Food processing dryer

A food processing and drying machine technology, applied in the direction of drying machines, drying, heating devices, etc., to achieve the effect of avoiding uneven drying and uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

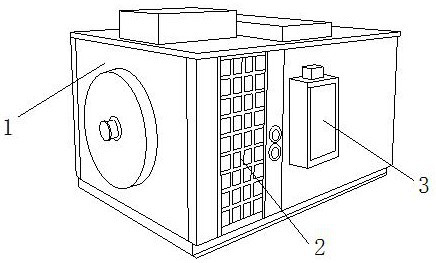

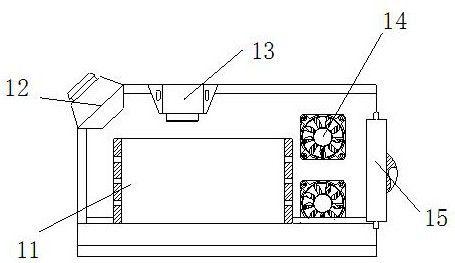

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The invention provides a food processing dryer, the structure of which includes a drying chamber 1, an air outlet 2, and an electric box 3. The outer end surface of the drying chamber 1 is embedded with an electric box 3, and the air outlet 2 is embedded Located on the outer end face of the drying bin 1, the electric box 3 is embedded and installed on the right side of the air outlet 2, and the drying bin 1 includes a storage bin 11, a material inlet 12, a heating machine 13, and a blower 14 1. The hatch 15, the storage bin 11 is embedded and installed directly under the heating machine 13, the feeding port 12 is connected to the upper left side of the drying bin 1 by welding, and the heating machine 13 is embedded and engaged Installed above the left side of the blower 14, the blower 14 is symmetrically installed on the upper and lower sides of the inner end of the drying bin 1, and the hatch door 15 is inlaid ...

Embodiment 2

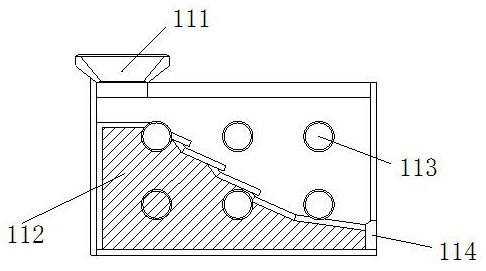

[0035] as attached Image 6to attach Figure 8 As shown: the partition block 121 includes a toggle ring 211, a flow groove 212, a blocking block 213, a movable rod 214, and a movable mechanism 215. The groove 212 is inlaid on the inner end surface of the partition block 121, the barrier block 213 is evenly inlaid and installed on the outer surface of the upper end of the toggle ring 211, the movable rod 214 is movably engaged and installed directly above the movable mechanism 215, the movable The mechanism 215 is embedded and installed above the inner side of the partition block 121 , and the inner end surface of the flow tank 212 is provided with a groove with the same diameter as the blocking block 213 for the blocking block 213 to slide up and down.

[0036] Wherein, the movable mechanism 215 includes a rotating disk 151, a connecting rod 152, a centrifugal wheel 153, a movable block 154, and a limit ring 155. The rotating disk 151 is inlaid and engaged with the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com