Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid the problem of uneven drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

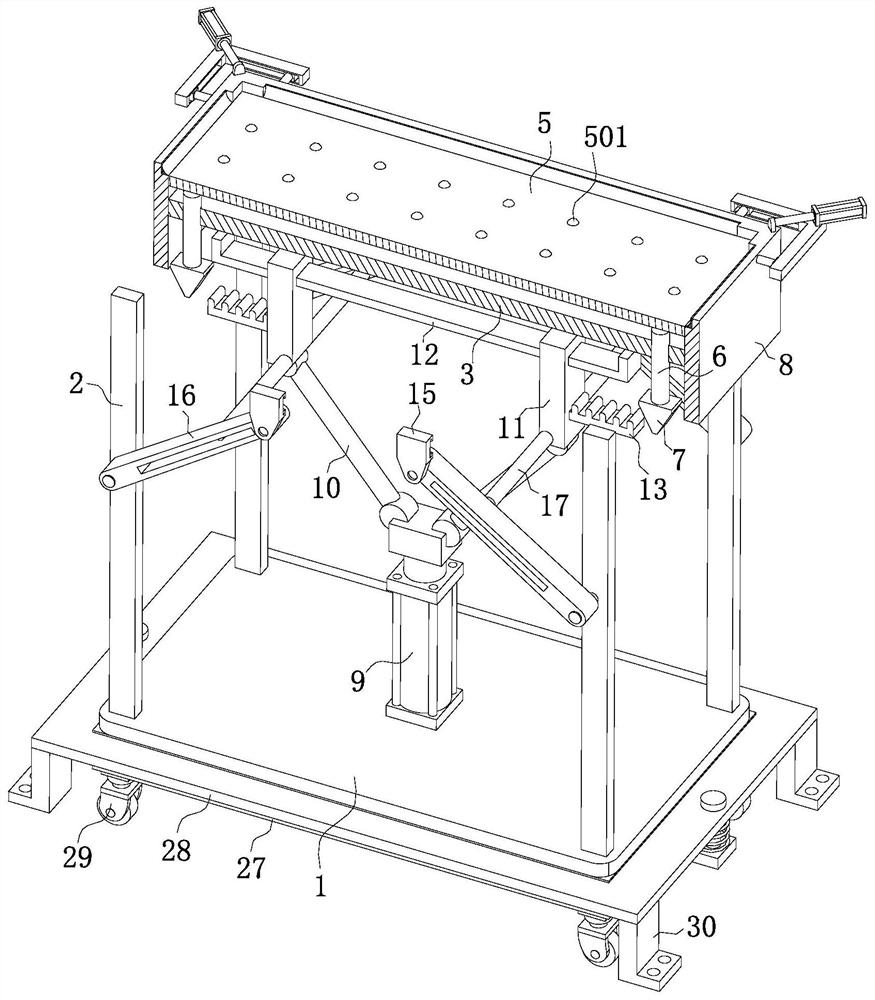

Textile fabric uniform drying device based on reciprocating motion

InactiveCN111442629AReduce water contentSpeed up dryingDrying gas arrangementsDrying machines with progressive movementsReciprocating motionStructural engineering

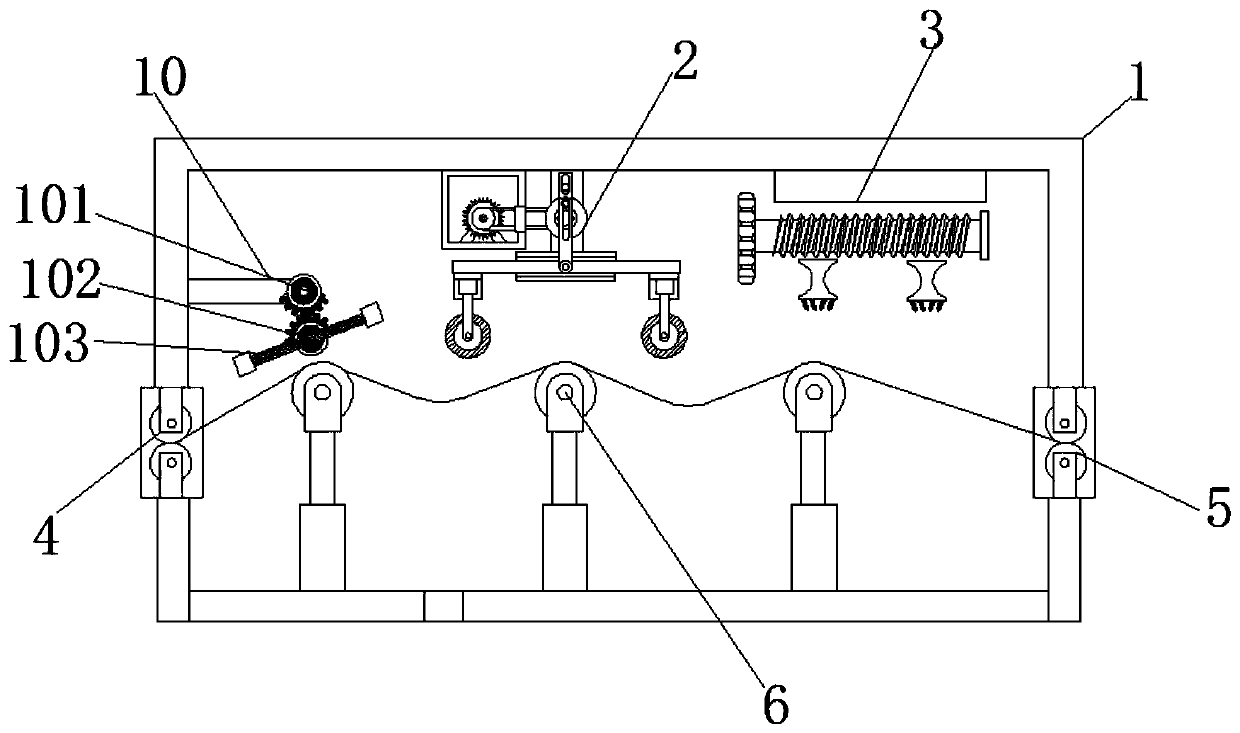

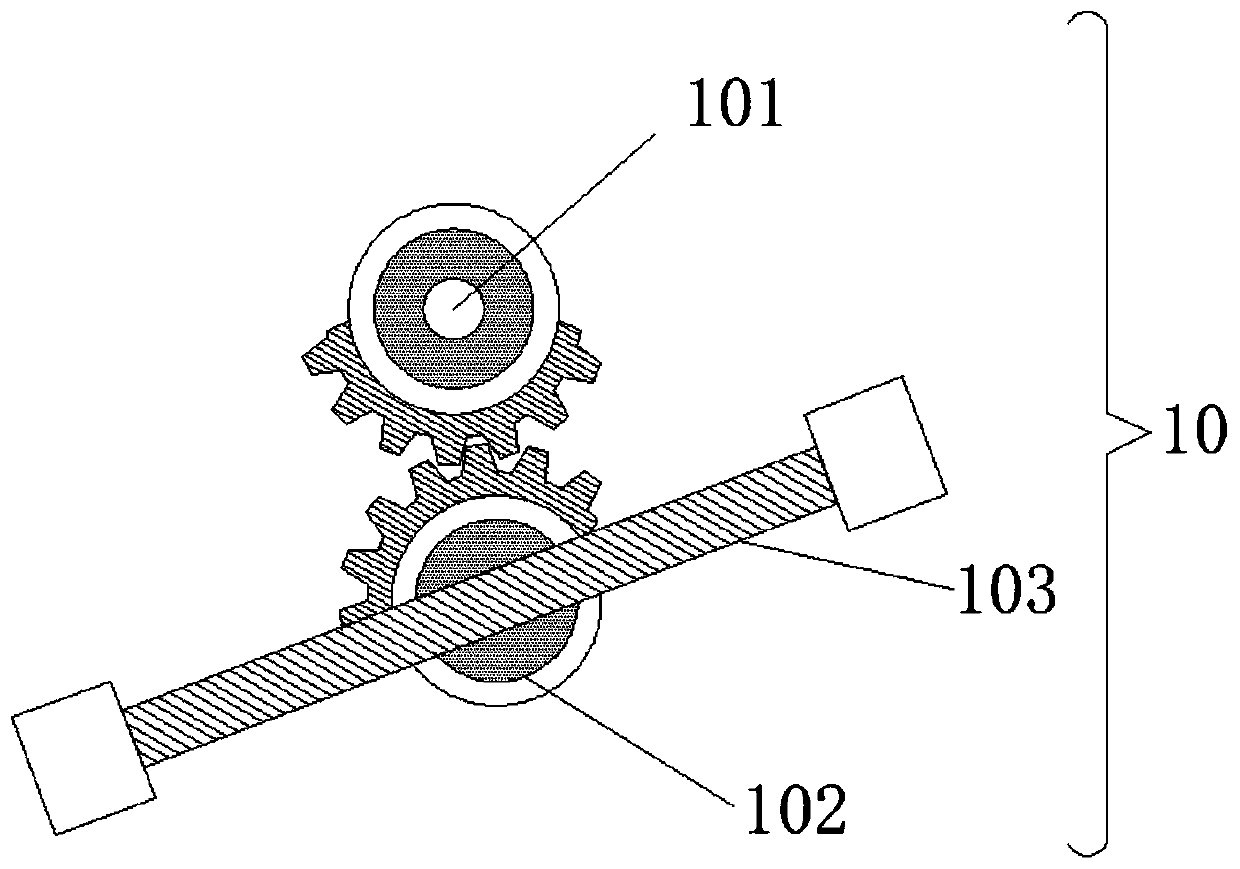

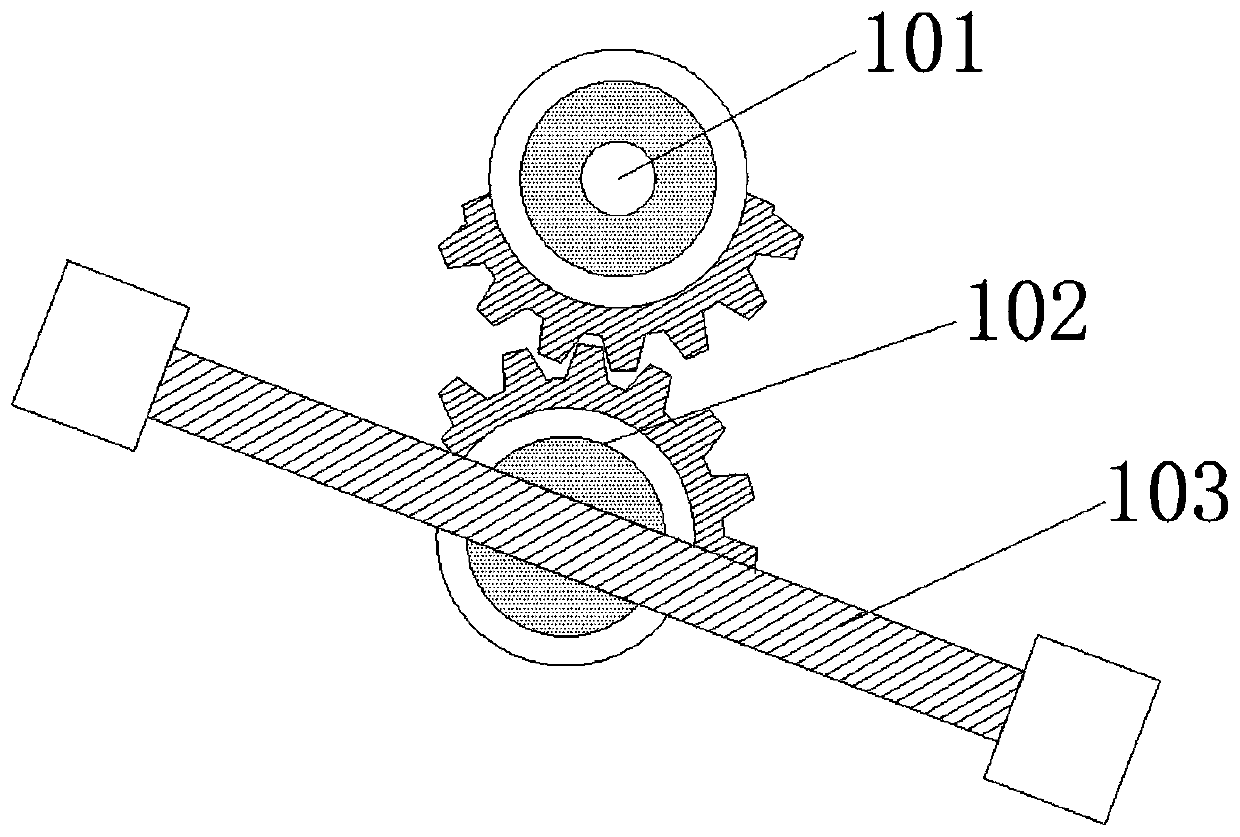

The invention relates to the technical field of textile fabrics, and discloses a textile fabric uniform drying device based on reciprocating motion. The textile fabric uniform drying device comprisesa device main body, wherein a beating device, a rolling drying device and a reciprocating heating device are arranged inside the device main body; a primary deflection gear and a secondary deflectiongear are arranged inside the beating device; a beating rod is arranged on the secondary deflection gear; and air jet holes are connected below a motion slide block. During use of the textile fabric uniform drying device based on reciprocating motion, textile fabrics are placed into the device main body from a fabric inlet, undried fabrics are overlapped on lifting drums to be sequentially transported to the beating device, the beating device works, the primary deflection gear rotates to drive the secondary deflection gear meshed below the primary deflection gear to start reciprocating motion,and then the beating rod arranged on the secondary deflection gear is driven to perform reciprocating beating in order to beat water drops on the undried fabrics, so that the situation that drying cannot be performed in subsequent procedures due to over high water content is avoided.

Owner:陈成祥

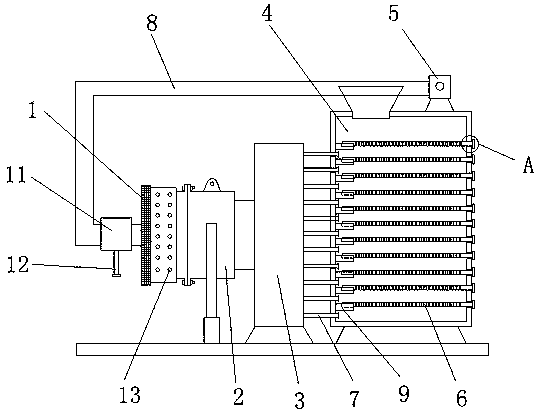

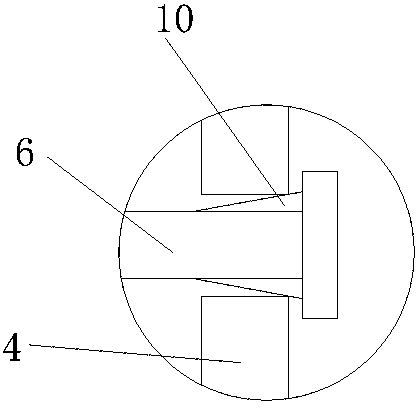

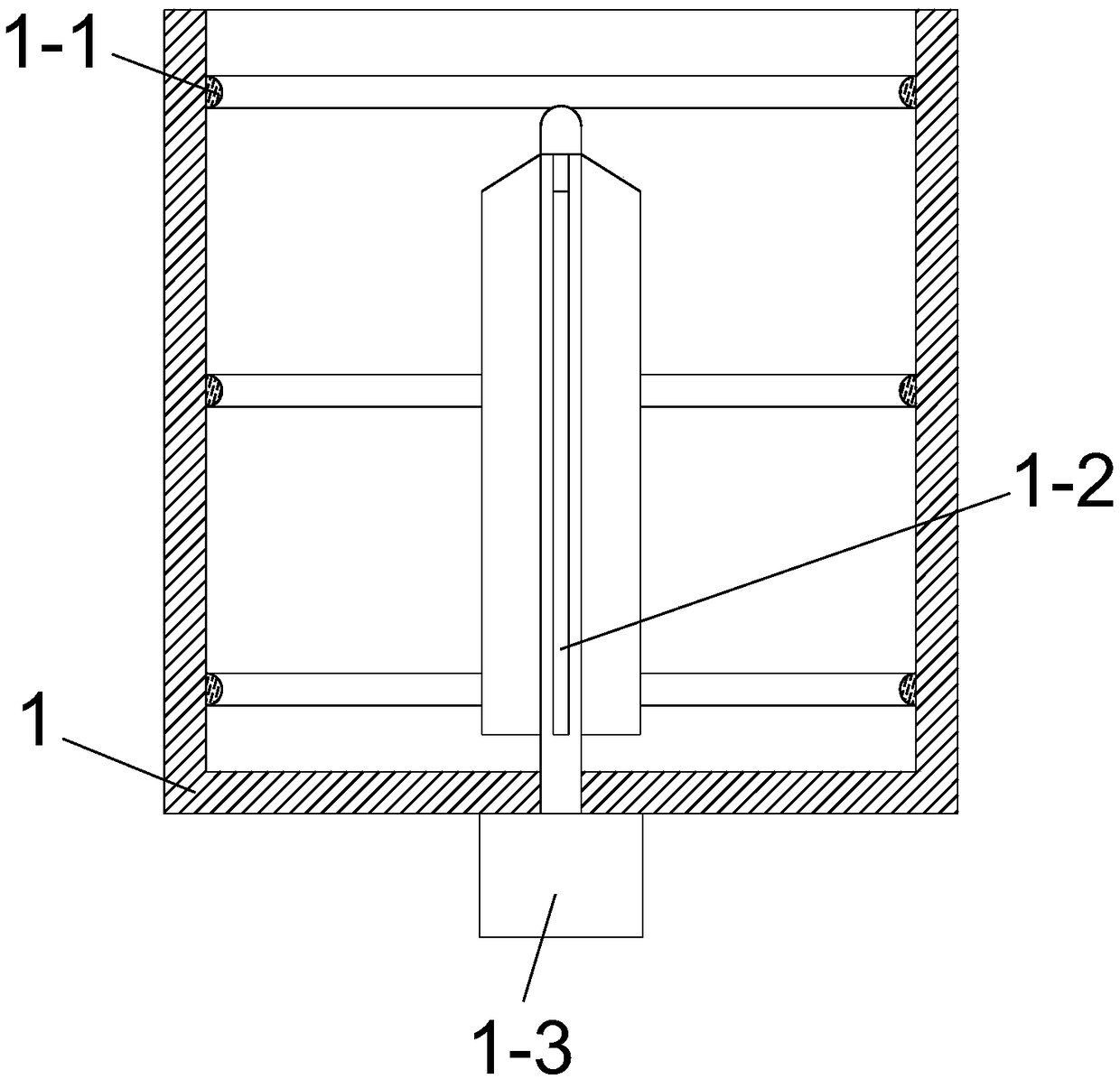

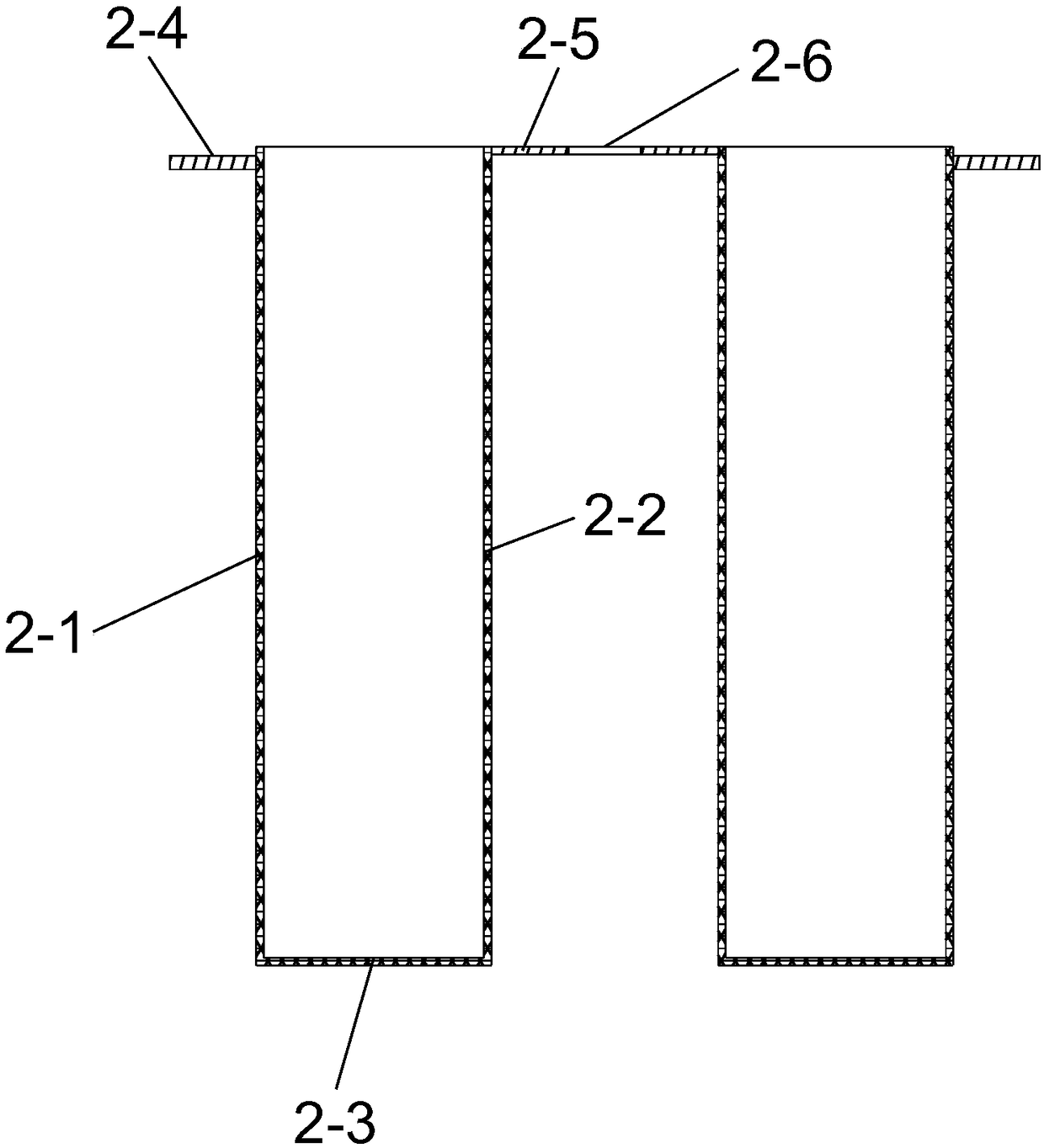

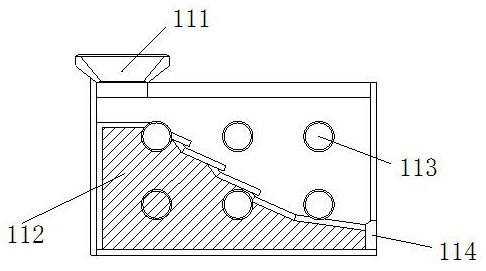

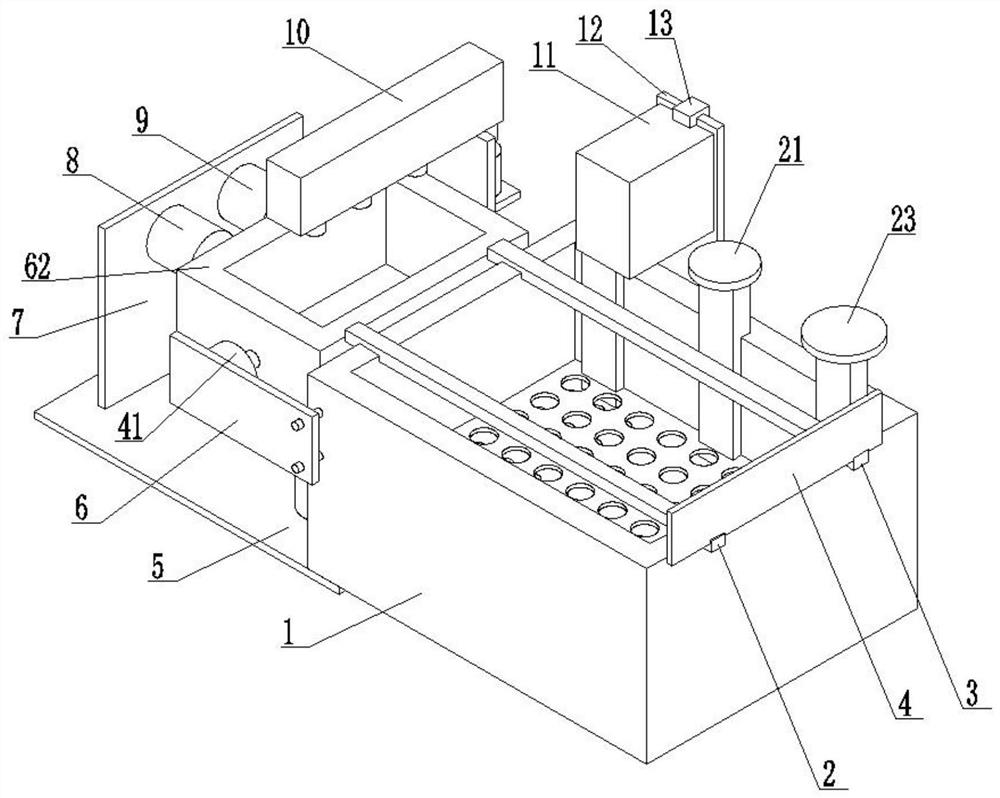

Rice drying device

InactiveCN108088225AExtended stayControl the speed of the slideSievingScreeningEngineeringDrying time

