Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Avoid heavy force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

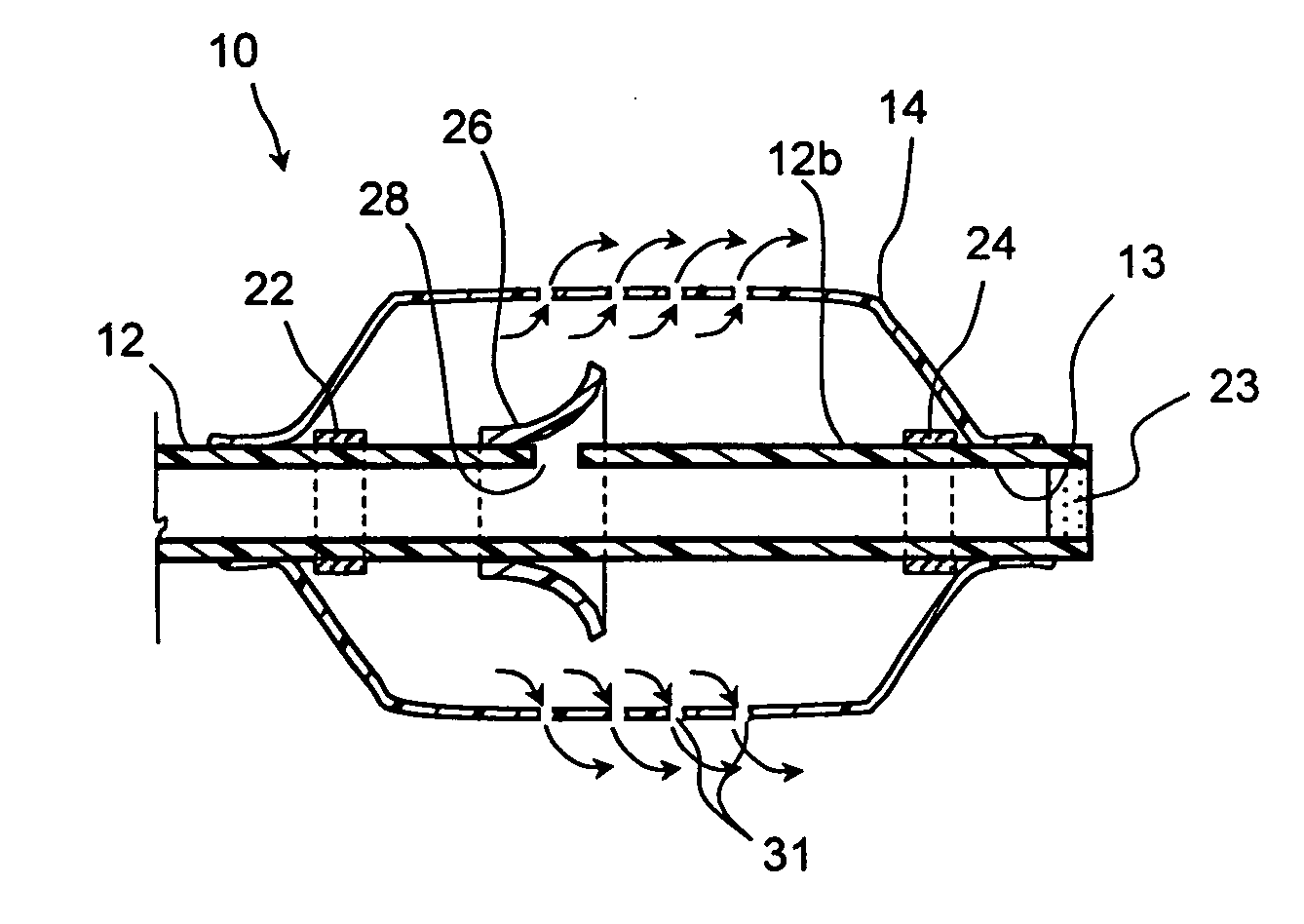

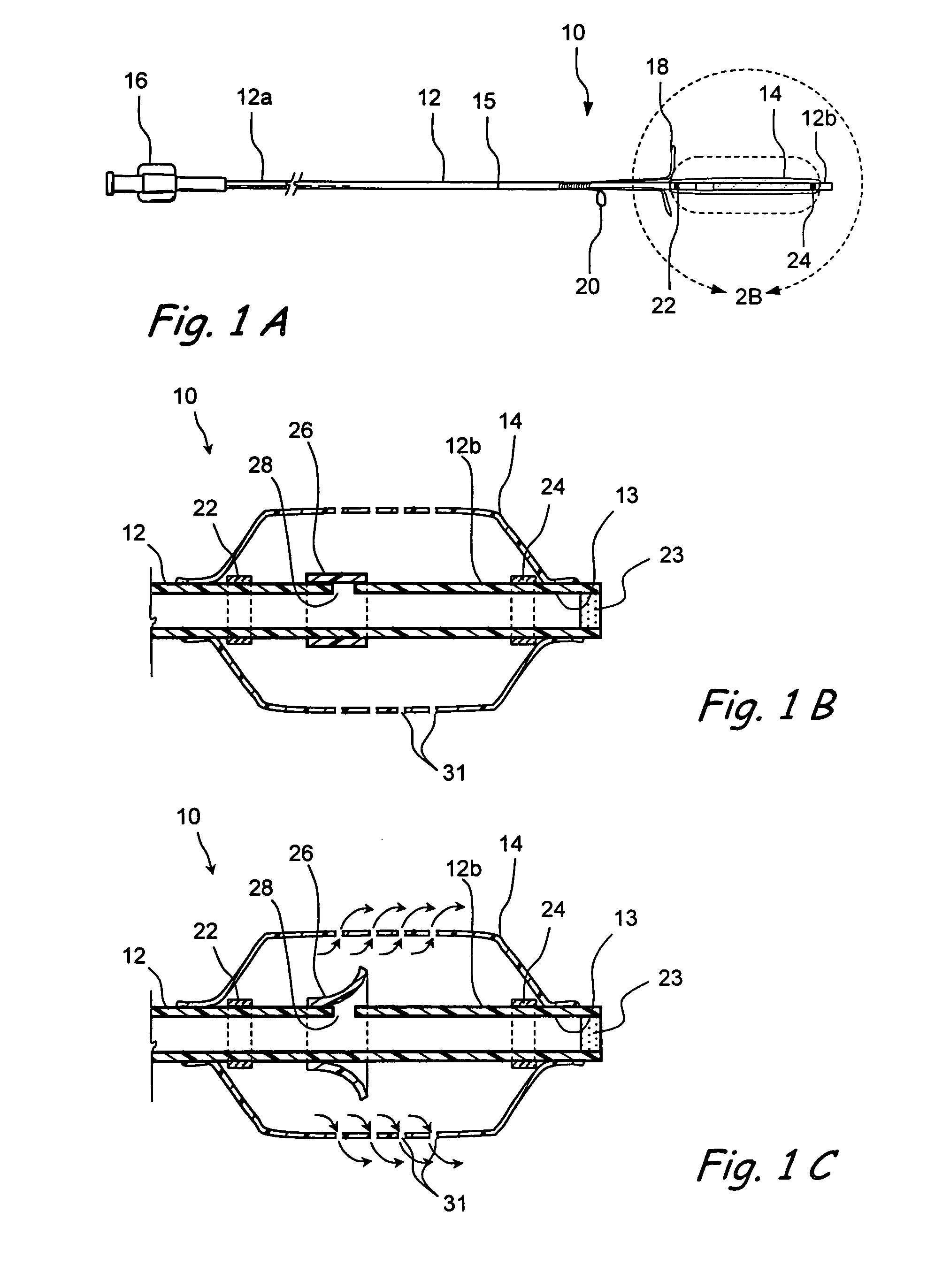

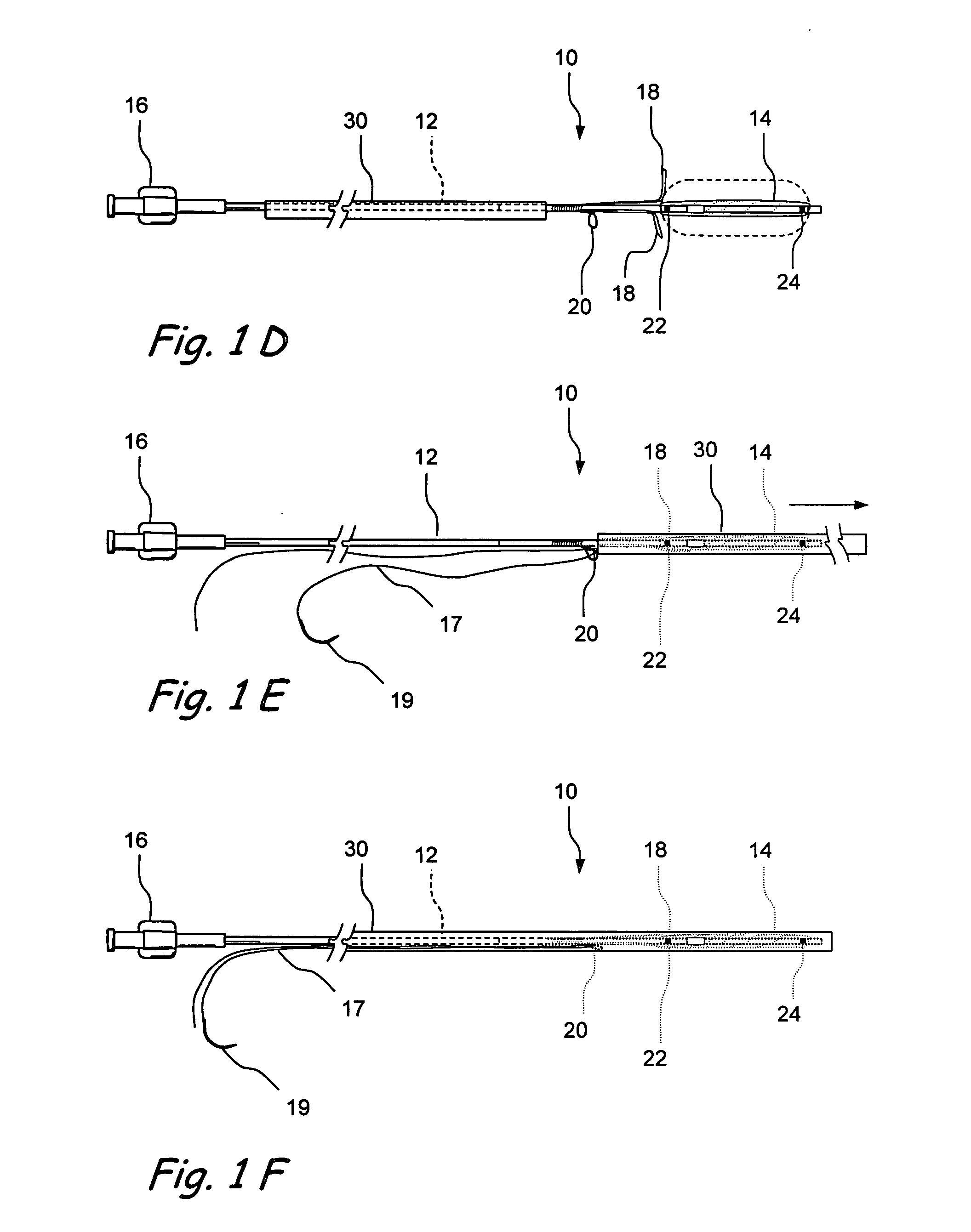

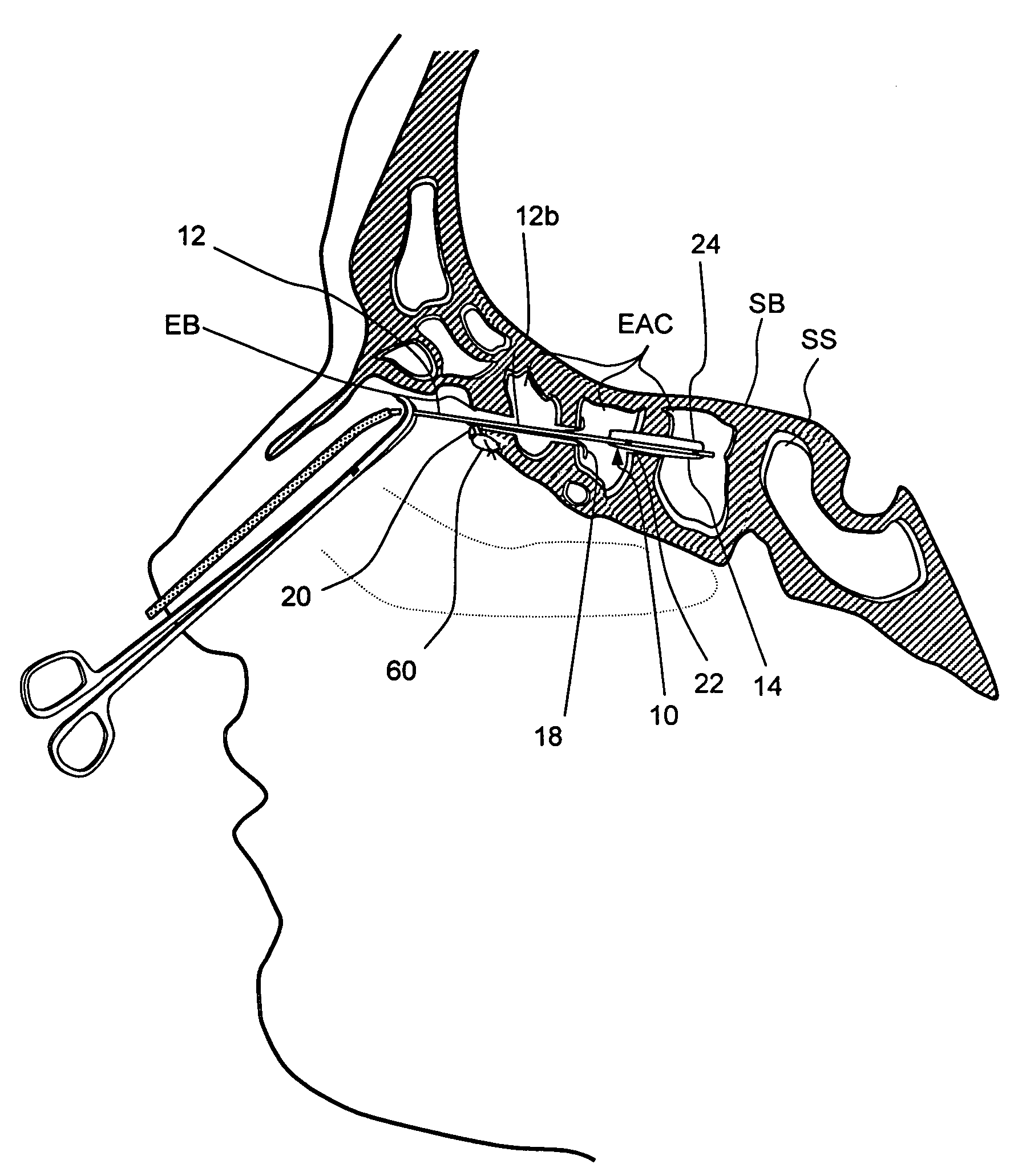

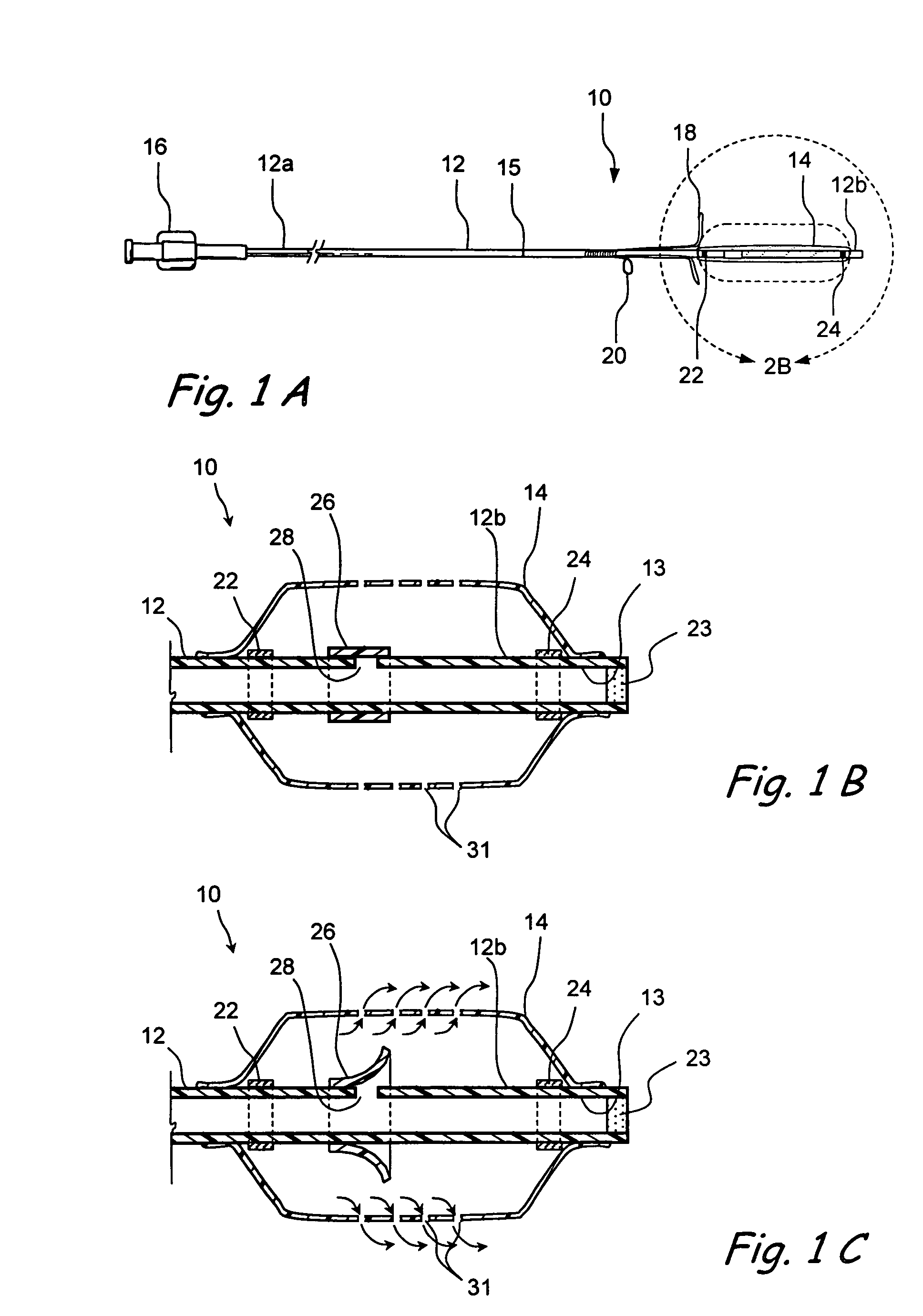

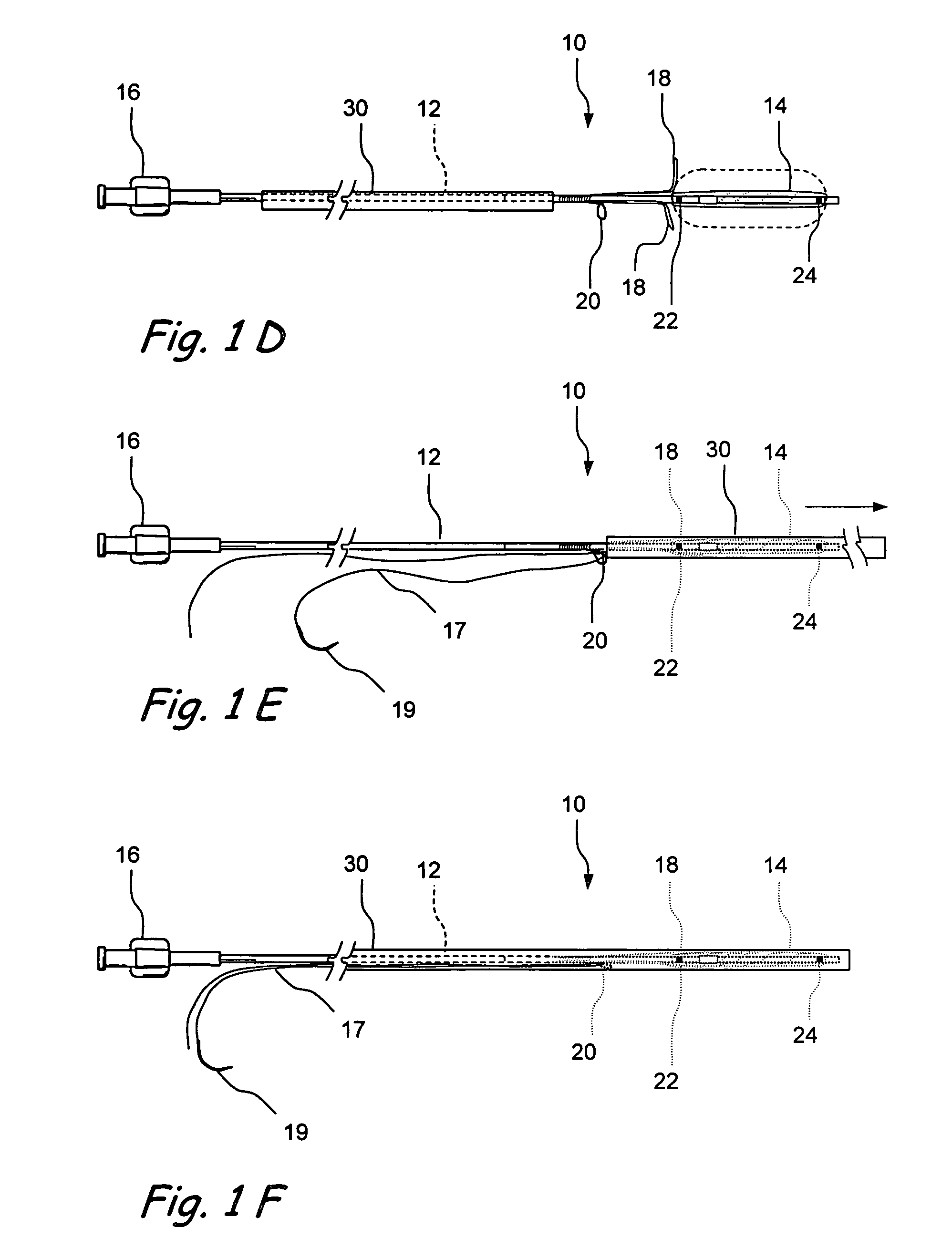

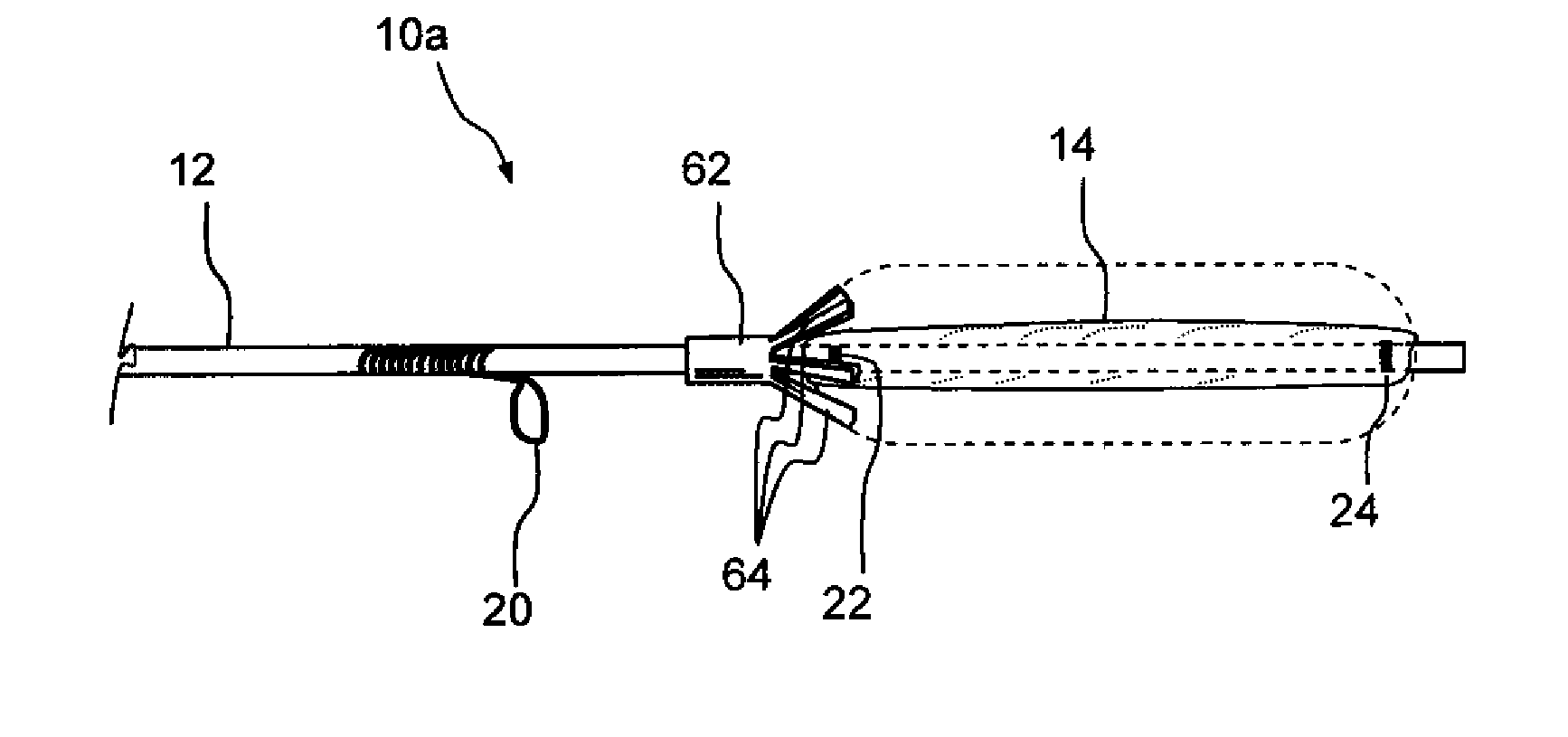

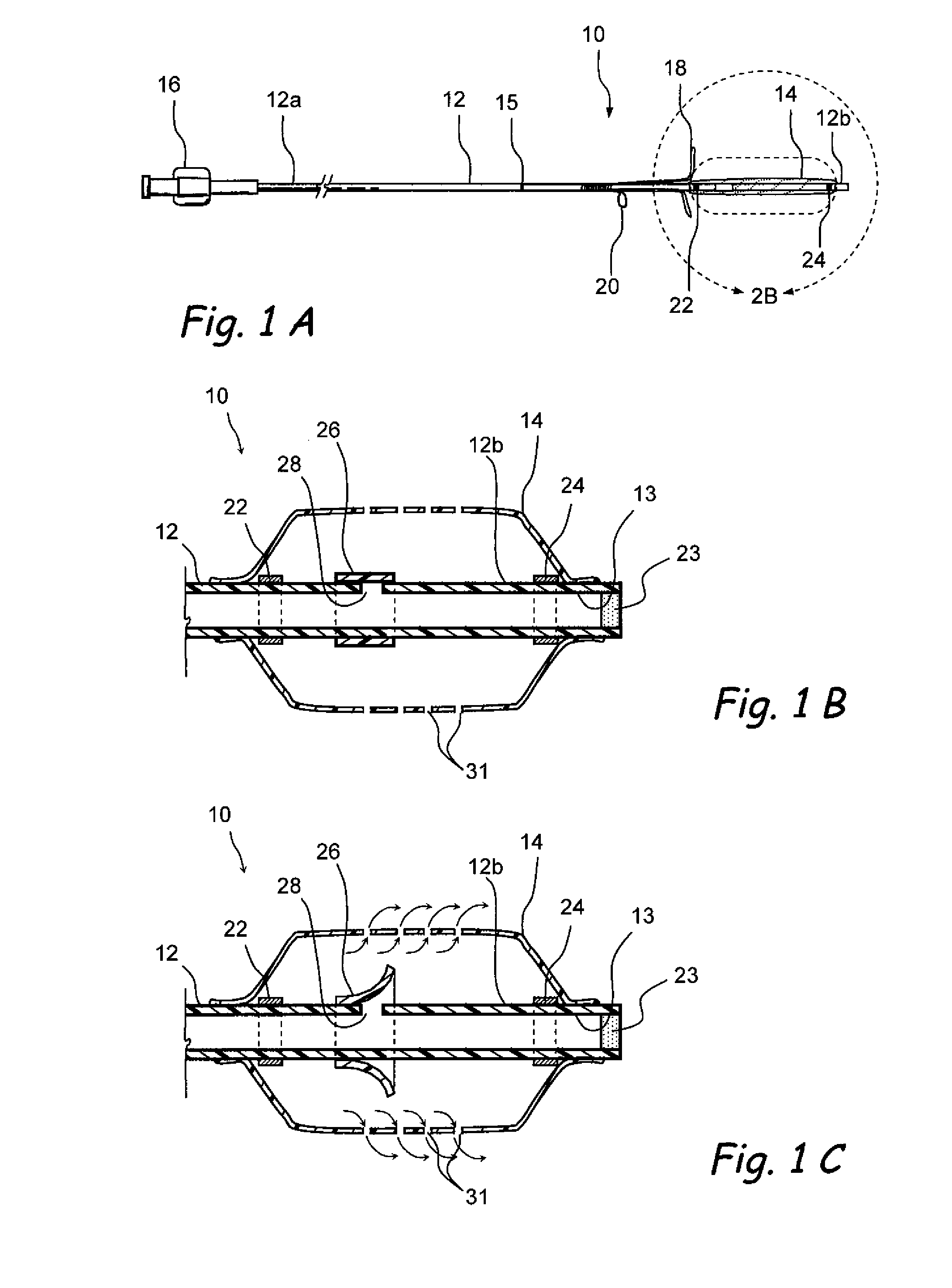

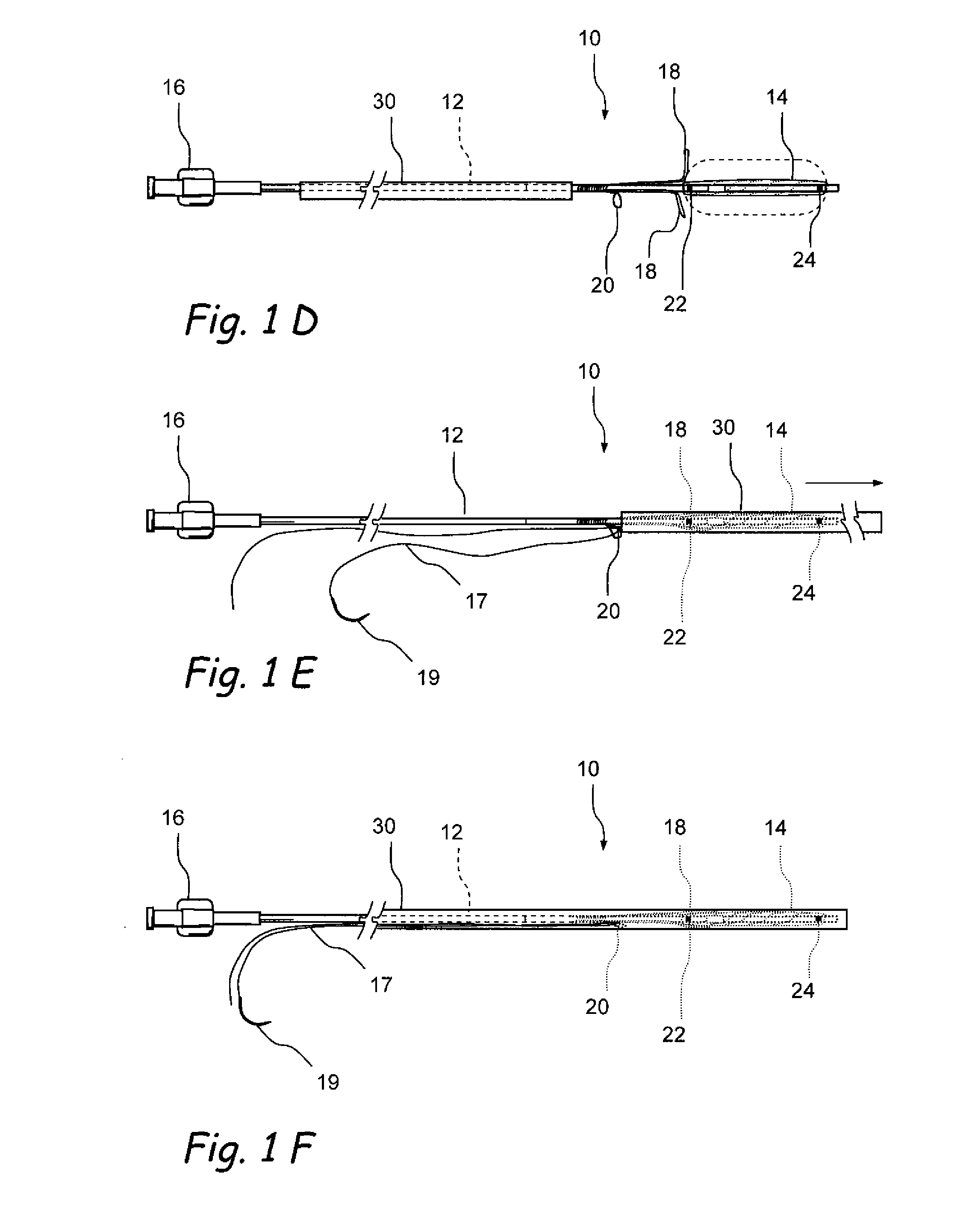

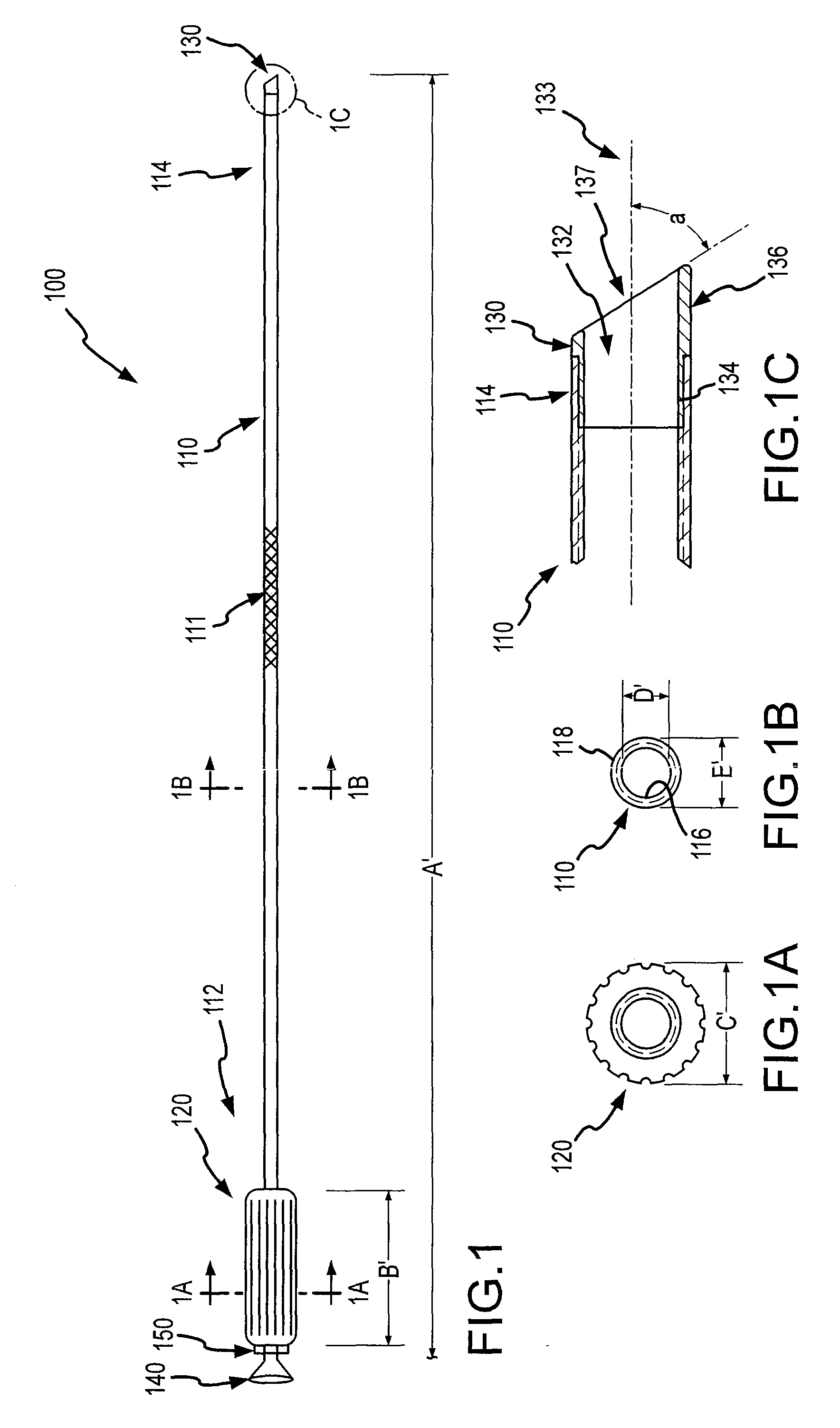

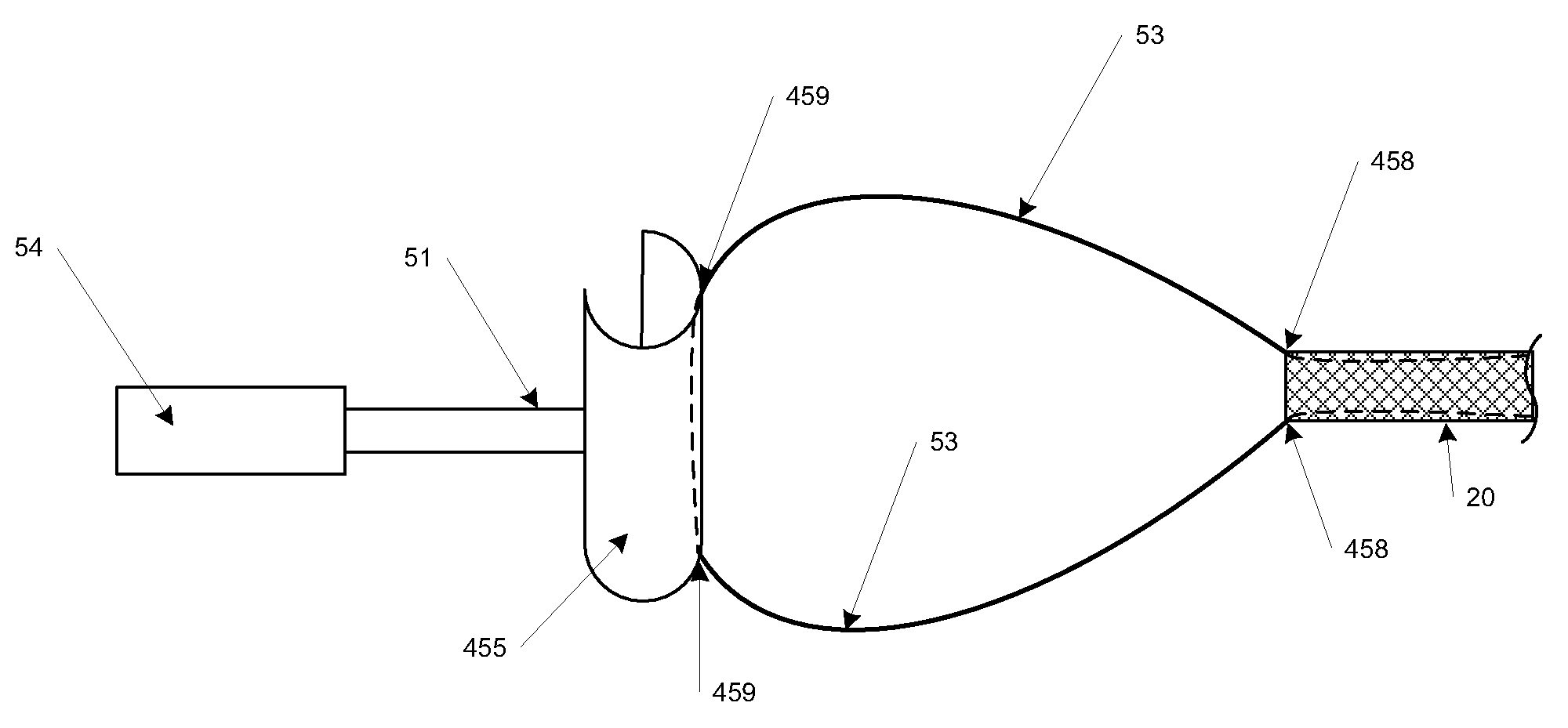

Implantable devices and methods for treating sinusitis and other disorders

ActiveUS20080015540A1Low profileMinimize traumaGuide needlesBalloon catheterParanasal sinusitisDisease

Devices, systems and methods for stenting, spacing, draining, ventilating and / or delivering drugs and other therapeutic or diagnostic substances to desired locations within the bodies of human or non-human animal subjects, including methods and systems for treating paranasal sinusitis and ethmoid disease.

Owner:ACCLARENT INC

Methods for treating ethmoid disease

ActiveUS7419497B2Low profileMinimize traumaGuide needlesBalloon catheterParanasal sinusitisHuman animal

Devices, systems and methods for stenting, spacing, draining, ventilating and / or delivering drugs and other therapeutic or diagnostic substances to desired locations within the bodies of human or non-human animal subjects, including methods and systems for treating paranasal sinusitis and ethmoid disease.

Owner:ACCLARENT INC

Implantable Devices and Methods for Treating Sinusitis and Other Disorders

ActiveUS20090028923A1Low profileMinimize traumaGuide needlesBalloon catheterParanasal sinusitisDisease

