Device for reducing water of high moisture granular mixture material in cabin in balanced mode

A technology for dispersing particles and materials, which is applied in the direction of drying gas arrangement, grain drying, and preservation of seeds through drying. It can solve the problems of uneven precipitation of materials, easy condensation, and mildew of materials, so as to improve uniformity and dryness. Efficiency, avoid uneven drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the technical solution of the present invention will be described in detail through specific examples.

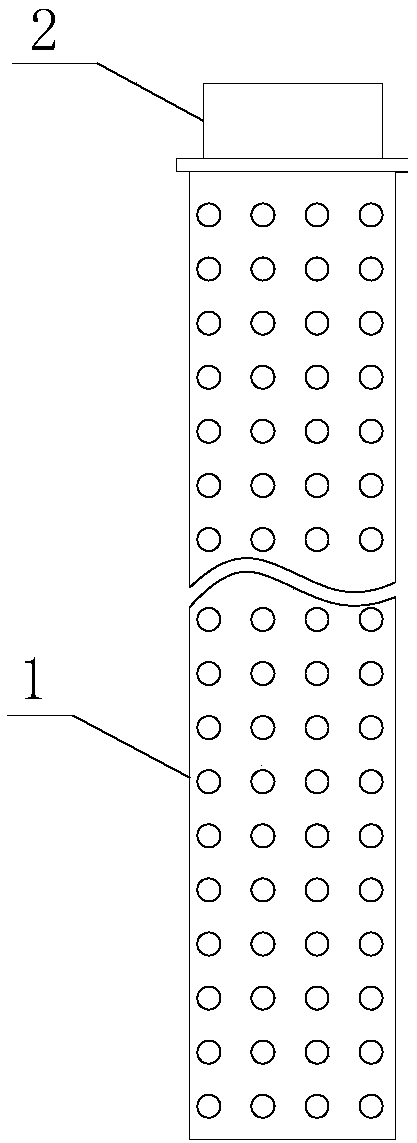

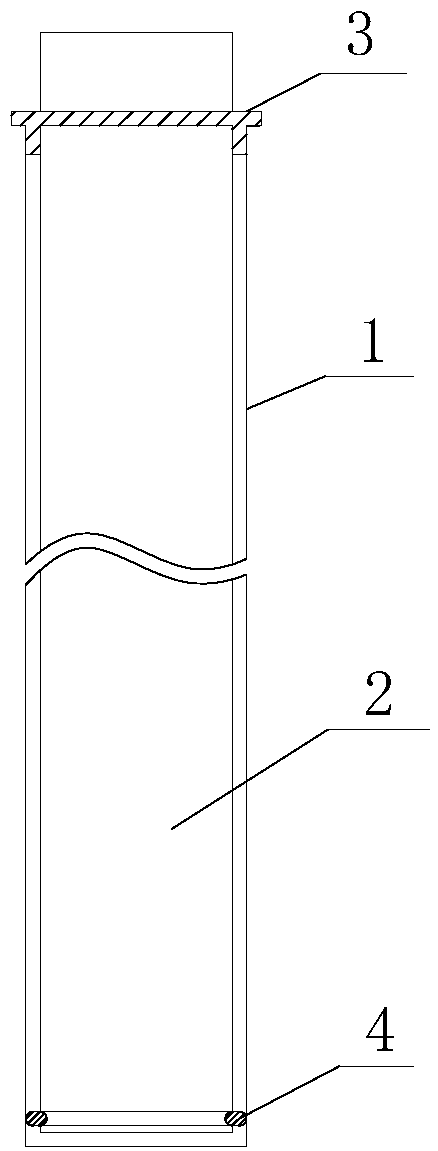

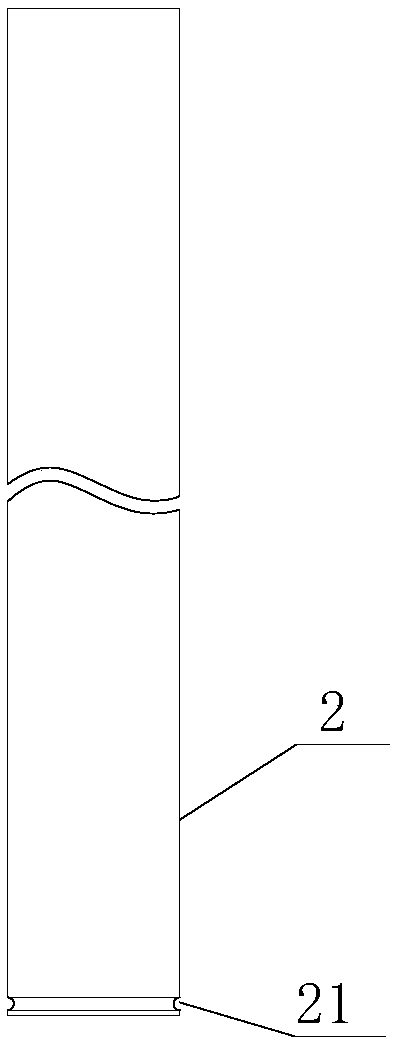

[0019] Such as Figure 1-5 as shown, figure 1 It is a structural schematic diagram of a device for balanced precipitation of high-water dispersed granular materials in a warehouse proposed by the present invention; figure 2 It is a structural schematic diagram of the probe in a device for balanced precipitation of high-water dispersed granular materials in a warehouse proposed by the present invention; image 3 It is a structural schematic diagram of the core column in a device for balanced precipitation of high-water dispersed granular materials in a warehouse proposed by the present invention; Figure 4 Working state of a device for balanced precipitation of high-water dispersed granular materials in a warehouse proposed by the present invention Figure 1 ; Figure 5 Working state of a device for balanced precipitation of high-water dispersed granular m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com