Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid mechanical collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

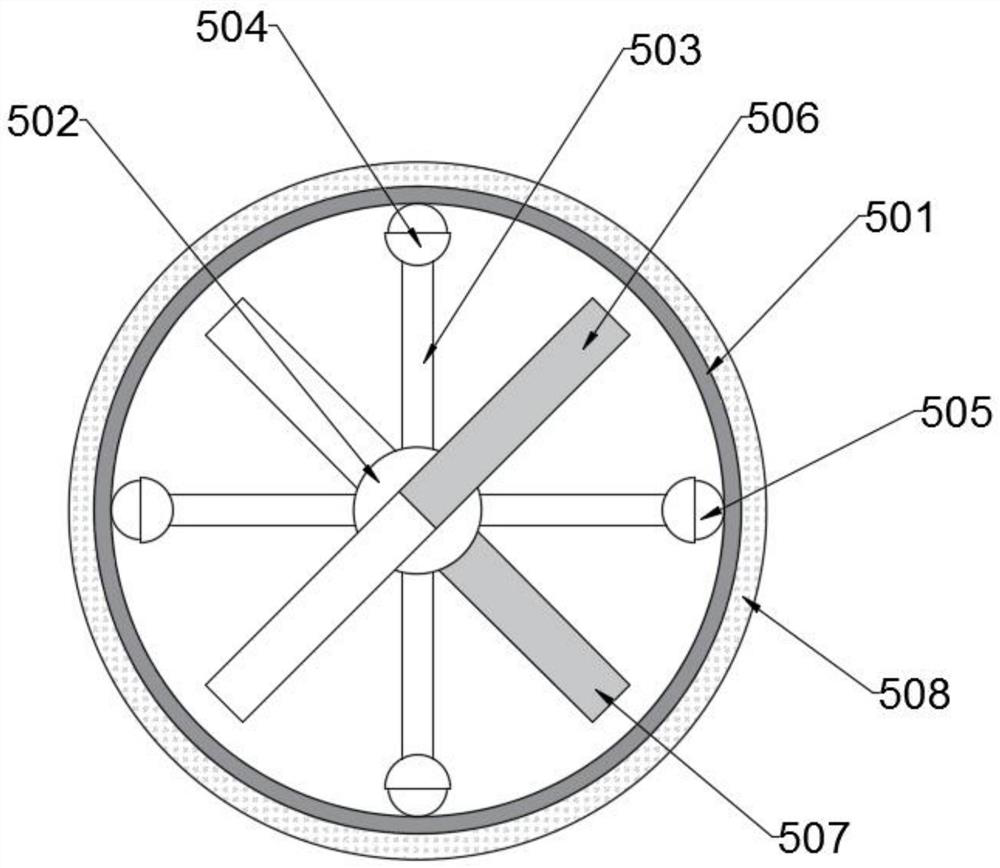

Multi-direction wideband energy harvesting device based on vibration friction

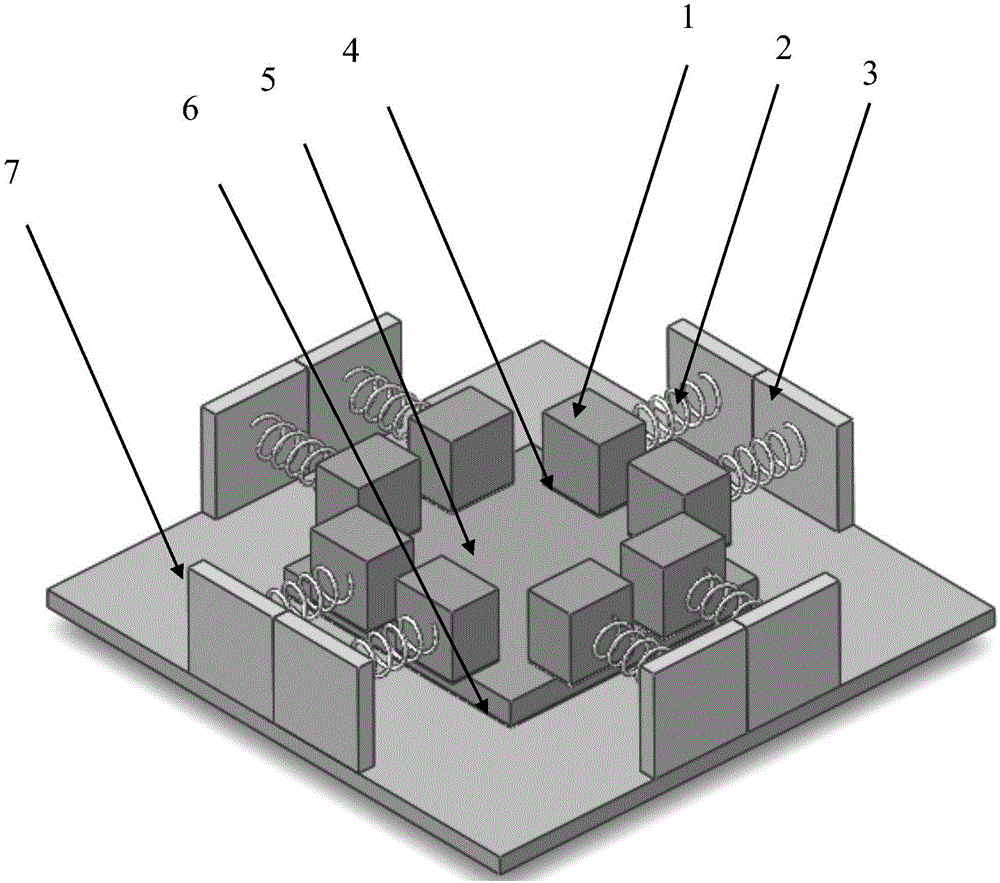

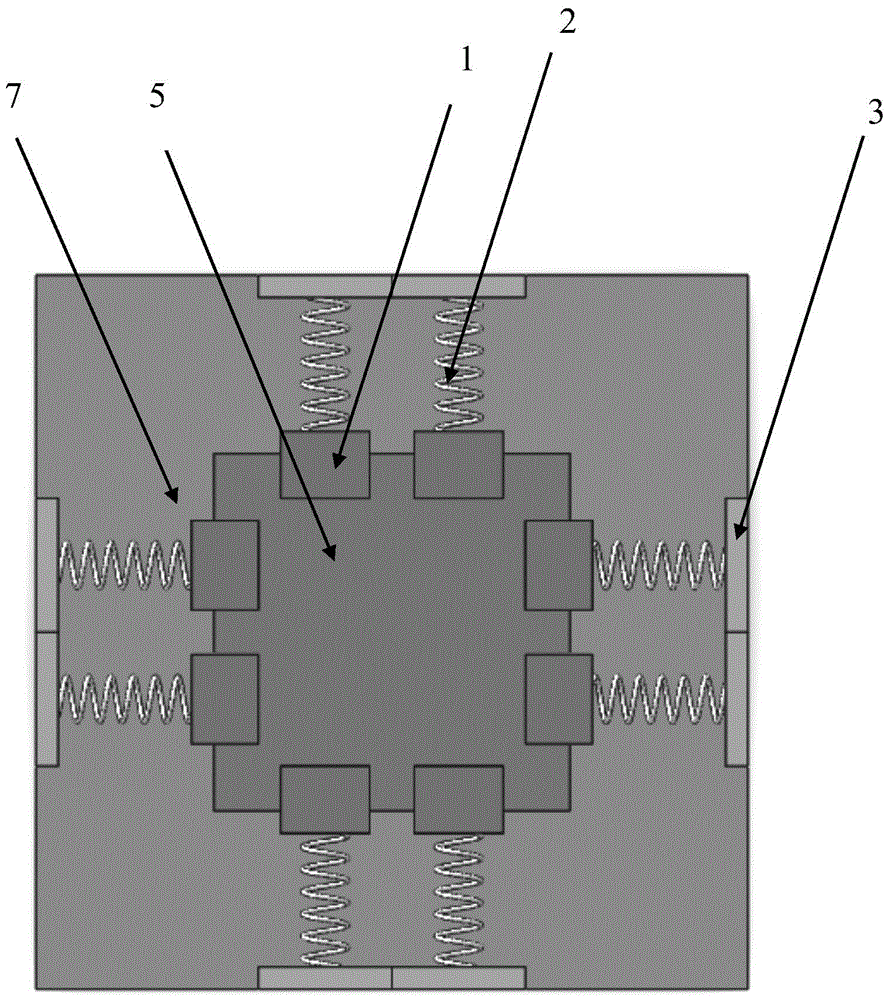

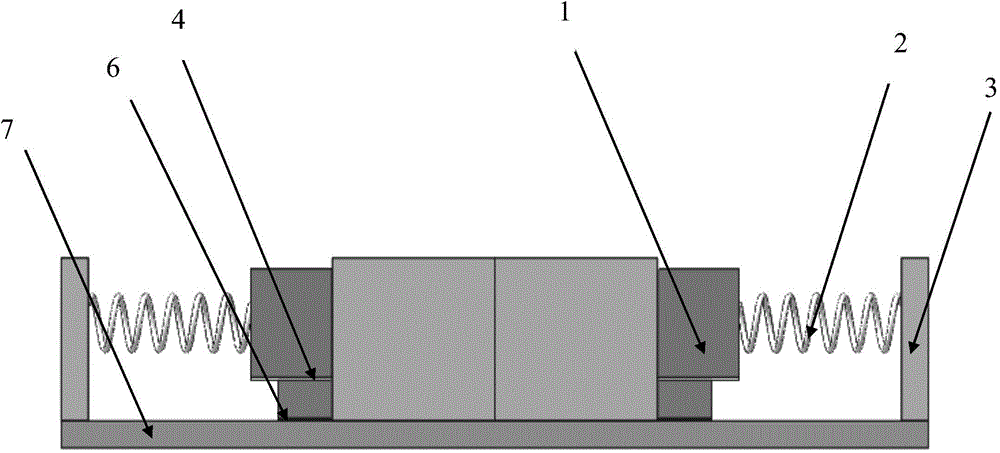

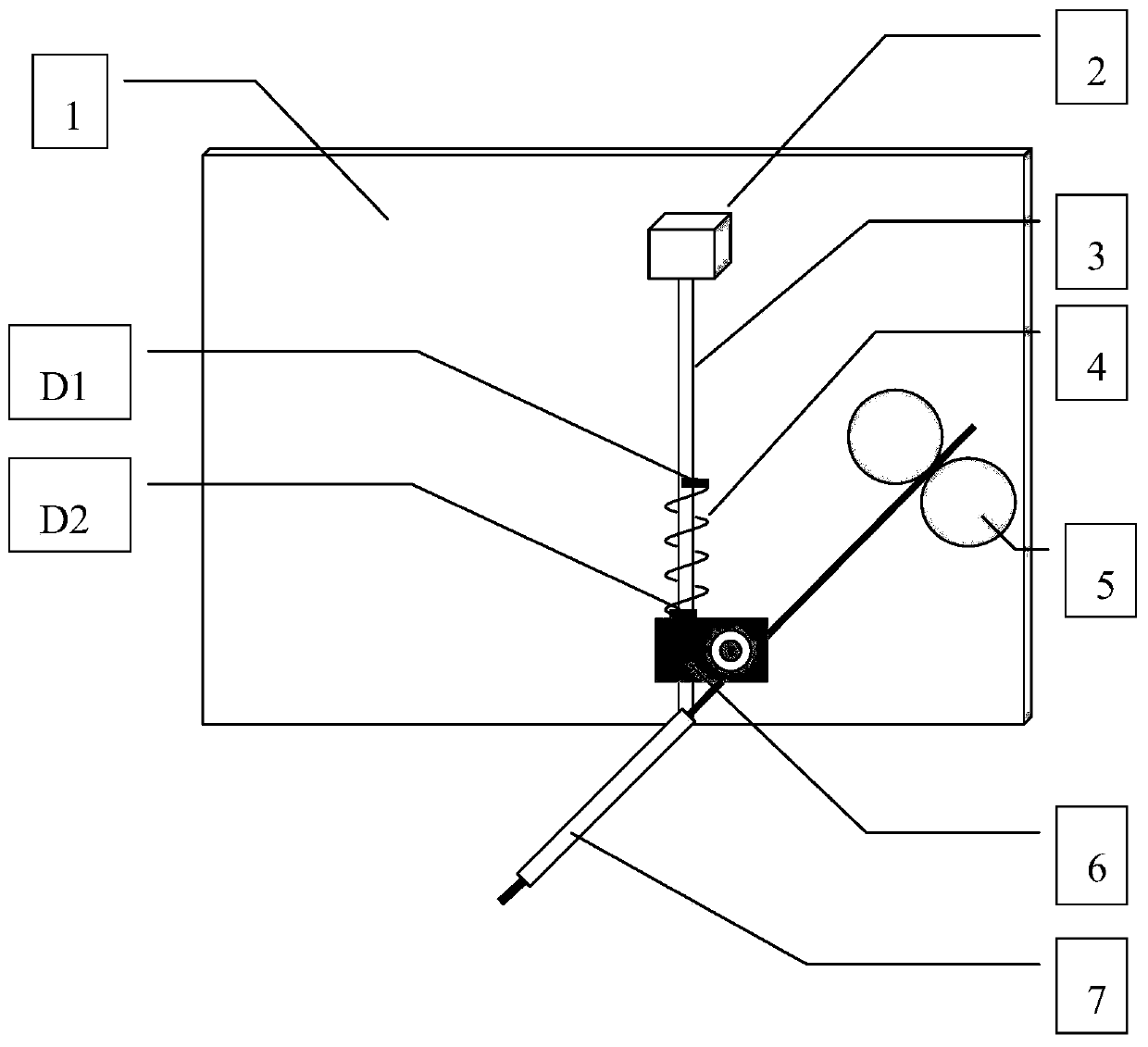

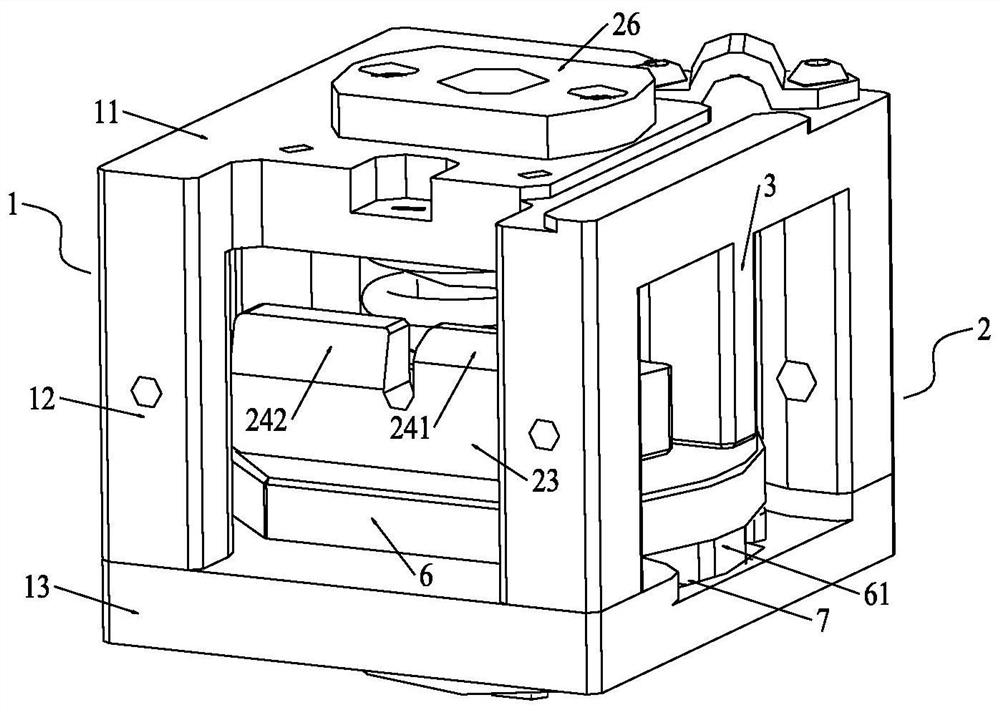

The invention provides a multi-direction wideband energy harvesting device based on vibration friction. The multi-direction wideband energy harvesting device comprises quality blocks, springs, fixed baffles, upper electrodes, a friction substrate, lower electrodes and a base. One faces of the quality blocks are connected with one ends of the springs. The other ends of the springs are connected with the fixed baffles to form quality-block-spring-fixed-baffle structures, and the springs are horizontally arranged and fixed to the periphery of the base. The upper electrodes are arranged on the lower surfaces of the quality blocks. The upper surface of the friction substrate makes contact with the upper electrodes. The lower electrodes are arranged on the lower surface of the friction substrate and fixed to the upper surface of the base. The upper electrodes and the lower electrodes are led out through wires and connected with a processing circuit. When the device bears outside excitation from different directions, the springs drive the quality blocks to vibrate, the mechanical energy is converted into electric energy through changes of relative contact areas of the upper electrodes on the quality blocks and the friction substrate, and the electric energy is output through the processing circuit through the upper electrodes and the lower electrodes to be supplied to a power consumption device. Meanwhile, the inherent frequency of the spring-quality-block structures can be set, and wideband energy harvesting is achieved.

Owner:XIAMEN UNIV

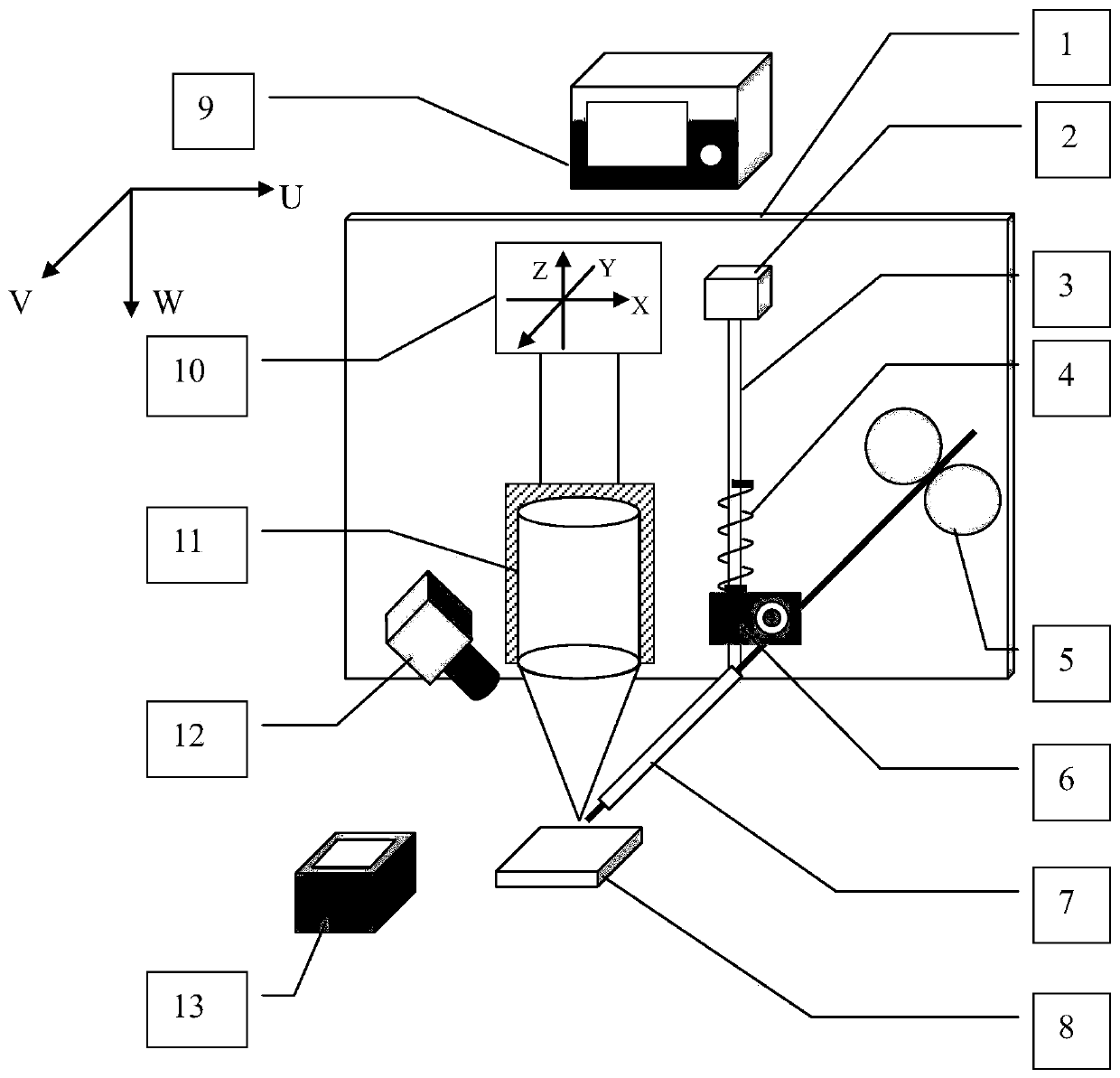

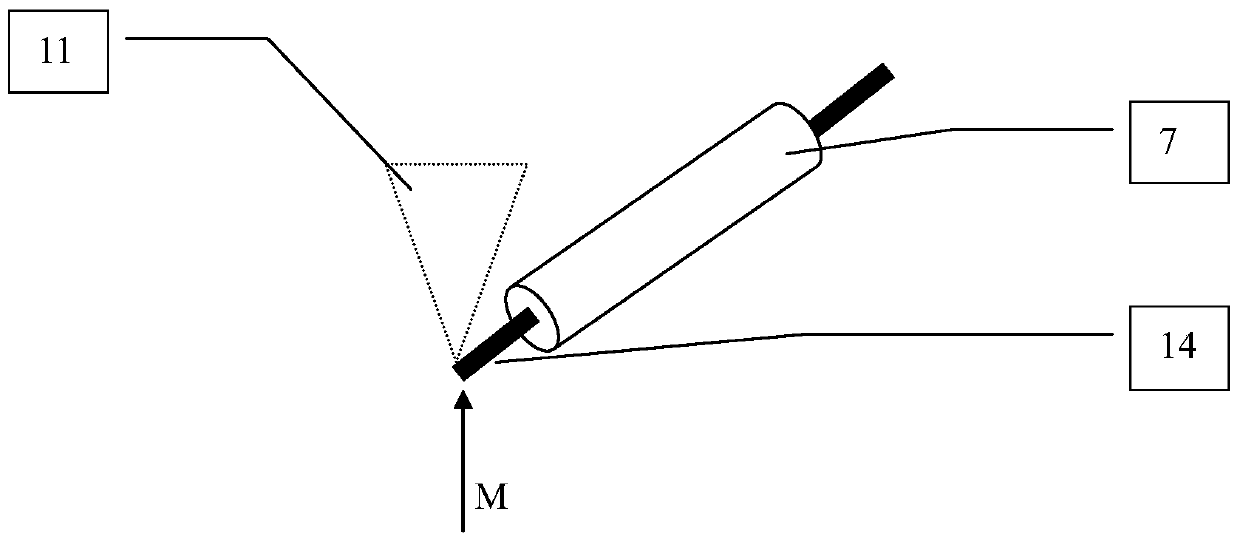

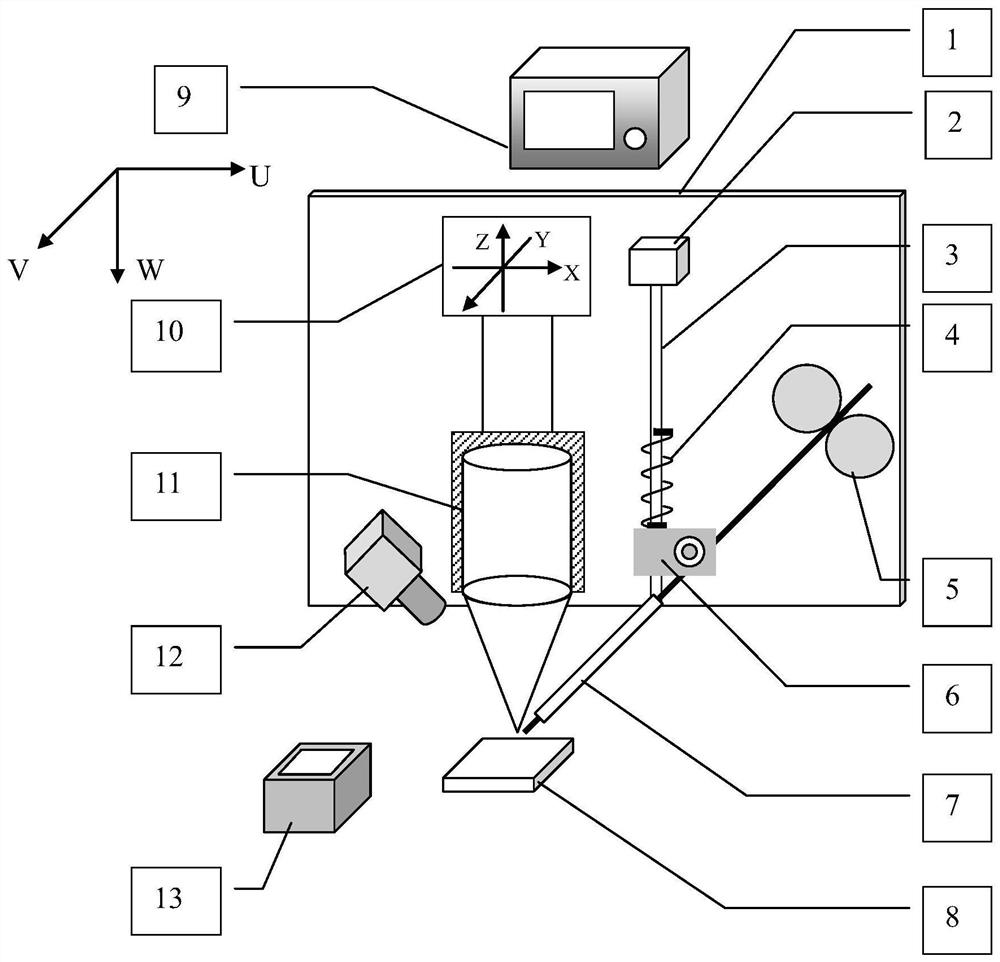

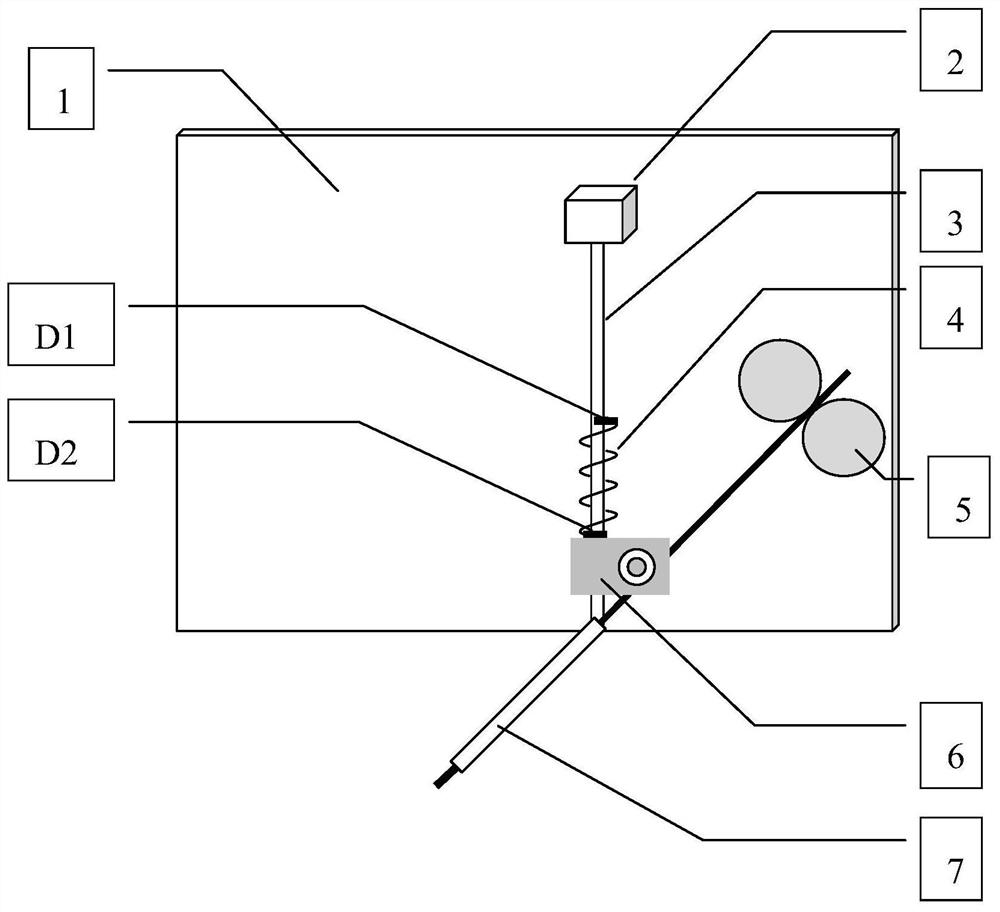

Laser welding tinning device and welding method

ActiveCN110961751AMake up for the influence of welding effectReduce processing fixture requirementsSolder feeding devicesSoldering auxillary devicesLaser processingLoop control

