Dropping grabbing tamping hammer

A technology of tamper and oil cylinder, applied in the field of tamper, can solve problems such as reducing service life, and achieve the effect of realizing work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

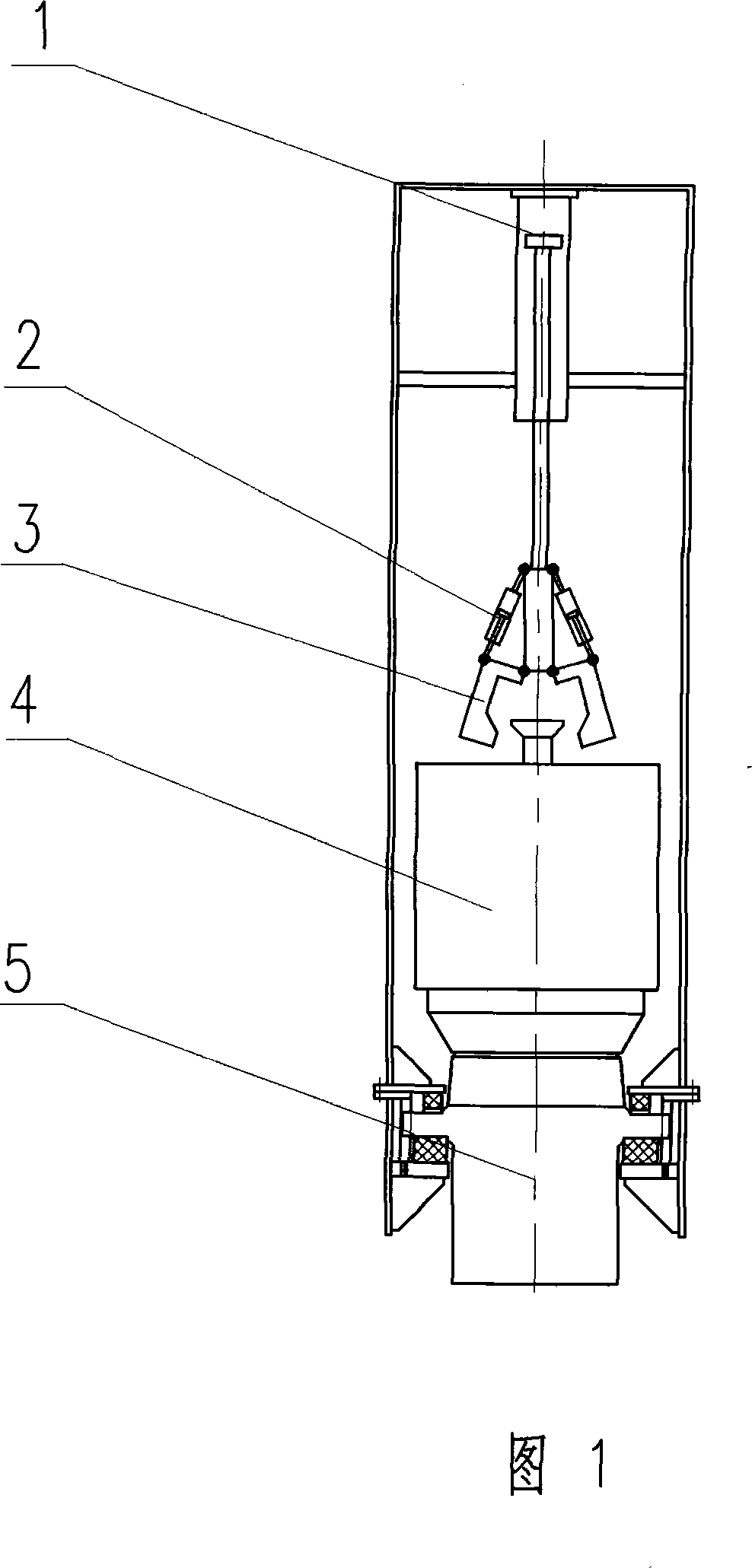

[0009] In the embodiment shown in Fig. 1, the lifting cylinder (1) is tightly coupled with the grasping and disengaging mechanism (3), and the lifting and lowering of the grasping and disengaging mechanism (3) can be realized through the expansion and contraction of the lifting cylinder (1). The expansion and contraction of the opening and closing small oil cylinder (2) can realize the grasping and loosening of the hammer core (4) by the grasping and disengaging mechanism (3). In this way, the grasping and disengaging mechanism (3) can grasp the hammer core (4), then lift it to a certain height, and then loosen the hammer core (4), so that the hammer core can fall rapidly by its own weight to meet the working requirements without driving the lifting The corresponding parts of the cylinder or other lifting device move quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com