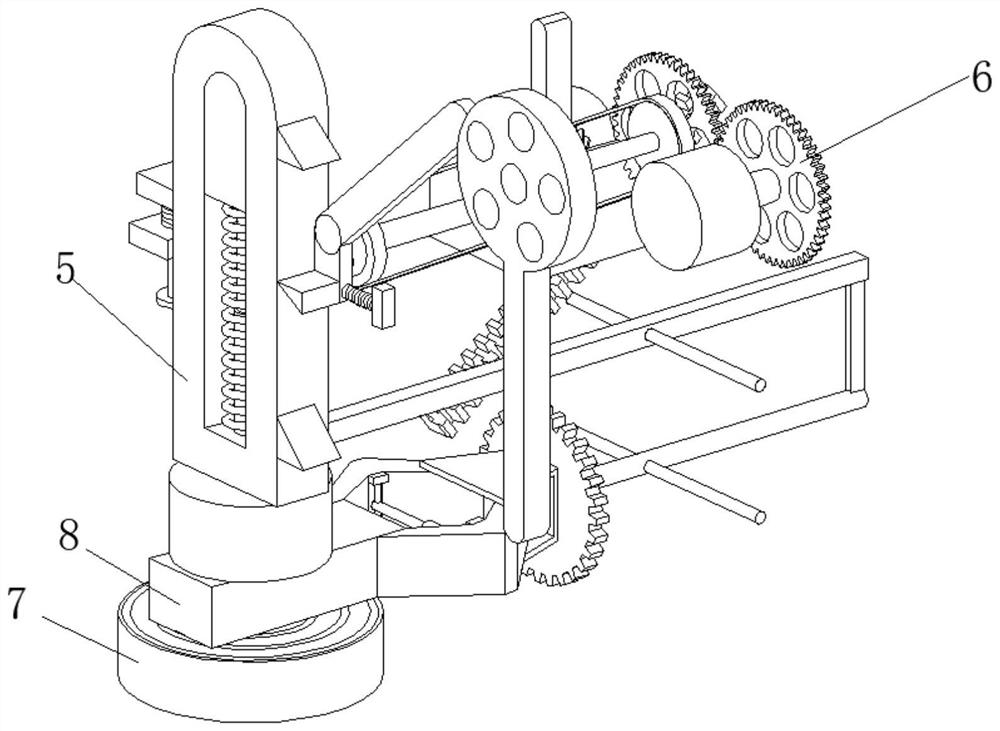

Gear blank forging device

InactiveCN112317664ASimple structureSimple and fast operationDrop hammersHammer drivesElectric machineGear wheel

The invention discloses a gear blank forging device. The gear blank forging device comprises a machine tool shell, wherein a transmission cavity is formed in the machine tool shell; a transmission mechanism, a driven mechanism and a knocking mechanism are arranged in the transmission cavity; a lifting cavity is formed in the upper end of the machine tool shell; a hammering mechanism is arranged inthe lifting cavity; the transmission mechanism comprises a rotating motor fixedly connected to the inner wall of the transmission cavity; a rotating shaft is in power connection with the rotating motor; a first gear is fixedly connected to the rotating shaft; and a locking arc is further fixedly connected to the rotating shaft. The gear blank forging device is simple in structure and easy and convenient to operate; when the gear blank forging device is used, a blank is placed and then automatically rotates, and a gear is forged through two times of hammering with the upper end surface; and manual operation is not needed in the forging process, potential safety hazards caused by high-temperature splashing are avoided, meanwhile, the blank does not need to be manually turned over, so that alot of manpower is saved, and the production efficiency is greatly improved through automatic production.