The invention designs a laser welding tinning device and a welding method. The tinning device comprises a back plate, a laser position correcting device, a camera, a laser machining head, a pushing wheel pair, a connecting rod, a tin feeding nozzle, a displacement sensor, an angle sensor, a balance spring, a controller and a residue box, wherein the angle sensor detects a swing angle of the connecting rod, the displacement sensor detects the vertical movement position of the connecting rod, the controller calculates the movement speed and the acceleration of the detection head according to thedisplacement amount and an angle change value of the detection head, during laser welding, laser working height closed-loop control is carried out by utilizing the position of the detection head, tinwire feeding speed closed-loop control is carried out by utilizing stress of the detection head, and closed-loop control that laser follows the position of a tin wire is carried out by utilizing theangle of the detection head, influence of the welding spot height difference on the welding effect can be made up, the product machining fixing requirement is lowered, and the application range of laser welding is expanded. The tinning device is advantaged in that mechanical collision or burning of a processing base material can be prevented, the process is stable, and the qualified rate is improved.

Owner:WUHAN BESKYS TECH CO LTD

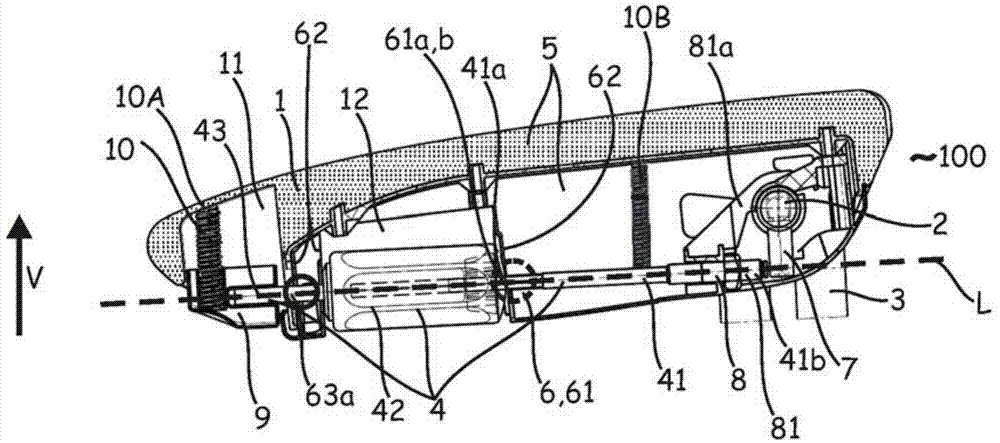

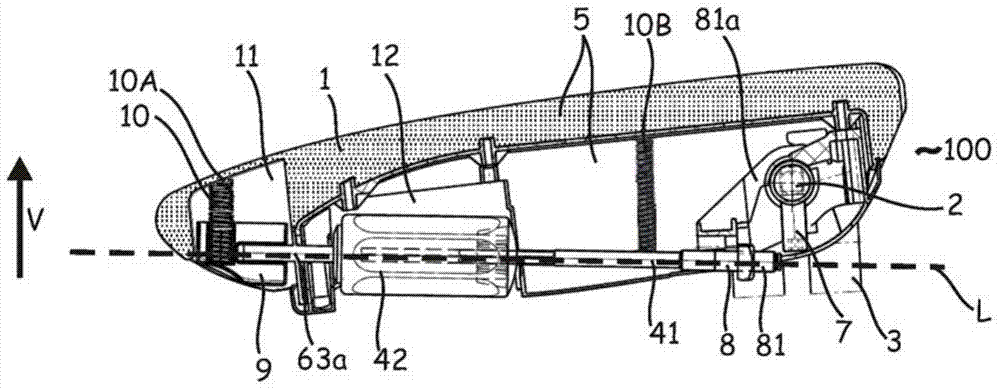

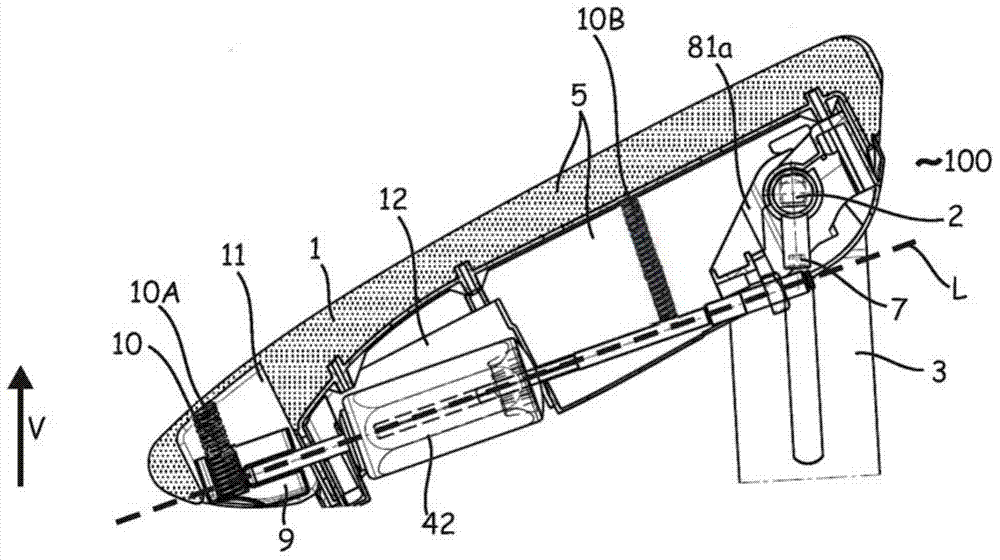

