Radial asymmetric feeding device driven by liquefied natural gas

A liquefied natural gas, asymmetric technology, applied in the driving device of the hammer, metal processing equipment, drop hammer, etc., can solve the problems of high forging frequency, loud machine noise, difficult to achieve, etc., to achieve high cutting section quality and production. The effect of high efficiency and high feeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

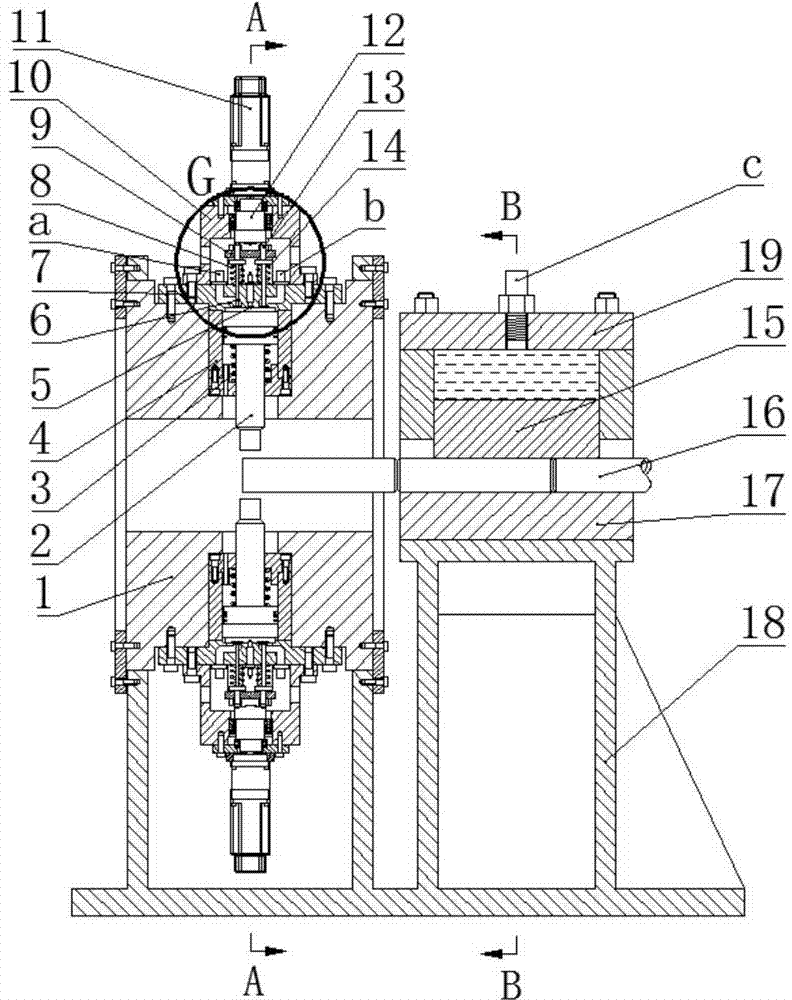

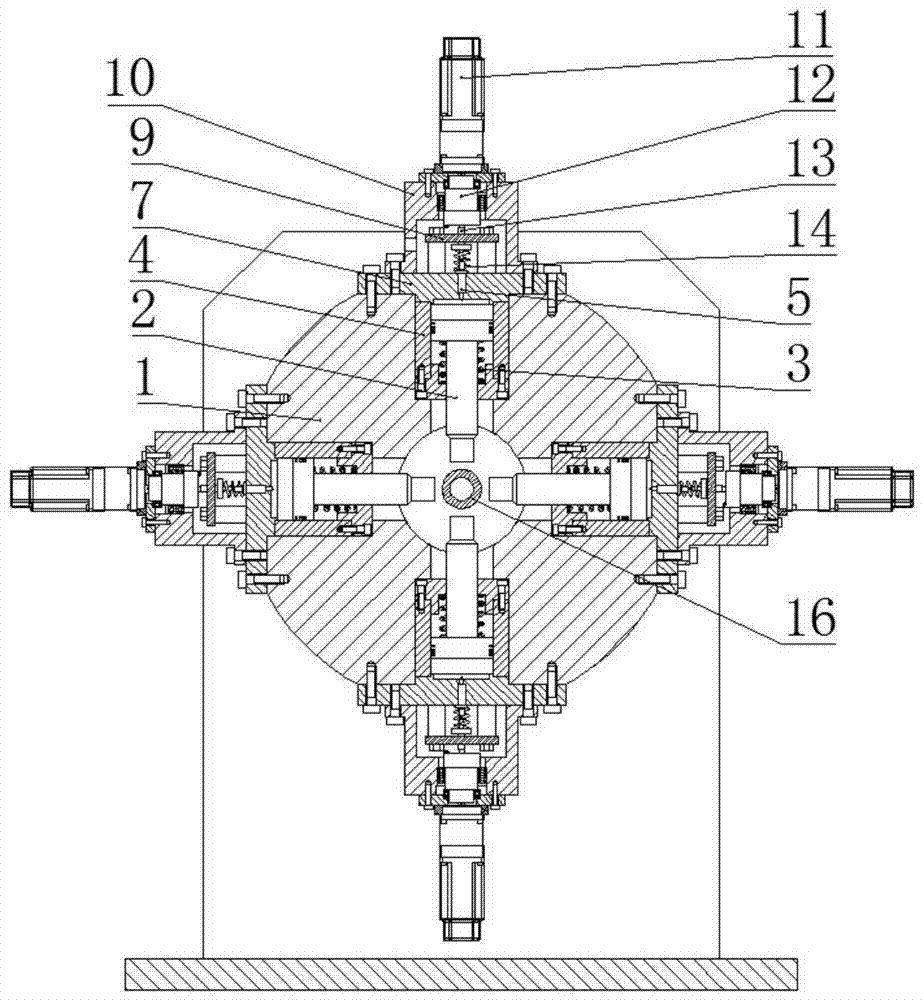

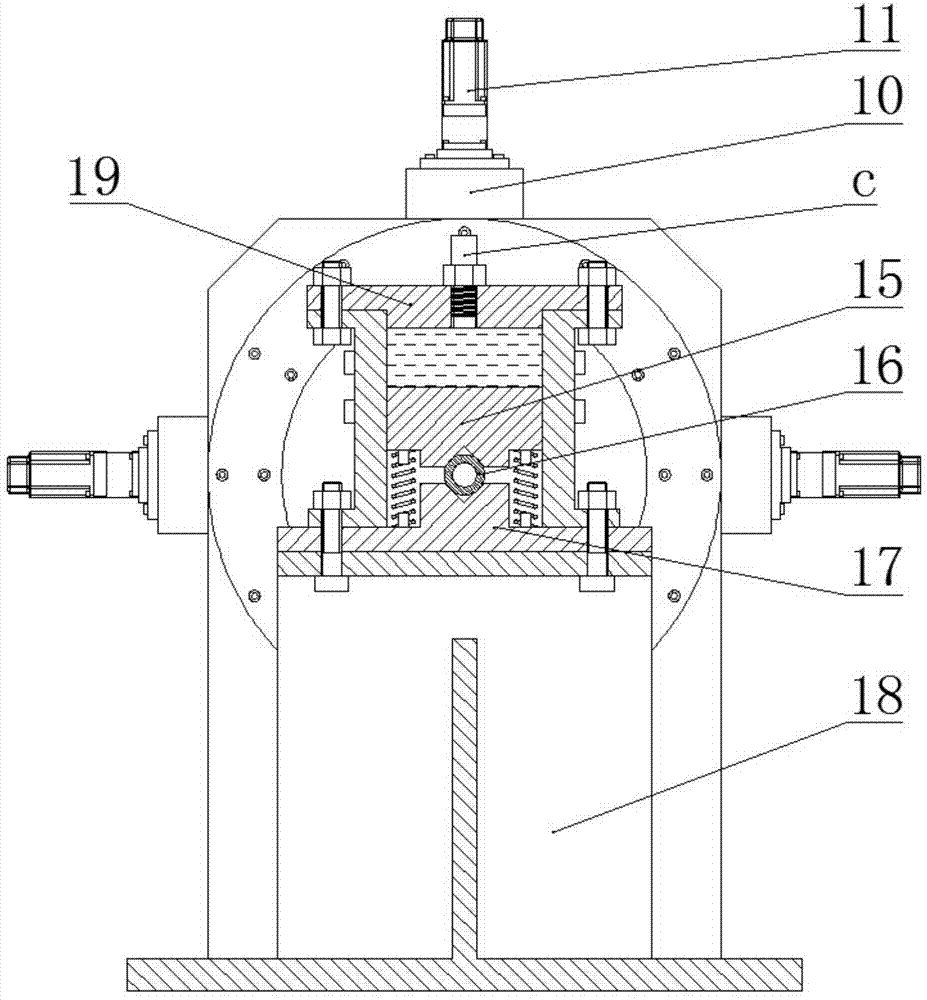

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a radial asymmetric feeding device driven by liquefied natural gas includes a main body and a gas distribution mechanism and a clamping mechanism matched with it, wherein the main body includes a main cylinder mounted on the frame 18 through two cover plates 1. The main cylinder body 1 is evenly distributed along the circumferential direction with four sets of the same forging mechanism consisting of the cylinder barrel 4, the spring 3 and the hammer head 2. Each set of forging mechanism is fixed on the main cylinder body 1 through the cylinder head 7, and the cylinder head 7 is equipped with a corresponding gas distribution mechanism;

[0019] The gas distribution mechanism includes an intake valve composed of an intake plug 6 and an intake spring 8 and an exhaust valve composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com