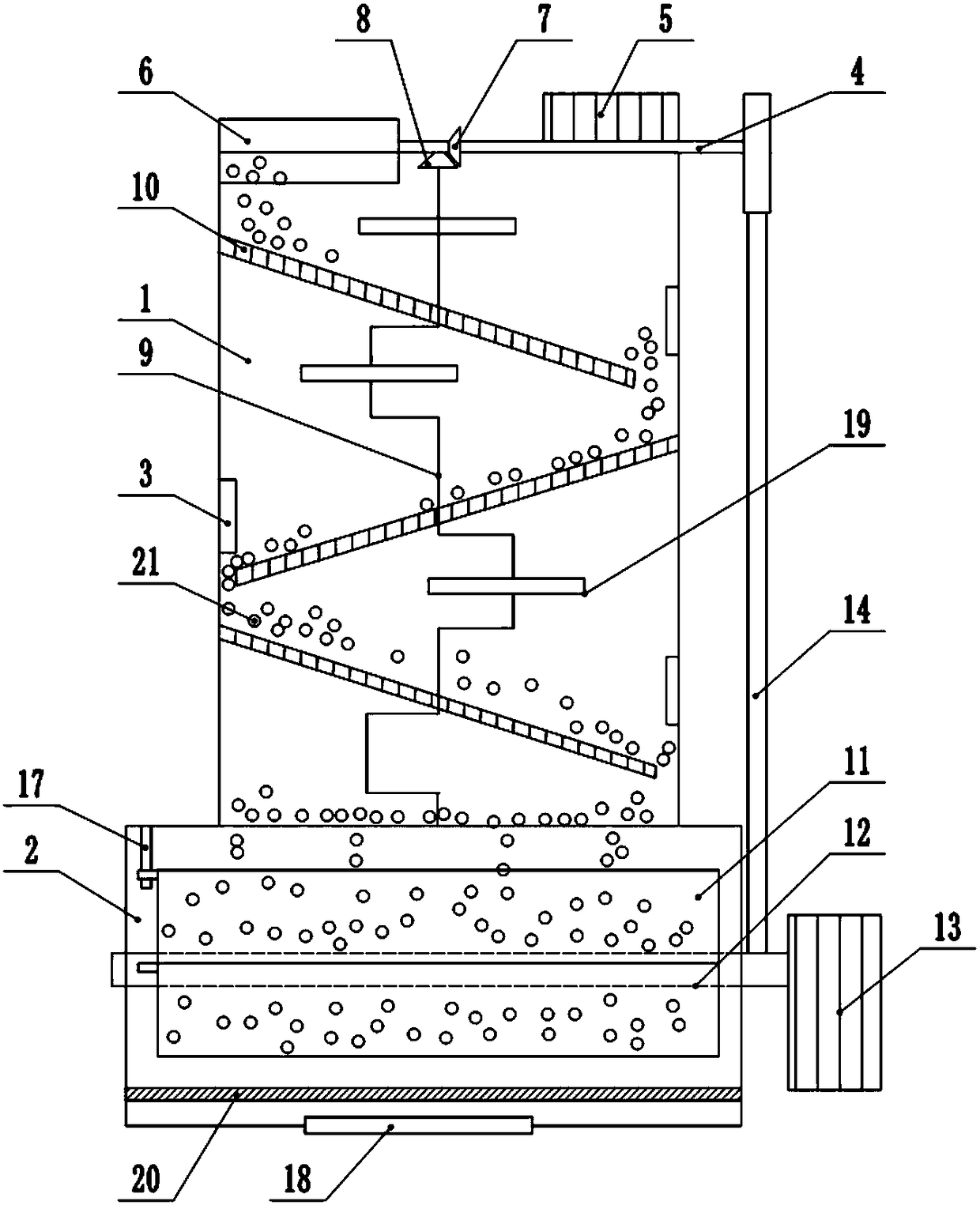

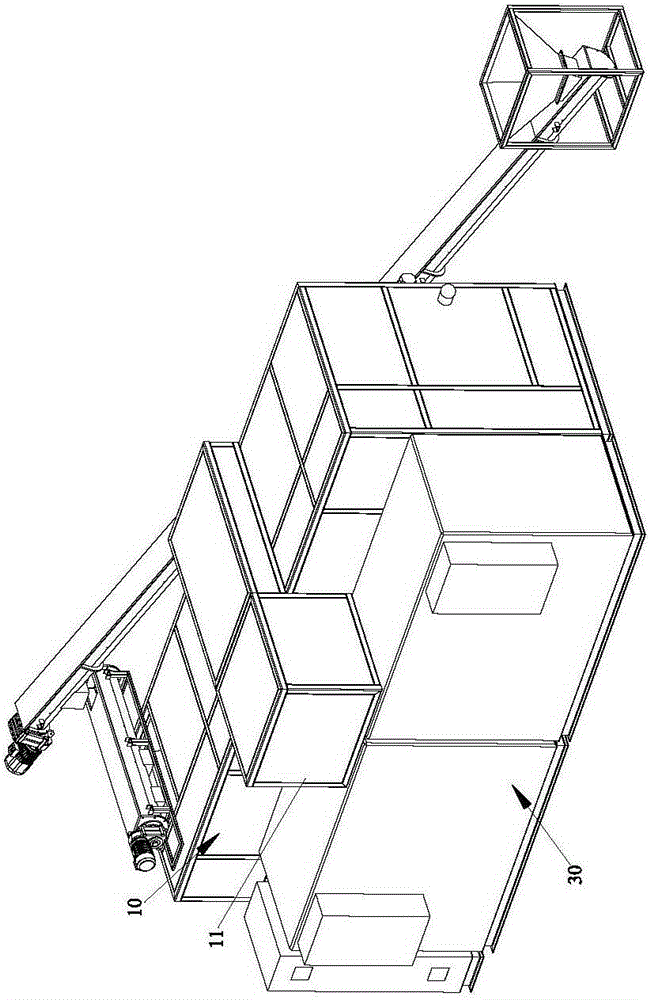

The invention relates to the technical field of rice drying, and specifically discloses a rice drying device. The rice drying device comprises a first drying box, a second drying box and hot air mechanisms, wherein the upper part of the first drying box is rotatably connected with a first rotary shaft; the first rotary shaft is connected with a motor; a charge hopper is fixedly mounted on the first rotary shaft; the first rotary shaft is connected with a crankshaft through a bevel gear; the other end of the crankshaft is rotatably connected on the lower wall of the first drying box; the side wall of the first drying box is hinged with a plurality of drying plates; the drying plates are equipped with material transfer ends; gaps are formed between the material transfer ends and side walls;the hot air mechanisms are arranged on the side walls which correspond to the material transfer ends; an unloading hole is formed in the bottom of the first drying box; an opening is formed in the upper part of the second drying box; a drying barrel is mounted in the second drying box; a second rotary shaft is arranged on the middle part of the drying barrel; the inner part of the second rotary shaft is hollow, and the second rotary shaft is equipped with an air outlet; the second rotary shaft is connected with a hot air blower; and a pulling rod is hinged between the second rotary shaft and the first rotary shaft. The rice drying device solves the problems such as long rice drying time, low efficiency and uneven drying.

Owner:重庆市合川区云天食品科技有限公司

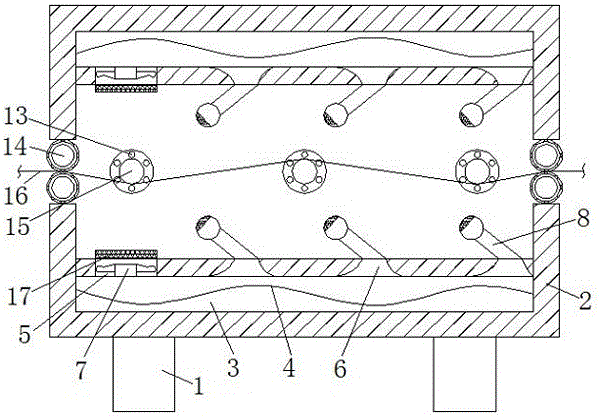

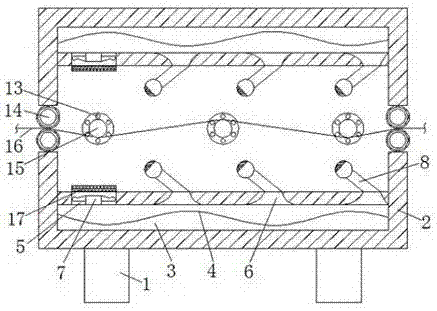

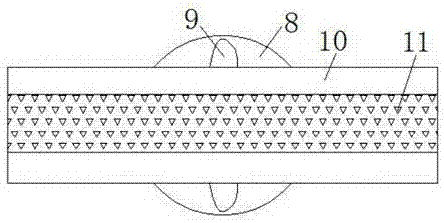

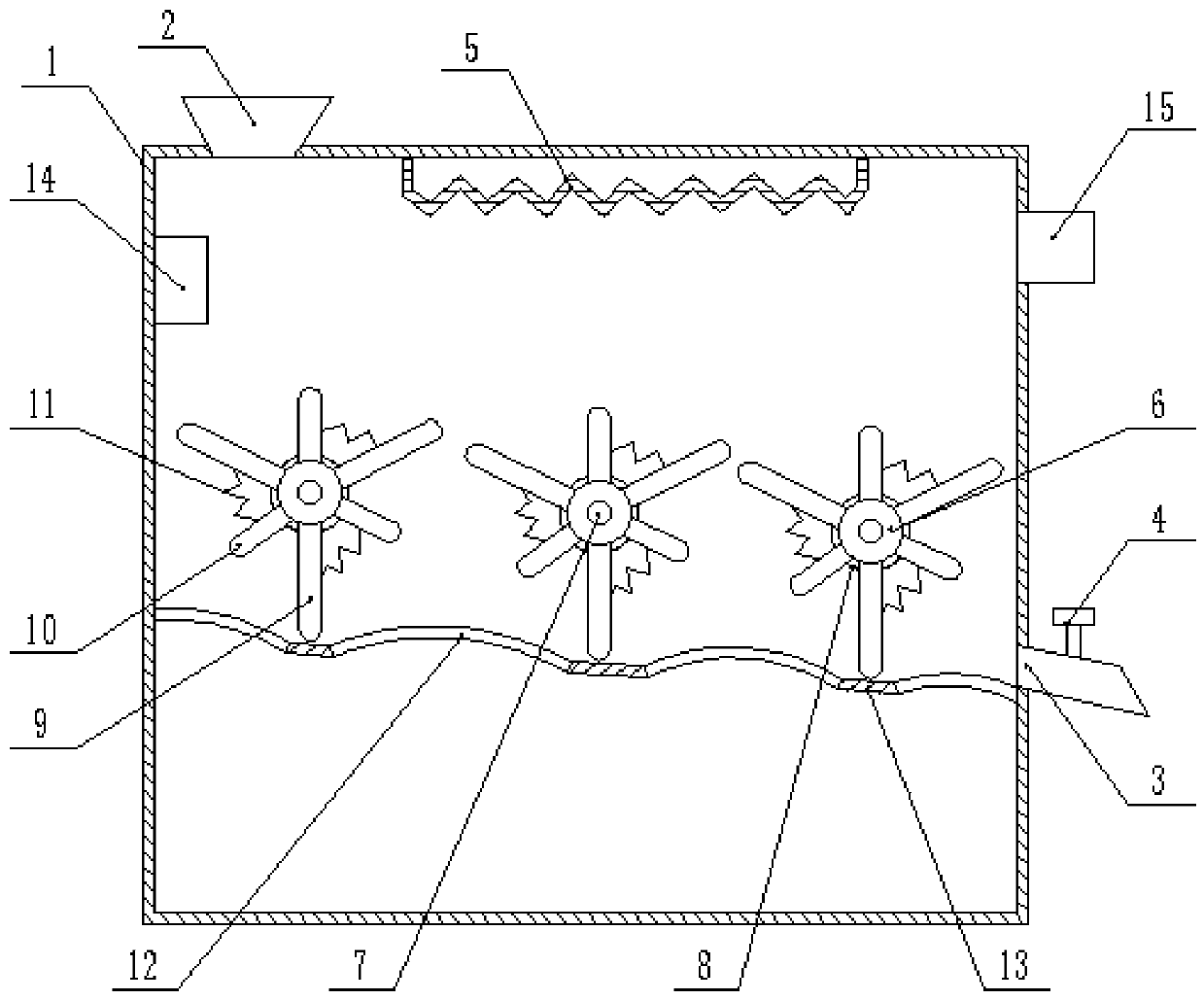

Double-faced circulation type textile cloth drying device

InactiveCN106705610ATo achieve the effect of heating and dryingAchieve energy saving effectDrying gas arrangementsDrying machines with progressive movementsEngineeringFan blade

The invention discloses a double-faced circulation type textile cloth drying device. The double-faced circulation type textile cloth drying device comprises support legs. A drying box is fixedly connected to the upper surfaces of the support legs. The inner top wall and the inner bottom wall of the drying box are each provided with a heating chamber. An electrical heating wire is arranged inside each heating chamber. The surface of each heating chamber is provided with a circulation inlet and circulation outlets. One end of each circulation inlet and one end of each circulation outlet communicate with the inner wall of the corresponding heating chamber. By means of the double-faced circulation type textile cloth drying device, the effect that a textile cloth body inside the drying box is heated to be dried is achieved; the inner top wall and the inner bottom wall of the drying box are each provided with the corresponding heating chamber, the upper surface and the lower surface of the textile cloth body can be dried at the same time, and the effects that residual heat, obtained after drying, in the drying box is recycled into the heating chambers, and after the temperature is raised through the electrical heating wires, drying is conducted continuously are achieved; and meanwhile, the energy-saving effect is achieved, and thus the problems that when a motor drives fan blades to conduct blowing in opposite directions, the drying effect is poor, and drying is not conducted uniformly are effectively solved.

