Textile product with waterproof breathable coating and method for preparing textile product

A waterproof and breathable textile technology, applied in the field of textiles, can solve problems such as complex manufacturing process, cracked coating, and inability to drain water efficiently and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] A preparation method of a waterproof breathable coated textile, comprising the following steps:

[0062] Step (1), material preparation: prepare a breathable cover layer, a coating liquid and a base material and a convex strip made of fibers; the coating liquid is N, N-dimethylformamide, polyurethane and a bridging agent Prepared according to the mass ratio of 1: (3-5): (0.1-0.4);

[0063] Step (2), forming a waterproof and breathable coating: evenly coat the coating liquid on the upper surface of the substrate, keep it for 5-15 minutes, then put the substrate coated with the coating liquid into 30-50°C water, Keep it for 8-24 hours, take it out, and dry it to obtain a substrate with a waterproof and breathable coating;

[0064] Step (3), the convex strips are evenly spaced and substantially parallel to each other on the waterproof and breathable coating, and the adhesive is evenly sprayed along the length direction of the convex strips at the interval between adjacent...

Embodiment 1

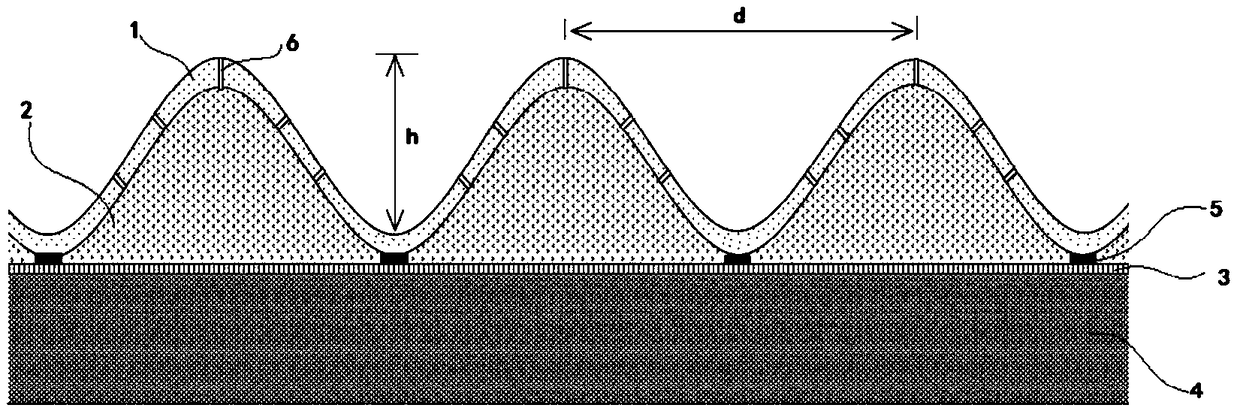

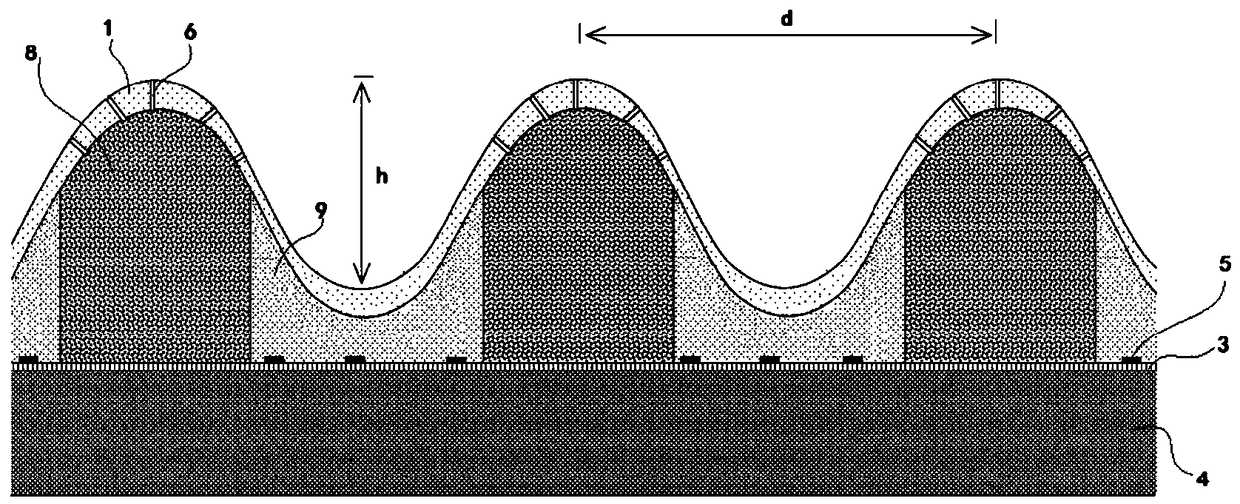

