Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Avoiding the Cons of Damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

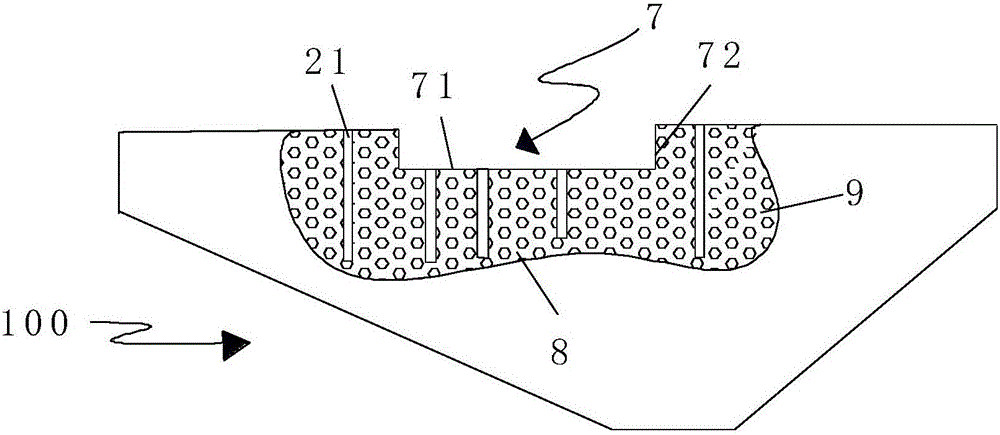

Full-automatic double-layer meeting limo

InactiveCN105216686AHigh degree of automationReduce manual workloadItem transportation vehiclesVehicle frameEngineering management

A full-automatic double-layer meeting limo comprises a traction car and a folding carriage, wherein the traction car is provided with a frame; the folding carriage comprises a front board, a rear board, a foldable base board, a left side board, a right side board, a top board, a left foldable top board, a right foldable top board, a lengthened flange board, an auxiliary flange board, a middle flange board, a top flange board and a floor board, wherein a hydraulic press is arranged between the front board, the rear board and the top board; the left top board and the right top board are hinged with the top board as well as the left side board and the right side board; the left side board and the right side board are hinged with the base board; the base board is hinged with the frame; the traction car further comprises an automatic unfolding mechanism which drives the base board, the left side board and the right side board to unfold and combines with the unfolding top board, the left top board and the right top board to form the carriage internally; the middle flange board is hinged with the front board and the rear board and fixed with the top board; the lengthened flange board is hinged with the front board and the rear board and fixed with the left side board and the right side board; the auxiliary flange board is hinged with the lengthened flange board and fixed with the left top board, the right top board and the middle flange board; the top flange board is hinged with the auxiliary flange board and fixed with the middle flange board, the left top board and the right top board; the floor board is hinged with the front board and the rear board and fixed with the side board and the lengthened flange board; and a corridor is arranged on the floor board.

Owner:QINGDAO FUMINGDA IND EQUIP

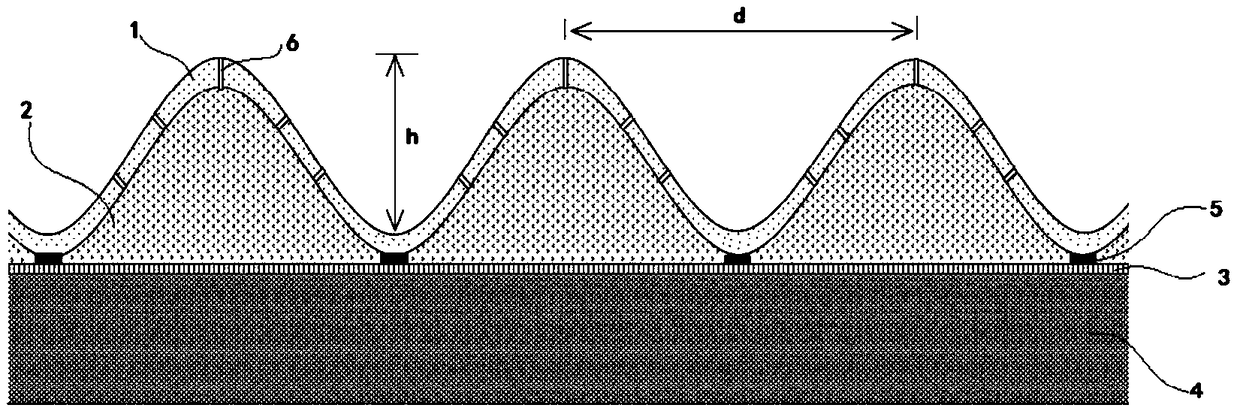

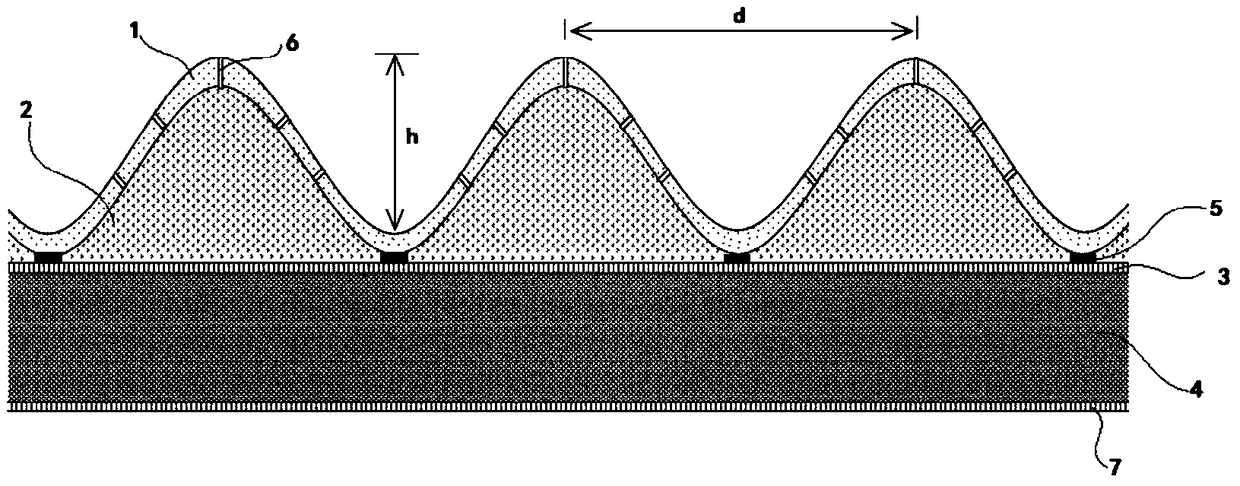

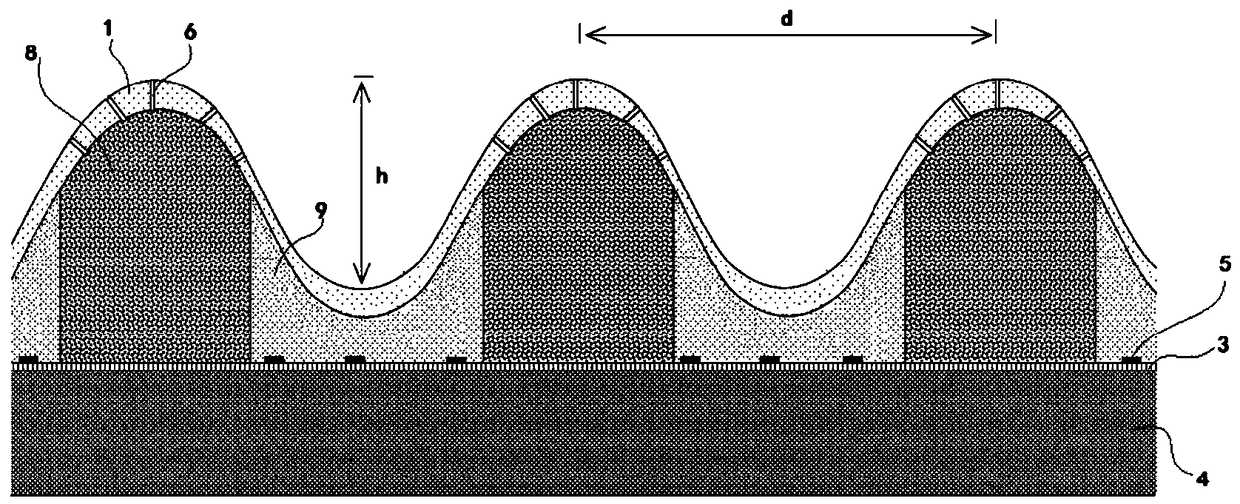

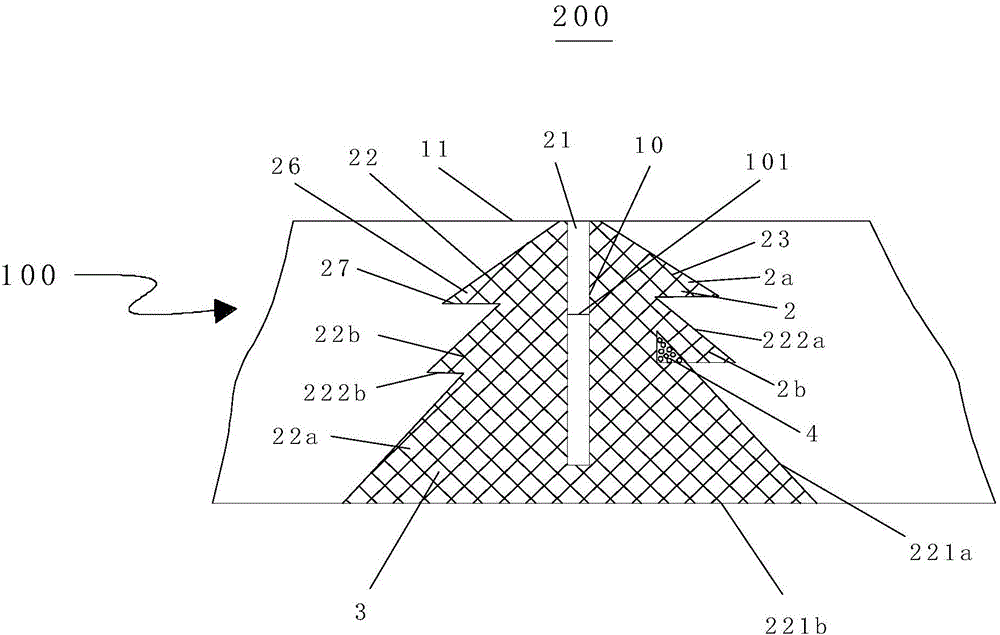

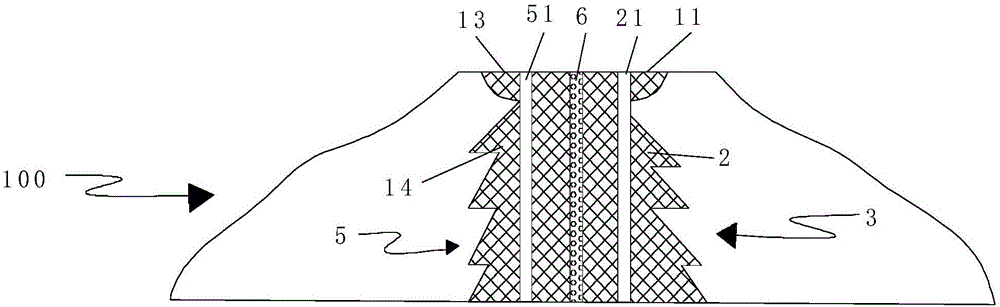

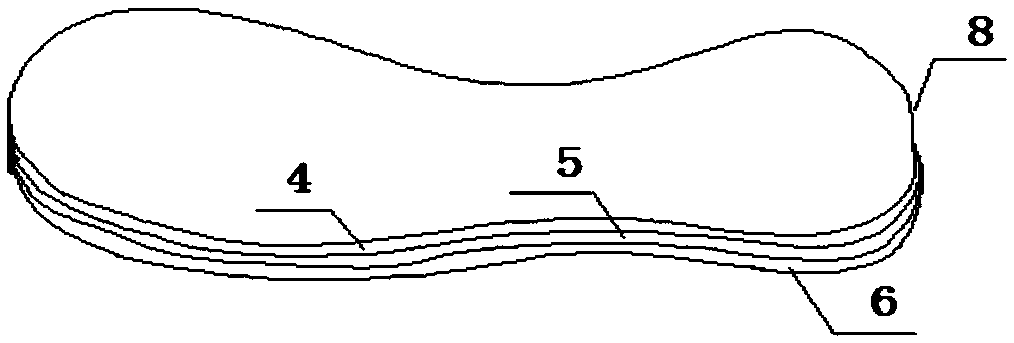

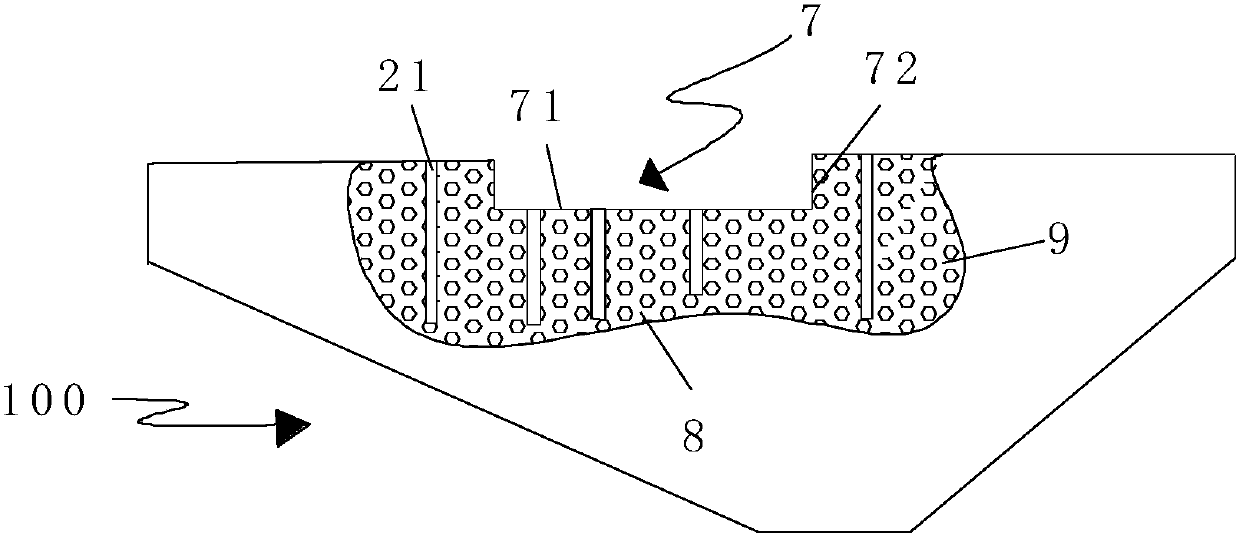

Textile product with waterproof breathable coating and method for preparing textile product

ActiveCN109130397AWaterproof and breathableGood drainageTents/canopiesLaminationFiberThermal insulation

The invention relates to the technical field of textile products, in particular to a textile product with a waterproof breathable coating and a method for preparing the textile product. The textile product comprises a base material, the waterproof breathable coating, a cover layer, and a plurality of cords or coarse fiber strips and fine fiber strips. The waterproof breathable coating is coated onthe upper surface of the base material, the cords or the coarse fiber strips and the fine fiber strips are uniformly arranged on the outer surface of the waterproof breathable coating at intervals, the cover layer can breathe and covers the multiple cords or the coarse fiber strips and the fine fiber strips, and protrusions and grooves are formed. The textile product and the method have the advantages that the textile product has excellent waterproof breathable functions and is excellent in thermal insulation property and drainage and long in service life; besides, processes for preparing thetextile product are simple and are high in production efficiency, mass industrial production can be facilitated, and the textile product and the method have broad market prospects.