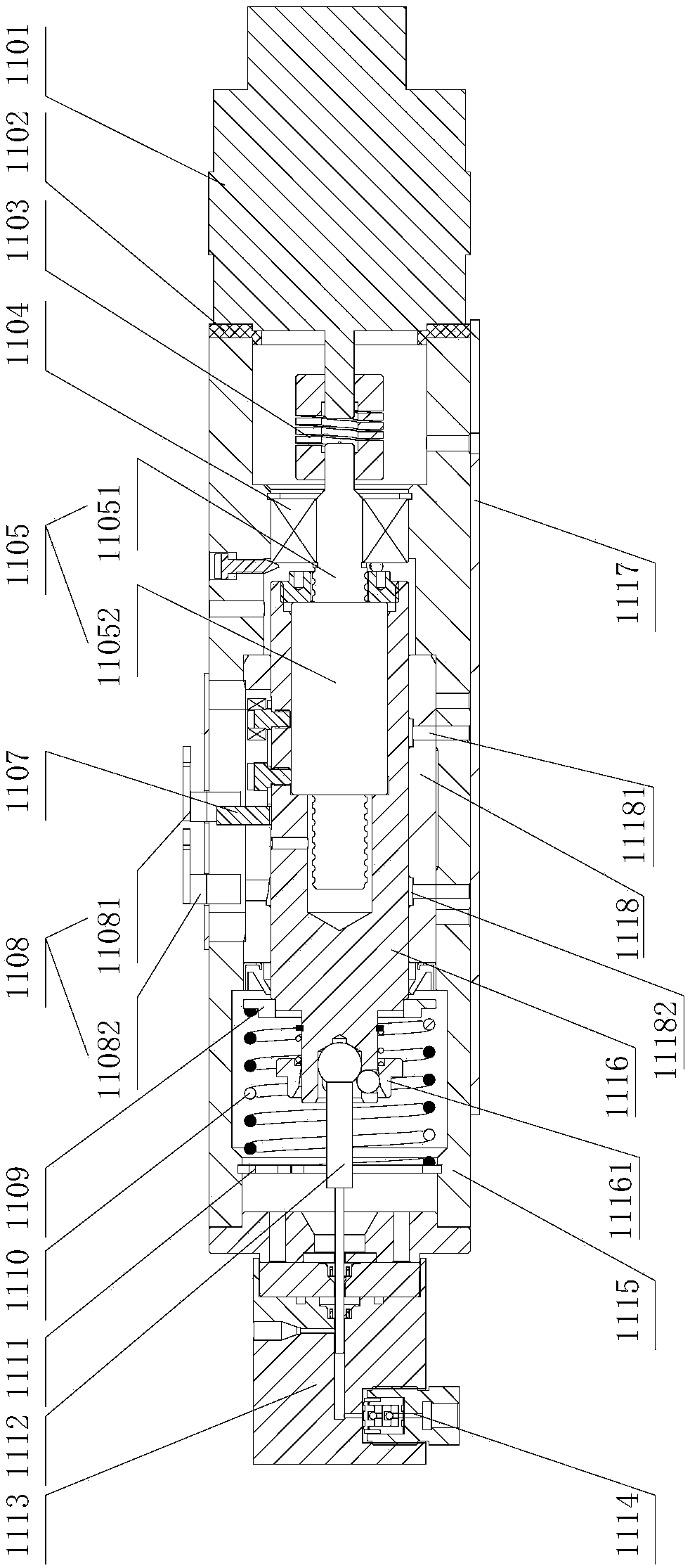

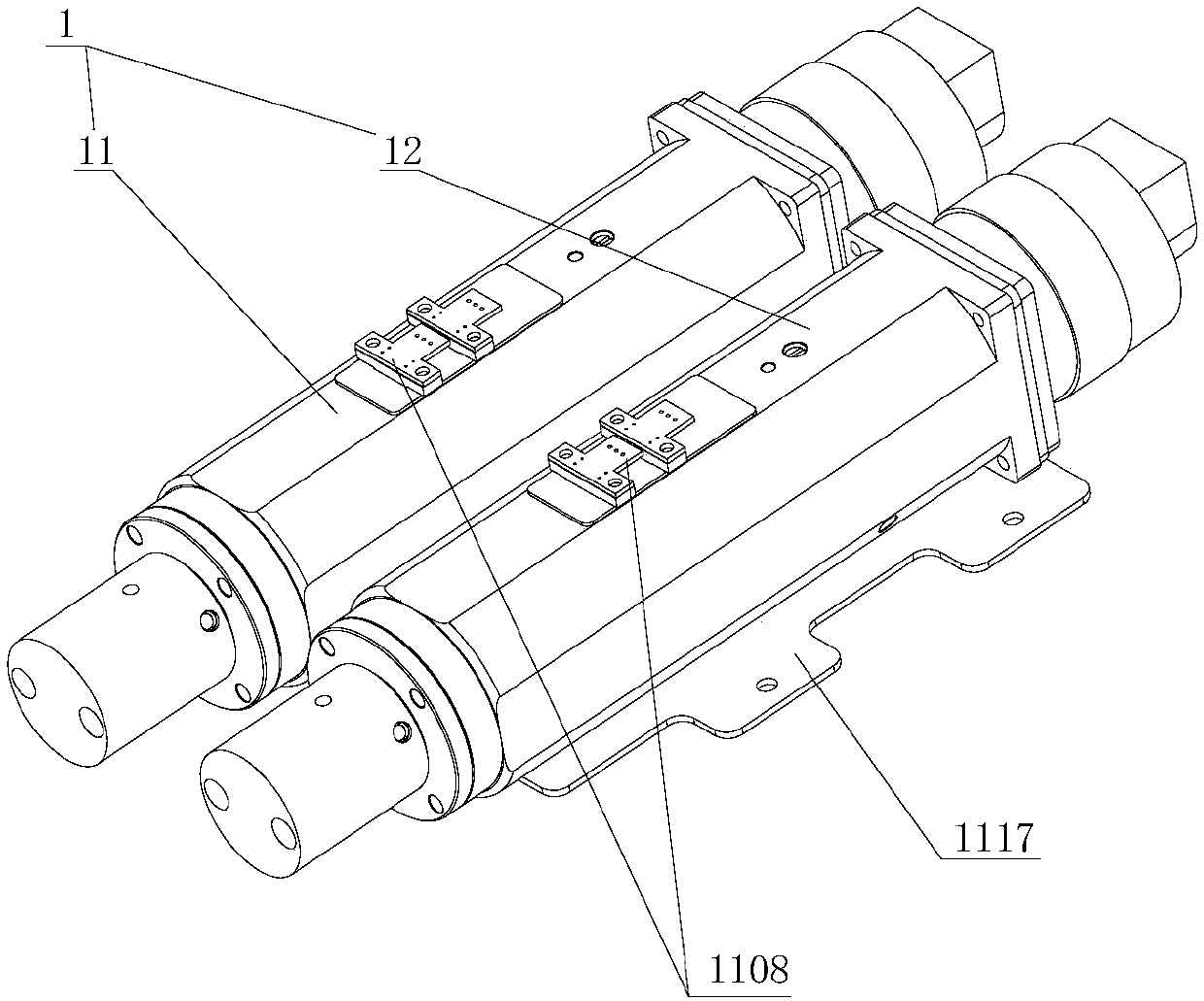

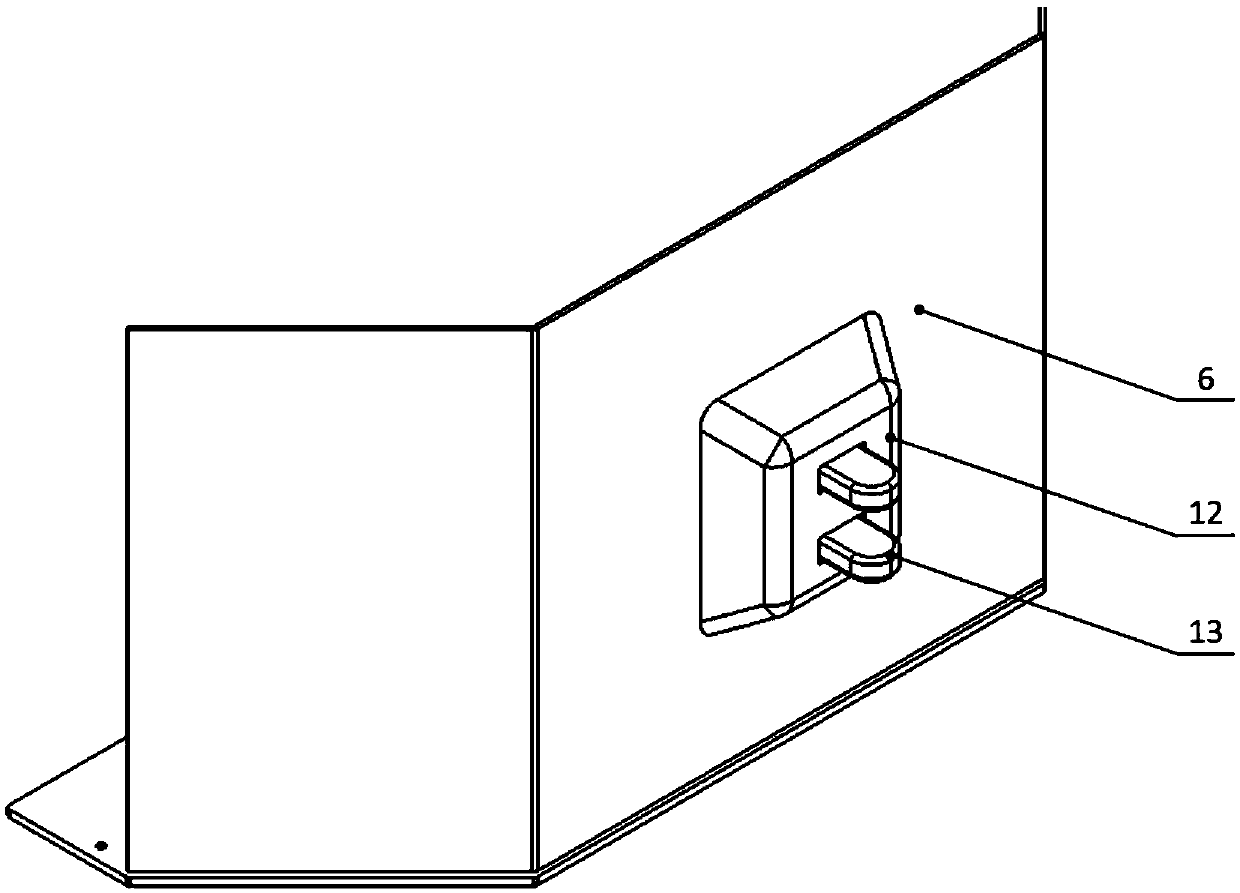

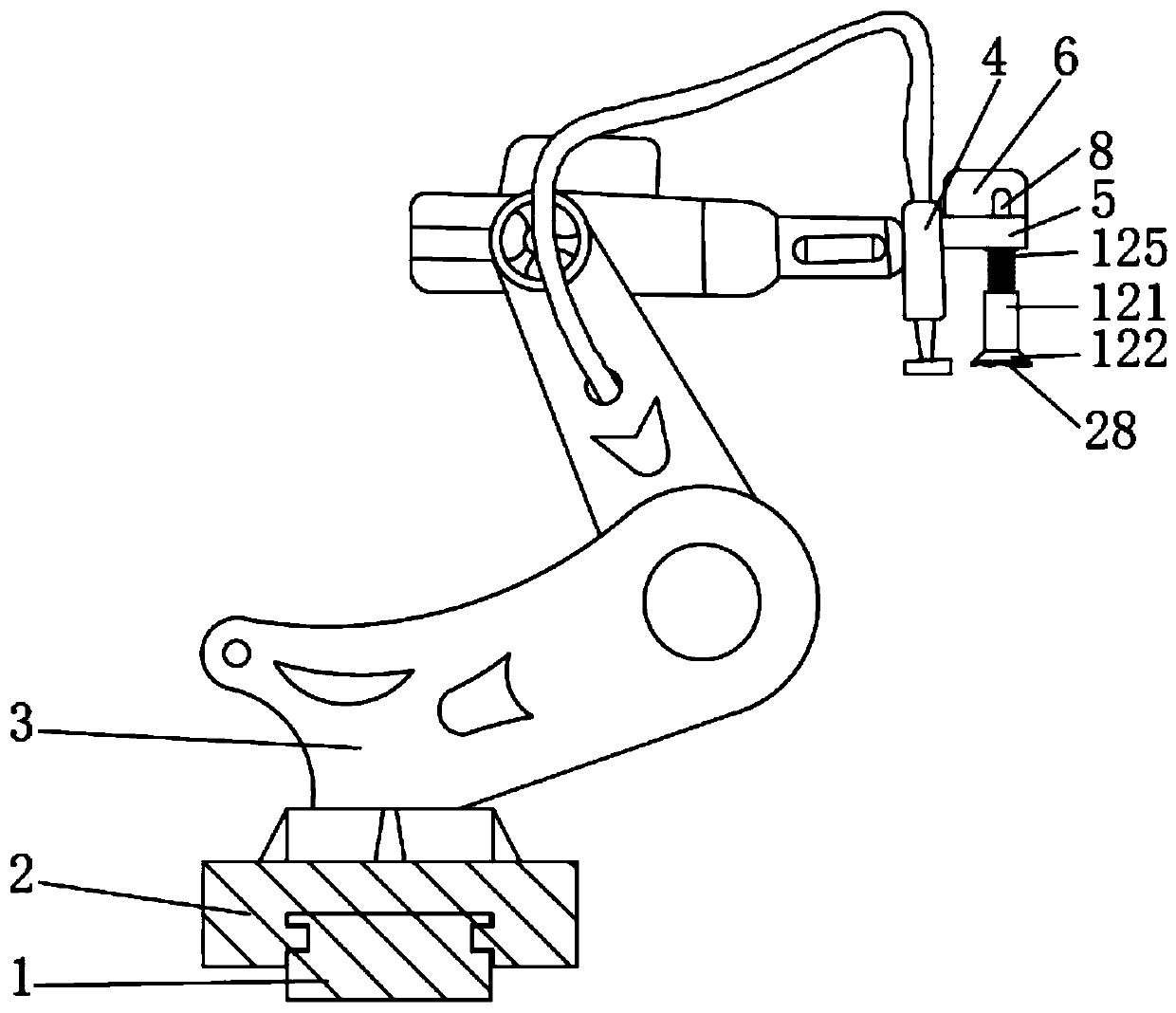

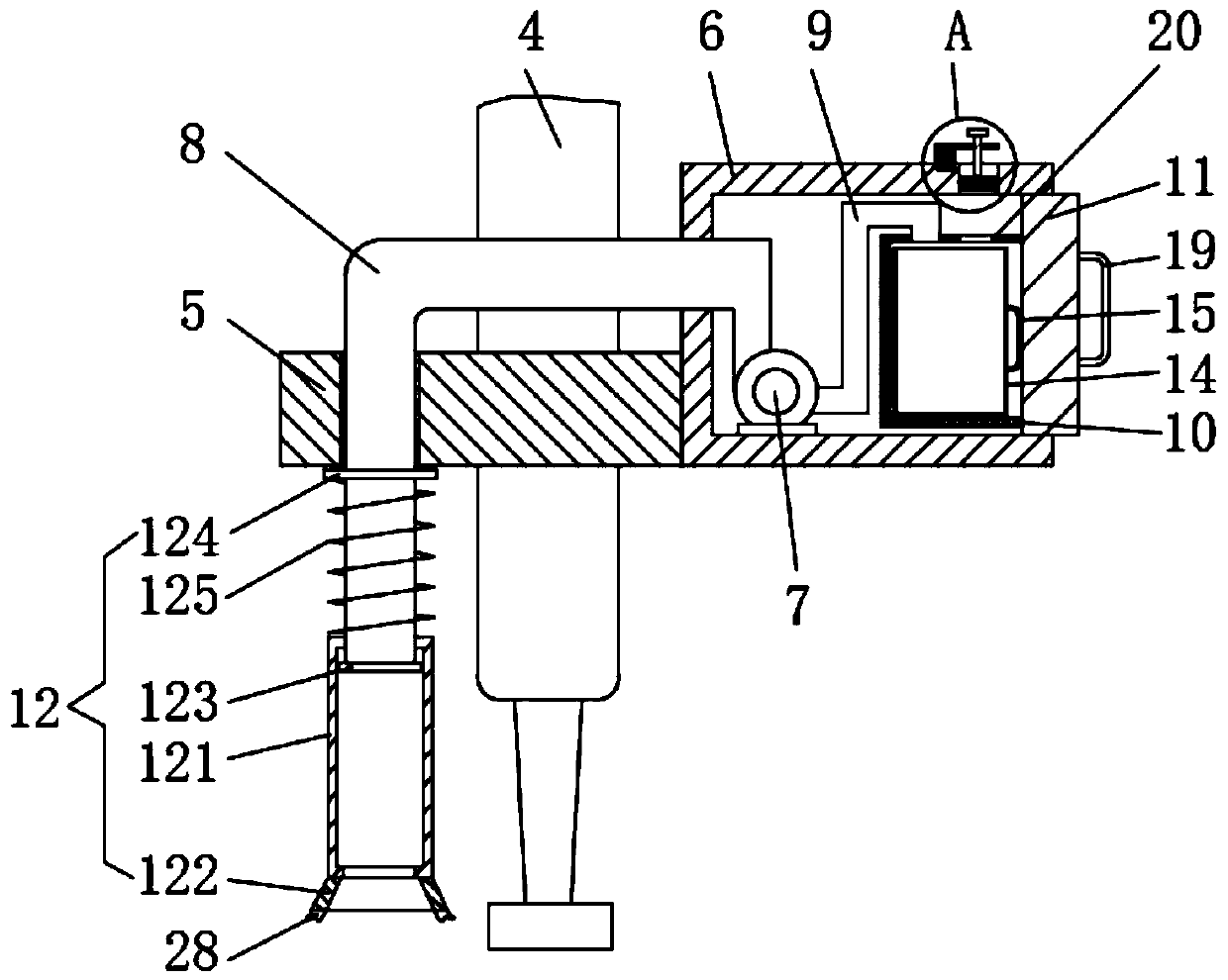

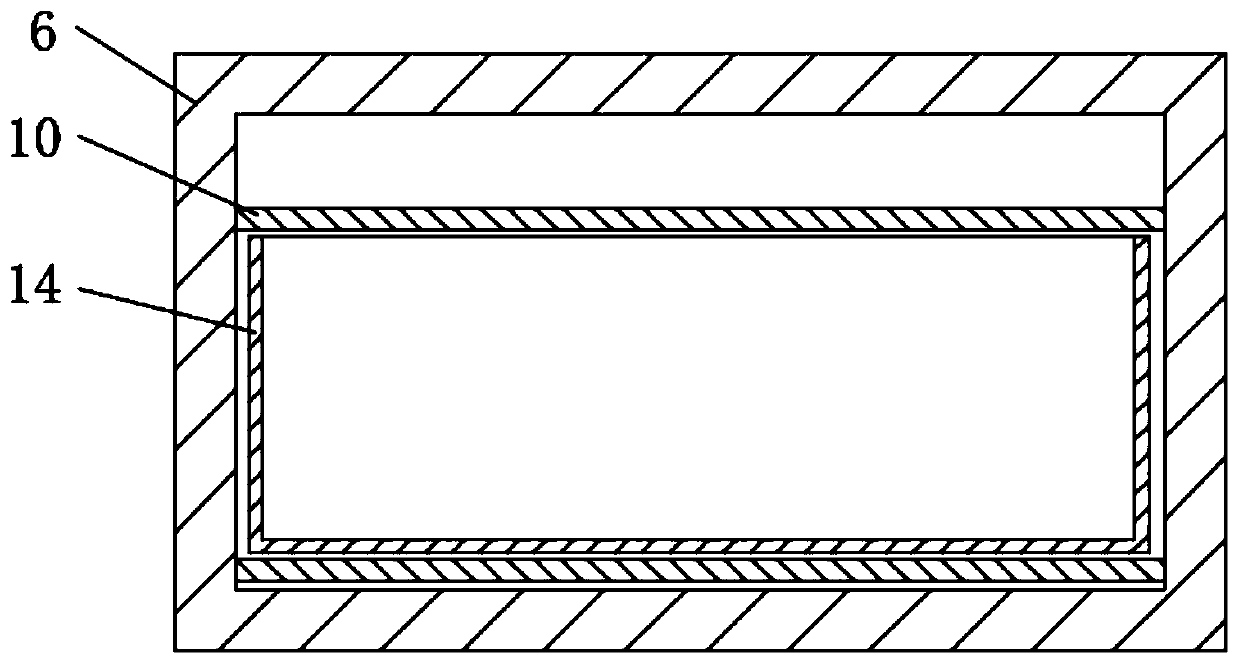

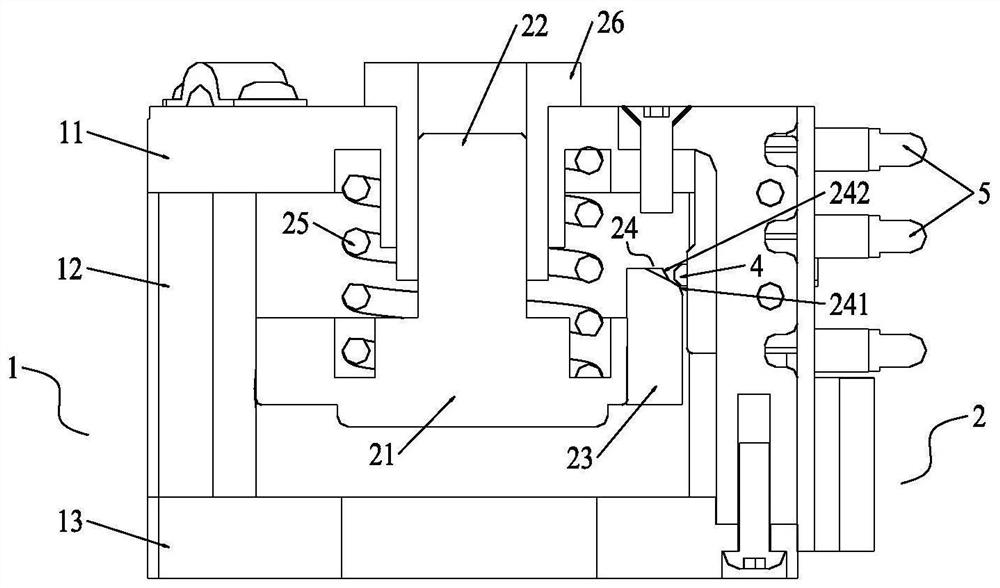

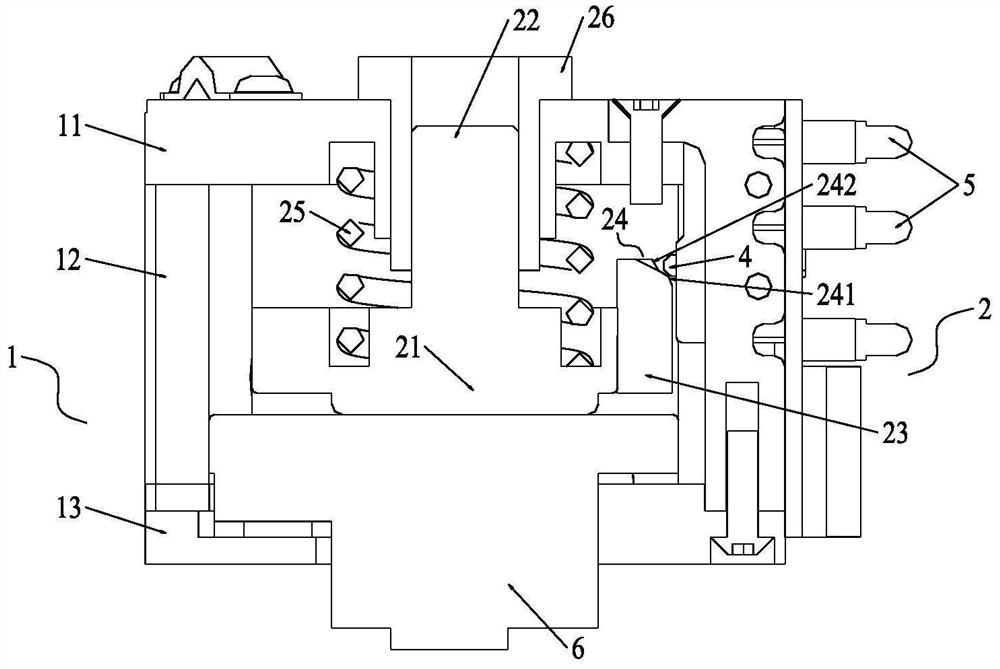

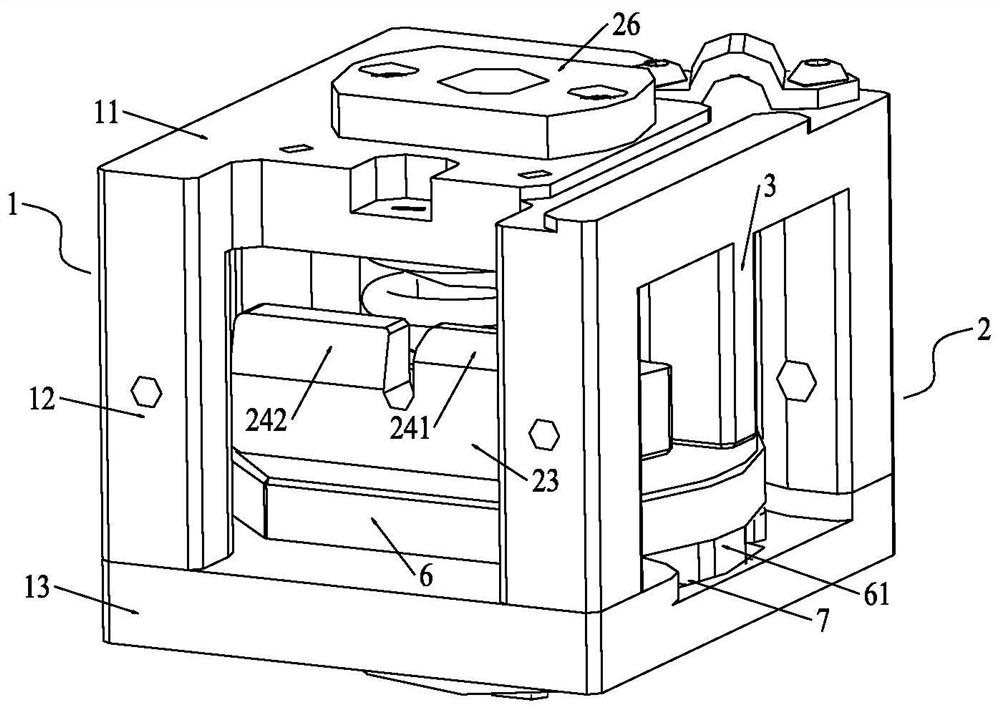

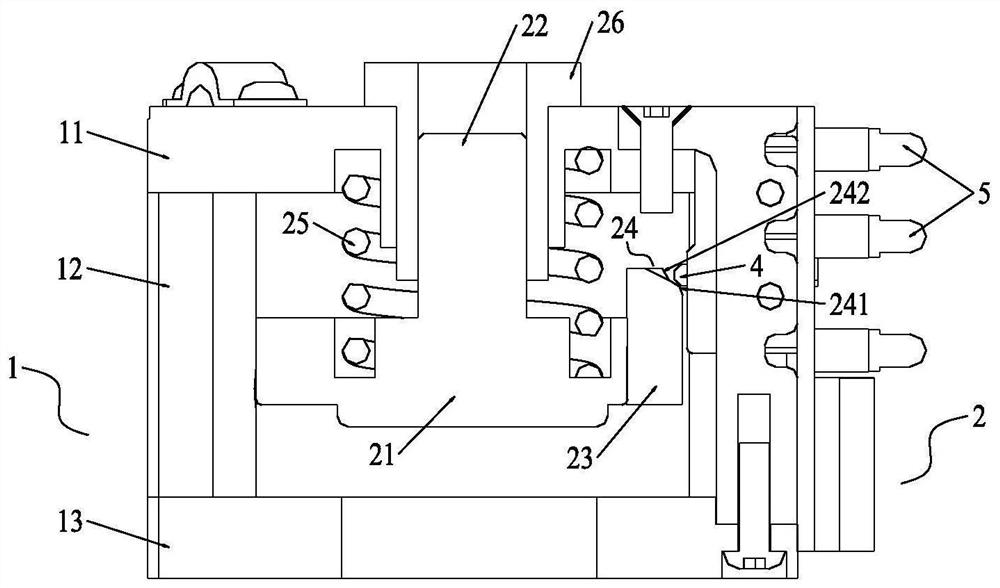

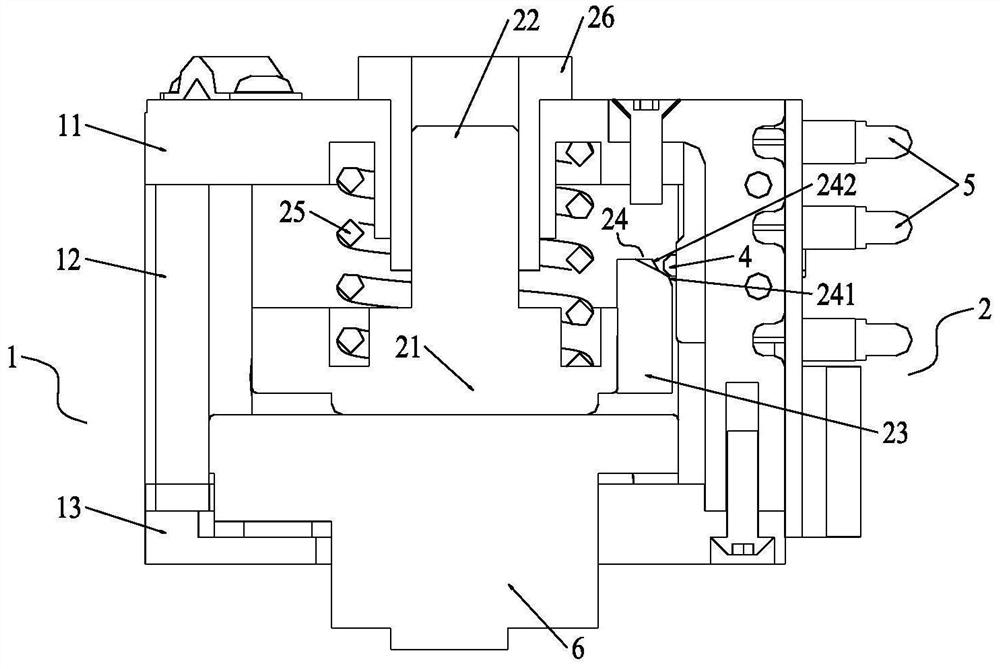

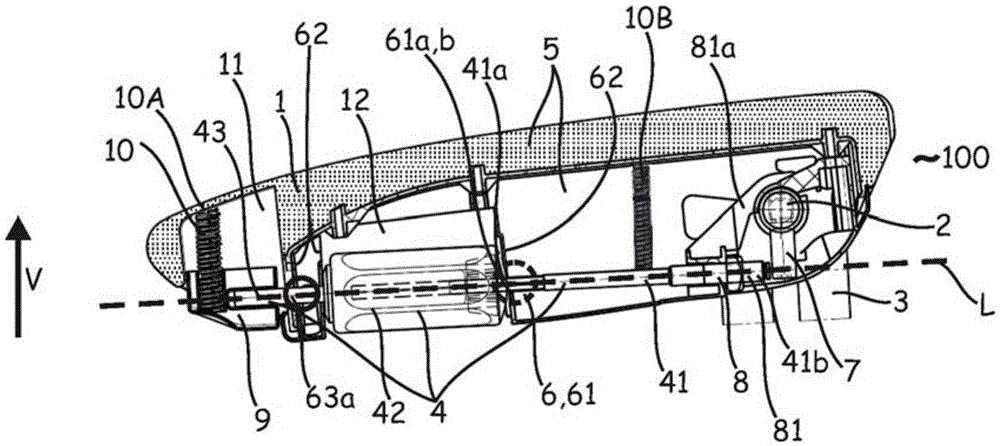

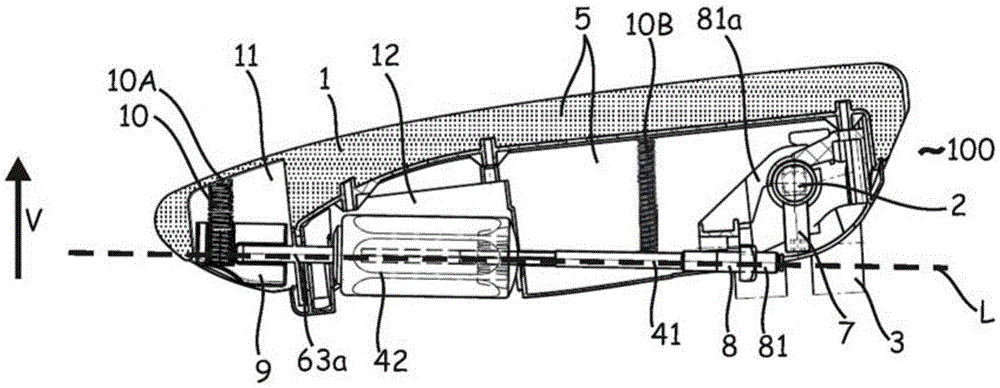

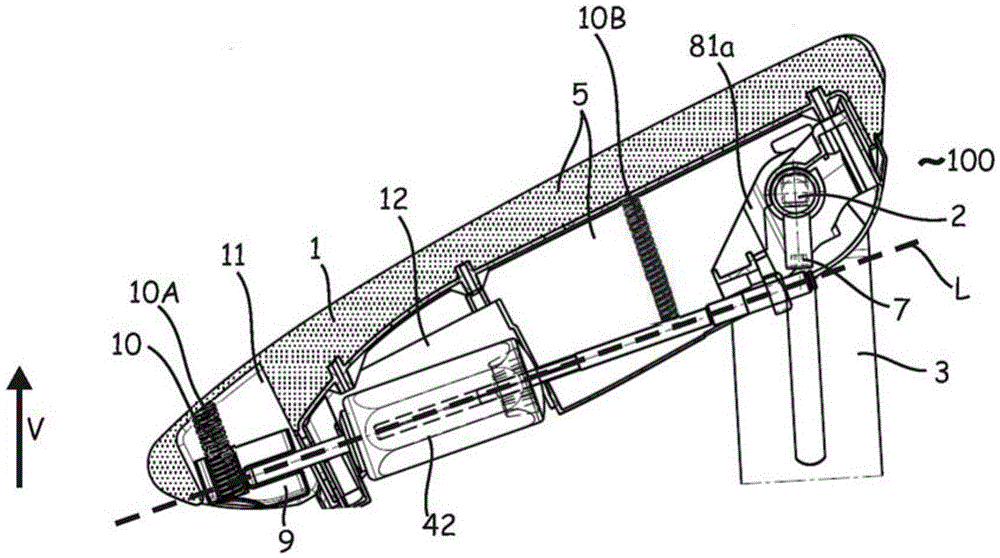

Arm rest arrangement for a seat, in particular for a vehicle seat

ActiveCN103863160AImprove operational stabilityExtended service lifeArm restsEngineeringAngle of inclination

The invention relates to an arm rest arrangement (100) for a seat, in particular for a vehicle seat, with an arm rest (1) which is pivotably connected by means of a bearing axis (2) to an arm rest support (3), wherein a latching and adjusting device (4) is provided for setting an angle of inclination between the arm rest (1) and the arm rest support (3) in a usage position and for folding down the arm rest (1) from the usage position into a non-usage position, wherein the latching and adjusting device (4) is mounted so as to be rotatable in a rotary element (6) within a housing (5) of the armrest (1) and the latching and adjusting device (4) is mounted so as to be rotatable about its longitudinal axis (L) in the housing for setting of the angle of inclination.