[0092] A waterproof and breathable coated textile, comprising a base material 4, a waterproof and breathable coating 3, a convex strip 2 and a covering layer 1, the upper surface of the base material 4 is coated with a waterproof and breathable coating 3, and the waterproof and breathable coating On the outer surface of the layer 3, a plurality of convex strips 2 are evenly spaced, and the covering layer 1 is breathable and covered on the plurality of convex strips 2 to form a convex portion, and a groove portion is formed between adjacent convex strips 2 ; At the position of the groove part, the inner surface of the covering layer 1 is directly bonded to the waterproof and breathable coating 3; the base material 4 and the protruding strip 2 are both fiber products.

[0093] The ridges 2 are parallel to each other and formed by scattered short fibers; the length of the short fibers is 20-100mm, and the linear density is 3.1-8.5dtex; the short fibers are hydrophobic chemical fib...

Embodiment 2

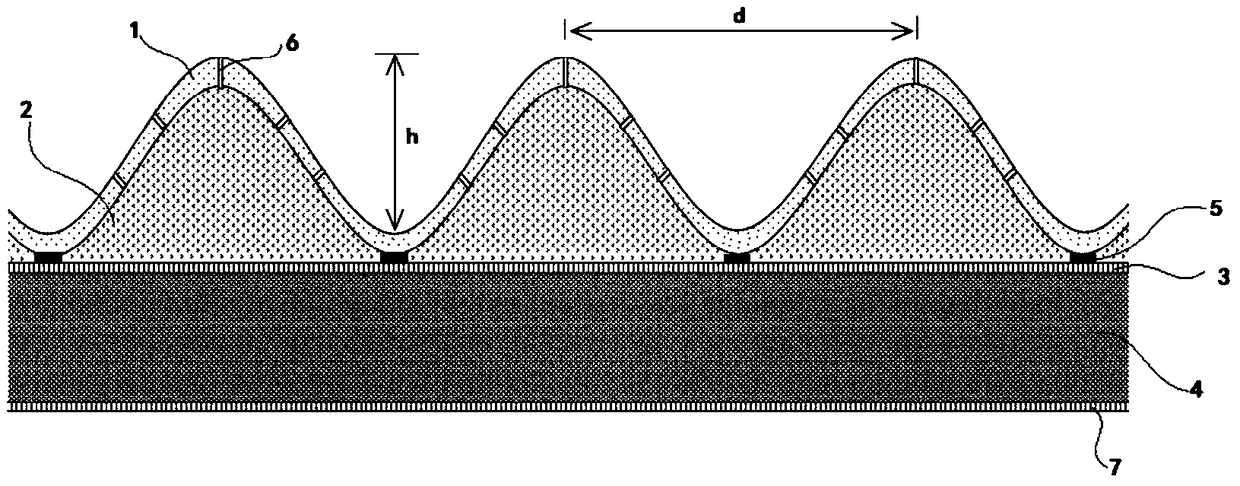

[0100] Embodiment two: embodiment two is basically the same as embodiment one, the difference is that in the waterproof breathable textile of embodiment two, the lower surface of substrate 4 is also coated with waterproof breathable coating. When forming a waterproof and breathable coating in step (2), the lower surface of the substrate 4 is also uniformly coated with the coating liquid, and finally a waterproof and breathable coating is also formed on the lower surface of the substrate 4, which is called the second waterproof and breathable coating. Layer 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com