Owner:东阳宋辰传动科技有限公司

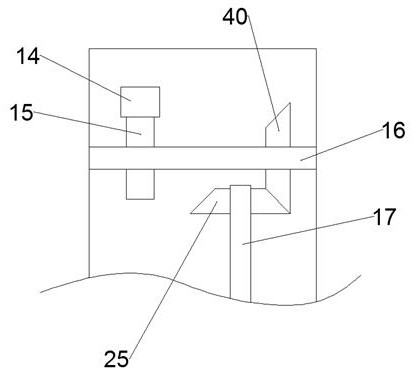

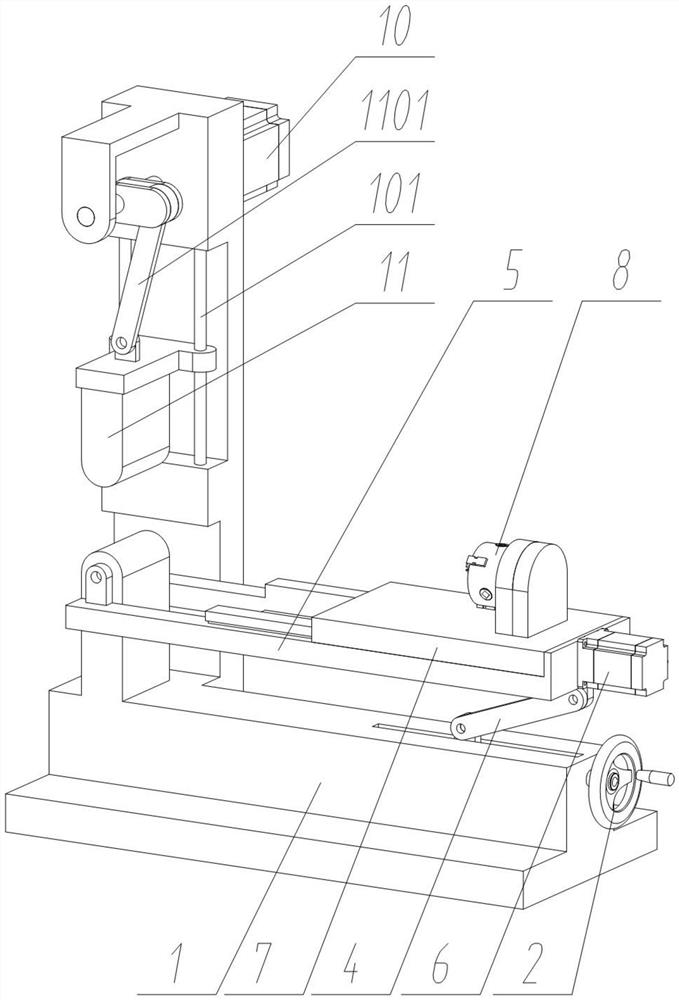

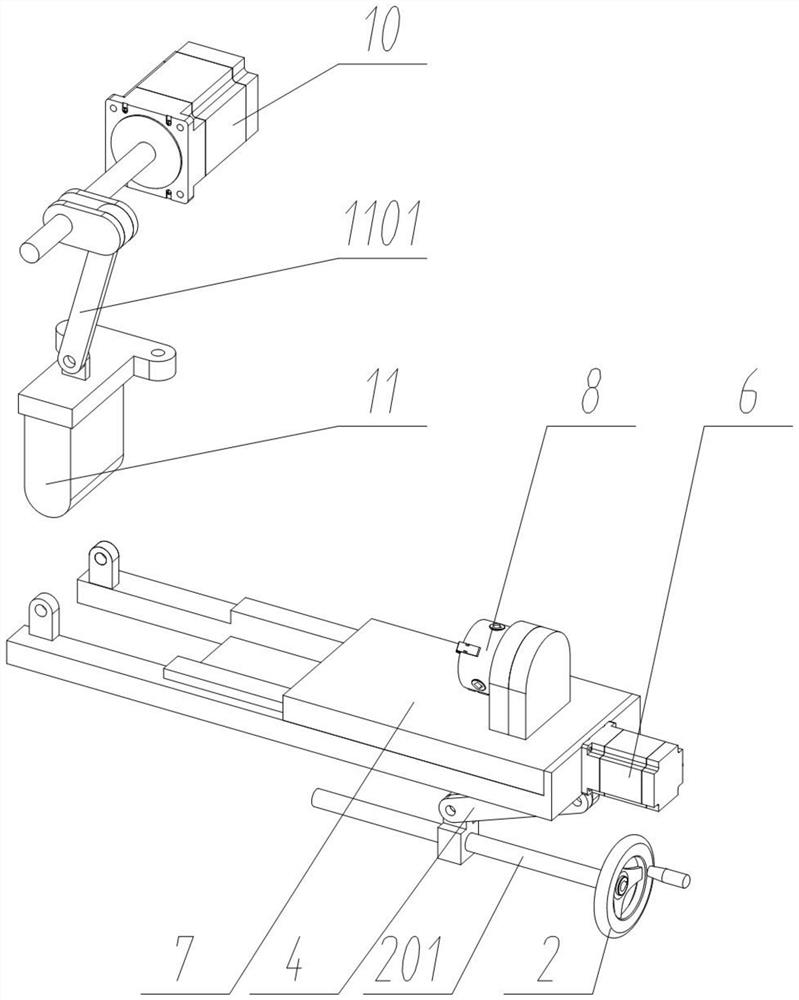

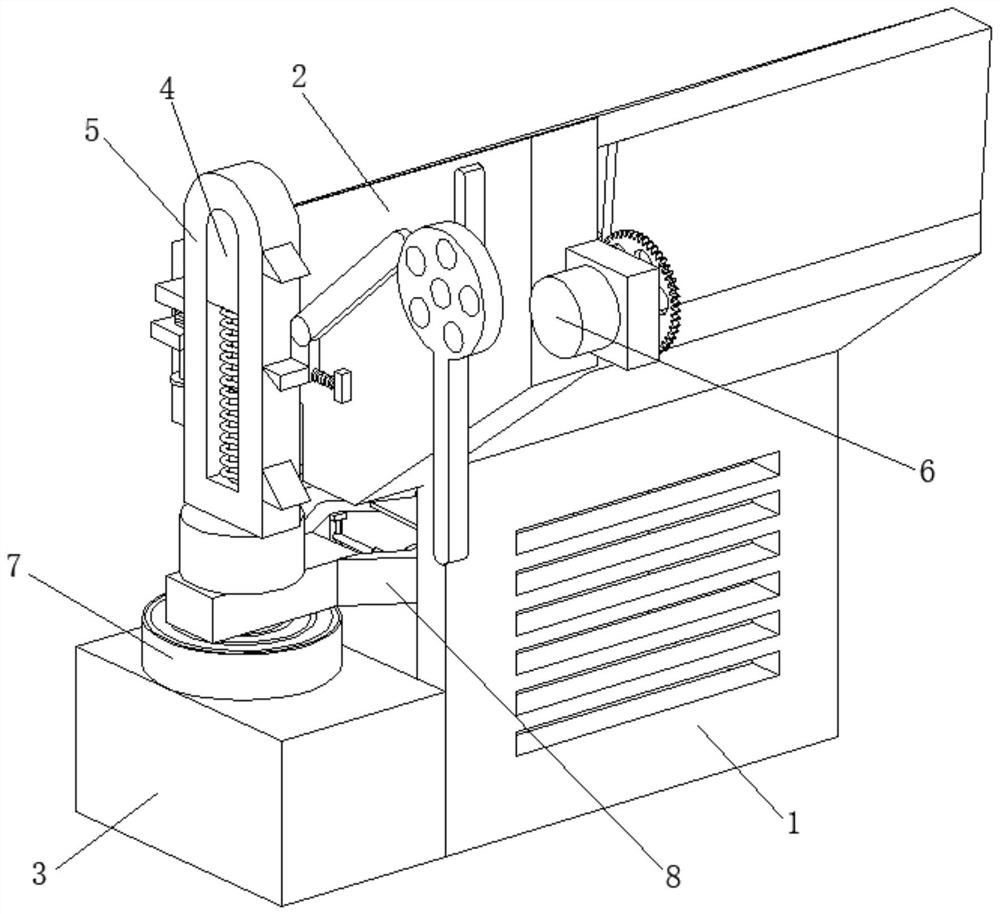

Forging device of air pick for engineering machine

InactiveCN111618226ARealize the feed actionRealize automatic flipDrop hammersHammer drivesMachineManual handling