Owner:GRAMMER AG

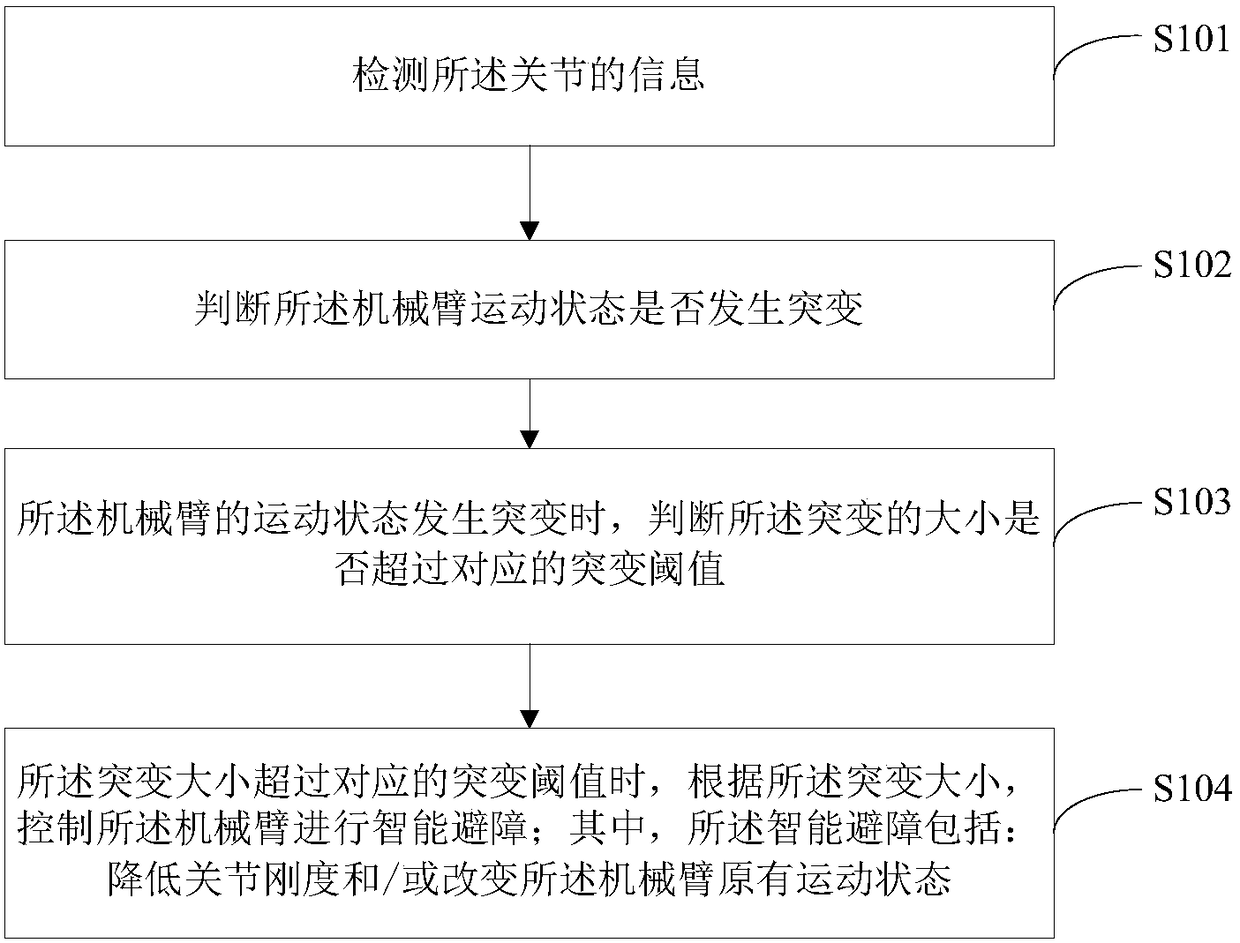

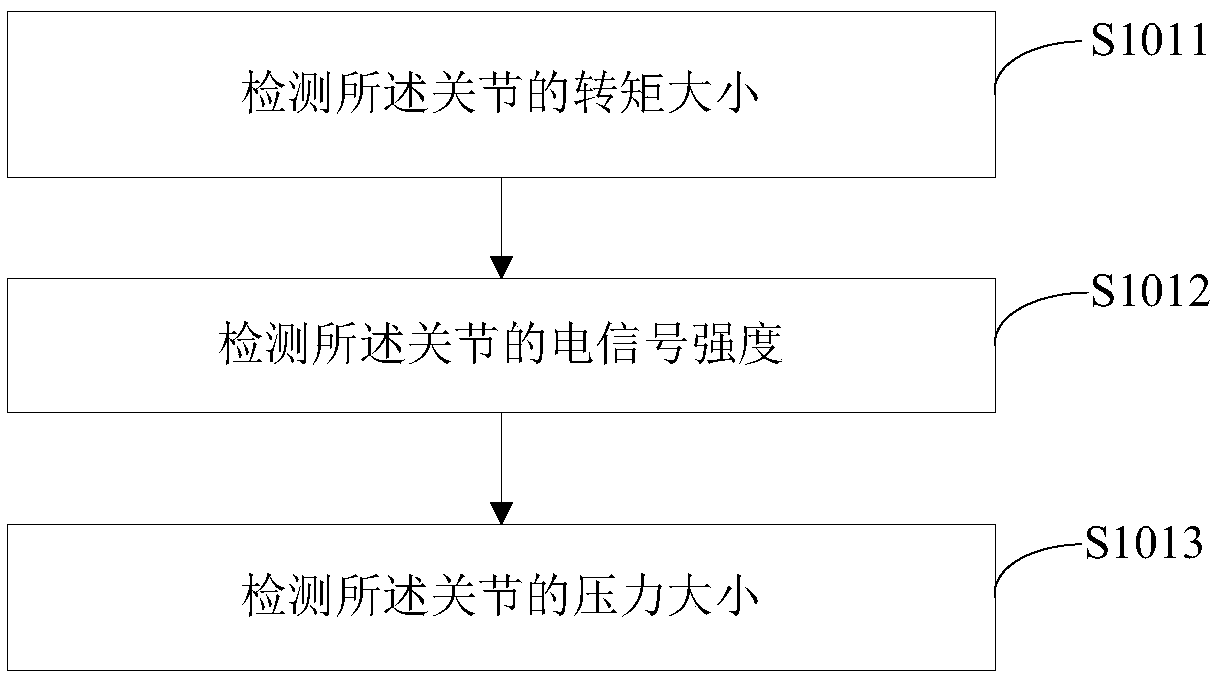

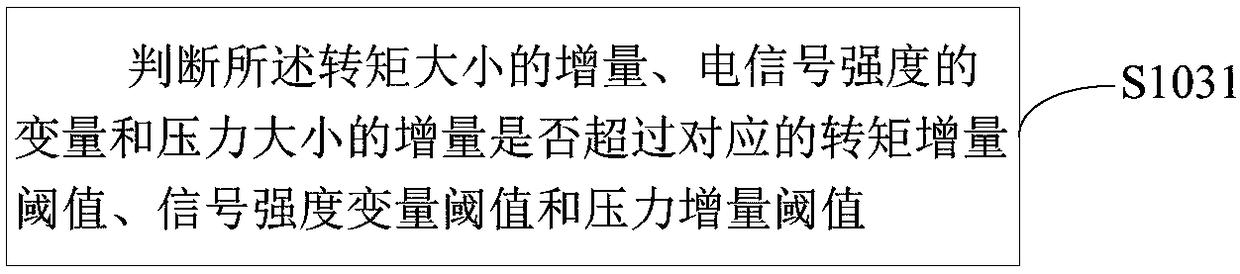

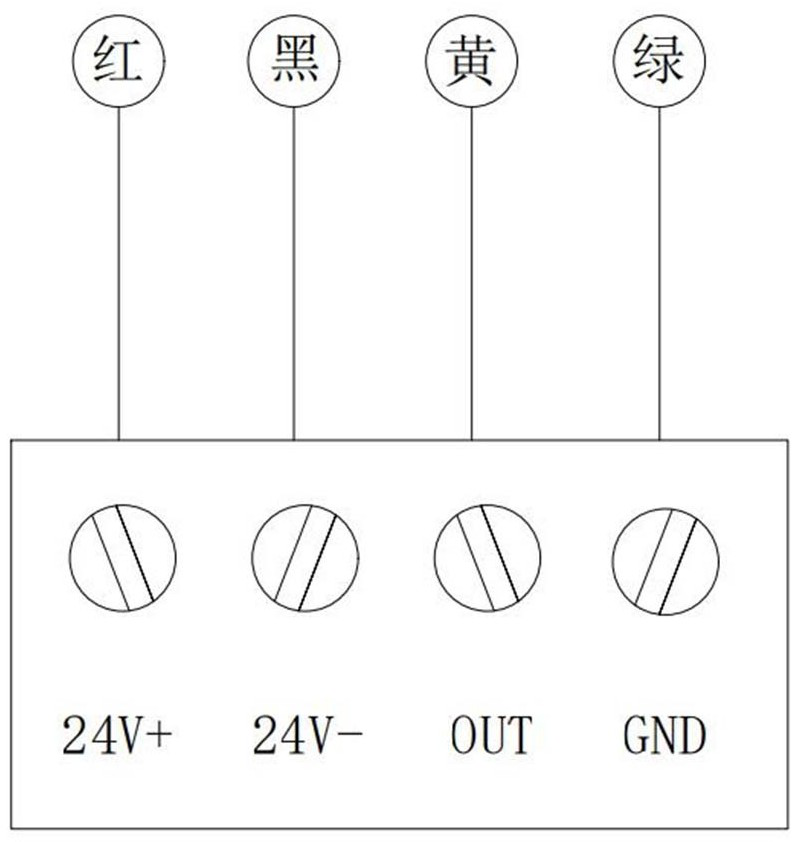

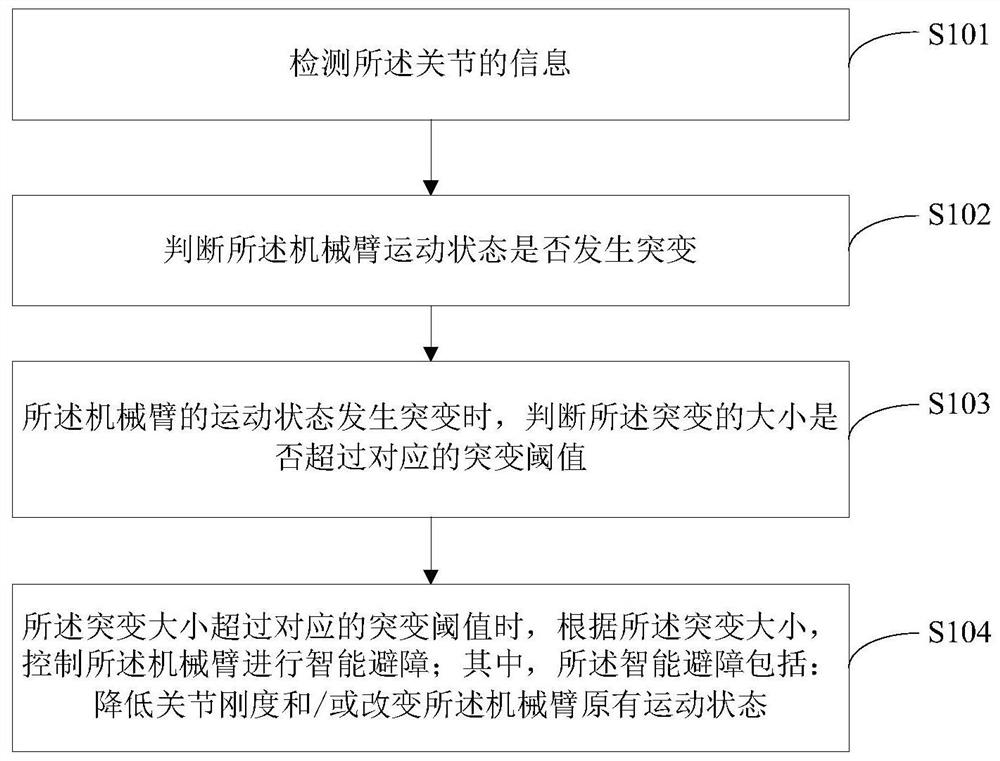

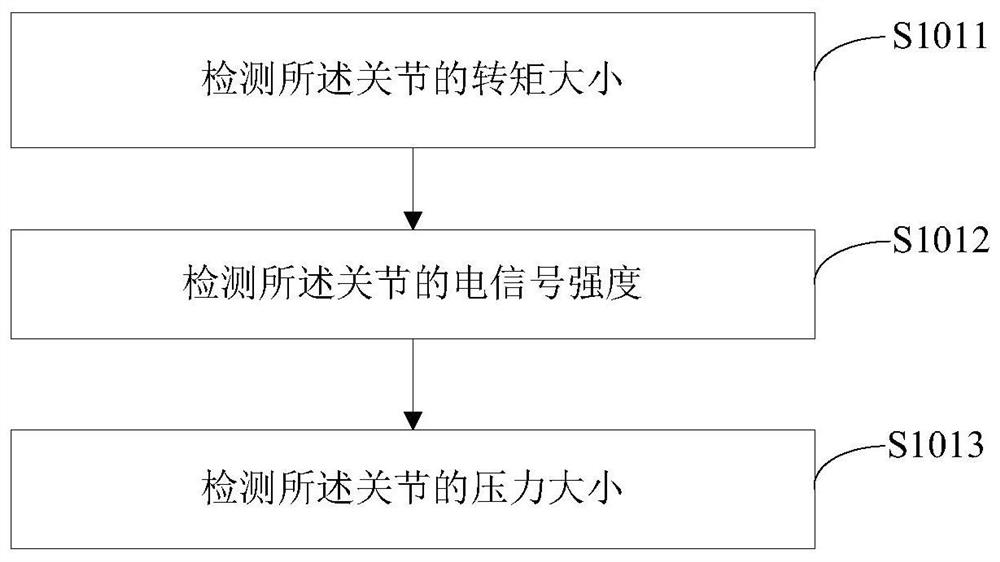

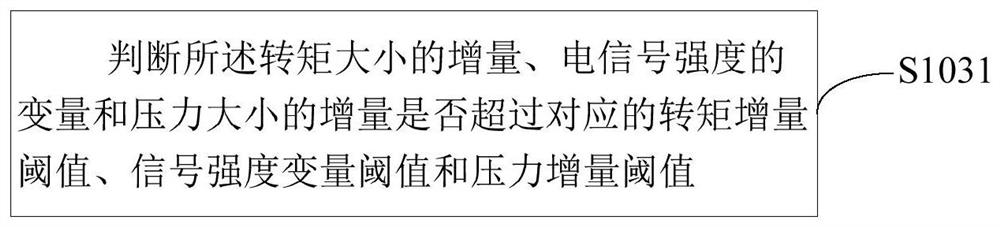

Flexible obstacle avoidance method and system of mechanical arm, and terminal equipment

ActiveCN108161939AAvoid mechanical collisionGuaranteed integrityProgramme-controlled manipulatorFailure rateTerminal equipment

The invention relates to the technical field of control of mechanical arms, and provides a flexible obstacle avoidance method and system of a mechanical arm, and terminal equipment. The method comprises the steps of detecting the information of a joint, judging whether the moving state of the mechanical arm is changed suddenly; judging the amplitude of sudden change exceeds the corresponding sudden change threshold value or not when the moving state of the mechanical arm is changed suddenly; and controlling the mechanical arm to avoid an obstacle according to the amplitude of sudden change when the amplitude of sudden change exceeds the corresponding sudden change threshold value, specifically, the intelligent obstacle avoidance comprises the step of reducing the joint rigidity and / or changing the original moving state of the mechanical arm. The method can effectively avoid direct mechanical collision between the mechanical arm and the obstacle, ensure integrity of the mechanical arm and reduce the failure rate of the mechanical arm.

Owner:SHENZHEN YUEJIANG TECH CO LTD

Infusion pump with self-protection function and self-checking resetting method thereof

The invention discloses an infusion pump with a self-protection function. The infusion pump includes a pump body assembly, and the pump body assembly includes a pump body, a piston rod, two optoelectronic switches, an optoelectronic switch separation blade and a controller. The piston rod is arranged in the pump body and connected with a driving motor through a transmission mechanism, and the driving motor can drive the piston rod to move back and forth in a linear mode in the pump body. The two optoelectronic switches are installed on the pump body at certain spacing, and the optoelectronic switch separation blade is fixed to the piston rod; when the optoelectronic separation blade moves to the optoelectronic switches, the optoelectronic switches can be shielded. The controller is electrically connected with the optoelectronic switches and the driving motor, and the controller controls running of the driving motor according to state signals output by the optoelectronic switches. The infusion pump can prevent exceptional mechanical collision caused when the piston rod is reset and after errors are accumulated. The invention further provides a self-checking resetting method capableof improving the resetting position accuracy of the piston rod.

Owner:RIGOL

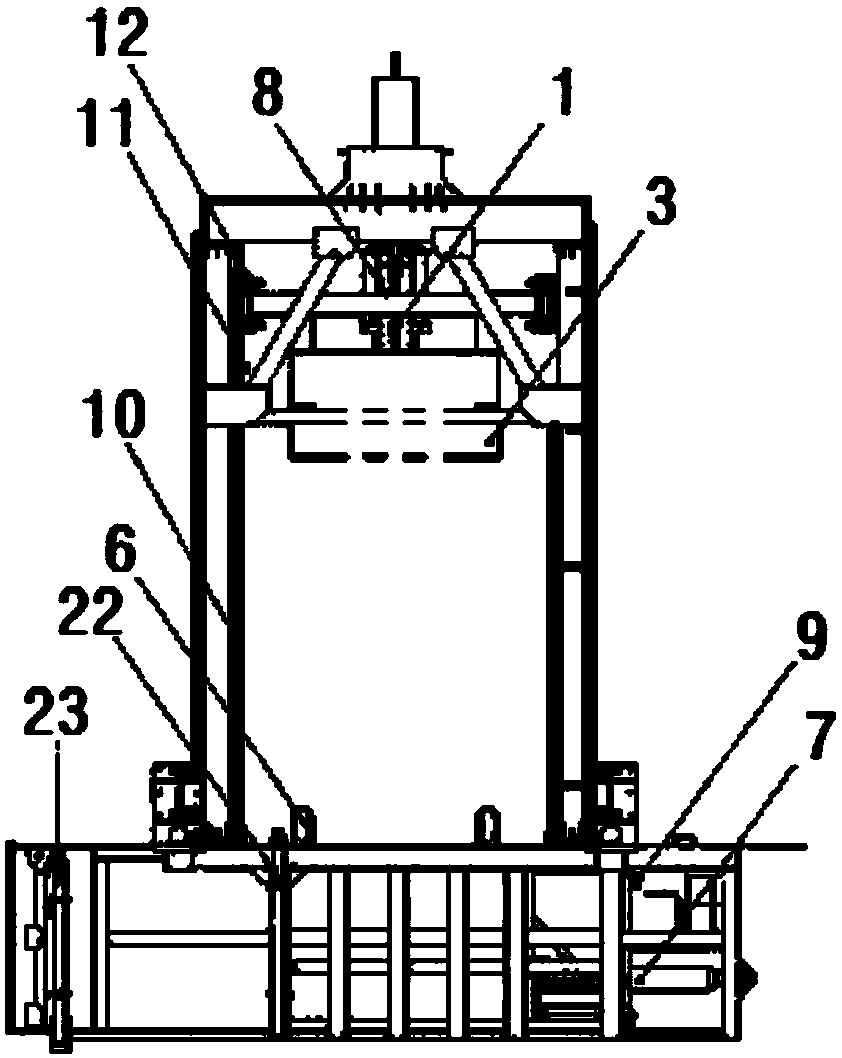

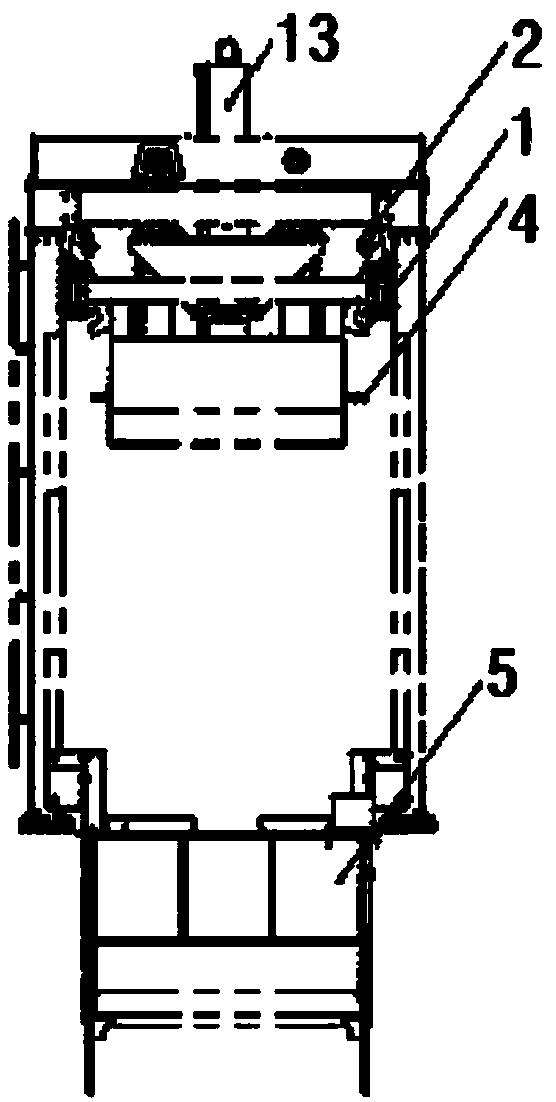

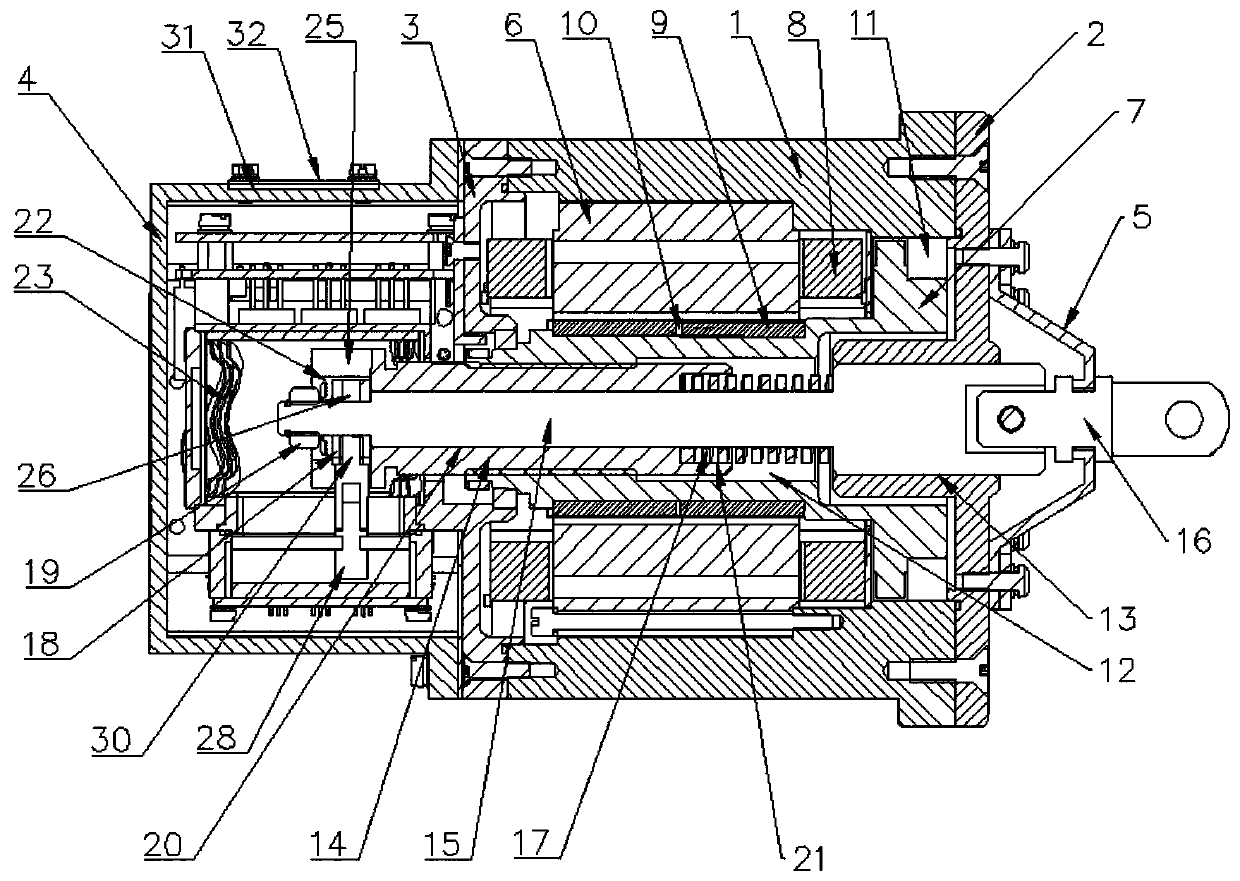

Vertical compressor

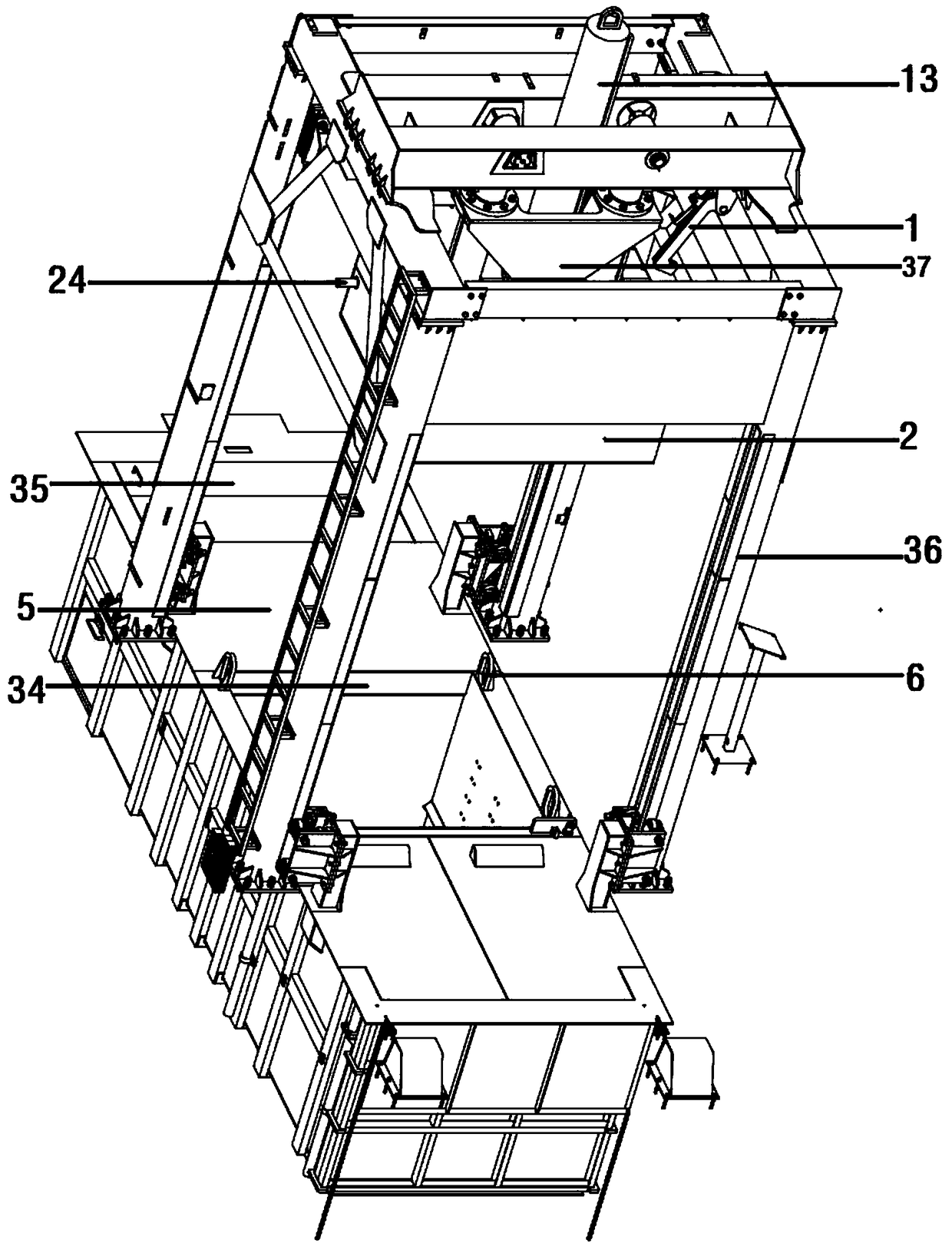

PendingCN108357133AShorter compression cycle timesImprove work efficiencyPressesCompression deviceCycle time

The invention discloses a vertical compressor which comprises a stand column, a tank (5), a pressure head device (3) for vertically compressing garbage, a horizontal compression device for horizontally compressing the garbage, and a controller (15). The stand column is arranged on the tank (5); the pressure head device (3) is arranged on the stand column; the horizontal compression device is arranged on the tank (5); an opening of the pressure head device (3) is formed in the top part of the tank (5) in a matching way; and the pressure head device (3) and the horizontal compression device areelectrically connected with the controller (15). Compared with the prior art, according to the vertical compressor provided by the invention, the compression cycle time is remarkably shortened, the working efficiency is improved, all mechanisms are controlled to act while the safety logic is considered, mechanical breakdown or unnecessary machine halt caused by a valve lock and internal leakage ofan oil cylinder is avoided, and the stability and the safety of a system are improved.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

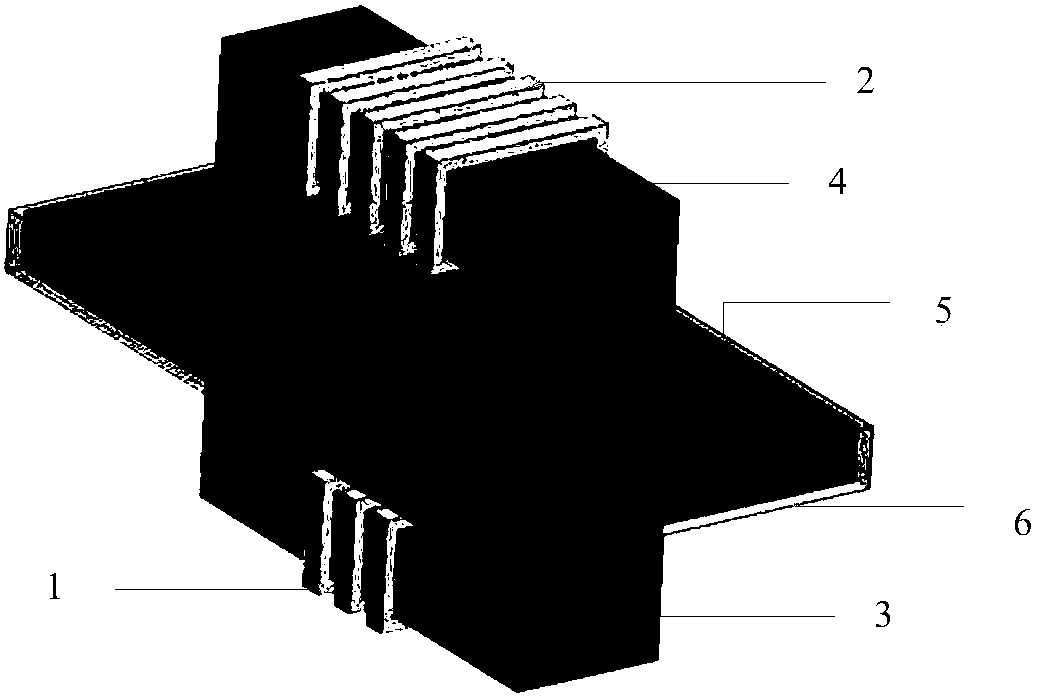

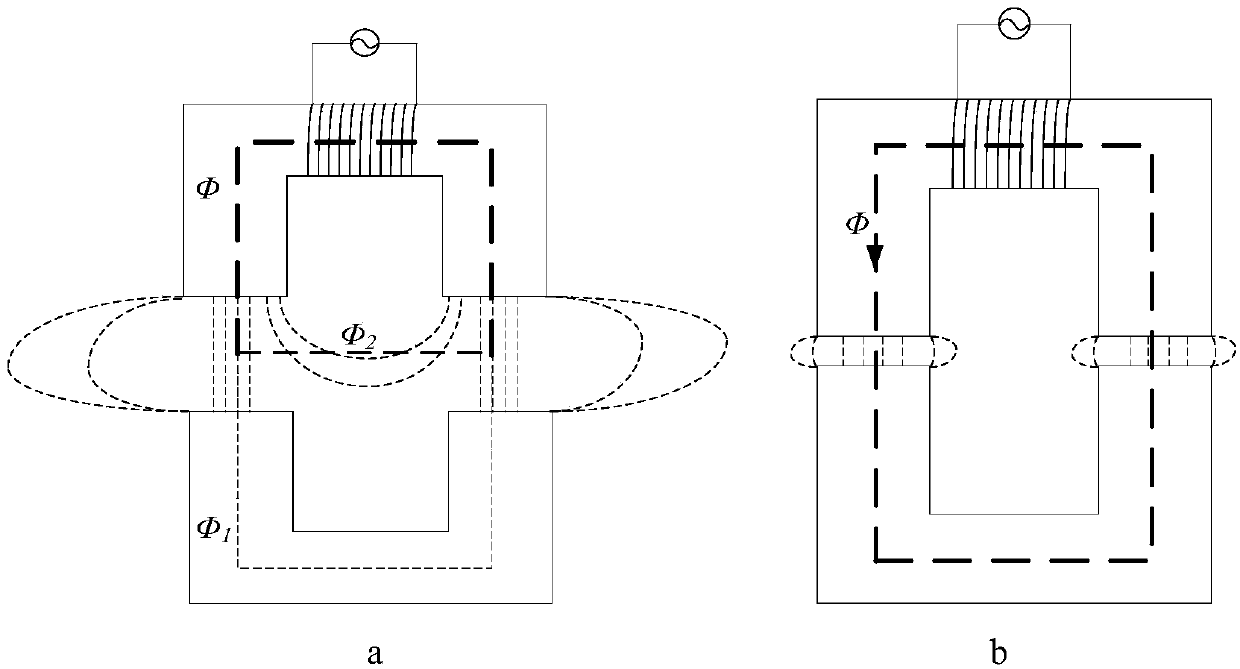

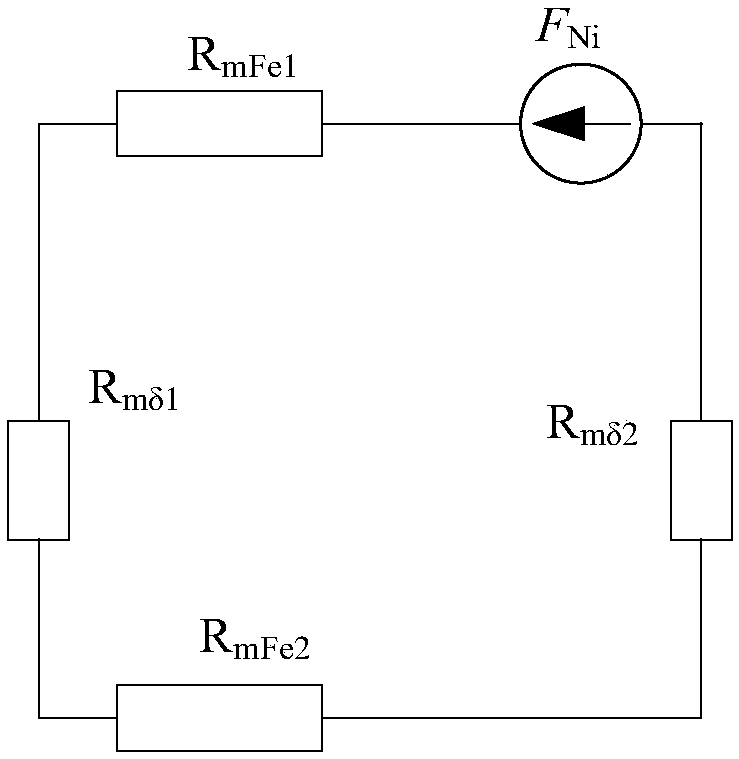

Magnetic coupling mechanism based on magnetic fluid and electric bus wireless charging system