Owner:江苏丰源布业有限公司

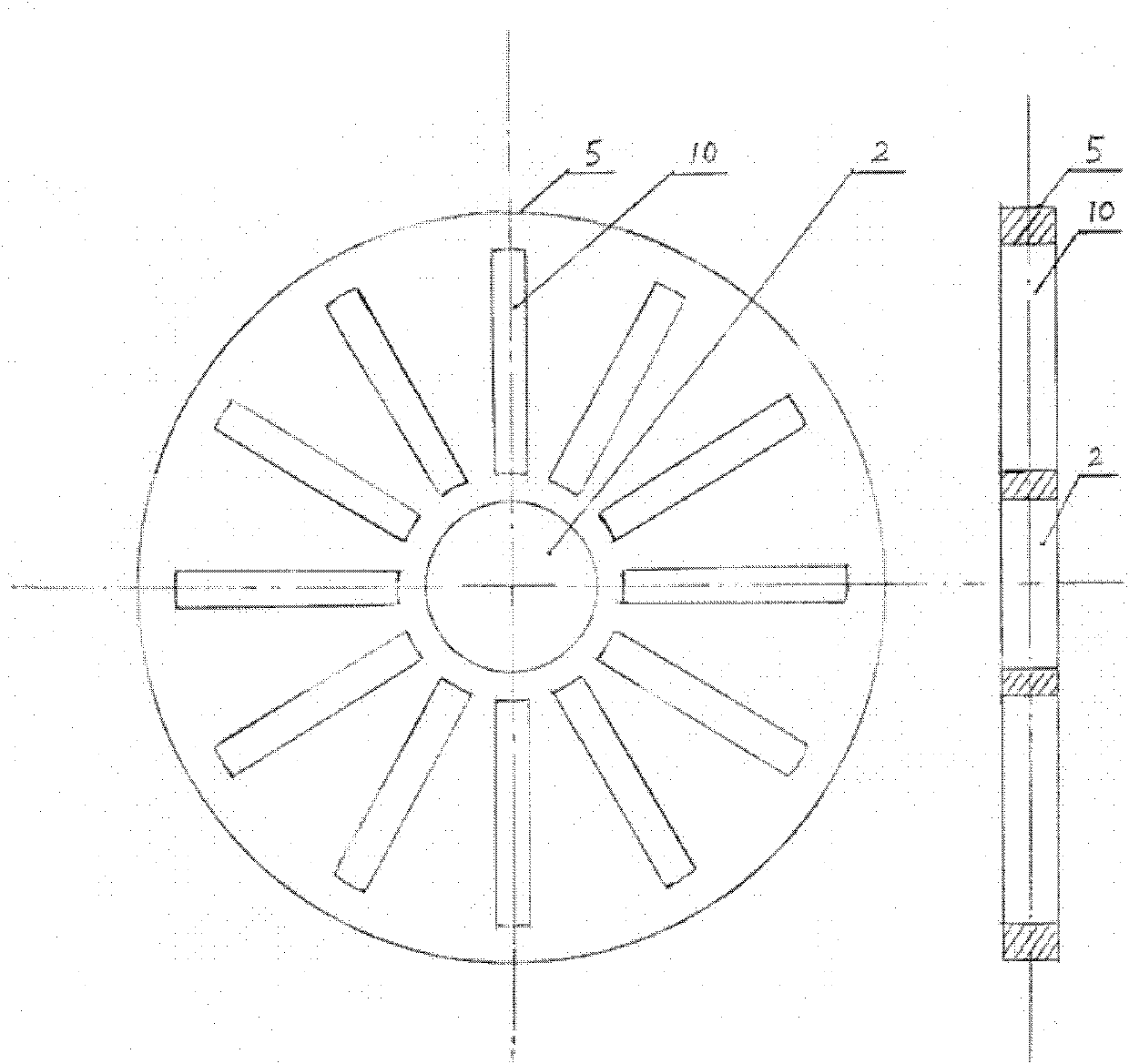

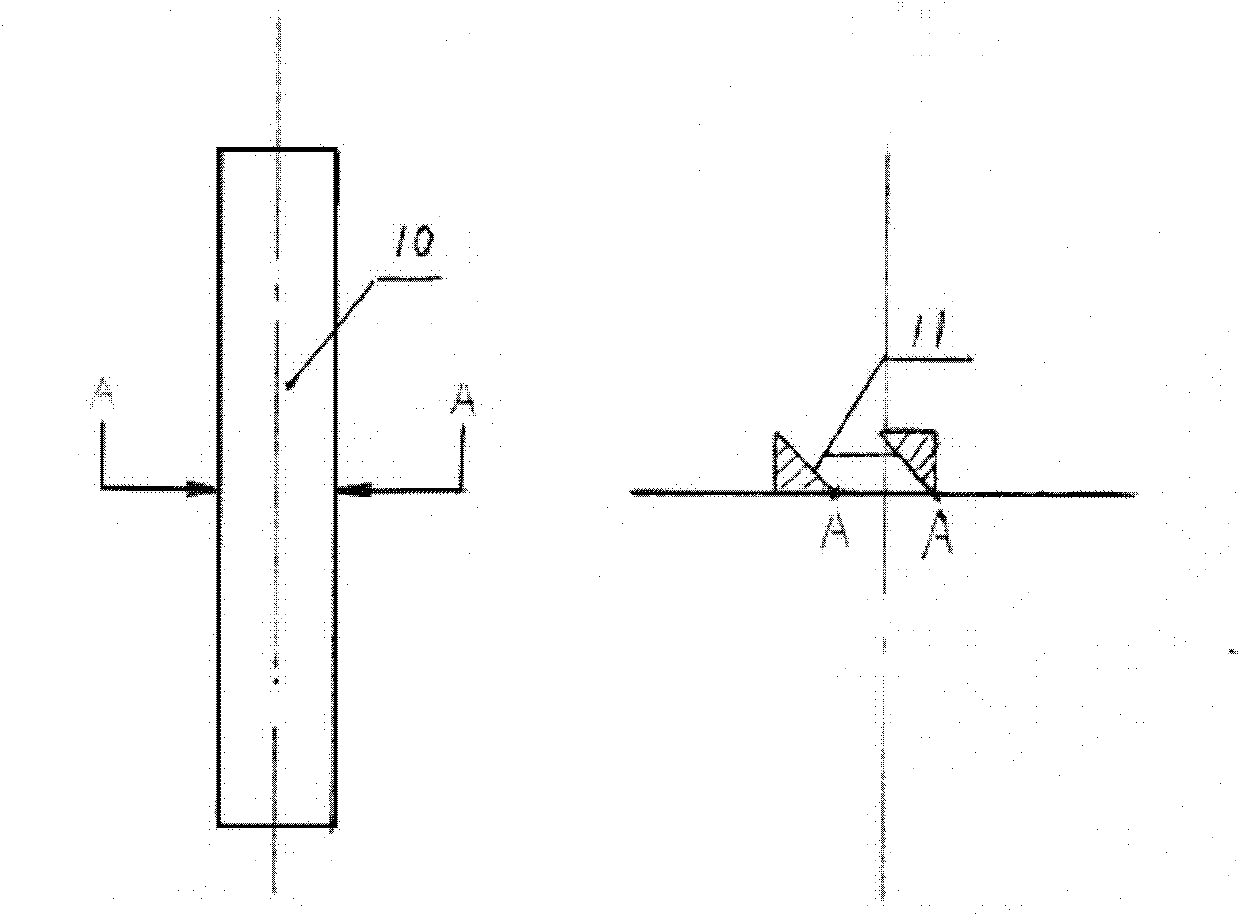

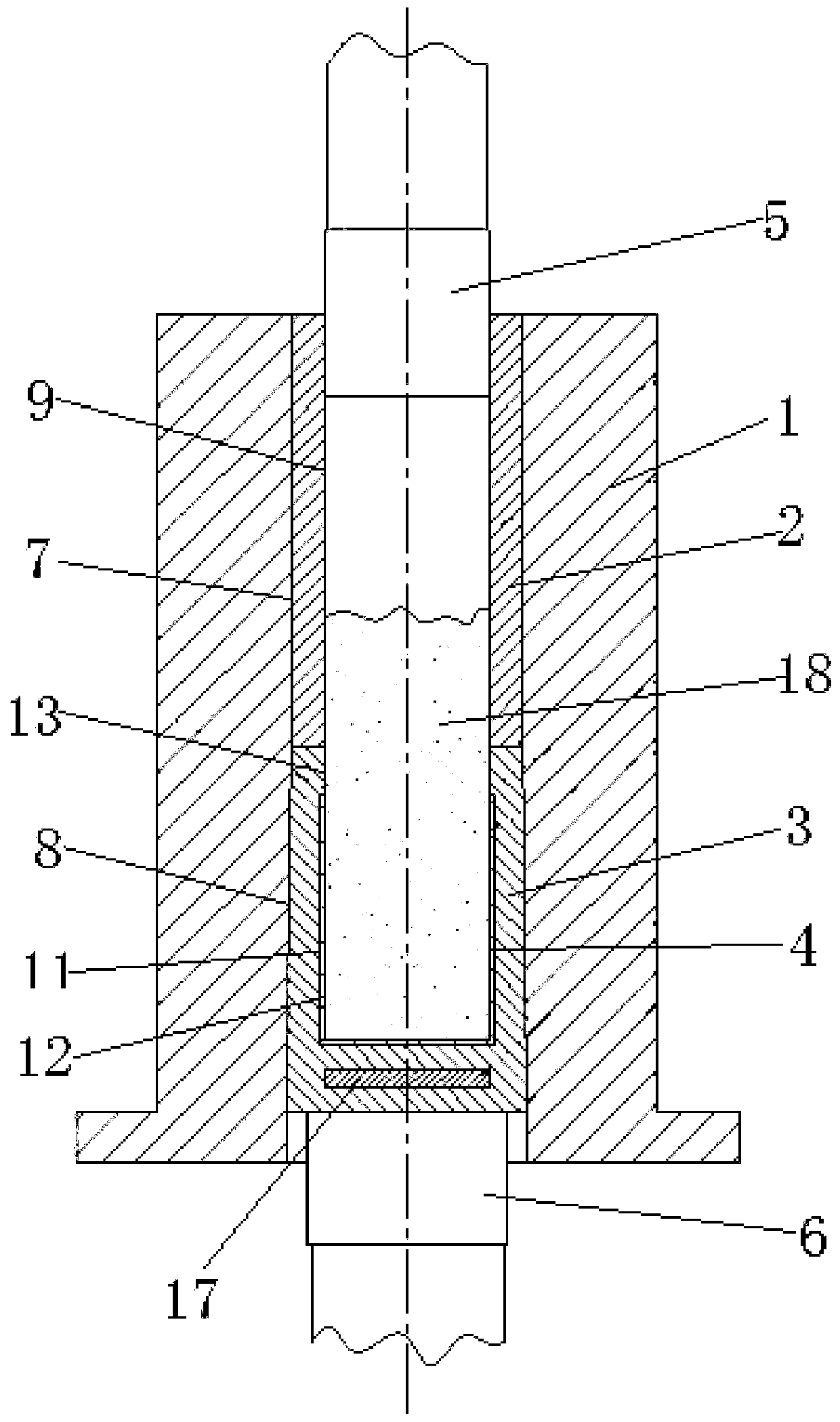

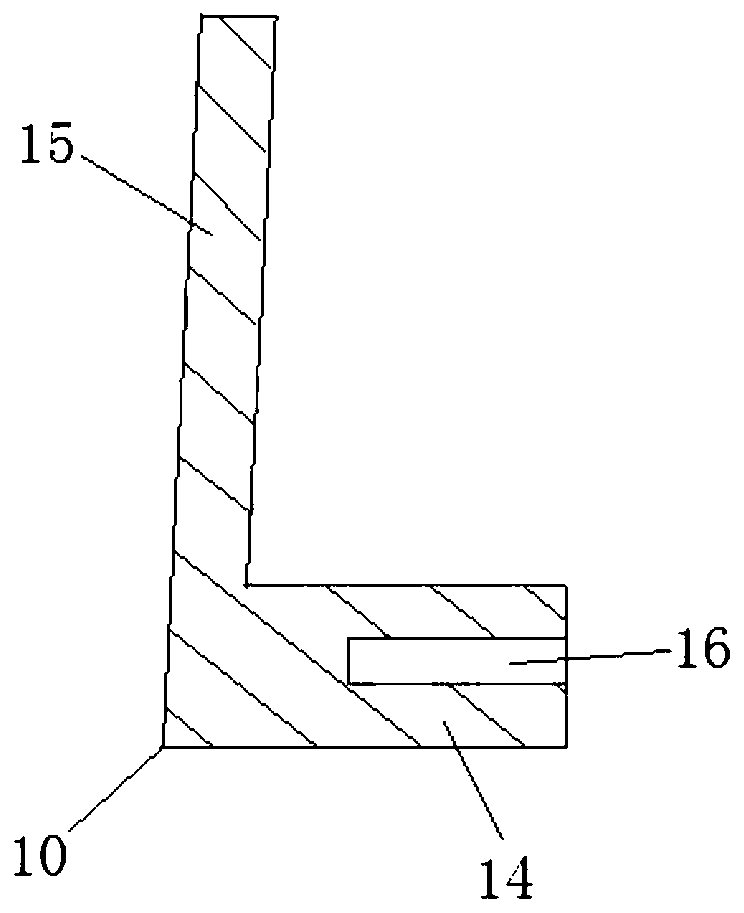

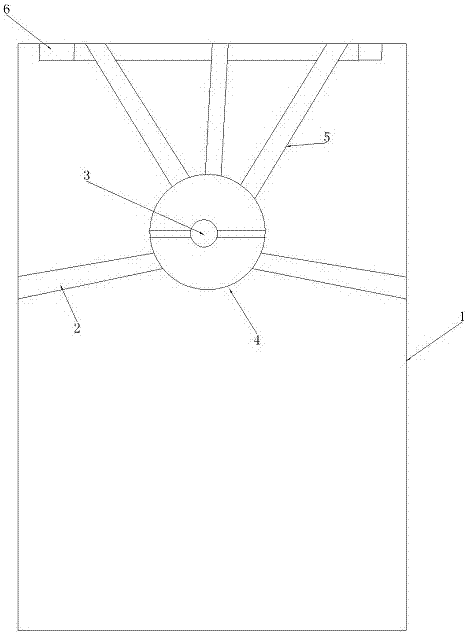

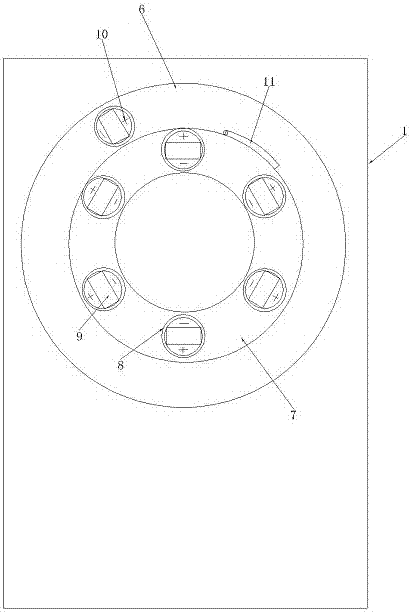

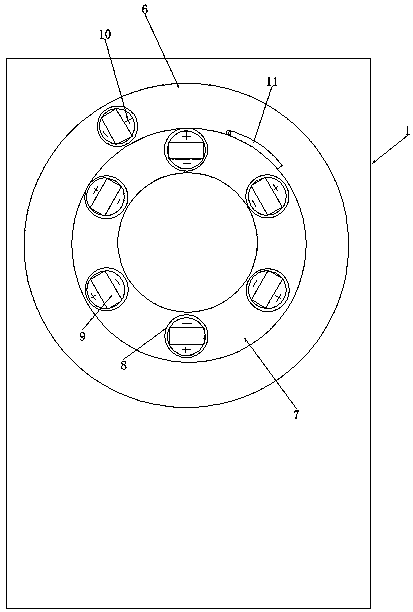

Disc type molecular pump

ActiveCN102889219AAvoiding the Cons of DamageIncrease pumping ratePump componentsAxial flow pumpsHigh resistanceSlant angle

The invention discloses a disc type molecular pump, which comprises a motive disc, a static disc and a pump body. The disc type molecular pump is characterized in that a radial rectangular or a ladder-shaped air flue is arranged on the motive disc and the static disc with certain thicknesses, so as to allow gas molecules on the discs to communicate; and slant angles between the two radial sides of the air flue and the horizontal planes of the discs can be changed from 0 to 180 degrees respectively. In the two radial sides of the air flue on the motive disc and the static disc, as one side mainly for delivering gas molecules, the inclination direction of the two is opposite, while the other side is subject to associating with the delivery of the gas molecules. An air exhaust unit comprising multi-stage motive discs and static discs drives the gas molecules to move in the fixed direction, so as to drag, deliver and compress the gas molecules, thereby performing air exhaust. The disc type molecular pump has the characteristics of simple structure, convenience in manufacturing and processing, large mechanical strength and high resistance against large flow gas impact, and can be widely applied to the medium and high vacuum fields.

Owner:李晨 +1

Reinforcement structure for barrier dam and construction method of reinforcement structure

ActiveCN105756019AImprove structural strengthImprove compactnessEarth-fill damsRock-fill damsSoil massUltimate tensile strength

The invention relates to a reinforcement structure for a barrier dam and a construction method of the reinforcement structure. The reinforcement structure comprises a plurality of layers of first cement bodies which are sequentially arranged on the surface of a first to-be-reinforced area of the barrier dam from top to bottom, wherein every two adjacent layers of cement bodies are in contact with each other to form a first reinforcement body of the barrier dam; and first grouting holes which are respectively communicated with the first cement bodies are formed in the first reinforcement bodies. The reinforcement structure has the advantages of being high in structural strength, good in soil mass stability, high in compactness and good in scouring resistance and permeation resistance.

Owner:TSINGHUA UNIV

Traditional Chinese medicine composition used for treating uterine myoma, ovarian cyst, and pelvic inflammation, medicine panty liner, and underpants

InactiveCN108743788AQuick treatmentAbundant and easy to obtainElectrotherapyAbsorbent padsPerineumCrotch

The invention belongs to the technical field of medicine, and more specifically relates to a traditional Chinese medicine composition used for treating uterine myoma, ovarian cyst, and pelvic inflammation, a panty liner, and underpants. Effect of the traditional Chinese medicine composition is achieved quickly; no relapse is caused. The health care panty liner is capable of achieving traditional Chinese medicine fumigation effect; drug effect is capable of acting on the perineums of patients directly; medicine effect is achieved quickly; using is convenient; antibacterial effect is achieved; when the panty liner is arranged at the crotch part of the underpants, massage function and magnetic therapy function are achieved, traditional Chinese medicine health care effect at the acupoints at the navel and the back of the waist is achieved, and adjuvant therapy effect is achieved.

Owner:滨州医学院附属医院

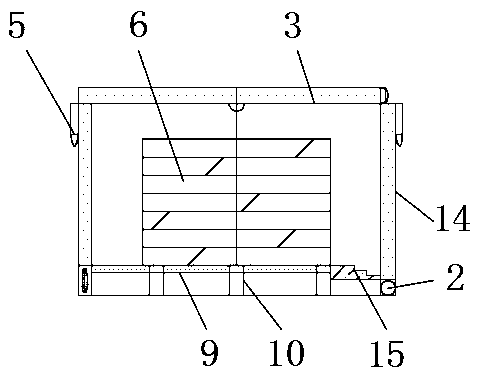

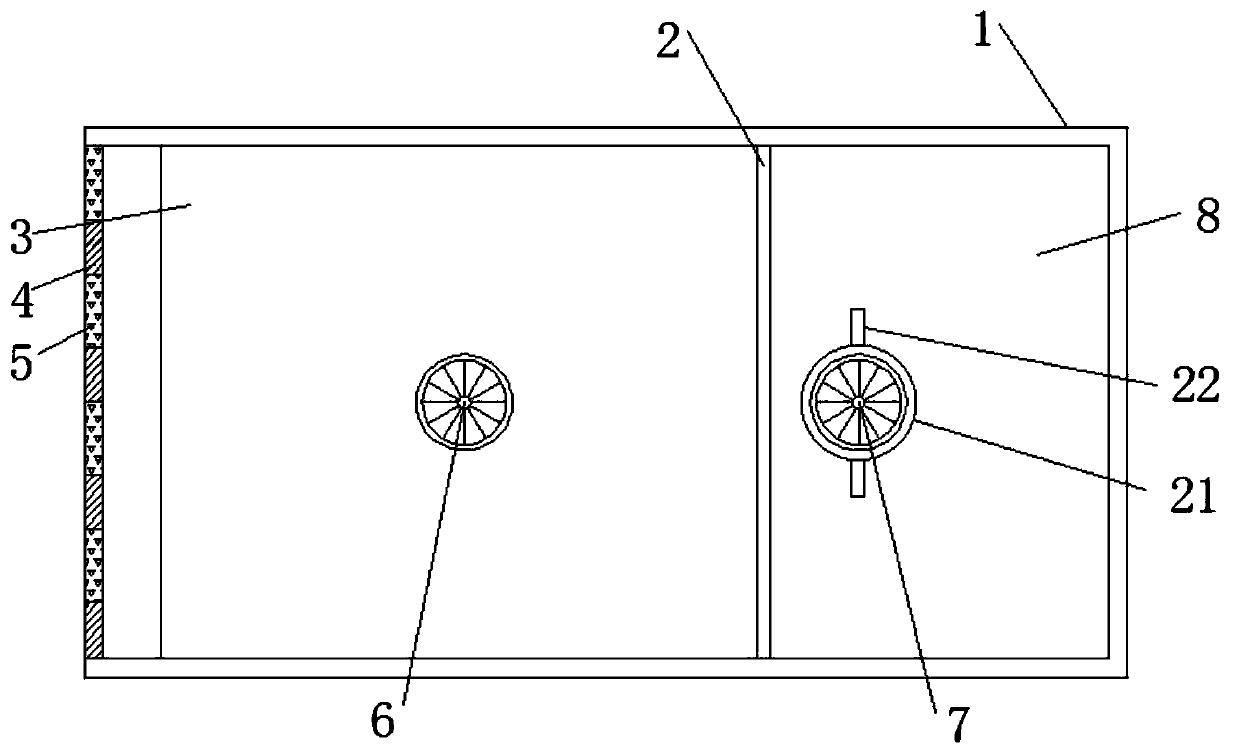

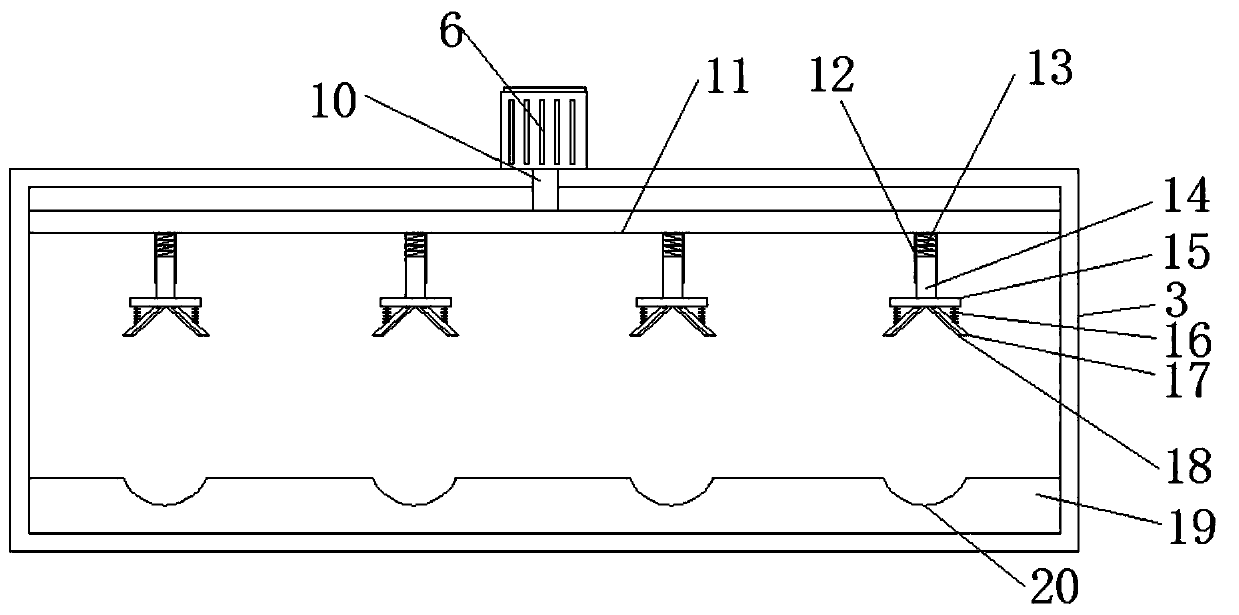

Glass transport packaging box

InactiveCN109292216AAvoiding the Cons of DamageReduce frictionNon-removalbe lids/coversContainers to prevent mechanical damageEngineeringCushion

The invention discloses a glass transport packaging box. The glass transport packaging box comprises a main backup plate, rotating shafts, cover plates, hooks, rubber cushions, a pressure adjusting shaft lock catch and buckle rings, wherein the rotating shafts are installed on the upper part of the main backup plate, the upper ends of the rotating shafts are connected with the cover plates, the hooks are installed at the top ends of the cover plates, and the handle is installed on the side edge of the main backup plate; glass placing chambers are arranged on the two sides of the main backup plate, pressure adjusting devices are installed on the inner sides of the glass placing chambers, air bags are installed at the tail ends of the pressure adjusting devices, vibration reduction supporting legs are arranged at the lower end of the bottom plate, and pressure adjusting shafts are installed among the vibration reduction supporting legs; and auxiliary sliding wheels are installed on the outer sides of the pressure adjusting shafts, pressure plates are installed at the upper ends of the auxiliary sliding wheels, the pressure adjusting shaft lock catch is installed between the pressureadjusting shafts, and the buckle rings are installed at the upper end of the pressure adjusting device. The glass transport packaging box wraps around the glass through plates, the glass is preventedfrom colliding with an object during transportation, and the defect that the glass is damaged in a transportation process is avoided.

