Forging device for iron pan manufacturing

A forging and iron pot technology, applied in forging/pressing/hammer devices, manufacturing tools, cleaning methods and utensils, etc., can solve problems such as time-consuming, potential safety hazards, sore arms of craftsmen, etc. forging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

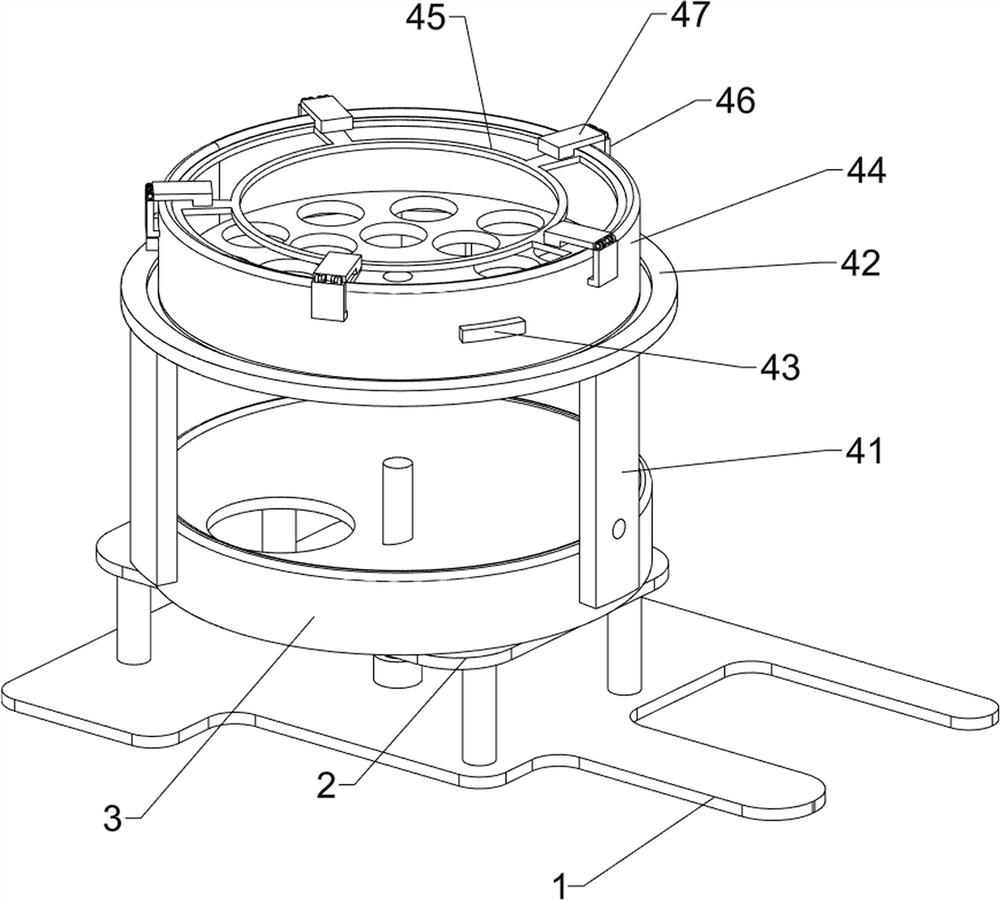

[0024] Such as Figure 1-4 As shown, a forging device for making iron pans includes a base 1, a placing platform 2, a waste hopper 3, a clamping device 4 and a hammering device 5, and the top of the base 1 is provided with a placing platform 2 connected by bolts. A waste hopper 3 is arranged on the top of the placing platform 2 , a clamping device 4 is arranged on the top of the base 1 , the clamping device 4 is located directly above the waste hopper 3 , and a hammering device 5 is arranged on the right side of the top of the base 1 .

