Cleaning and drying integrated equipment for woolen sweater processing

A woolen sweater and equipment technology, which is applied in the field of integrated cleaning and drying equipment for woolen sweater processing, can solve the problems of shrinkage and deformation of woolen sweaters, and achieve the effect of accelerating drying efficiency and avoiding uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

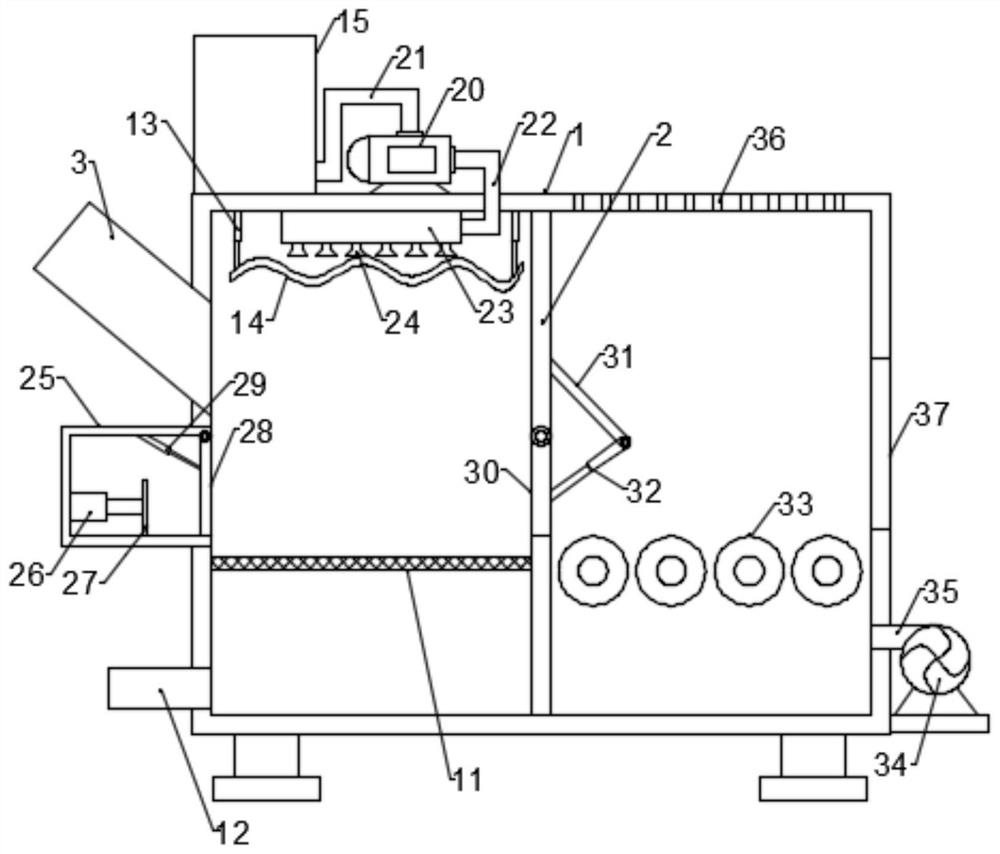

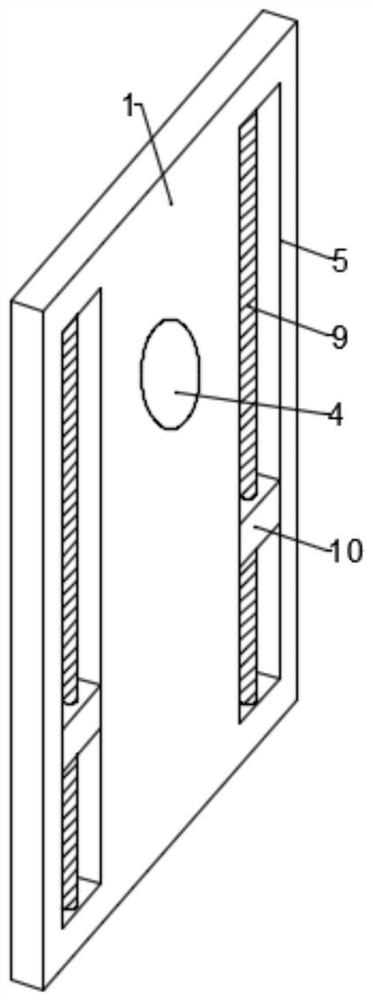

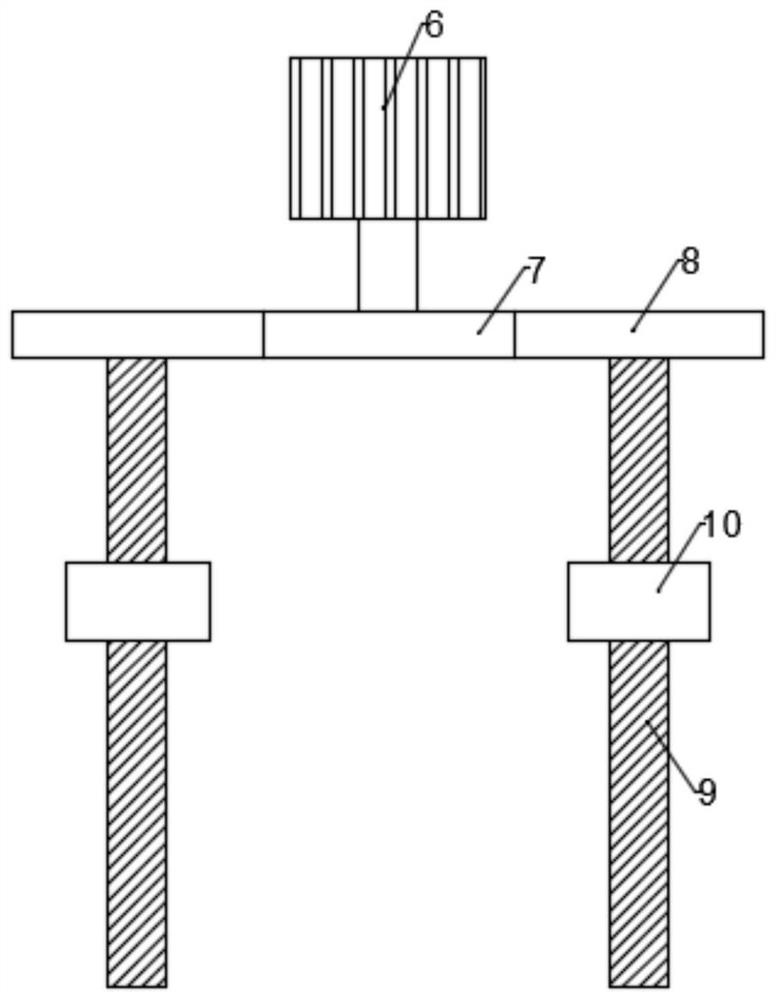

[0032] like figure 1 As shown, the embodiment of the present invention provides an integrated washing and drying equipment for woolen sweater processing, the equipment includes a box body 1, the inside of the box body 1 includes a cleaning chamber and a drying chamber, and the cleaning chamber There is a partition 2 between the drying chamber; the side wall of the cleaning chamber is provided with a feed pipe 3, the bottom of the cleaning chamber is provided with a sewage outlet 12, and the supporting filter screen 11 is movable and installed on the said cleaning chamber through a lifting mechanism. The inside of the cleaning chamber, the top of the cleaning chamber is equipped with a kneading and pressing assembly and a spraying mechanism; the side wall of the drying chamber is provided with a pick-up plate 37, and the inside of the drying chamber is equipped with a spreading drying mechanism; A pushing mechanism is installed on the side wall of the box body 1 , and a second ...

Embodiment 2

[0046] like figure 1 As shown, in yet another embodiment provided by the present invention, the pushing mechanism includes an external connection box 25, and a second automatic telescopic rod 26 is installed on the external connection box 25, and the top of the second automatic telescopic rod 26 is fixed with Pushing plate 27, the first flap 28 is hinged at the connection between the external box 25 and the side wall of the box body 1, and the first flap 28 is installed through the first hydraulic telescopic push arm 29; the second flap The position of the plate 30 corresponds to the position of the first flap 28, the second flap 30 is hinged with a second hydraulic telescopic push arm 32, the other end of the second hydraulic telescopic push arm 32 is connected to the connecting rod 31 is hinged, and the other end of the connecting rod 31 is fixed on the partition 2.

[0047] After the woolen sweater is cleaned, start the lifting mechanism to drive the support filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com