Owner:泗阳县联吉木业有限公司

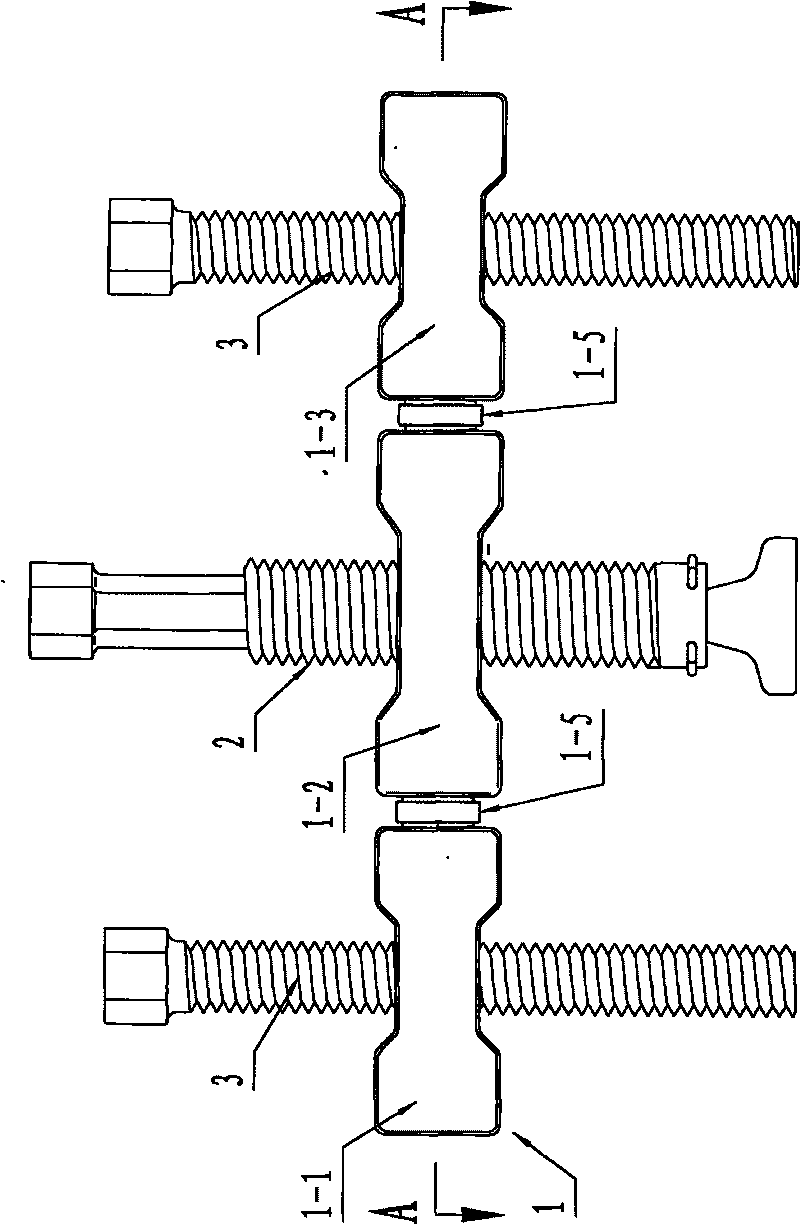

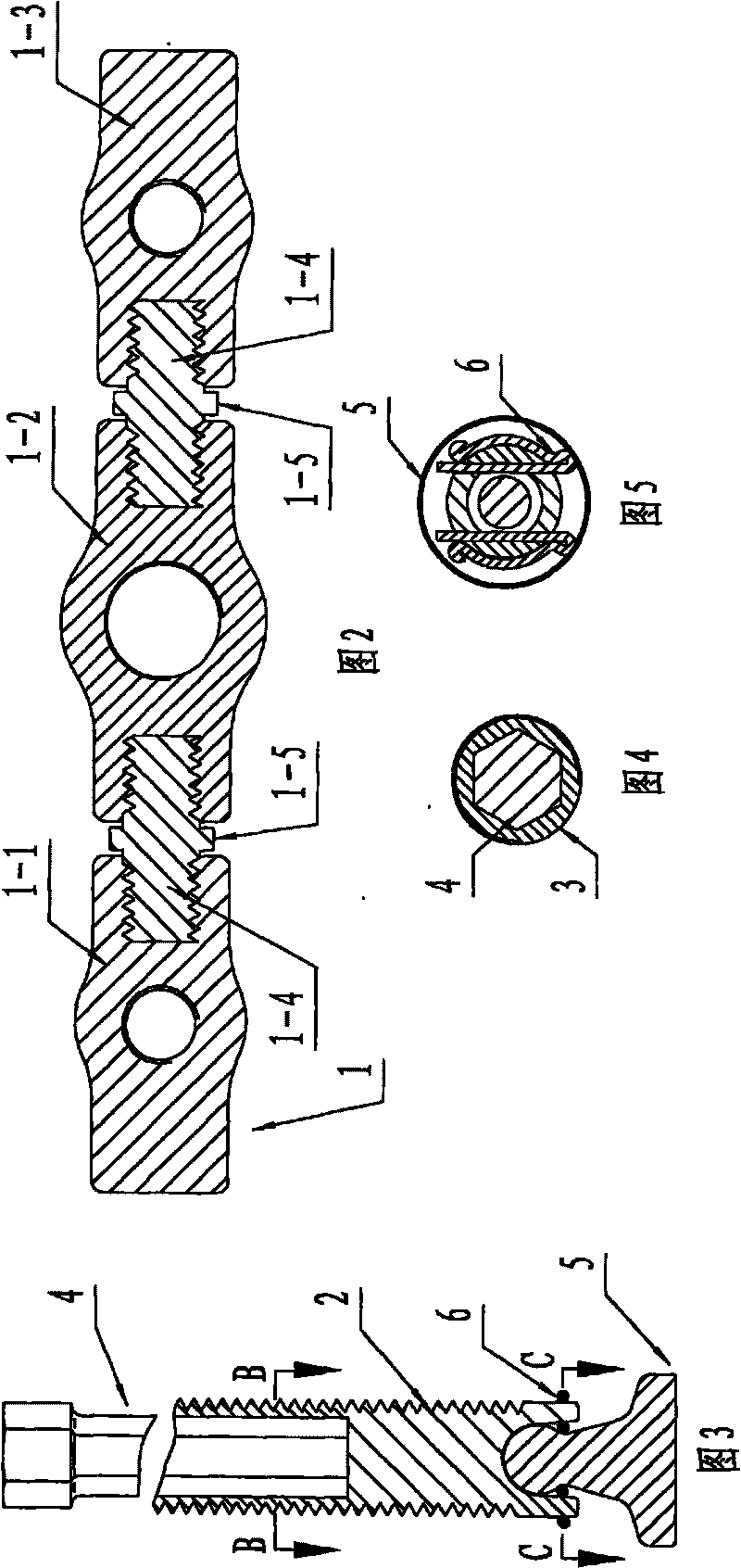

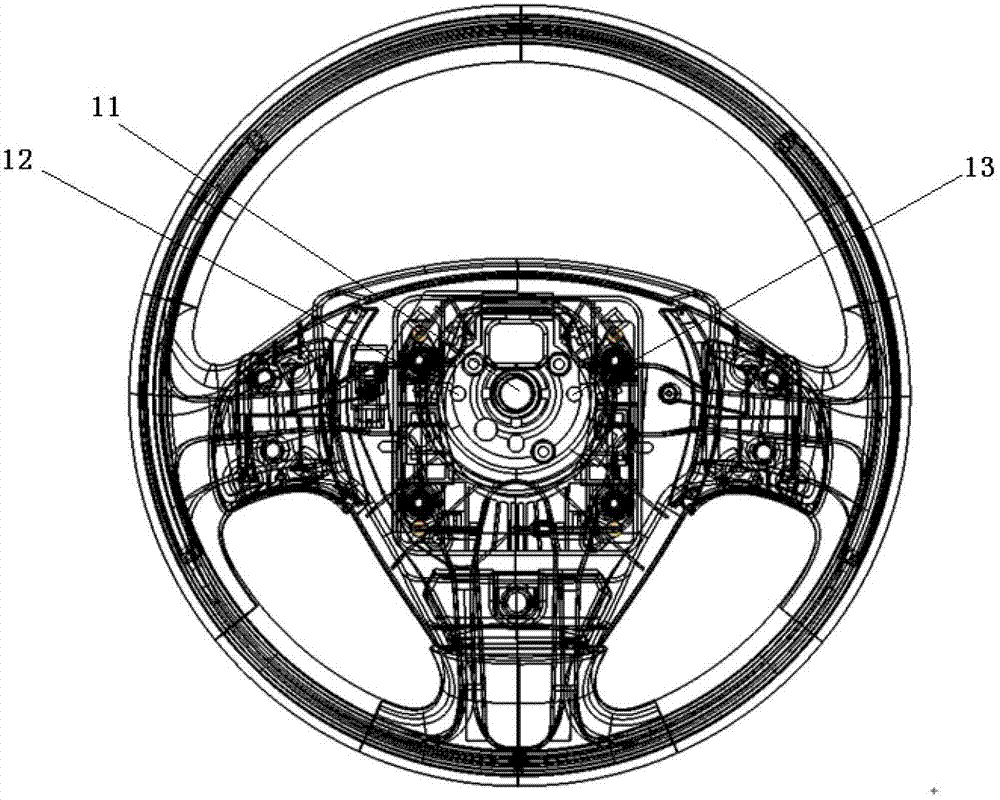

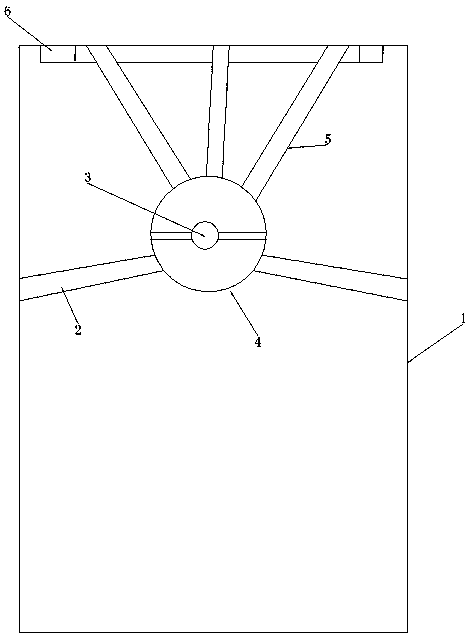

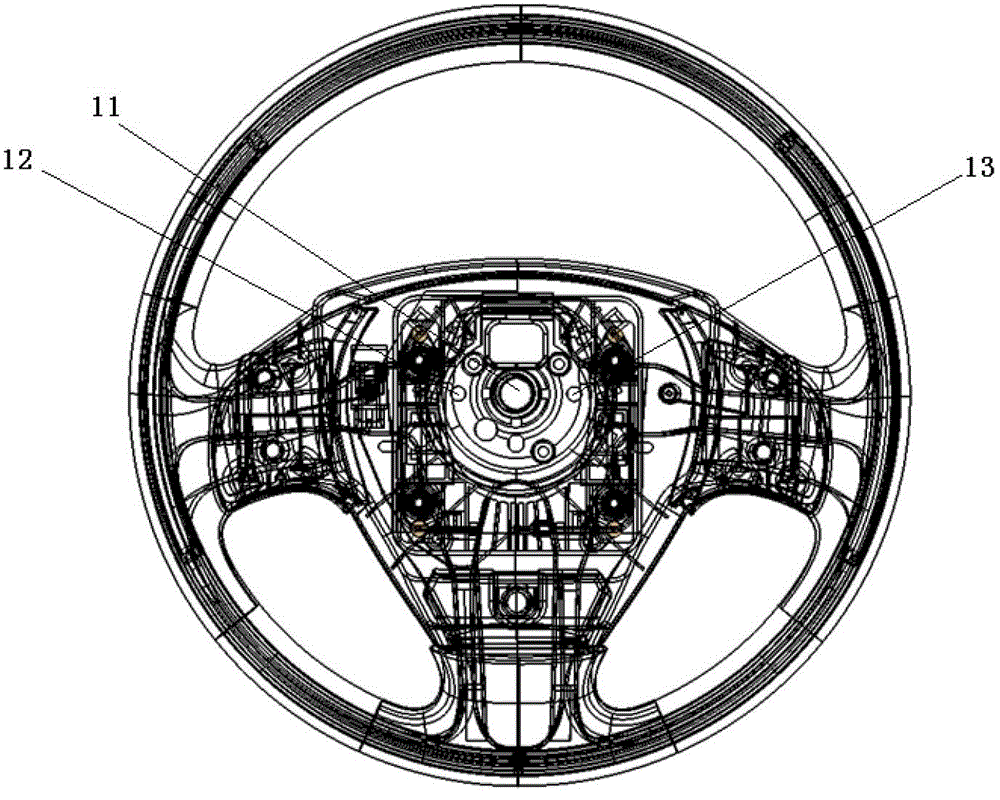

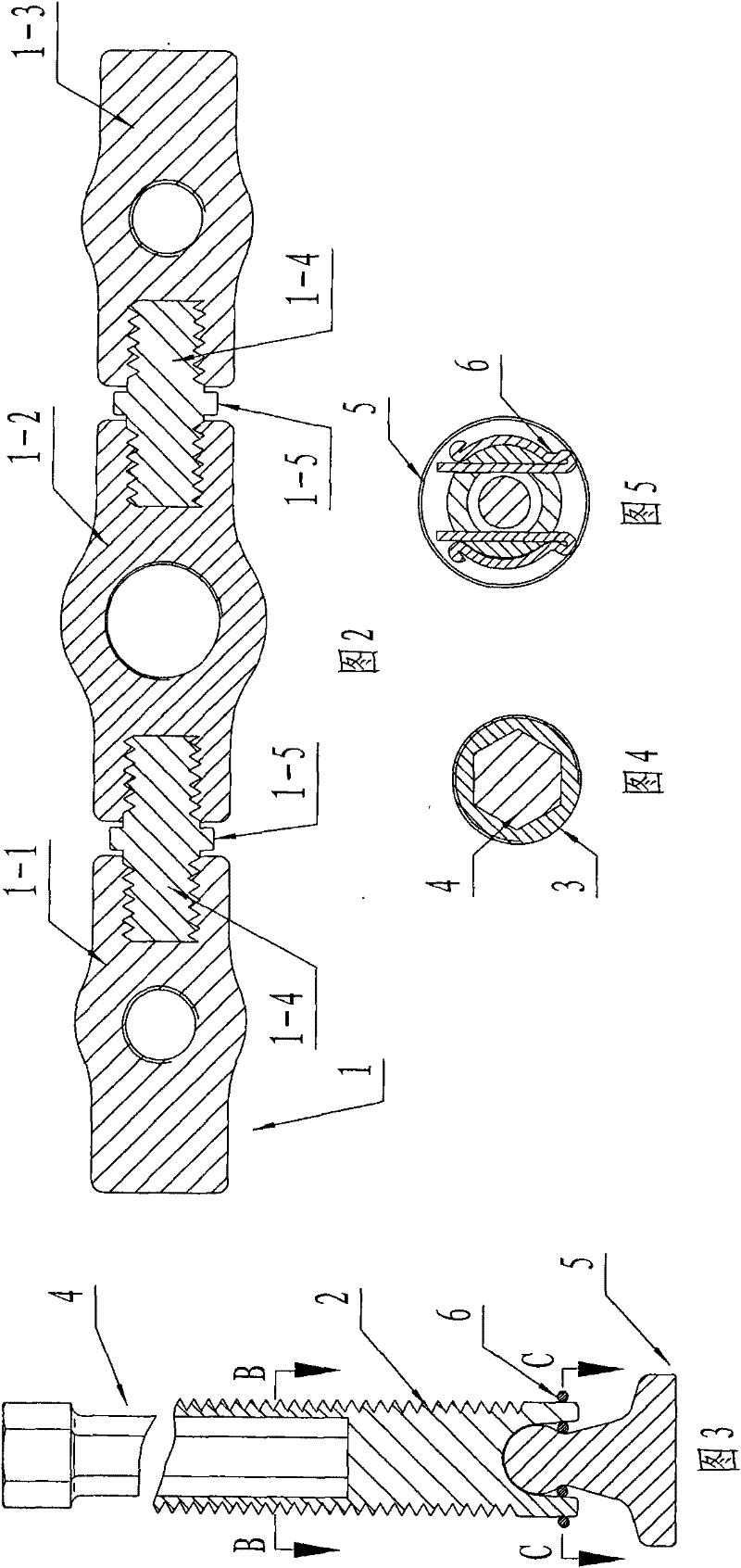

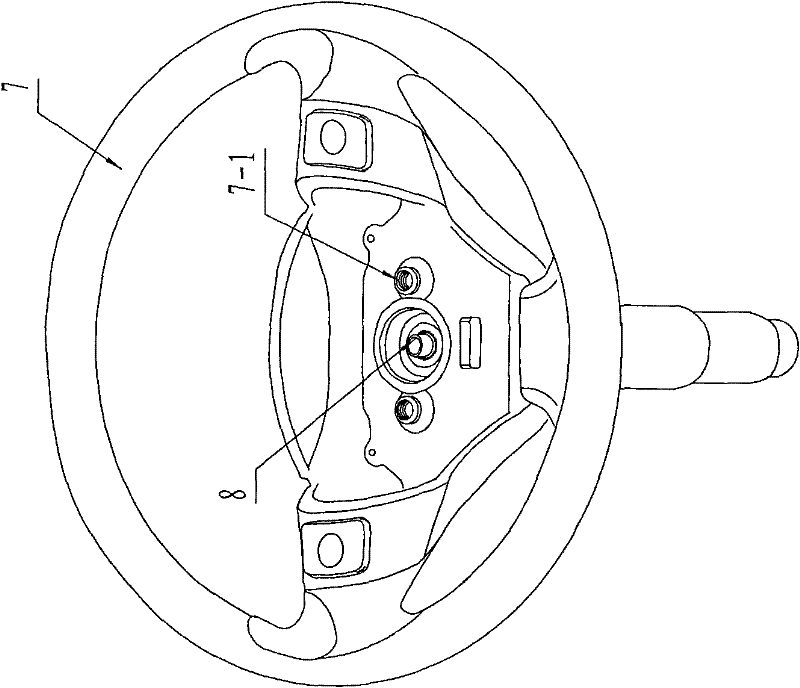

Automobile steering wheel disassembling tool

InactiveCN101708604AImprove work efficiencyAvoid damageMetal-working hand toolsSupport pointSteering wheel

The invention relates to an automobile steering wheel disassembling tool for solving the problem of difficult disassembly of a steering wheel. The technical scheme of the automobile steering wheel disassembling tool is that the automobile steering wheel disassembling tool comprises a supporting mechanism, a main screw and drawing bolts; the main screw is positioned on the middle part of the supporting mechanism and is in screw fit with the supporting mechanism; and the drawing bolts are symmetrically arranged on both sides of the main screw and are in screw fit with the supporting mechanism respectively. The automobile steering wheel disassembling tool takes a shaft end of a steering shaft of the steering wheel as a supporting point to support the main screw, ingeniously uses a fixed screwed hole on a framework of the steering wheel to make the drawing bolts in threaded connection with the fixed screw hole, rotates the main screw and lifts the steering wheel up by the drawing bolts in a screw transmission mode to easily disassemble the steering wheel. To be suitable for disassembling the steering wheels of different vehicle types, an adjustable spacing connection is designed between the main screw and the drawing bolts. The automobile steering wheel disassembling tool has simple and rapid disassembly, and time and labor conservation, and can effectively avoid the defect of damage to the parts of the steering wheel caused by an improper operation of maintenance personnel. The automobile steering wheel disassembling tool also has the characteristics of convenient carrying and strong popularity.