Owner:郭斌

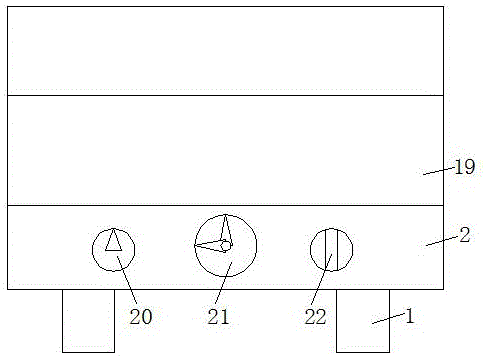

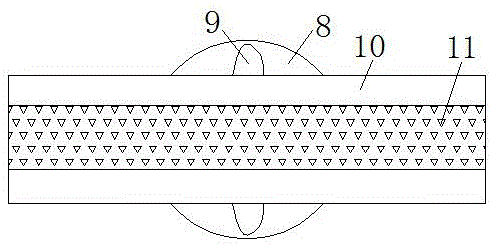

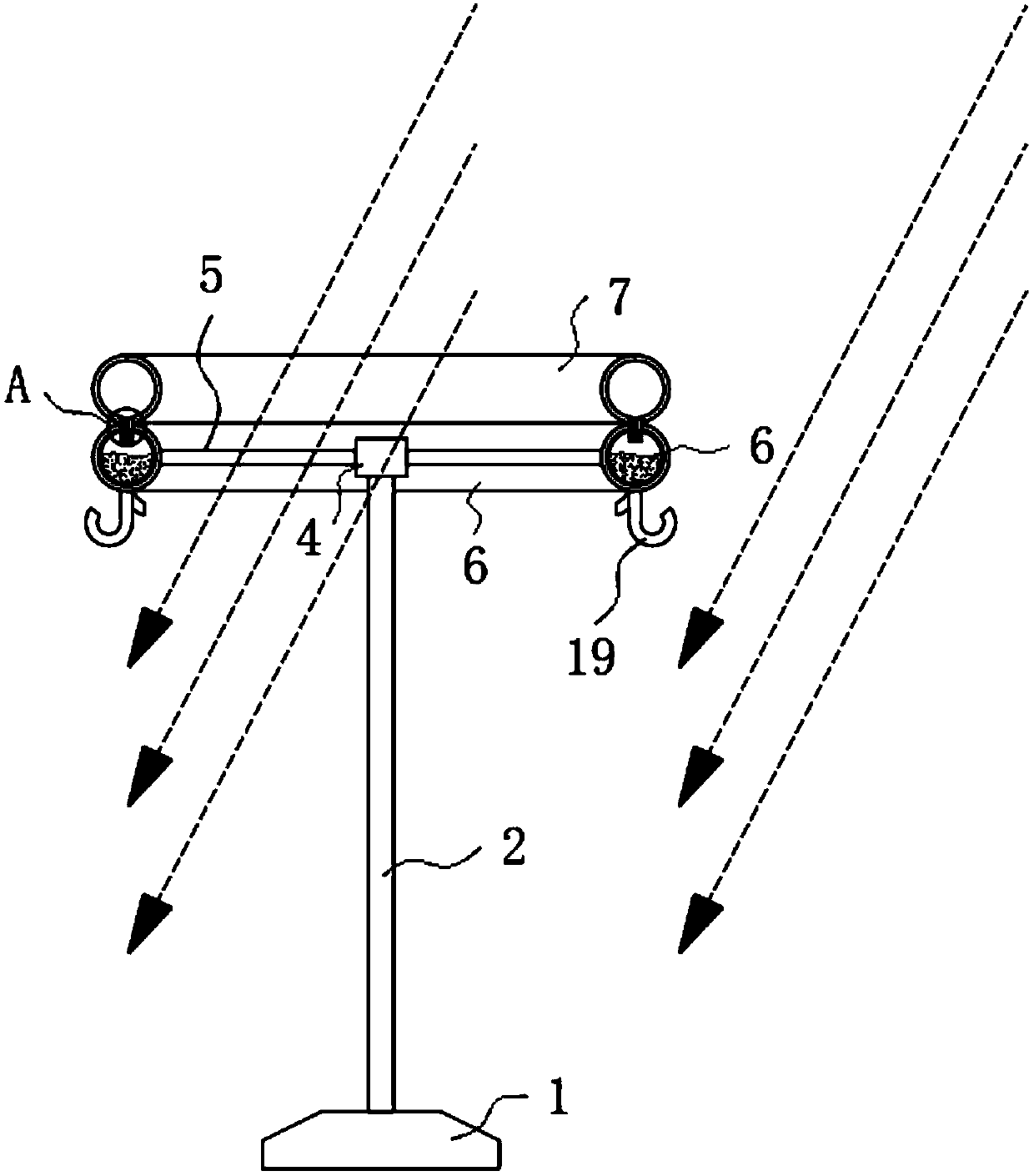

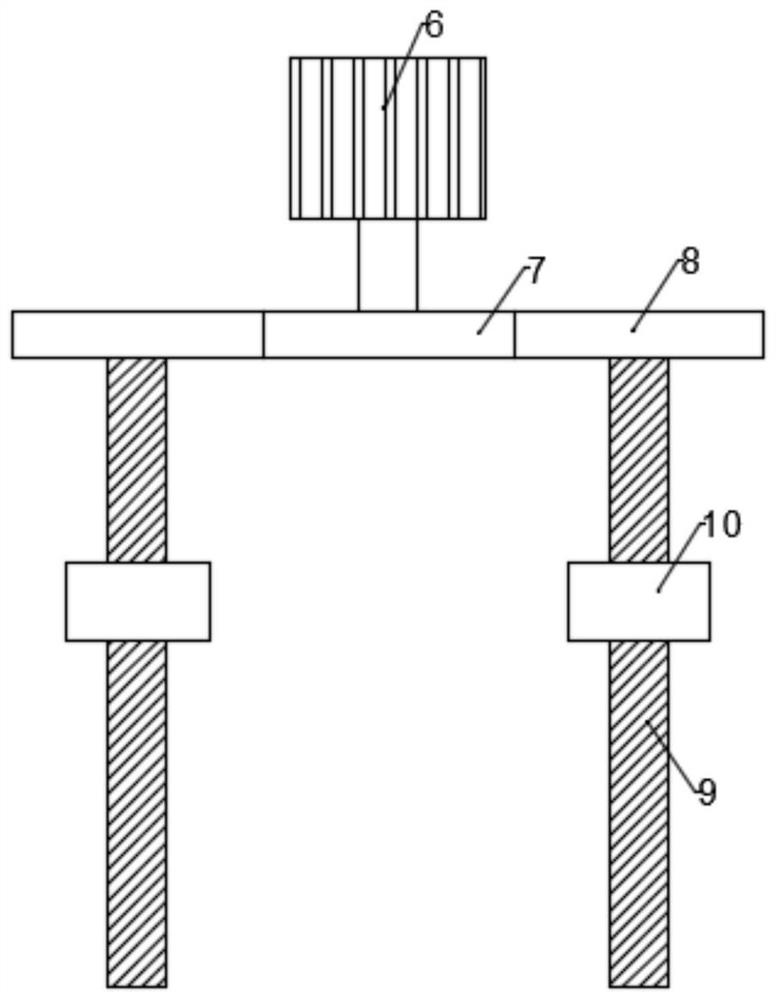

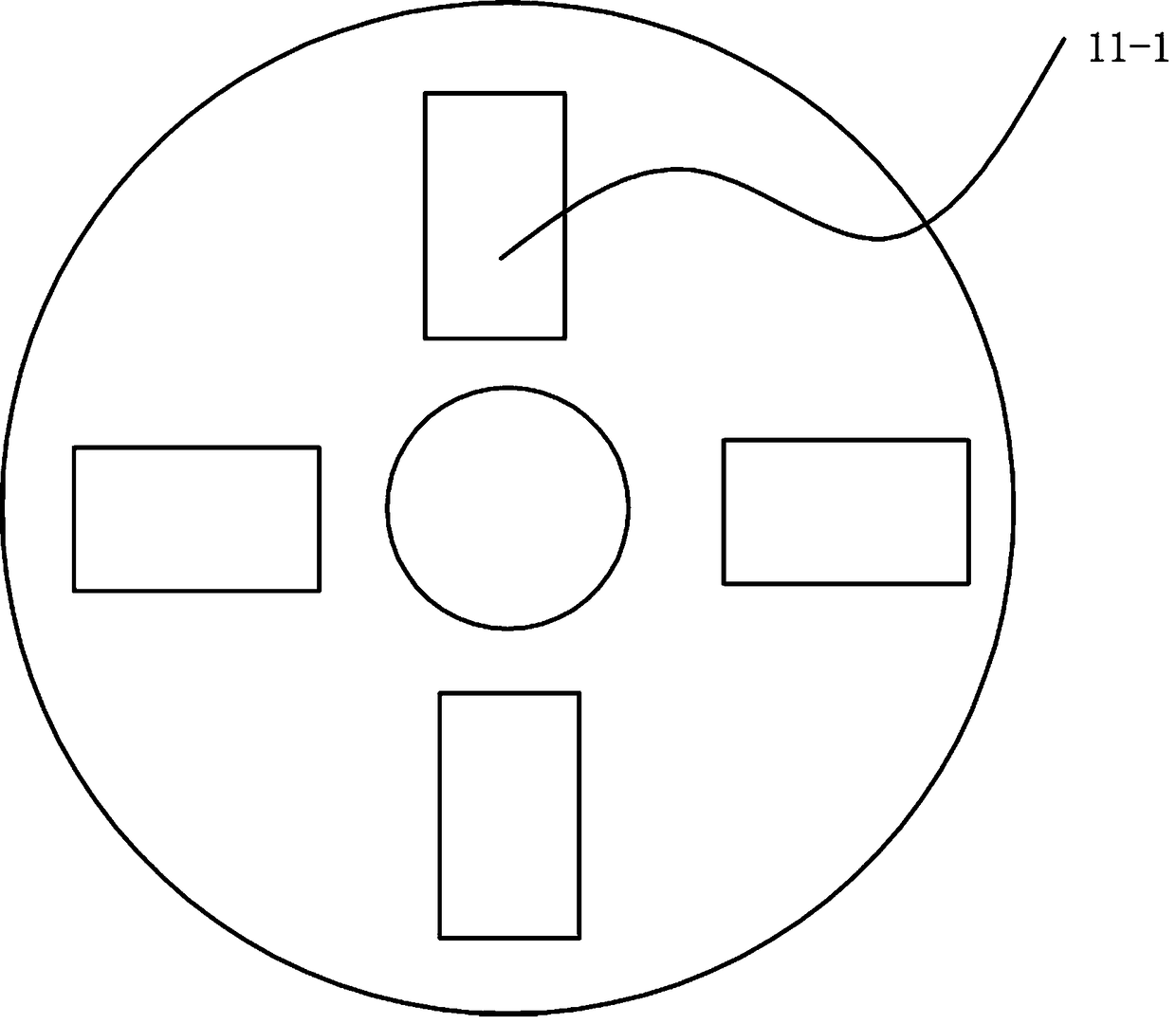

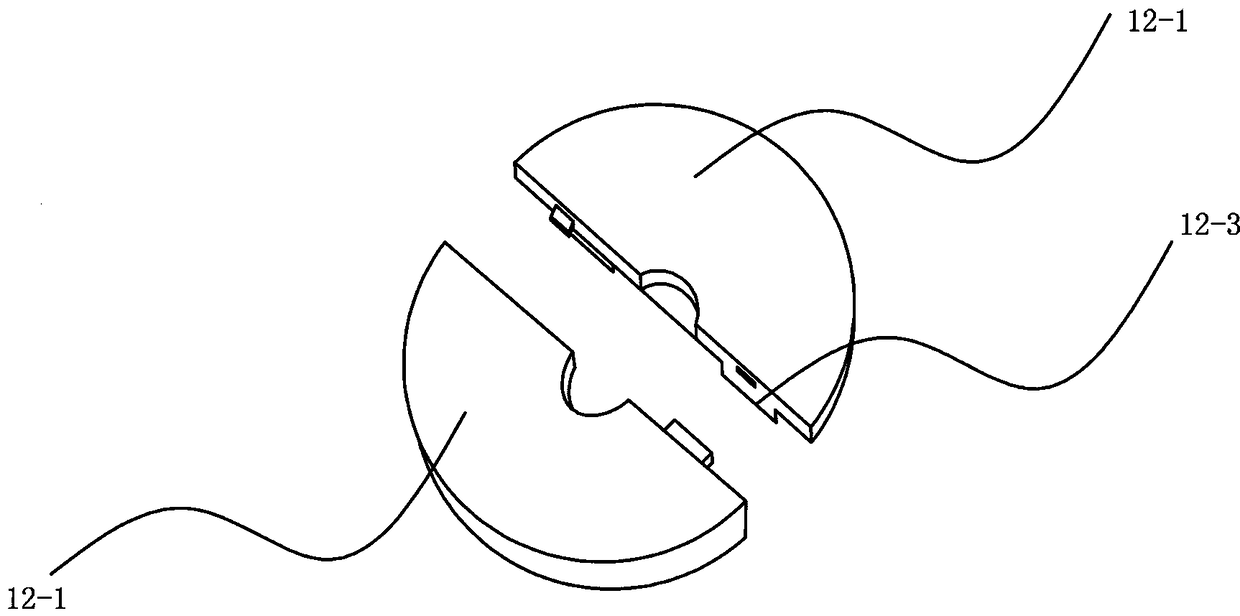

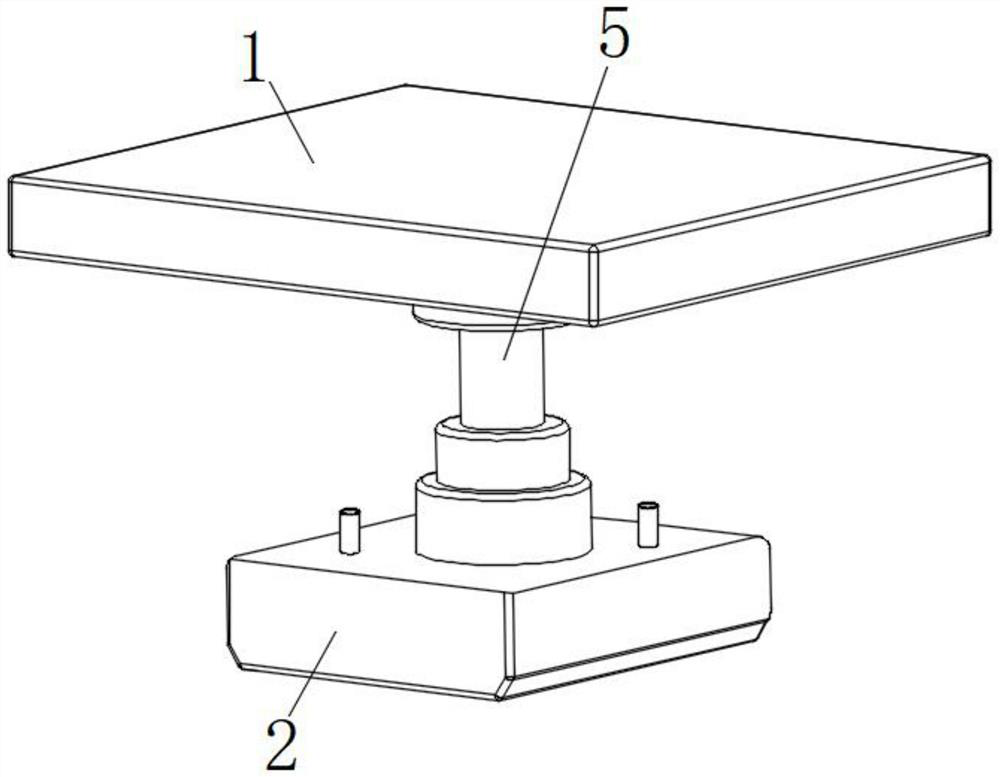

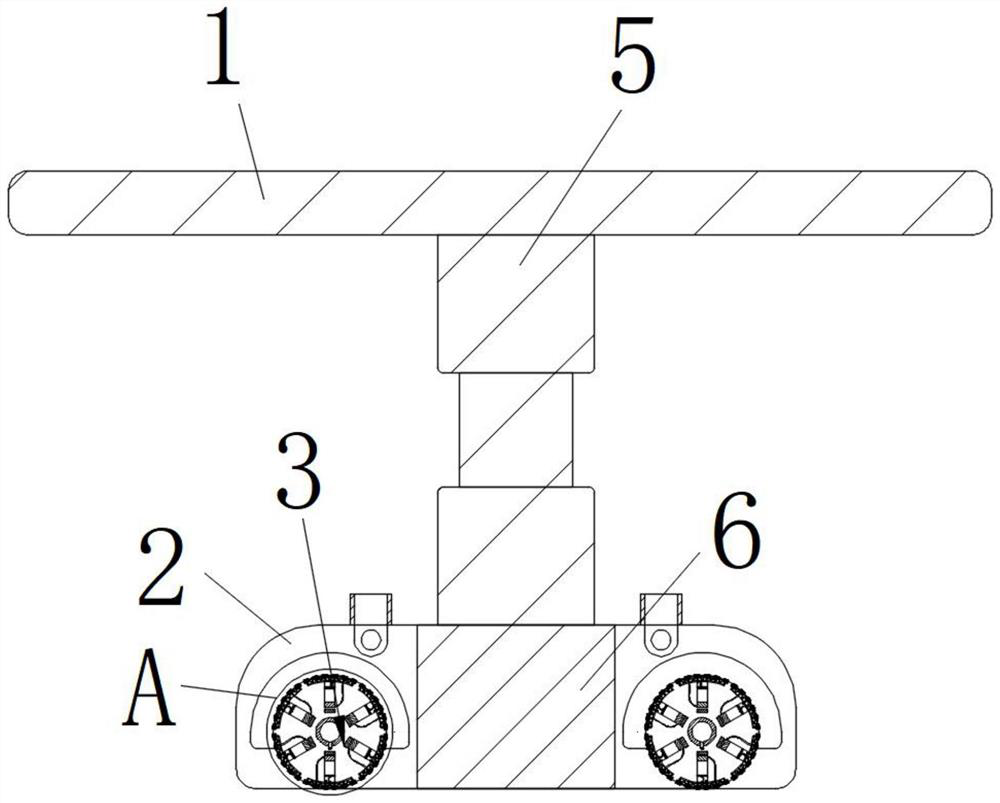

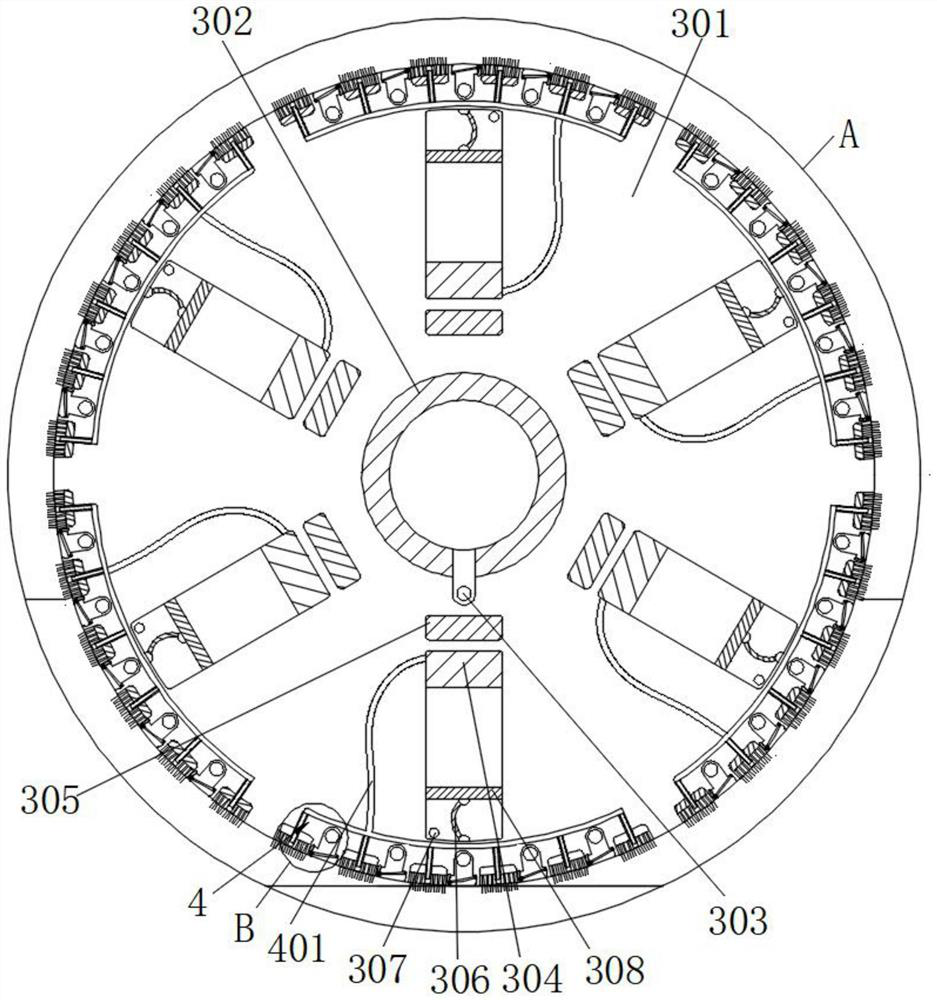

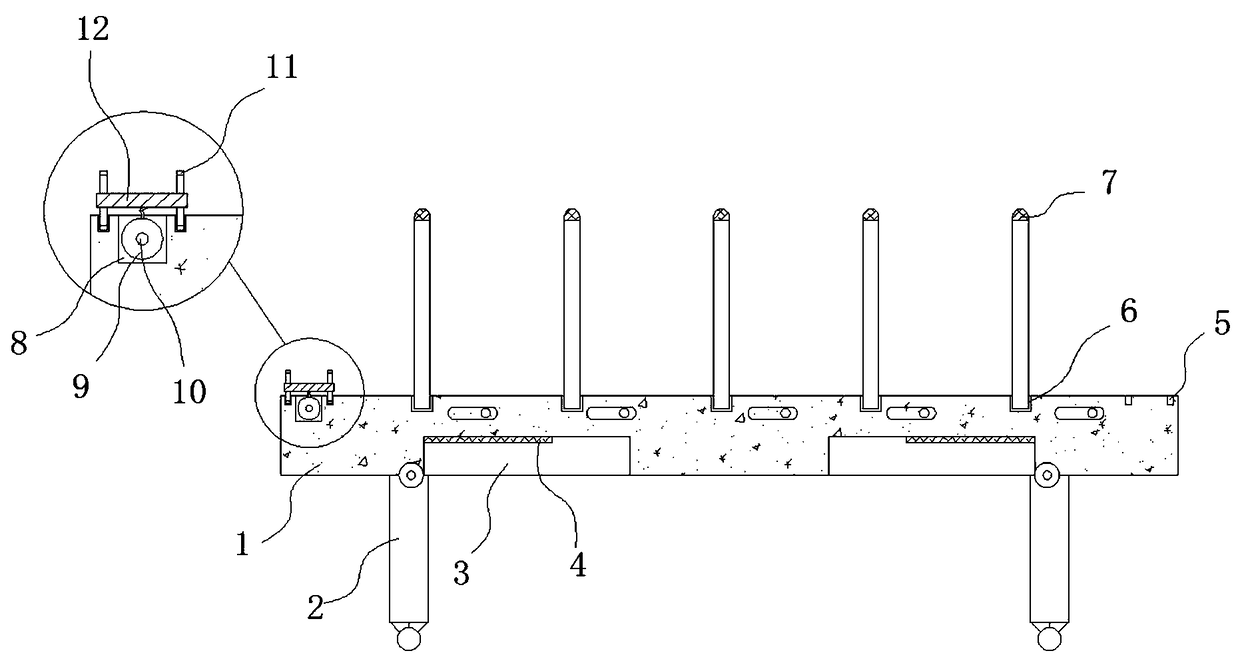

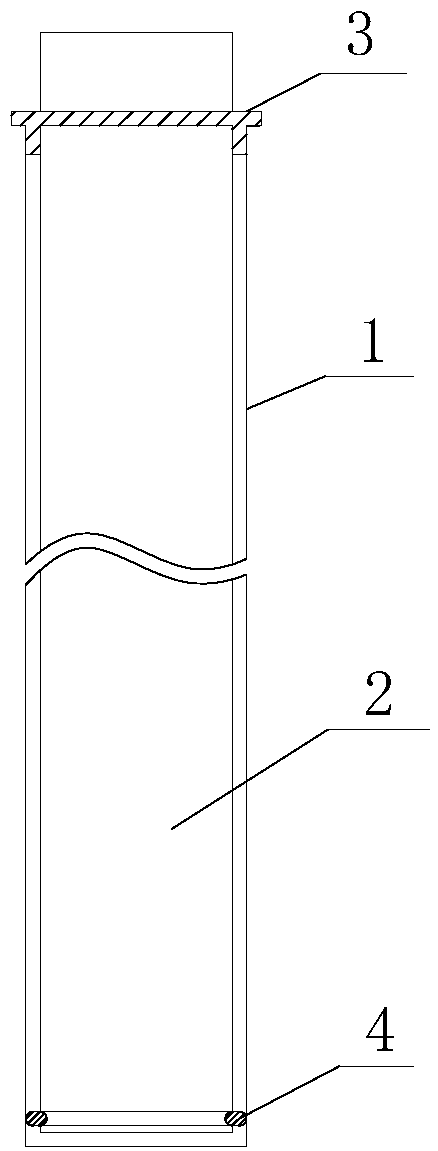

Laundry rack uniform in drying

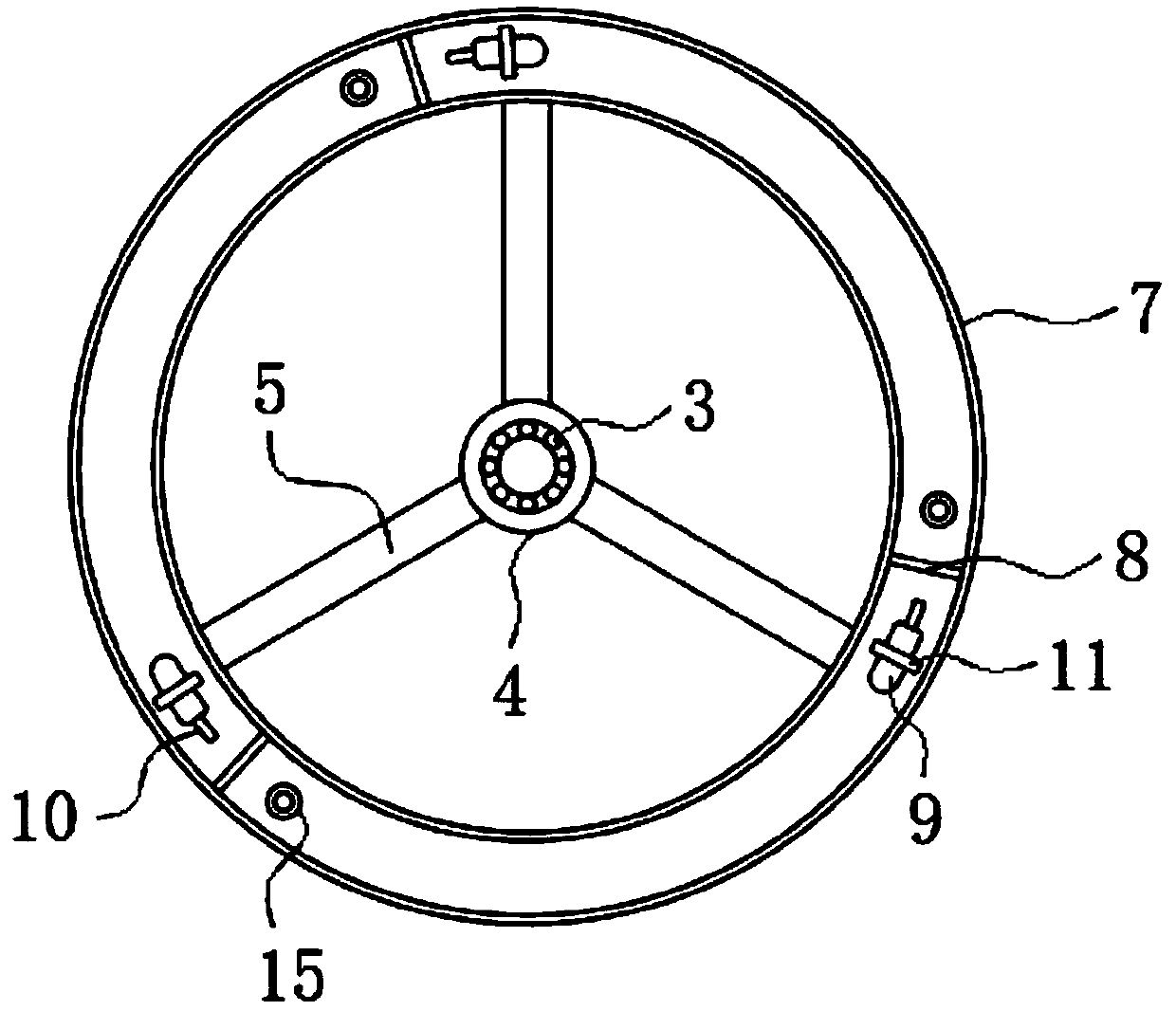

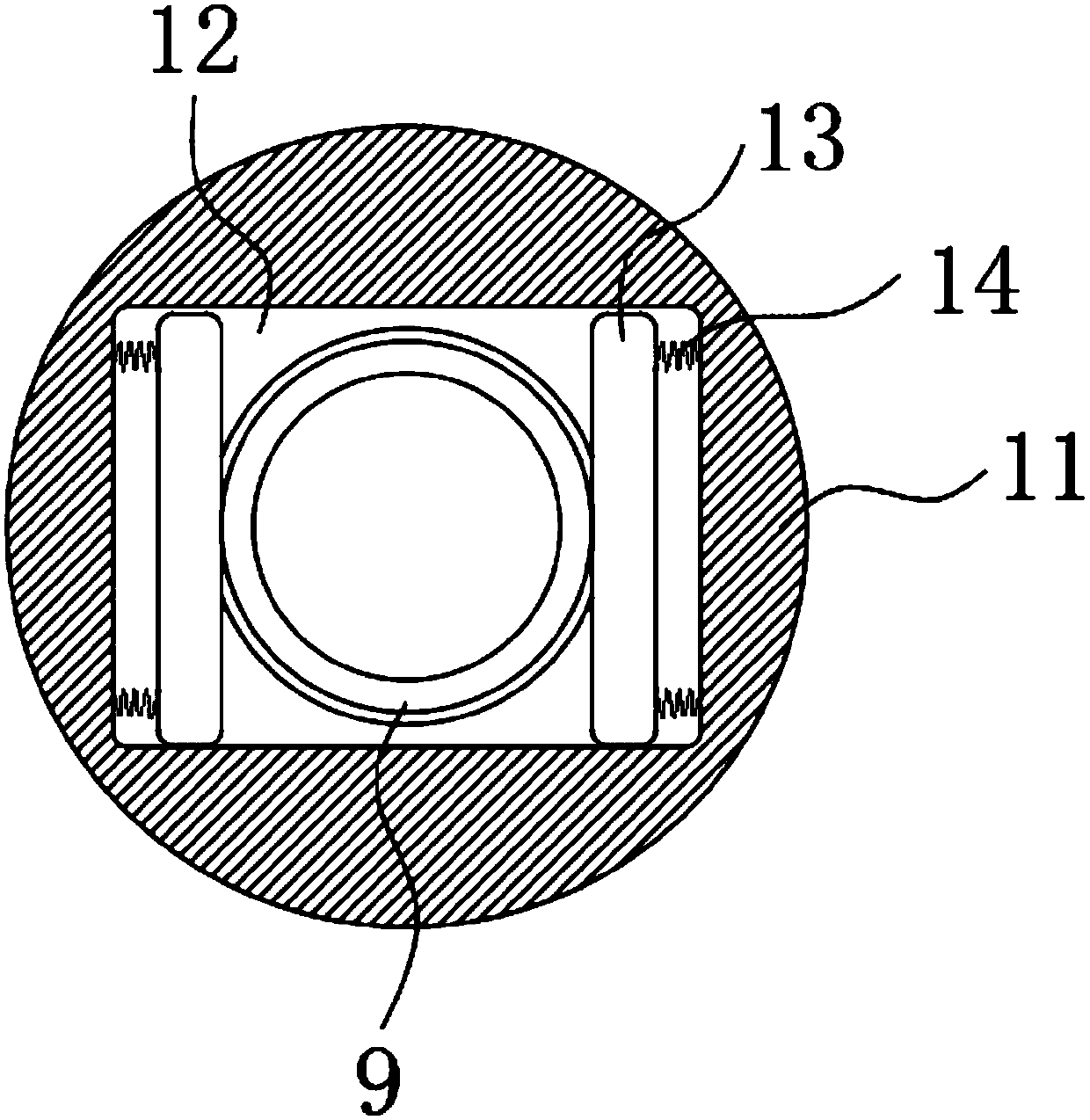

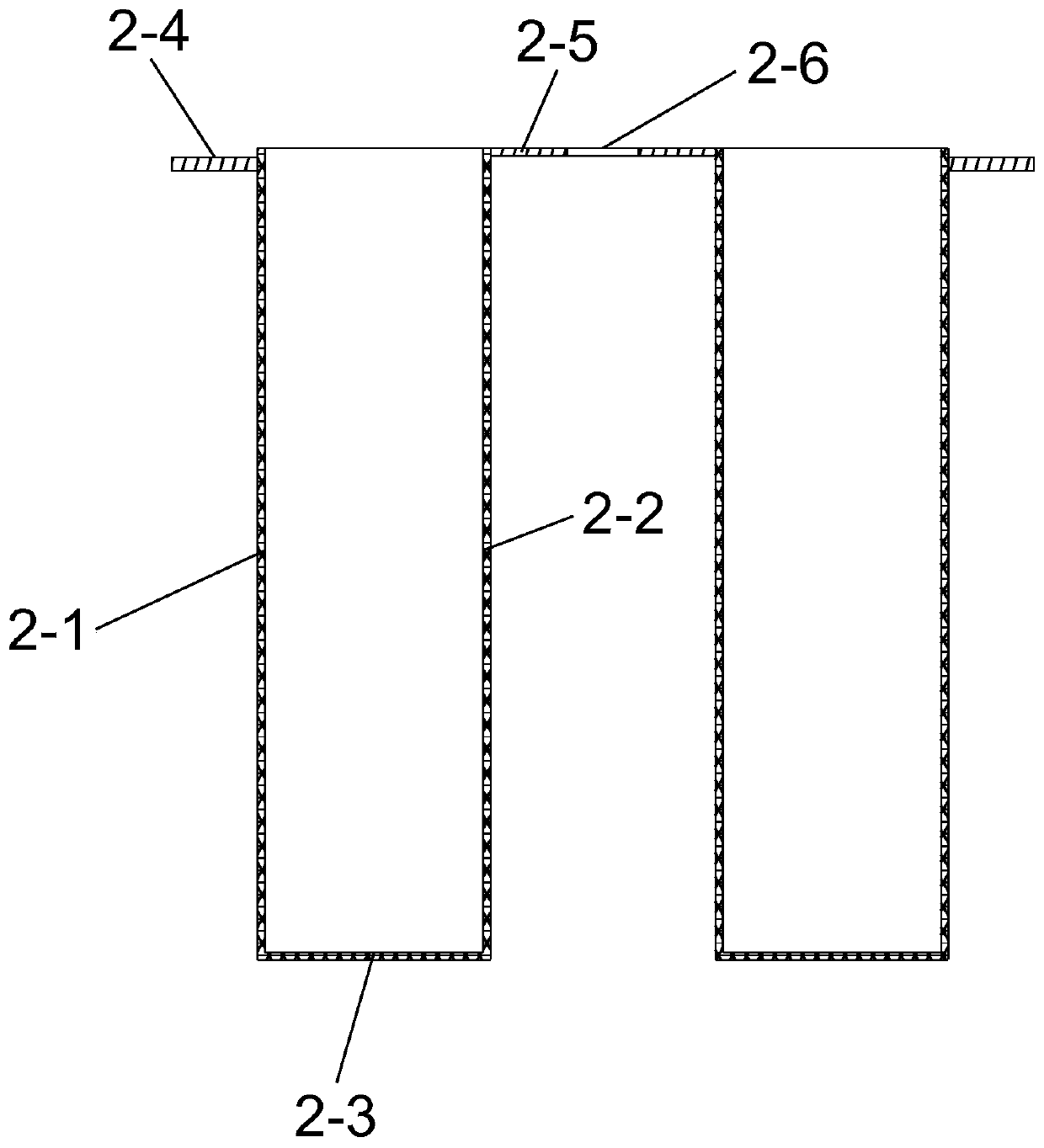

InactiveCN109097957AFully receivedAvoid the problem of uneven dryingOther drying apparatusTextiles and paperEngineeringLaundry