ActiveCN107640047AImprove energy transfer efficiencySmall magnetic resistanceTransformersMagnetic liquidsPower exchangeMagnetic flux

The invention relates to a magnetic coupling mechanism based on magnetic fluid and an electric bus wireless charging system, and relates to the field of energy transmission and wireless charging. Themagnetic coupling mechanism comprises a primary side U-shaped core and a secondary side U-shaped core which are symmetrically arranged; the secondary side U-shaped core is arranged in an electric bus,a secondary side coil is wound around the secondary side U-shaped core, and the secondary side coil is used for charging a battery pack of the electric bus; the primary side U-shaped core is arrangedoutside the electric bus and used for being coupled with the secondary side U-shaped core, and a primary side coil is wound around the primary side U-shaped core and used for conducting power exchange with the secondary side coil; two magnetic fluid devices are arranged between the primary side U-shaped core and the secondary side U-shaped core, and when the primary side U-shaped core and the secondary side U-shaped core conduct energy transmission through magnetic coupling, flexible connection of both ends of the primary side U-shaped core and the secondary side U-shaped core is achieved through the magnetic fluid. The magnetic coupling mechanism based on the magnetic fluid and the electric bus wireless charging system have the advantages that in the condition that the number of turns and electric current of the primary side coil are not changed, a larger magnetic flux density is generated, and the magnetic coupling efficiency is improved on a large scale.

Owner:CHONGQING YUXIN PINGRUI ELECTRONICS

Method for separating adhered magnetic cores

InactiveCN101552131AReduce breakage rateSimple processInductances/transformers/magnets manufactureEngineeringThermal expansion

The invention provides a method for separating adhered magnetic cores, comprising the following steps of: adding a certain amount of water which can spread across the adhered magnetic cores in a heating container and then heating to be boiling; putting 3kg to 5kg of adhered magnetic cores into the water for hot boiling for 1 to 3 minutes, and stirring during the hot boiling, then automatically separating part of adhered magnetic cores; and taking out the unseparated magnetic cores from the boiling water and softly and manually kneading until the adhered magnetic cores are separated. The method utilizes the principle of expanding with heat and contracting with cold to separate the adhered magnetic cores, has simple technology and simple and convenient operation, avoids mechanical collision during mechanical cutting, causes no damage to the products, and has extremely low damage rate to the magnetic cores, simultaneously, 3kg to5kg of the magnetic cores are separated in 1 to 3 minutes; therefore, relative mechanical cutting efficiency is greatly improved.

Owner:LAIWU TAIDONG POWDER TECH

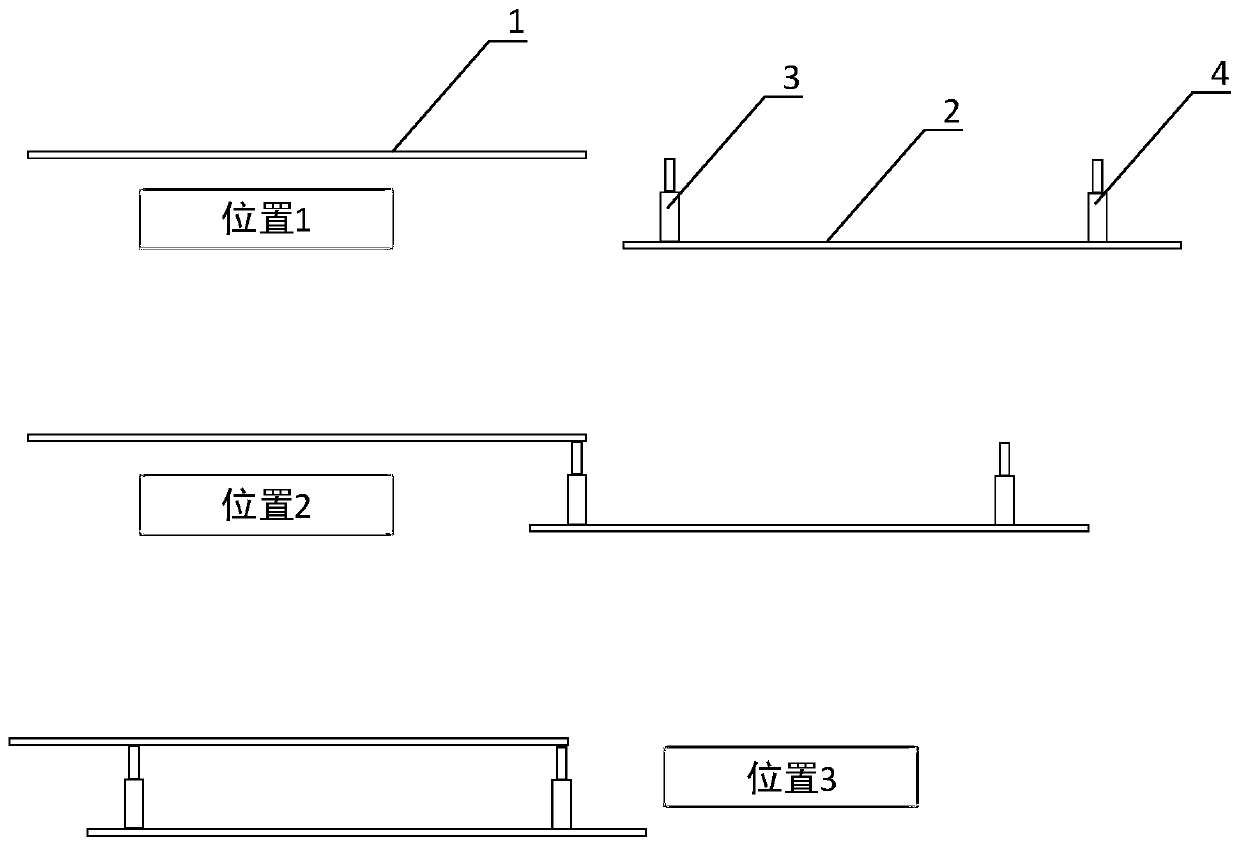

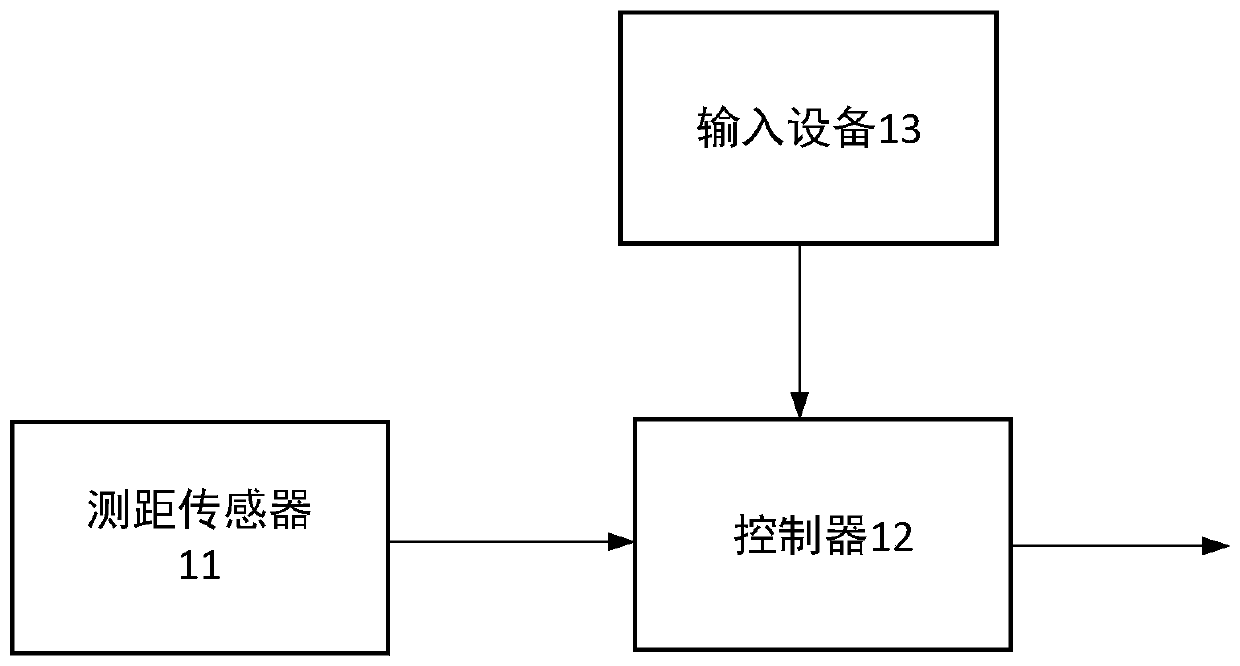

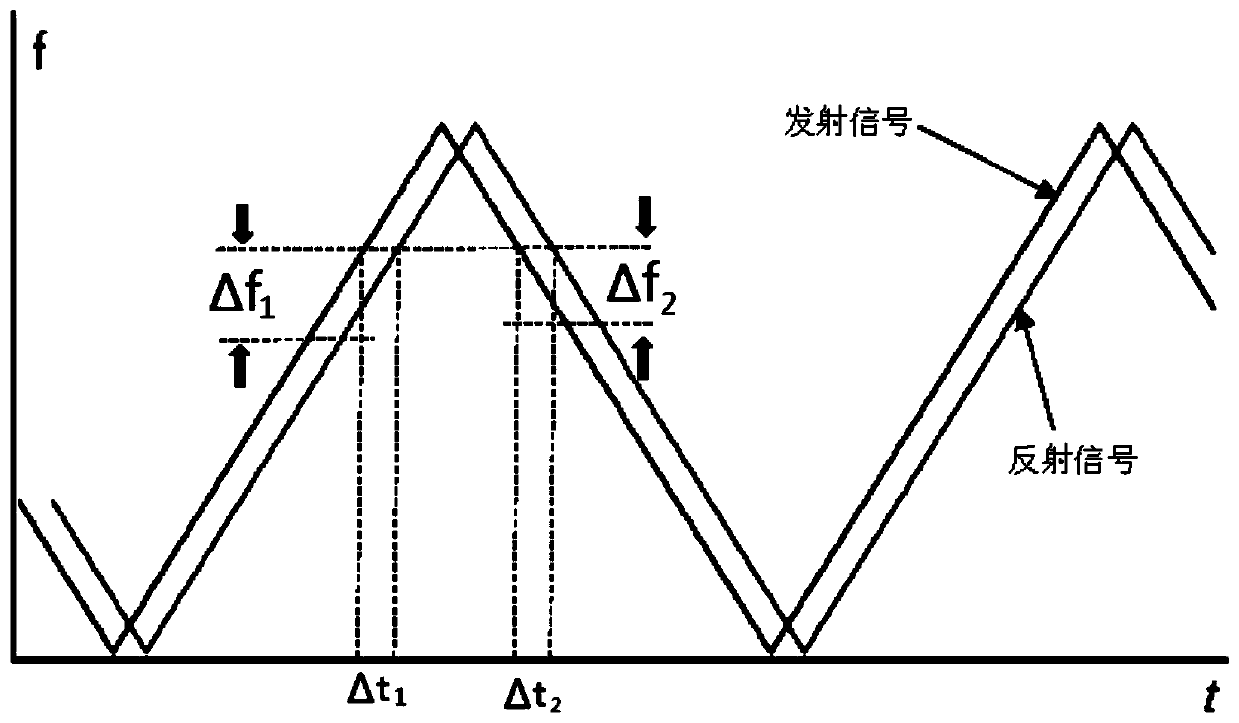

Lifting equipment system and control method thereof

PendingCN109733992AImprove reliabilityFlexible parameter settingSpecial data processing applicationsRunwaysControl signalRadar

The invention discloses a lifting equipment system and a control method thereof. The control method adopts a radar distance measuring mode to detect a motion distance of lifting equipment, corrects the motion distance, and controls the motion of the lifting equipment according to the corrected distance and a preset threshold. The lifting equipment system comprises a distance measuring sensor, a controller, an execution mechanism and input mechanism; the distance measuring sensor is used for measuring the motion of the lifting equipment; the controller calculates the motion distance for correction according to measured data, and outputs control signals; the execution mechanism is acted according to the control signals; and the input equipment is used for inputting parameters. The motion distance of the lifting equipment can be precisely measured to prevent mechanical collision, so that the damage of the lifting equipment is reduced.

Owner:浙江东川自动化科技有限公司

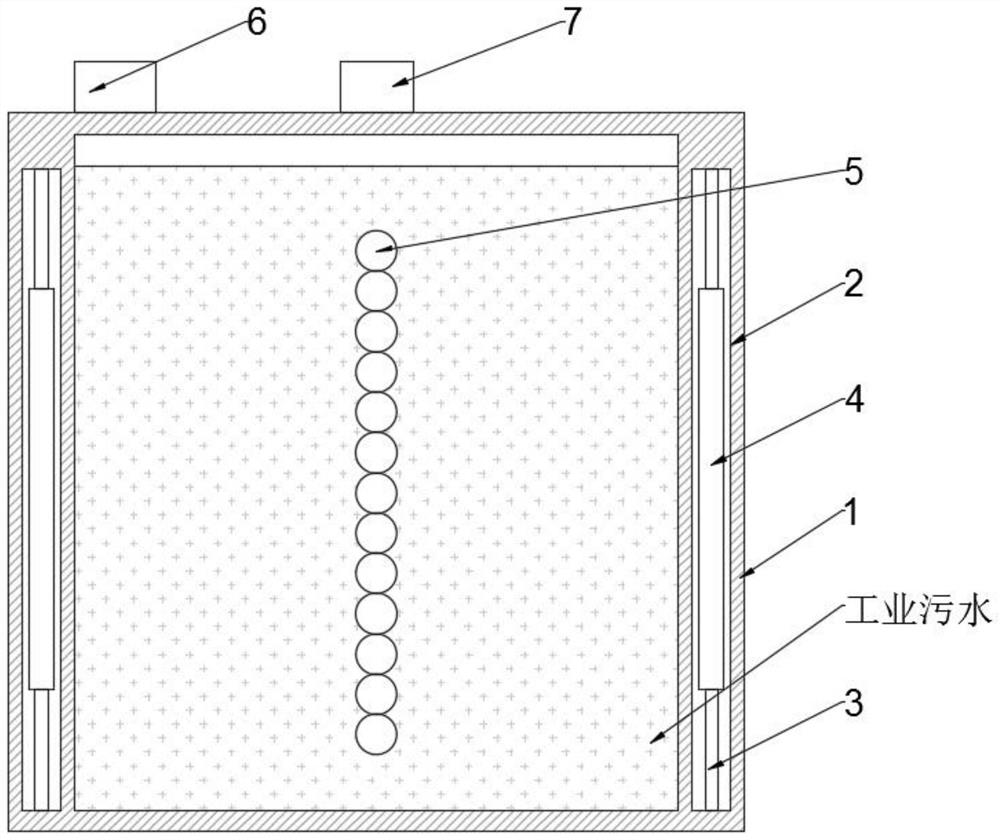

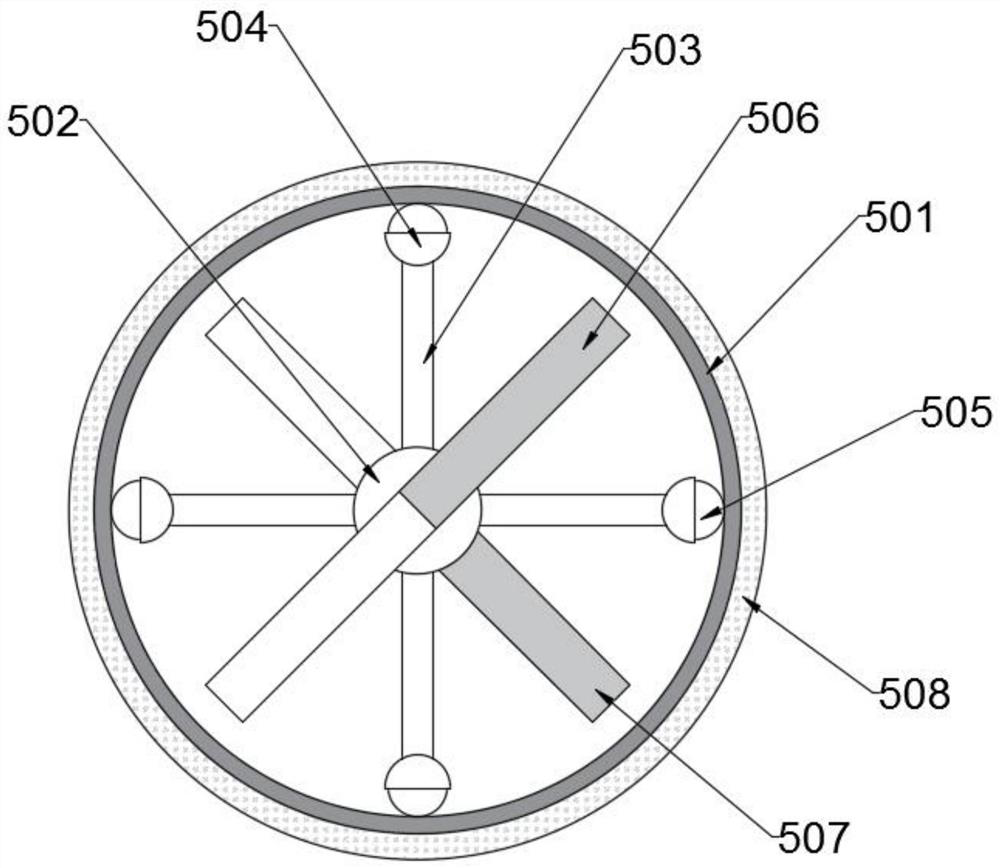

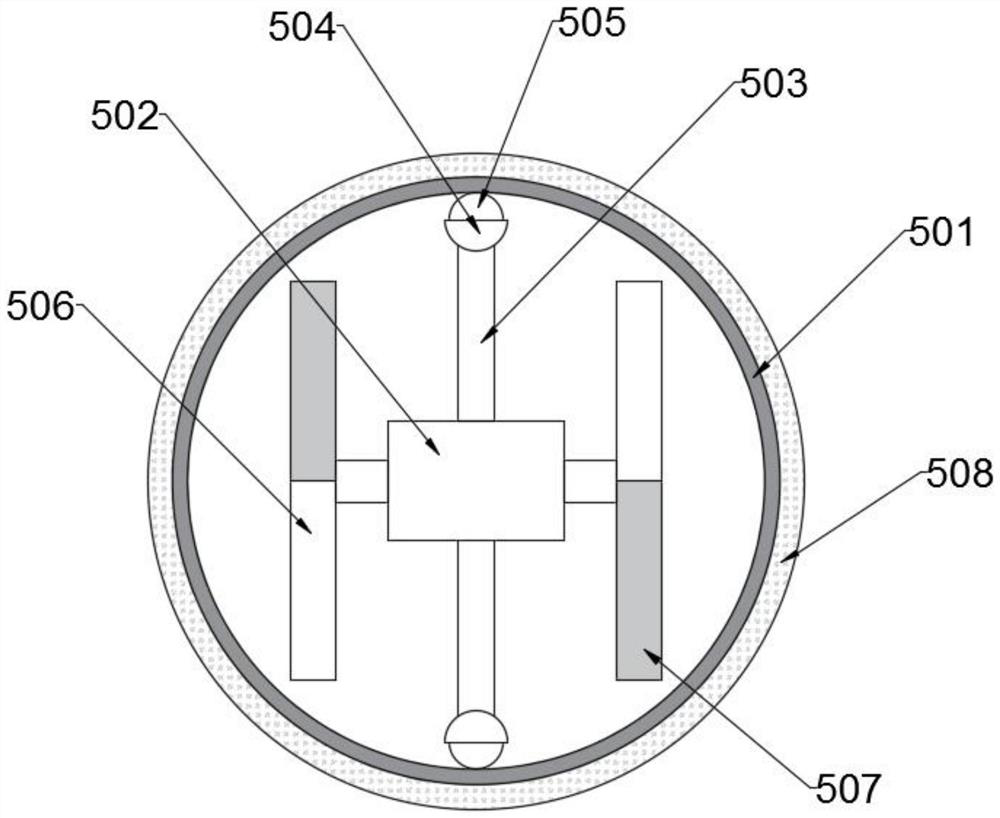

Industrial sewage treatment equipment and use method thereof

ActiveCN112028202AFully contactedImprove flocculation efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusFlocculationSewage

The invention discloses industrial sewage treatment equipment and a use method thereof, belongs to the technical field of sewage treatment. The industrial sewage treatment equipment comprises a hard plastic cylinder and flocculation balls for flocculation, and each flocculation ball comprises a hollow plastic ball and a mounting cylinder arranged in the hollow plastic ball. The plurality of flocculation balls are driven to do irregular multi-angle free movement in industrial sewage by utilizing the acting force among the flocculation balls, so that an organic flocculation functional membrane is in full contact with the industrial sewage, the necessary stirring procedure in the flocculation process in the prior art is replaced, the cost of flocculation equipment is reduced, meanwhile, the phenomenon of scattering of flocculation gel lumps caused by shearing force generated by stirring of a stirring rod is avoided, the sewage flocculation efficiency is greatly improved, and after flocculation is finished, the multiple flocculation gel lumps can be adsorbed together and sink to the bottom in the hard plastic cylinder, so that sewage and the flocculation gel lumps are conveniently separated and collected.

Owner:山东艾普特暖通技术有限公司

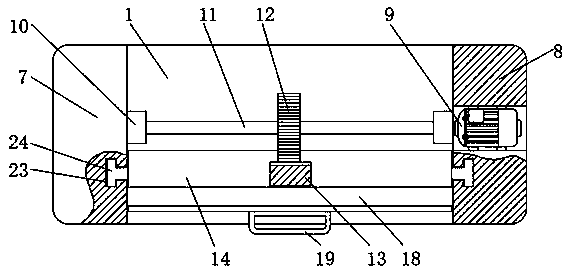

Multifunctional machine tool limiting device

PendingCN108907845AAvoid mechanical collisionImprove safety and reliabilityFeeding apparatusMetal working apparatusEngineeringMultiple function

The invention discloses a multifunctional large-scale guide rail limiting device. The limiting device comprises a hydraulic buffering mechanism used for stopping rapid movement of a machine tool moving unit, a mechanical base used for allowing the hydraulic buffering mechanism to be installed and indirectly bearing the impact force of the machine tool moving unit, and detection feedback components, wherein the mechanical base is installed on a machine tool, and the hydraulic buffering mechanism is fixedly installed on the mechanical base. According to the multifunctional large-scale guide raillimiting device, when the machine tool moving unit moves quickly and impacts the hydraulic buffering mechanism, direct mechanical collision is effectively prevented, so that a certain safety protection effect is achieved; a pressure sensor is used for conducting real-time feedback detection, when a detection signal reaches a warning value, the machine tool can make a timely action command; and the limiting device solves the problems that an existing machine tool limiting device is poor in reliability, short in service life and the like, and has a certain application prospect.

Owner:SHAANXI SCI TECH UNIV

Elasticity test winding device for producing lace fabric for shapewear

The invention discloses an elasticity test winding device for producing lace fabric for a shapewear. The device comprises a fixing seat, the top of which is fixedly connected with a placing table, wherein the top of the placing table is provided with a clamping plate, clamping rods are fixedly connected to both sides of the bottom of the clamping plate, a clamping groove is formed in the fixing seat, and the bottom ends of the clamping rods extend into the clamping groove. By setting the fixing seat, the placing table, the clamping plate, the clamping rods, the clamping groove, a clamping mechanism, a first fixing column, a second fixing column, a servo motor, a bushing, a transmission rod, a gear, a tooth plate, a sliding plate, a clamp, an anti-collision mechanism, a range finder and a limit plate which are used cooperatively, the elasticity test winding device for producing lace fabric for a shapewear solves the problem of slowness in the test of the existing elasticity test windingdevice, and has the advantage of short test time, thereby improving the subsequent detection speed.