Owner:GREAT WALL MOTOR CO LTD

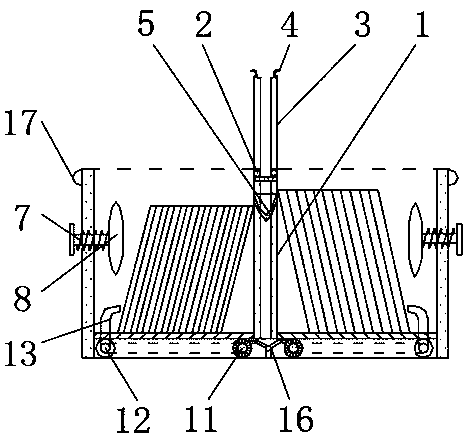

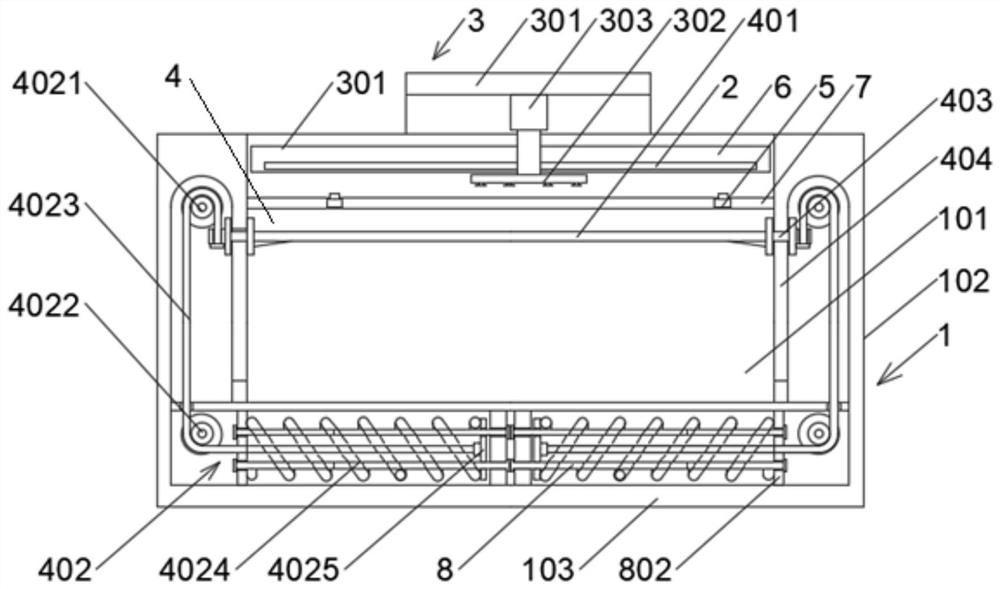

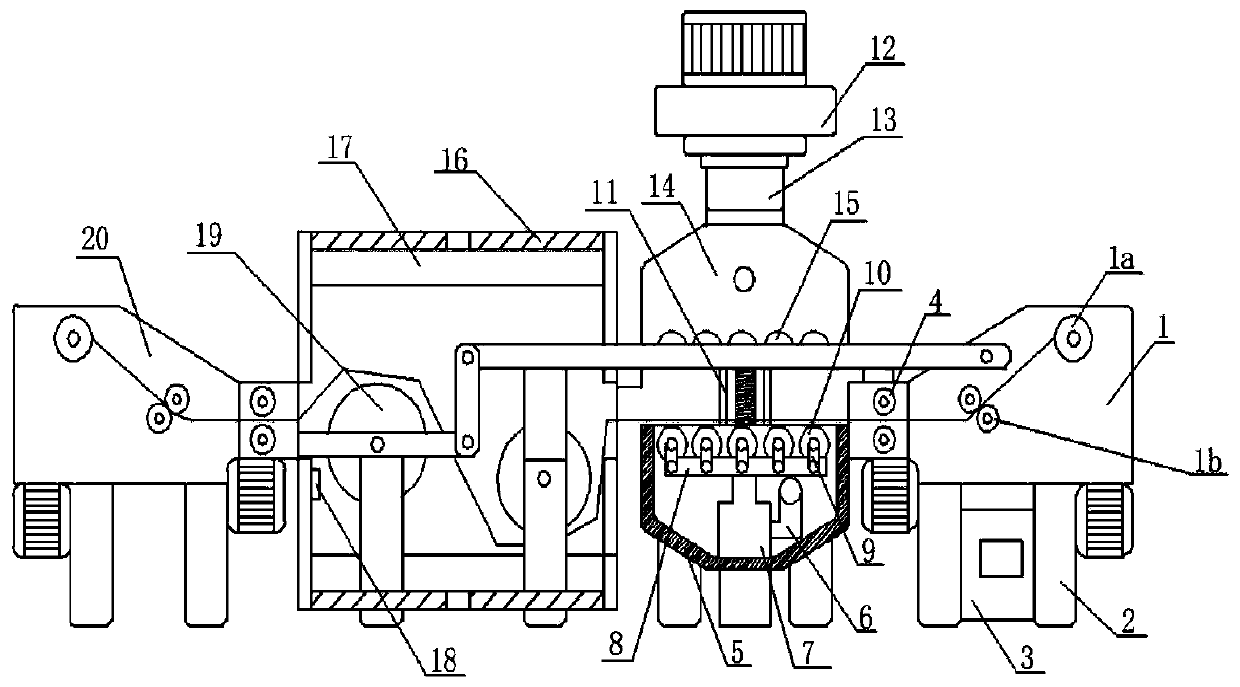

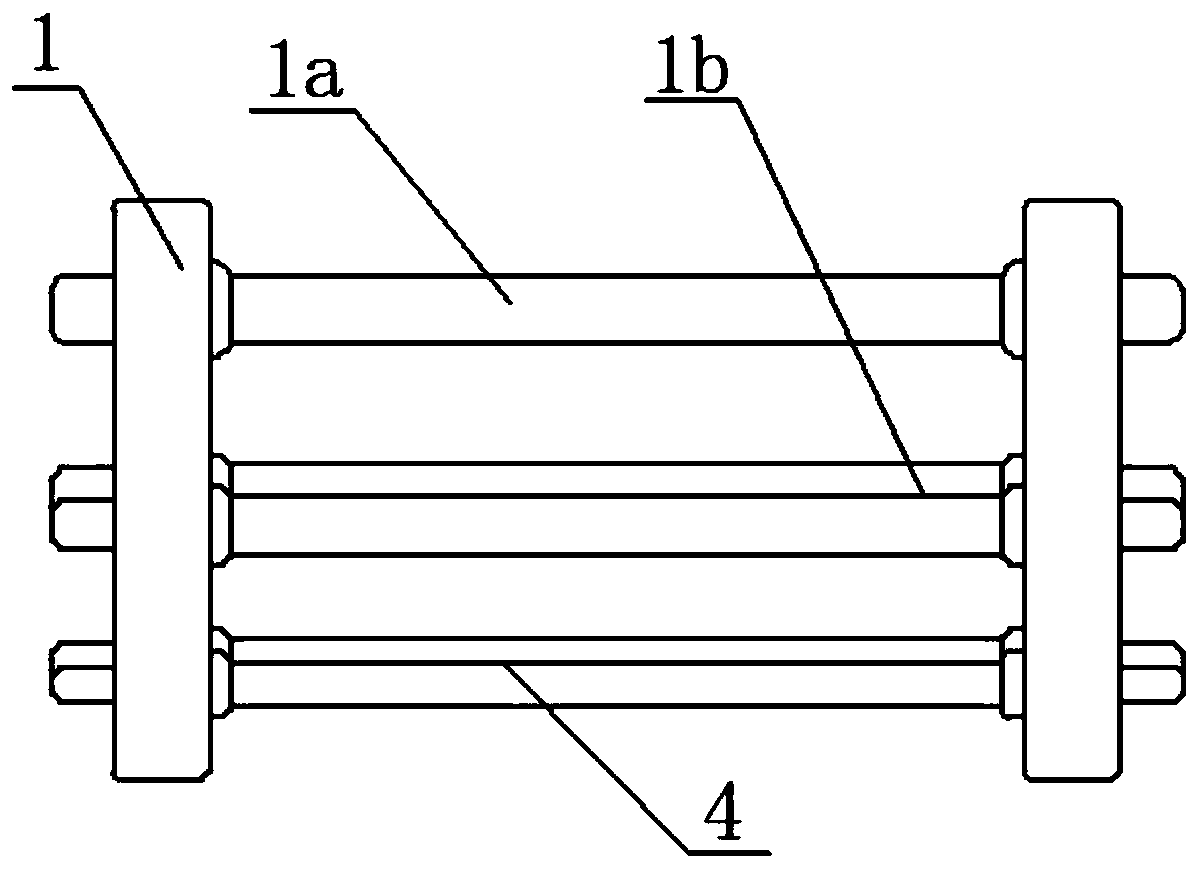

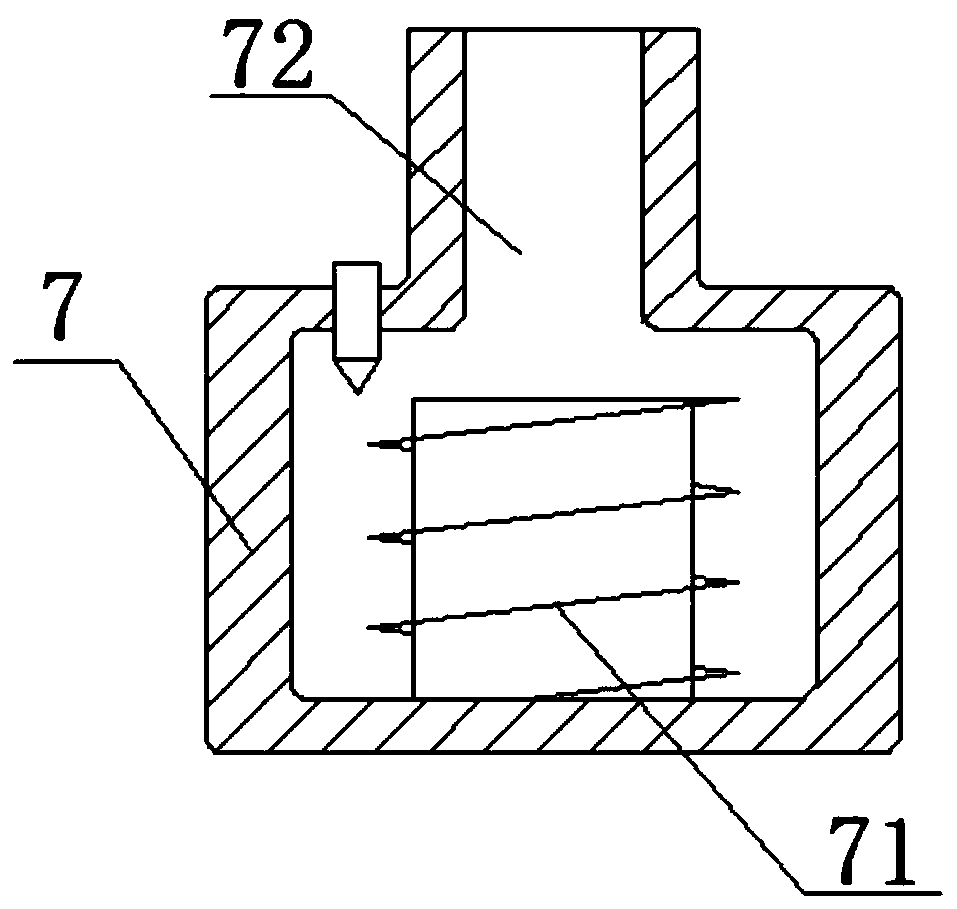

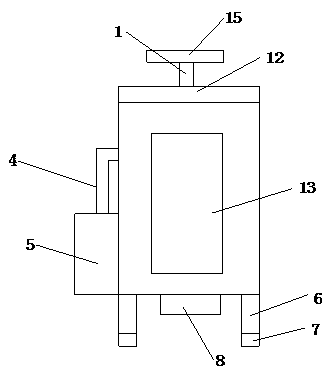

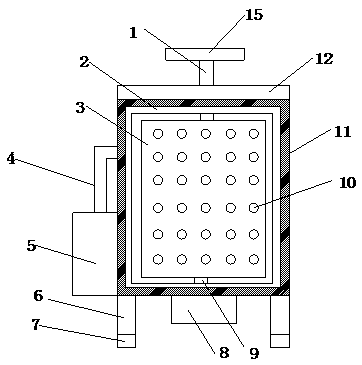

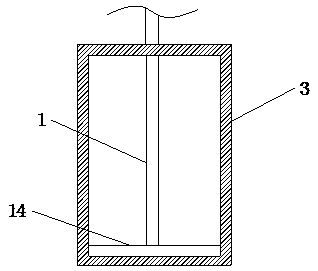

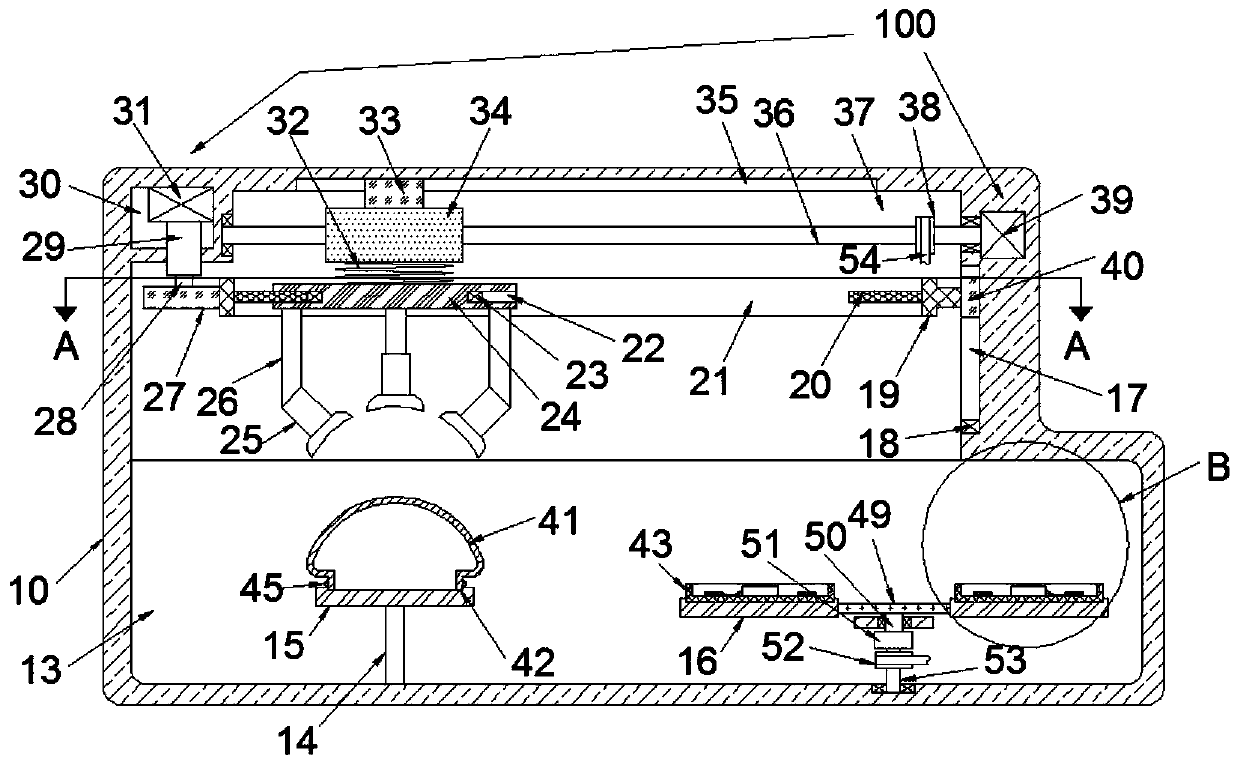

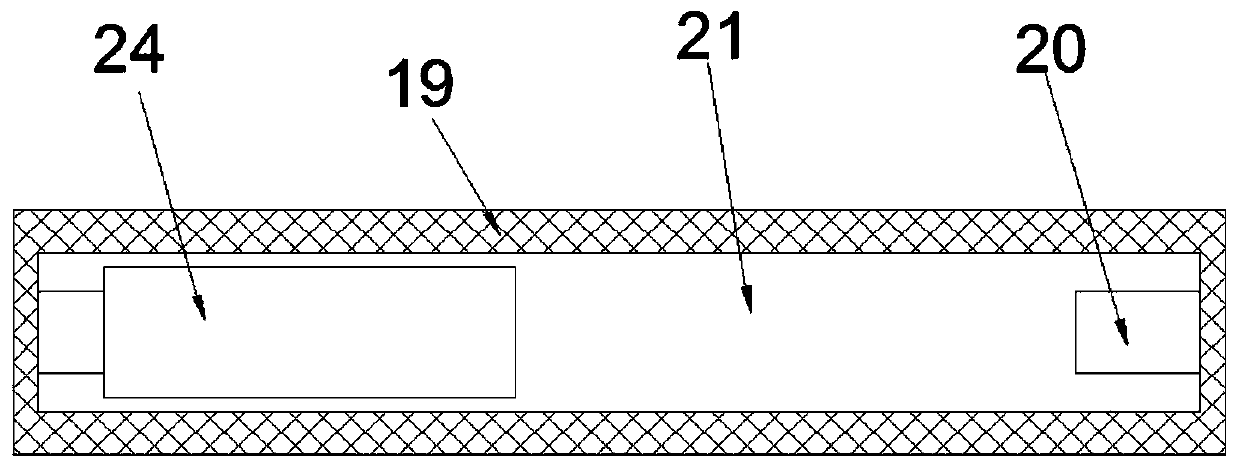

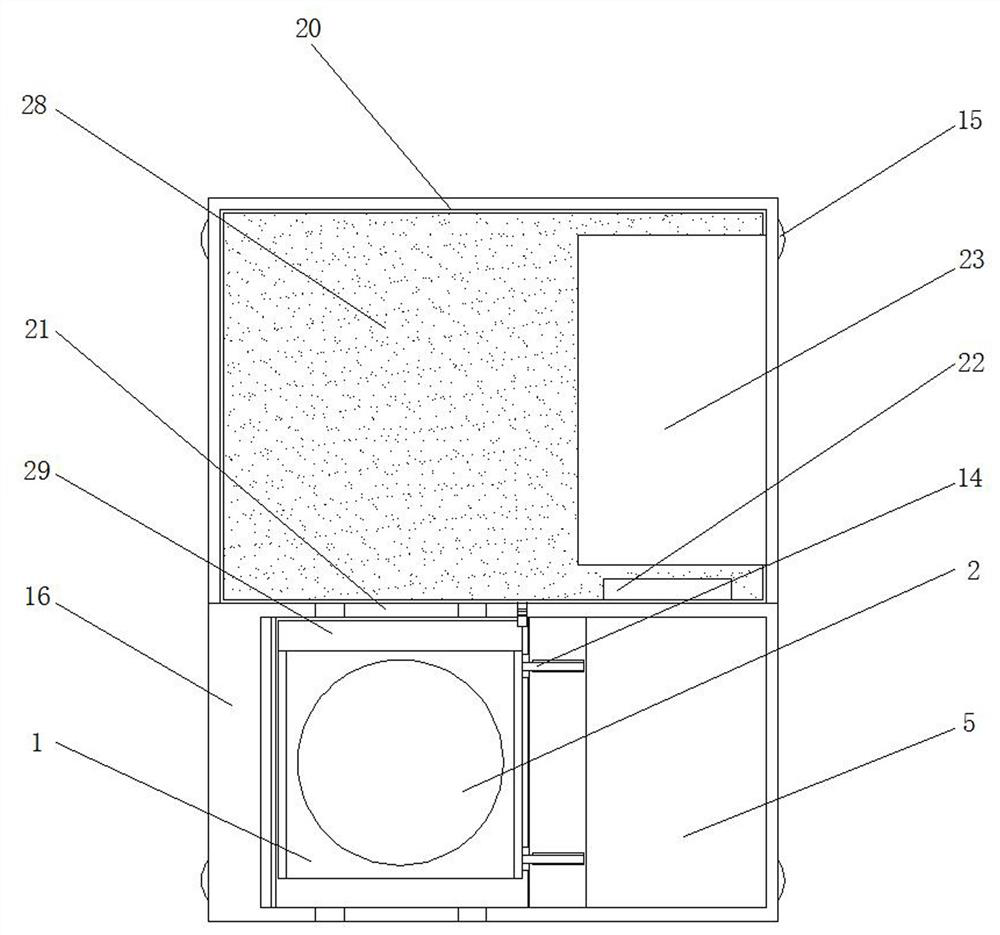

Line quality testing equipment and method applied to power switch control cabinet

ActiveCN111842213AAvoiding the Cons of DamageElectrical testingSortingStructural engineeringProcess engineering

The invention discloses line quality testing equipment and method applied to a power switch control cabinet. The equipment comprises a storage box for storing copper bar buses, wherein a suspended separating mechanism is mounted in the storage box, the copper bar buses in the storage box are automatically fed to the suspended separating mechanism through an automatic feeding mechanism, the copperbar buses on the top of the storage box are hoisted by means of the suspended separating mechanism, and a bus detection device for detecting the hoisted copper bar buses is mounted on the box wall ofthe storage box. As the copper bar buses on the uppermost side in the storage box are hoisted by means of the suspended separating mechanism, the detected copper bar buses are separated from to-be-detected copper bar buses below. The hoisted copper bar buses are detected by means of the bus detection device in the storage box, so that the deficiency that the copper bar buses which fall from a highaltitude are damaged when the copper bar buses are transferred outside the storage box to be detected is avoided.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

Mild dredging agent for kitchen pipelines

InactiveCN110042014AAct as cooling infiltrationDisperse fastInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhospholipidBlock structure

The invention discloses a mild dredging agent for kitchen pipelines, belongs to the technical field of pipeline cleaning, and solves the problem of pipeline damage due to alkalinity of current commonpipeline dredging agents and local overtemperature of pipelines. Ferrous nitrate and ferric nitrate produce nano ferroferric oxide in an alkaline system to have a cooling permeation effect on blockedpipelines, blocking parts are contracted with cold, and block is hindered. A selenium-containing agent is added and can react with ions such as iron at low temperature to produce metal selenide, the rapid dredging effect can be realized in combination with following foaming and viscosity reduction effects, and added phospholipid has an emulsification effect so as to damage blocking structures formed by oil, vegetable leaves and other impurities. After gas spills, microbubbles can be adsorbed around oil and matched with polyallylamine storing CO2 to have further viscosity reduction and dredgingeffects with permeation of blocking substances, and corrosion and high-temperature damage to the pipelines can be avoided.