Owner:ACCLARENT INC

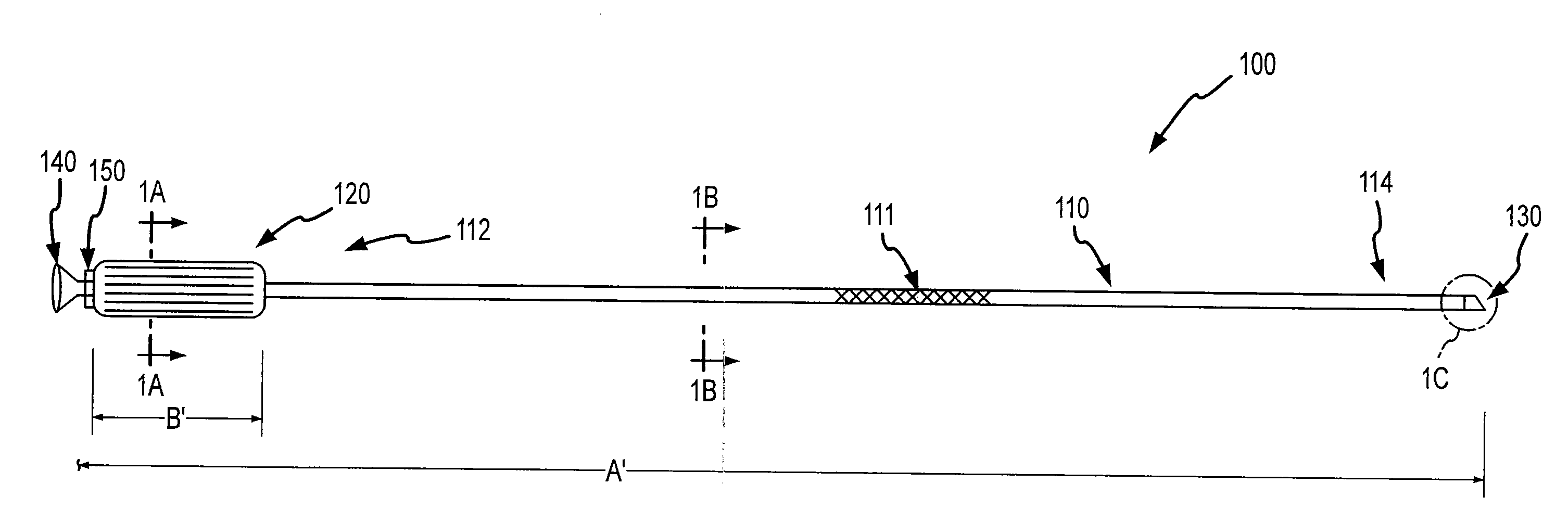

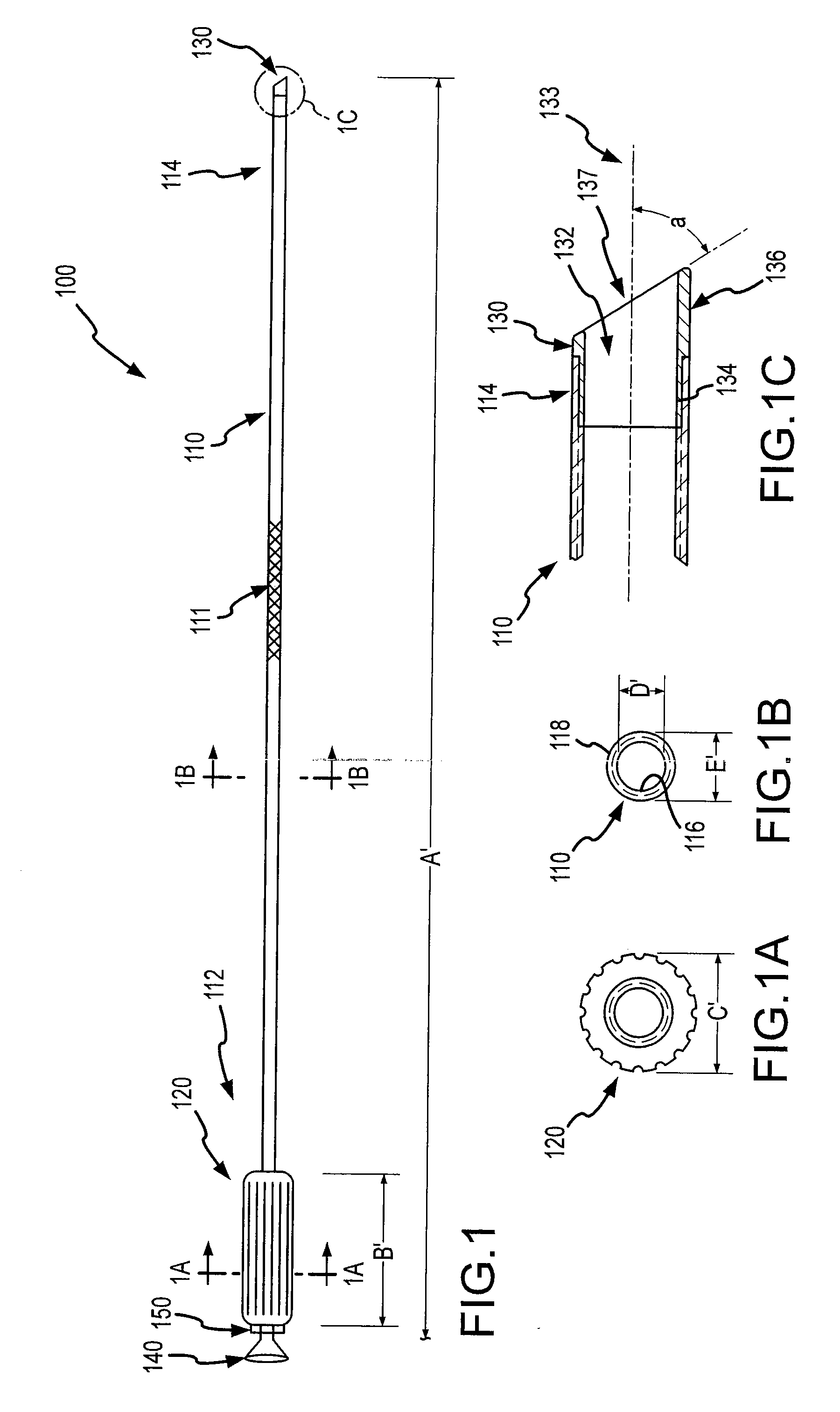

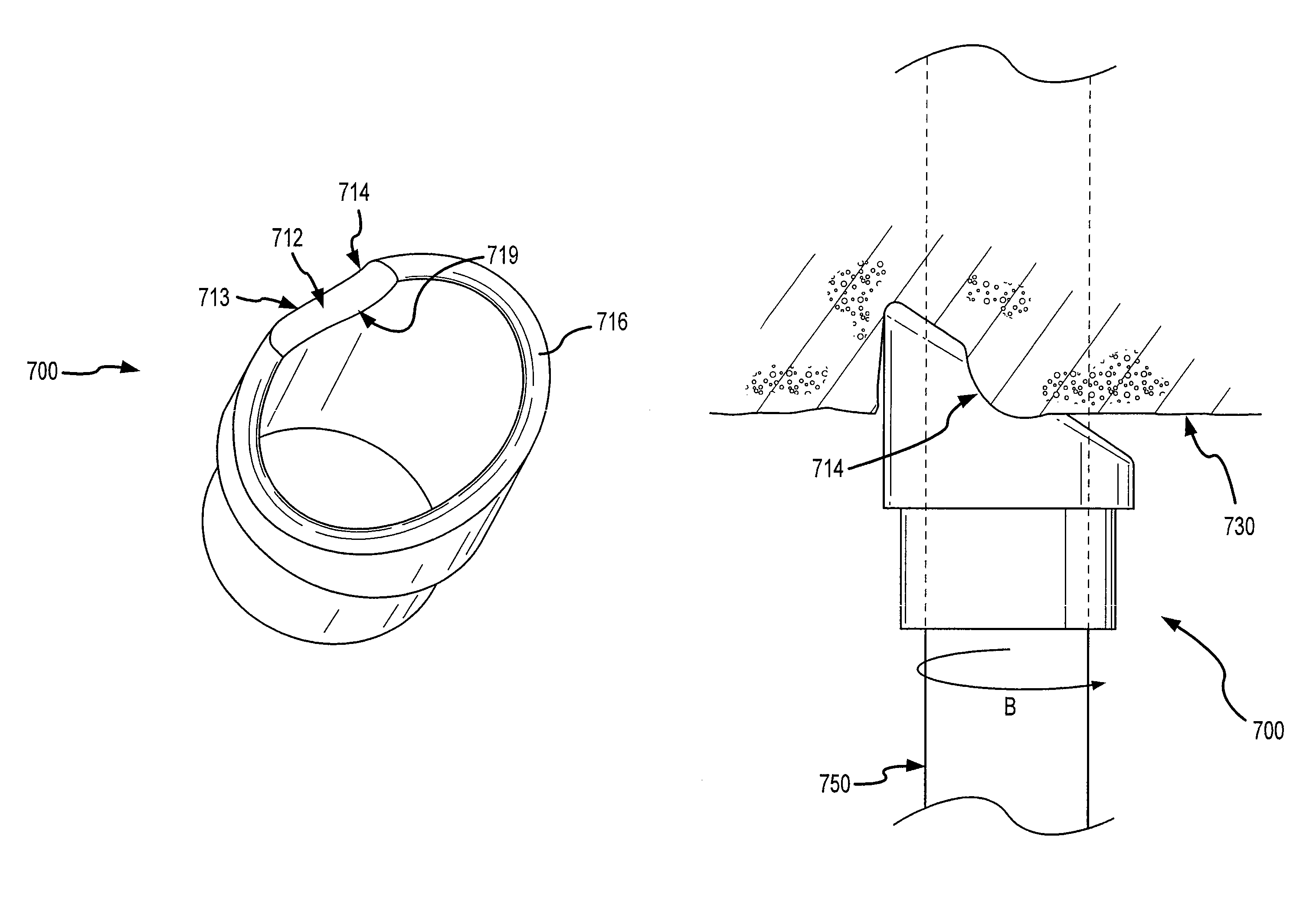

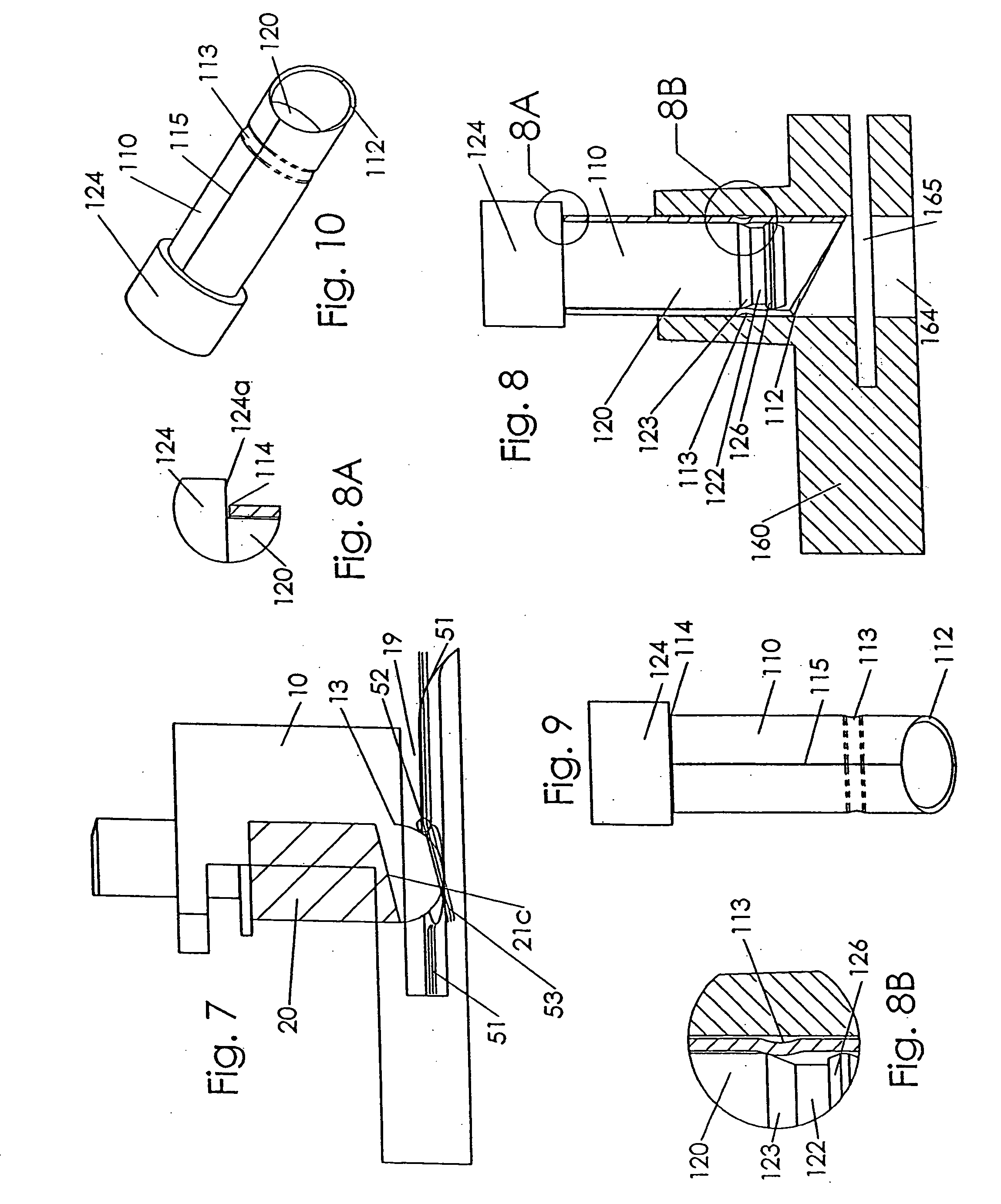

Tissue Separating Systems and Methods

ActiveUS20080154296A1Smooth connectionReduce morbidityTransvascular endocardial electrodesBlunt dissectorsEngineeringBiomedical engineering

Systems and methods for separating an object such as a pacing lead from a patient tissue involve a flexible and torqueable shaft having an internal lumen sized to receive the object, and a hard separating mechanism for separating the object from the tissue. Typically the shaft and separating mechanism are advanced along or toward the object, and the separating mechanism is contacted with the tissue. The shaft is rotated to effect separation between the object and the tissue. The systems and methods are well suited for use in cardiac pacing or defibrillator lead explant procedures.