The invention discloses a laundry rack uniform in drying. The laundry rack comprises a base and is characterized in that a support rod is welded to the middle of the upper end of the base, a bearing fixedly sleeves the upper end of the support rod, a fixing sleeve fixedly sleeves the bearing, evaporation tubes are fixedly connected to the outer lateral wall of the fixing sleeve through a pluralityof connecting rods, a plurality of hooks are fixedly connected to the lower ends of the evaporation tubes, condensation tubes are fixedly connected to the upper ends of the evaporation tubes, a plurality of partitions are arranged inside the evaporation tubes and the condensation tubes, one side, close to the corresponding evaporation tube and the corresponding condensation tube, of each partition is in sealing connection with the corresponding evaporation tube and the corresponding condensation tube, the partitions separate the interior of each evaporation tube into a plurality of evaporation chambers, and a solar heat-absorption membrane is adhered to the inner wall of each evaporation chamber. The laundry rack is uniform in drying, good in drying effect, small in space occupation, capable of being driven only by light, energy-saving, environmentally friendly and safe and does not need extra drive power sources and electric components.

Owner:张冰冰

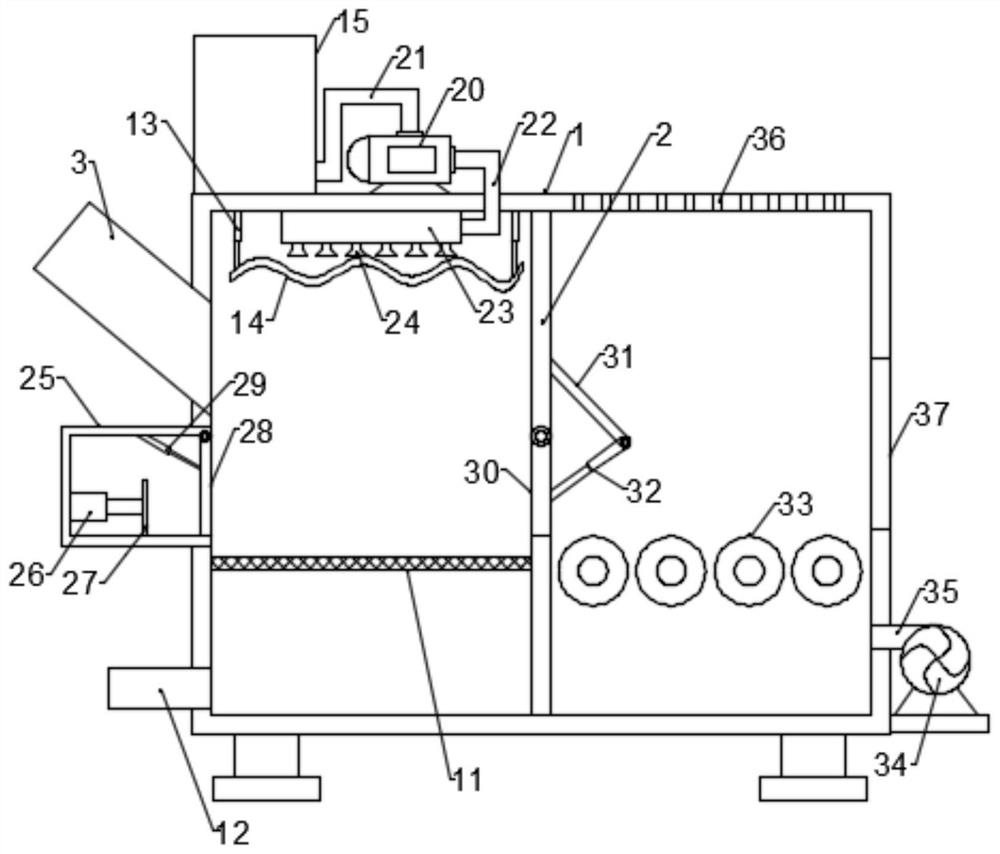

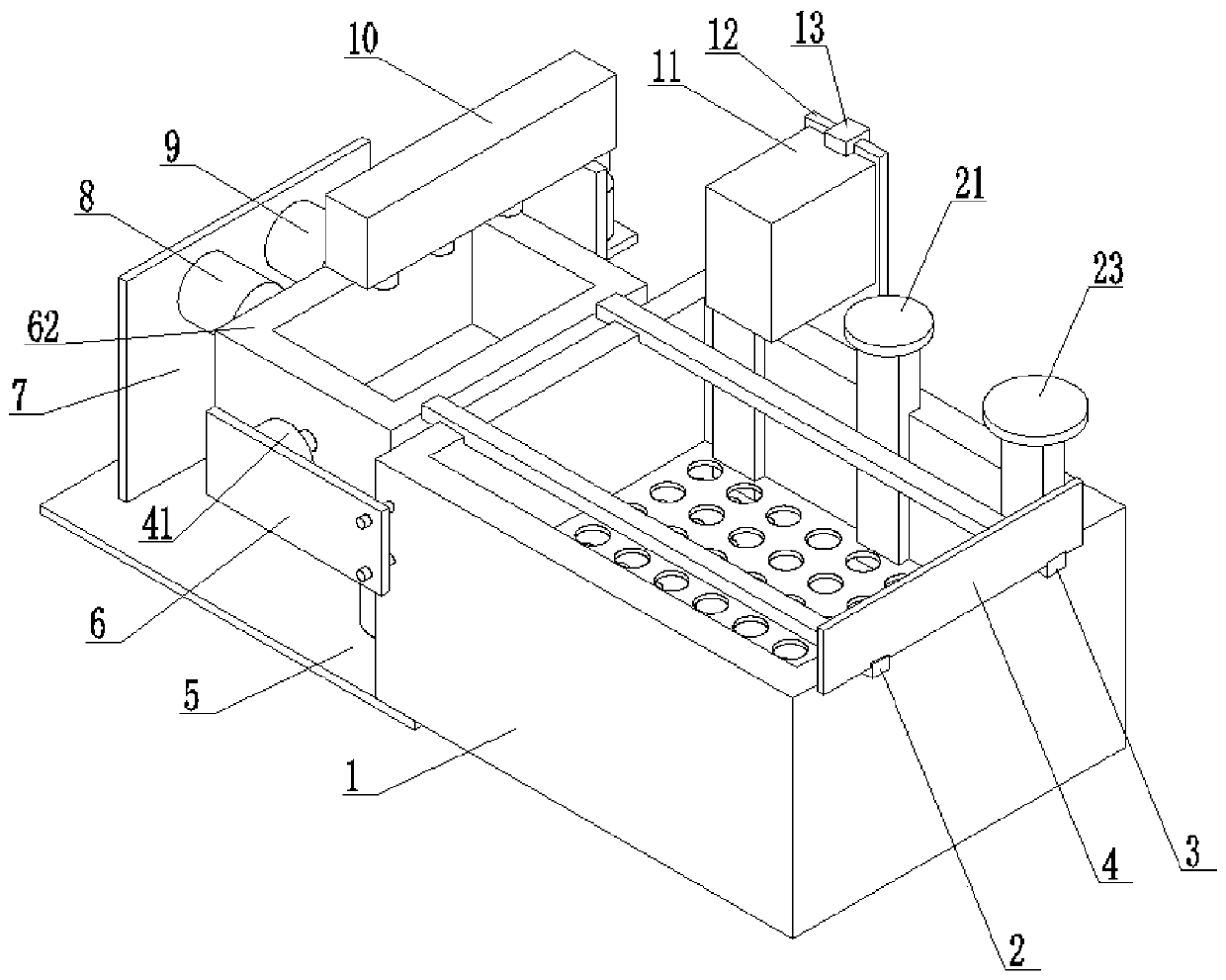

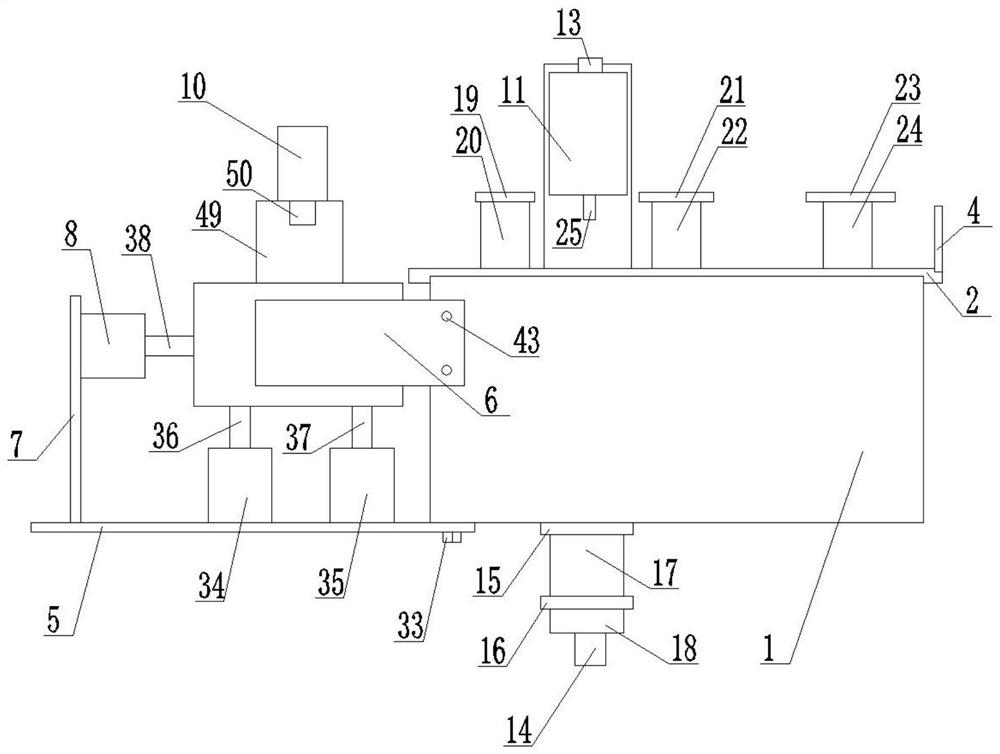

Cleaning and drying integrated equipment for woolen sweater processing

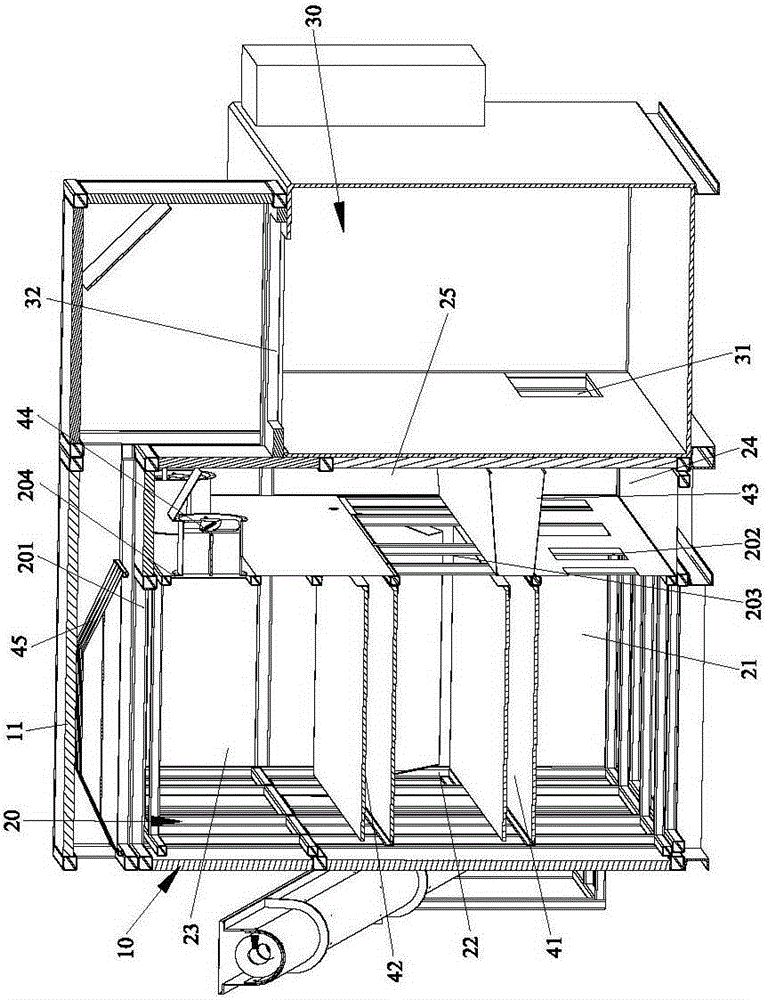

InactiveCN111636171AAvoid injuryAvoid the problem of uneven dryingOther washing machinesWashing machine with receptaclesProcess engineeringSewage

The invention is suitable for the technical field of woolen sweater processing, and provides cleaning and drying integrated equipment for woolen sweater processing. The equipment comprises a box body,wherein the box body internally comprises a cleaning cavity and a drying cavity; a partition plate is arranged between the cleaning cavity and the drying cavity; a feeding tube is arranged on the side wall of the cleaning cavity; a sewage hole is formed in the bottom of the cleaning cavity; a supporting filter screen can be movably mounted inside the cleaning cavity through a lifting mechanism; the top of the cleaning cavity is equipped with a kneading assembly and a spraying mechanism; a material taking plate is arranged on the side wall of the drying cavity; a spreading drying mechanism ismounted inside the drying cavity; a pushing mechanism is mounted on the side wall of the box body; and a second turnover plate is mounted on the partition plate. The cleaning and drying integrated equipment can automatically clean and dry woolen sweaters, can avoid vigorous mechanical kneading of the wool sweaters through matching of the spraying mechanism, the kneading assembly and the supportingfilter screen, can quicken drying efficiency through the spreading drying mechanism, and avoids uneven drying due to accumulation.

Owner:WUJIANG CITY QIDU TOWN MIAOGANG YADI KNITTING GARMENT FACTORY

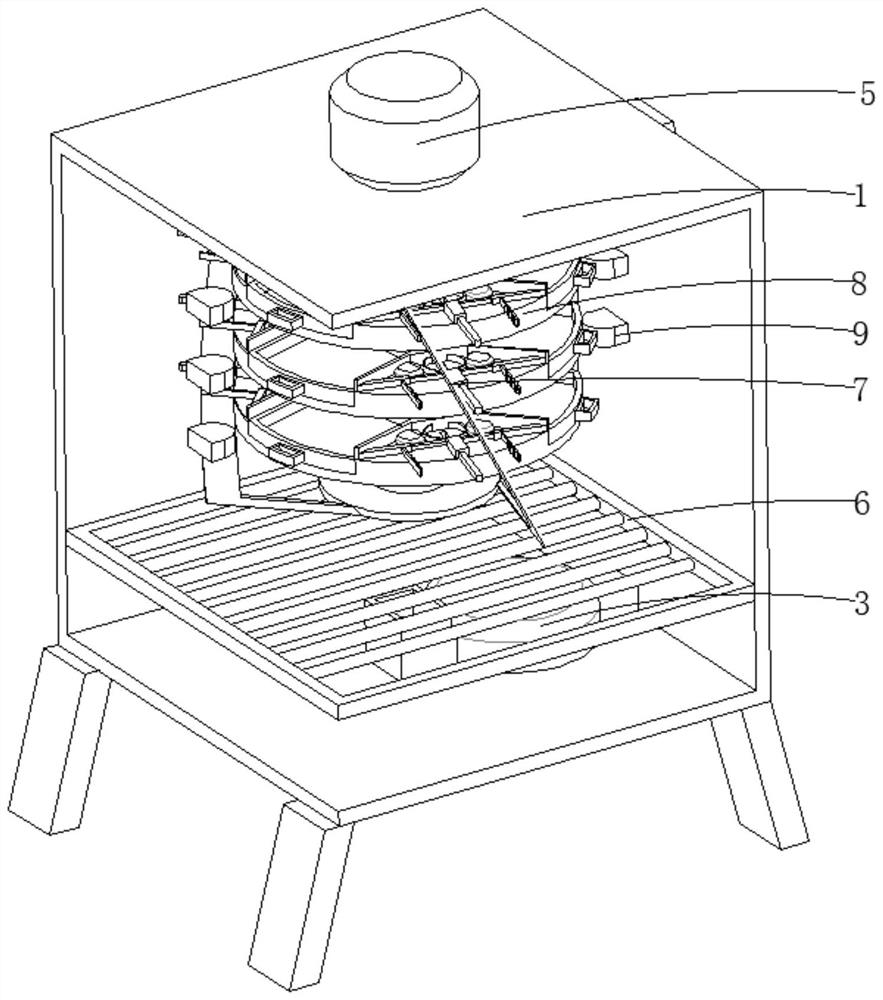

Tea processing device

ActiveCN111014022AFirmly connectedEasy inspection and maintenanceSievingPre-extraction tea treatmentEngineeringMechanical engineering

The invention discloses a tea processing device which comprises a processing chamber, a bottom plate, a connecting piece, a side plate and a vibration heating chamber. A first filtering net, a secondfiltering net and a third filtering net are arranged in the processing chamber. The top face of the first filtering net, the top face of the second filtering net and the top face of the third filtering net are fixedly connected with the bottom of a first connecting rod, the bottom of a second connecting rod and the bottom of a third connecting rod correspondingly in a welded manner. A bottom holeis formed in the bottom of the processing chamber. A vertical plate is fixed to the front end face of the vibration heating chamber. A heater and a fixing bottom plate are fixed to the side face of the vertical plate. An air supply device is fixed to the end face of the fixing bottom plate. A drying device is fixed to the top face of the vertical plate. The drying device is used for heating tea stored in the vibration heating chamber. The problems that in the prior art, the functions of tea screening and fast drying cannot be achieved, and adaptive matching of vibration input cannot be achieved are solved; and the tea processing device can be better applied and popularized.

Owner:通城县百丈潭茶业有限责任公司

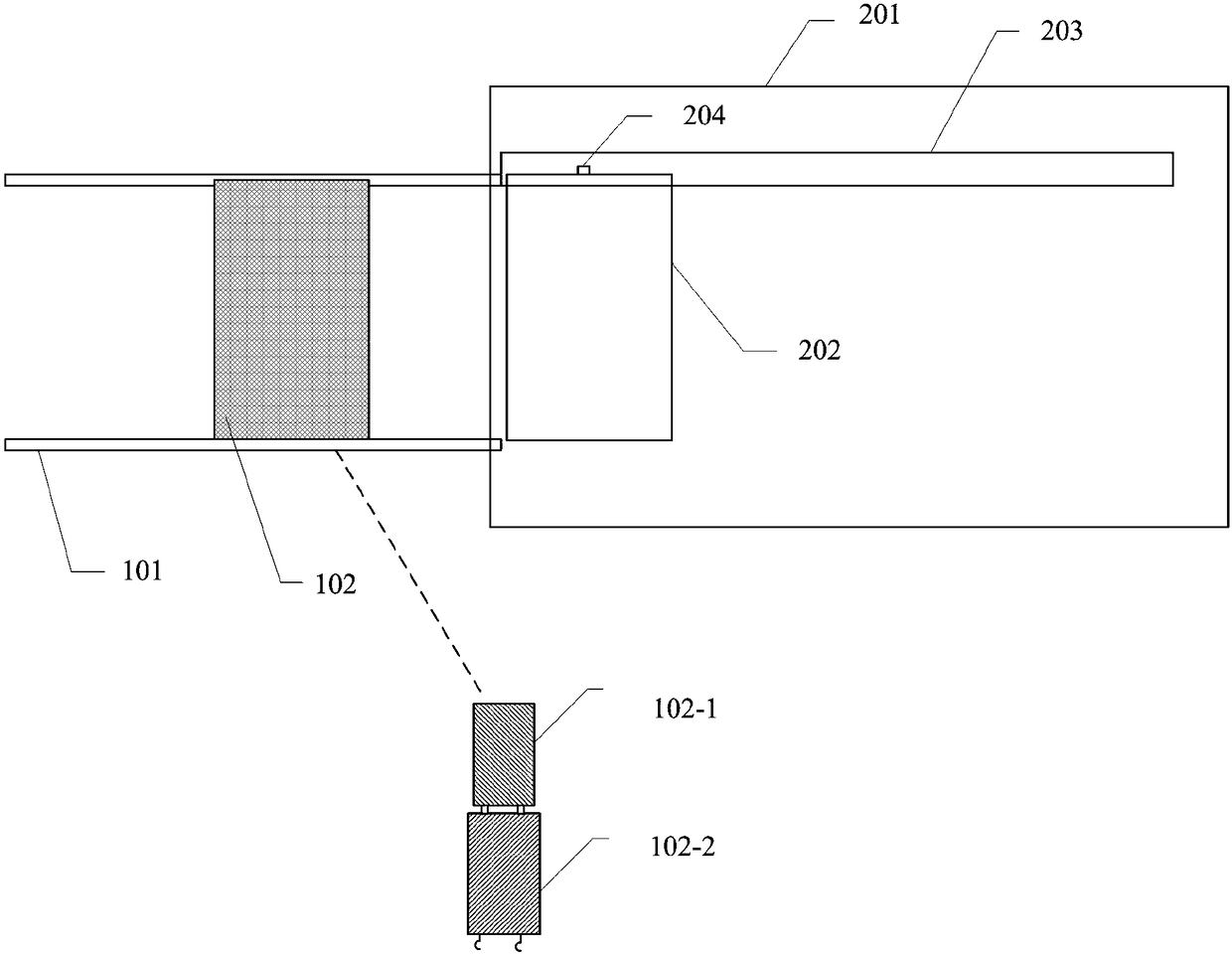

Method for drying roses and rose product prepared by method

ActiveCN109282579AFragrance is smallLittle nutrient lossPre-extraction tea treatmentDrying solid materials with heatMicrowaveDesiccant

The invention provides a method for drying roses and a rose product prepared by the method. The method for drying the roses comprises the steps that the roses are subjected to microwave or far infrared radiation, and first treatment roses are obtained; food desiccants are laid on a bottom layer, and the first treatment roses are spread on the food desiccants in a monolayer; after hot air circulation, warm-keeping and drying under 25-45 DEG C, second treatment roses are obtained; and the dried second treated roses are separated from the desiccants to obtain dried roses. According to the methodfor drying roses, the roses in the rose product are prepared; the water removing process has the characteristics of high efficiency, low energy consumption, and low aroma and nutrient loss; the dryingprocess is uniform and low in loss of rose color; and the rose products prepared by the method have the characteristics of rich flavor, good color and good shape.

