High-speed air-actuated hammer-forging device

A forging hammer, high-speed technology, applied in the field of high-speed pneumatic forging hammer device, can solve the problems of high cost, liquid impact phenomenon and high cost of heavy presses, and achieve the effect of good promotion and use value, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

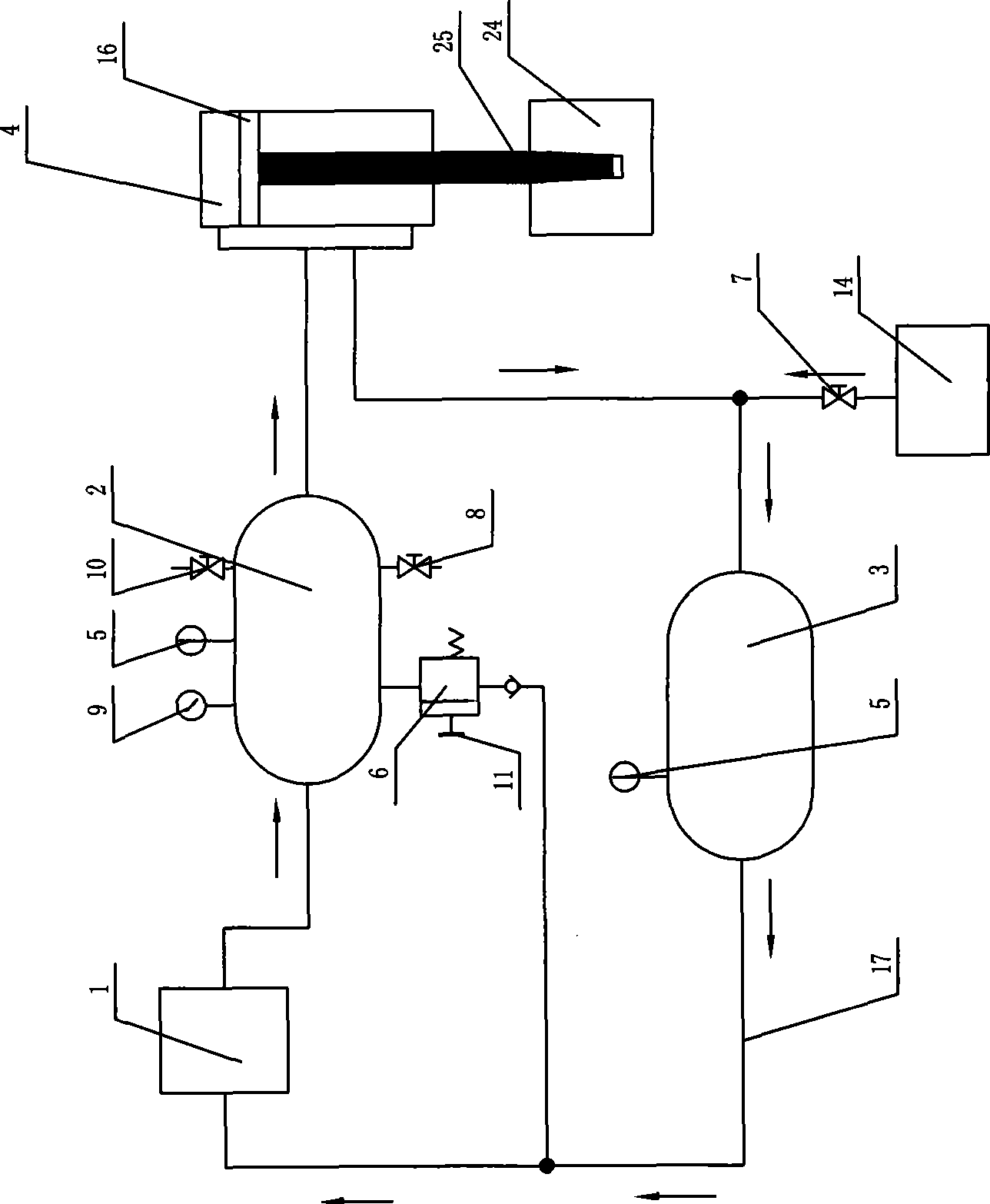

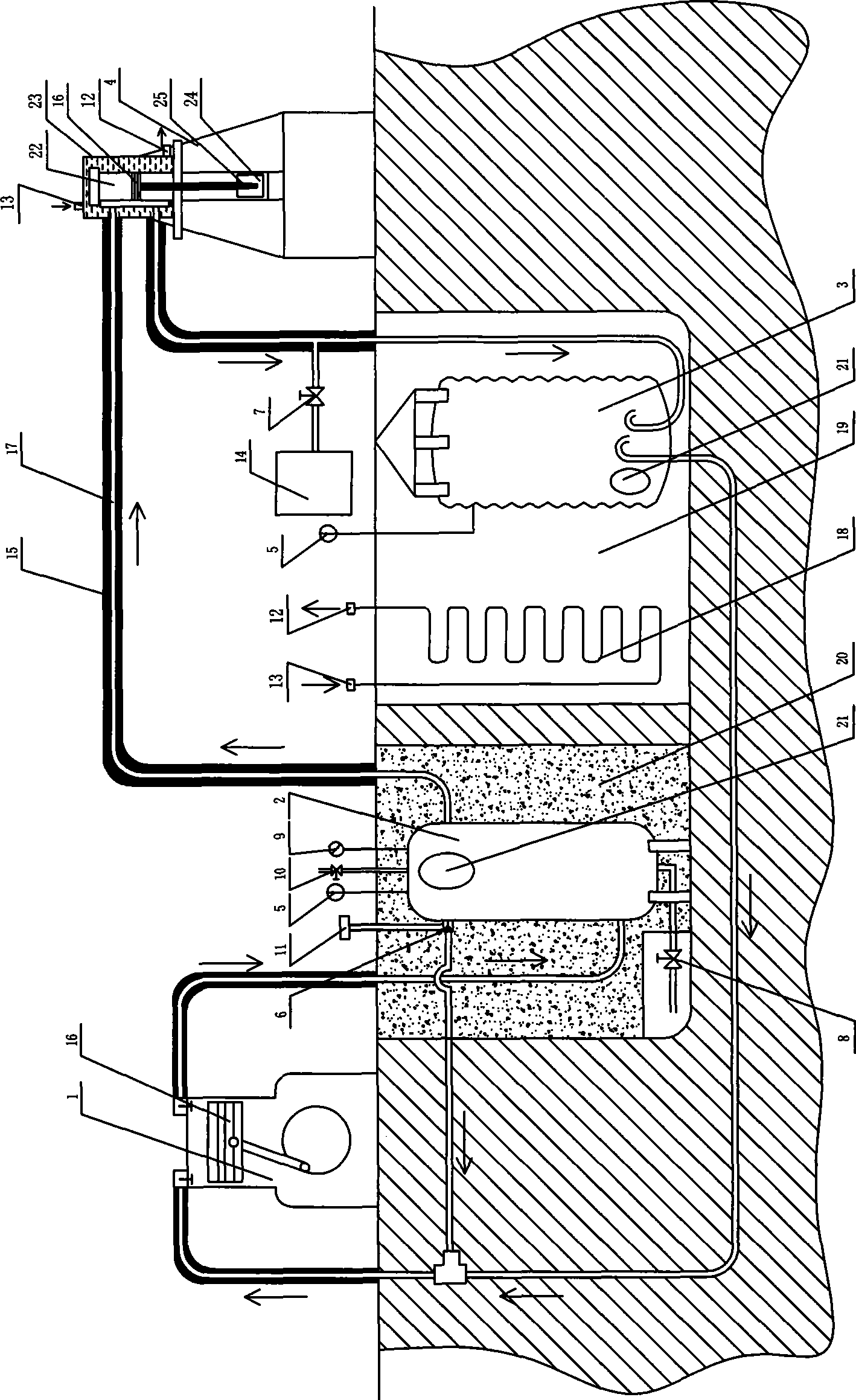

[0020] The high-speed pneumatic forging hammer device of the present invention comprises a compressor 1, an air storage tank 2, a buffer air bag 3, a forging hammer 4, an inflator 14, and an air delivery pipe 17. The air outlet of the buffer air bag 3 is connected to the compressor through the air delivery pipe 17. The air inlet of compressor 1 is connected, the air outlet of compressor 1 is connected with the air inlet of air storage tank 2 through air delivery pipe 17, the air outlet of air storage tank 2 is connected with forging hammer 4 through air delivery pipe 17, and the forging hammer 4 communicate with the air inlet of the buffer airbag 3 through the air delivery pipe 17; the inflator 14 communicates with the air inlet of the buffer airbag 3 through the air delivery pipe 17; 17 is provided with an air supplement valve 7.

[0021] The inflator 14 is a small molecular sieve nitrogen generator, and the nitrogen purity reaches 99.99%.

[0022] The gas outlet of the gas ...

Embodiment 2

[0031] The high-speed pneumatic forging hammer device of the present invention comprises a compressor 1, an air storage tank 2, a buffer air bag 3, a forging hammer 4, an inflator 14, and an air delivery pipe 17. The air outlet of the buffer air bag 3 is connected to the compressor through the air delivery pipe 17. The air inlet of compressor 1 is connected, the air outlet of compressor 1 is connected with the air inlet of air storage tank 2 through air delivery pipe 17, the air outlet of air storage tank 2 is connected with forging hammer 4 through air delivery pipe 17, and the forging hammer 4 communicate with the air inlet of the buffer airbag 3 through the air delivery pipe 17; the inflator 14 communicates with the air inlet of the buffer airbag 3 through the air delivery pipe 17; 17 is provided with an air supplement valve 7.

[0032] The inflator 14 is a small air dryer with an air dew point of -40°C.

[0033] The gas outlet of the gas storage tank 2 is communicated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com