Electric auxiliary paper collecting device for automatic die-cutting machine

A die-cutting machine and auxiliary delivery technology, which is used in transportation and packaging, thin material handling, and sending objects, etc., can solve the problems of scratched printed matter, reduced delivery quality, and uneven delivery, and achieves improved service life. The effect of improving delivery quality and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

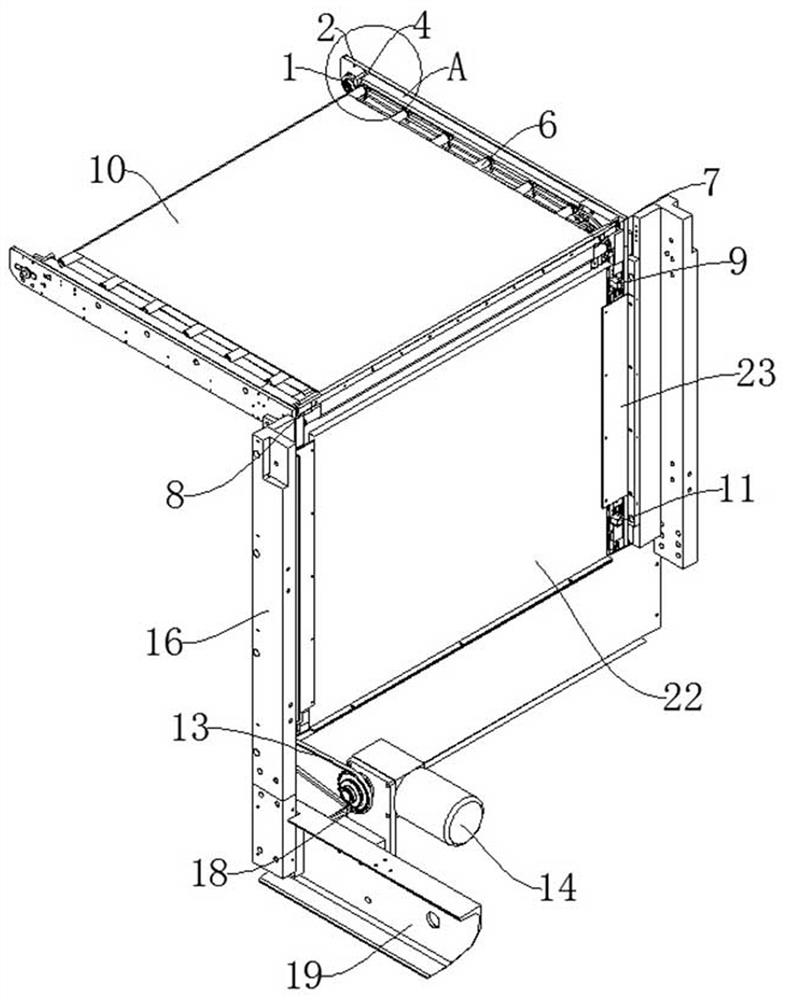

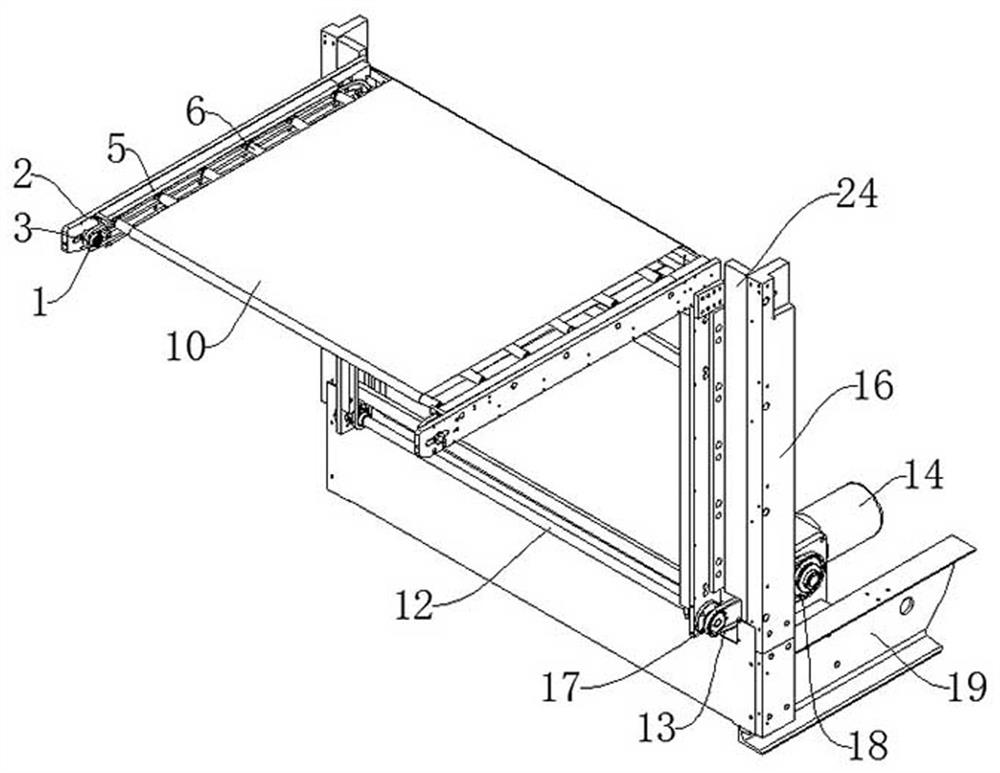

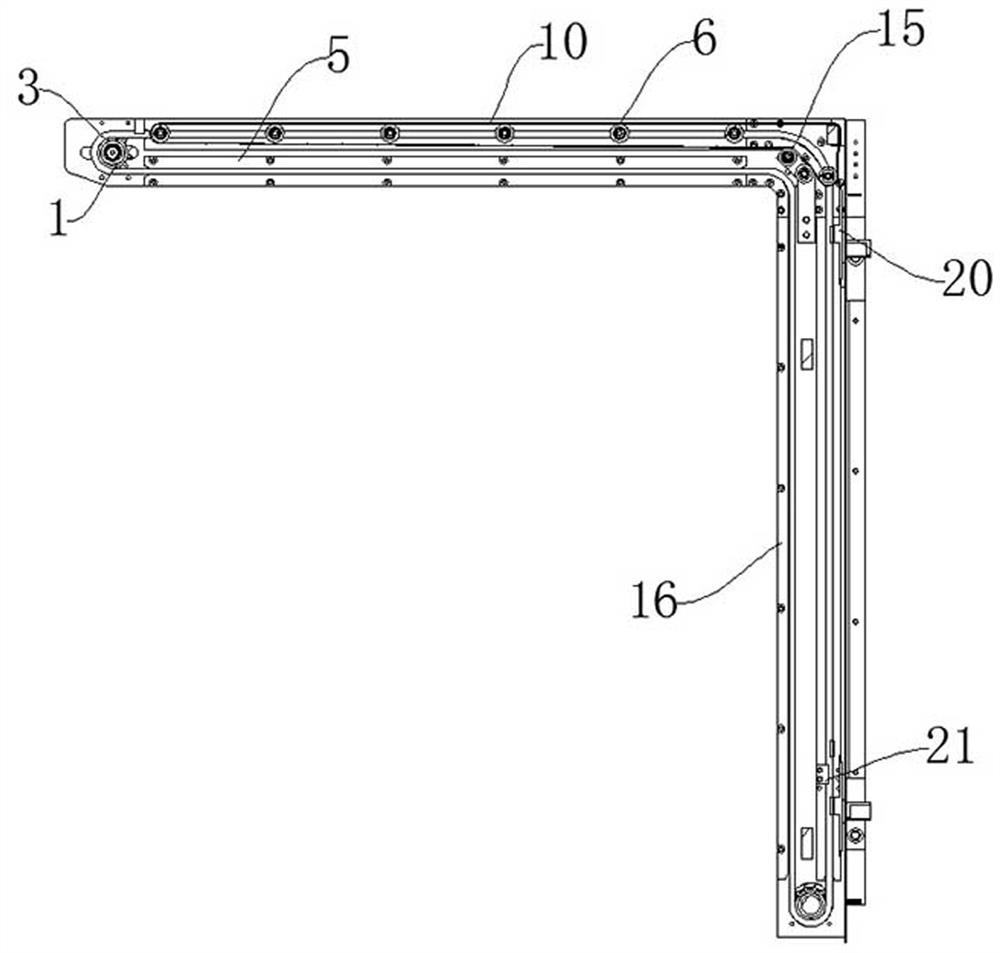

[0036] Such as Figure 1-Figure 4As shown, an electric auxiliary delivery device for an automatic die-cutting machine includes a support plate 2, a vertical plate 16, a chain guide rail 5 and an upper limit switch 9, and the vertical plate 16 is provided on one side of the support plate 2 , the support plate 2 and the vertical plate 16 all have two, the chain guide rail 5 is installed on the support plate 2 and the vertical plate 16, and the chain guide rail 5 is located on the support plate 2 An upper limit block 4 is installed at one end, and a lower limit block 21 is installed at the other end of the chain guide rail 5 on the vertical plate 16, and the upper limit block 4 and the lower limit block 21 can be used when the belt 10 is abnormal When working, the stable use of the device is ensured by resisting the paper support roller 6. The support roller transmission chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com