Owner:苏州优捷纺织品有限公司

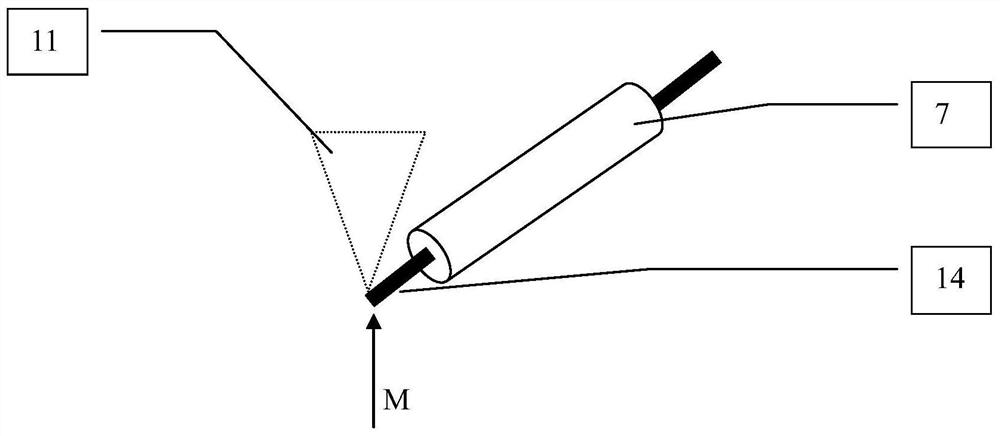

Laser welding tinning device and welding method

ActiveCN110961751BMake up for the influence of welding effectReduce processing fixture requirementsSolder feeding devicesSoldering auxillary devicesLaser processingLoop control

The present invention designs a laser welding tinning device and welding method. The tinning device includes a back plate, a laser position correction device, a camera, a laser processing head, a push wheel pair, a connecting rod, a tin feeding nozzle, a displacement sensor, an angle sensor, a balance Spring, controller, residue box, the angle sensor detects the swing angle of the connecting rod, the displacement sensor detects the up and down movement position of the connecting rod, and the controller calculates the moving speed and acceleration of the detecting head according to the displacement and angle change value of the detecting head; laser welding When using the position of the probe head for closed-loop control of the laser working height, closed-loop control of the feeding speed of the tin wire by using the force of the probe head, and closed-loop control of the position of the laser following the tin wire by using the probe head angle, it can make up for the height difference of the solder joints. The impact of the effect reduces the fixed requirements for product processing and expands the application range of laser welding. It can prevent mechanical collision or burn the processing base material, the process is stable, and the rate of qualified products is improved.

Owner:WUHAN BESKYS TECH CO LTD

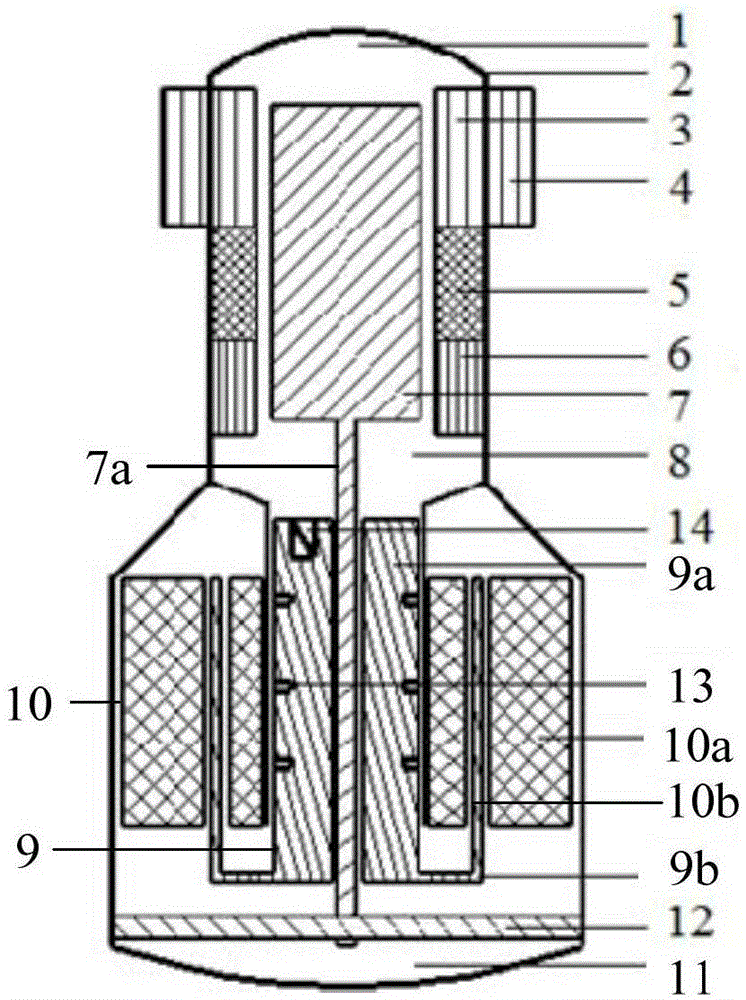

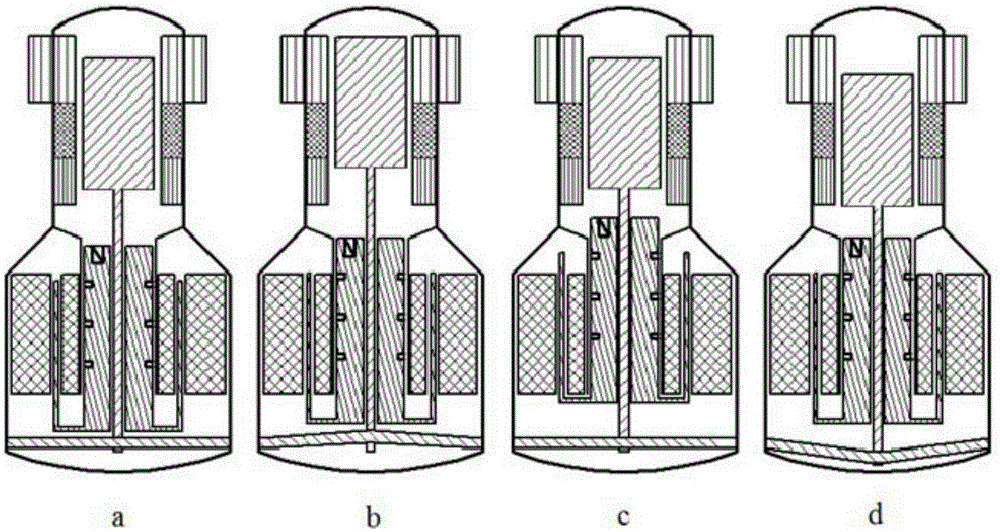

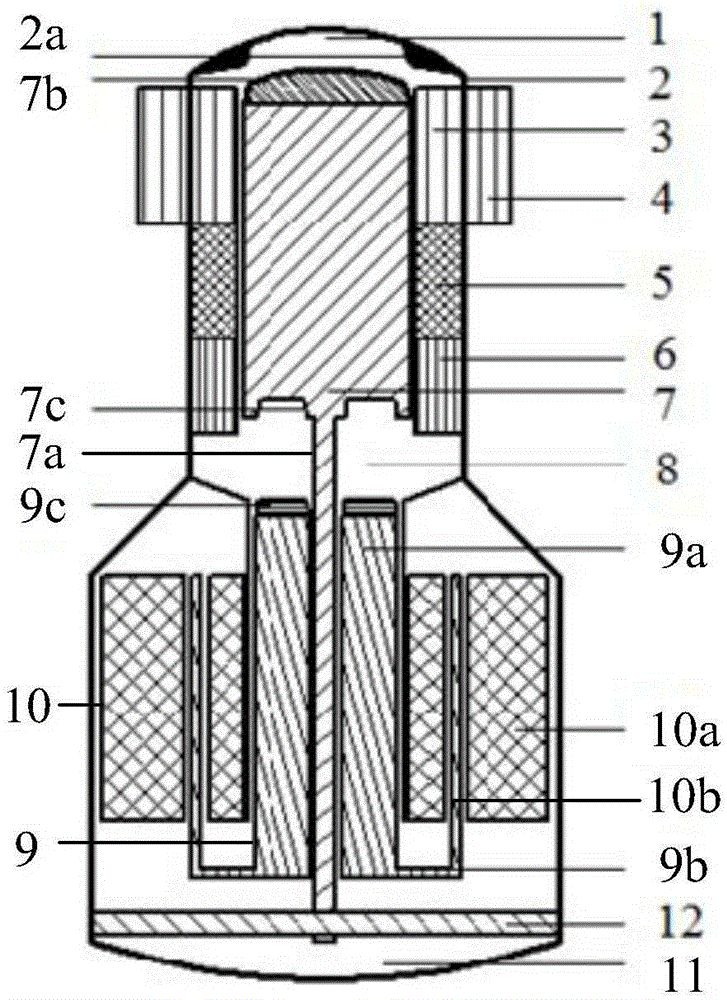

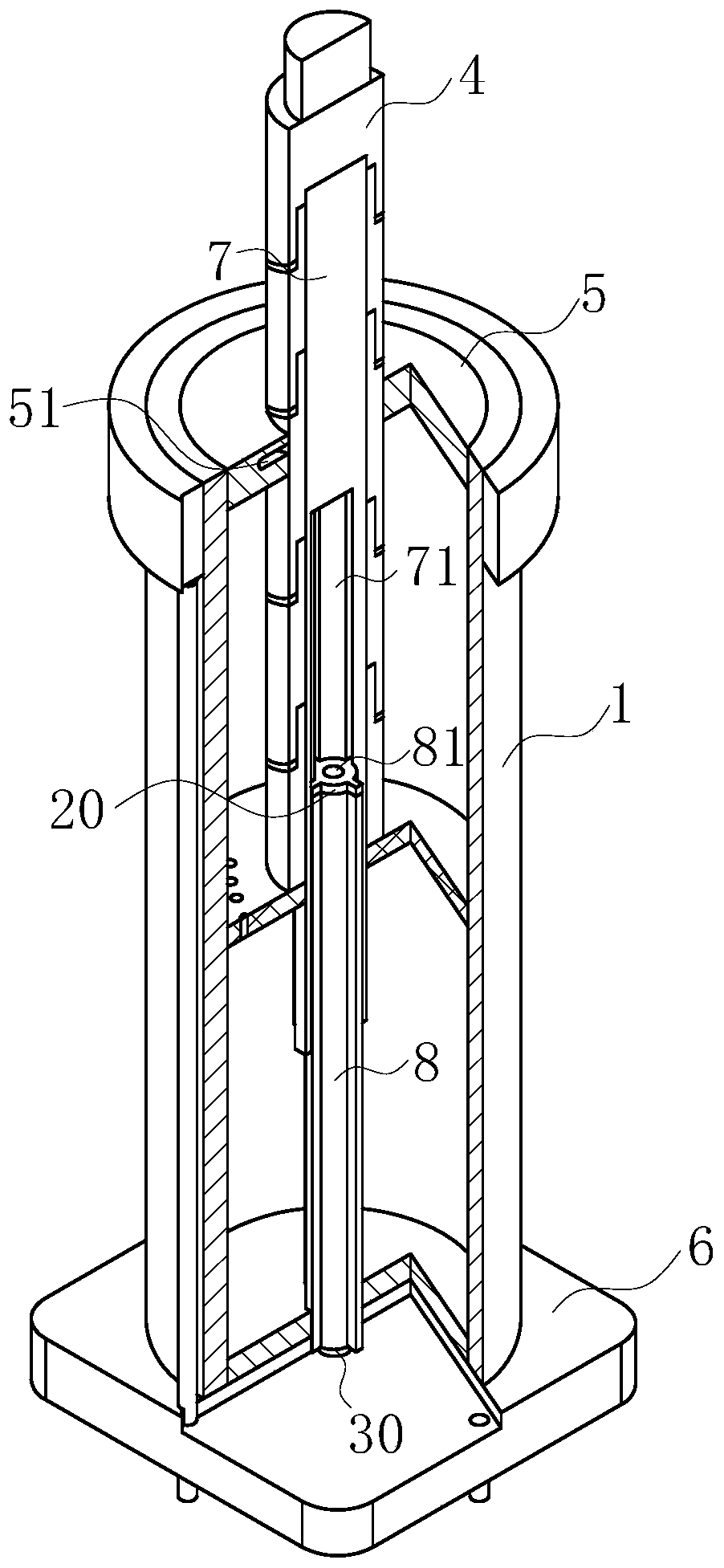

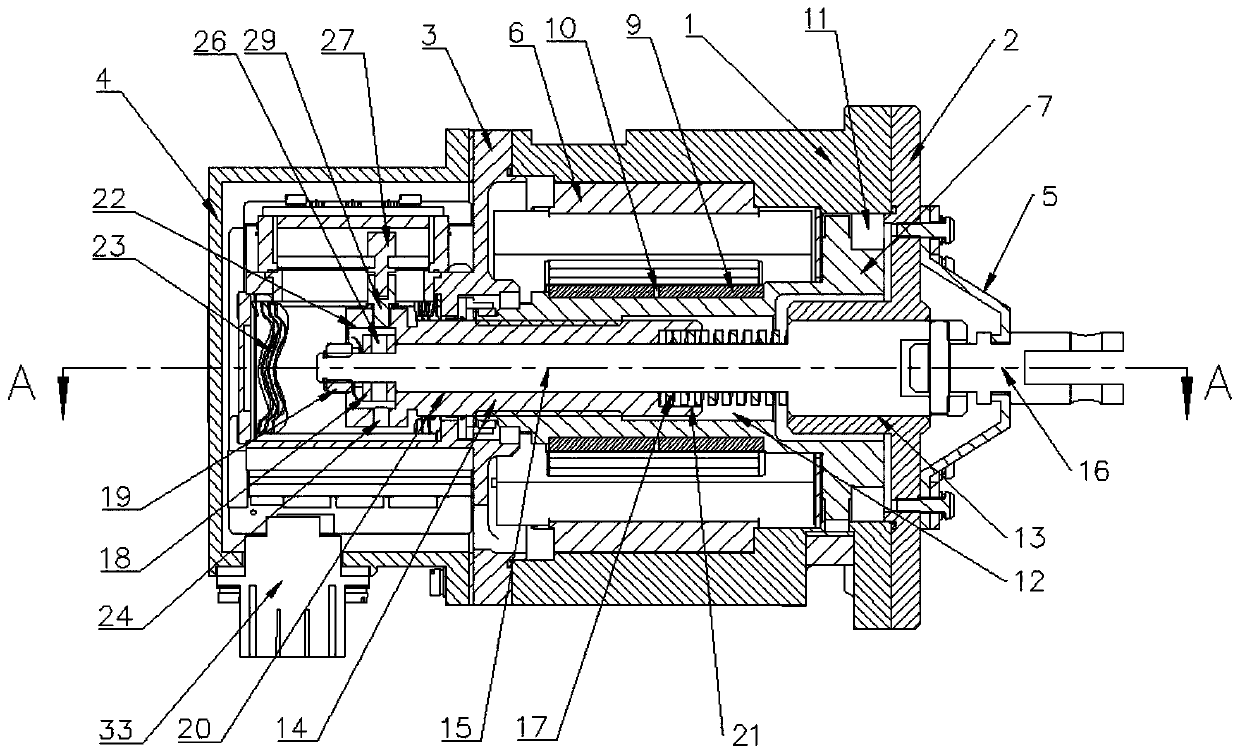

Free Piston Stirling Generator

ActiveCN104500262BAvoid mechanical collisionSimple structureEngine componentsHot gas positive displacement engine plantsElectric machineGas spring

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

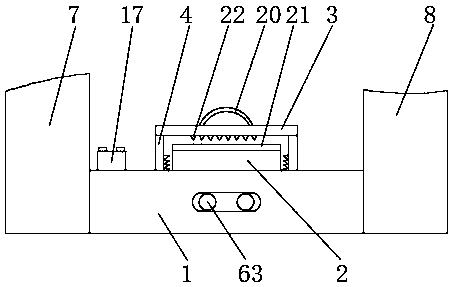

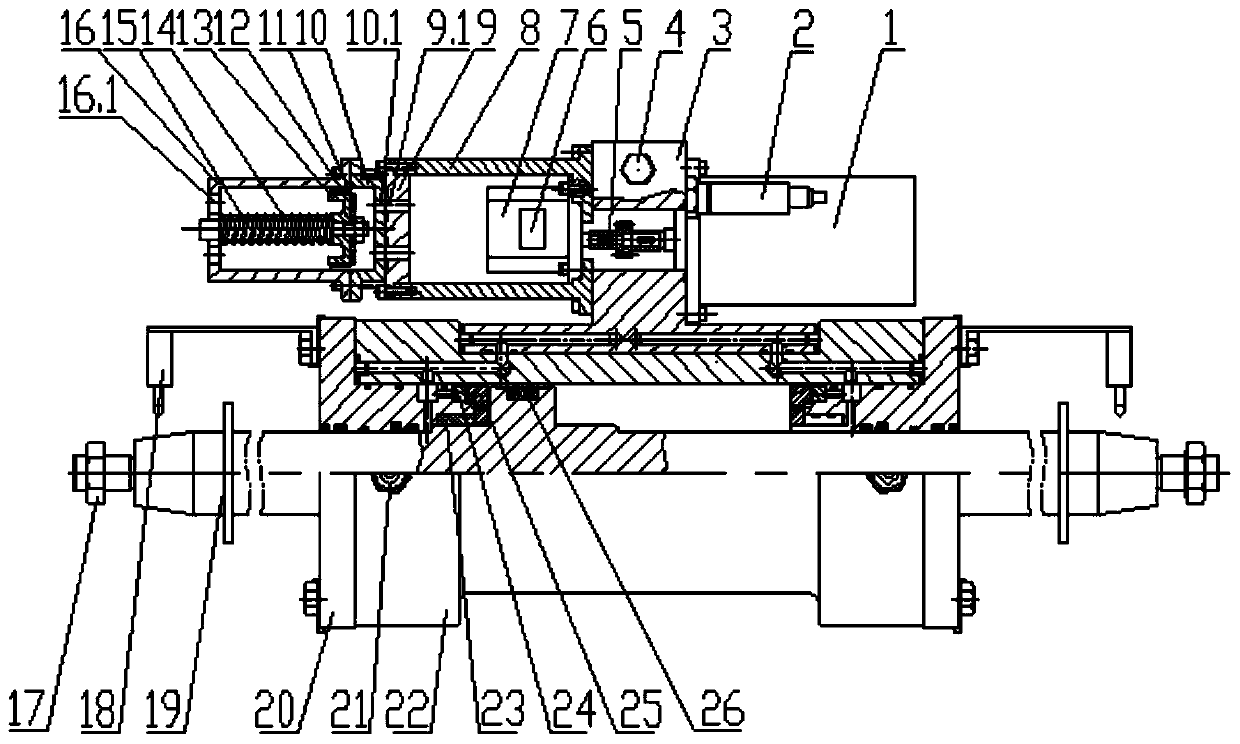

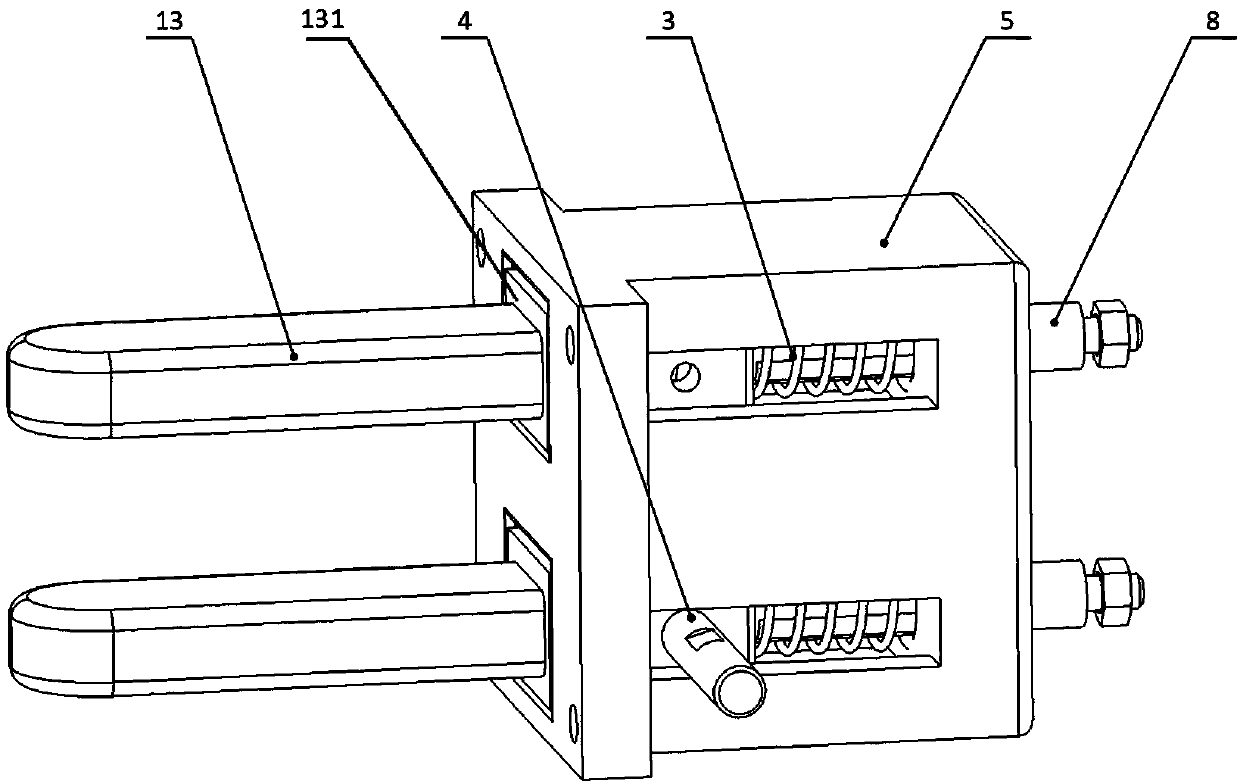

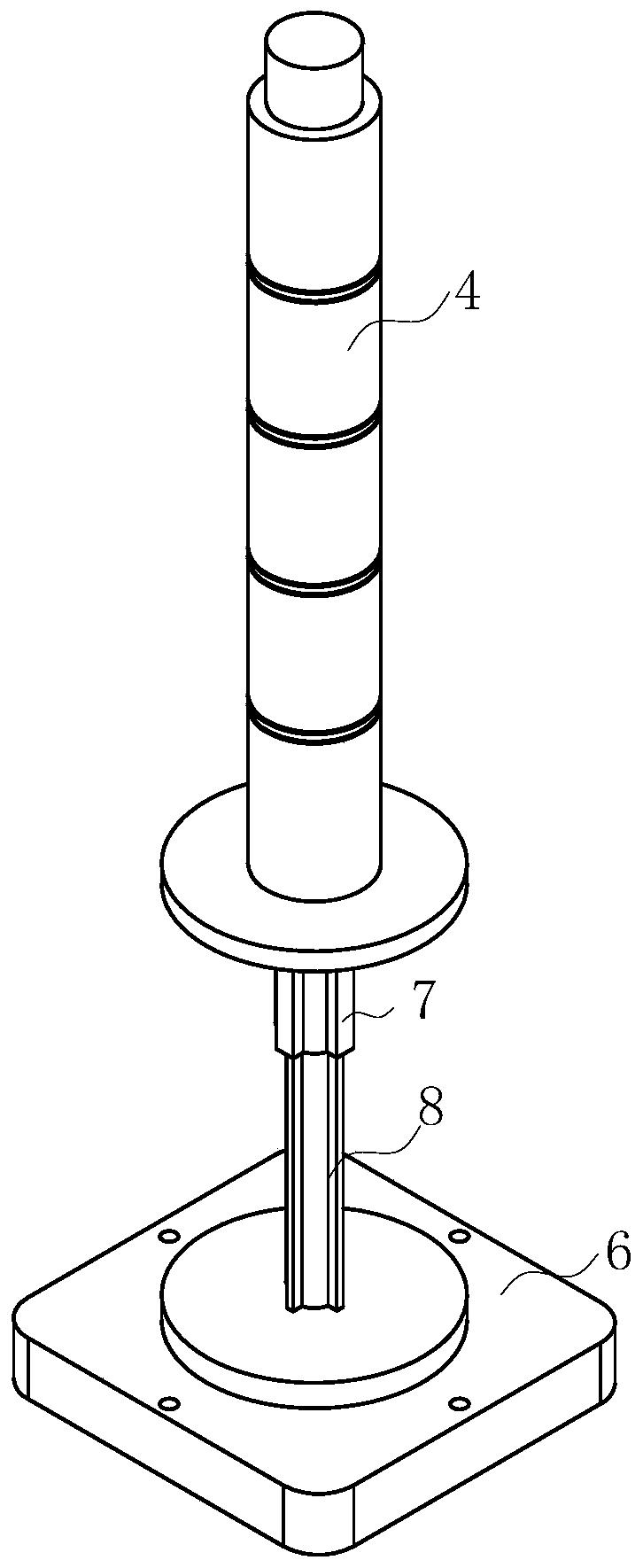

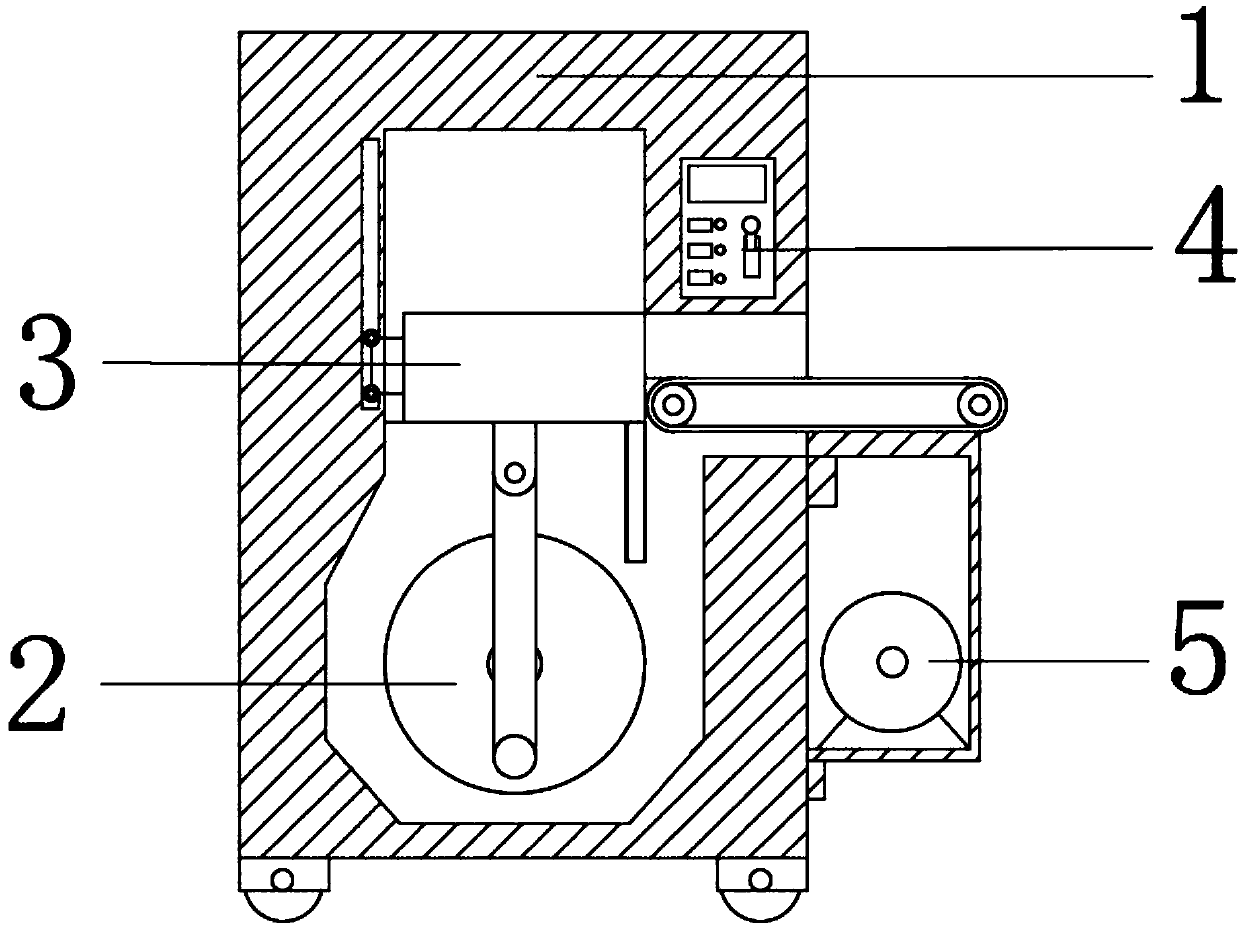

Walnut fixing device suitable for oriented extruding

PendingCN108685104APosition unchangedAvoid mechanical collisionHuskingHullingEngineeringProduct processing