The invention discloses a forging device of an air pick for an engineering machine and relates to the technical field of machining. The forging device of the air pick for the engineering machine solves the problems that an existing forging device needs manual operation and is troublesome in operation, and meanwhile, due to instability of handholding and other reasons, the existing forging device is prone to causing personal injuries, poor in safety and low in production efficiency. The forging device of the air pick for the engineering machine comprises a support body. A forging driving pieceis fixedly connected to the rear side of the top of the support body. A forging hammering piece is connected to the front side of the upper part of the support body in a sliding manner. An overturningadjustment plate is hinged to the left side of the support body. The upper part of the bearing sliding piece is rotationally connected with an air pick head fixing piece. An air pick head overturningintermediate transmission piece is rotationally connected with the inner side of the bearing sliding piece. The forging device of the air pick for the engineering machine can greatly replace manual operation, lowers the labor intensity of workers, is convenient to use and easy to operate, and improves production efficiency; meanwhile, the forging device does not need handholding during operation,so that personal injuries are effectively avoided, and safety is high; and the forging device of the air pick for the engineering machine has good adjustment performance.

Owner:姚富坤

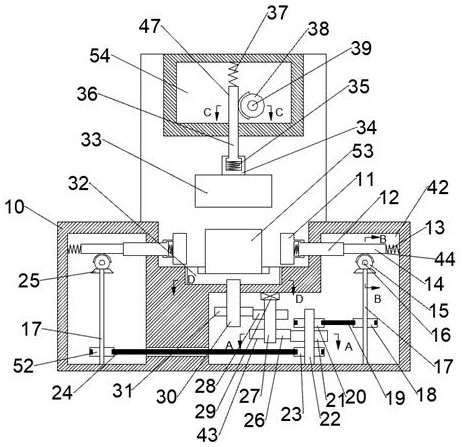

Full-automatic metal forging forming equipment

InactiveCN112475169AReduce the burden onExtended service lifeDrop hammersHammer drivesFully automaticBolt connection

The invention relates to the technical field of forging forming, and discloses full-automatic metal forging forming equipment. The full-automatic metal forging forming equipment comprises a box body,wherein a mounting plate and a supporting box are respectively welded to the front part of the box body; a limiting block is welded to the front part of the mounting plate, and a forging mechanism isarranged on the surface of the limiting block; a transmission mechanism is arranged on the right side of the mounting plate; a placing plate is connected to the top of the supporting box through bolts; and a clamping mechanism is arranged at the top of the containing plate. Through cooperative operation of the transmission mechanism, the forging mechanism and the clamping mechanism, steel can be automatically clamped and overturned while forging is conducted, therefore manual overturning of workers is not needed, the labor intensity of the workers is reduced, and the situation that the workingefficiency becomes low and even safety accidents are caused by fatigue due to long-time work of the workers is prevented. The steel can rotate intermittently through the transmission mechanism, therefore the steel cannot rotate during forging, the steel and a hammer head are prevented from interfering with each other, and the device cannot be damaged.

Owner:谢娟

Forging technique of full fiber for hollow cone axis in express locomotive

InactiveCN100382915CImprove performanceImprove mechanical propertiesDrop hammersHammer drivesMetal fibersForge

A full-fiber forge technology for manufacturing the conic hollow shaft of high-speed locomotive includes such steps as quantitative blanking, choosing steel pipe with proper diameter, fixing upper die to hammer, fixing lower die to hammer base, putting the conic core die in the heated seamless steel pipe, and forging for alternative elongating and shaping. It features the continuously distributed metallic fibers for higher mechanical performance.

Owner:DALIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com