Owner:甘肃铭启洋生物科技有限公司

Drying device for ceramic particles

InactiveCN105276949AIntegrity guaranteedEfficient take awayDrying gas arrangementsDrying solid materialsEngineeringExhaust pipe

The invention discloses a drying device for ceramic particles. The drying device comprises a shell forming a drying tunnel, a heater and a conveying belt. The continuous conveying belt is erected in the shell. The two sides of the shell are provided with a feeding port and a discharging port respectively. Ventilation holes are formed in the conveying belt. The drying tunnel is divided into a radiation drying section and a cooling section. The heater is installed below the radiation drying section, and a first air inlet pipe is installed in the position, below the heater, of the shell. A double-layer exhaust pipe is arranged between the radiation drying section and the cooling section. A second air inlet pipe is arranged below the cooling section. The first air inlet pipe is communicated with an outer pipe, and the second air inlet pipe is communicated with an inner pipe. The input end of the second air inlet pipe and the input end of the first air inlet pipe are communicated with a draught fan. The drying device has the beneficial effects that the ceramic particles are static on the conveying belt, and the collision among the ceramic particles can be effectively avoided.

Owner:CHONGQING JINYOUYUAN BUILDING MATERIAL

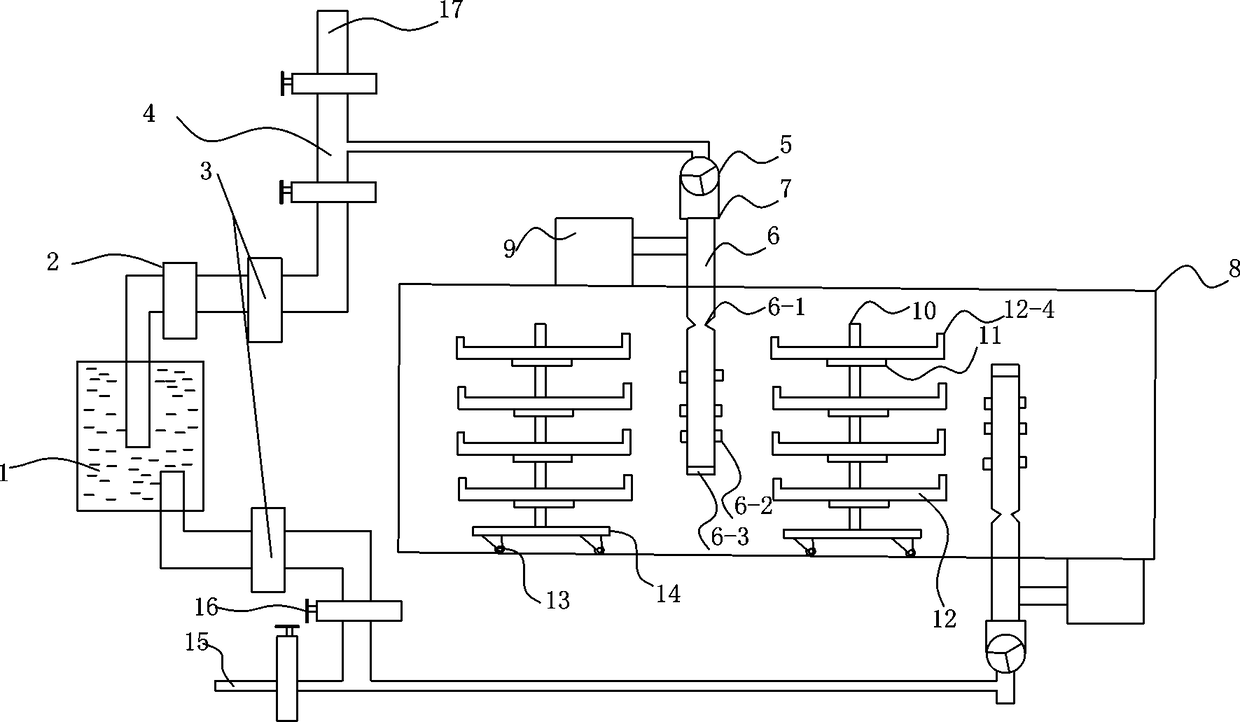

Drying device for dehydrated vegetables

InactiveCN108813673AAvoid uneven dryingImprove drying efficiencyFood treatmentAir separationEngineering

The present invention discloses a drying device for dehydrated vegetables. The device is characterized by comprising a heat exchange box, an air blower, an air separation chamber, a drying box and anexhaust fan; the air blower, the air separation chamber and the drying box are sequentially connected to one side of the heat exchange box along the flow direction of steam; a plurality of receiving nets used for stacking materials are movably and horizontally inserted in the drying box; an air inlet pipe is arranged between every two receiving nets; the air inlet pipe connects the air separationchamber with the drying box; the upper end face of the drying box is provided with the exhaust fan; and the exhaust fan communicates with the other side of the heat exchange box through an exhaust pipe. A drying cylinder is divided into a multi-layer structure, an air inlet pipe is arranged between every two layers, high-temperature gas drying is carried out on each layer of material, so that theproblem of uneven drying is effectively avoided, and the drying efficiency and the drying quality can be greatly improved.

Owner:兴化市绿禾食品有限公司

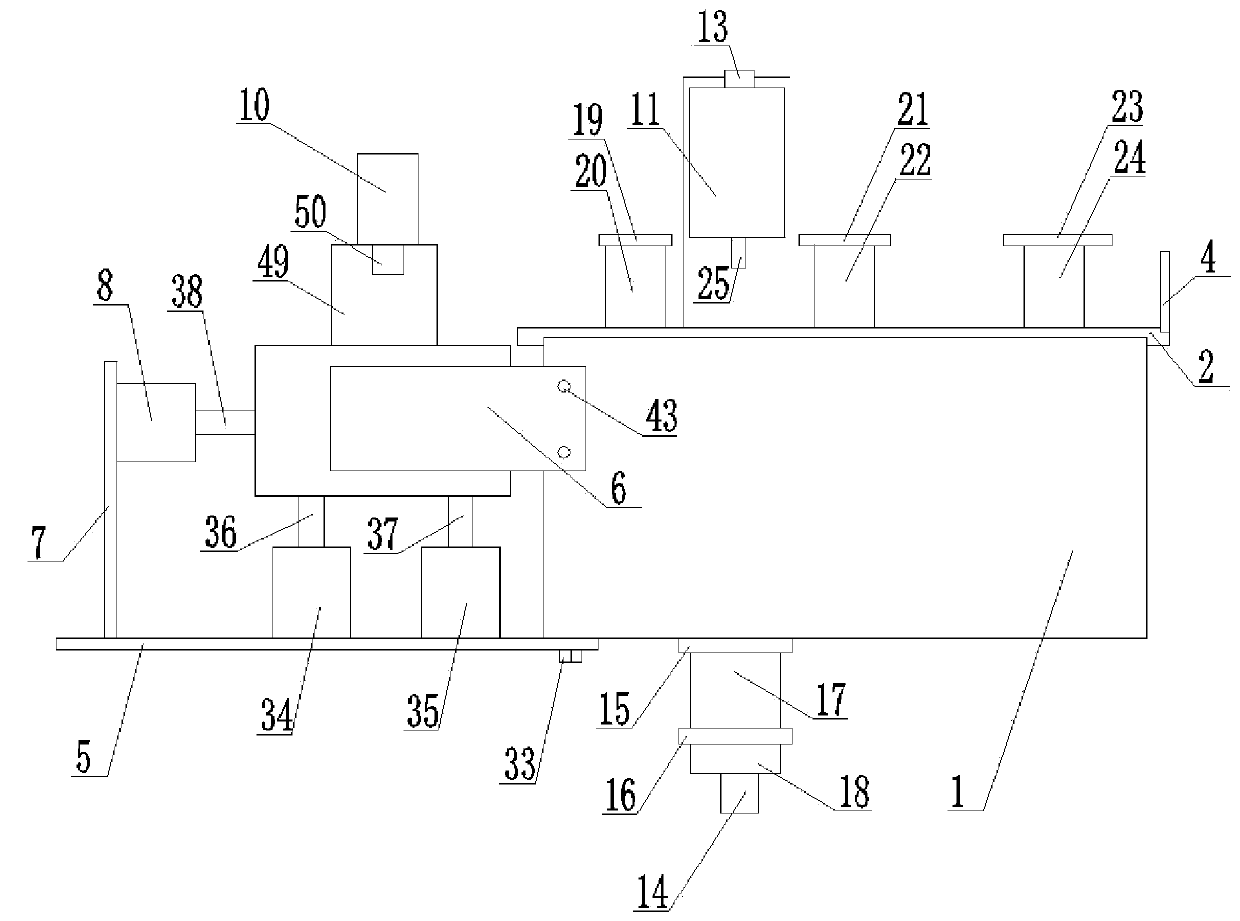

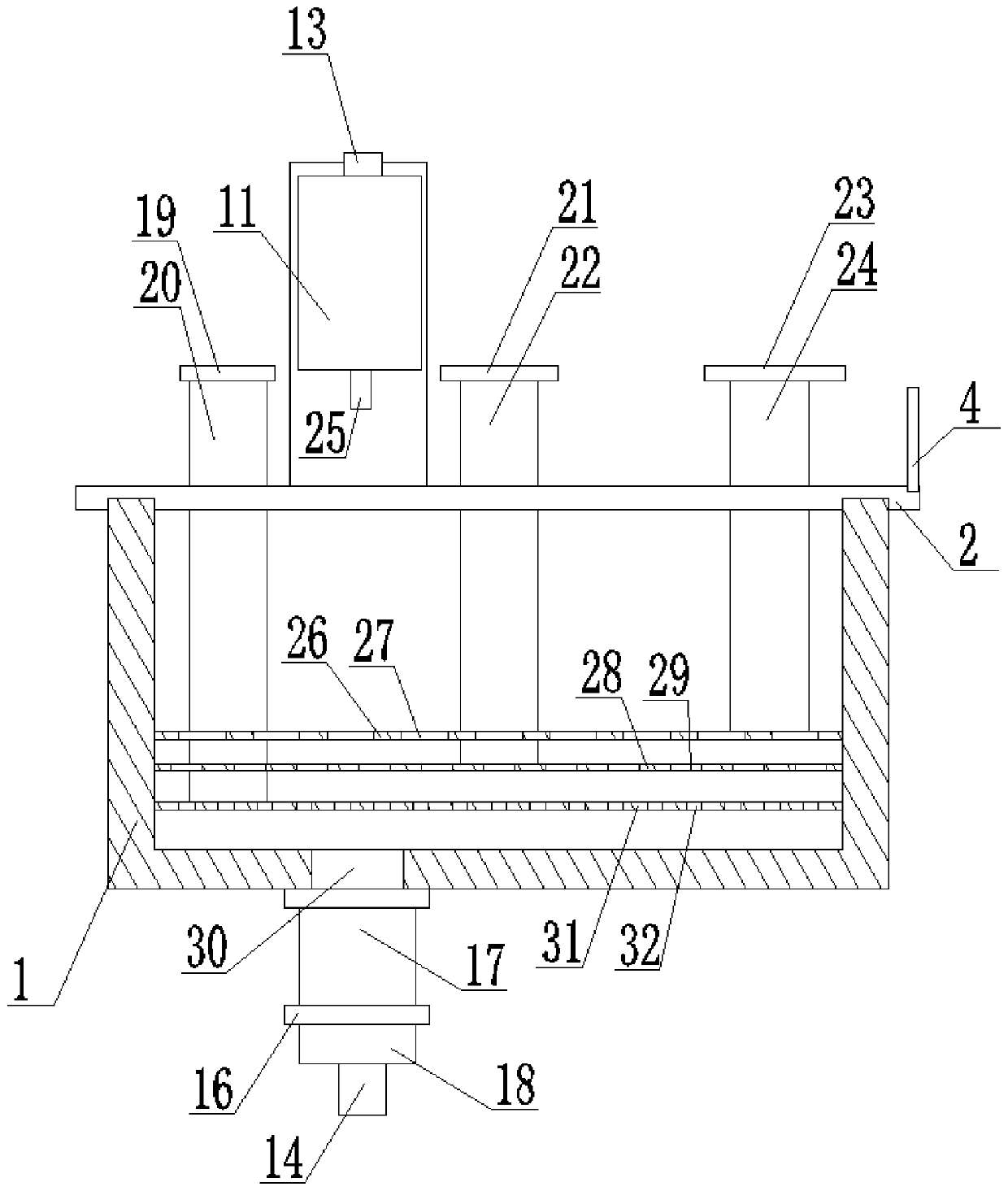

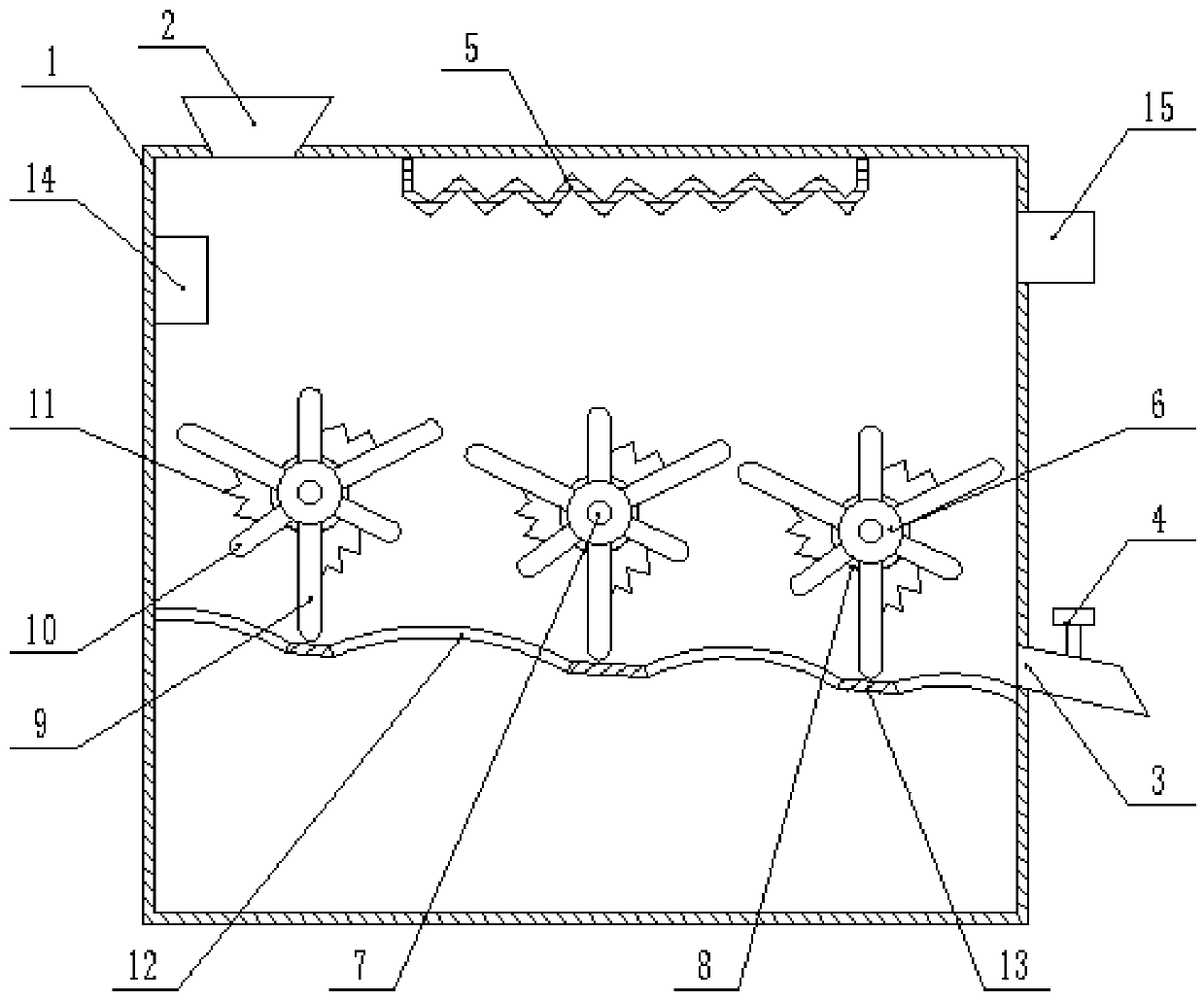

Rapid drying device for day lilies

InactiveCN107806748AIncrease the heating areaAvoid the problem of uneven dryingDrying solid materialsDrying machines with local agitationEngineeringSwash

The invention discloses a rapid drying device for day lilies. The rapid drying device for the day lilies comprises a box body, wherein an inlet and outlet mouth is formed in the top of the front surface of the box body, a movable door is movably arranged at the position, corresponding to the inlet and outlet mouth, of the front surface of the box body through hinges, the top of the inner wall of the box body is fixedly provided with a heating plate, and a holding plate is arranged inside the box body and located at the bottom of the heating plate; and connecting plates are fixedly connected tothe two ends of the holding plate, connecting rods are fixedly connected to the bottoms of the connecting plates, convex blocks are fixedly connected to the bottoms of the connecting rods and a motoris fixedly arranged on the back surface of the inner wall of the box body. According to the rapid drying device for the day lilies, the connecting plates, the connecting rods, the convex blocks, themotor, a rotating rod, idler wheels, movable blocks, reset plates, a spring 1, movable rods, sloping plates and sliding rails are matched with each other so as to make the holding plate continuously move up and down, and thus the positions of the day lilies are continuously changed; and the heating area is enlarged, the problem of uneven drying is avoided, and therefore the rapid drying device forthe day lilies is convenient to use.

Owner:黄久兰

All-directional drying device for woven cloth

InactiveCN107514887ATo achieve the effect of heating and dryingAchieve energy saving effectDrying gas arrangementsDrying chambers/containersEngineeringElectric heating

The invention discloses an all-directional drying device for woven cloth. The device comprises support legs; the upper surfaces of the support legs are fixedly connected with a drying box; heating cavities are respectively formed in the inner top wall and the inner bottom wall of the drying box; electric heating wires are arranged in the heating cavities; circulating inlets and circulating outlets are respectively formed in the surfaces of the heating cavities; and one ends of the circulating inlets and the circulating outlets both communicate with the inner walls of the heating cavities. The double-surface circulating woven cloth drying device achieves a heating drying effect on woven cloth bodies in the drying box; the heating cavities are respectively formed in the inner top wall and the inner bottom wall of the drying box for synchronously drying the upper surfaces and the lower surfaces of the woven cloth bodies to achieve the continuous drying effect after heating through electric heating wires by recovering remaining heat into the heating cavities after drying in the drying box; meanwhile, the energy saving effect is achieved; and the problems of weak drying effect and nonuniform drying caused by opposite blowing directions of fan blades driven by a motor are effectively solved.

Owner:如皋市明德包装有限公司

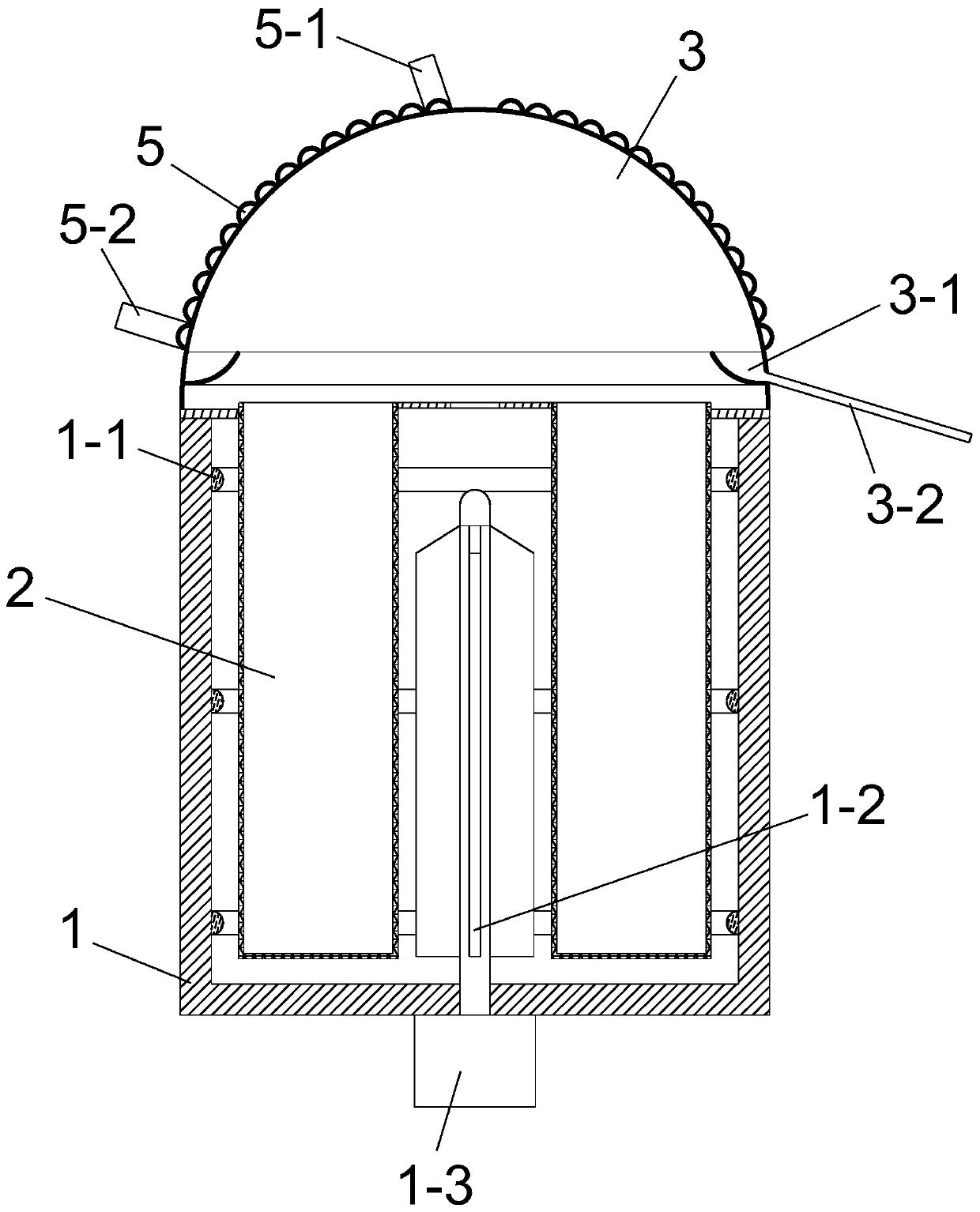

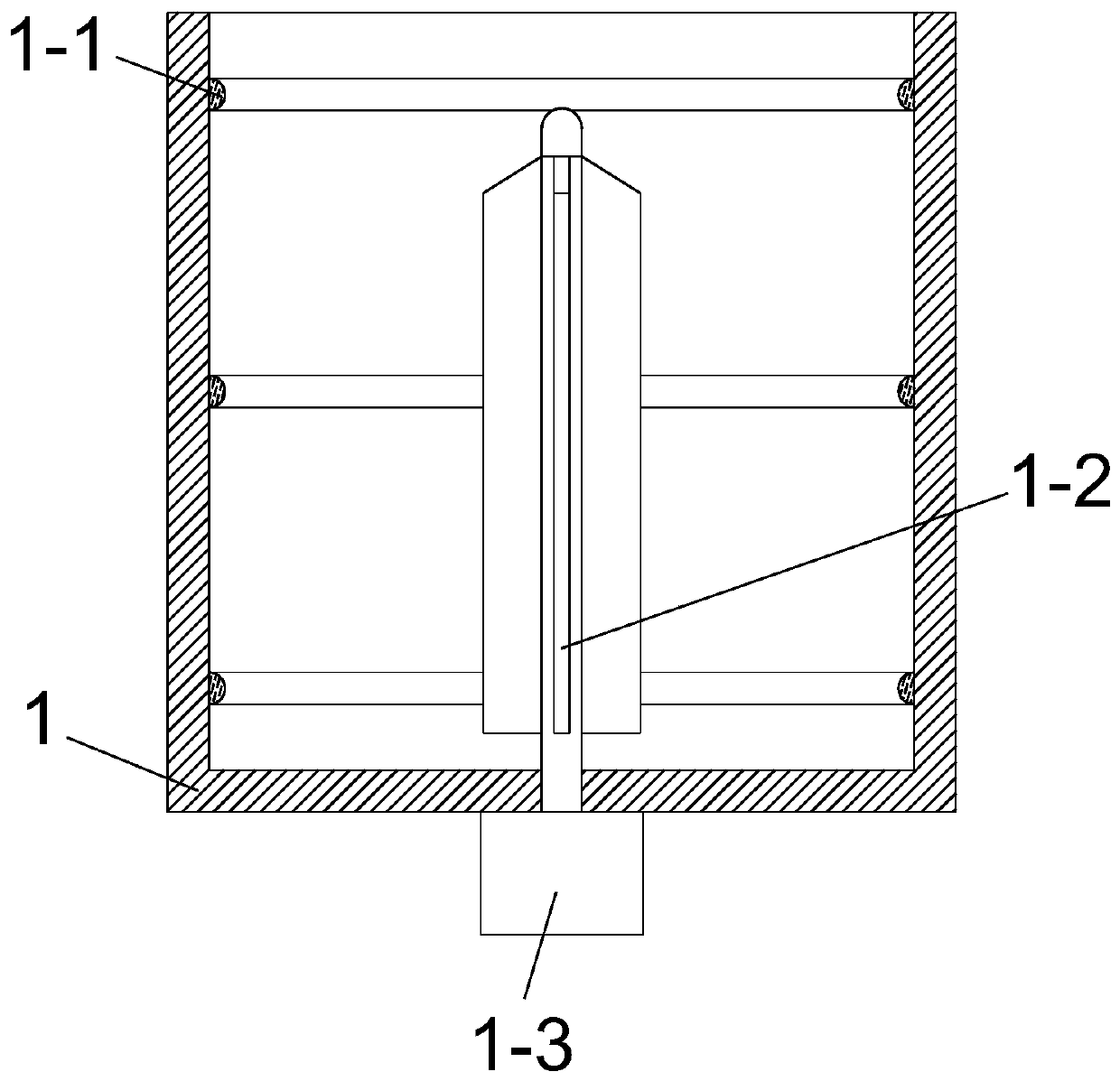

Infrared drying apparatus for edible fungi

ActiveCN108576870AReduce humidityImprove drying effectFood processingFood treatmentThermal insulationEngineering

