Drying machine for acrylic resin emulsion powder production

A technology of acrylic resin and drying machine, which is applied in the direction of non-progressive drying machine, drying machine, drying solid materials, etc., and can solve the problem that it is not easy to achieve uniform drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

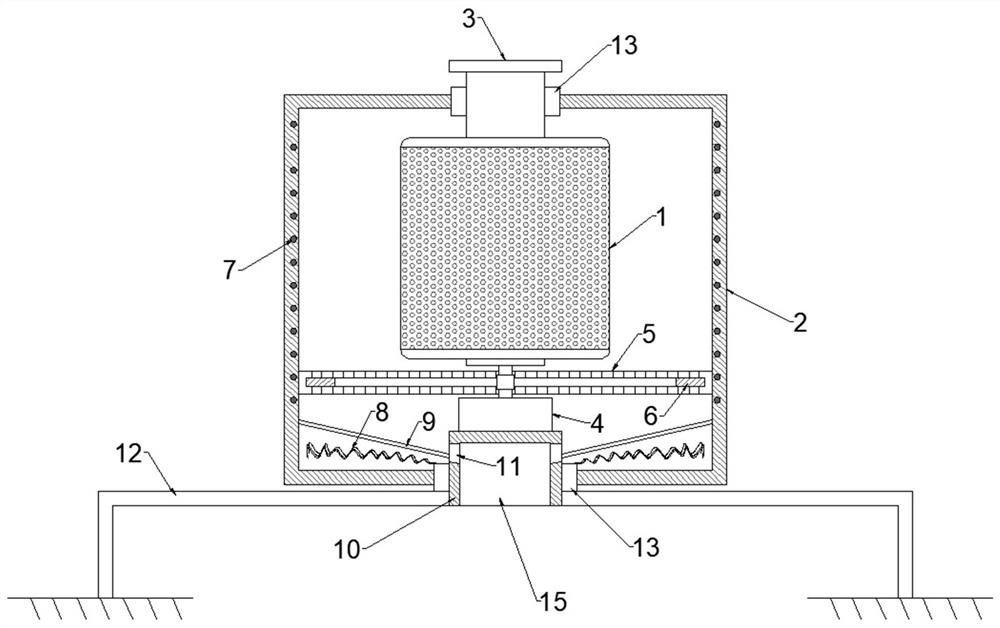

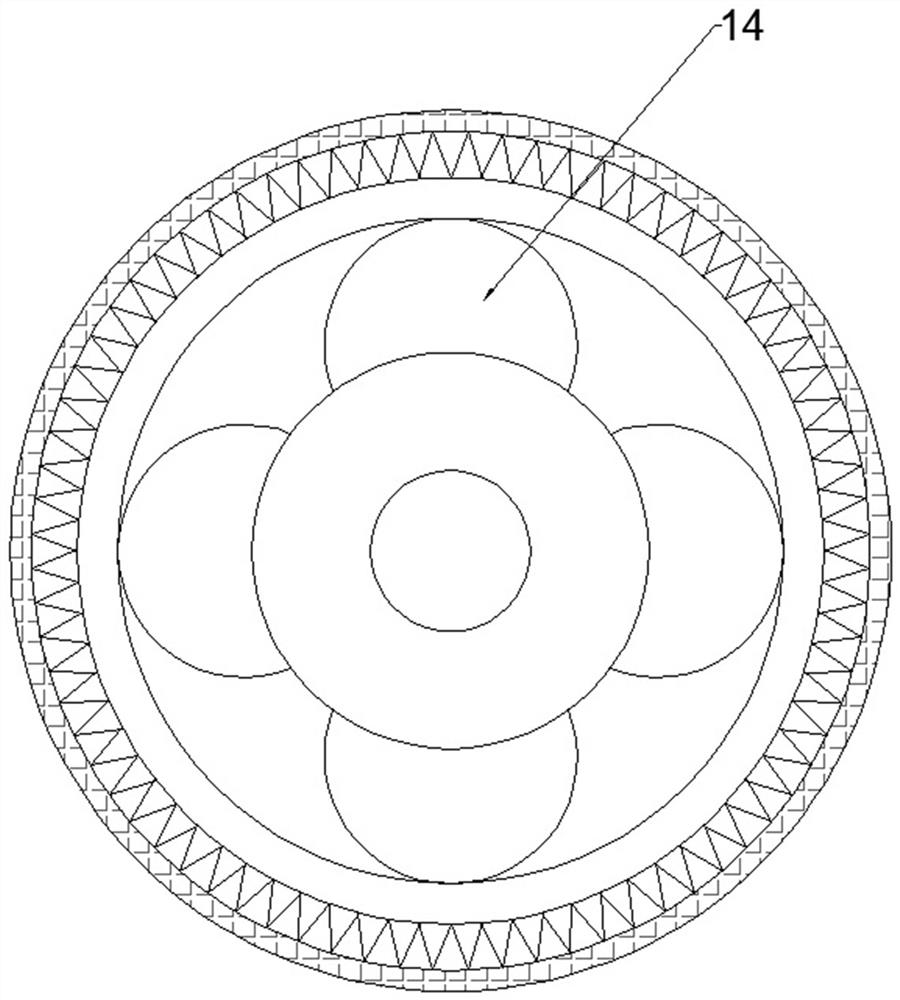

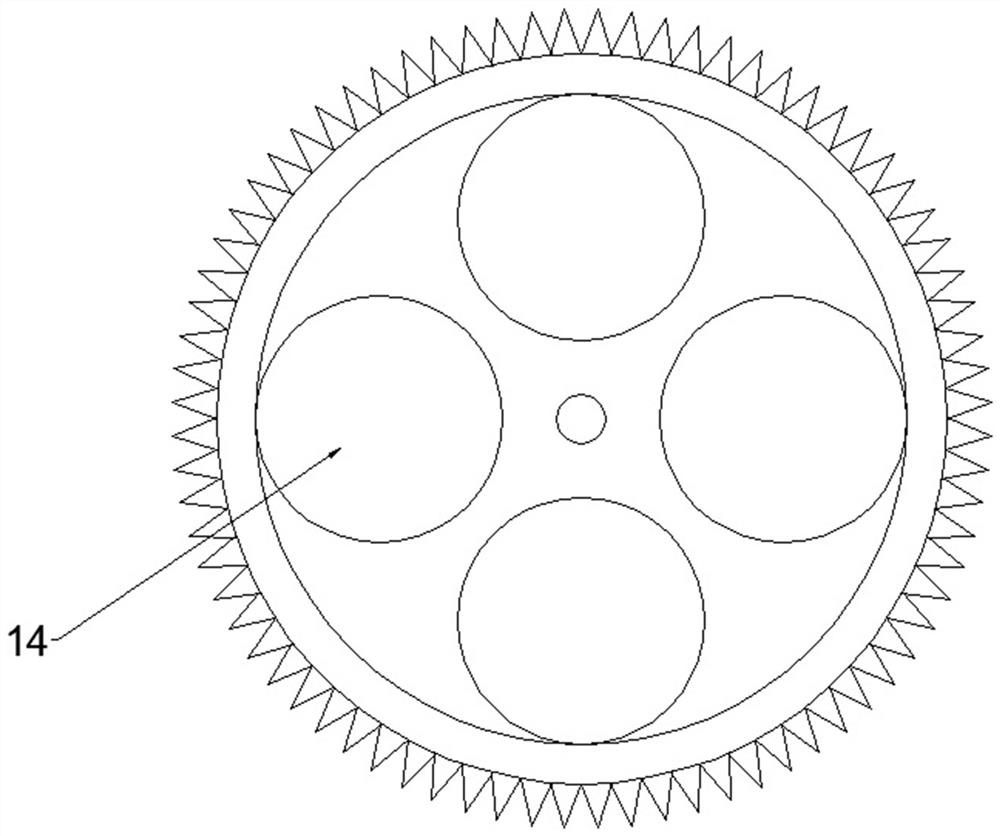

[0028] refer to figure 1 with figure 2 As shown, a dryer for the production of acrylic resin milk powder includes a centrifuge bucket 1 uniformly opened with through holes on the surface, and a drying bucket 2 installed coaxially with the centrifuge bucket 1, and the centrifuge bucket 1 is located in the drying bucket 2. The centrifugal barrel 1 is located at the axis of the drying barrel 2 and rotates coaxially, that is to say, the centrifugal barrel 1 rotates in the drying barrel 2, and the drying barrel 2 rotates around the axis of the centrifugal barrel 1. Its specific implementation method is to use a motor 4 to drive the centrifugal barrel 1 to rotate. In order to complete the installation of this structure, a discharge barrel 10 is coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com