Anti-caking material drying equipment

A drying equipment and anti-caking technology, applied in drying, drying machine, non-progressive drying machine and other directions, can solve the problems of blockage of the discharge port and poor drying effect, so as to prevent caking and speed up the drying process. The effect of air flow and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

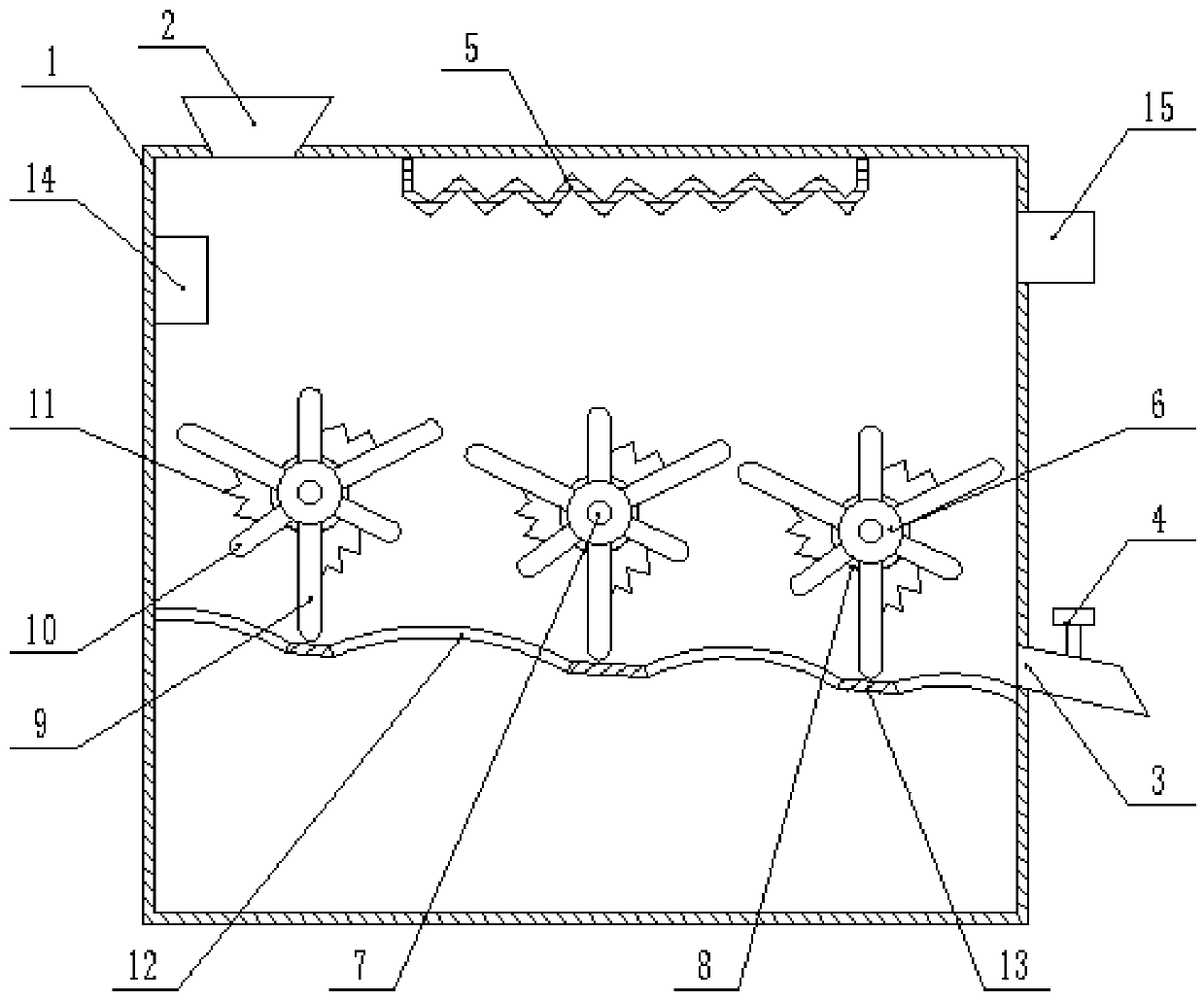

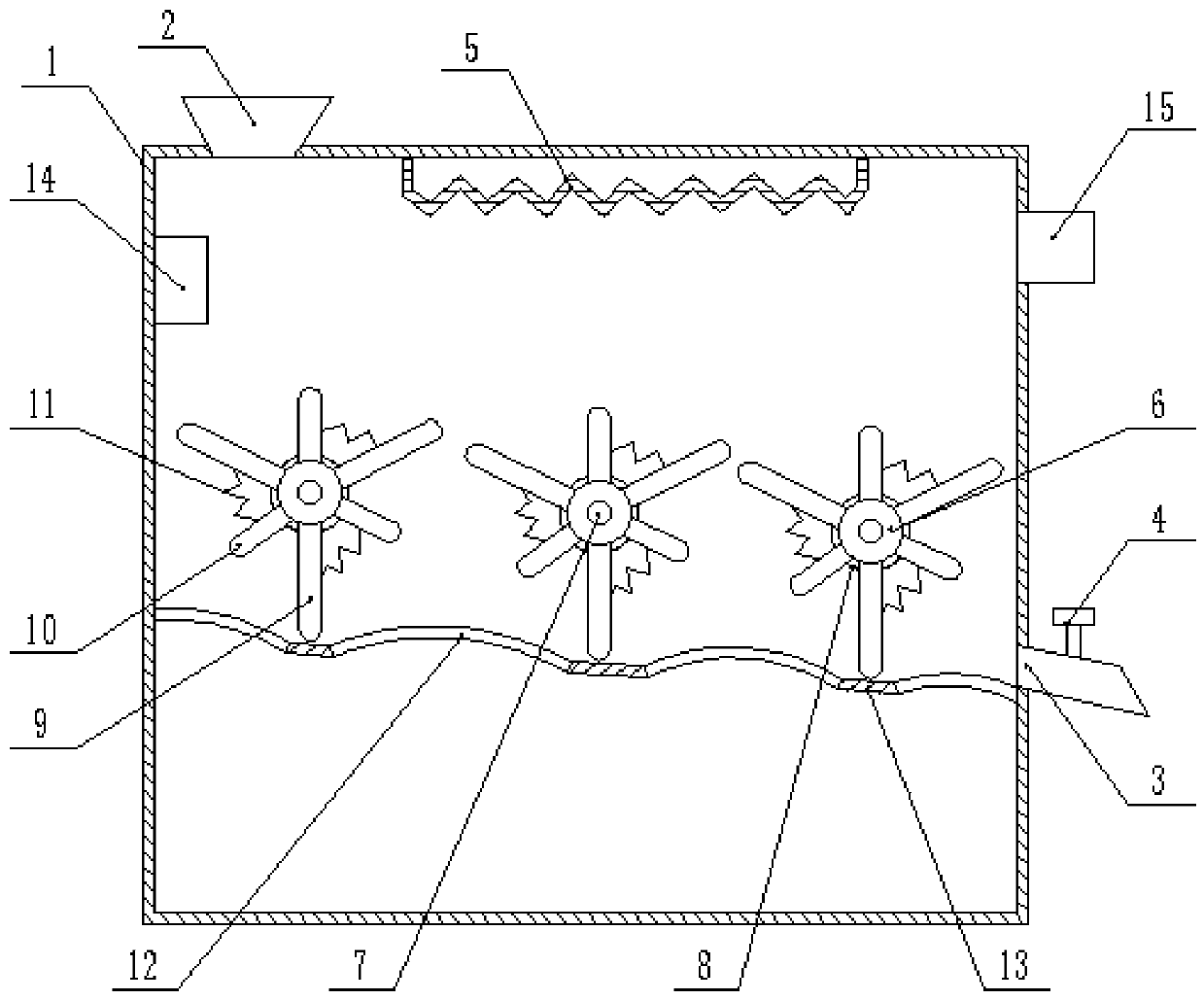

[0017] The reference signs in the accompanying drawings of the specification include: chassis 1, material inlet 2, material outlet 3, valve 4, first heating wire 5, roller 6, second heating wire 7, wire mesh 8, first punching wire Plate 9, the second beating plate 10, spring 11, raised plate 12, elastic plate 13, temperature sensor 14, dust collector 15.

[0018] This embodiment is basically as attached figure 1 , figure 2 Shown:

[0019] The anti-caking type material drying equipment includes a chassis 1, which is provided with a material inlet 2 and a material outlet 3, and a valve 4 is installed at the 3rd place of the material outlet, and the top of the inner cavity of the chassis 1 is welded with a first heating wire 5. Three rollers 6 are welded in the inner cavity of the chassis 1, and each roller is connected by a belt drive. The second heating wire 7 is welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com