Air draft drying device for board

A drying device and a technology for wood panels, applied in the field of wood panel processing, can solve problems such as affecting product quality, increasing drying time, reducing drying efficiency, etc., to achieve the effects of improving uniformity and drying efficiency, and ensuring drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

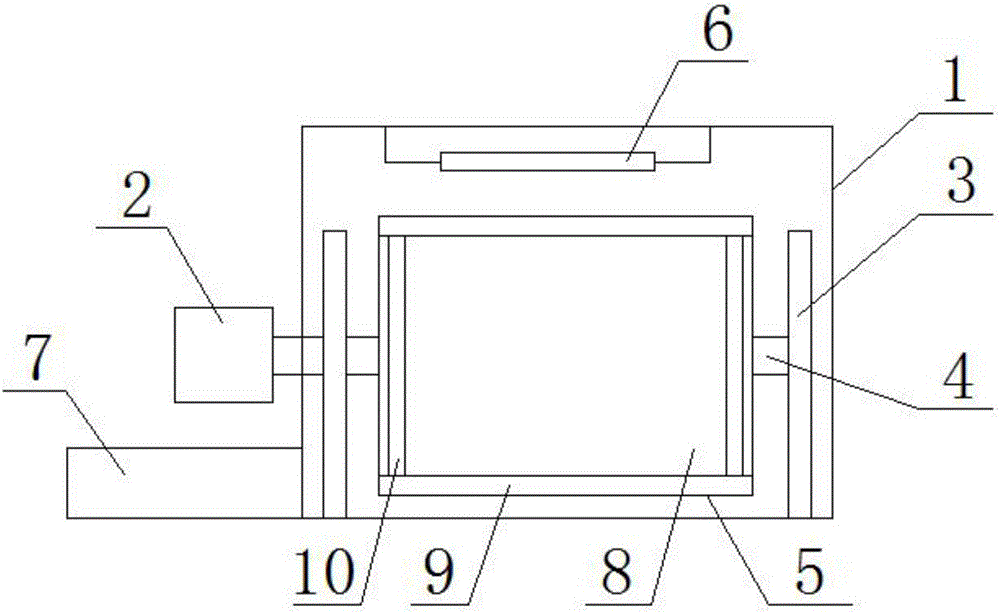

[0015] Such as figure 1 As shown, a draft drying device for planks includes a drying box 1, a motor 2, two support frames 3 and a rotating shaft 4, and the two support frames 3 are vertically spaced in the drying box 1 Inside; the rotating shaft 4 is erected on the two supporting frames 3, and the tail and the middle part of the rotating shaft 4 are equipped with bearings to connect with the two supporting frames 3; the motor 2 is placed in the drying On one side of the casing 1, the head of the rotating shaft 4 passes through the drying casing 1 and is connected with the output shaft of the motor 2; the rotating shaft 4 is provided with a fixing device 5 for fixing a plank; The inner top of the drying box 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com