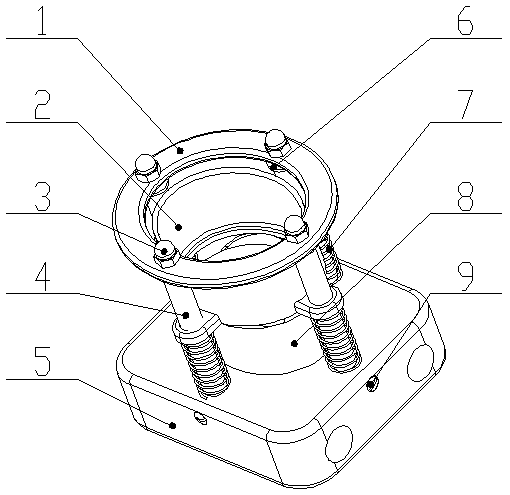

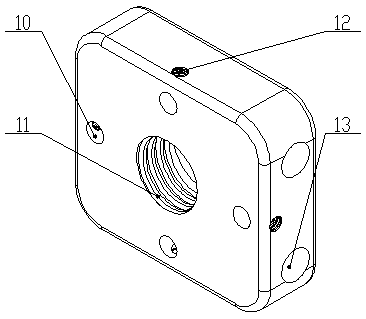

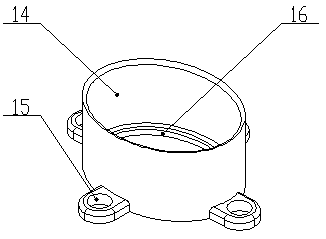

The invention relates to the field of processing of agricultural products, in particular to a walnut fixing device suitable for oriented extruding, specifically relates to the fixing device capable ofmaintaining positions of walnuts unchanged in transporting, processing and extruding courses, and aims that each walnut is always stressed and extruded in the direction of a short axis, so that in the extrusion course, damage of walnut kernels is reduced, and the effects of extruding and shell breaking of the walnuts are improved. The walnut fixing device suitable for oriented extruding is characterized by consisting of nine parts of a protecting ring (1), a fixing sleeve (2), four cap nuts (3), four sliding rods (4), a base (5), four flat gaskets (6), four compression springs (7), a bottom pressing head (8) and four sliding rod extruding screws (9).

Owner:SOUTHWEST FORESTRY UNIVERSITY

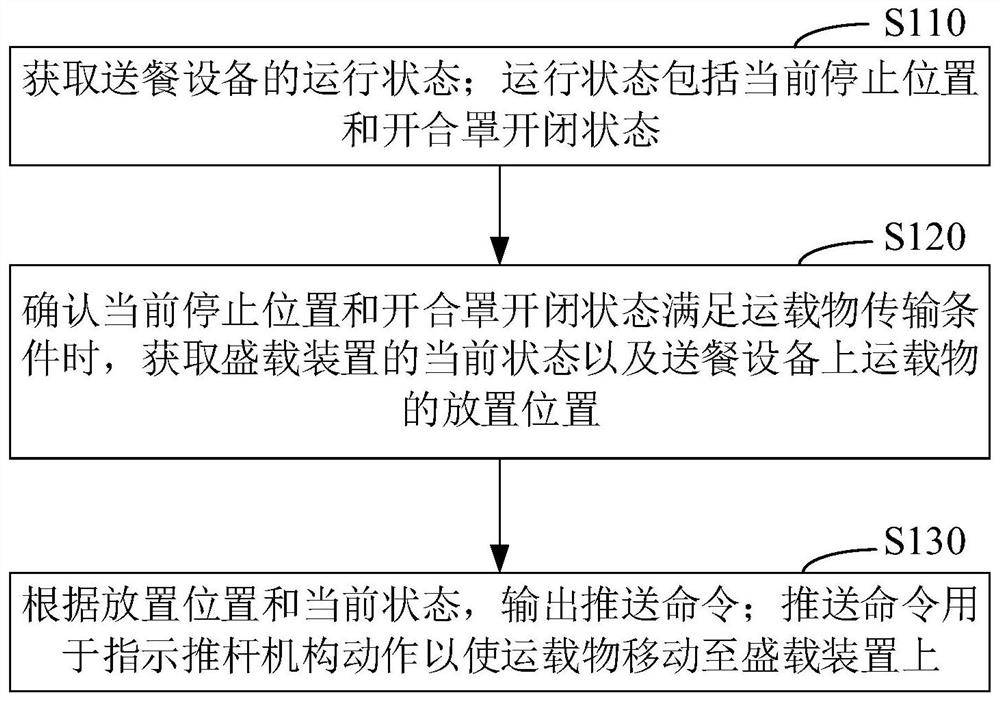

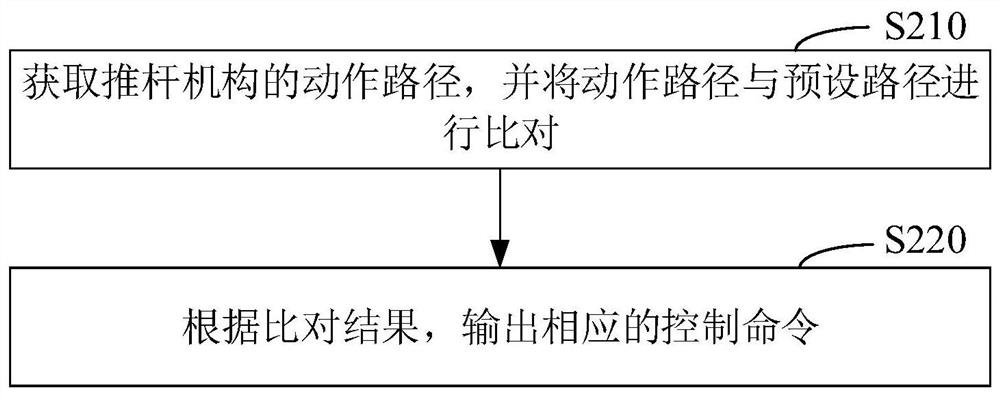

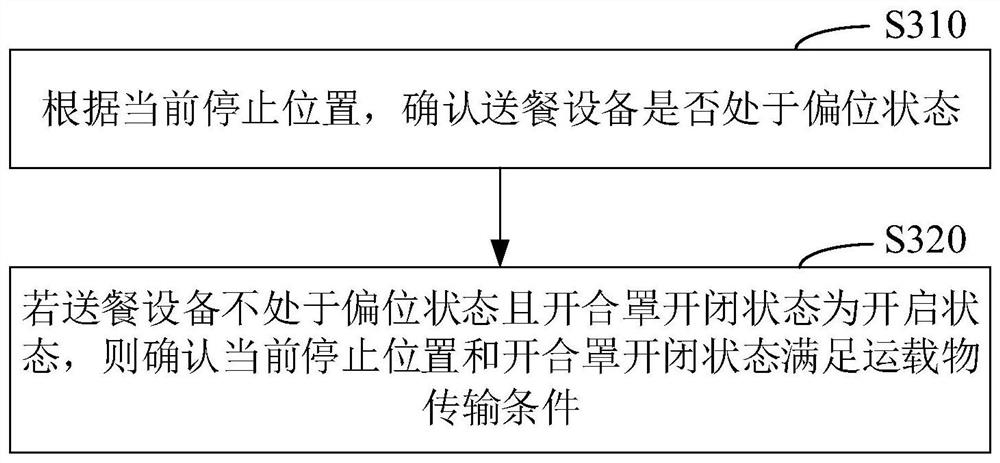

Conveying method of carried objects, meal delivery equipment and storage medium

PendingCN112612271APrevent fallingReduce the risk of fallingScene recognitionPosition/course control in two dimensionsControl engineeringMechanical engineering

The invention relates to a conveying method of carried objects, meal delivery equipment and a storage medium. The conveying method for the carried objects comprises steps that a running state of meal delivery equipment is obtained; wherein the running state comprises a current stop position and an opening and closing state of the opening and closing cover; when it is confirmed that the current stop position and the opening and closing state of the opening and closing cover both meet the conveying condition of the carried objects, the current state of the containing device and the placement position of the carried objects on the meal delivery equipment being obtained; and outputting a push command according to the placement position and the current working state. The method is advantaged in that parking precision of the meal delivery equipment is improved by obtaining the current stop position of the meal delivery equipment, and then the situation that when a follow-up push rod mechanism acts, carried objects fall off due to the fact that the pushing position is inaccurate is prevented; an opening and closing state of the opening and closing cover is obtained to avoid mechanical collision between the push rod mechanism and the opening and closing cover; and a pushing command is outputted according to the placement position and the current working state so as to reduce the risk that the carried object falls off in the pushing process due to the fact that the placement position is not centered.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

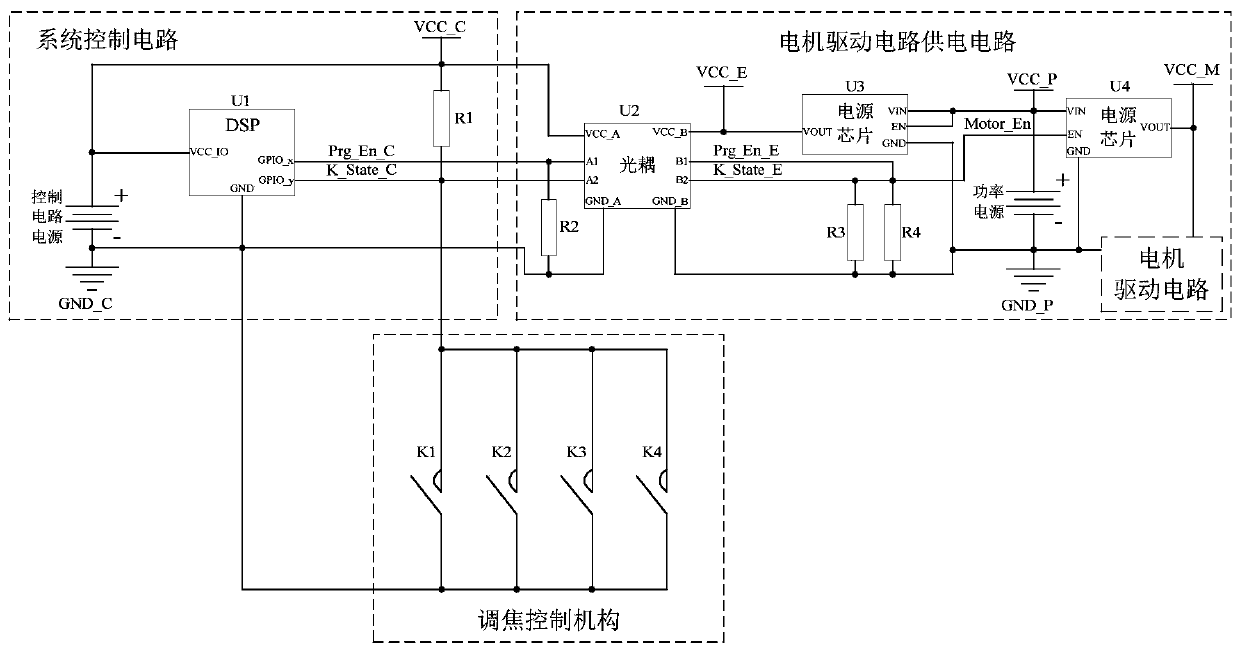

A safety limit control method for focusing mechanism

ActiveCN107678122BMinimize the impact on reliabilityDoes not involve processingMountingsControl systemControl engineering

A safety limit control method for a focus adjustment mechanism, in which a limit switch is installed at the left and right limit positions of at least one stroke interval of the focus adjustment mechanism, and the output ends of all the limit switches are short-circuited to lead out a "limit status feedback" signal , used to drive the GPIO pin of the control system processor and one signal input pin of the dual optocoupler chip; the control system processor receives the "limit status feedback" signal and outputs the "software power-on enable" signal; " Both the "limit status feedback" signal and the "software power-on enable" signal are input to the signal input terminal of the dual-channel optocoupler chip, and are isolated and output by the dual-channel optocoupler chip, and then pulled down to the reference ground of the power supply through a resistor, and then output "Drive circuit power-on enable" signal; when the "drive circuit power-on enable" signal is high level, it provides power to the motor drive circuit; otherwise, cuts off the power supply to realize the safety limit of the focusing mechanism.

Owner:北京长峰科威光电技术有限公司

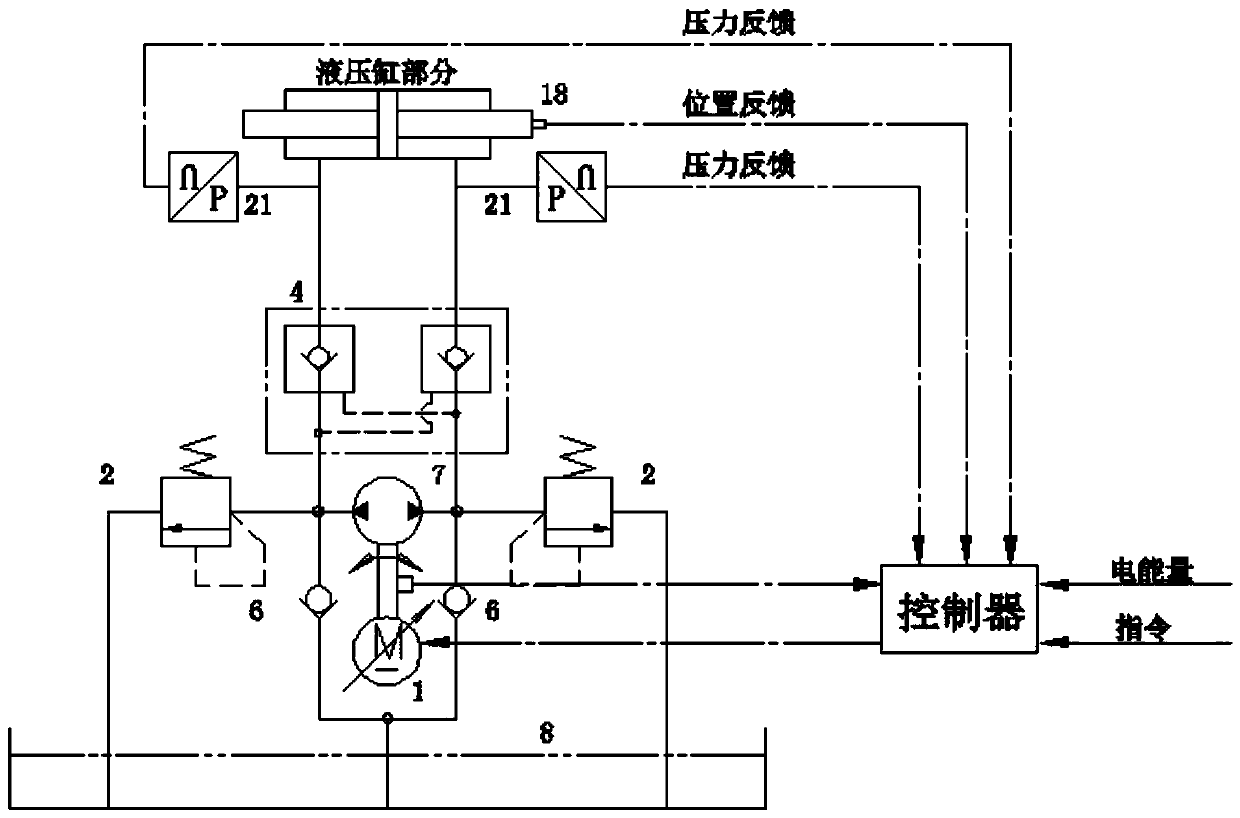

Electrostatic hydraulic actuator for deep sea

ActiveCN109340220BHigh level of integrationReduce volumeFluid-pressure actuator componentsHydraulic circuitHydraulic pump

The invention discloses an electric static liquid actuator for deep sea. An integrated-type integrated structure is adopted. The movement of a hydraulic cylinder is controlled by a two-way hydraulic pump. The forward and reverse of a motor is adjusted and controlled, and the displacement and accelerated speed of a piston rod of the hydraulic cylinder are controlled through speed regulation operation; and a hydraulic direction-changing valve, a reducing valve and other control valves are cancelled, and an arranged sensor monitors and adjusts the working condition of a system. A pressure compensator is arranged outside the system and used for compensating system pressure and adapting high pressure environment of the deep sea. A hydraulic circuit adopts a plate-type connection without external connection pipelines, only an interface for power supply and signal transmission is arranged on the exterior of the hydraulic circuit, the advantages of a hydraulic actuating system and an electricactuating system are both had, system composition is simplified greatly, and the equipment volume is greatly reduced. Therefore, the electric static liquid actuator for the deep sea has a wide application prospect in deep-sea operating equipment and shipping equipment.

Owner:BEIJING UNIV OF TECH

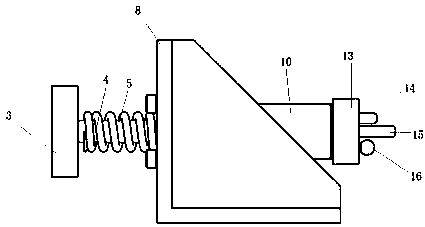

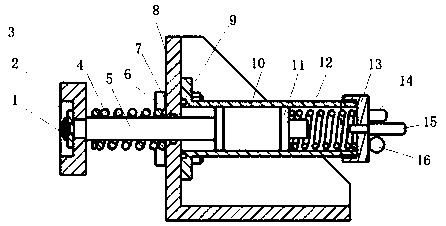

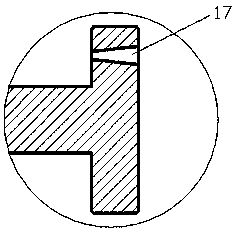

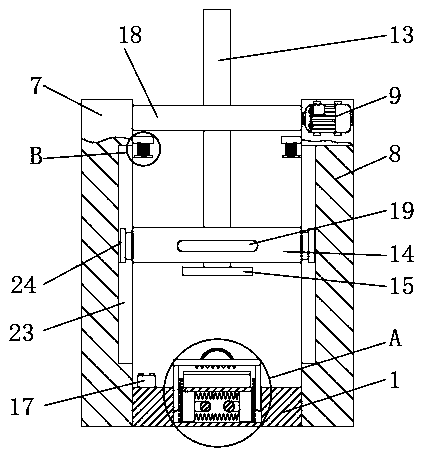

Charging mechanism of robot charging station

ActiveCN111327086AContact stabilityContinuous power supplyBatteries circuit arrangementsCoupling contact membersEngineeringControl theory

The invention relates to the technical field of robot charging, and particularly relates to a charging mechanism of a robot charging station. The charging mechanism comprises a shell, an inner insulating seat, a first microswitch and a second microswitch, wherein the inner insulating seat is arranged in the shell; the first microswitch and the second microswitch are respectively arranged at two sides of the inner insulating seat; a first sliding column and a second sliding column are arranged in the inner insulating seat; the front end of each sliding column is provided with a power connectioncopper bar, and the rear end of each sliding column is provided with a power connection column; each sliding column is sleeved with a spring; the springs are arranged between the rear end of the power connection copper bar and the rear wall of the inner insulating base; trigger blocking columns are arranged on the outer sides of the first sliding column and the second sliding column; the triggerblocking column on the first sliding column is matched with the first microswitch; and the trigger blocking column on the second sliding column is matched with the second microswitch. Stable contact and continuous power supply of the electrodes are guaranteed, walking errors in the autonomous charging process of the robot can be made up, mechanical collision is prevented, the microswitch is additionally arranged for charging confirmation, false triggering is prevented, and the safety is improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

A kind of industrial sewage treatment equipment and using method thereof

ActiveCN112028202BFully contactedImprove flocculation efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusFlocculationProcess engineering

Owner:山东艾普特暖通技术有限公司

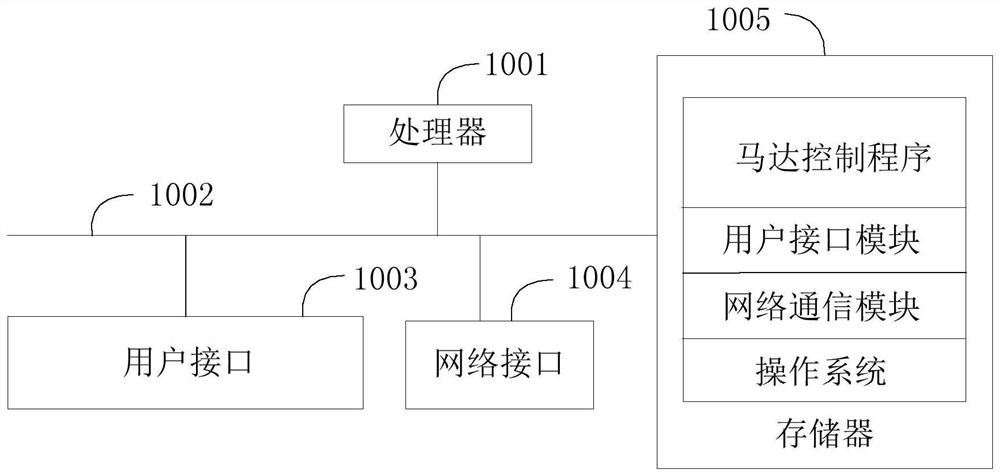

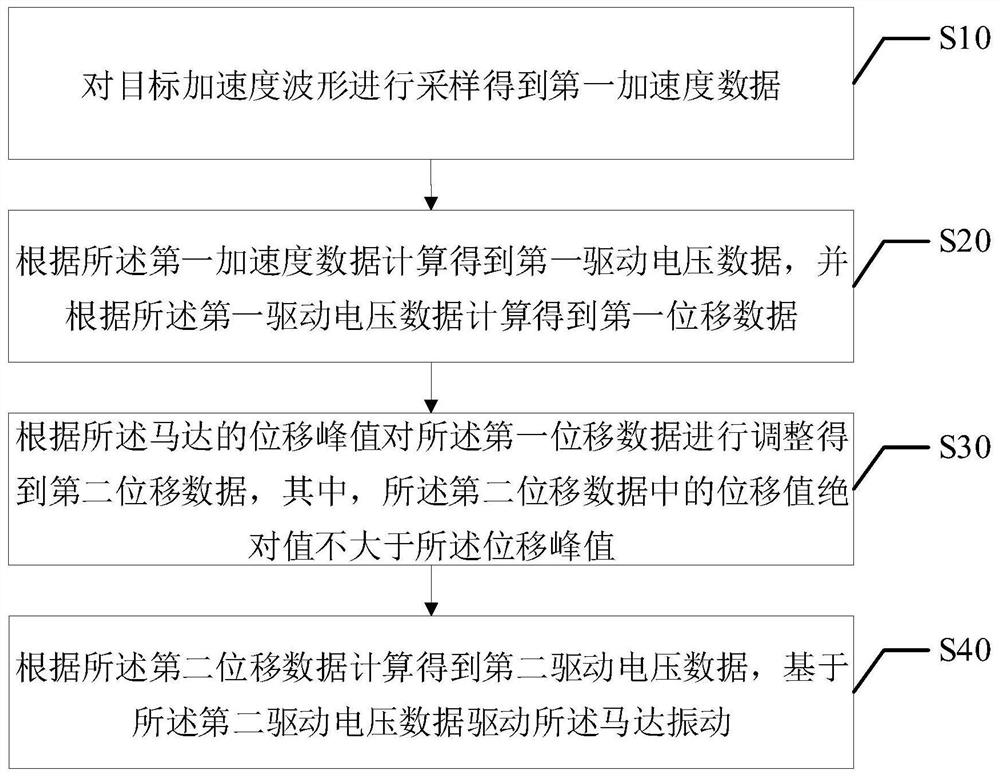

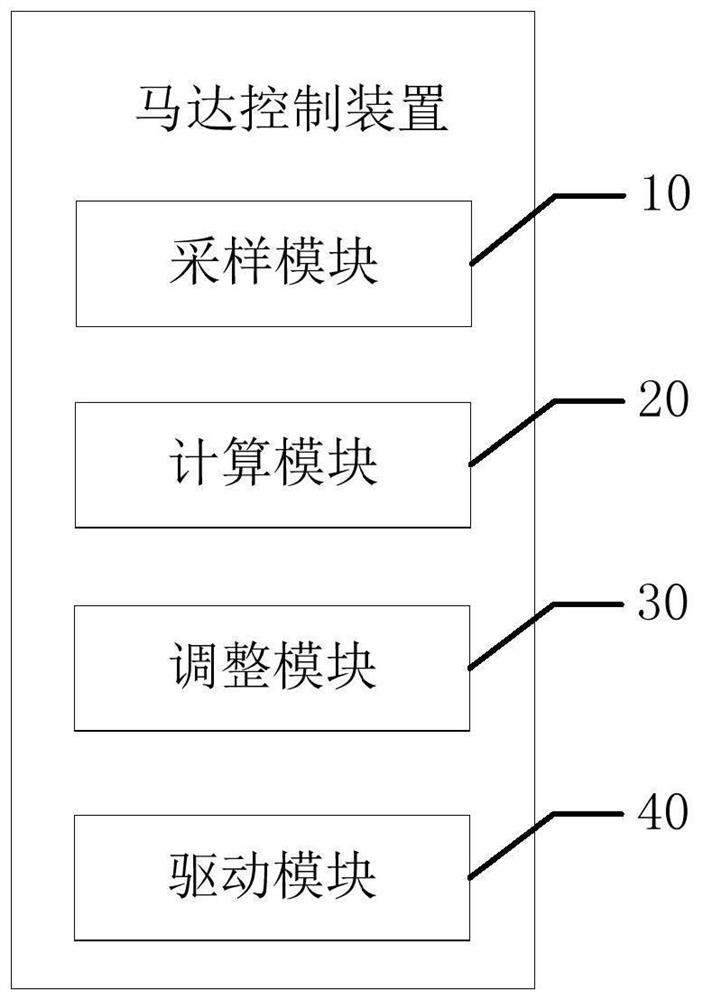

Motor control method, device and equipment and computer readable storage medium

PendingCN113992106AGuaranteed normal vibrationAvoid mechanical collisionMotor parameters estimation/adaptationDrive motorElectrical and Electronics engineering

The invention discloses a motor control method, device and equipment and a computer readable storage medium. The method comprises the following steps: sampling a target acceleration waveform to obtain first acceleration data; calculating first driving voltage data according to the first acceleration data, and calculating first displacement data according to the first driving voltage data; according to a displacement peak value allowed by hardware design of the motor, adjusting the first displacement data to obtain second displacement data, wherein the absolute value of a displacement value in the second displacement data is not larger than the displacement peak value; and calculating second driving voltage data according to the second displacement data, and driving the motor to vibrate based on the second driving voltage data. According to the invention, mechanical collision between the motor vibrator and the shell due to the fact that the driving displacement corresponding to the acceleration waveform exceeds the maximum displacement range allowed by the hardware design of the motor can be avoided, so that performance reduction or damage of the motor can be avoided, and normal vibration of the motor is ensured.