Owner:陈太师

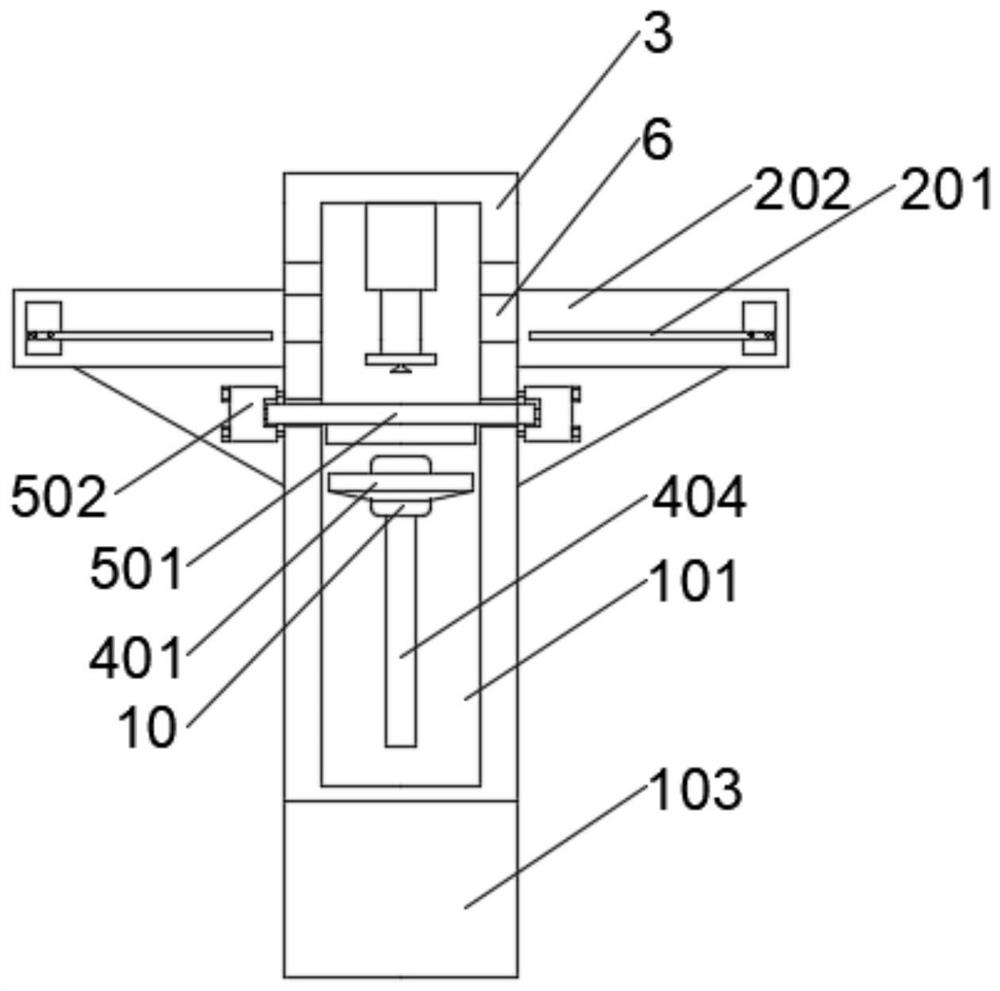

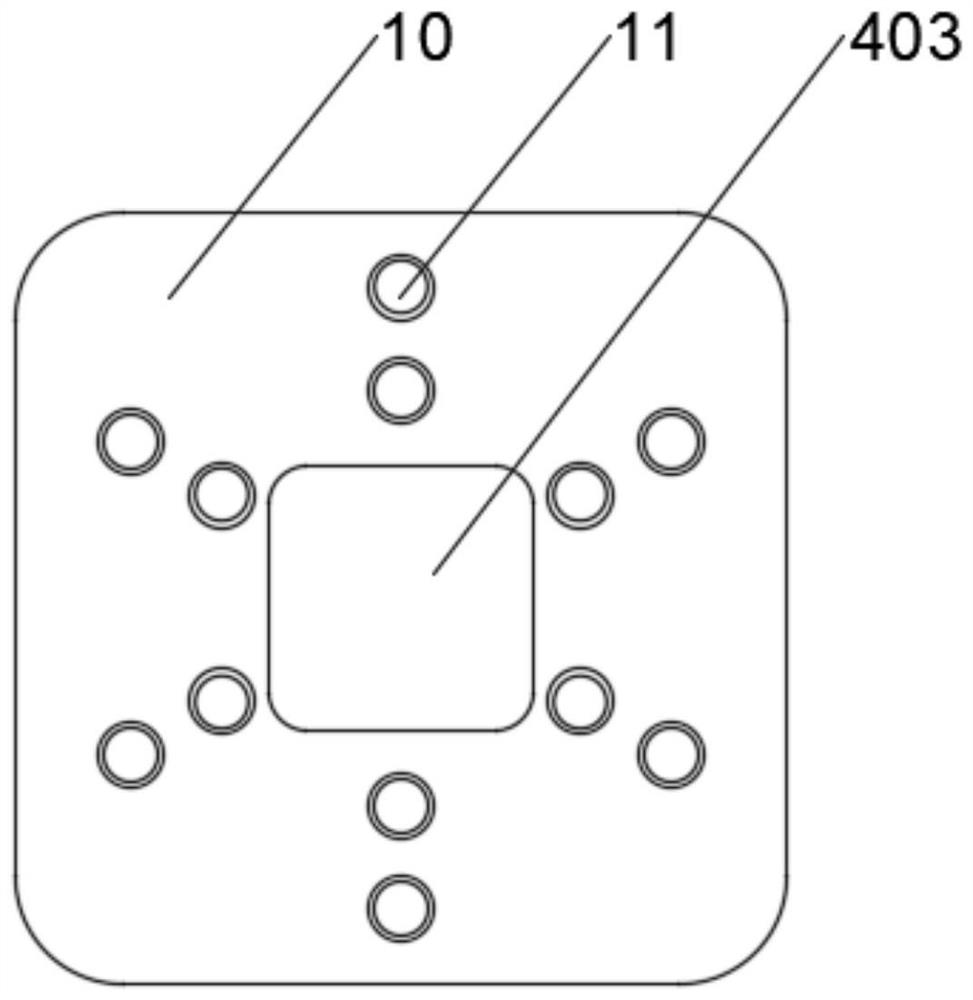

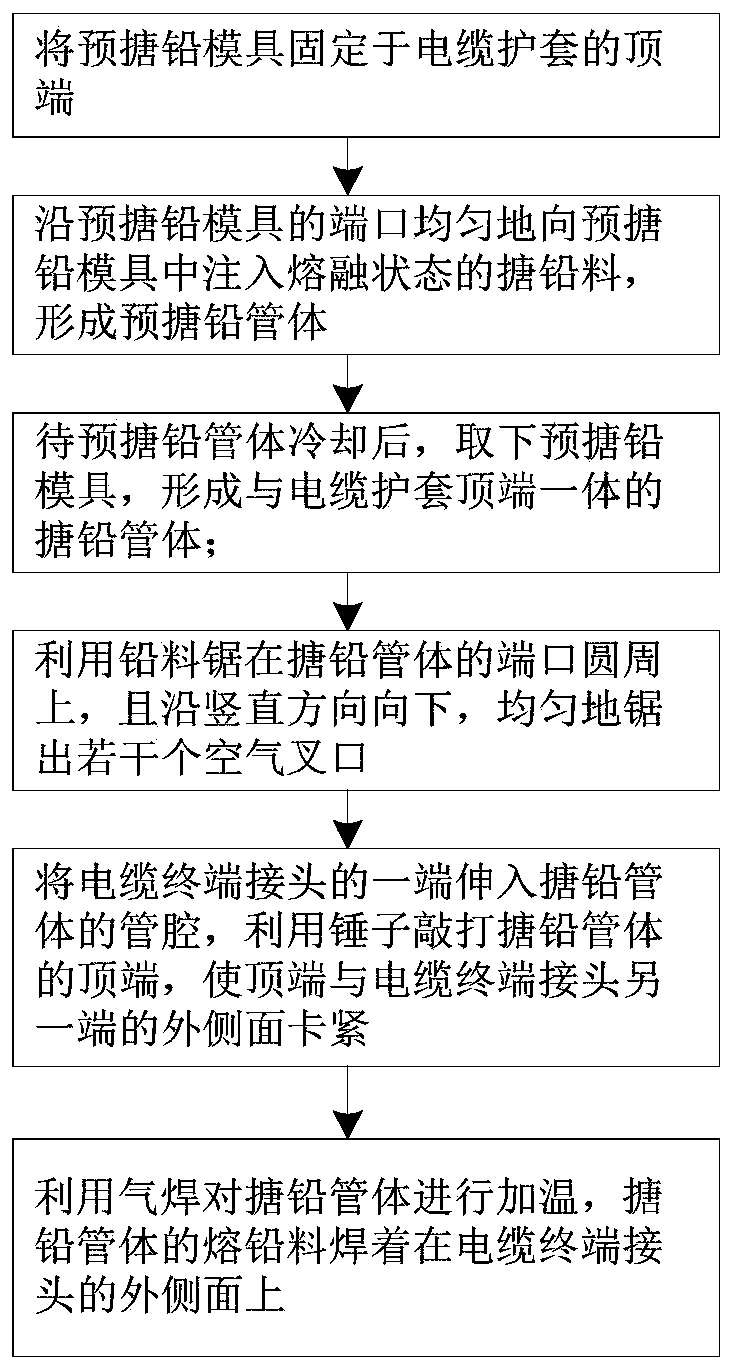

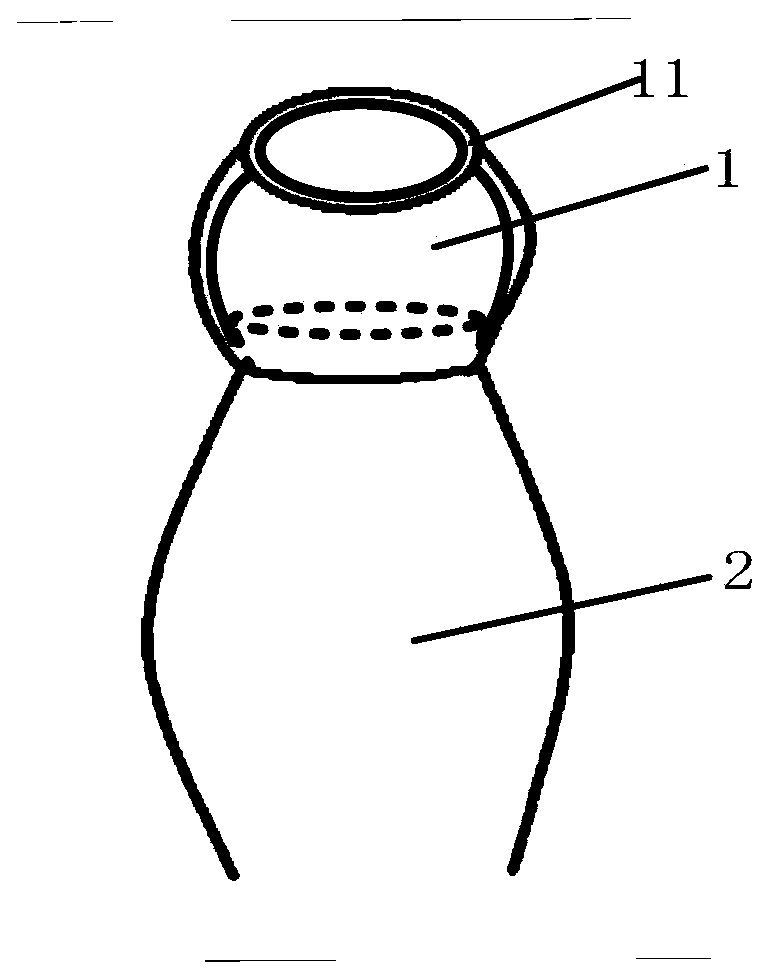

Improved cable lead coating method

ActiveCN110867783AExtend your lifeReducing the technical requirements of lead enamel processApparatus for joining/termination cablesEngineeringElectric cables

The invention provides an improved cable lead coating method. The method comprises the following steps: fixing a lead pre-coating mold at the top end of a cable sheath; injecting a lead coating material in a molten state into the lead pre-coating mold at a constant speed along the port of the lead pre-coating mold; after the lead pre-coating pipe body is cooled, taking down the lead pre-coating mold; carrying out sawing to obtain a plurality of air fork openings; allowing one end of a cable intermediate joint to stretch into a pipe cavity of the lead coating pipe body, and knocking the top endof the lead coating pipe body by using a hammer, so that the top end is clamped with the outer side surface of the other end of the cable intermediate joint; and heating the lead coating pipe body. According to the invention, the defect is overcome that in a traditional cable lead coating method, a worker needs to conduct lead coating on the cable intermediate joint and the cable sheath at the same time, so the requirement for the lead coating process technology of the worker is lowered, the working efficiency of the worker is improved, the lead coating completion quality is further improved,and the service life of the cable intermediate joint is further prolonged.

Owner:GUANGDONG POWER GRID CO LTD +1

Cloth integral ironing drying equipment and use method thereof

ActiveCN111172694AImprove drying efficiencyImprove drying effectDrying machines with progressive movementsProgramme control in sequence/logic controllersElectric machineryEngineering

The present invention discloses cloth integral ironing drying equipment and a use method thereof. The equipment comprises a feeding structure, and the bottom end of the feeding structure is fixedly provided with support legs through screws; one sides of the support legs are fixedly provided with a power box by screws; and the tail end of the feeding structure is rotationally provided with a material arranging roller, the material arranging roller is driven to rotate by a motor, and a lower ironing structure is arranged behind the material arranging roller. By arranging the lower ironing structure, an upper ironing structure, an upper ironing pipe, a lower ironing pipe and a drying column, integral optional ironing is realized through upper ironing and lower ironing; and the overall dryingfitness of cloth is improved by arranging a tubular contact structure, the displacement phenomenon generated by wind-direction blow drying is avoided through contact drying and non-contact drying, andthe drying experience of the equipment is improved.