Owner:SPECTRANETICS

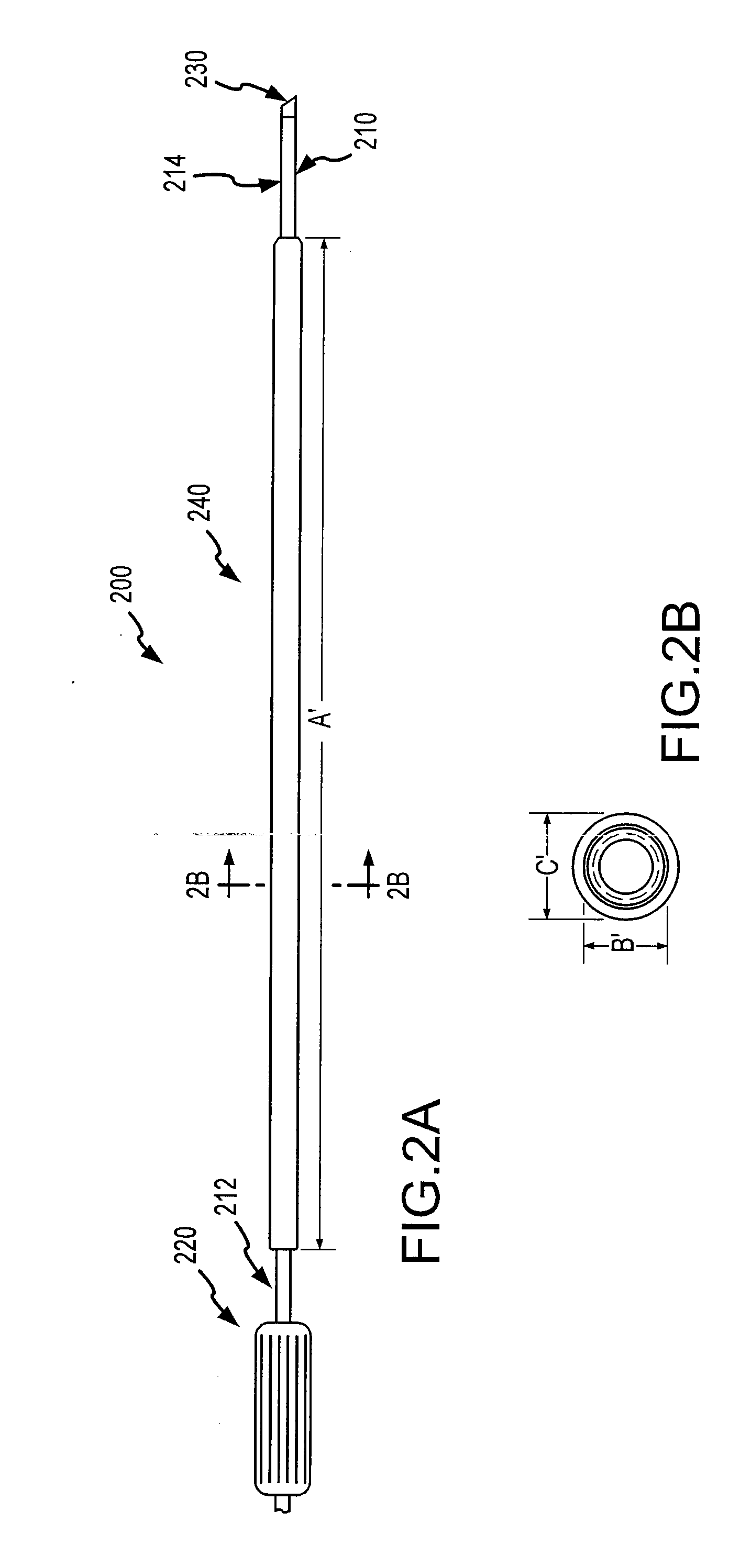

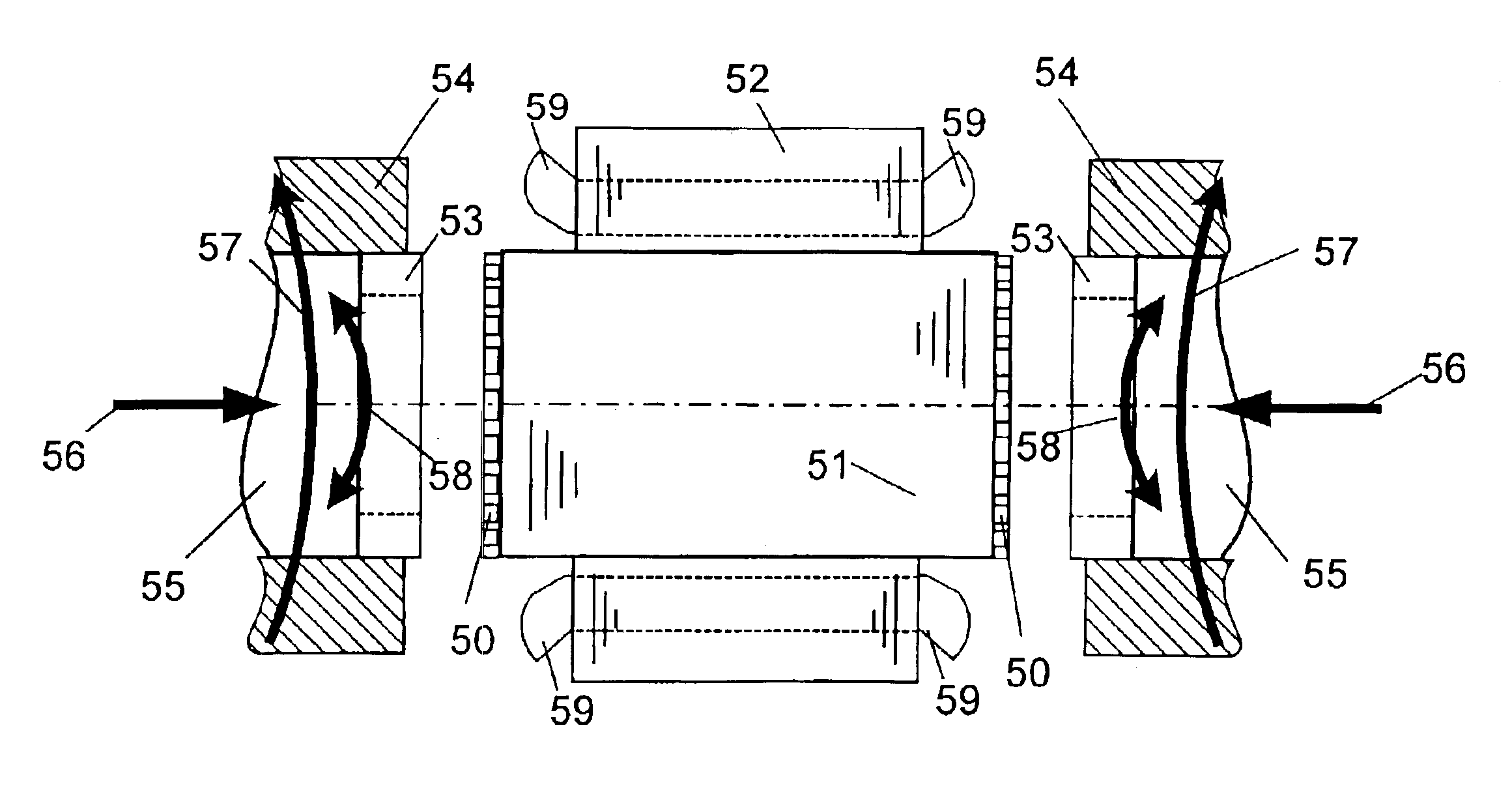

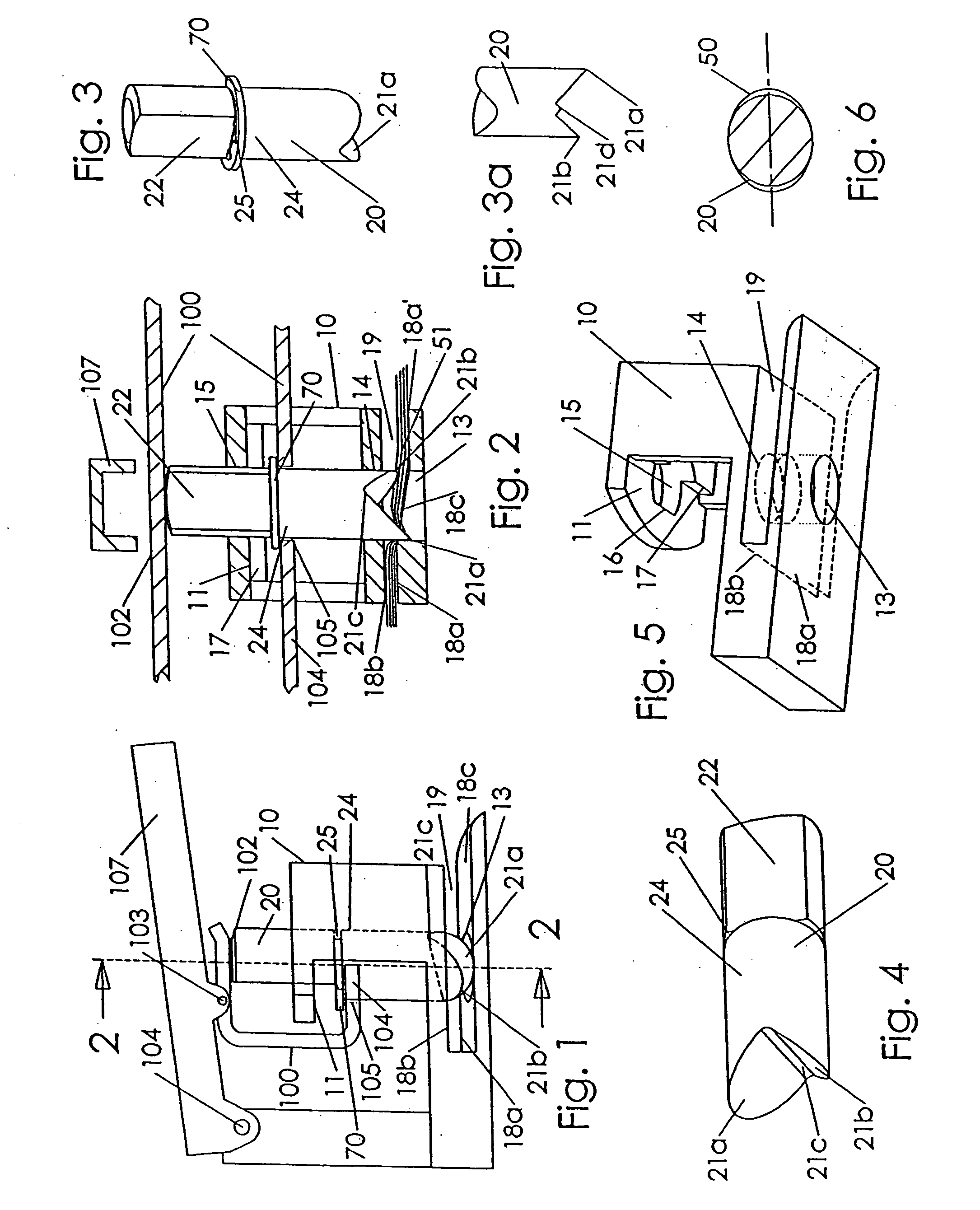

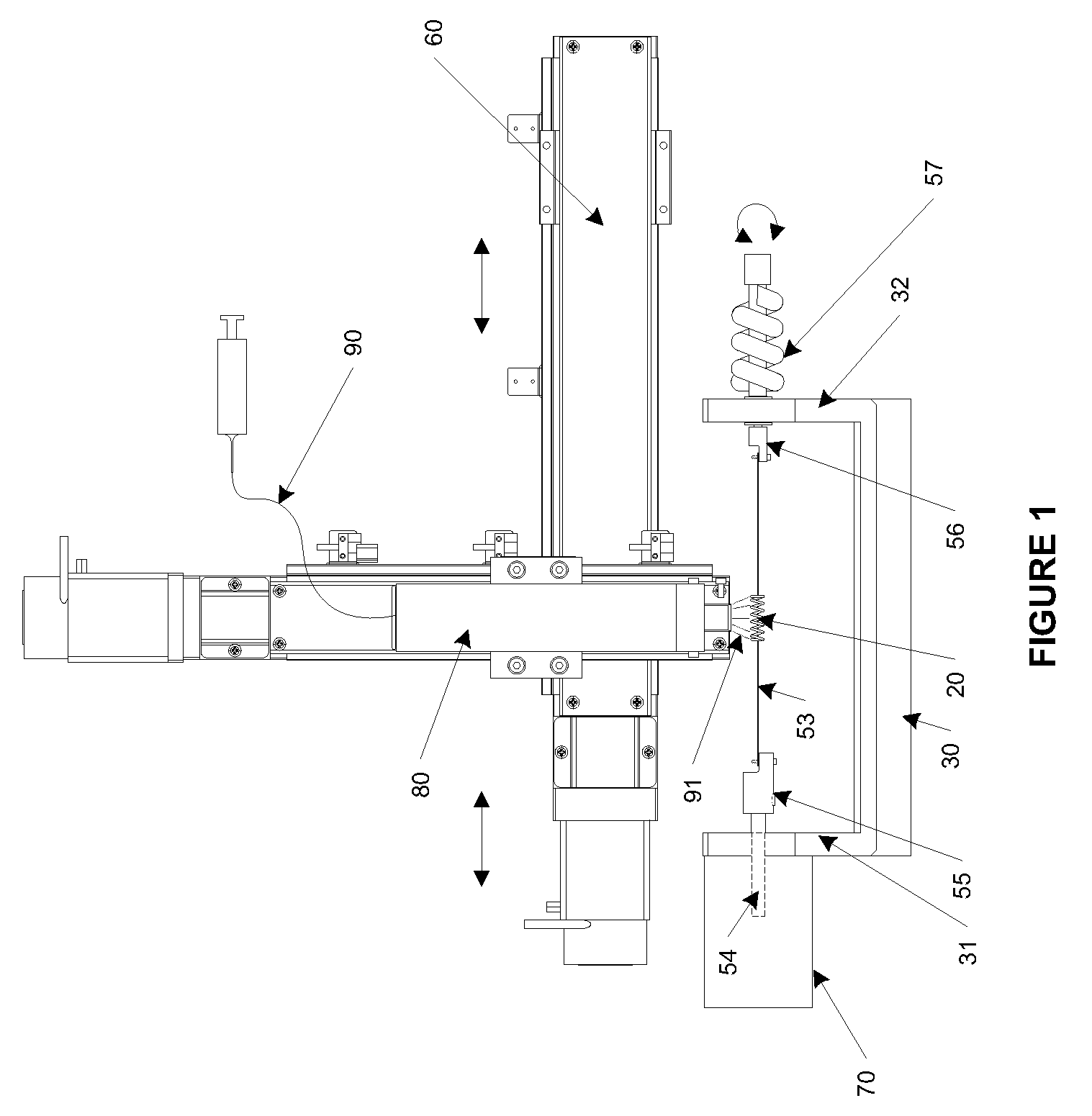

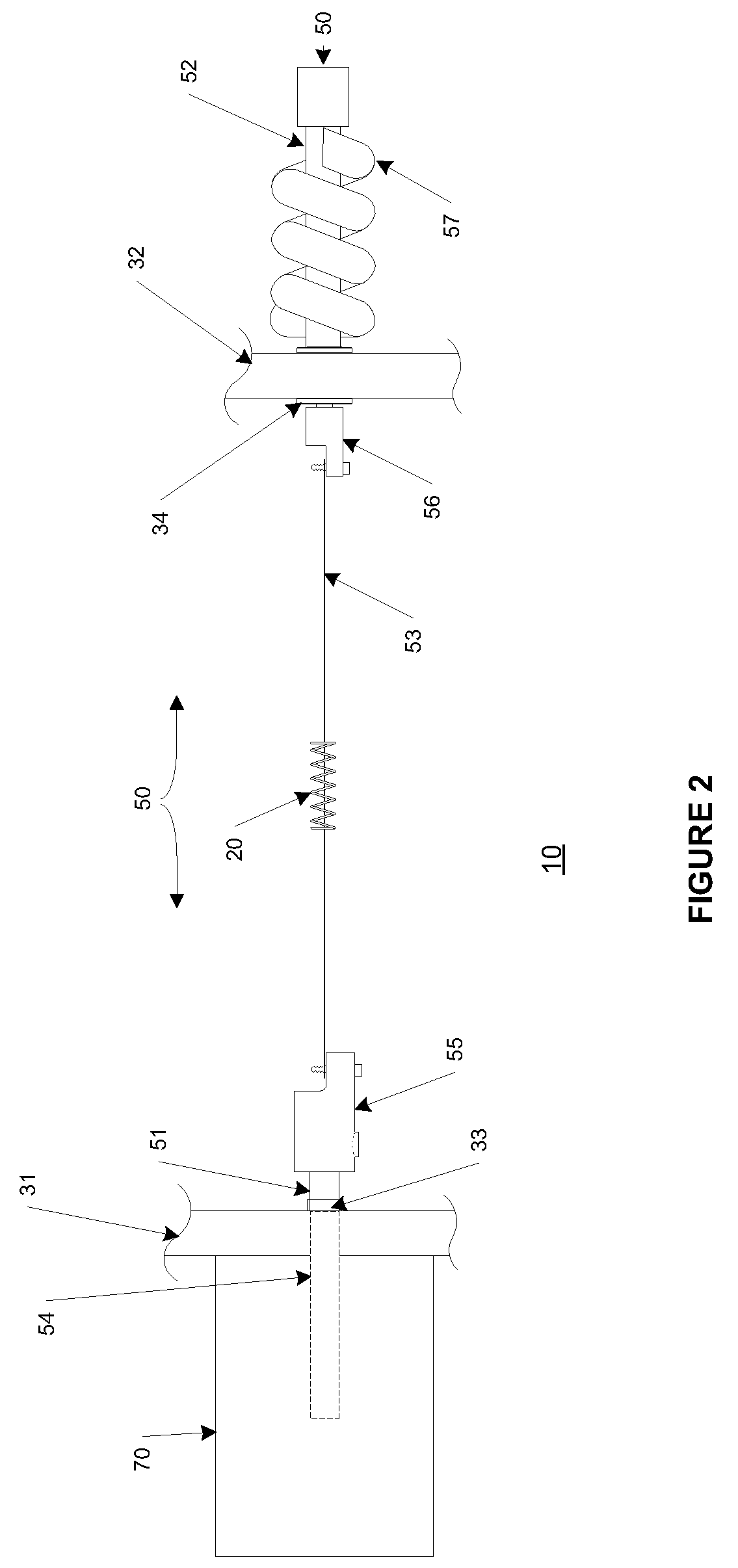

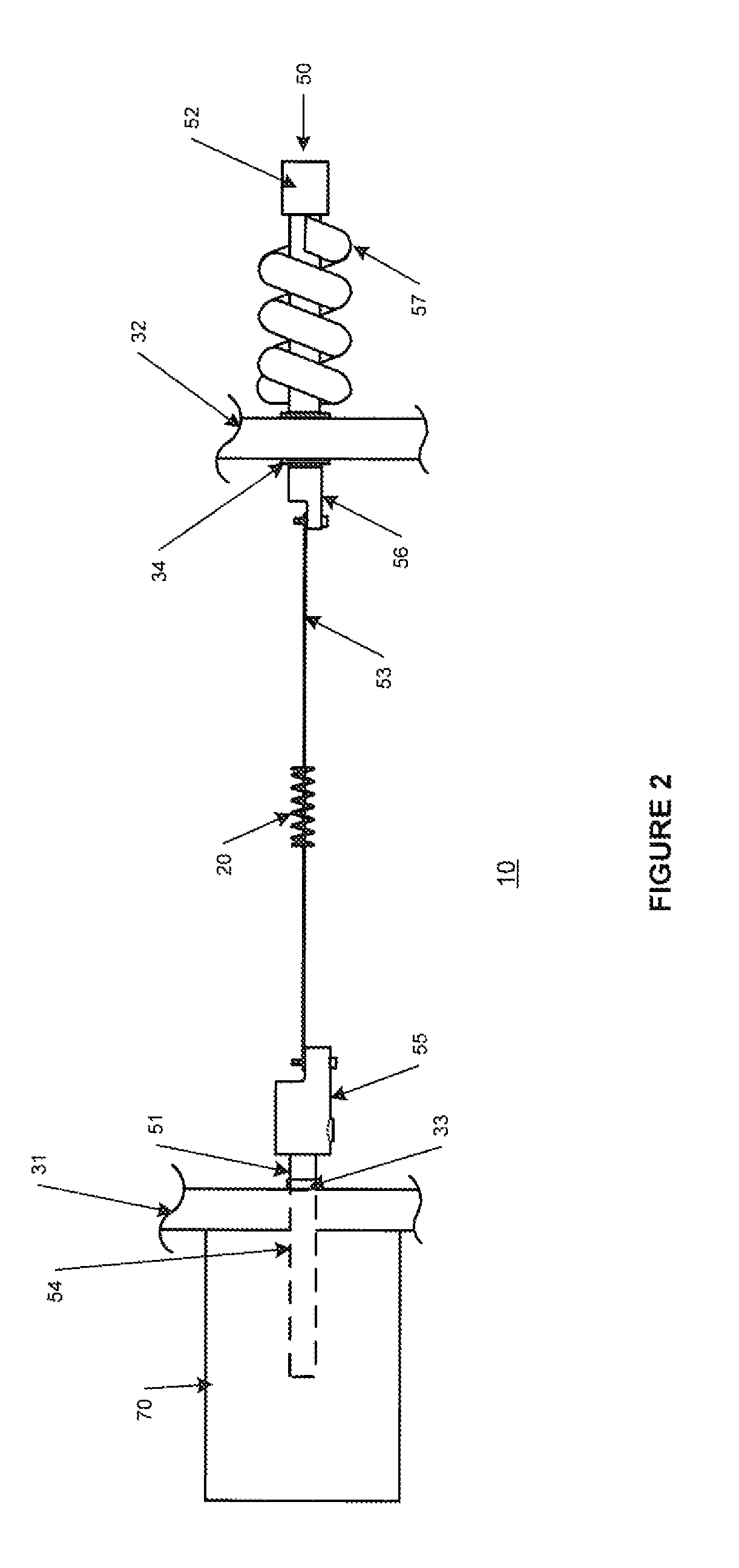

Method for Holding a Medical Device During Coating

InactiveUS20090093870A1Remove shadowsSolve the lack of tensionStentsBalloon catheterMedical deviceBiomedical engineering

The present invention is directed towards the holding of medical devices during manufacture to enable the application of therapeutic and / or protective coatings. More specifically, the present invention provides medical device holders that securely retain stents and other medical devices during the application of a coating while minimizing compressive and tensile forces applied to the stents. The invention avoids disruptions to coating quality due to holder blockage during coating deposition. The invention discloses an improved device containing a mandrel and frame that may improve coating uniformity by eliminating shadowing from the frame of the medical device holder when applying coatings to stents and other medical devices.

Owner:BACOUSTICS LLC

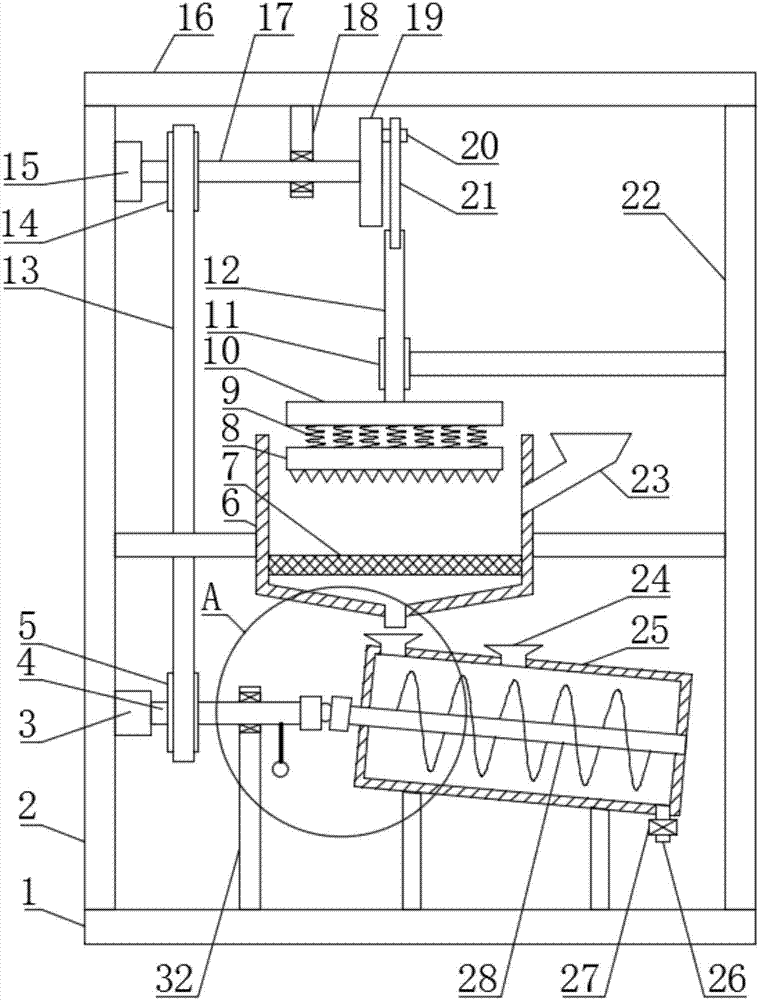

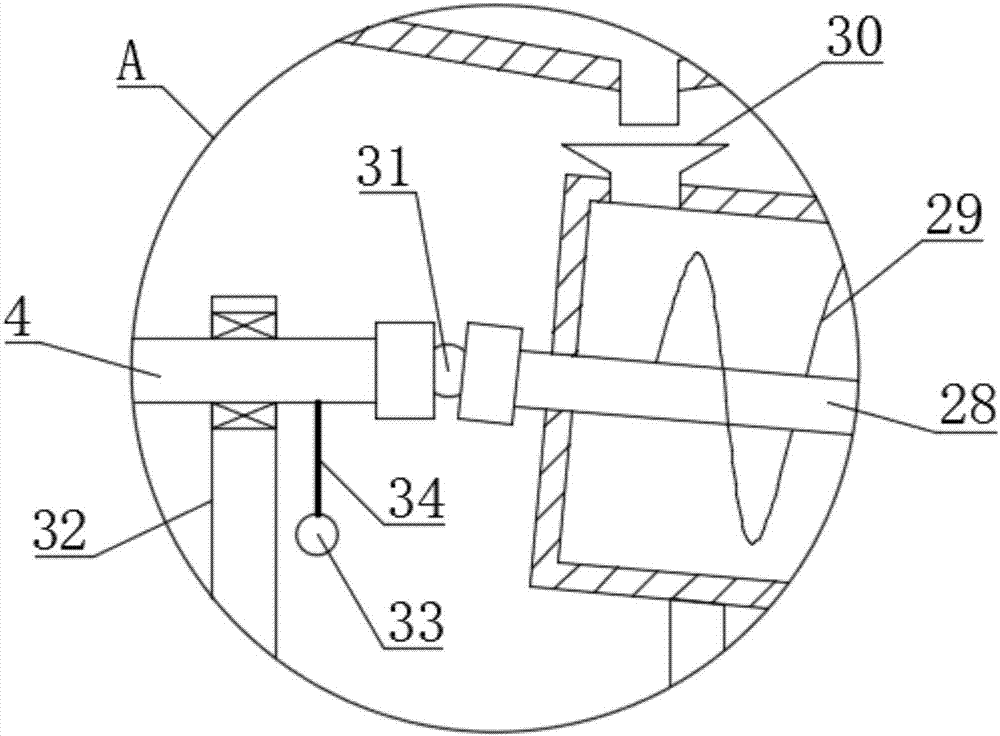

Stone-crushing concrete preparation device for buildings

InactiveCN107415049APlay a buffer roleAvoid cloggingMixing operation control apparatusPretreatment controlStone particleSpiral blade

The invention discloses a stone-crushing concrete preparation device for buildings. The stone-crushing concrete preparation device comprises a base, wherein a left supporting plate and a right supporting plate are correspondingly arranged on the left side and the right side of the base; a crushing box is fixedly arranged between the left supporting plate and the right supporting plate through a support; an extruding plate is fixedly arranged at the inner bottom of the crushing box; a marble is connected to a first rotating shaft through a snapline and positioned below the crushing box; an agitator is obliquely arranged on the base through a support, and a receiving hopper is arranged on the left side of the top of the agitator; a third rotating shaft is rotationally connected to the interior of the agitator; a spiral blade is mounted on the third rotating shaft; and the left end of the third rotating shaft penetrates the left side wall of the agitator and is connected with the right end of the first rotating shaft through a universal coupler. According to the stone-crushing concrete preparation device, the bottom of the crushing box is knocked by the marble, so that adhesion blockage is prevented; and screened stone particles directly enter the agitator to prepare concrete without manual control, so that the processing efficiency is effectively improved.

