Drop-forging hammer for making toothed wheels

A technology for die forging hammers and gears, applied in forging/pressing/hammer devices, drop hammers, forging/pressing/hammering machines, etc. The effect of compact power system, compact structure and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

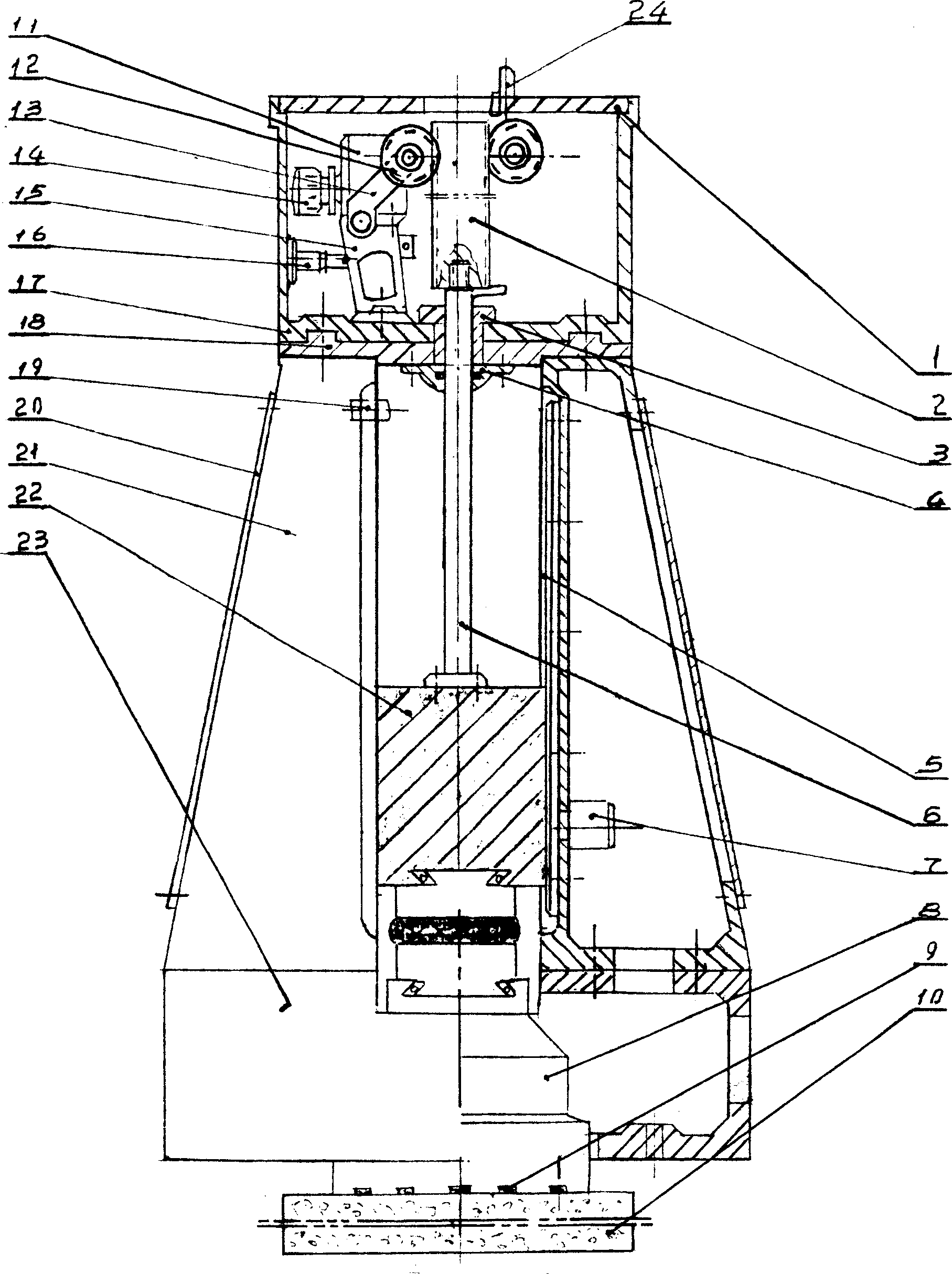

[0017] Embodiment 1: The composition of the gear die forging hammer includes an anvil, and the anvil is composed of a lower anvil 10, an upper anvil 8, and a shock absorber 9 arranged between the upper and lower anvils. Install the base 23 on the anvil. Body 21 is installed on the base, and connecting plate 18 is arranged on the top of the body. Hammer head 22 links to each other with hammer rod. A driving mechanism is installed on the hammer rod. The drive mechanism includes a casing 17 installed on the top of the body, in which a support 15, a support 13, a motor 14, a reduction box 11, a clutch 16, a gear 12 and a rack 2 are arranged. The hammer rod extends into the box body, and the connection relationship of each part in the box body is as follows: the rack is connected with the hammer rod, the support is installed on the lower part of the box body and the bracket is hinged on the support, the motor and the reduction box are installed on the bracket, and the gear Insta...

Embodiment approach 2

[0018] Embodiment 2: On the basis of Embodiment 1, a cylinder type accelerator 24 is arranged on the top of the box. When the hammer rod is lifted, the air in the cylinder is compressed, and when the hammer head is lowered, the compressed air in the accelerator expands rapidly to achieve the effect of acceleration and boosting and increase the impact force.

Embodiment approach 3

[0019] Embodiment 3: On the basis of Embodiment 1 or 2, a dust-proof pad 3 is provided between the hammer rod and the connecting plate on the body, and a bearing bush or bearing is arranged at the contact part between the hammer rod, the connecting plate and the box body, That is to ensure the flexible movement of the hammer rod, and prevent the dust generated by the blow from entering the bearing bush and other moving parts in the box, so as to reduce wear and improve the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com