Owner:NINGBO JINGYE GARMENTS

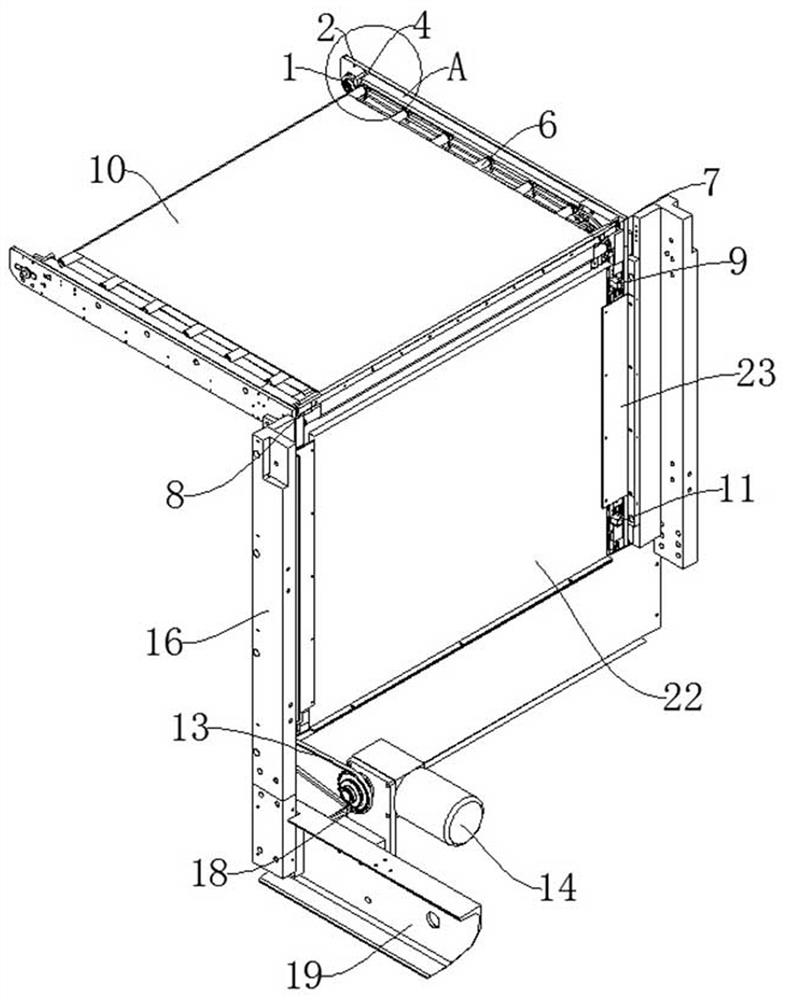

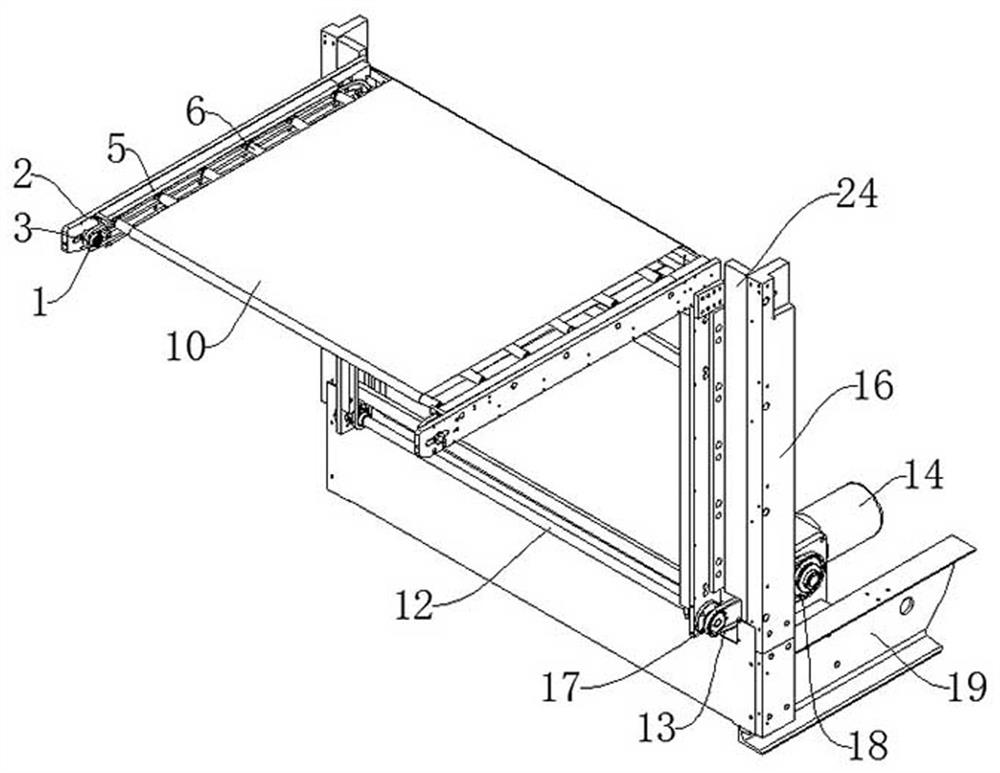

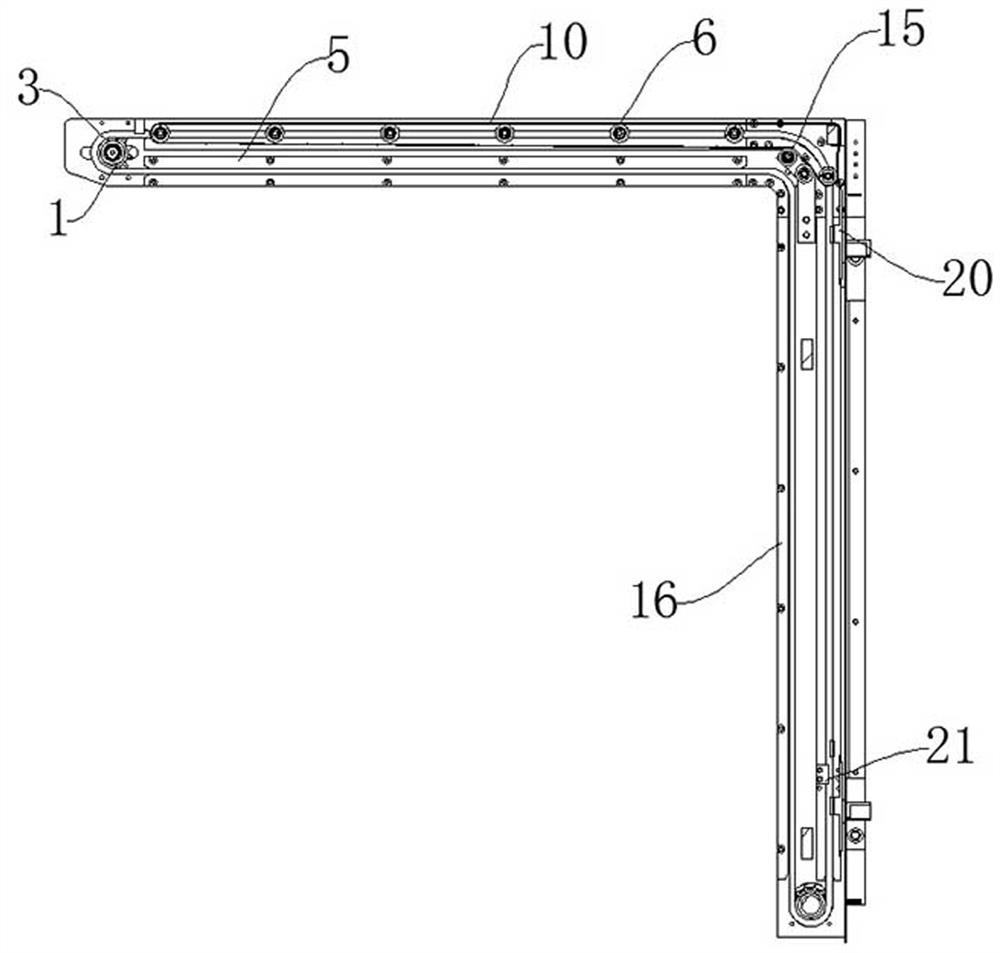

Electric auxiliary paper collecting device for automatic die-cutting machine

PendingCN114560335AEffective clampingAchieve clamping and fixingArticle deliveryControl engineeringControl theory

The invention discloses an electric auxiliary paper collecting device for an automatic die-cutting machine. The paper collecting device has the beneficial effects that by arranging a chain guide rail, an upper limiting switch, a lower limiting switch, an upper limiting block, a lower limiting block, a belt fixing clamping plate and a belt fixing plate, when the paper collecting device is used, on one hand, the vertical movement position of a belt in the normal transmission process can be effectively limited under the action of the upper limiting switch and the lower limiting switch; on the other hand, when an upper limiting switch and a lower limiting switch are out of order, effective limiting of the belt in the lifting process can be achieved under the abutting action of an upper limiting block and a lower limiting block and a paper supporting roller, the stability of the device in the using process is greatly improved, and meanwhile through mutual cooperation of a belt fixing clamping plate and a belt fixing plate, the device is convenient to use. The belt can be effectively clamped and fixed when moving relative to the paper supporting roller, and therefore the defects that in the using process of the device, paper on the lowermost portion of a paper pile is disordered, printed matter is scratched, and paper collection is not tidy are effectively overcome.

Owner:唐山恒峰机械制造有限公司

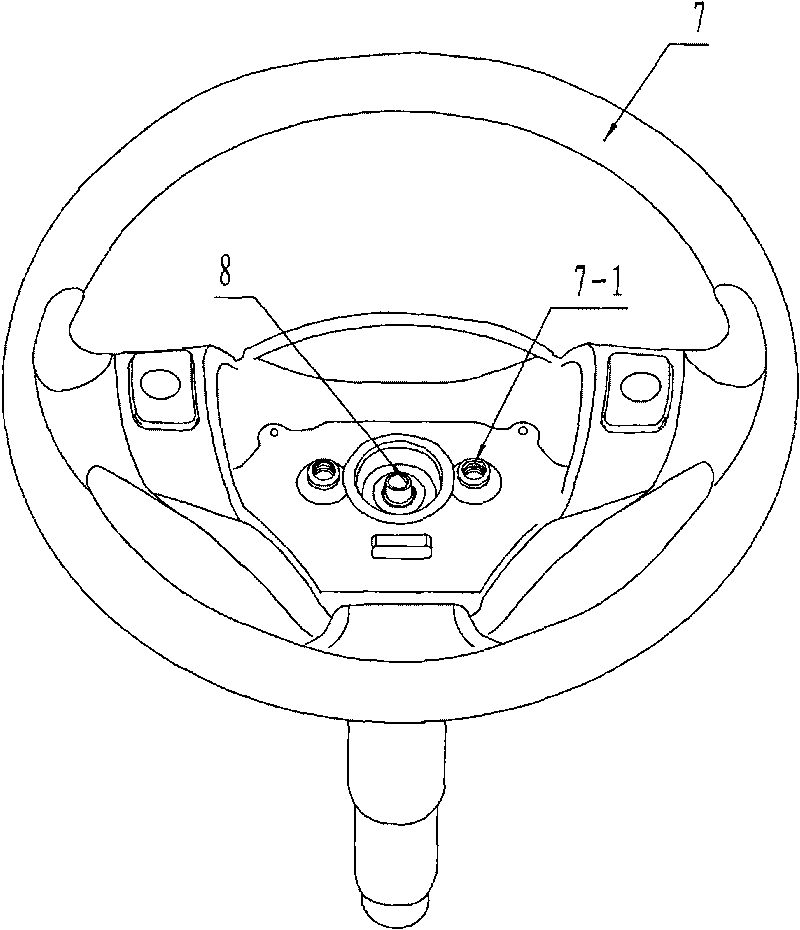

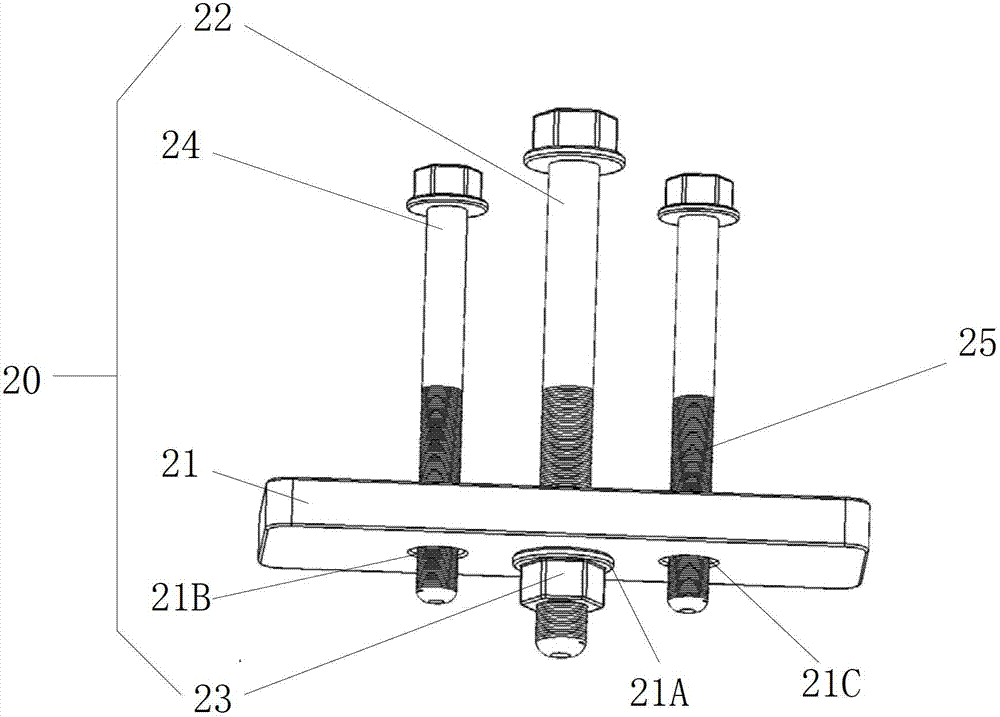

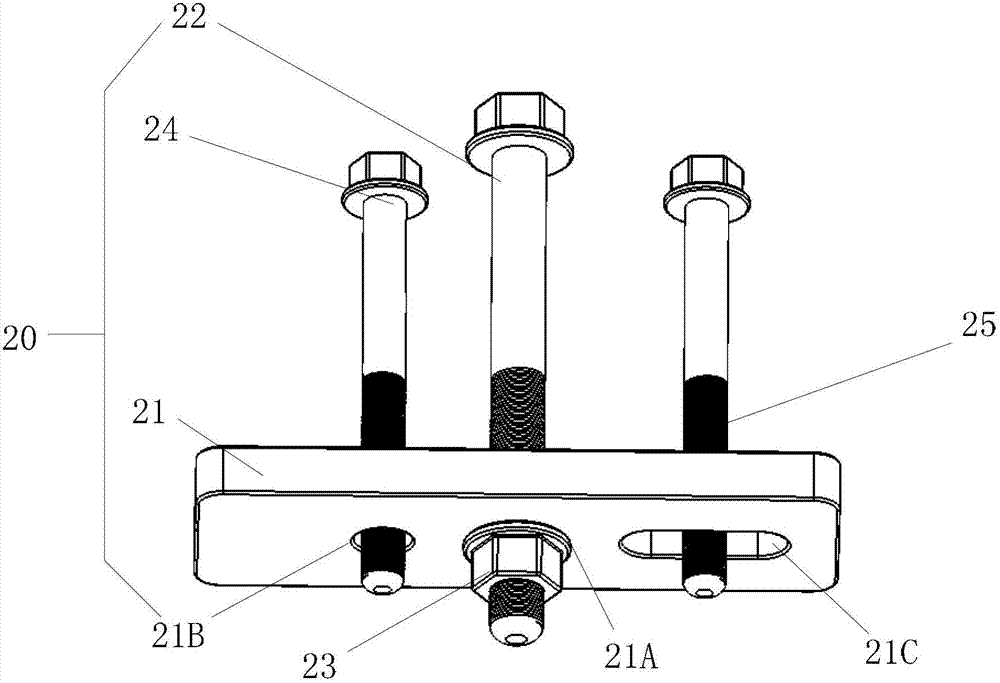

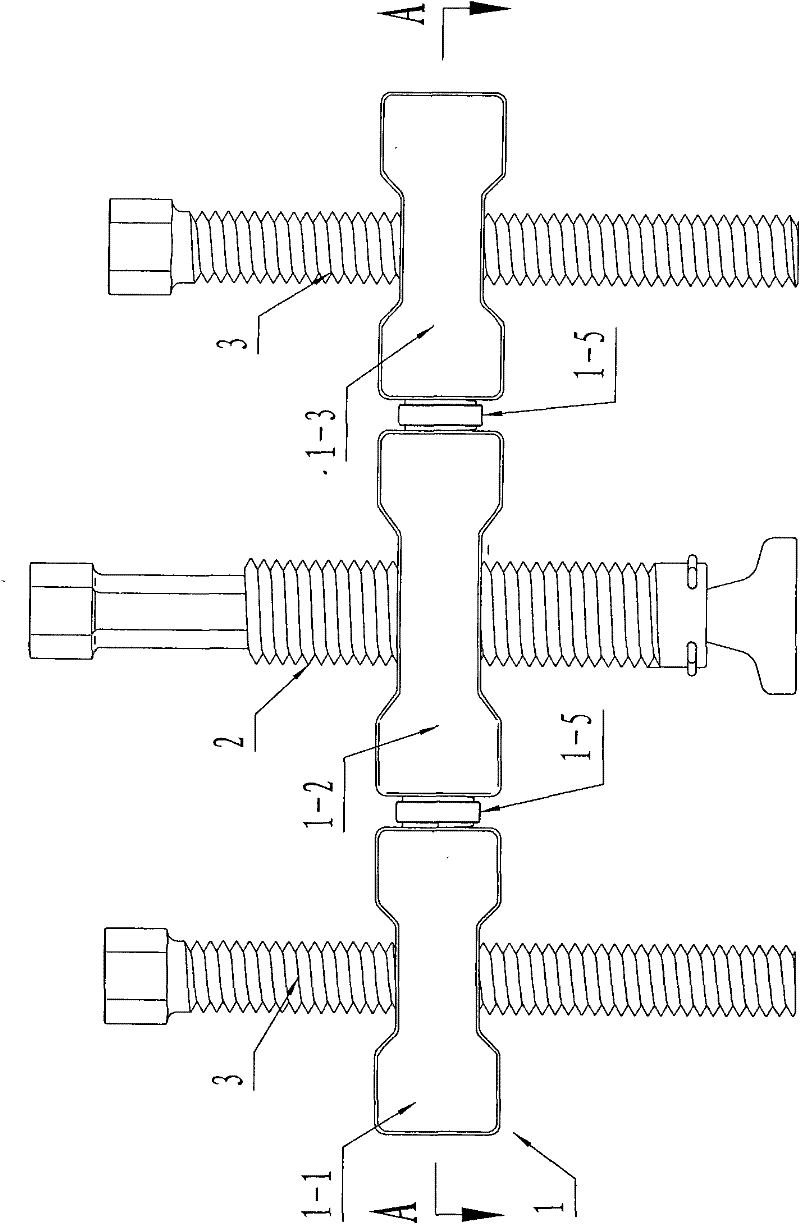

Disassembling tool for steering wheel of automobile and disassembling method

ActiveCN102922481AQuick releaseAvoiding the Cons of DamageMetal-working hand toolsSteering wheelSteering column

The invention discloses a disassembling tool for a steering wheel of an automobile and a disassembling method and belongs to the field of automobiles. The disassembling tool is used for disassembling the steering wheel of the automobile. A steering column shaft end screw hole and two steering fixing screw holes are formed in the steering wheel of the automobile. The disassembling tool for the steering wheel of the automobile comprises a support plate, a main screw bolt bar, a self-locking nut, a first drawing bolt and a second drawing bolt, wherein a main screw bolt bar hole, a first drawing bolt hole and a second drawing bolt hole are formed in the support plate; the main screw bolt bar hole, the first drawing bolt hole and the second drawing bolt hole are used for leading the corresponding main screw bolt bar, the first drawing bolt and the second drawing bolt to pass through; and the self-locking nut is arranged on the main screw bolt bar. According to the embodiment of the invention, the steering wheel can be quickly disassembled in the production or maintenance process of the automobile, and the disassembling tool has the advantages that the disassembling is simple, fast, time-saving and labor-saving. In addition, the defect of damage on parts of the steering wheel due to the misoperation of operators can be effectively avoided.