The invention relates to an infrared drying apparatus for edible fungi. The infrared drying apparatus for edible fungi comprises a cylindrical dryer, and a placing basket which is arranged at an upper-end opening of the cylindrical dryer and stretches into an inner cavity of the cylindrical dryer; infrared heating rings are arranged on the inner side wall of the cylindrical dryer; and an exhaust fan is arranged at the center of the inner bottom surface of the cylindrical dryer. The infrared drying apparatus for edible fungi further comprises a thermal insulation cover arranged on the upper-endopening of the cylindrical dryer; a spiral water-cooling passageway is arranged around the outer circumferential wall of the thermal insulation cover; and a water collection groove is arranged alongthe lower edge of the inner circumferential wall of the thermal insulation cover. The infrared drying apparatus for edible fungi provided by the invention is highly efficient and energy-saving. The infrared drying apparatus for edible fungi has the following advantages: the infrared drying apparatus for edible fungi comprises the cylindrical dryer, and the placing basket which is arranged at the upper-end opening of the cylindrical dryer and stretches into the inner cavity of the cylindrical dryer; and the infrared heating rings are arranged on the inner side wall of the cylindrical dryer, sothat drying treatment can be directly performed on edible fungi by the infrared heating rings. And thus, the infrared drying apparatus for edible fungi is highly efficient and energy-saving.

Owner:FUJIAN YISHENG FOOD

Device for canned food production

InactiveCN109387056ARealize pumping treatmentAchieve vacuum dryingDrying gas arrangementsDrying chambers/containersAir filterPulp and paper industry

The invention provides a device for canned food production. The device comprises a drying chamber, exhaust fans are arranged on the upper surface and the lower surface of the drying chamber respectively, the exhaust fan on the upper surface of the drying chamber is connected with a pipeline which is connected with an upper exhaust opening, a control valve is arranged at the upper exhaust opening,the pipeline is connected with an air drying box, an air filter and an air washer, and a control valve is arranged on the portion, in front of the air drying box, of the pipeline. The exhaust fan on the lower surface of the drying chamber is connected with a pipeline which is connected with a lower exhaust opening, a control valve is arranged at the lower exhaust opening, the pipeline is connectedwith the air drying box and the air washer, and a control valve is arranged on the portion, in front of the air drying box, of the pipeline. The exhaust fans are arranged on the upper surface and thelower surface of the drying chamber respectively, the pipelines are negative pressure air pipelines, and the pipelines on the exhaust fan on the upper surface of the drying chamber are mutually communicated. The exhaust fans are arranged on the upper surface and the lower surface of the drying chamber respectively, so that forward and reverse circulating air flow is achieved, it is achieved thatthe front side and the back side of food are quickly dried, and it is achieved that the drying speed is increased.

Owner:宜昌天元罐头有限公司

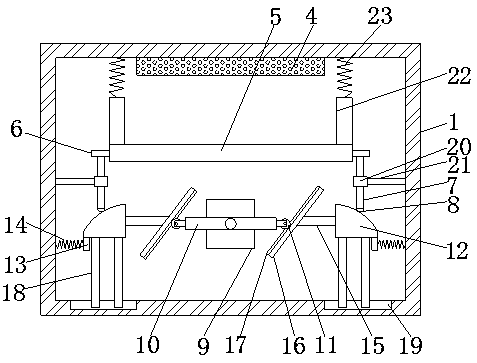

Household textile finished product detection device with drying and dehumidifying functions

PendingCN114791486AImprove drying effectAvoid the problem of uneven dryingMechanical cleaningPressure cleaningStructural engineeringManufacturing engineering

The invention discloses a household textile finished product detection device with drying and dehumidifying functions, which comprises a top plate, the bottom of the top plate is fixedly connected with an electric telescopic rod, the bottom of the electric telescopic rod is fixedly connected with an electric detection machine, and the outer wall of the electric detection machine is fixedly connected with a connecting block. A multi-directional drying mechanism is arranged in the connecting block, through the arrangement of the multi-directional drying mechanism, a push block vibrates back and forth along with the bounce of an elastic plate, and through the magnetic attraction force with the outer wall of a sliding plate, the sliding plate is synchronously driven to rotate and vibrate back and forth in an air injection groove; and then air sprayed out through the air holes A and passing through the sliding plate continuously rotates along with the sliding plate, the spraying direction is automatically swung and changed back and forth, the problem that cloth is dried unevenly due to single-direction spraying through the air spraying groove is avoided, the overall drying effect is improved, and the beneficial effect of being high in practicability is achieved.

Owner:南通市通州区晋峰纺织有限公司

Food processing dryer

InactiveCN112129087AAvoid uneven dryingUniform drying effectDrying gas arrangementsDrying solid materialsAgricultural engineeringAgricultural science

The invention discloses a food processing dryer. The food processing dryer structurally comprises a drying bin, an air outlet and an electric box; the electric box is fixedly installed on the end faceof the outer side of the drying bin in an embedded mode; the air outlet is formed in the end face of the outer side of the drying bin in an embedded mode; the electric box is fixedly installed at theright side of the air outlet in an embedded mode; due to the fact that collecting grooves and penetration holes are formed in the outer end face of a leakage mechanism, part of bean food flows downwards to an interlayer between separation blocks along the inner contour of the leakage mechanism when the bean food falls downwards to the moment, and due to the fact that the interlayer between the separation blocks is longitudinally arranged, the bean food can be effectively dried when airflow flows towards a separation mechanism in the middle along ventilation openings in the left side and the right side; and the problem of uneven drying is avoided.

Owner:广州佳优华信息科技有限公司

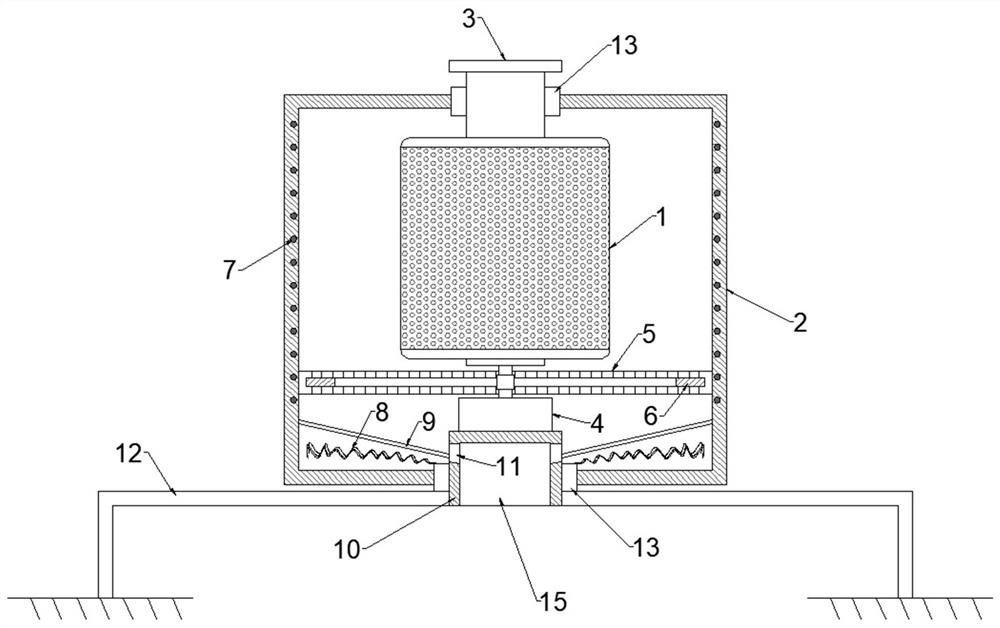

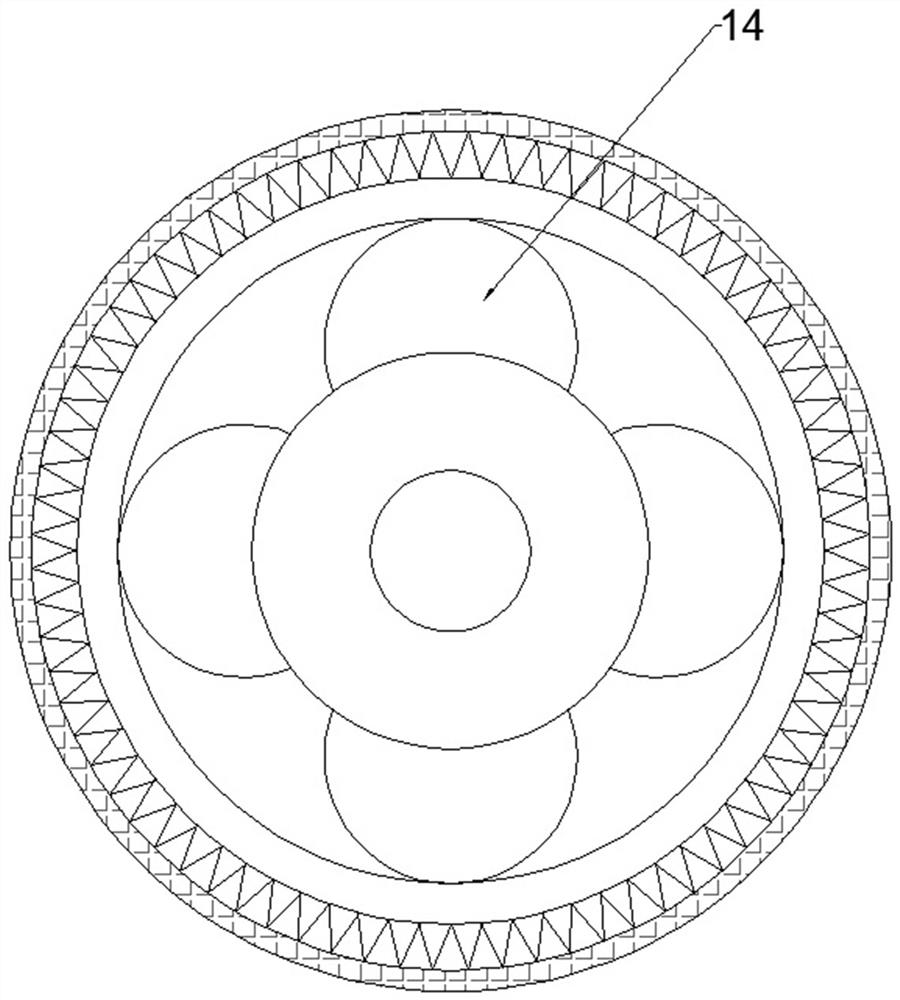

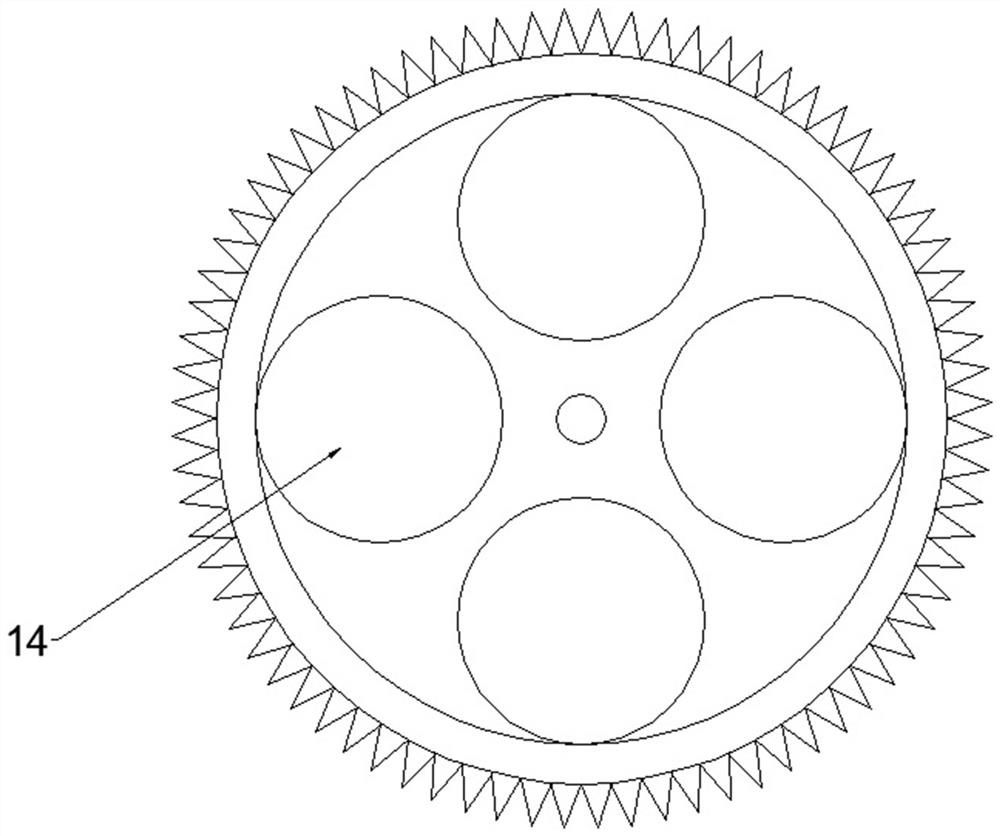

Drying machine for acrylic resin emulsion powder production

InactiveCN112815634ADry evenlyAvoid the problem of uneven dryingDrying solid materials without heatDrying chambers/containersEmulsionAcrylic resin

The invention relates to a drying machine for acrylic resin emulsion powder production. The drying machine comprises a centrifugal barrel and a drying barrel, through holes are evenly formed in the surface of the centrifugal barrel, the drying barrel and the centrifugal barrel are coaxially installed, and the centrifugal barrel is located in the drying barrel. A first heating wire and a second heating wire are arranged on the side wall and the bottom of the drying barrel correspondingly. A discharging barrel is coaxially arranged on the axis of the bottom of the drying barrel, the discharging barrel is fixed to a rack, and an opening of the discharging barrel faces downwards to serve as a discharging opening. A motor is fixed to the top of the discharging barrel, and the motor is connected with the centrifugal barrel and used for driving the centrifugal barrel to rotate. A rotating shaft of the motor is coaxially provided with a gear disc, the inner wall of the drying barrel is provided with a circle of teeth meshed with the gear disc, and the gear disc is provided with a plurality of round holes. A plurality of discharging holes are formed in the side wall of the discharging barrel, the discharging holes are used for communicating the drying barrel with the discharging opening, and according to the scheme, uniform drying of the acrylic resin emulsion powder can be achieved, and the drying efficiency is improved.

Owner:宁夏嘉铂睿环保科技集团有限公司

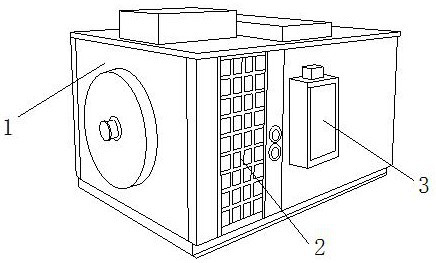

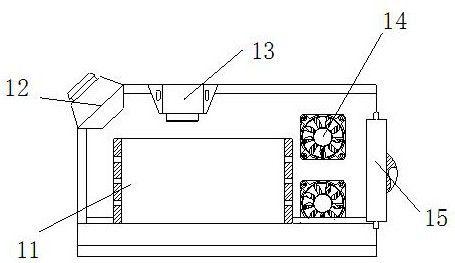

Air flue air distribution structure of heat pump drying machine

ActiveCN105222570AReasonable layoutAvoid churnDrying gas arrangementsDrying machines with progressive movementsSludgeProcess engineering

The invention discloses an air flue air distribution structure of a heat pump drying machine. The air flue air distribution structure comprises a shell, a drying chamber and a heat pump main engine. The shell is formed by packaging an insulation board. A lower conveying net belt and an upper conveying net belt are arranged in the drying chamber. First space is formed below the lower conveying net belt. Second space is formed between the upper conveying net belt and the lower conveying net belt. Third space is formed above the upper conveying net belt. A first air opening is formed in the top of the drying chamber. Second air openings, third air openings and fourth air openings are formed in the sided face of the drying chamber from bottom to top in sequence. An inner circulation air flue and an outer circulation air flue can be formed, the air flues are arranged reasonably and inlaid in the drying chamber, closed circulation is achieved, full heat preservation is achieved, heat is prevented from being lost, and the cost for manufacturing an outer independent air flue is omitted. In addition, dry air can be fully saturated to take away more water, the drying efficiency is improved, and the problem that sludge on the upper conveying net belt is dried unevenly is solved.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

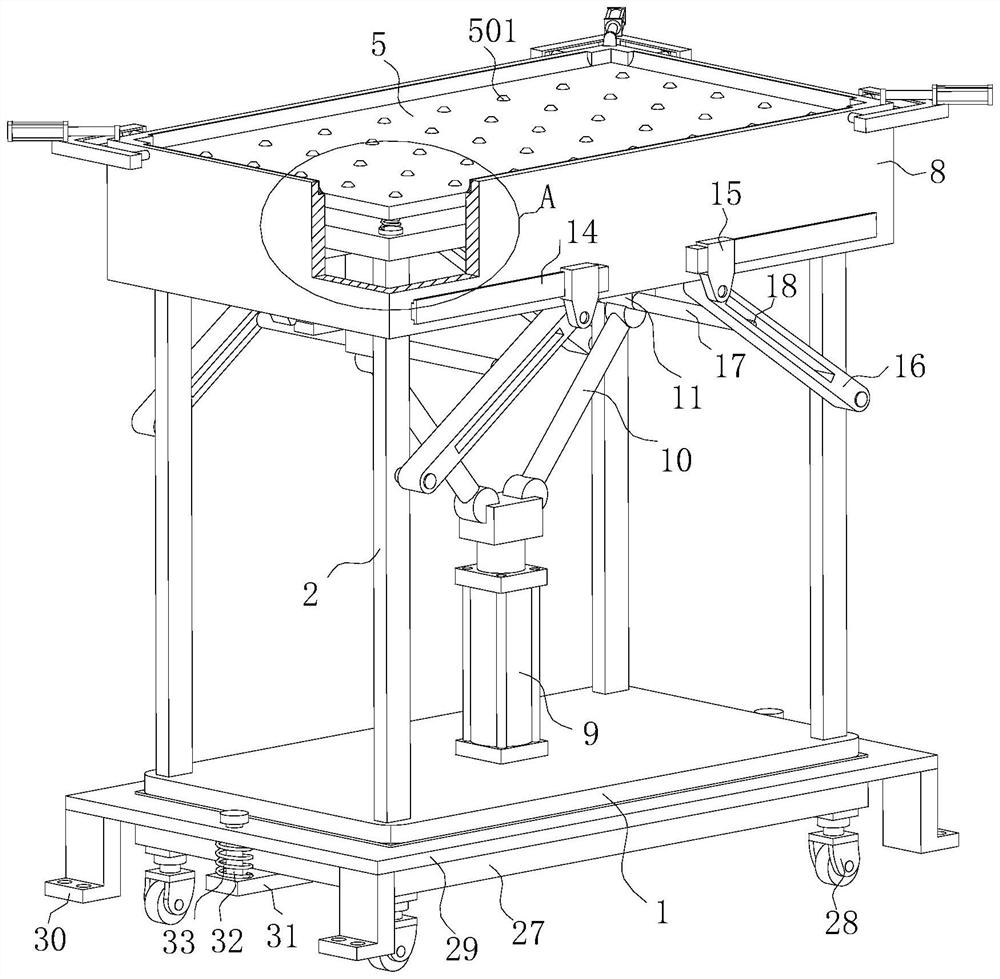

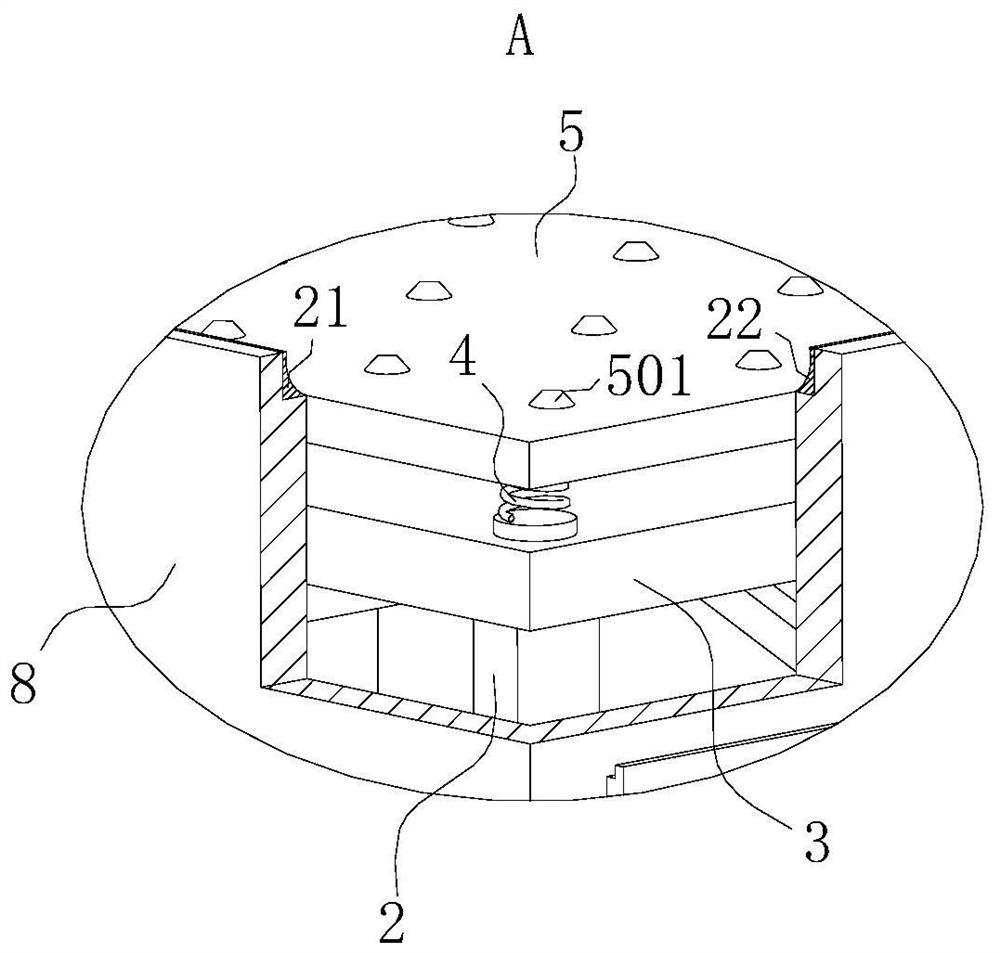

Agricultural seed airing device

ActiveCN111649557AAchieve flippingDry thoroughlySeed and root treatmentDrying solid materialsAgricultural engineeringMechanical engineering

Owner:淮北雷德机电科技有限公司

A kind of tea processing equipment

ActiveCN111014022BFirmly connectedEasy inspection and maintenanceSievingPre-extraction tea treatmentEngineeringMechanical engineering

The invention discloses a tea processing device which comprises a processing chamber, a bottom plate, a connecting piece, a side plate and a vibration heating chamber. A first filtering net, a secondfiltering net and a third filtering net are arranged in the processing chamber. The top face of the first filtering net, the top face of the second filtering net and the top face of the third filtering net are fixedly connected with the bottom of a first connecting rod, the bottom of a second connecting rod and the bottom of a third connecting rod correspondingly in a welded manner. A bottom holeis formed in the bottom of the processing chamber. A vertical plate is fixed to the front end face of the vibration heating chamber. A heater and a fixing bottom plate are fixed to the side face of the vertical plate. An air supply device is fixed to the end face of the fixing bottom plate. A drying device is fixed to the top face of the vertical plate. The drying device is used for heating tea stored in the vibration heating chamber. The problems that in the prior art, the functions of tea screening and fast drying cannot be achieved, and adaptive matching of vibration input cannot be achieved are solved; and the tea processing device can be better applied and popularized.

