Display panel for acoustic metal functional diaphragm

A display panel and metal technology, applied in the direction of electrical components, sensors, etc., can solve the problems of reducing the fixing efficiency, reducing the heat dissipation efficiency of the panel, and the inconvenient fixing and processing spot welding of the display panel, so as to improve the fixing stability and realize the commutation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

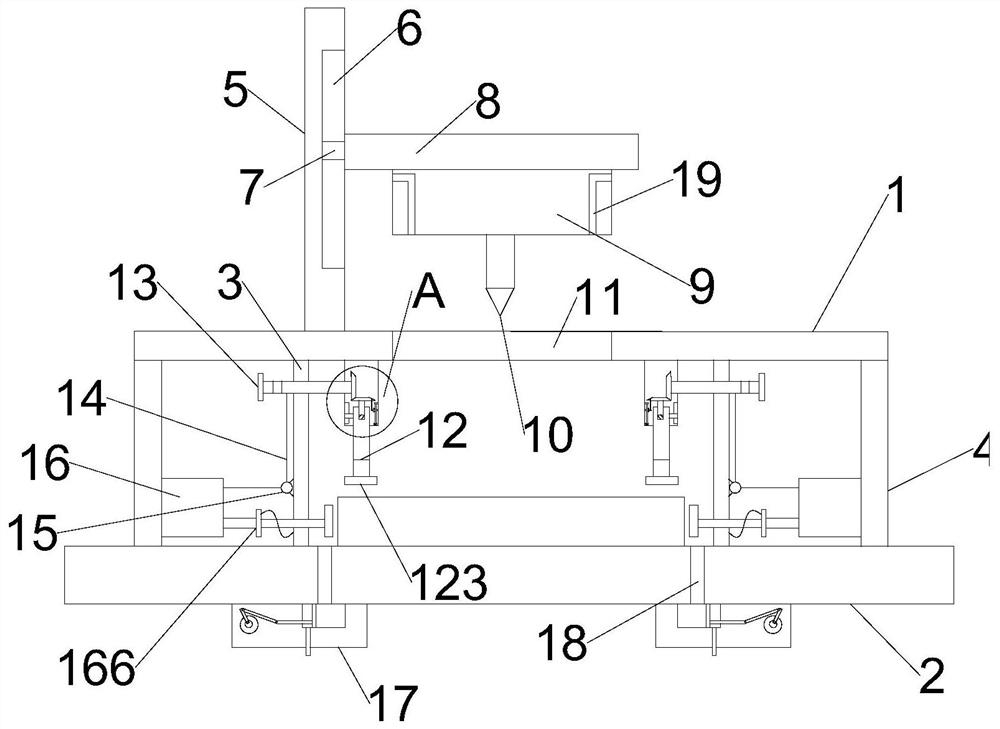

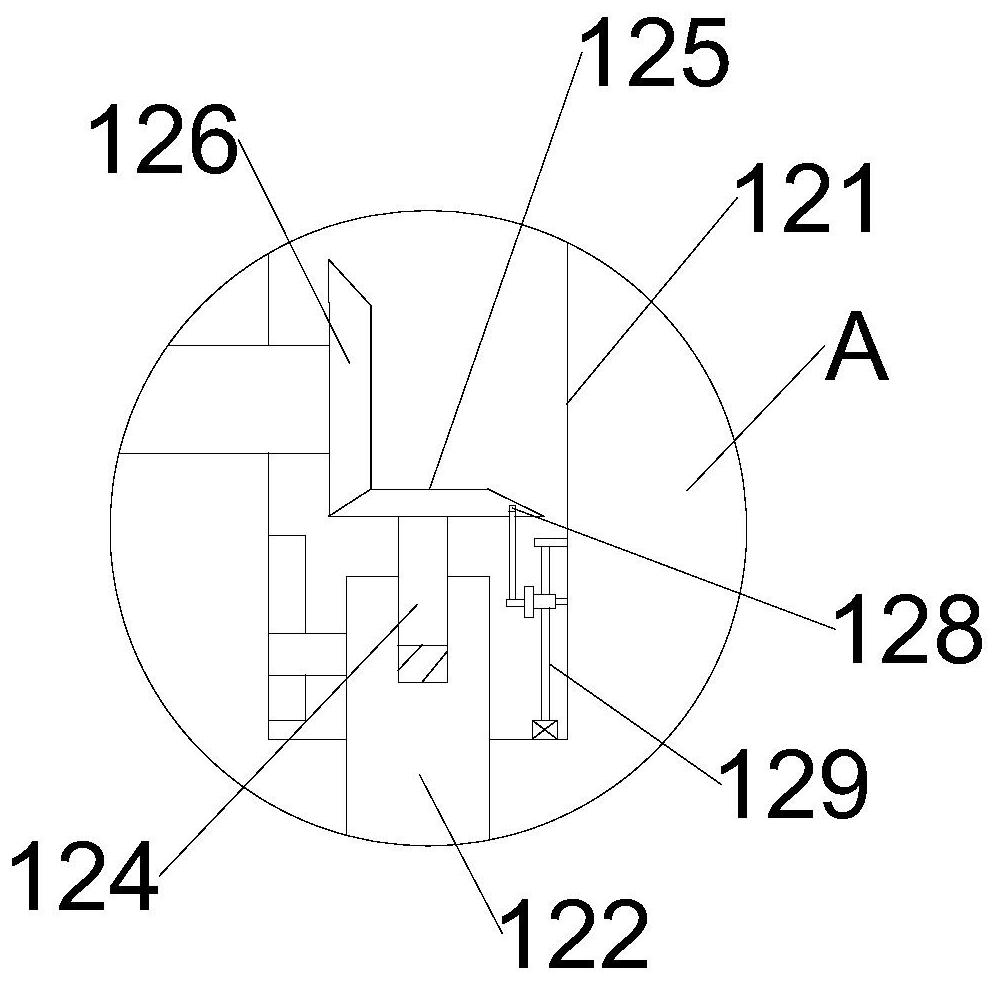

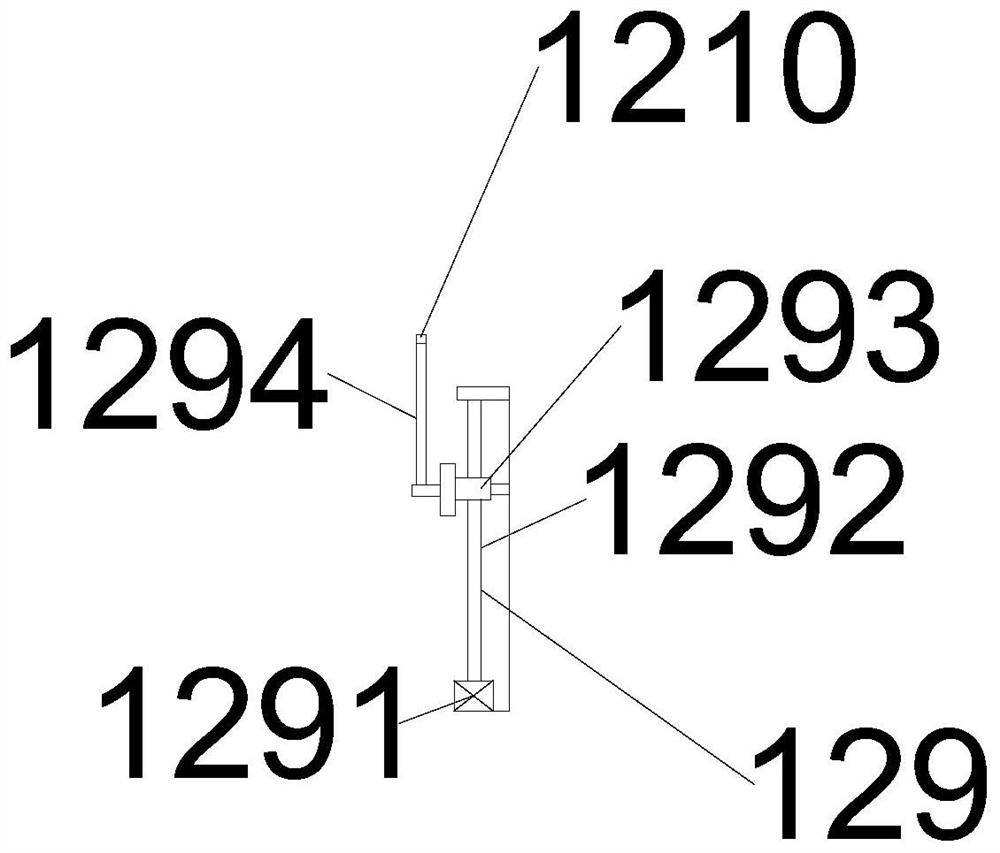

[0026] see Figure 1-6 , in the present invention, the display panel used for the acoustic metal functional diaphragm includes a processing table 1 and a mounting seat 2, and the processing table 1 and the mounting seat 2 are connected and arranged through a reinforcing column 4, and the processing table 1 and the mounting seat 2 are also connected. A processing box 3 is provided, and a valve is provided on the front side wall of the processing box 3. The opening and closing of the valve is used for taking and placing the display panel. Rail 6, the electric slide rail 6 slides and is provided with electric slider 7, and electric slider 7 is connected with lifting table 8, and the lower part of lifting table 8 is provided with sealing table 9, and the lower part of sealing table 9 is provided with electric welding machine 10, and described processing table 1 is provided with the port 11 of the processing box 3, and the sealing table 9 can be used for the sealing setting of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com