Owner:李小强

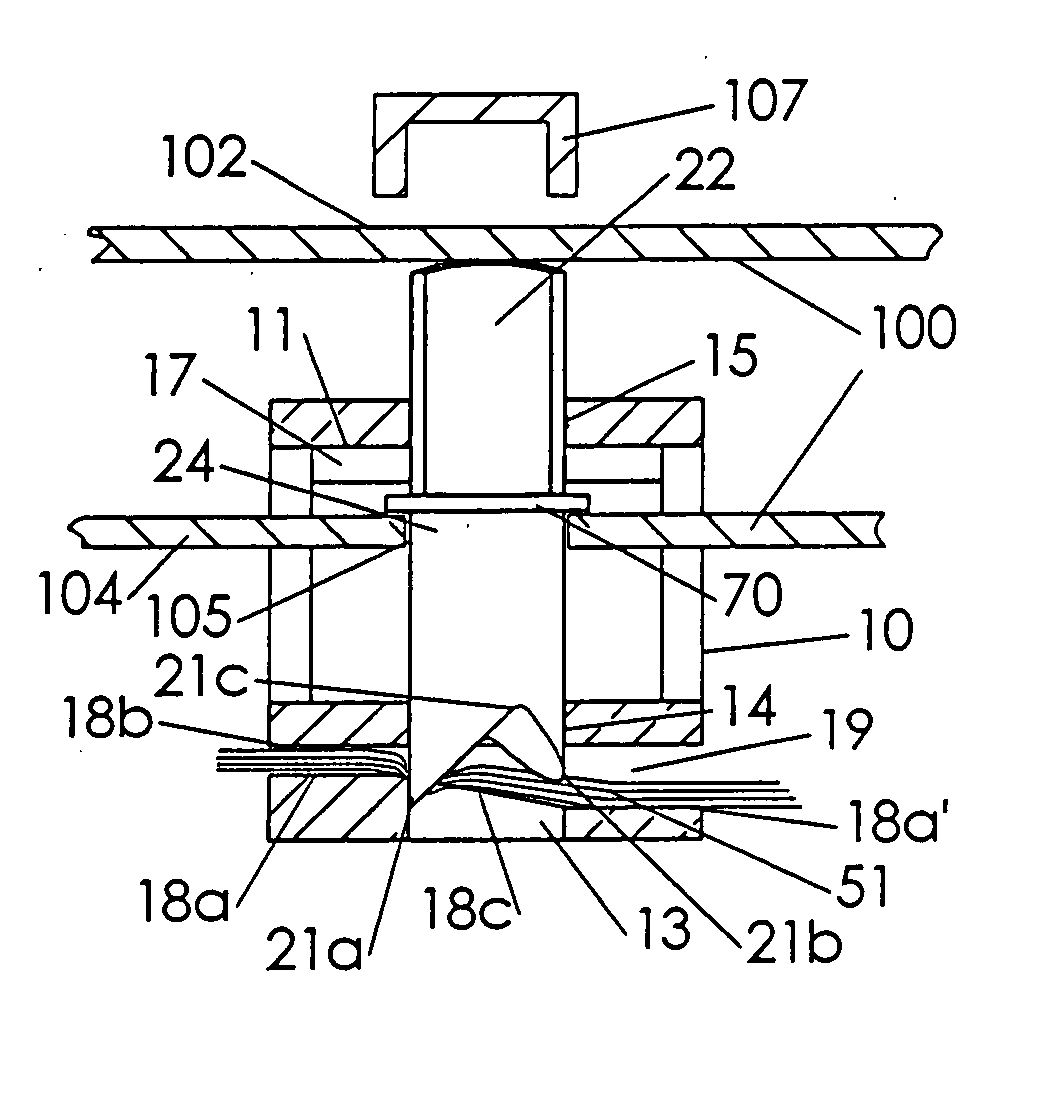

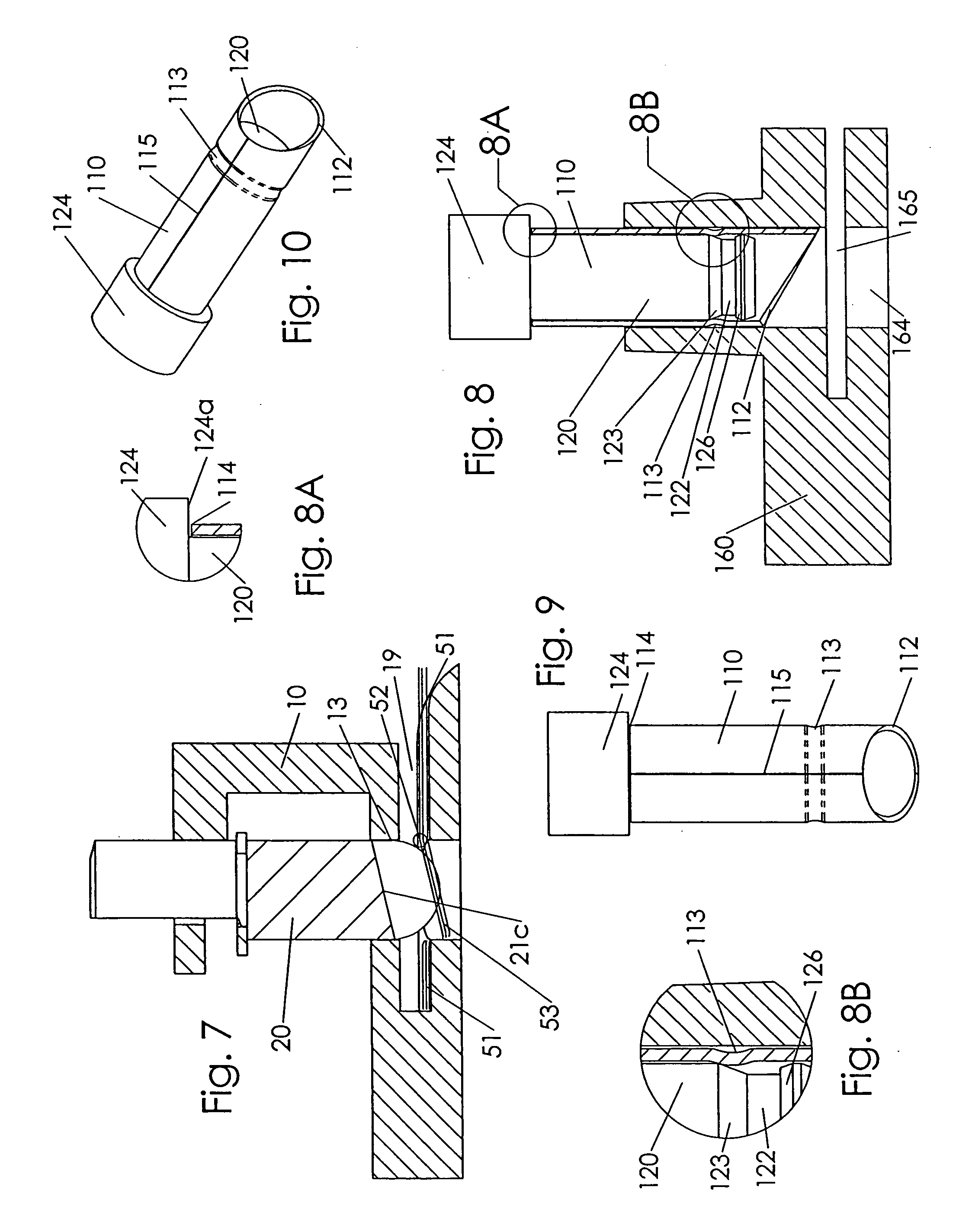

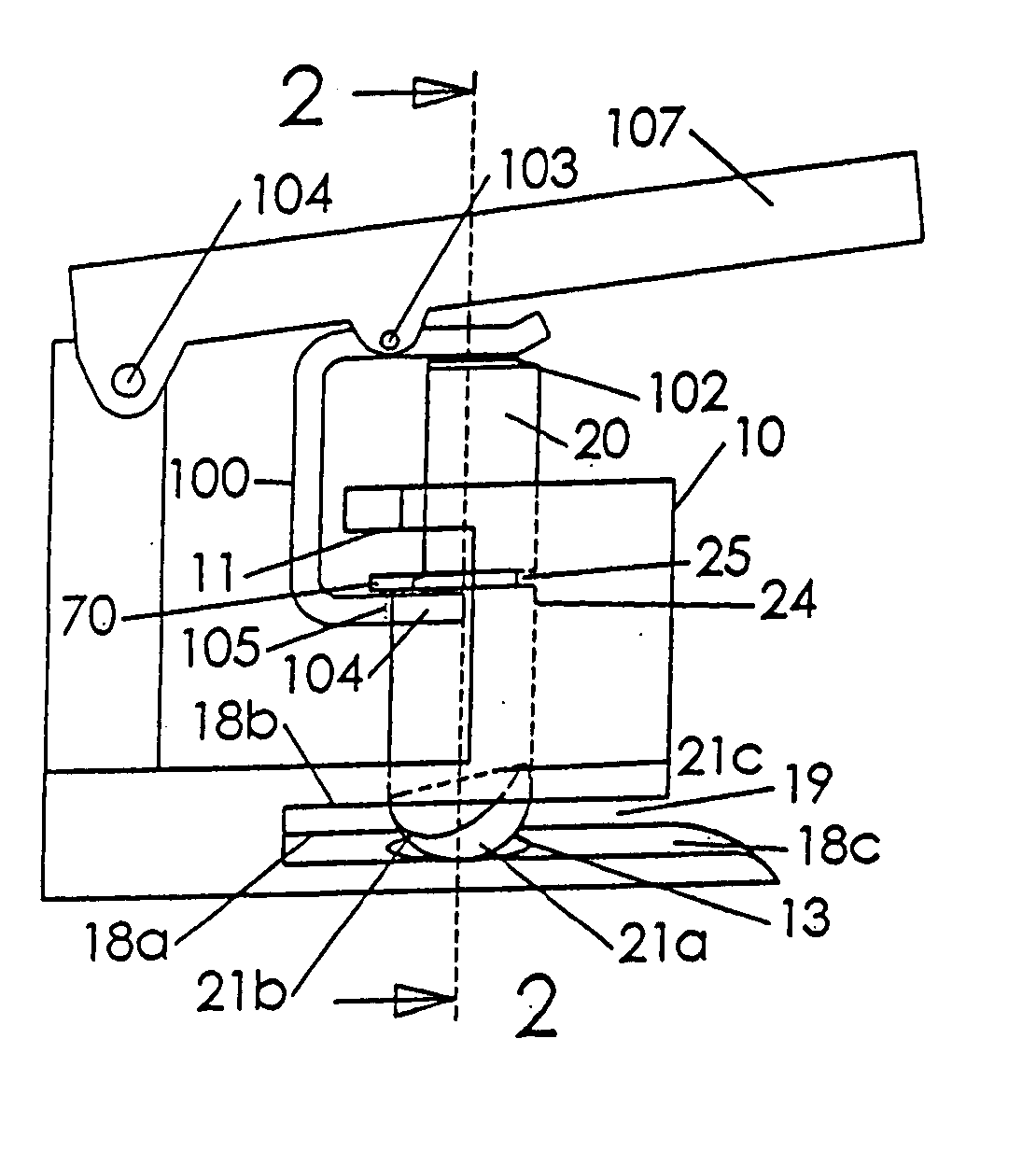

Hole punch element

InactiveUS20070044618A1Reduce punching effortMinimize return spring forceMetal working apparatusClassical mechanicsStructural engineering

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create a bend in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. A long lead-in surface in the frame helps installing sheet media into the feed slot of the punch element.

