Gear blank forging device

A blank and gear technology, applied in the field of gear forging, can solve the problems of low production efficiency, hidden safety hazards, and labor consumption, and achieve the effects of easy operation, avoiding hidden safety hazards, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

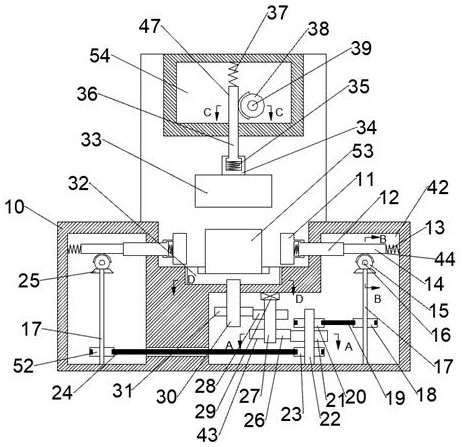

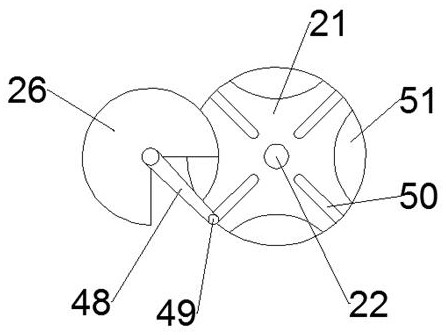

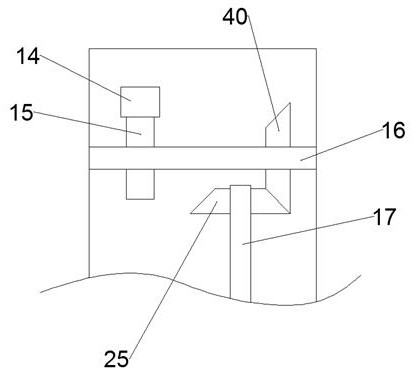

[0017] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] combined with Figure 1-6 The described gear blank forging equipment includes a machine tool housing 10, a transmission chamber 42 is arranged in the machine tool housing 10, a transmission mechanism 43, a driven mechanism 44 and a knocking mechanism 45 are arranged in the transmission chamber 42, and the The upper end of the machine tool housing 10 is provided with a lifting cavity 46, and the lifting cavity 46 is provided with a hammering mechanism 47. The transmission mechanism 43 includes a rotating motor 29 fixedly connected to the inner wall of the transmission cavity 42. The rotating motor 29 is connected with a rotating shaft 27, the rotating shaft 27 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com