Device for canned food production

A technology of canned food and drying chamber, applied in the direction of drying gas arrangement, non-progressive dryer, dryer, etc., which can solve the problems affecting the development of canned food, high drying cost, complex structure, etc., and avoid uneven drying by hot air , the drying speed is improved, and the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

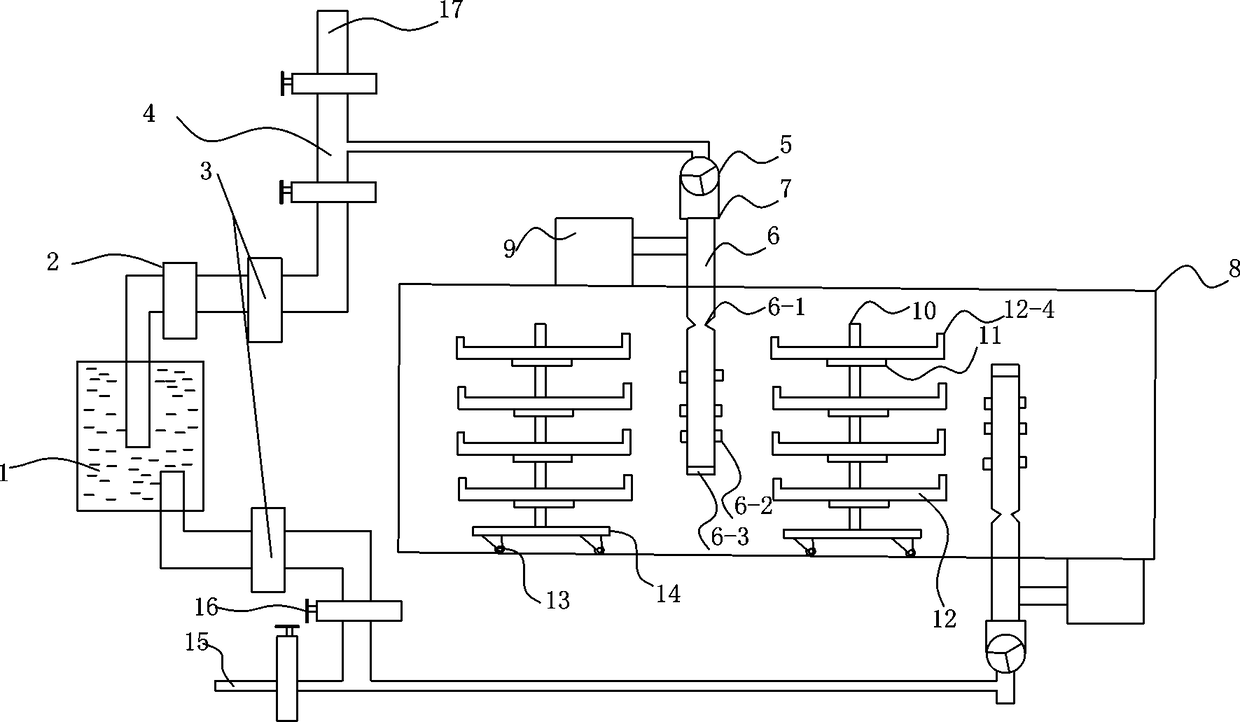

[0020] A device for the production of canned food, comprising a drying chamber 8, the upper surface and the lower surface of the drying chamber 8 are provided with an exhaust fan 5, the exhaust fan 5 on the upper surface of the drying chamber 8 is connected to a pipeline 4, and the pipeline 4 is connected to an upper suction port 17 , the upper suction port 17 is provided with a control valve, the pipeline 4 is connected to the air drying box 3, the air filter 2 and the air cleaner 1, the pipeline 4 before the air drying box 3 is provided with a control valve, and the exhaust air on the lower surface of the drying chamber 8 The machine is connected to the pipeline 4, the pipeline 4 is connected to the lower air outlet 15, the lower air outlet 15 is provided with a control valve, the pipeline 4 is connected to the air drying box 3 and the air cleaner 1, and the pipeline 4 before the air drying box 3 is provided with a control valve, Drying chamber 8 upper surface and lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com