Bracelet repairing and rounding equipment

A technology of bracelets and equipment, which is applied in the field of bracelet repairing equipment, can solve problems such as time-consuming and laborious, low efficiency, and bracelets that are not rounded, and achieve the effects of uniform beating, improved rounding efficiency, and good rounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

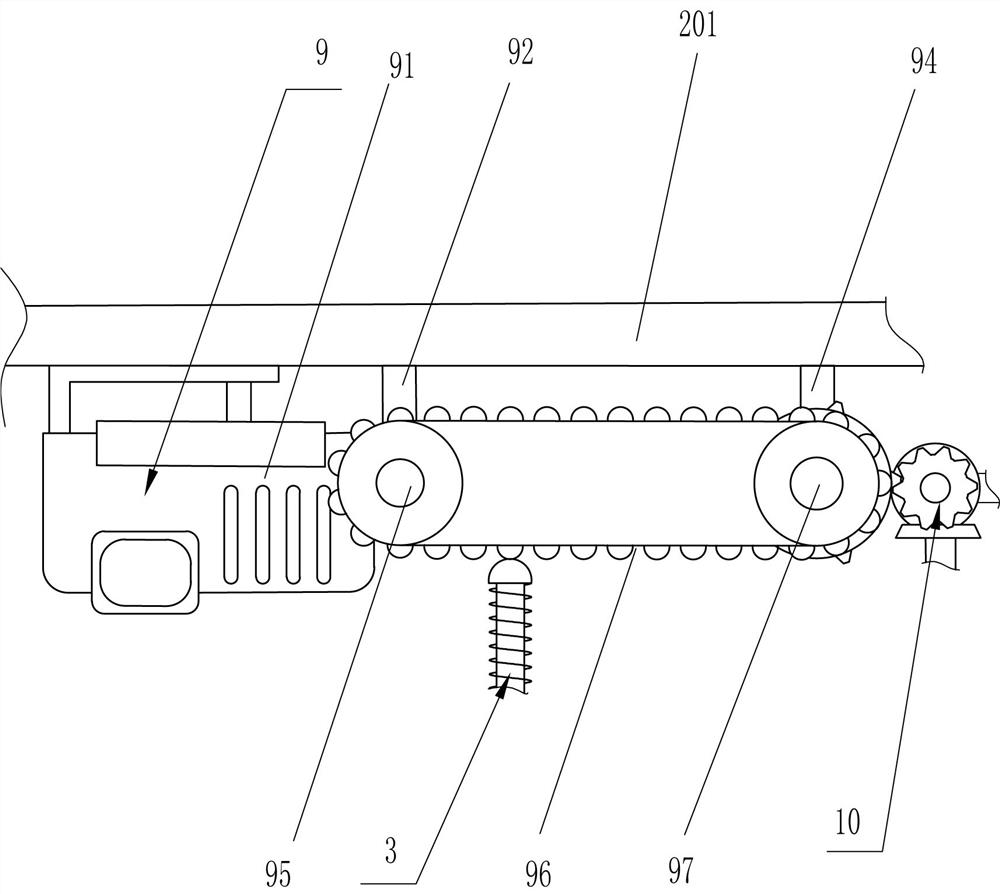

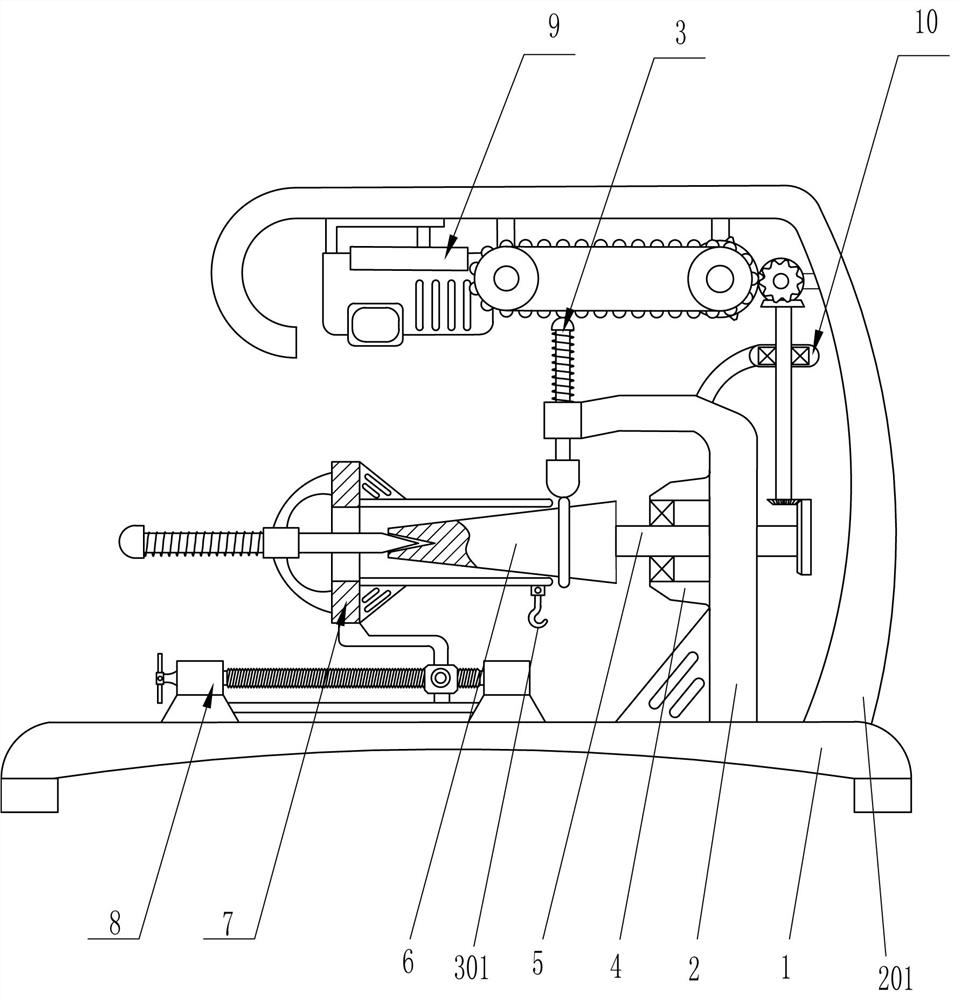

[0030] A bracelet repair full circle device such as figure 1 As shown, it includes a base 1, a mounting frame 2, a support frame 201, a knocking assembly 3, a first bearing seat 4, a first rotating rod 5, a round platform 6, a stabilizing device 7, a moving device 8 and a driving device 9, specifically :

[0031] One side of the base 1 is connected with a mounting frame 2, the base 1 is connected with a support frame 201, the upper side of the mounting frame 2 is provided with a knocking assembly 3, and the mounting frame 2 is near the knocking assembly 3 side A first bearing seat 4 is connected, and a first rotating rod 5 is connected inside the first bearing seat 4. A round table 6 is connected to one side of the first rotating rod 5 near the striking assembly 3, and the other side of the round table 6 A stabilizing device 7 is provided, the round table 6 is in contact with the stabilizing device 7, a mobile device 8 is provided on the other side of the base 1, the mobile d...

Embodiment 2

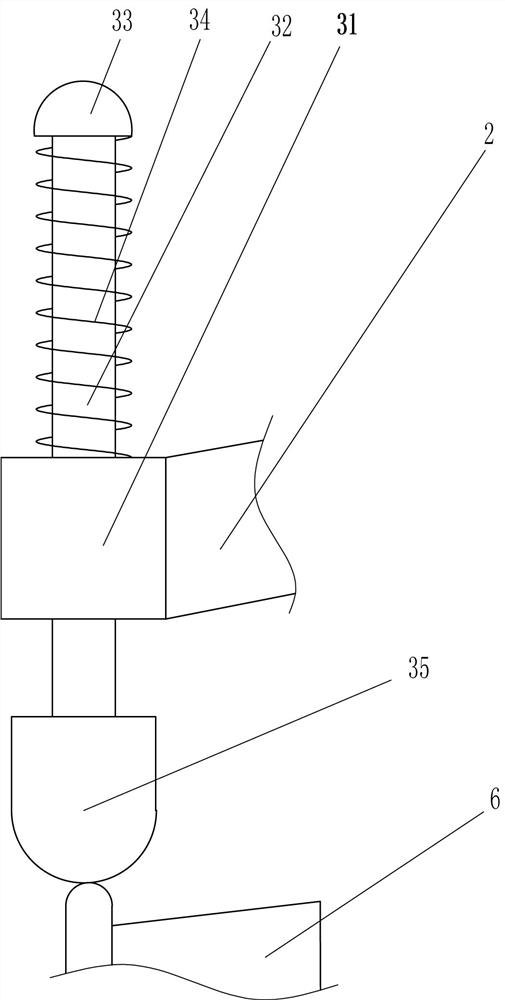

[0034] A bracelet repair full circle device such as Figure 2-5As shown, the knocking assembly 3 includes a first guide sleeve 31, a guide rail 32, a contact block 33, a first elastic member 34 and a knocking block 35, specifically:

[0035] The left side of the mounting bracket 2 is provided with a first guide sleeve 31, and a guide rail 32 is slidably connected to the inside of the first guide sleeve 31, and a contact block 33 is provided on the top of the guide rail 32, and the contact block 33 is connected to the driving device 9 For contact, a first elastic member 34 is connected between the bottom of the contact block 33 and the top of the first guide sleeve 31 , and a knocking block 35 is connected to the bottom of the guide rail 32 .

[0036] In the specific operation of this embodiment, when the bracelet needs to be repaired to a full circle, the driving device 9 is rotated by starting the driving device 9 to contact the contact block 33, and the contact block 33 is p...

Embodiment 3

[0048] A bracelet repair full circle device such as Figure 6 As shown, a transmission device 10 is also included, and the transmission device 10 includes a support rod 101, a third bearing seat 102, a second rotating rod 103, a first bevel gear 104, a second bevel gear 105, and a third bevel gear 106 , fixed rod 107, third rotating shaft 108, fourth bevel gear 109, circular gear 1010 and missing gear 1011, specifically:

[0049] The upper part of the mounting frame 2 is provided with a support rod 101, the third bearing seat 102 is arranged on the support rod 101, the second rotating rod 103 is installed in the third bearing seat 102, and the bottom of the second rotating rod 103 A first bevel gear 104 is provided, a second bevel gear 105 is provided on the right part of the first rotating rod 5, and the first bevel gear 104 meshes with the second bevel gear 105, and the top of the second rotating rod 103 is provided with The third bevel gear 106, the support frame 201 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com