Owner:CHERY AUTOMOBILE CO LTD

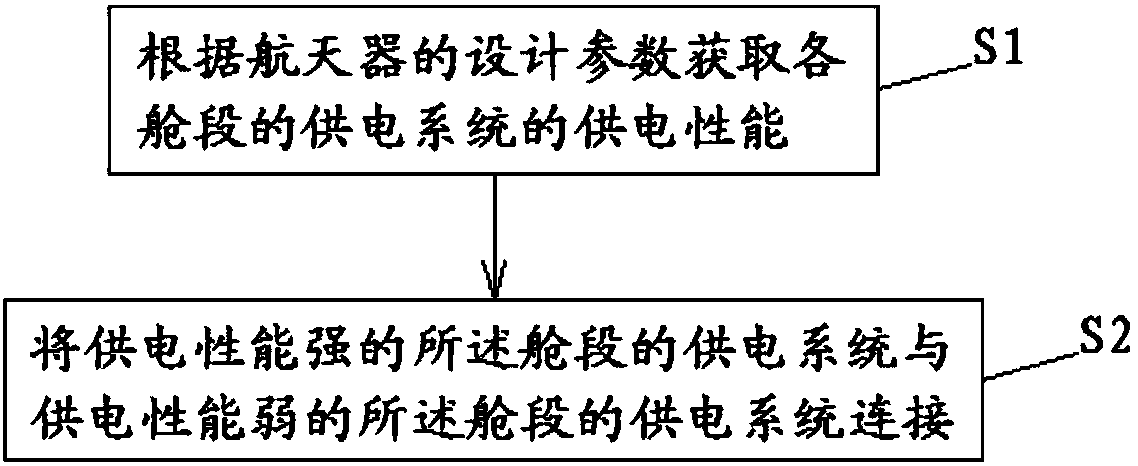

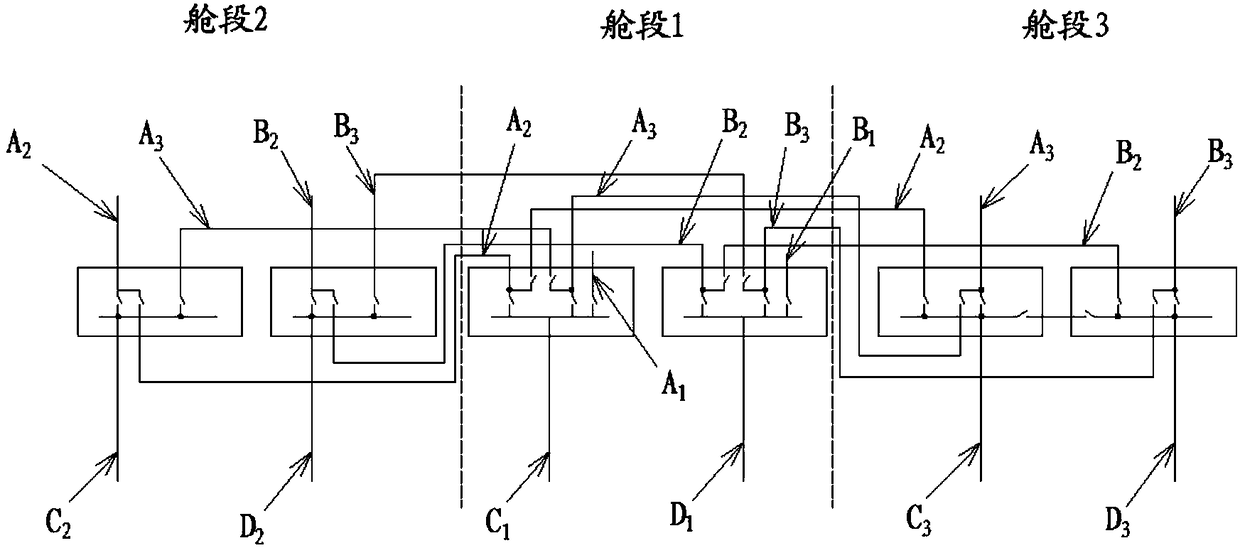

Spacecraft power supply system building method

InactiveCN108183513ASolve the disadvantages of failureExtended service lifeGeometric CADAc-dc network circuit arrangementsSystem buildingSpacecraft

The invention relates to a spacecraft power supply system building method. The method comprises steps: S1, the power supply performance of a power supply system in each cabin is acquired according todesign parameters of the spacecraft; and S2, the power supply system in the cabin with strong power supply performance is connected with the power supply system in the cabin with weak power supply performance. Through connecting the power supply systems in different cabins, the power supply capability between the cabins is dispatched in a unified mode, and electric energy can be used between the cabins. When a power supply system in a single cabin fails, power can be supplied through other connected power supply systems, and the shortcoming of failure of the whole cabin when the power supply system in a single cabin fails can be effectively solved. The service life of a power supply system with weak power supply performance is effectively enhanced, and the reliability of the power supply system in the whole cabin is improved.

Owner:BEIJING SPACE TECH RES & TEST CENT

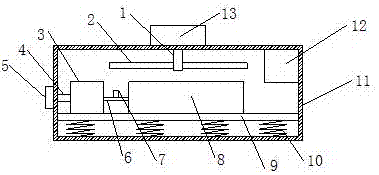

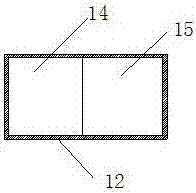

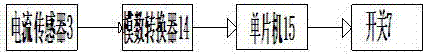

LED driving power supply having protection device

PendingCN108012374AAvoiding the Cons of DamageImprove cooling effectElectrical apparatusElectroluminescent light sourcesMicrocomputerVibration attenuation

The invention relates to an LED driving power supply having a protection device. The LED driving power supply comprises a connection shaft, fan blades, a current sensor, a current inlet line, an analog-digital converter and a singlechip microcomputer, wherein a motor is fixed at an upper end of a protection shell, the connection shaft is fixed at a lower end of a main shaft of the motor, a lower end of the connection shaft penetrates through the protection shell and extends to the protection shell, the two fan blades are symmetrically fixed at a left end and a right end of a stirring shaft, asupport plate is arranged in the protection shell, more than two vibration-attenuation springs are arranged and are fixed on a lower end surface of the support plate at equal distance, the more than two vibration-attenuation springs are fixed at a bottom end of the protection shell, a driving power supply main body is fixed on an upper end surface of the support plate, a connection line is arranged at a left end of the driving power supply main body, and a left end of the connection line is connected with the current sensor. The LED driving power supply can be automatically disconnected, heatcan be dissipated, and vibration can be reduced.

Owner:中山市江奇照明科技有限公司

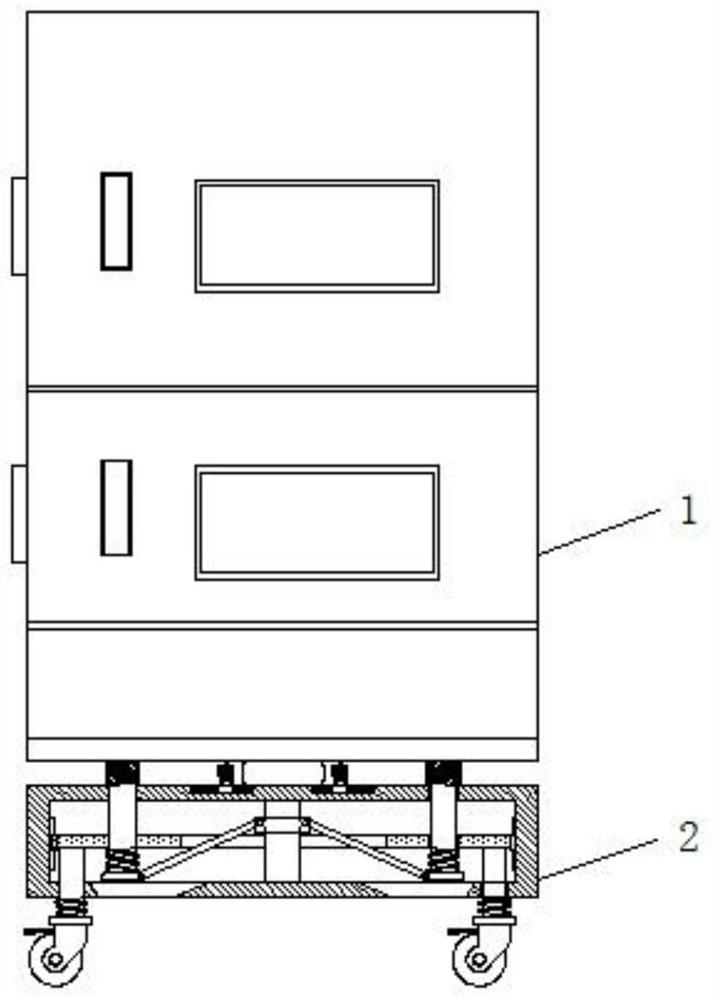

Pharmacy department medicine storing and taking device with metering function

InactiveCN112278565AReduce vibrationEasy to moveContainers to prevent mechanical damageExternal fittingsPharmacy medicineRoad surface

The invention discloses a pharmacy department medicine storing and taking device with a metering function. The pharmacy department medicine storing and taking device comprises a medicine storing and taking device main body, a damping base of a hollow structure is arranged below the medicine storing and taking device main body, a damping plate is movably installed in the damping base, and symmetrically-arranged connecting columns are fixedly installed at the bottom of the medicine storing and taking device main body. Through multi-stage damping and buffering, vibration generated when the medicine storing and taking device main body encounters an uneven road surface in the moving process can be greatly reduced, the damping effect is good, the defect that parts in the medicine storing and taking device main body are damaged due to excessive vibration is avoided, the service life of the whole pharmacy department medicine storing and taking device is greatly guaranteed, it is guaranteed that the medicine storing and taking device main body is more stable in the moving process, the vibration force is smaller, property losses caused by device damage due to excessive vibration are reduced,and the existing use requirements are greatly met.

Owner:郭树宾

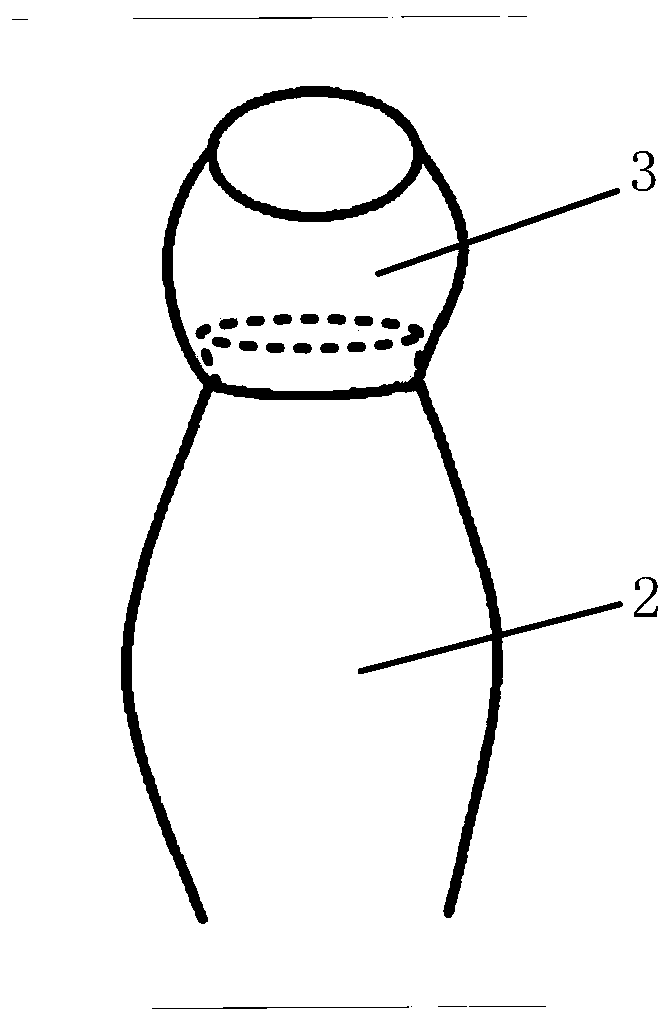

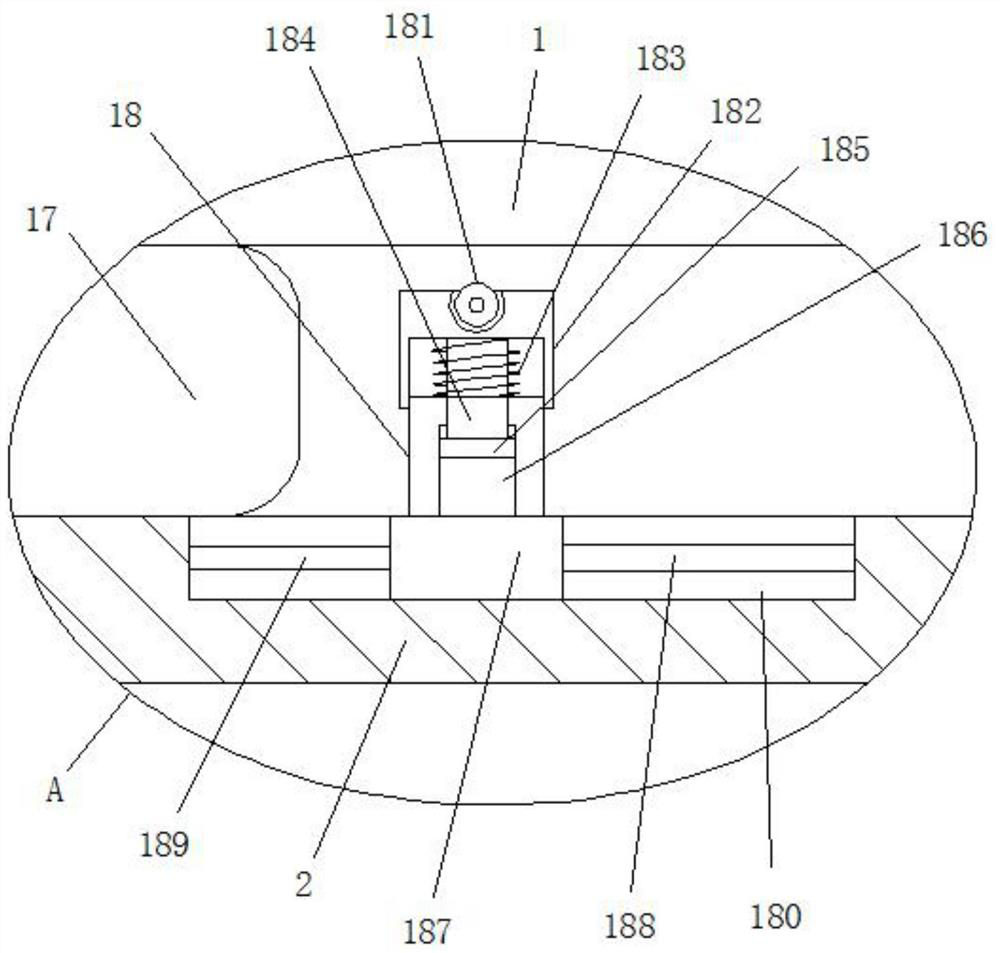

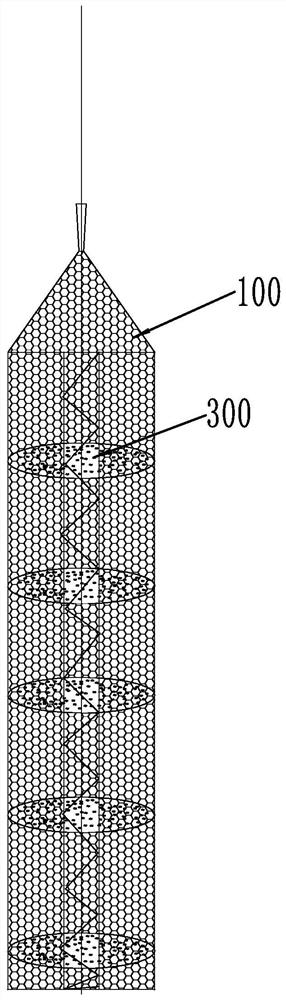

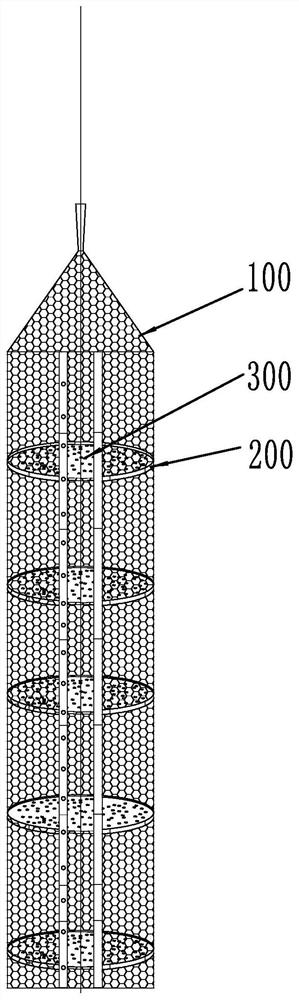

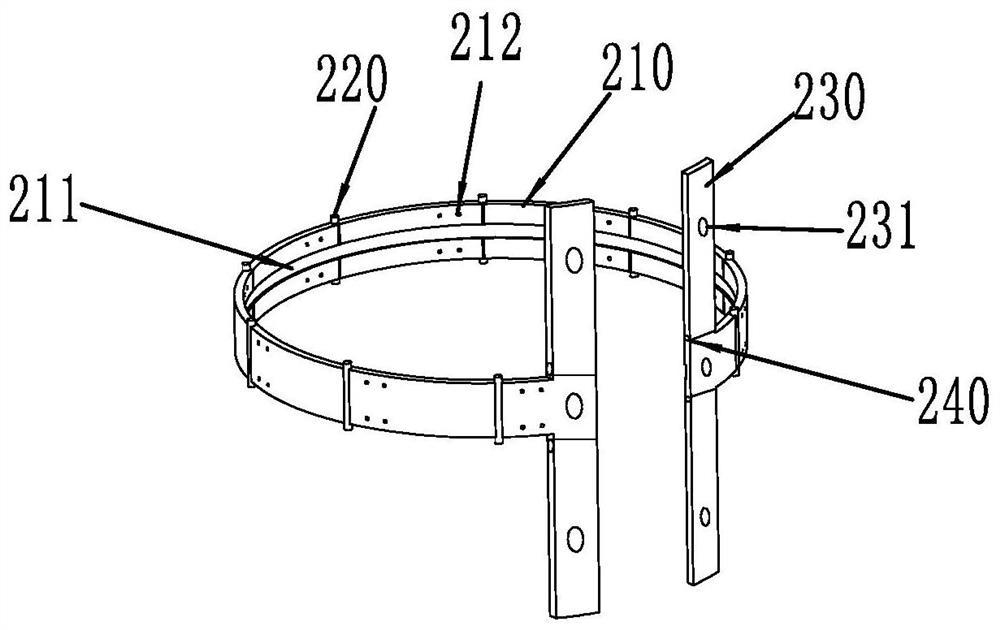

A kind of scallop breeding cage

ActiveCN110463634BQuick loading and unloadingExtended service lifeClimate change adaptationPisciculture and aquariaEngineeringStructural engineering

The invention provides a scallop cultivation cage, which includes a cage net and a placement tray; and several intermediate pieces arranged in a row, each of which includes at least two connecting joints, and the ends of a plurality of the connecting joints are hinged And buckled into a circular ring-shaped intermediate piece; a slot is opened inside the connecting joint, and the outer edge of the placement tray is installed in the slot to realize the convenient loading and unloading of the cage net and the placement tray. The invention can quickly load and unload the cage net and the partition, and when cleaning the breeding cage, the cage net and the partition are separated into two separate parts, and the cage net and the partition can be classified and cleaned, so that the cleaning is more efficient, and Cleanup is more thorough.

