Impact machine and a method of forming a body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

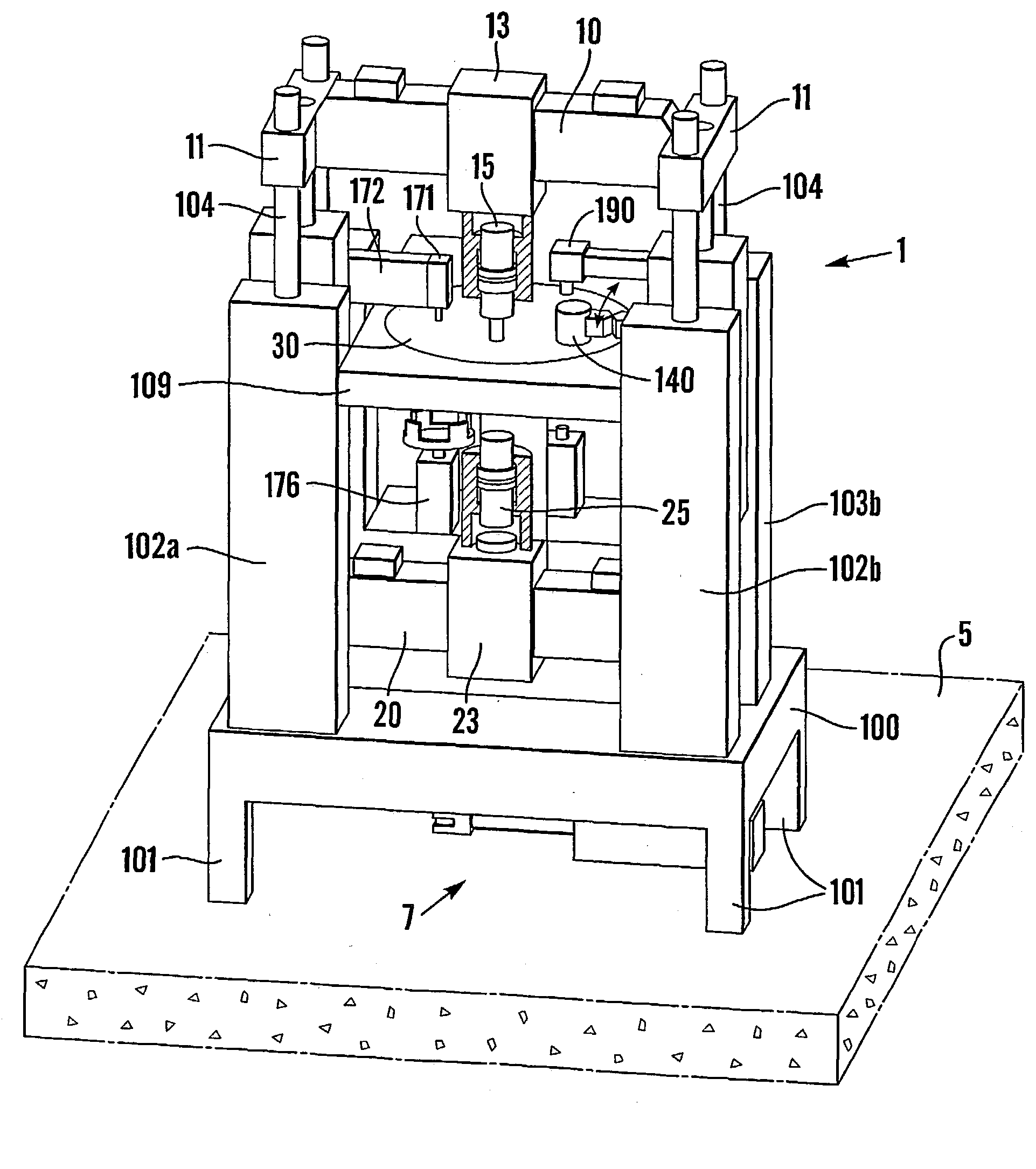

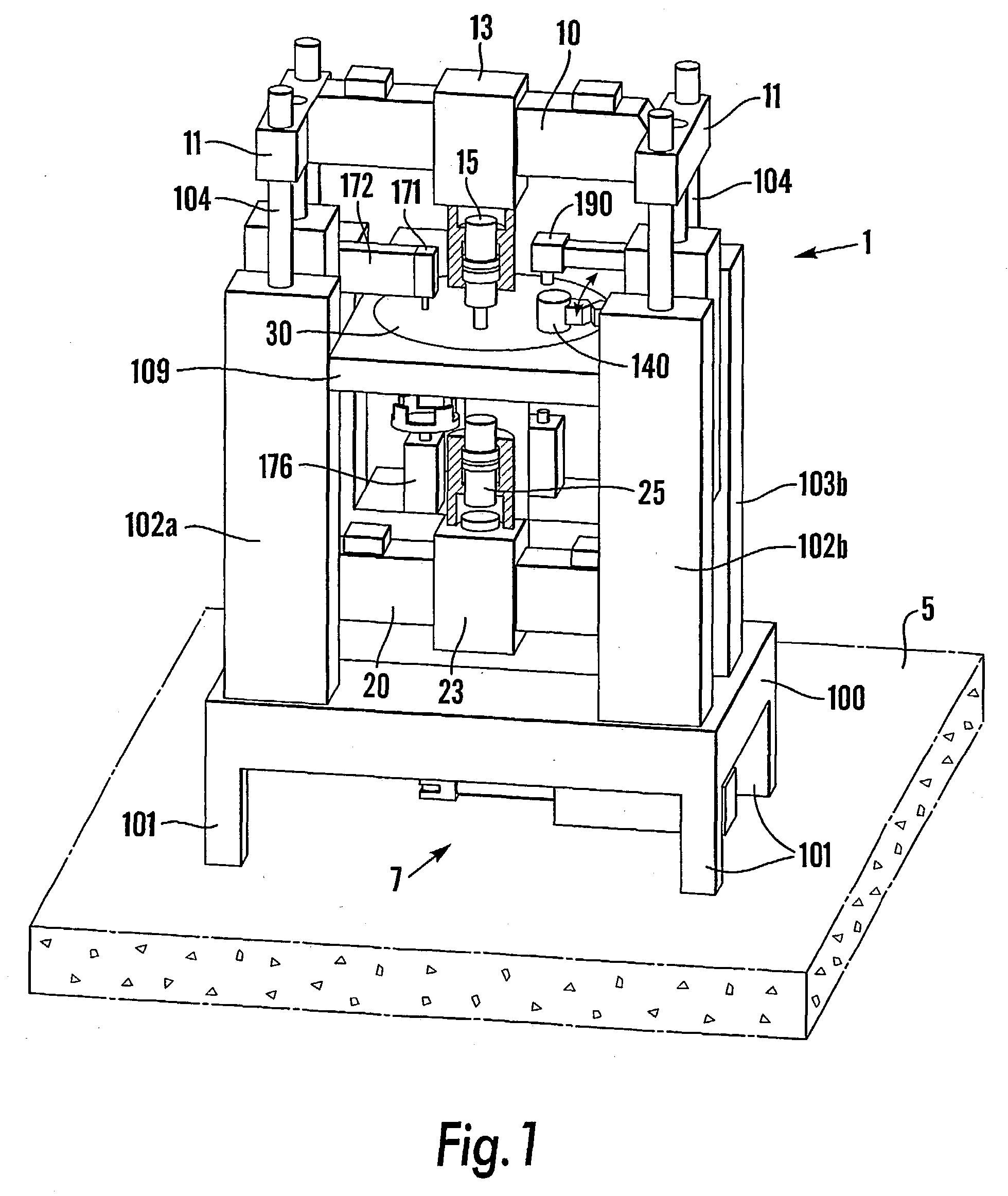

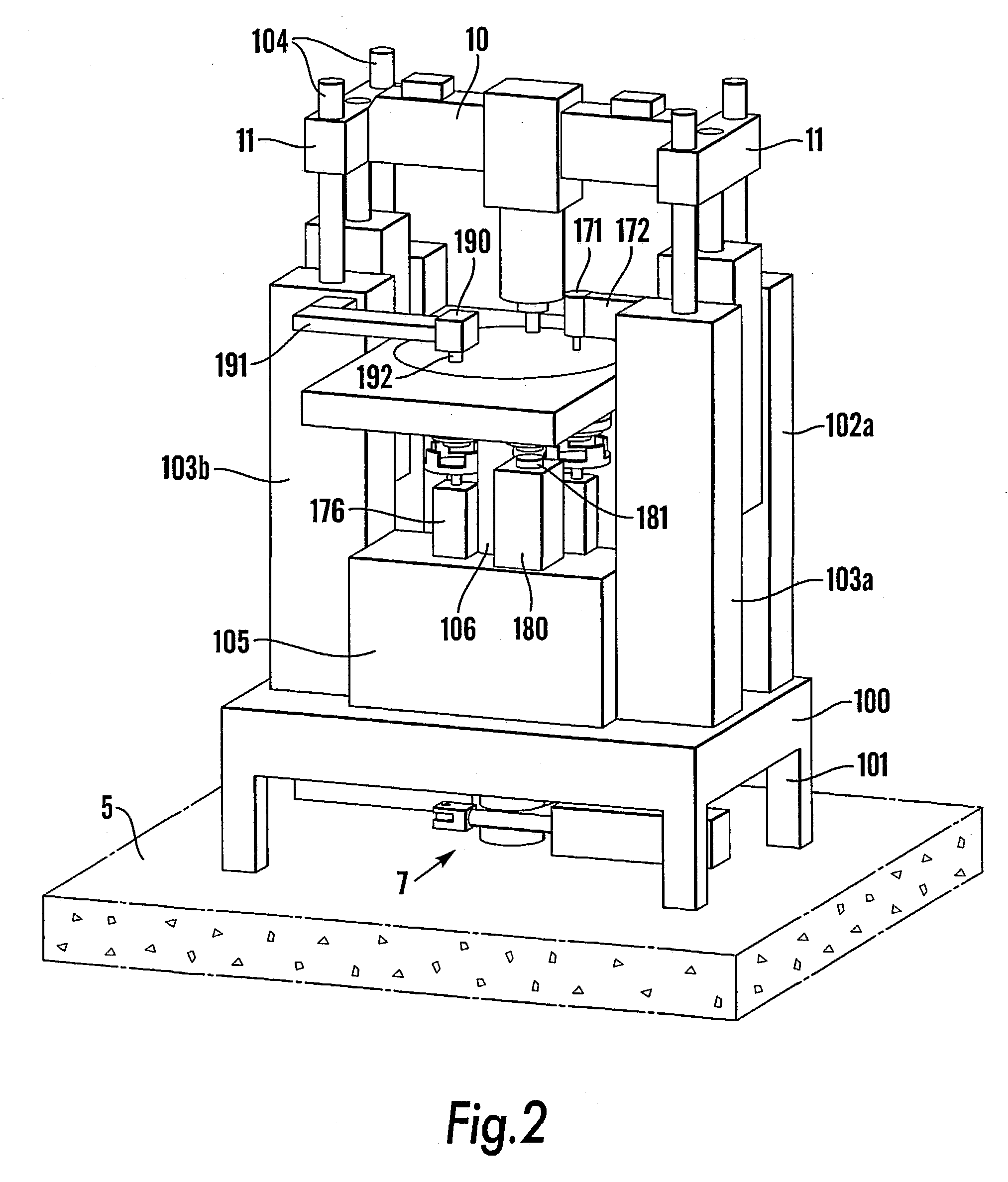

Image

Examples

Embodiment Construction

[0132] In a conceived case, the masses, the cross-section areas, and the stroke lengths were the following:

[0133] The pressure in the working chamber of the impact cylinder=300 bar.

[0134] The total mass m.sub.1 of the impact piston and the impact body (in the upper impact unit 2)=350 kg.

[0135] The stroke length s.sub.1 of the impact piston=100 mm.

[0136] The displaced volume in the return chamber of the impact cylinder=500 cm.sup.3.

[0137] The cross-section area A.sub.1 of the working chamber 245 of the converter 240=200 cm.sup.2.

[0138] The cross-section area A.sub.2 of the secondary chamber 242 of the converter 242=10 cm.sup.2.

[0139] The cross-section area A.sub.B of the four working chambers 209 of the lifting cylinders 205=50 cm.sup.2.

[0140] The pressure in the working chamber 245 of the converter 240=about 19 bar.

[0141] The total mass of the anvil assembly.congruent.7000 kg.

[0142] When the above conditions apply, the anvil assembly, i.e. the anvil 200 with the tool unit 32', will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com