Air flue air distribution structure of heat pump drying machine

A heat pump drying and air duct technology, applied in progressive dryers, drying gas layouts, dryers, etc., can solve problems such as high cost, high drying efficiency, heat loss, etc., to improve efficiency, reasonable air duct layout, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

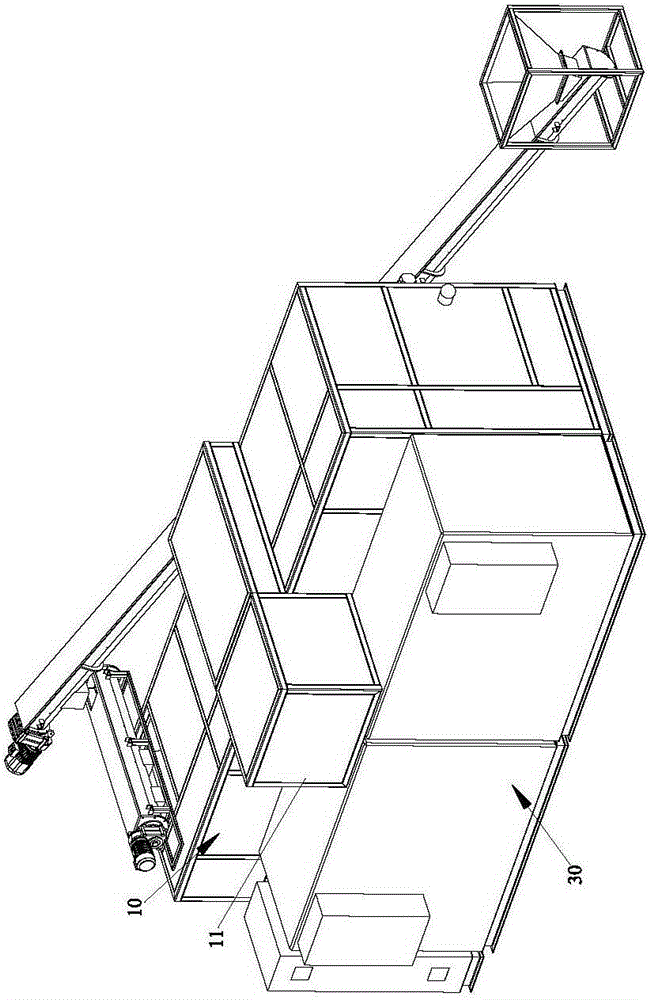

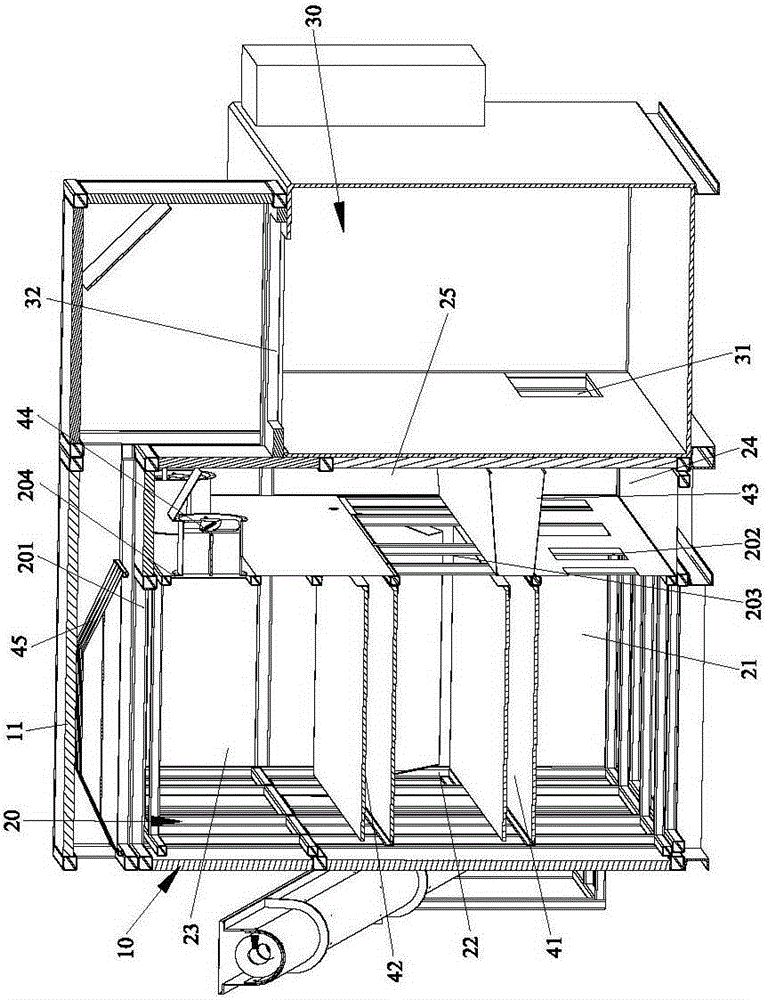

[0027] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a casing 10 , a drying chamber 20 and a heat pump host 30 .

[0028] The housing 10 is formed by encapsulating the insulation board 11. The drying chamber 20 is arranged in the housing 10. The drying chamber 20 is provided with a lower conveying mesh belt 41 and an upper conveying mesh belt 42. The lower conveying mesh belt 41 is formed with a first Space 21, the second space 22 is formed between the upper conveying mesh belt 42 and the lower conveying mesh belt 41, the third space 23 is formed above the upper conveying mesh belt 42, and the top of the drying chamber 20 is provided with a first tuyere 201 for drying The side of the chamber 20 is provided with a second tuyere 202, a third tuyere 203 and a fourth tuyere 204 in sequence from bottom to top; a windshield 43 is set between the heat pump main unit 30 and the drying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com