Hydraulic forging device

A hydraulic and forging technology, which is used in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machines, etc. Improve processing quality, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

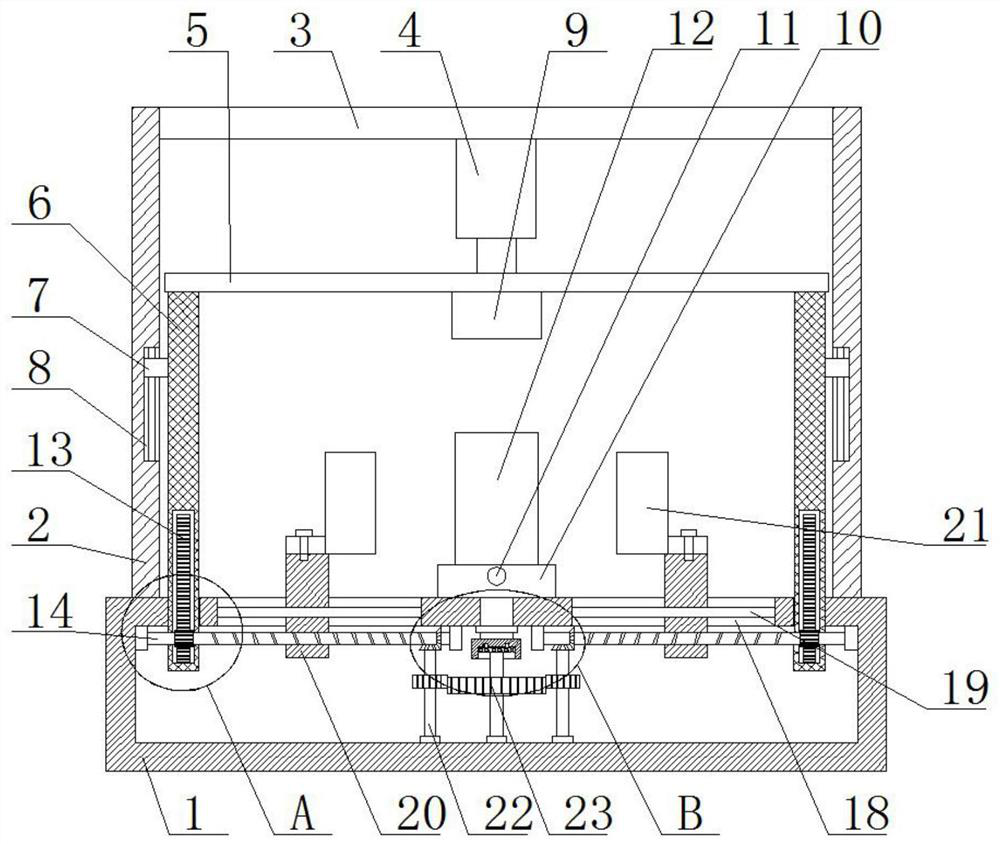

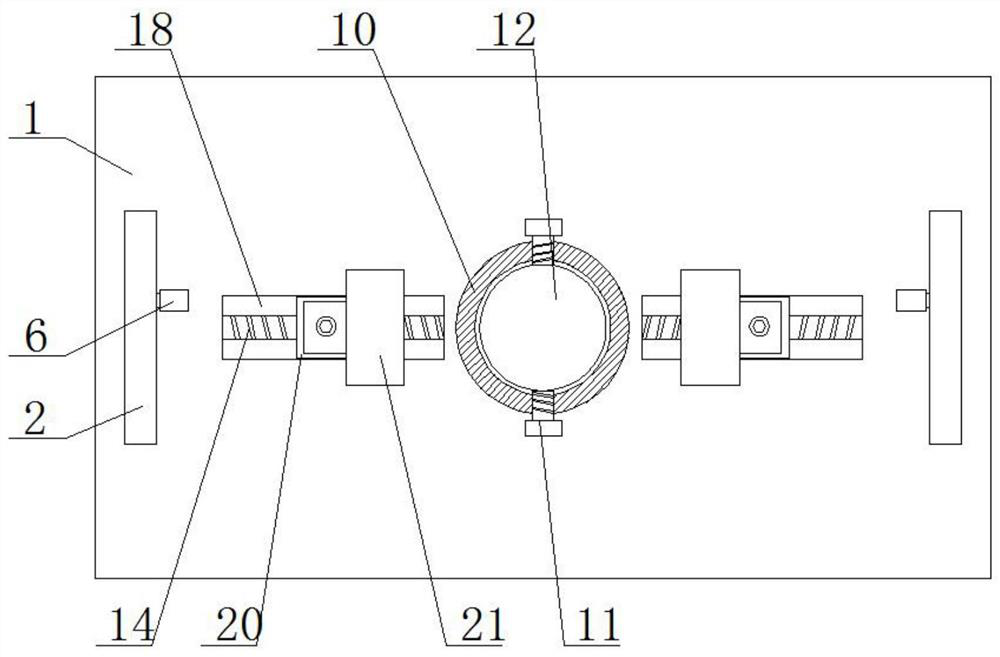

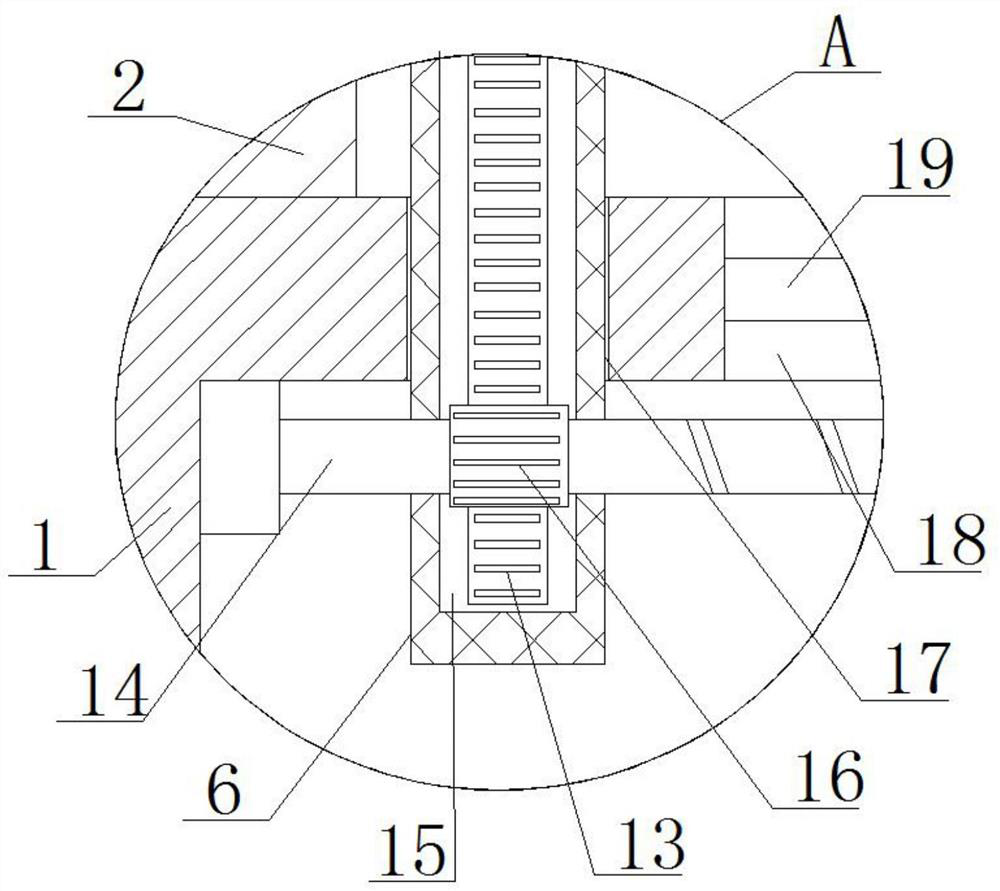

[0027] refer to Figure 1-6 , a hydraulic forging device, comprising a fixed box 1, the top of the fixed box 1 is provided with a placement seat 10, the top of the placement seat 10 is provided with a placement groove, a forging part 12 is placed in the placement groove, and the top of the fixed box 1 is fixedly installed with Two welding rods 2, the top of the two welding rods 2 is fixedly installed with the same ejector rod 3, the bottom of the ejector rod 3 is fixedly connected with a hydraulic push rod 4, and the output shaft of the hydraulic push rod 4 is fixedly connected with a connecting rod 5, The bottom of connecting rod 5 is fixedly connected with top forging head 9, and the bottom of connecting rod 5 is fixedly installed with two vertical rods 6, and two vertical rods 6 are all slidingly connected with fixed box 1, and there are two symmetrical rotations installed in fixed box 1. Threaded rod 14, two threaded rods 14 are respectively adapted to two vertical rods 6,...

Embodiment 2

[0036] refer to Figure 1-6, a hydraulic forging device, comprising a fixed box 1, the top of the fixed box 1 is provided with a placement seat 10, the top of the placement seat 10 is provided with a placement groove, and a forging part 12 is placed in the placement groove, and the top of the fixing box 1 is fixed by welding Two welding rods 2 are installed, the tops of the two welding rods 2 are fixedly installed with the same ejector rod 3 by welding, the bottom of the ejector rod 3 is fixedly connected with a hydraulic push rod 4, and the output shaft of the hydraulic push rod 4 passes The connecting rod 5 is fixedly connected with the screw, and the bottom of the connecting rod 5 is fixedly connected with the top forging head 9 through the screw, and the bottom of the connecting rod 5 is fixedly installed with two vertical rods 6 by welding, and the two vertical rods 6 slide with the fixed box 1 Connection, two threaded rods 14 are installed symmetrically through the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com