Forging device of air pick for engineering machine

A technology of engineering machinery and pneumatic picks, which is applied in hammer driving devices, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of manual operation, low production efficiency, personal injury, etc., and achieve Avoid personal injury, improve production efficiency, and have high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

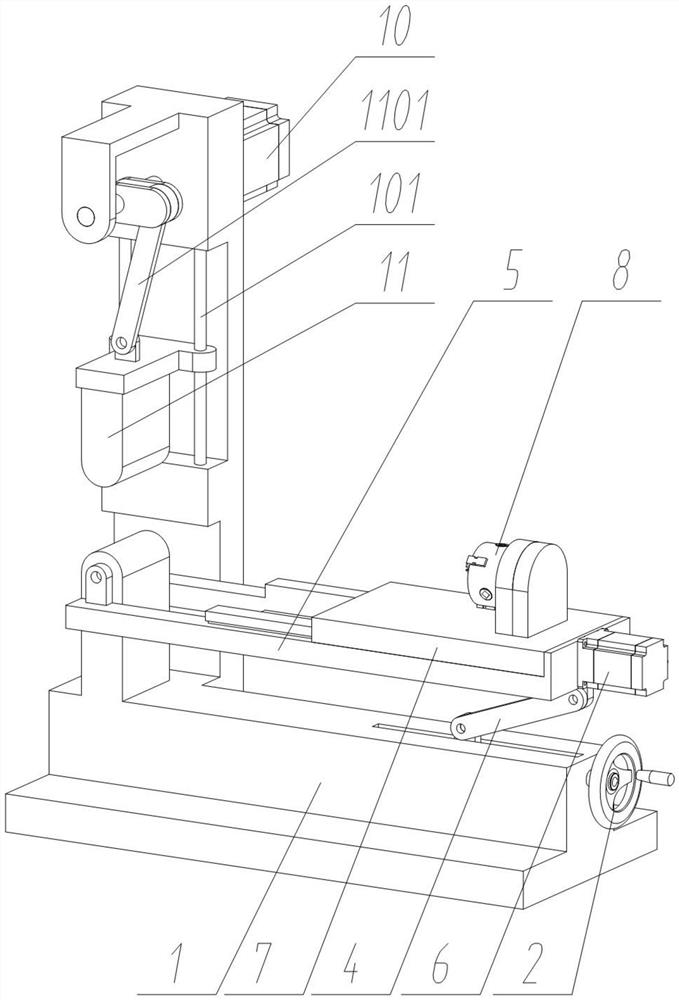

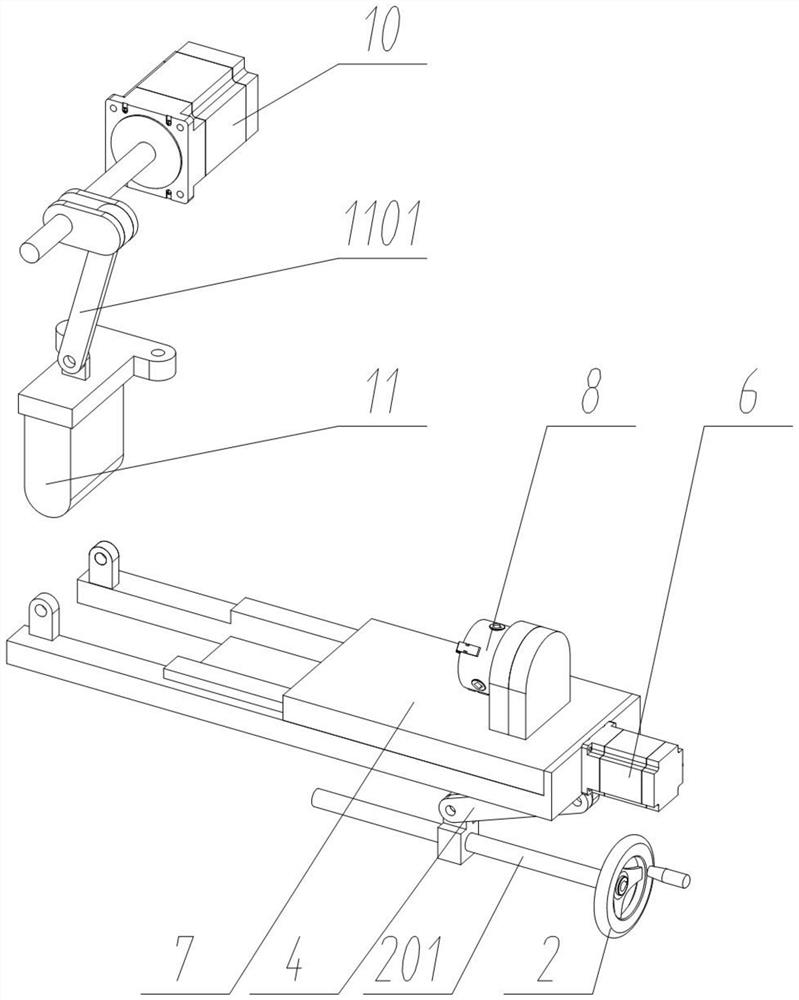

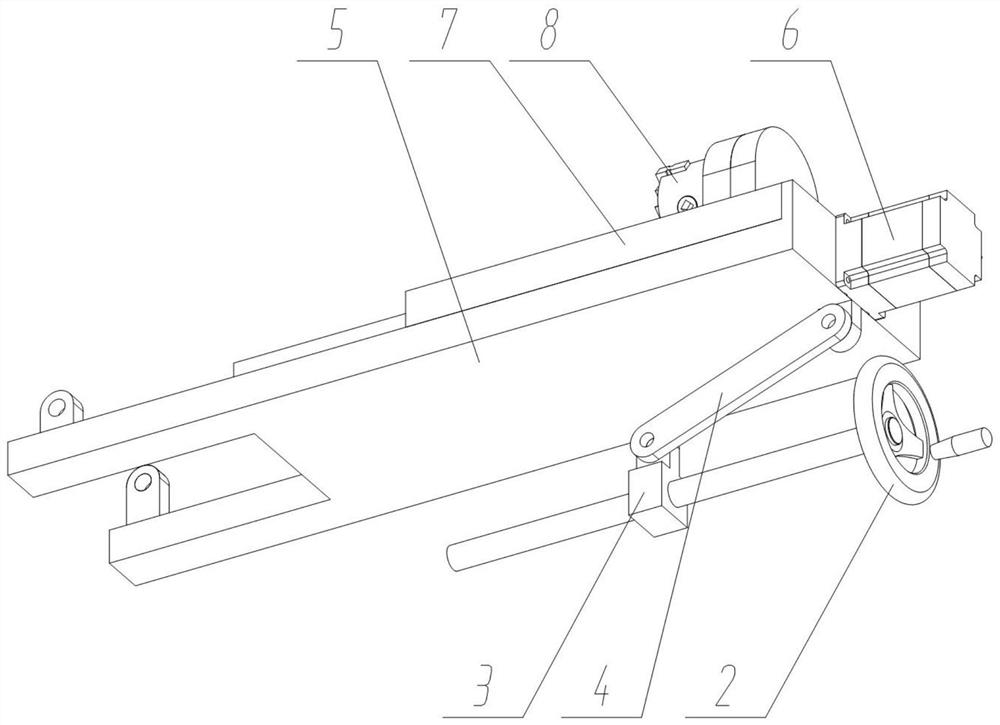

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a pneumatic pick forging device for construction machinery, including a bracket body 1; a group of forging drive parts 10 is fixedly connected to the top rear of the bracket body 1; Forged hammering parts 11; the lower right side of the bracket body 1 is rotatably connected with a set of adjustment handwheels 2; the inner side of the lower part of the bracket body 1 is slidingly connected with a set of adjustment sliders 3; the top hinge of the adjustment slider 3 is connected with a set of adjustment linkages 4. The left side of the support body 1 is hinged to a group of flip adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com