Owner:新昌县健丰轴承有限公司

Automotive chassis part surface treatment efficient drying device

InactiveCN108120245AEasy to observeEven contactDrying gas arrangementsDrying chambers/containersEngineeringElectric motor

The invention relates to an automotive chassis part surface treatment efficient drying device. The automotive chassis part surface treatment efficient drying device comprises a connecting rod, a thermal conducting plate, a drum, a device housing, an upper cover plate, a transparent observing window, a containing plate and a handle; the left end of the device housing is provided with a high-temperature heater, the upper end of the high-temperature heater is provided with a connecting pipe, and the inner wall of the device housing is fixedly provided with the thermal conducting plate; the upperend of the connecting pipe penetrates through the device housing and is fixedly connected with the thermal conducting plate; the lower end of the device housing is fixedly provided with support legs and an electromotor, the upper end of the spindle of the electromotor is provided with a connecting shaft, and the upper end of the connecting shaft penetrates through the device housing and the thermal conducting plate, extends to the above the thermal conducting plate and is provided with the drum; the drum is provided with a plurality of air holes; the upper end of the device housing is providedwith an upper cover plate; the bottom end of the inside of the drum is provided with a containing plate. The automotive chassis part surface treatment efficient drying device is good in drying effects, capable of absorbing vibration and convenient to observe.

Owner:崔文良

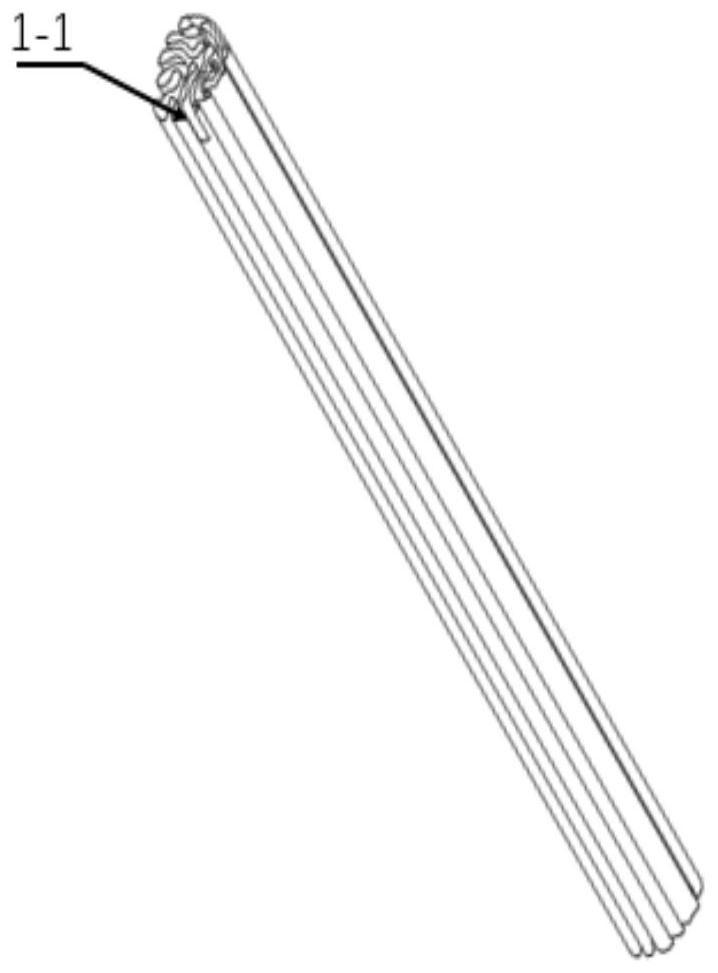

Cylindrical lithium ion battery roll core center pin and battery

PendingCN114142106APrevent collapseImprove wettabilityFinal product manufactureSecondary cellsEngineeringStructural engineering

The invention discloses a cylindrical lithium ion battery roll core center pin and a battery, and belongs to the technical field of storage batteries, the cylindrical lithium ion battery roll core center pin is characterized by comprising a strip-shaped body made of a shape memory material, and the strip-shaped body is of a hollow structure; in an initial state, the outer diameter of the strip-shaped body is smaller than the inner diameter of a central hole of a battery roll core; and after the battery is heated and recovered, the outer wall of the strip-shaped body is attached to the inner wall of the central hole of the battery roll core. The central needle is made of the shape memory material, is hollow or approximately hollow before being inserted into the roll core, and is a thin-strip-shaped alloy rod, so that the central needle can be conveniently inserted into the central hole of the roll core in the production process, and the defect that the interior of the roll core is damaged due to overlarge diameter in the insertion process of the central needle can be effectively avoided. And in the heating process of the battery, the central needle can recover to a cylindrical structure with a certain diameter and is tightly attached to the roll core, so that the interior of the roll core is effectively supported, and the roll core is prevented from collapsing inwards.

Owner:TIANJIN SPACE POWER TECH CO LTD

Brush box convenient to use by fine arts students

The invention belongs to the field of fine arts, in particular to a brush box convenient to use by fine arts students. In order to solve the problems that an existing brush box is simple in structure,poor in fixing and protection effect on brushes, few in function and low in practicability, the following scheme is provided. The brush box convenient to use by fine arts students comprises a deviceshell, wherein an installation partition plate is fixedly installed at the upper end of the device shell, a first shell is fixedly installed at the left end of the installation partition plate, the right end of the installation partition plate is fixedly provided with a second shell, an electric cylinder is fixedly installed at the upper end of the first shell, a lifting rod is connected to the output end of the electric cylinder, the lower end of the lifting rod penetrates through the first shell and extends into the first shell, a lifting plate is fixedly installed, four connecting cylindersare fixedly installed at the lower end of the lifting plate at equal intervals, and connecting rods are installed on the inner walls of the four connecting cylinders. The brush box convenient to useby fine arts students is good in protective effect, high in safety, high in automation degree, and good in practicability.

Owner:TANGSHAN NORMAL UNIV

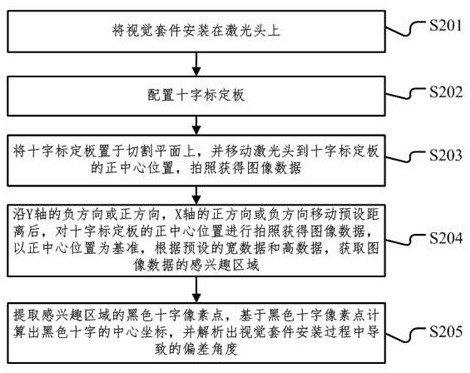

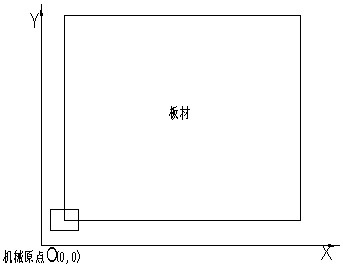

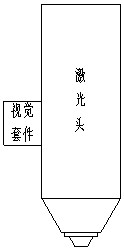

Plate edge searching method of laser cutting machine, calibration system and edge searching system

ActiveCN113828948AImprove cutting accuracySmall footprintLaser beam welding apparatusEngineeringLaser cutting

The invention provides a plate edge searching method and system of a laser cutting machine, and relates to the technical field of laser cutting. The plate edge searching method is divided into a camera calibration part and a plate edge searching part. A camera, a light source and a protective cover are integrated; distortion correction is carried out on the camera; a visual kit is installed at a proper position of a laser head; automatic calibration is carried out, and the coordinate difference between the laser head and the camera, the tiny deviation angle caused in the camera installation process and the proportionality coefficient of the real world and the pixel world can be obtained through calibration; the laser head is moved to a mechanical origin position, picture taking is conducted, a rough coordinate of an angular point of a plate is calculated, and the camera view center is moved to a coordinate position; picture taking is conducted, the accurate coordinate of the angular point of the plate and the inclination angle of the plate are calculated, and the laser head is moved to the position over the angular point of the plate; and the edge searching precision is verified through a frame, the cutting precision is improved, the position corresponding to the laser head is arranged according to actual needs, the occupied space is smaller, mounting and dismounting are flexible, and protection is in place.

Owner:JINAN BODOR LASER CO LTD

Metal powder forming device

The invention discloses a metal powder forming device, and relates to the technical field of forming devices. The metal powder forming device comprises a mold, an upper sleeve, a lower sleeve, a blankouter shell, an upper punch head and a lower punch head, a cylindrical hole and a conical hole which communicate with each other in an up-down mode are formed in the mold, the upper sleeve is a cylindrical barrel matched with the cylindrical hole, a through hole is formed in the center of the upper sleeve, the lower sleeve is a conical barrel matched with the conical hole, the lower sleeve is formed by a plurality of sleeve parts which are detachably connected, the upper surface of the lower sleeve can be in contact with the lower surface of the upper sleeve, a first cylindrical groove is formed in the center of the upper surface of the lower sleeve, the blank outer shell is a cylindrical shell body matched with the first cylindrical groove, a second cylindrical groove is formed in the center of the blank outer shell, the second cylindrical groove has the same diameter as the through hole, the upper punch head is a cylindrical punch head matched with the through hole and can move up and down, and the lower punch head is used for supporting the lower sleeve and can move up and down. The demoulding force produced during demoulding is lowered, and the safety of product forming and the integrity of products are improved.

Owner:HARBIN ENG UNIV

Automatic assembly line of cable-containing lamp

InactiveCN110076724AAvoiding the Cons of DamageSuitable for useMetal-working hand toolsEngineeringAssembly line

The invention discloses an automatic assembly line of a cable-containing lamp. The automatic assembly line comprises an assembling box and an assembling cavity arranged in the assembling box, the automatic assembly line is characterized that the front wall of the assembling cavity is provided with a first charging hole penetrating back and forth, the front wall of the assembling cavity is providedwith a second charging hole which is positioned on the right side of the first charging hole and penetrates through the front wall of the assembling cavity. Compared with a traditional automatic assembly line of a large lamp, the automatic assembly line is simple in structure, low in cost and suitable for being used by small and medium-sized lamp enterprises, only one person needs to be used forfilling materials, the lamp cover and the base can be automatically assembled, so that the assembly efficiency is greatly improved.

Owner:广州雅松商贸有限公司

Anti-usb damage computer case

ActiveCN107092317AAdjustable distanceMeet distance requirementsDigital processing power distributionEngineeringUSB

The invention belongs to the field of calculator assistance devices and particularly relates to an anti-usb damage case. The case comprises a shell; a first ring groove and a second ring groove which are concentric are formed in the upper surface of the shell; a rotary plate capable of auto-rotating is connected into the second ring groove in a sliding manner; a usb jack is formed in the rotary plate; an opening connected with the first ring groove is formed in the circumference of an outer circle of the second ring groove; a baffle is hinged to the end part of the opening; a line concentration ball is further arranged in the shell of the case; a transmitter used for signal transmission is arranged in the line concentration ball; an upper half ball and a lower half ball of the line concentration ball are rotationally connected; a bendable telescopic pipe is arranged on the ball surface of the upper half ball; the top of the telescopic pipe is fixedly connected with the bottom of the rotary plate; and a lead wire in the telescopic pipe leads into the line concentration ball and is connected with the transmitter. According to the case, the usb jack can be prevented from being damaged, and the position and direction of the jack can be changed for satisfying simultaneous insertion of a plurality of devices, so that the device utilization rate is increased; and the operation is simple.

Owner:南通易准软件有限公司

usb anti damage computer case

ActiveCN107092317BEasy to operateAvoiding the Cons of DamageDigital processing power distributionUSBCalculator

The invention belongs to the field of calculator assistance devices and particularly relates to an anti-usb damage case. The case comprises a shell; a first ring groove and a second ring groove which are concentric are formed in the upper surface of the shell; a rotary plate capable of auto-rotating is connected into the second ring groove in a sliding manner; a usb jack is formed in the rotary plate; an opening connected with the first ring groove is formed in the circumference of an outer circle of the second ring groove; a baffle is hinged to the end part of the opening; a line concentration ball is further arranged in the shell of the case; a transmitter used for signal transmission is arranged in the line concentration ball; an upper half ball and a lower half ball of the line concentration ball are rotationally connected; a bendable telescopic pipe is arranged on the ball surface of the upper half ball; the top of the telescopic pipe is fixedly connected with the bottom of the rotary plate; and a lead wire in the telescopic pipe leads into the line concentration ball and is connected with the transmitter. According to the case, the usb jack can be prevented from being damaged, and the position and direction of the jack can be changed for satisfying simultaneous insertion of a plurality of devices, so that the device utilization rate is increased; and the operation is simple.

Owner:南通易准软件有限公司

Automobile steering wheel removal tool and removal method

ActiveCN102922481BQuick releaseAvoiding the Cons of DamageMetal working apparatusMetal-working hand toolsSteering wheelSteering column

The invention discloses a disassembling tool for a steering wheel of an automobile and a disassembling method and belongs to the field of automobiles. The disassembling tool is used for disassembling the steering wheel of the automobile. A steering column shaft end screw hole and two steering fixing screw holes are formed in the steering wheel of the automobile. The disassembling tool for the steering wheel of the automobile comprises a support plate, a main screw bolt bar, a self-locking nut, a first drawing bolt and a second drawing bolt, wherein a main screw bolt bar hole, a first drawing bolt hole and a second drawing bolt hole are formed in the support plate; the main screw bolt bar hole, the first drawing bolt hole and the second drawing bolt hole are used for leading the corresponding main screw bolt bar, the first drawing bolt and the second drawing bolt to pass through; and the self-locking nut is arranged on the main screw bolt bar. According to the embodiment of the invention, the steering wheel can be quickly disassembled in the production or maintenance process of the automobile, and the disassembling tool has the advantages that the disassembling is simple, fast, time-saving and labor-saving. In addition, the defect of damage on parts of the steering wheel due to the misoperation of operators can be effectively avoided.

Owner:CHERY AUTOMOBILE CO LTD

Self-weight clamping intelligent watch charging seat

InactiveCN113270926AEasy to placeAvoid the risk of sheddingBatteries circuit arrangementsElectric powerMechanical engineeringUltraviolet germicidal light

The invention discloses a self-weight clamping intelligent watch charging seat, and belongs to the technical field of intelligent watches. The self-weight clamping intelligent watch charging seat comprises a base with the top in an opening shape, a partition plate is arranged at one end in the base, and a transmission cavity is formed between the inner side of the partition plate and the base; a bearing plate is in the base at the outer side of the partition plate, a pair of grooves are symmetrically formed in the two sides of the bottom of the bearing plate, and connecting rods are hinged to the two ends of the interior of each groove. According to the present invention, a stirring assembly is arranged, an ultraviolet sterilization lamp is installed in a collecting box, and a stirring plate at the stirring assembly has a one-way overturning effect, namely the overturning direction of the stirring plate is limited to be the same as the overall descending direction of the bearing plate; when the bearing plate and an intelligent watch are charged and need to be lifted up and reset, the watch is overturned into the collecting box to be collected by prizing the stirring plate, and the intelligent watch is sterilized and disinfected by the ultraviolet sterilizing lamp, so that the cleanliness of the daily wearing and use of the intelligent watch is improved.

Owner:SHENZHEN XINKEYING TECH CO LTD

A plate edge-finding method, calibration system and edge-finding system for a laser cutting machine

ActiveCN113828948BImprove cutting accuracySmall footprintLaser beam welding apparatusEngineeringLaser cutting

The invention provides a method and system for finding the edge of a plate for a laser cutting machine, and relates to the technical field of laser cutting. The invention is divided into a camera calibration part and a plate edge finding part. Integrate the camera, light source, and protective cover; correct the distortion of the camera; install the vision kit at the appropriate position of the laser head; automate calibration, after calibration, you can obtain the coordinate difference between the laser head and the camera, the slight deviation angle caused by the camera installation process, Scale factor of real world to pixel world. Move the laser head to the mechanical origin position, take pictures, calculate the approximate coordinates of the corners of the sheet, and move the center of the camera field of view to the coordinate position; take pictures, calculate the exact coordinates of the corners of the sheet and the inclination angle of the sheet, and move the laser head to the corner of the sheet Click directly above; walk the border to verify the edge-seeking accuracy, improve cutting accuracy, and set it to the corresponding position of the laser head according to actual needs, taking up less space, flexible installation and disassembly, and protection in place.

Owner:JINAN BODOR LASER CO LTD

A reinforcement structure for damming body and its construction method

ActiveCN105756019BImprove structural strengthImprove compactnessEarth-fill damsRock-fill damsUltimate tensile strengthMaterials science

The invention relates to a reinforcement structure for a barrier dam and a construction method of the reinforcement structure. The reinforcement structure comprises a plurality of layers of first cement bodies which are sequentially arranged on the surface of a first to-be-reinforced area of the barrier dam from top to bottom, wherein every two adjacent layers of cement bodies are in contact with each other to form a first reinforcement body of the barrier dam; and first grouting holes which are respectively communicated with the first cement bodies are formed in the first reinforcement bodies. The reinforcement structure has the advantages of being high in structural strength, good in soil mass stability, high in compactness and good in scouring resistance and permeation resistance.

Owner:TSINGHUA UNIV

Automobile steering wheel disassembling tool

InactiveCN101708604BImprove work efficiencyAvoiding the Cons of DamageMetal-working hand toolsSteering wheelEngineering

The invention relates to an automobile steering wheel disassembling tool for solving the problem of difficult disassembly of a steering wheel. The technical scheme of the automobile steering wheel disassembling tool is that the automobile steering wheel disassembling tool comprises a supporting mechanism, a main screw and drawing bolts; the main screw is positioned on the middle part of the supporting mechanism and is in screw fit with the supporting mechanism; and the drawing bolts are symmetrically arranged on both sides of the main screw and are in screw fit with the supporting mechanism respectively. The automobile steering wheel disassembling tool takes a shaft end of a steering shaft of the steering wheel as a supporting point to support the main screw, ingeniously uses a fixed screwed hole on a framework of the steering wheel to make the drawing bolts in threaded connection with the fixed screw hole, rotates the main screw and lifts the steering wheel up by the drawing bolts ina screw transmission mode to easily disassemble the steering wheel. To be suitable for disassembling the steering wheels of different vehicle types, an adjustable spacing connection is designed between the main screw and the drawing bolts. The automobile steering wheel disassembling tool has simple and rapid disassembly, and time and labor conservation, and can effectively avoid the defect of damage to the parts of the steering wheel caused by an improper operation of maintenance personnel. The automobile steering wheel disassembling tool also has the characteristics of convenient carrying and strong popularity.

Owner:GREAT WALL MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com