Owner:GOERTEK INC

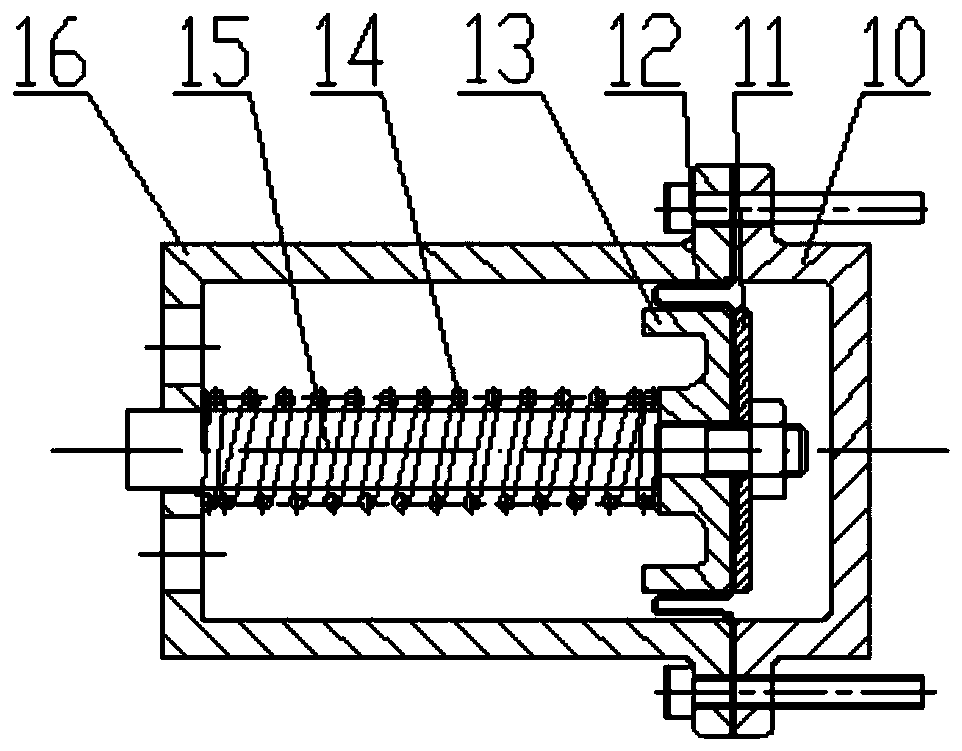

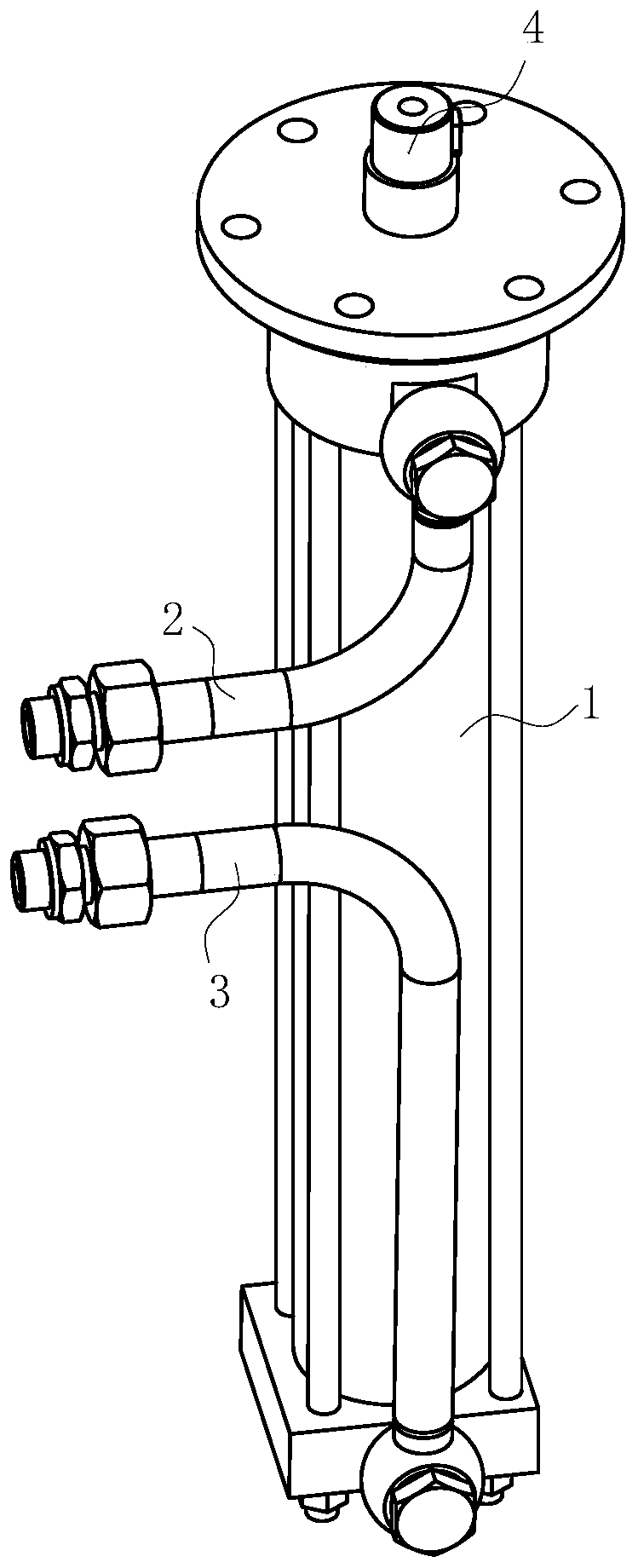

Static pressure supporting and guiding hydraulic cylinder

ActiveCN110792654APlay the role of axial rotation limitAvoid reciprocatingFluid-pressure actuatorsHydraulic cylinderEngineering

The invention belongs to the technical field of hydraulic cylinders, and particularly relates to a static pressure supporting and guiding hydraulic cylinder. The static pressure supporting and guidinghydraulic cylinder comprises a cylinder body, wherein an upper oil pipe and a lower oil pipe are mounted at the upper end and the lower end of the cylinder body, and an oil cavity is formed in the cylinder body; a hydraulic rod is slidably arranged in the oil cavity, and a sealing plug is arranged at the bottom end of the hydraulic rod; an upper end cover is arranged at the upper end of the cylinder body, and a lower end cover is mounted at the lower end of the cylinder body; damping holes for static pressure supporting are formed in the sealing plug and the upper end cover correspondingly; across-shaped guiding groove is formed in the vertical direction of a piston rod, and a cross-shaped guiding strip is fixedly inserted in the cross-shaped guiding groove; a cross-shaped sliding cavityis formed in the vertical direction of the cross-shaped guiding strip, and a guiding sliding rod is slidably inserted in the cross-shaped sliding cavity; the bottom end of the guiding sliding rod isfixed to the lower end cover; the hydraulic rod is formed by splicing a plurality of guiding columns; and the guiding sliding rod can play a role in axial rotation limiting on the cross-shaped guidingstrip, and thus the extending hydraulic rod can only slide in the cylinder body in a reciprocating mode and cannot axially rotate in the cylinder body.

Owner:烟台星辉劳斯堡液压机械有限公司

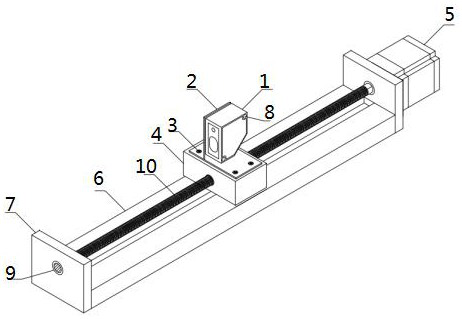

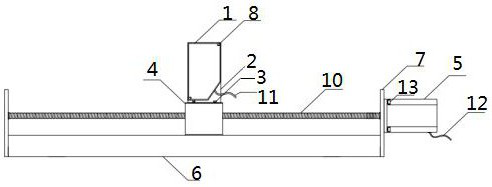

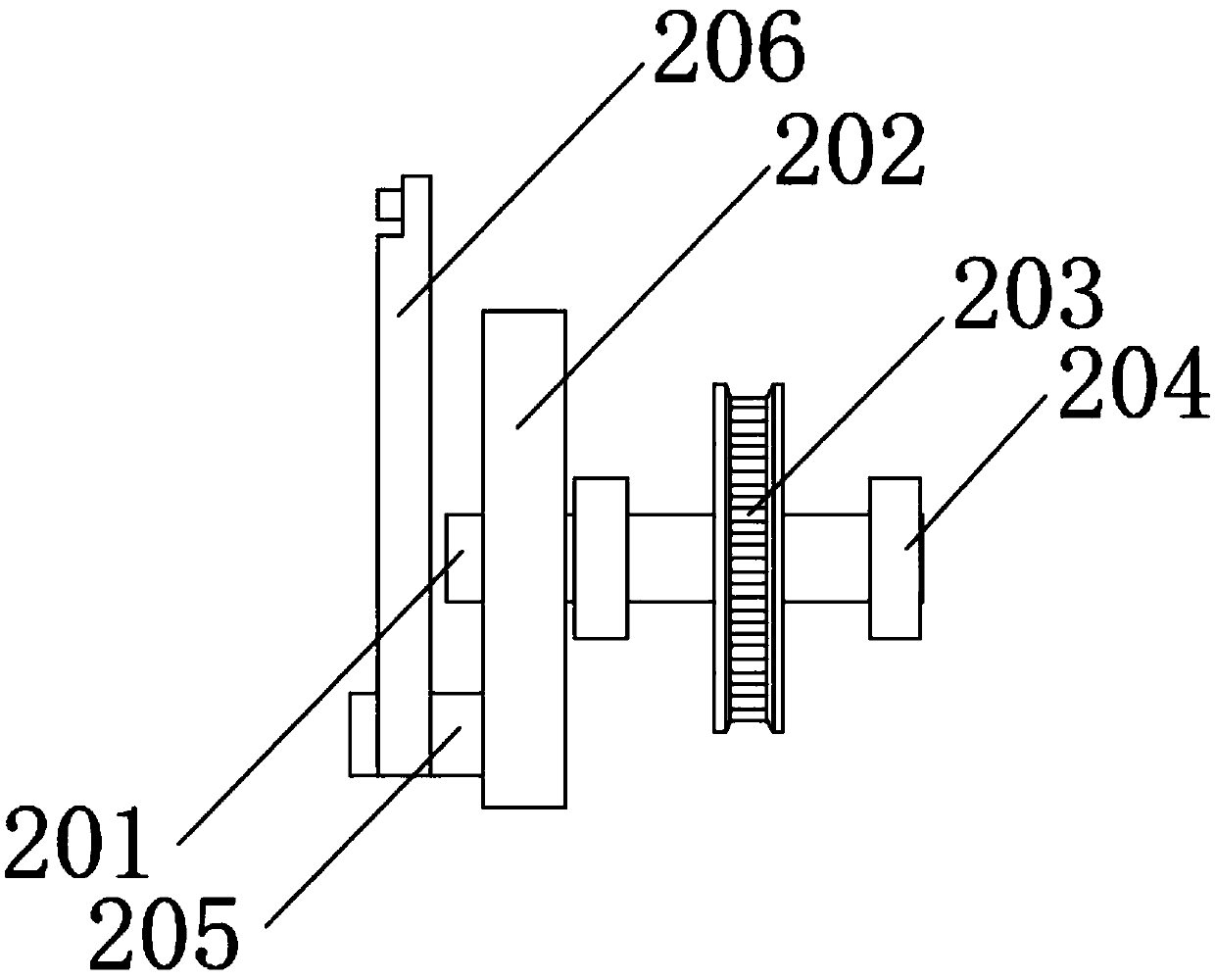

Sliding table type laser displacement sensor and sensor system comprising same

InactiveCN114184128AAccurate measurementGuaranteed accuracy and stabilityUsing optical meansLaser transmitterSensor system

The invention discloses a sliding table type laser displacement sensor and a sensor system comprising the sliding table type laser displacement sensor, the sliding table type laser displacement sensor comprises a sliding rail base, a ball screw, ball screw supporting pieces and a motor, the ball screw supporting pieces are fixedly connected to the two sides of the sliding rail base, the ball screw is erected between the two ball screw supporting pieces, and the motor is arranged on the sliding rail base. The ball screw is rotationally connected with the ball screw supporting piece, the ball screw is in driving connection with the motor, the motor is fixedly connected with the ball screw supporting piece, the ball screw is sleeved with the sliding block, the sliding block is fixedly connected with the laser transmitter, and the laser transmitter is used for collecting distance signals between the laser transmitter and a measured object. The sliding table type laser displacement sensor has the advantages of being simple in structure, convenient to install, high in reliability and flexible and accurate in measurement process.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Flexible obstacle avoidance method, system and terminal equipment for a robotic arm

ActiveCN108161939BAvoid mechanical collisionGuaranteed integrityProgramme-controlled manipulatorFailure rateSimulation

The invention relates to the technical field of control of mechanical arms, and provides a flexible obstacle avoidance method and system of a mechanical arm, and terminal equipment. The method comprises the steps of detecting the information of a joint, judging whether the moving state of the mechanical arm is changed suddenly; judging the amplitude of sudden change exceeds the corresponding sudden change threshold value or not when the moving state of the mechanical arm is changed suddenly; and controlling the mechanical arm to avoid an obstacle according to the amplitude of sudden change when the amplitude of sudden change exceeds the corresponding sudden change threshold value, specifically, the intelligent obstacle avoidance comprises the step of reducing the joint rigidity and / or changing the original moving state of the mechanical arm. The method can effectively avoid direct mechanical collision between the mechanical arm and the obstacle, ensure integrity of the mechanical arm and reduce the failure rate of the mechanical arm.

Owner:SHENZHEN YUEJIANG TECH CO LTD

Intelligent grinding device for environment-friendly machining

ActiveCN109015218BAddresses an issue where cleaning collections did not perform wellEasy to useGrinding machinesGrinding/polishing safety devicesEngineeringSlide plate

Owner:泉州市信贵机械设备有限公司

A collision warning device for a manipulator

ActiveCN111823280BPlay a protective effectAchieve the effect of graded touch warningProgramme-controlled manipulatorRobot handSimulation

The invention discloses a manipulator collision prompting device, which belongs to the technical field of manipulator manufacturing, and specifically includes: a frame and an anti-collision assembly arranged in a support mechanism, the anti-collision assembly includes a support plate, and is fixed to the top of the support plate. The connecting slide bar and the pressing plate fixed on the edge of the support plate, the top end of the slide bar is located in the frame and is slidingly matched with the frame, the outside of the slide bar is covered with a spring, and the The two ends of the spring are in contact with the frame and the supporting plate respectively, and a plurality of contact switches are provided on the frame corresponding to the pressing plate, and the plurality of contact switches are respectively connected to warning devices in corresponding states, The warning device is controlled according to the pressing plate touching the contact switch to give graded warnings. The present invention moves different distances of the pressing plate to respectively press different contact switches, and then activates different warning devices, which can effectively achieve the effect of graded touch warning.

Owner:WUHAN ZNION TECH CO LTD

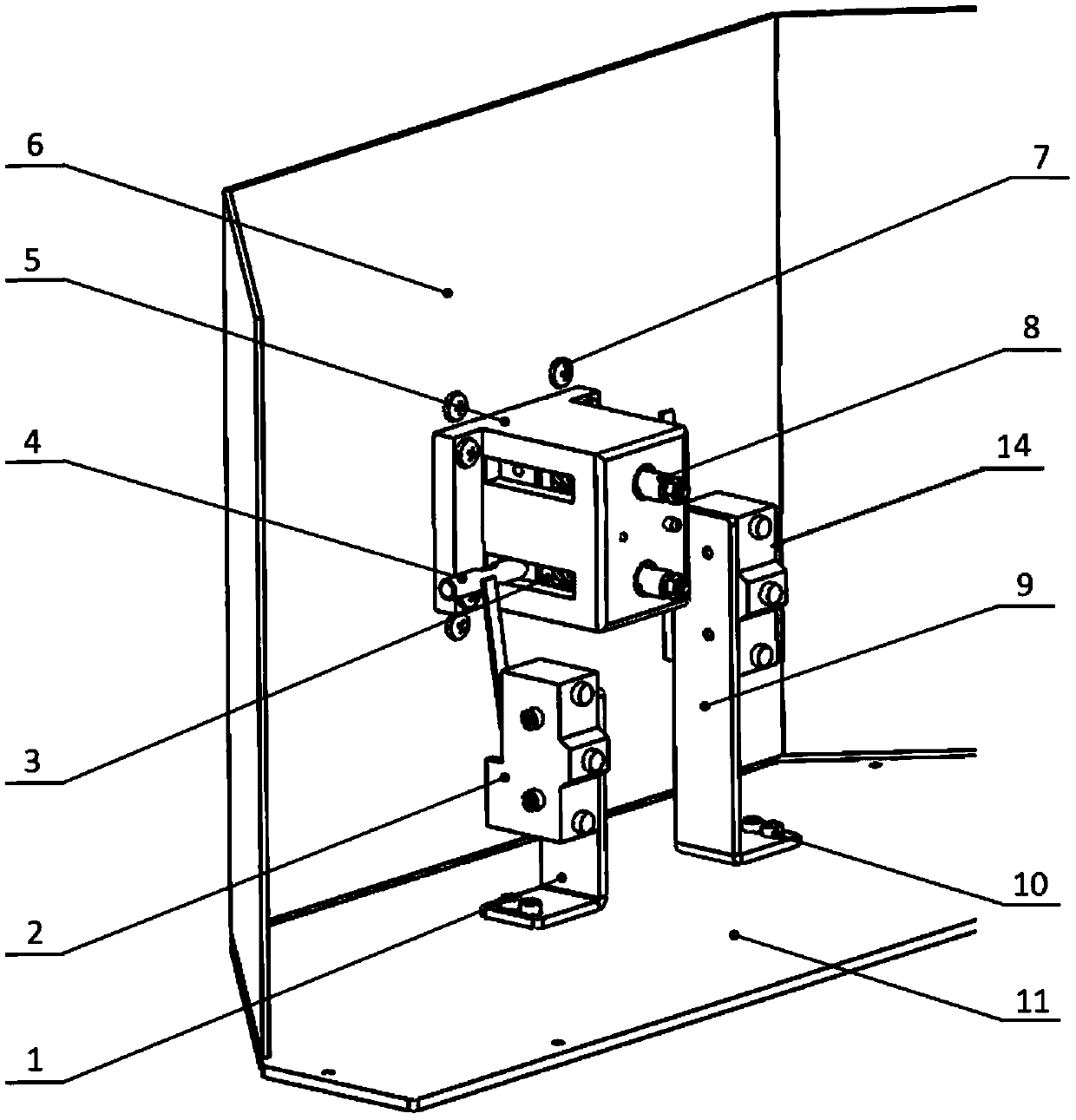

Manipulator collision prompting device

ActiveCN111823280APlay a protective effectAchieve the effect of graded touch warningProgramme-controlled manipulatorStructural engineeringManipulator

The invention discloses a manipulator collision prompting device, and belongs to the technical field of manipulator production and manufacturing. The manipulator collision prompting device particularly comprises a rack and an anti-collision assembly arranged in a supporting mechanism, wherein the anti-collision assembly comprises a supporting plate, a sliding rod fixedly connected with the top ofthe supporting plate and a pressing plate fixedly arranged on the edge of the supporting plate, the top end of the sliding rod is located in the rack and is in sliding fit with the rack, the outer side of the sliding rod is sleeved with a spring, the two ends of the spring abut against the rack and the supporting plate, a plurality of contact switches are arranged at the positions, corresponding to the pressing plate, of the rack, the plurality of contact switches are connected with warning devices in corresponding states, and the warning devices are controlled to perform graded warning according to the fact that the pressing plate touches the contact switches. According to the manipulator collision prompting device, different contact switches are pressed by moving the pressing plate by different distances, then different warning devices are started, and the graded touch warning effect can be effectively achieved.

Owner:WUHAN ZNION TECH CO LTD

Seats, especially armrests for vehicle seats

Owner:GRAMMER AG

Intelligent locating pin

ActiveCN110138137AExtend working lifeAvoid the possibility of magnetizationSingle motor speed/torque controlSwitch power arrangementsEngineeringPosition sensor

The invention relates to an intelligent locating pin, belongs to the technical field of electronic equipment control, and solves the technical problems of mechanical failure and low reliability existing in the existing locating pin control technology. The technical scheme is as follows: the intelligent locating pin comprises a housing, a lead screw drive device, a brushless DC motor, a position sensor and a control module. The housing comprises a main housing, a front cover plate, an electrical support and a rear cover. The front cover plate is arranged on one side of the main housing. The rear cover is arranged on the other side of the main housing. The electrical support is arranged in the internal cavity of the rear cover. The electrical support is fixed between the rear cover and the main housing. A drive device through hole is arranged in the middle of the front cover plate. A dust cover is arranged on the front cover plate of the outer side of the drive device through hole. The intelligent locating pin has the advantages of simple structure, convenient operation, avoiding mechanical failure and high reliability.

Owner:山西泰润达科技有限公司

Vertical lifting feeding system of automatic packaging machine for beef jerky

PendingCN109515826AImprove work efficiencyAvoid accumulationPackagingReciprocating motionElectric machinery

The invention provides a vertical lifting feeding system of an automatic packaging machine for beef jerky and relates to the technical field of beef jerky packaging. The vertical lifting feeding system of the automatic packaging machine for the beef jerky comprises feeding system main equipment. A vertical lifting device is arranged inside an inner chamber of the feeding system main equipment. A material collection box device is arranged at the position, corresponding to the vertical lifting device, of the top of the feeding system main equipment. A feeding device is arranged at one side of the feeding system main equipment. A power motor device is arranged at the bottom of the feeding device. An eccentric wheel is connected with a driving connecting rod; the driving connecting rod drivesan adjustable material collection box; when the eccentric wheel rotates, the driving connecting rod can perform rotary motion; by means of the driving connecting rod which performs rotary motion, it can be guaranteed that the adjustable material collection box performs reciprocating motion; rapid intermittent type feeding can be achieved for the automatic packaging machine through the adjustable material collection box; in addition, by means of the reciprocating motion of the adjustable material collection box, piling of the beef jerky or insufficient feeding can be prevented; and the work efficiency of the automatic packaging machine is improved.

Owner:重庆莉莱食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com