Owner:WORKTOOLS

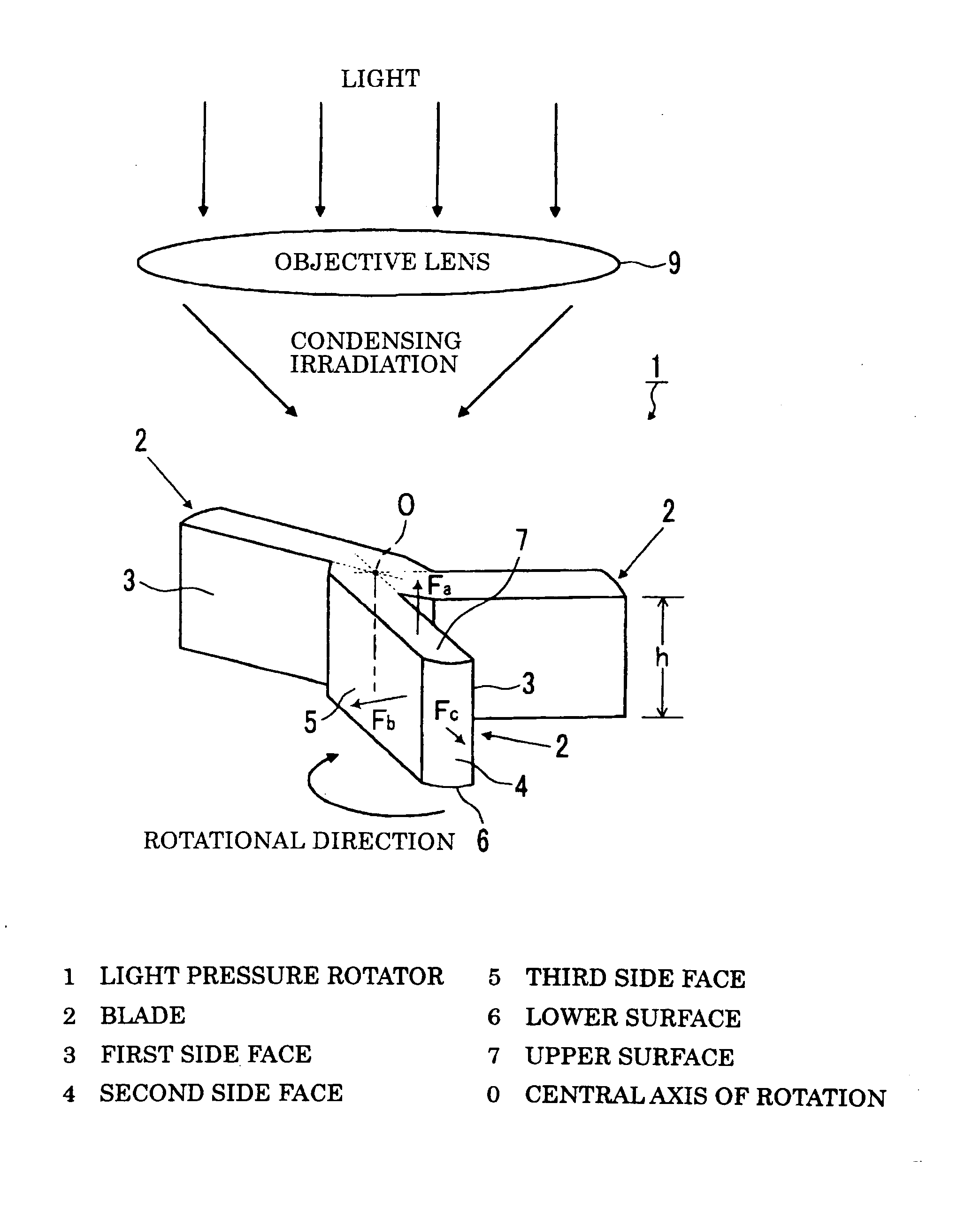

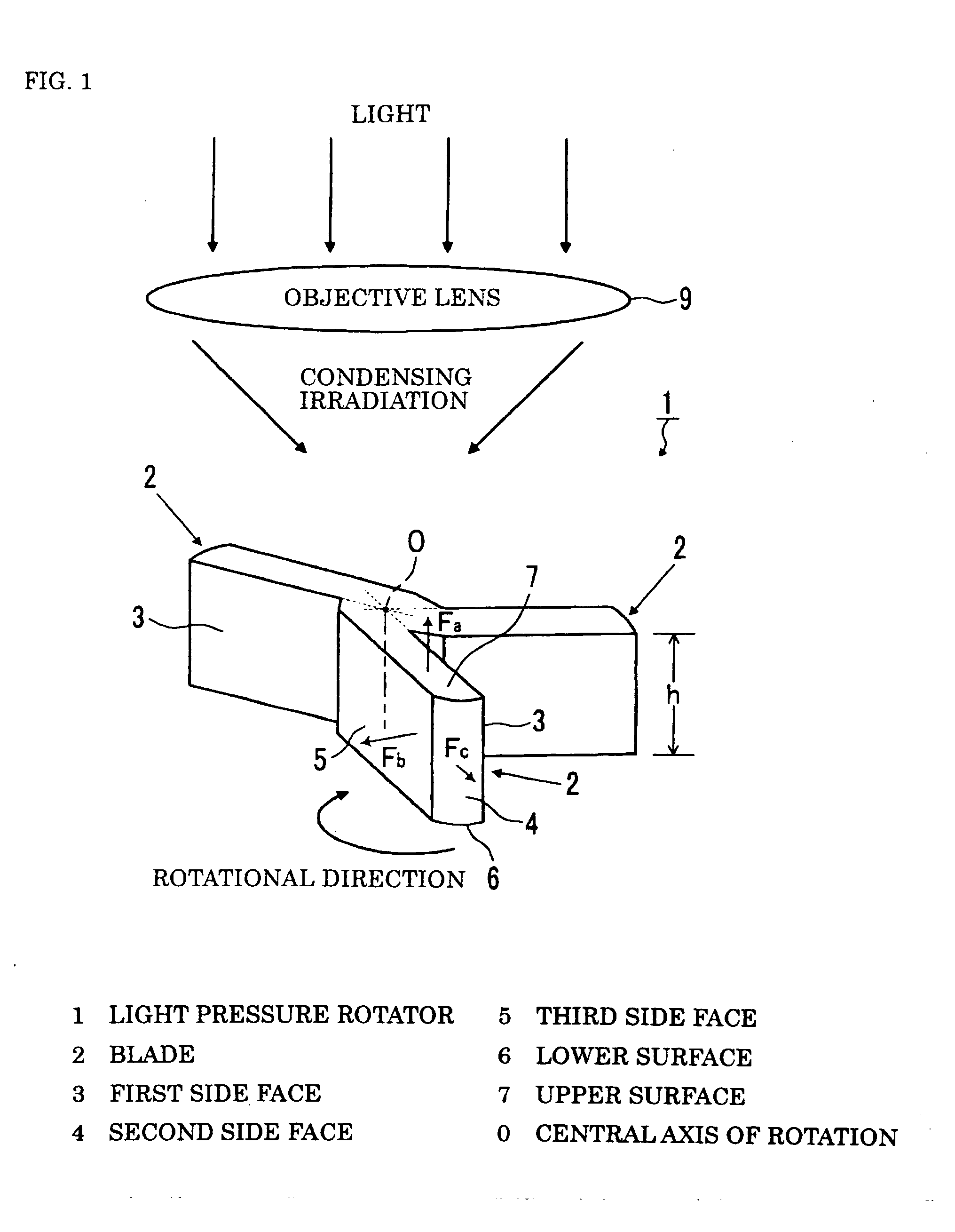

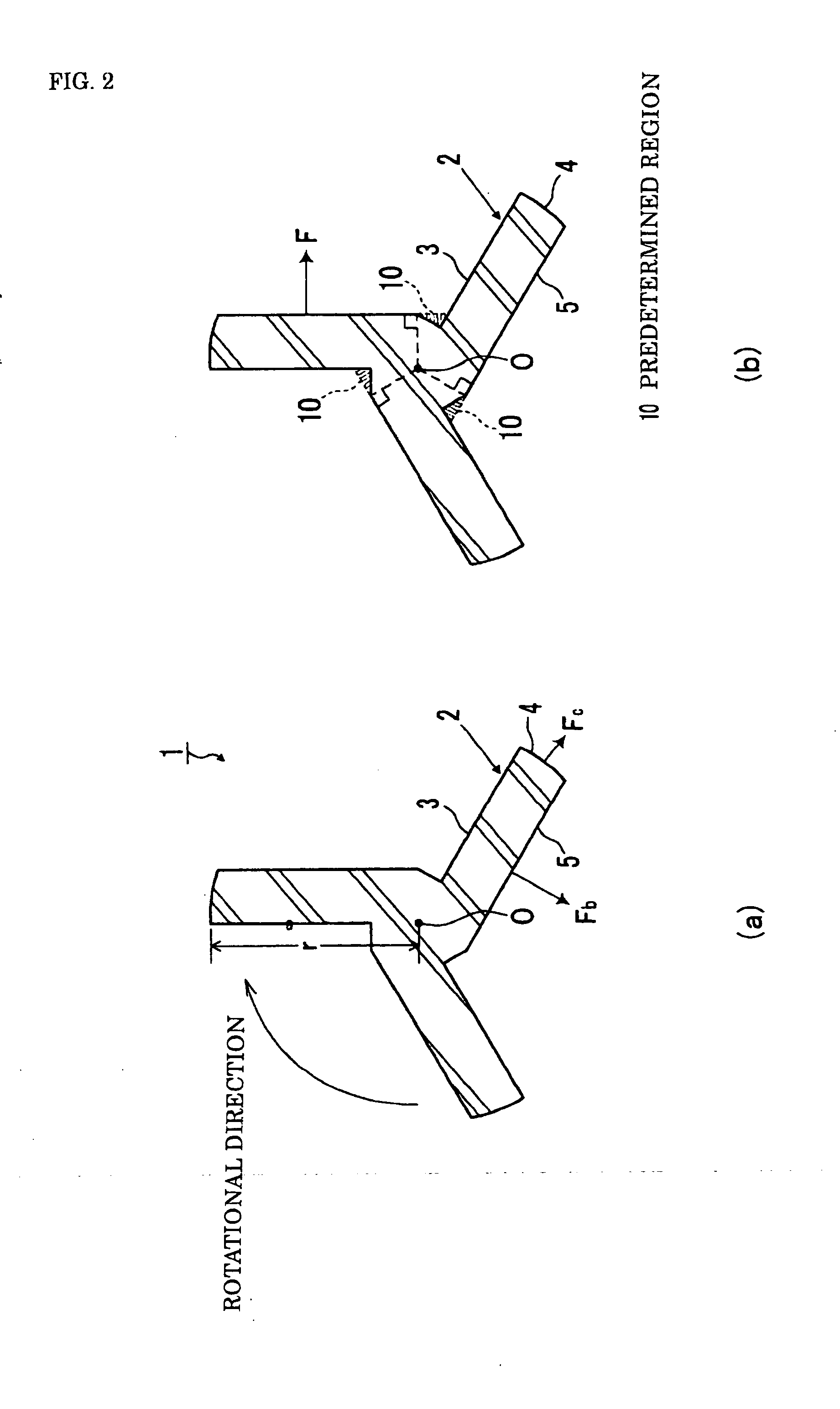

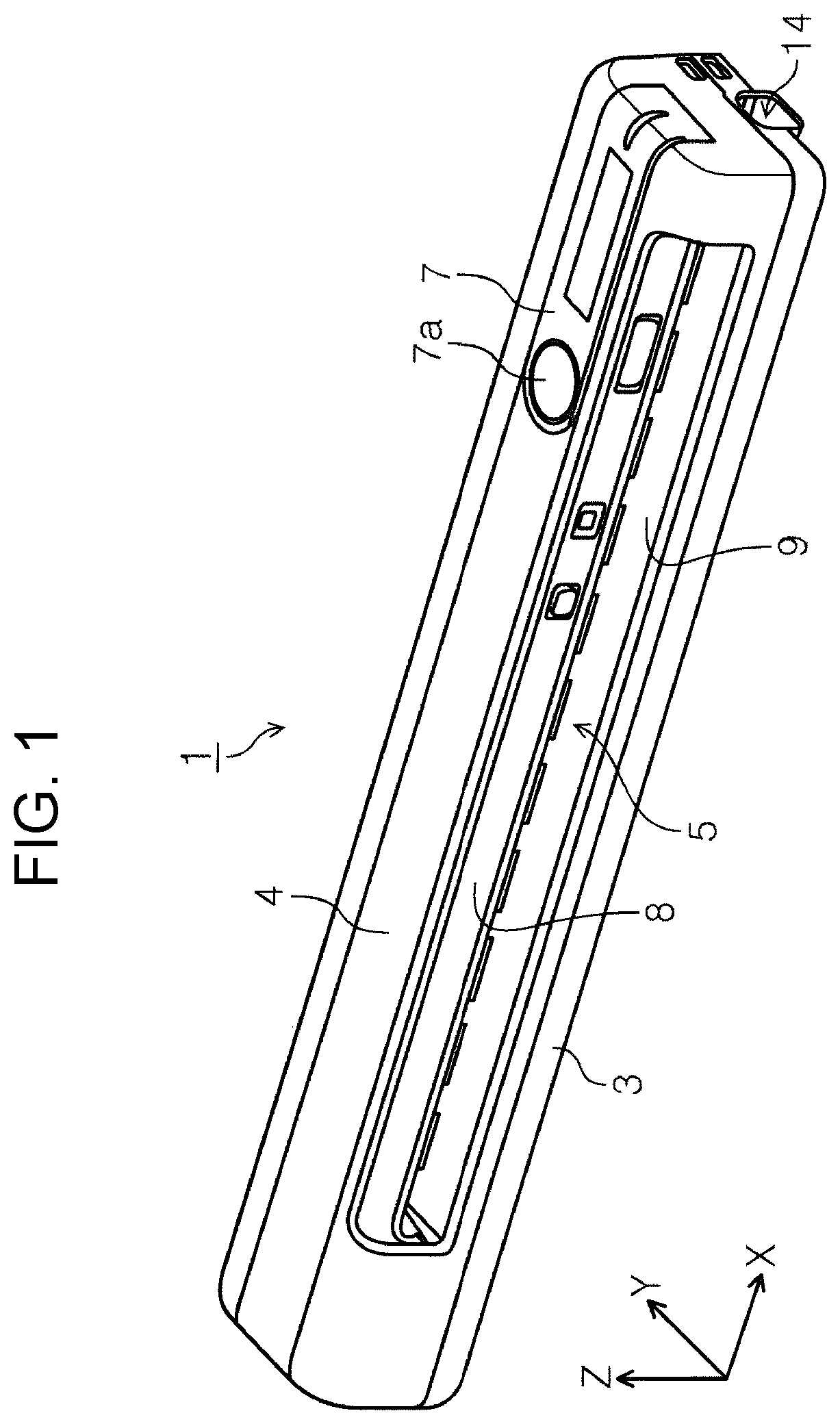

Light Pressure Rotator and Light Pressure Rotating Device

InactiveUS20080031088A1Faster light pressure rotationEffective stirringShaking/oscillating/vibrating mixersFrom solar energyEngineeringIrradiation

The light pressure rotator (1) is the light pressure rotator being light pressure trapped by irradiation with light and light pressure rotating about the central axis O of rotation, characterized in that a reverse torque generating section generating a torque for rotating the rotator in the direction reverse to the predetermined direction is removed from a section arranged with three blades (2) each having a first side face (3) extending in the radial direction from the central axis O of rotation, a second side face (4) facing the central axis O of rotation, a third side face (5) facing the first side face (3), a lower surface (6) intersecting the central axis O of the rotation, and an upper surface (7) facing the lower surface (6). The light pressure rotating device comprises the light pressure rotator (1), a light source (C), and an objective (condenser) lens D.

