Moxa beating machine for wormwood

A technology of velvet machine and wormwood, applied in the field of velvet machine, can solve the problems of low efficiency, insufficient beating and low quality of wormwood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

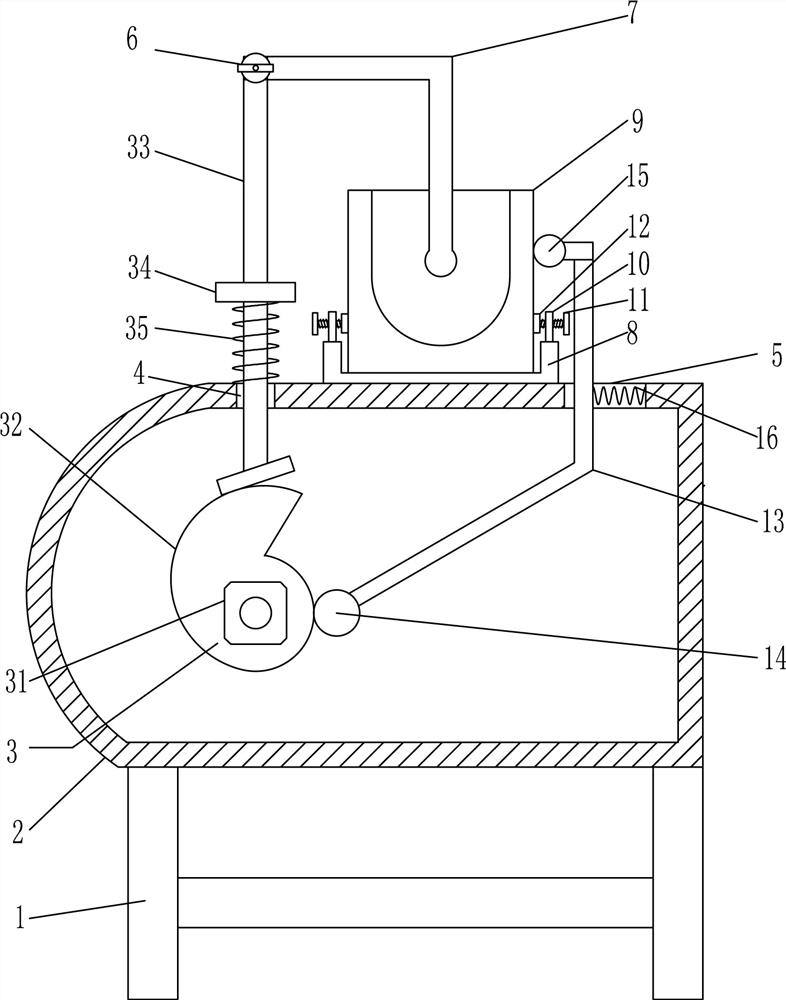

[0019] A kind of wormwood fleece machine, such as figure 1 As shown, it includes a support frame 1, a box body 2, a lifting mechanism 3, a fastening bolt 6, a pestle 7, a groove plate 8 and a mortar 9. The top of the support frame 1 is provided with a box body 2, and the left side of the box body 2 There is a lifting mechanism 3, the upper part of the lifting mechanism 3 is disassembled and a pestle 7 is provided, and the connection between the pestle 7 and the lifting mechanism 3 is provided with a fastening bolt 6, and a groove plate 8 is arranged in the middle of the top of the box body 2, and the groove plate 8 A mortar 9 is placed on it, and the pestle 7 is positioned directly above the mortar 9.

[0020] The lifting mechanism 3 includes a servo motor 31, a cam 32, a lifting rod 33, a pressing plate 34 and a first spring 35, the left side of the casing 2 is provided with a servo motor 31, and the output shaft of the servo motor 31 is provided with a cam 32, and the casing...

Embodiment 2

[0024] On the basis of Example 1, such as figure 1 As shown, it also includes a fixed block 10, a fixed nut 11 and a rubber block 12. The left and right sides of the top of the groove plate 8 are symmetrically provided with a fixed block 10, and the middle part of the fixed block 10 is equipped with a fixed nut 11. Rubber blocks 12 are all provided.

[0025] Also includes moving bar 13, roller 14, ball hammer 15 and second spring 16, has rectangular through hole 5 on the right side of box body 2 top, and rectangular through hole 5 is positioned at groove plate 8 right side, and slides in rectangular through hole 5 The type is provided with a moving rod 13, the rotating type of the lower part of the moving rod 13 is provided with a roller 14, the roller 14 is in contact with the cam 32, the upper part of the moving rod 13 is provided with a spherical hammer 15, and the spherical hammer 15 is in contact with the mortar 9, and the right side of the moving rod 13 is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com