Owner:通城县百丈潭茶业有限责任公司

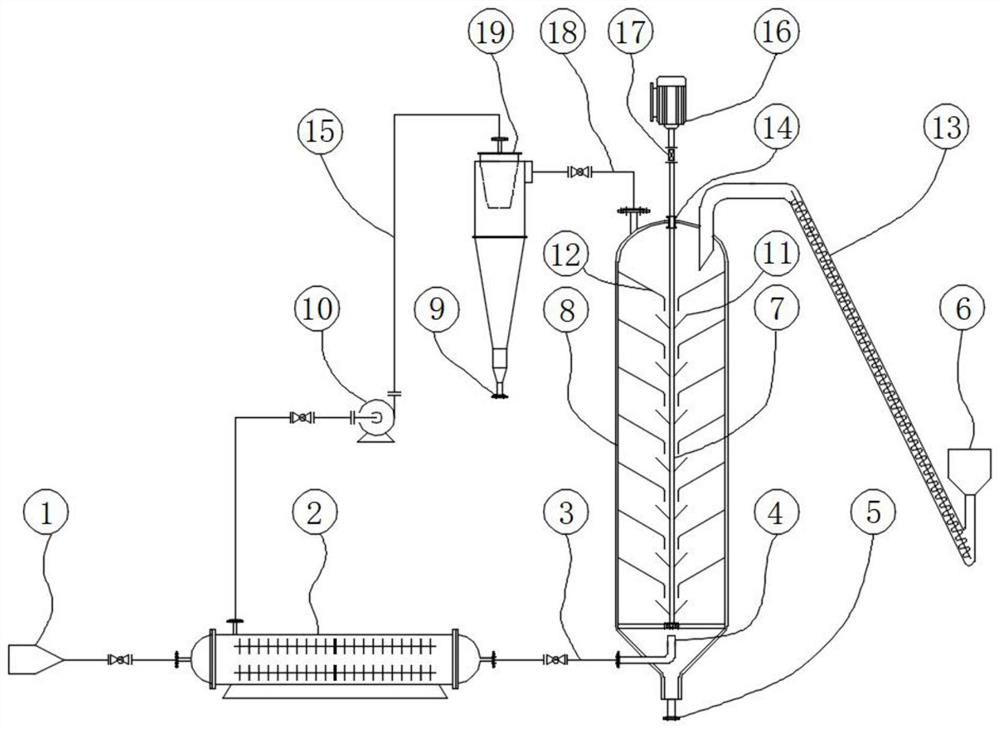

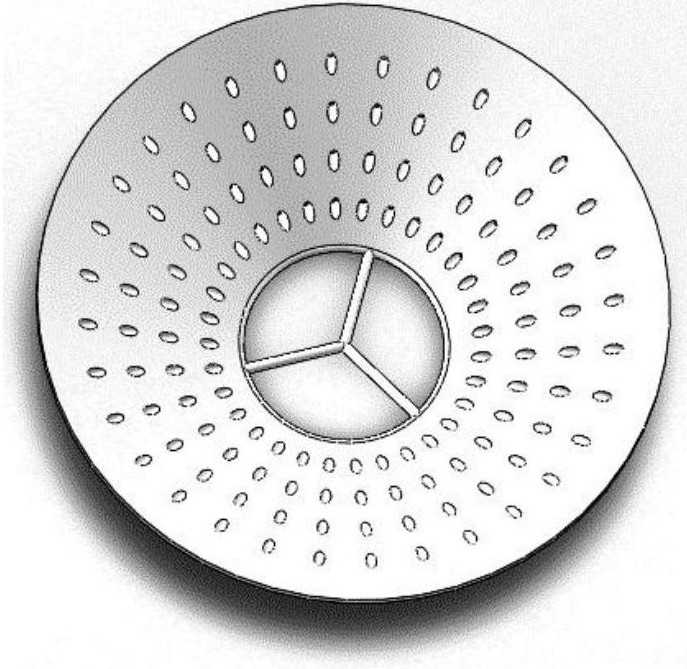

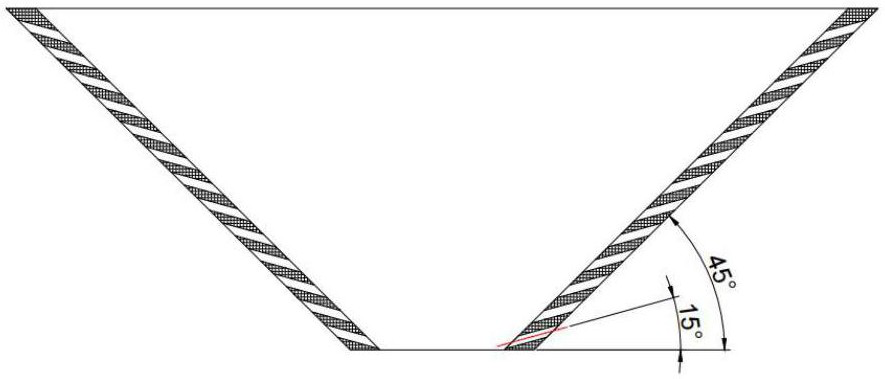

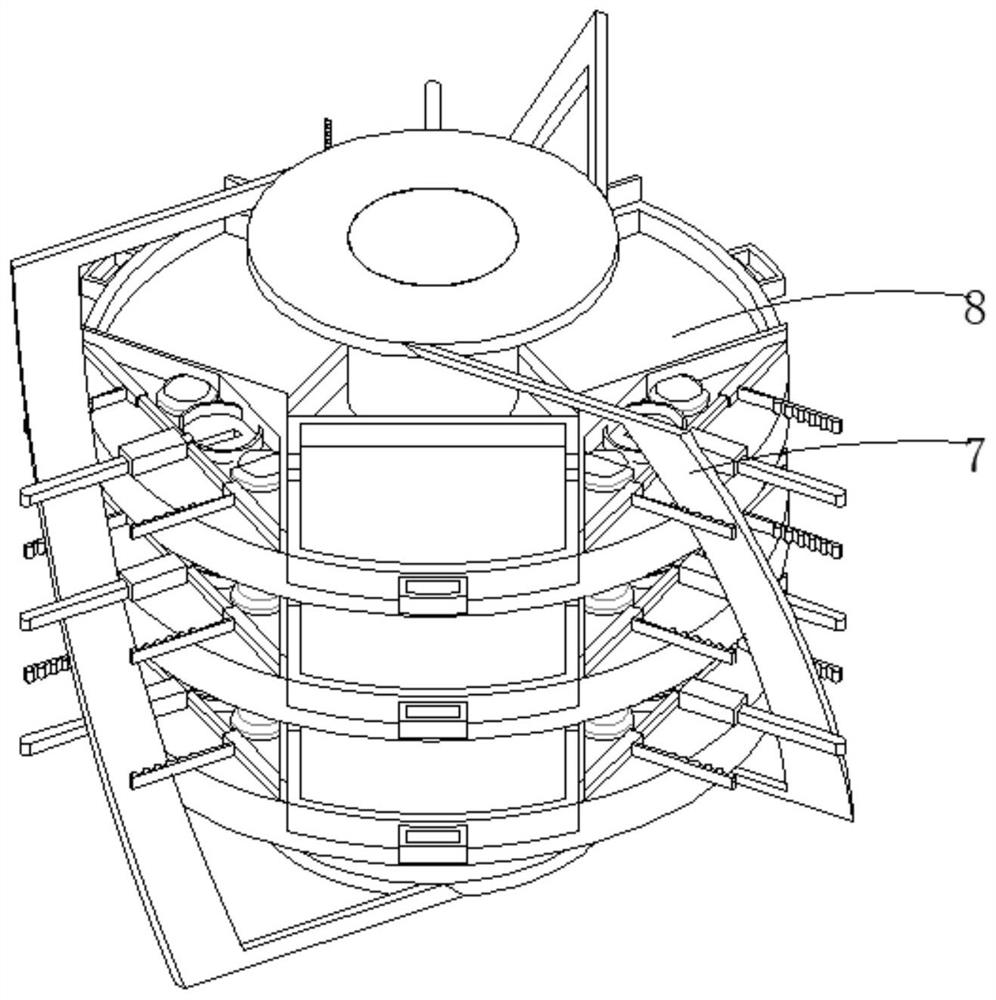

Conical disc type superheated steam drying device and method suitable for granular materials

ActiveCN114322506ASolve the difficult problem of fluidized dryingHigh heat and mass transfer efficiencyDrying solid materials with heatDrying solid materials without heatEngineeringCentrifugal force

The invention relates to a conical disc type superheated steam drying device suitable for granular materials, the granular materials are in a fluidized state by utilizing centrifugal force generated by rotation of a rotating conical disc, the heat and mass transfer efficiency is high, the conical disc type superheated steam drying device is suitable for drying materials of various particle sizes such as A-type materials to D-type materials, and particularly the problem that the D-type large particles are difficult to be subjected to fluidized drying is solved. And the drying medium only performs heat and mass transfer with the material and does not participate in the particle fluidization process, so that the pressure drop problem caused by a traditional fluidized bed is avoided, the use amount of the drying medium is effectively reduced, and energy conservation is facilitated. According to the invention, materials with various particle sizes can be uniformly distributed in the dryer and fully transfer heat and mass with a drying medium, so that the problem of non-uniform drying of the materials caused by the phenomena of channeling and the like easily occurring in a traditional fluidized bed is avoided.

Owner:TIANJIN AGRICULTURE COLLEGE

Probiotic constant-temperature drying device and drying method

InactiveCN113865310AEvenly heatedAvoid localized heatDrying gas arrangementsDrying chambers/containersBiotechnologyElectric machinery

The invention discloses a probiotic constant-temperature drying device and a drying method, and relates to the technical field of probiotics. The probiotic constant-temperature drying device comprises a device body, a motor is fixed to the top of the device body, an output shaft of the motor penetrates through and is rotationally installed at the top of the device body, an auxiliary drying device used for promoting probiotics to be dried is fixed to the bottom of the output shaft of the motor, an exhaust port and an electric heating controller are sequentially fixed to the right side of the device body from top to bottom, and a drying fan is fixed to the bottom of the inner wall of the device body. Through cooperation of the motor and a rotating shaft, the motor drives a bearing circular truncated cone and material containing frames to rotate, and therefore probiotics on the material containing frames are dried in the device body in a rotating manner, the probiotics can be heated evenly, the problem that due to local heating of the probiotics and uneven temperature distribution, the probiotics are not dried thoroughly or comprehensively is solved, and then the drying efficiency of the probiotics is improved.

Owner:农少文

Agricultural product airing device for agriculture

InactiveCN109373720AEasy to operateAvoid accumulationDrying chambers/containersDrying machines with local agitationAgricultural engineeringAgriculture

The invention discloses an agricultural product airing device for agriculture. The agricultural product airing device for agriculture comprises a fixed frame, wherein two grooves are formed in two sides of the bottom part of the fixed frame; magnet boards are arranged on the left sides of the inner walls of the top parts of the four grooves; support legs are hinged to four corners of the bottom part of the fixed frame; inserting slots distributed equidistantly are formed in two sides of the top part of the fixed frame; one same support is inserted into the two opposite inserting slots; two clamping slots are formed in four corners of the top part of the fixed frame; a storage groove is formed in the middle of the left side of the top part of the fixed frame; and one same winding shaft is connected to the inner walls of two ends of the storage groove through bearings. According to the agricultural product airing device for agriculture provided by the invention, agricultural products canbe effectively prevented from being blown to be accumulated during the airing process, the occurrence of the problem of nonuniformity of agricultural product airing caused by the fixed position of apressing block can be avoided, a mothproof effect can be achieved during airing, and the agricultural product airing device for agriculture is convenient to operate, capable of being folded, less in floor space when in use, and convenient to store.

Owner:龚敬怡

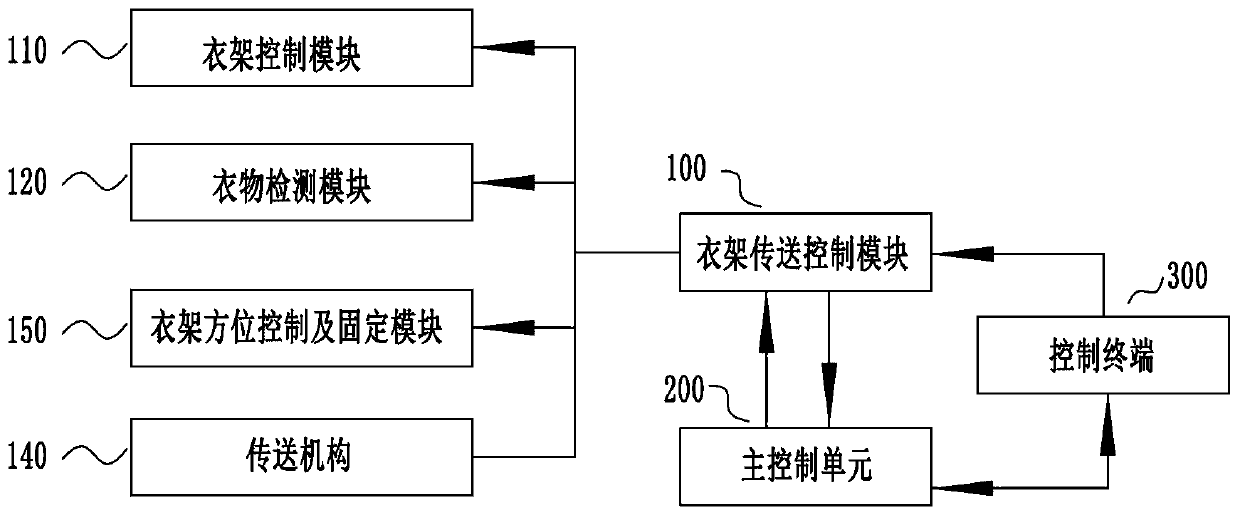

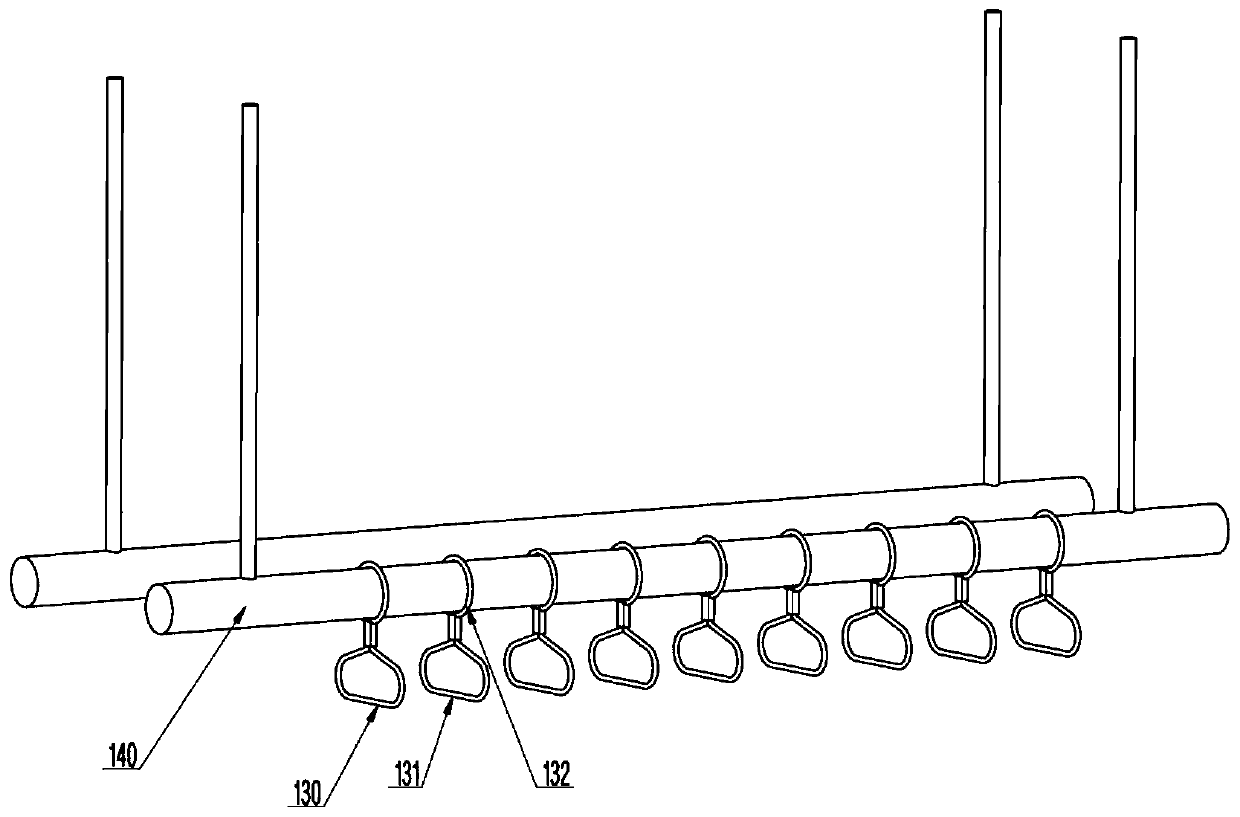

Intelligent clothes air-drying rack capable of intelligently controlling clothes hangers and control method

InactiveCN110195339AAvoid uneven dryingPrevent clothing from fadingApparel holdersOther drying apparatusSet distanceClothes hanger

The invention relates to an intelligent clothes air-drying rack capable of intelligently controlling clothes hangers and a control method, relates to the technical field of smart homes, and is used for solving the technical problem of nonuniform clothes air-drying in the prior art. The intelligent clothes air-drying rack capable of intelligently controlling the clothes hangers comprises a clotheshanger conveying control module, wherein the clothes hanger conveying control module comprises clothes hanger control modules arranged on the clothes hangers, and the distance between the two adjacentclothes hangers is kept at a set distance through the clothes hanger control modules on the clothes hangers, so that a user does not need to manually separate the clothes hangers, and clothes can besufficiently dried, thereby avoiding the problem of nonuniform air-drying.

Owner:GREE ELECTRIC APPLIANCES INC +1

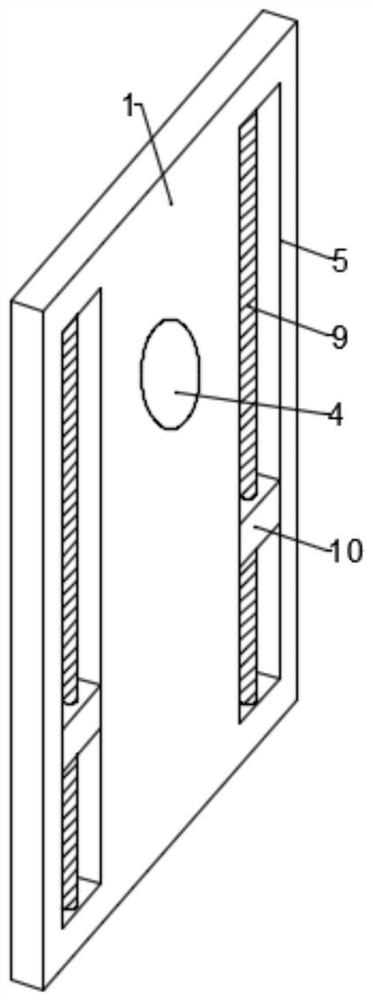

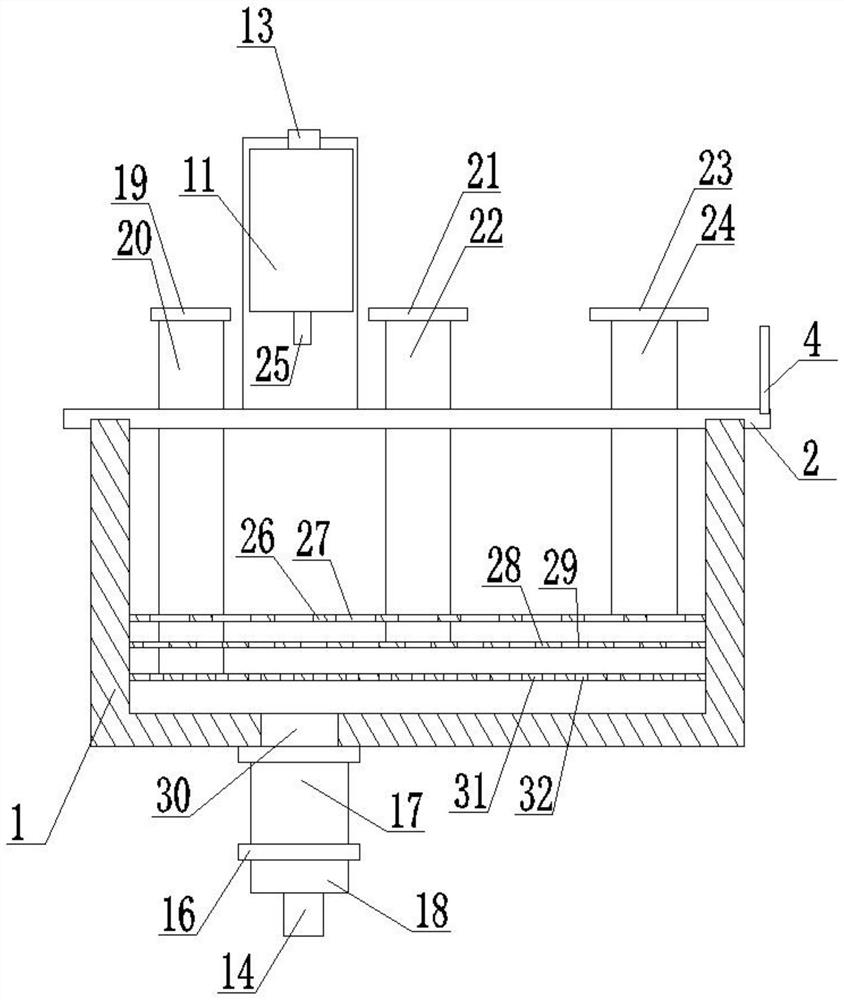

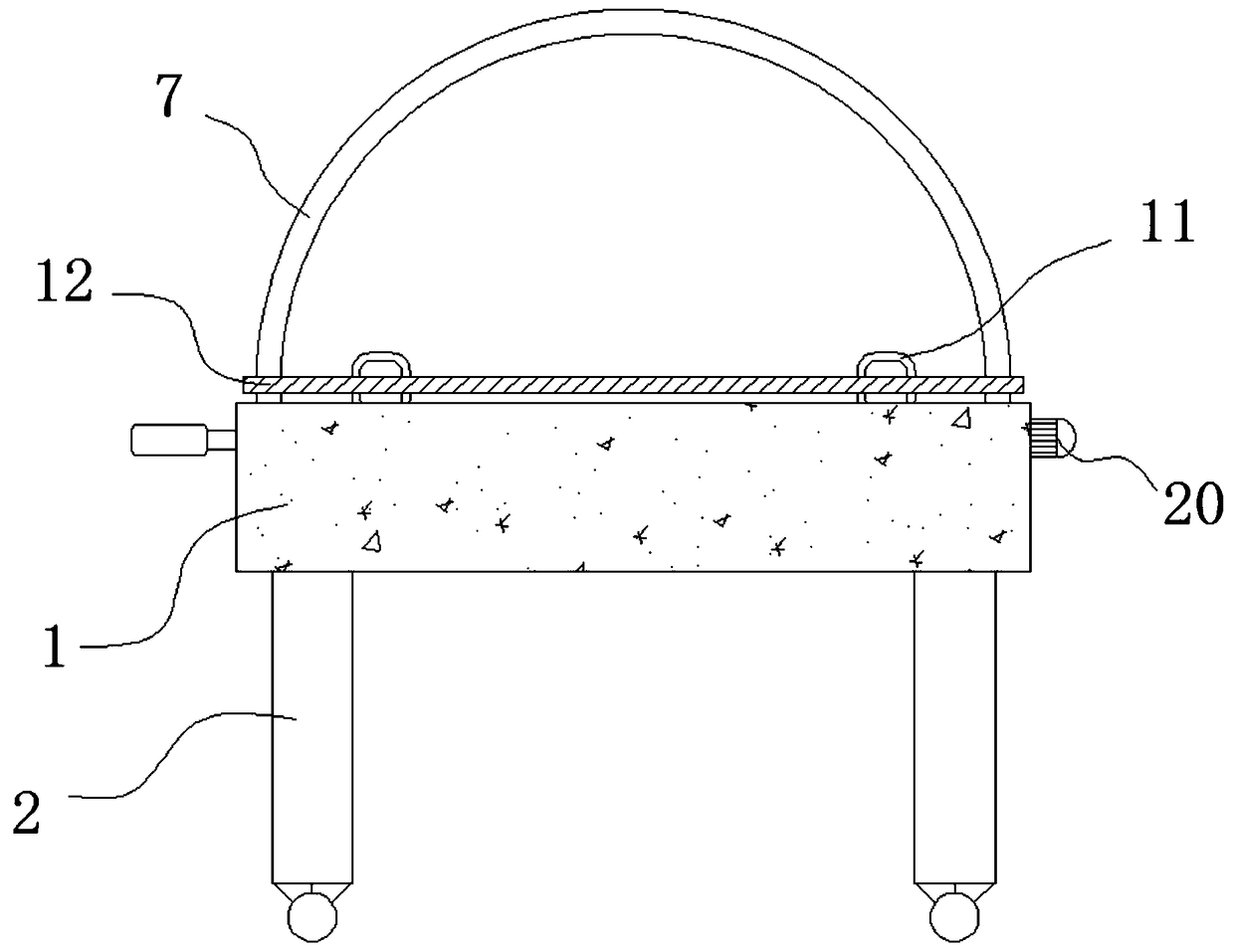

A device for drying medicinal materials in sheet form

ActiveCN109210901BAvoid the problem of uneven dryingDrying chambers/containersDrying machines with progressive movementsMedicinal herbsMetallurgy