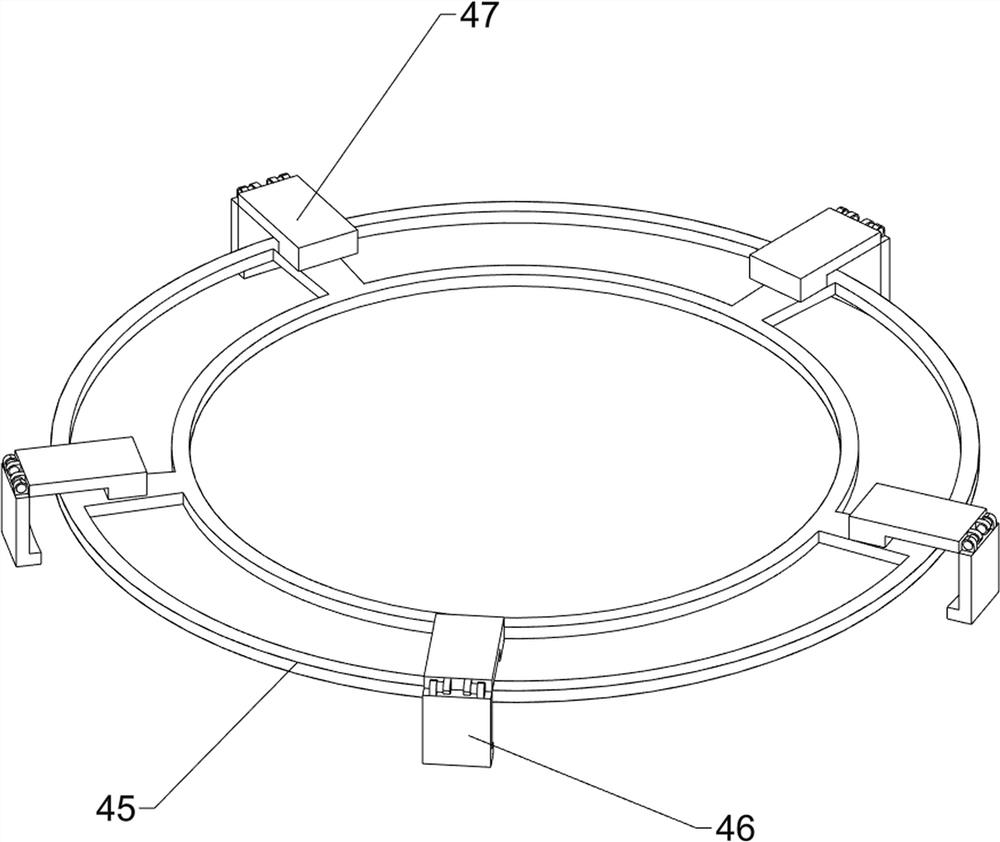

[0025] The clamping device 4 includes a support frame 41, an annular slide rail 42, a fan-shaped slide block 43, a rotating barrel 44, a placement frame 45, a fixed block 46 and a splint 47. The annular slide rail 42 is arranged on the top of the base 1 through the support frame 41, and the ring The axle center of slide rail 42 coincides with the axle center of waste material hopper 3, and fan-shaped slide block 43 is evenly slidably arranged ...

Embodiment 2

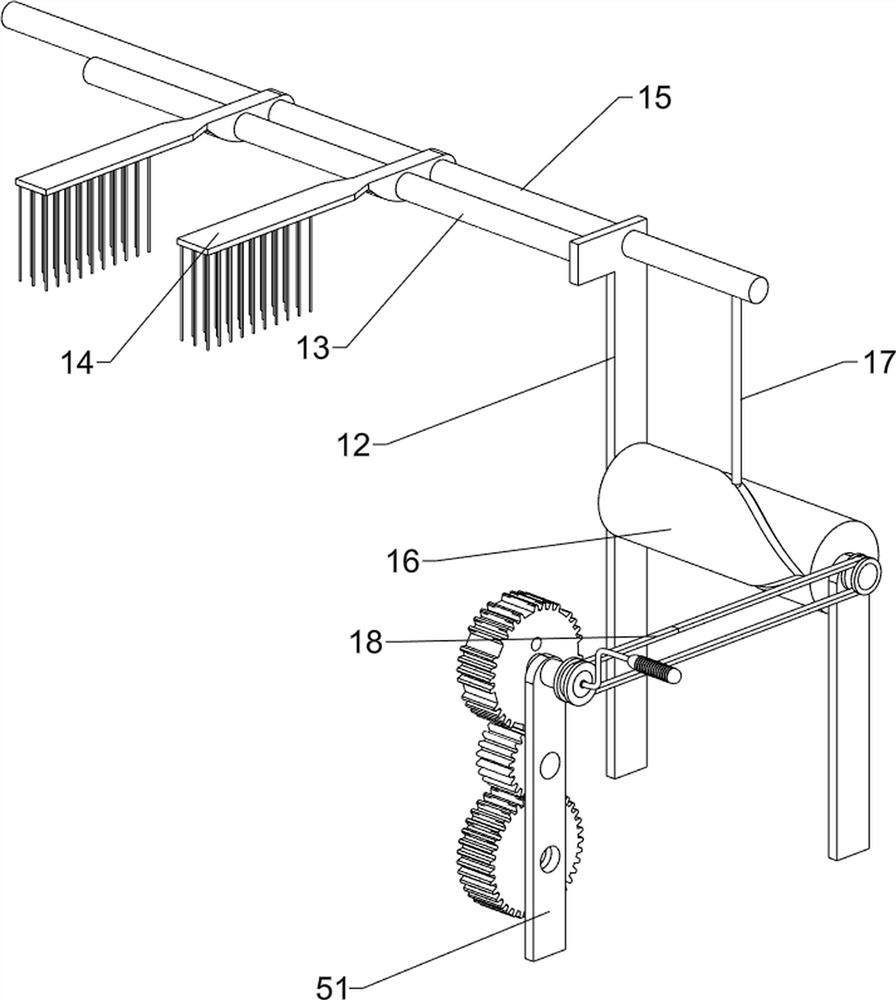

[0029] Such as Figure 5-6 As shown, on the basis of Example 1, a forging device for making iron pots also includes a bearing seat 6, a horizontal shaft 7, a large gear 8, a pinion 9, a vertical shaft 10, a bevel gear 11, and a base 1 The top is located at the position below the placement platform 2 and a bearing seat 6 is provided. A horizontal rotation shaft 7 is rotatably provided between the bearing seat 6 and the lower part of the mounting plate 51 . Pinion 9, pinion 9 meshes with bull gear 8 and missing gear 53 respectively, and the center of the bottom of rotating barrel 44 is provided with vertical shaft 10, and the lower end of vertical shaft 10 passes through placement platform 2 and is connected with base 1 in a rotational manner, and the bottom of vertical shaft 10 is connected with Bevel gears 11 are provided on the left ends of the horizontal rotation shafts 7, and the two bevel gears 11 mesh.

[0030] The staff turns the rocking bar 52, and the rocking bar 52 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com