The invention discloses a drying device for sliced medicinal materials, and belongs to the technical field of processing of traditional Chinese medicinal materials. The drying device for the sliced medicinal materials solve the problem of uniform drying due to different sizes and non-uniform arranging of existing sliced medicinal materials. The device comprises a horizontal spreading and conveyingunit and a roasting unit, wherein the horizontal spreading and conveying unit comprises a conveying track and a net plate; a pair of pulleys is arranged on two top ends of the bottom part of the netplate, and the sizes of the pulleys are matched with the width of the conveying track; the roasting unit comprises a roasting box body, heating plates and a roasting track; the heating plates are hollowed out; the roasting track is arranged on the top end of the roasting box body; at least a pair of heating plates is fixed to the roasting track through rotary sliding shafts; the roasting track isconnected to one end of the conveying track; and the size of the net plate is matched with a hollowed-out area in each heating plate.

Owner:安徽承庆堂国药股份有限公司

Edible mushroom infrared drying device

ActiveCN108576870BReduce humidityImprove drying effectFood processingFood treatmentBiotechnologyThermal insulation

The invention relates to an infrared drying apparatus for edible fungi. The infrared drying apparatus for edible fungi comprises a cylindrical dryer, and a placing basket which is arranged at an upper-end opening of the cylindrical dryer and stretches into an inner cavity of the cylindrical dryer; infrared heating rings are arranged on the inner side wall of the cylindrical dryer; and an exhaust fan is arranged at the center of the inner bottom surface of the cylindrical dryer. The infrared drying apparatus for edible fungi further comprises a thermal insulation cover arranged on the upper-endopening of the cylindrical dryer; a spiral water-cooling passageway is arranged around the outer circumferential wall of the thermal insulation cover; and a water collection groove is arranged alongthe lower edge of the inner circumferential wall of the thermal insulation cover. The infrared drying apparatus for edible fungi provided by the invention is highly efficient and energy-saving. The infrared drying apparatus for edible fungi has the following advantages: the infrared drying apparatus for edible fungi comprises the cylindrical dryer, and the placing basket which is arranged at the upper-end opening of the cylindrical dryer and stretches into the inner cavity of the cylindrical dryer; and the infrared heating rings are arranged on the inner side wall of the cylindrical dryer, sothat drying treatment can be directly performed on edible fungi by the infrared heating rings. And thus, the infrared drying apparatus for edible fungi is highly efficient and energy-saving.

Owner:FUJIAN YISHENG FOOD

Drying device for sliced medicinal materials

ActiveCN109210901AAvoid the problem of uneven dryingDrying chambers/containersDrying machines with progressive movementsPulley

The invention discloses a drying device for sliced medicinal materials, and belongs to the technical field of processing of traditional Chinese medicinal materials. The drying device for the sliced medicinal materials solve the problem of uniform drying due to different sizes and non-uniform arranging of existing sliced medicinal materials. The device comprises a horizontal spreading and conveyingunit and a roasting unit, wherein the horizontal spreading and conveying unit comprises a conveying track and a net plate; a pair of pulleys is arranged on two top ends of the bottom part of the netplate, and the sizes of the pulleys are matched with the width of the conveying track; the roasting unit comprises a roasting box body, heating plates and a roasting track; the heating plates are hollowed out; the roasting track is arranged on the top end of the roasting box body; at least a pair of heating plates is fixed to the roasting track through rotary sliding shafts; the roasting track isconnected to one end of the conveying track; and the size of the net plate is matched with a hollowed-out area in each heating plate.

Owner:安徽承庆堂国药股份有限公司

A method for drying roses and rose products prepared by the method

ActiveCN109282579BEasy to storeIncrease surface temperaturePre-extraction tea treatmentDrying solid materials with heatDesiccantFar infrared

The invention provides a method for drying roses and a rose product prepared by the method. The method for drying the roses comprises the steps that the roses are subjected to microwave or far infrared radiation, and first treatment roses are obtained; food desiccants are laid on a bottom layer, and the first treatment roses are spread on the food desiccants in a monolayer; after hot air circulation, warm-keeping and drying under 25-45 DEG C, second treatment roses are obtained; and the dried second treated roses are separated from the desiccants to obtain dried roses. According to the methodfor drying roses, the roses in the rose product are prepared; the water removing process has the characteristics of high efficiency, low energy consumption, and low aroma and nutrient loss; the dryingprocess is uniform and low in loss of rose color; and the rose products prepared by the method have the characteristics of rich flavor, good color and good shape.

Owner:甘肃铭启洋生物科技有限公司

Anti-caking material drying equipment

ActiveCN108007137BUniform temperatureQuick releaseDrying machines with non-progressive movementsDrying solid materialsEngineeringMaterials processing

The invention relates to the technical field of material processing device, and discloses an anti-blocking material drying device. The anti-blocking material drying device comprises a case; a feedingopening and a discharging opening are formed on the case; the top end of an inner cavity of the case is fixedly connected with a heater strip; the inner cavity is rotatably connected with rollers; therollers is internally provided with heater strips; the outer surfaces of the rollers are provided with wire meshes; first flapping plates and second flapping plates are connected with the rollers; the first flapping plates and the second flapping plates are arranged on the rollers at intervals in the circumferential direction; the inner cavity of the case is fixed with multiple convex plates; elastic plates are connected between each two adjacent convex plates; the convex plates and the elastic plates are both located below the rollers; the length of the first flapping plate is greater than the length of the second flapping plate; and the first flapping plate is in clearance fit with the elastic plates. The problem of poor drying effect and blocking of the discharging opening in the drying equipment of the existing technology because material caking cannot be effectively prevented is solved.

Owner:宁波江北文增新材料科技有限公司

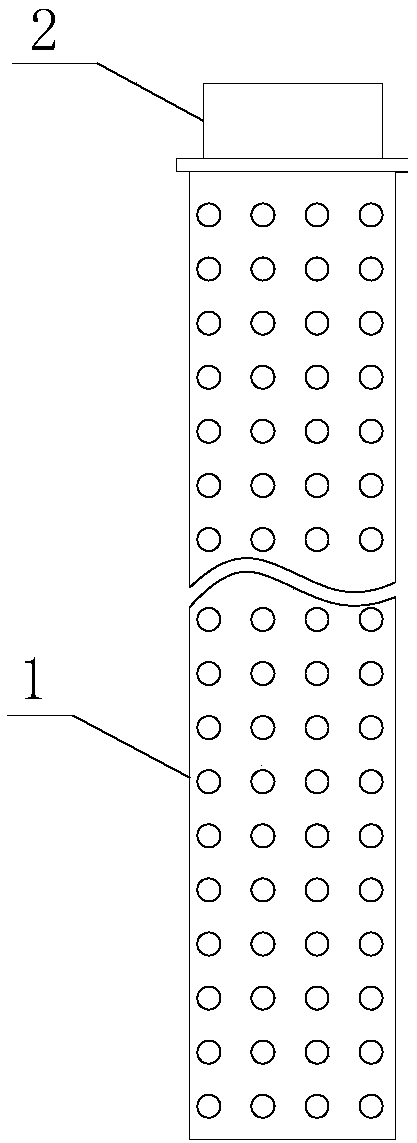

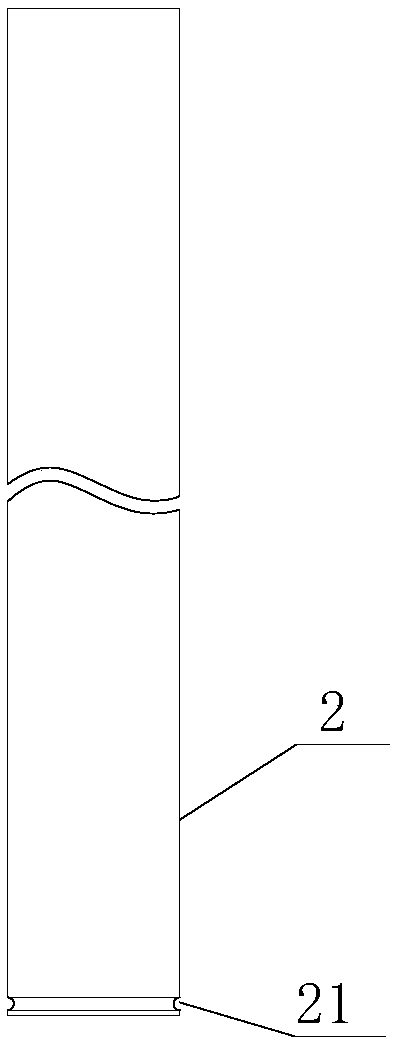

Device for reducing water of high moisture granular mixture material in cabin in balanced mode

PendingCN108692559AImprove uniformity and drying efficiencyAvoid uneven dryingDrying gas arrangementsSeed preservation by dryingEngineeringGrain drying

The invention discloses a device for reducing water of a high moisture granular mixture material in a cabin in a balanced mode. The device comprises an exploring tube and a core column, wherein two ends of the exploring tube penetrate, and a plurality of pores are formed in the side wall of the exploring tube; and one end of the core column stretches into the exploring tube and can slide up and down in the exploring tube. According to the device disclosed by the invention, the exploring tube is inserted into the cabin to guide air, and the core column moves up and down in the exploring tube tocontrol the height of an air guiding section of the exploring tube to guide a dry medium (air) into a high moisture material gathering region in the cabin in a fixed direction and in a positioned mode for reducing water and drying the material, so that moisture and moisture gradient in a material pile meet the demand. Therefore, the ventilating and drying uniformity and the drying efficiency of cereals in the cabin are improved, and the problem that in the prior art, the cereals are not uniformly dried in a drying mode of straight air can be solved.

Owner:合肥弘恩机电科技有限公司

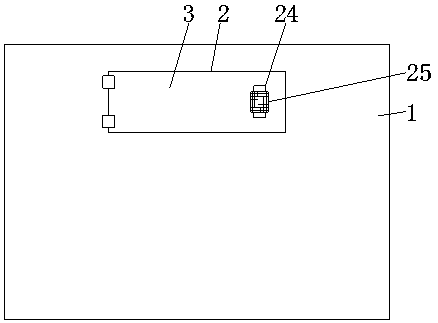

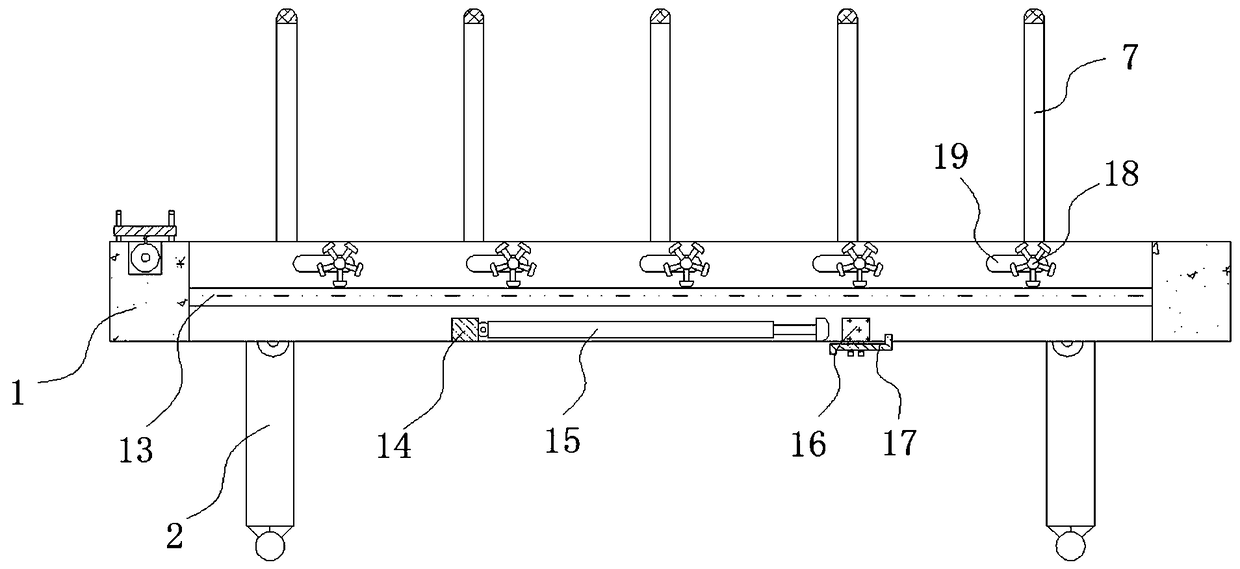

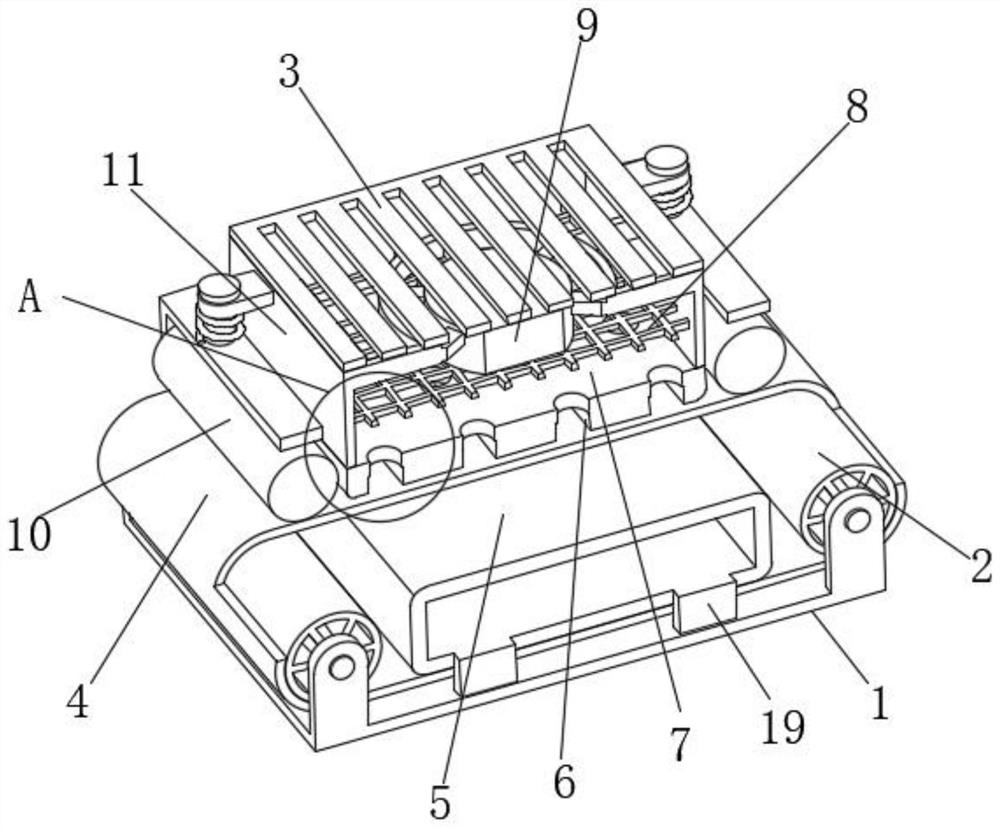

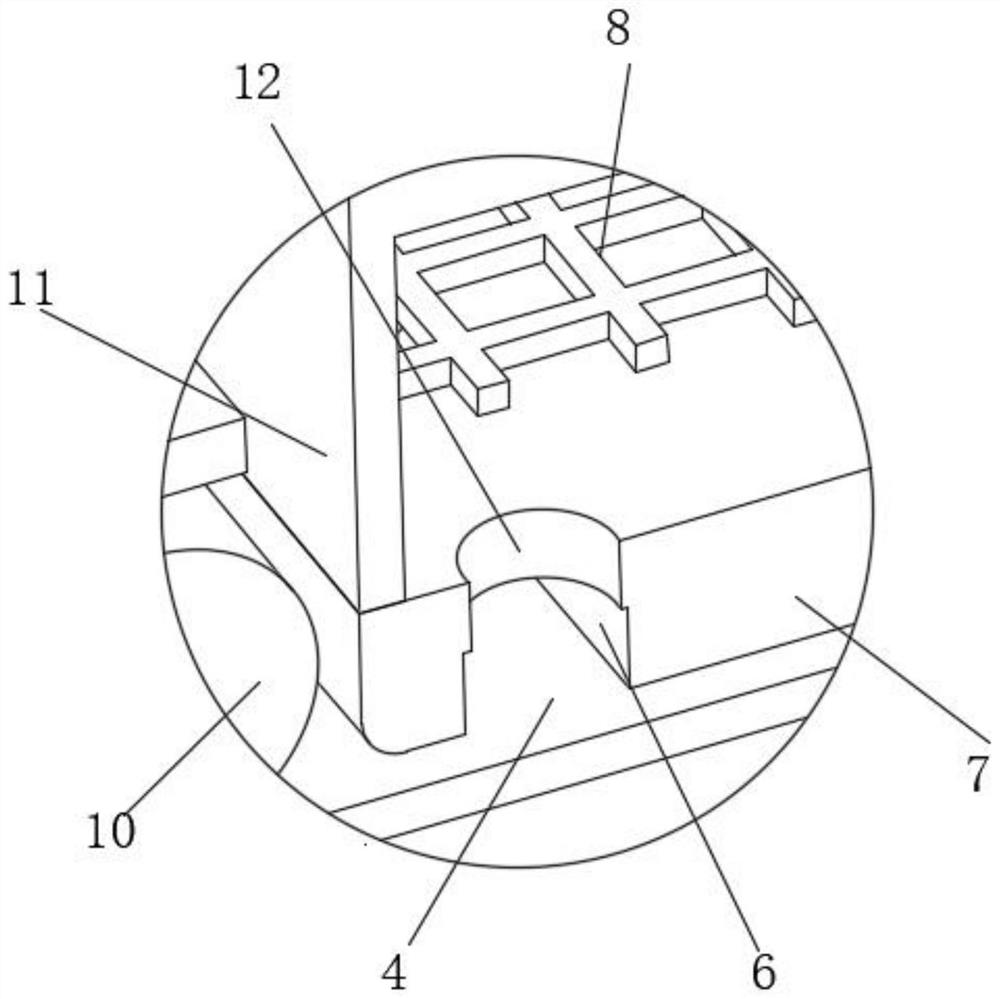

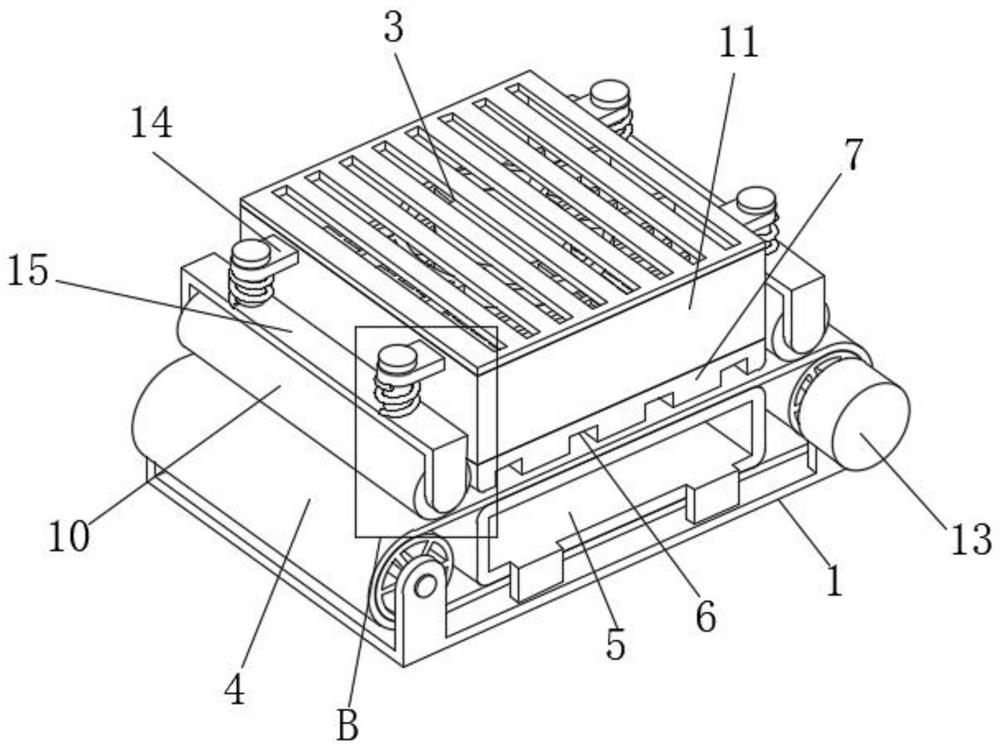

Drying device and control method of digital direct injection machine

ActiveCN111391524BFlow is easy to controlAvoid the problem of uneven dryingOther printing apparatusEngineeringMechanical engineering

The present invention relates to the technical field of digital direct injection machines, in particular to a drying device for digital direct injection machines and a control method thereof. An installation frame is provided, the bottom of the installation frame is connected with a cover plate, and a plurality of strip-shaped guide grooves are provided on the bottom surface of the cover plate, the guide grooves are parallel to each other, and the cover plate is evenly opened There are a plurality of ventilation holes, the ventilation holes communicate with one of the guide grooves, a heating screen is horizontally fixed in the installation frame, there is a gap between the heating screen and the cover plate, and the heating screen A cooling fan is arranged above, and the cooling fan is fixedly connected with the inner wall of the installation frame through a fixing frame. The invention can reduce energy consumption and realize uniform drying.

Owner:ZHEJIANG GONGZHENG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com