Owner:THE RITSUMEIKAN TRUST

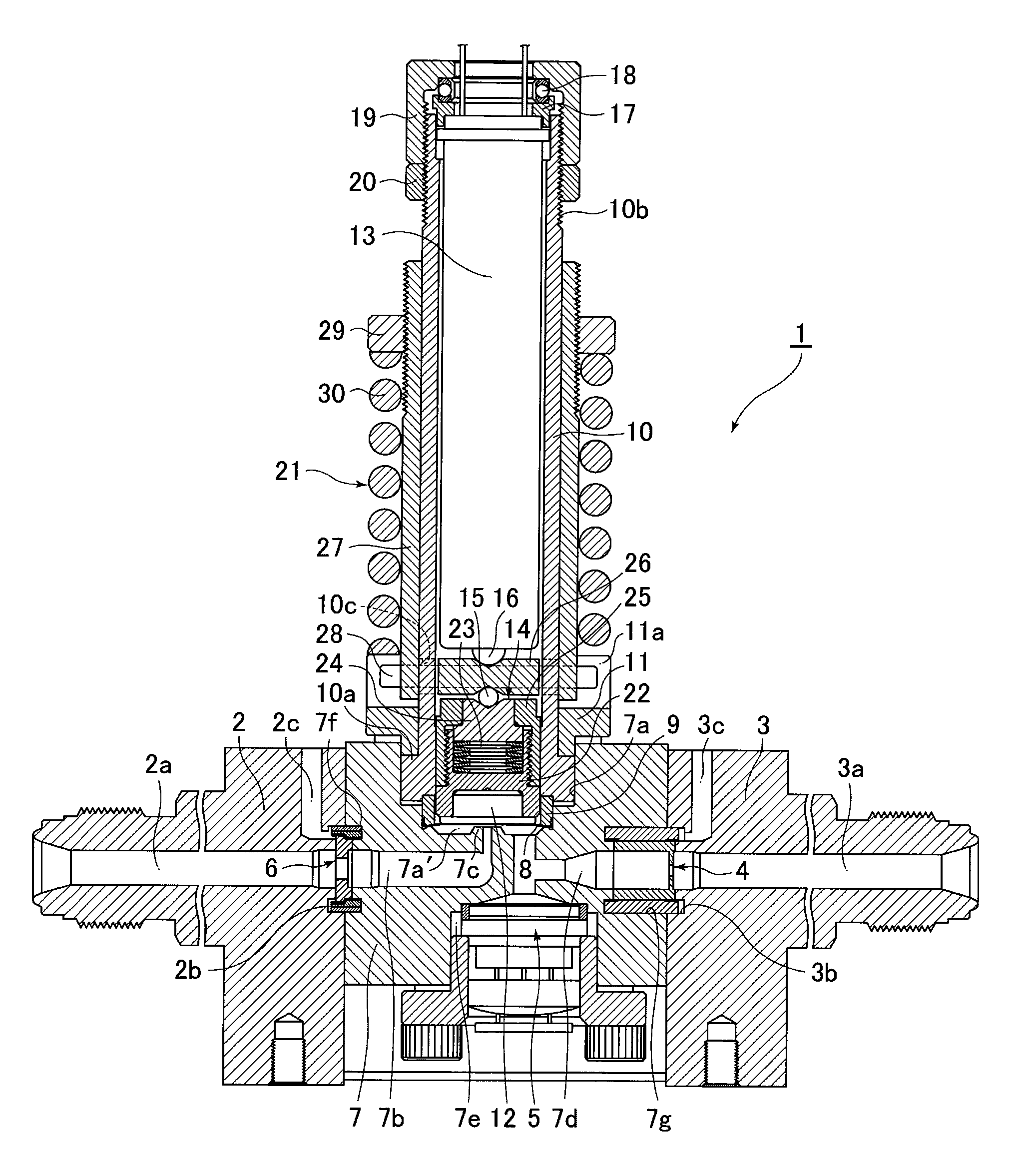

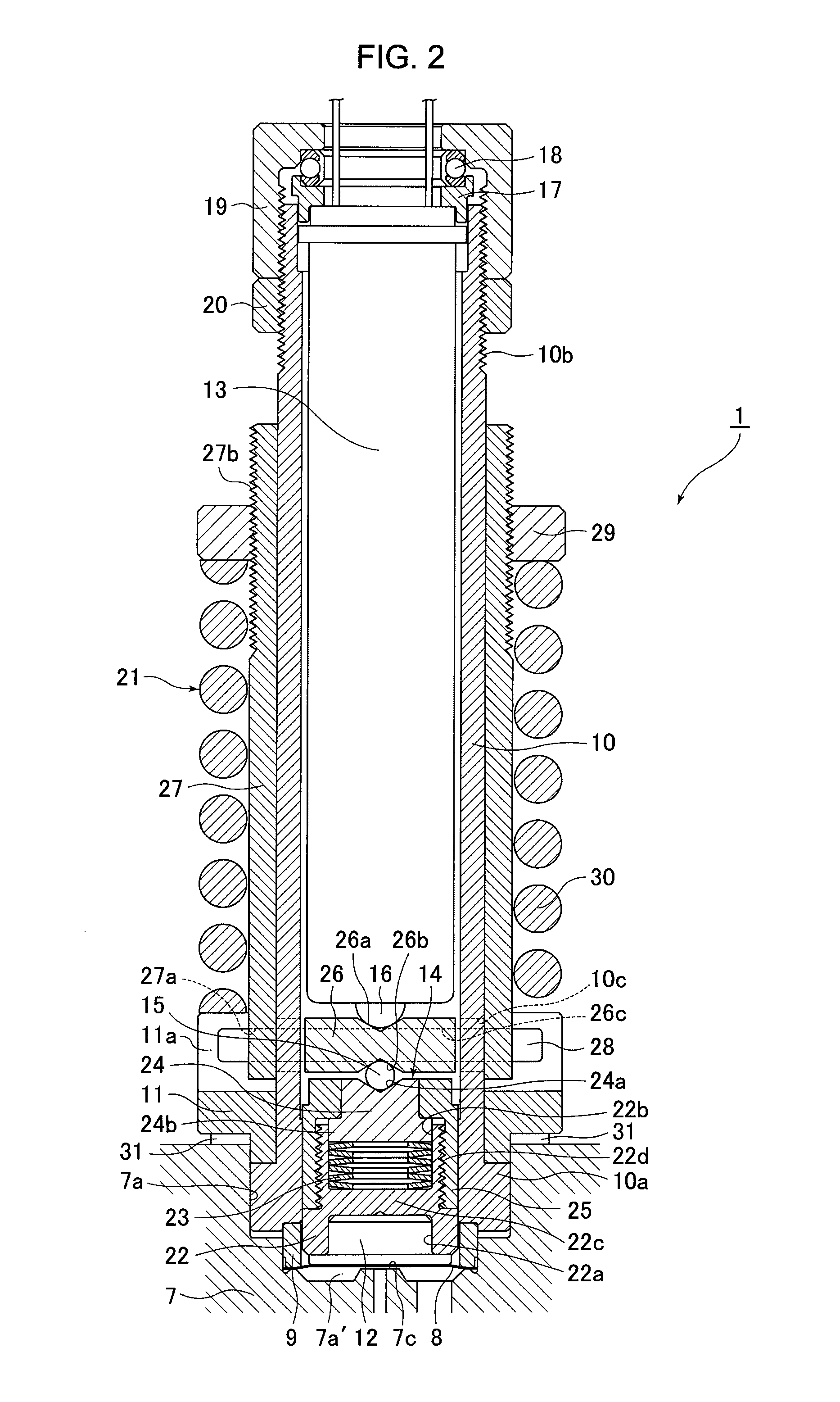

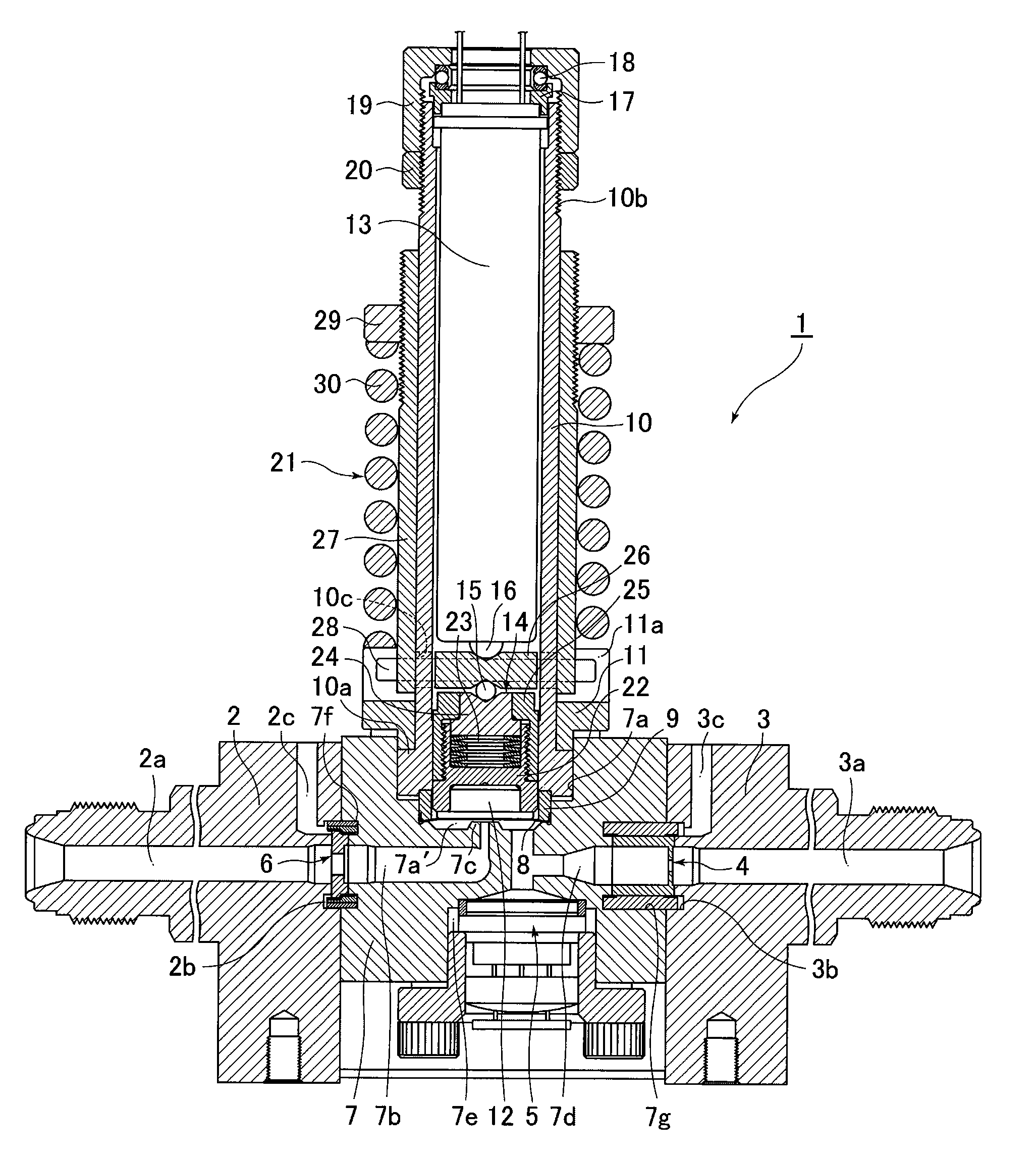

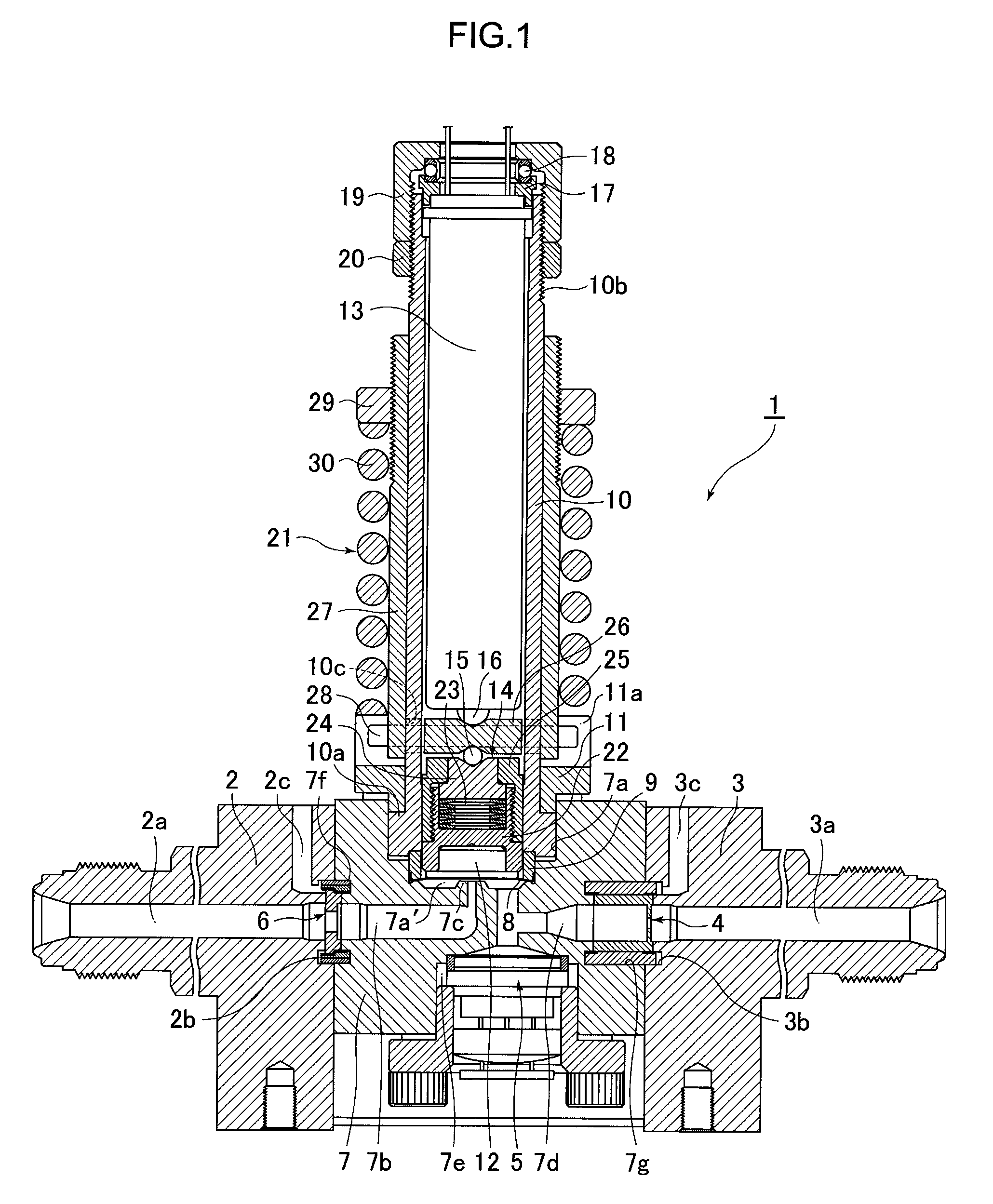

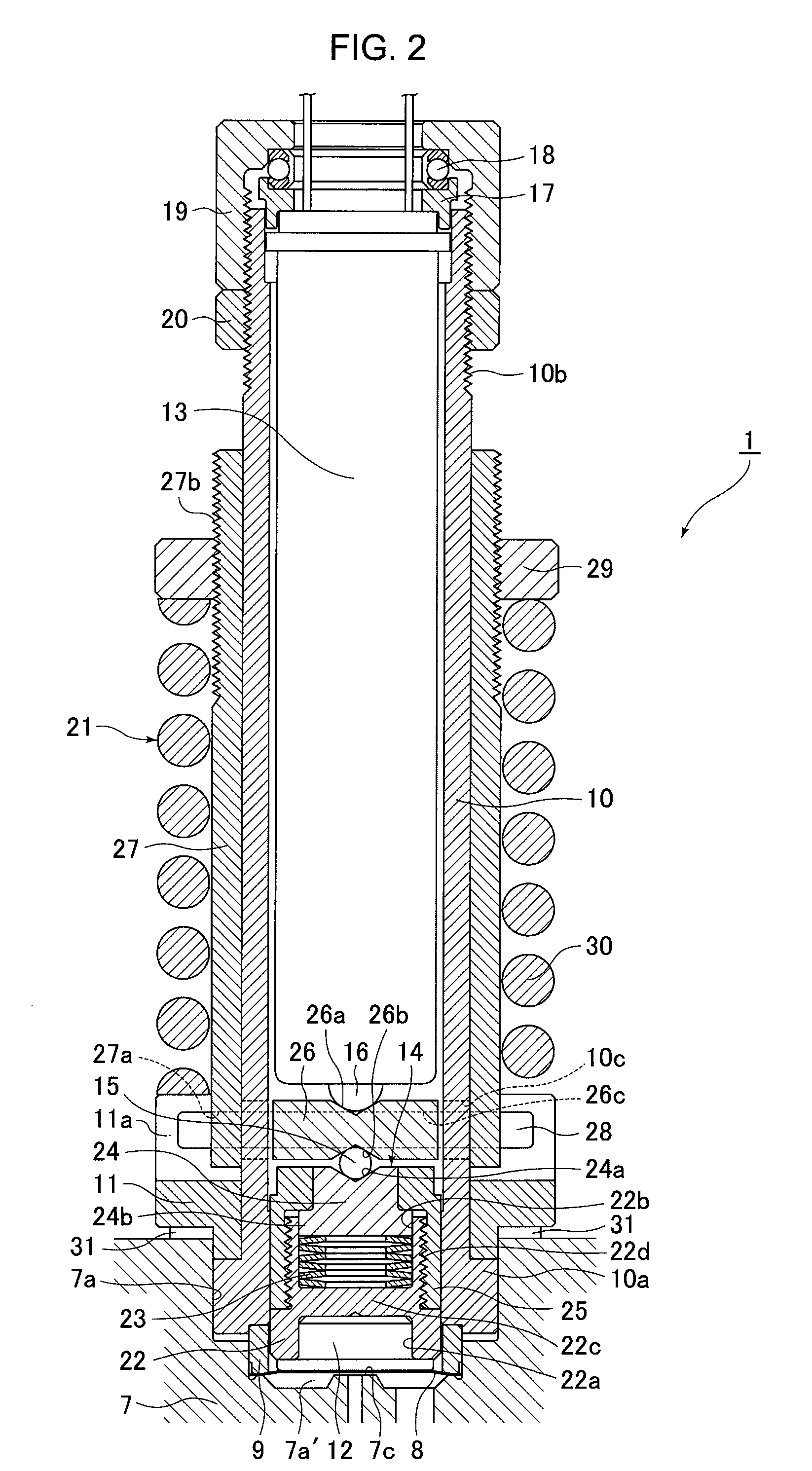

Normally open type piezoelectric element driven metal diaphragm control valve

ActiveUS20100294964A1Precise flow controlReduce loadDiaphragm valvesOperating means/releasing devices for valvesElectricityEngineering

A control valve has a body that forms a valve chamber and a valve seat, a metal diaphragm installed inside the valve chamber and making contact with and departing from the valve seat, an actuator box fixed to the side of the body, a piezoelectric element installed inside the actuator box to thrust the metal diaphragm through mediation of a metal diaphragm presser by elongating downward when voltage is applied, a conical spring mechanism that absorbs elongation of the piezoelectric element at the time when the metal diaphragm makes contact with the valve seat and a prescribed thrust is applied to the valve seat and the like, and a preload mechanism that applies upward compressive force to the piezoelectric element all the time wherein the compressive force applied to the piezoelectric element is externally adjustable.

Owner:FUJIKIN INC

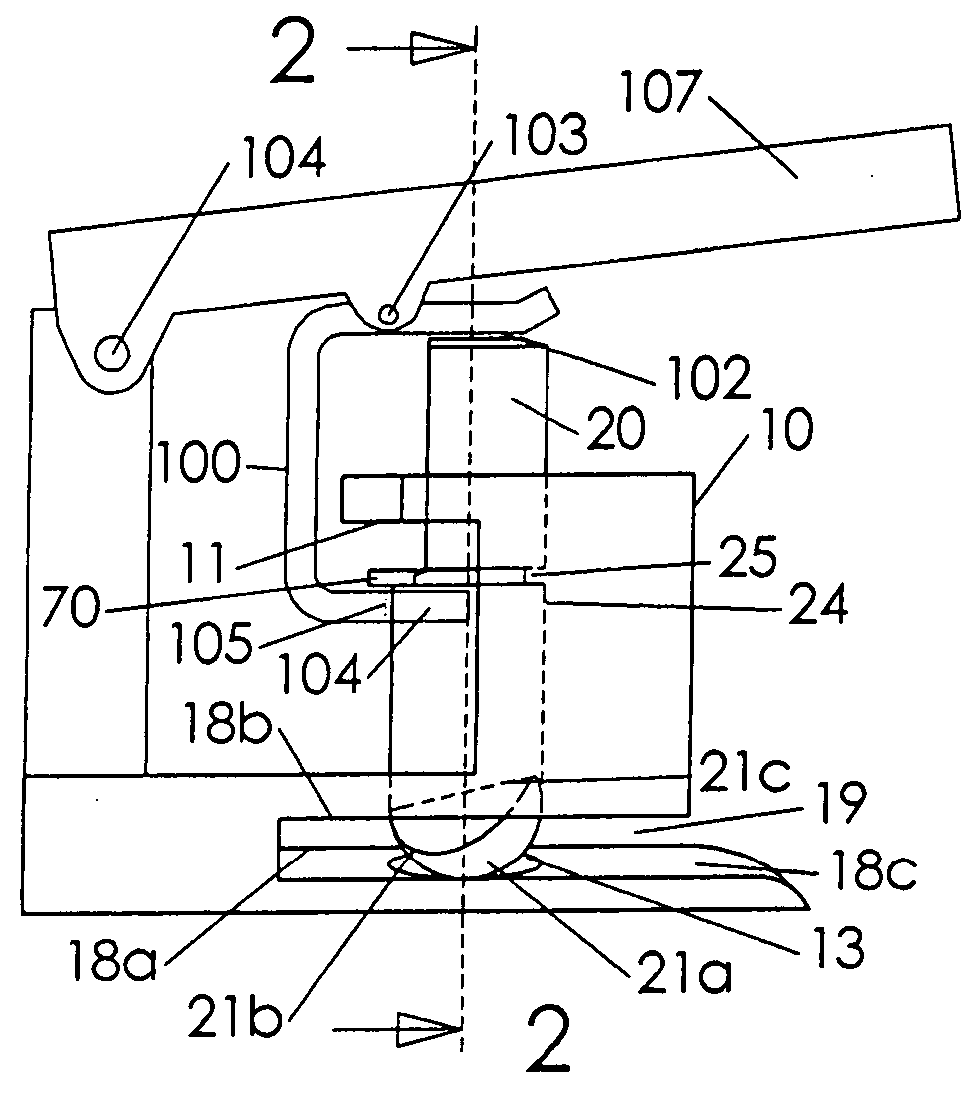

Tissue separating systems and methods

ActiveUS9028520B2Smooth connectionReduce morbidityEar treatmentCannulasEngineeringBiomedical engineering

Systems and methods for separating an object such as a pacing lead from a patient tissue involve a flexible and torqueable shaft having an internal lumen sized to receive the object, and a hard separating mechanism for separating the object from the tissue. Typically the shaft and separating mechanism are advanced along or toward the object, and the separating mechanism is contacted with the tissue. The shaft is rotated to effect separation between the object and the tissue. The systems and methods are well suited for use in cardiac pacing or defibrillator lead explant procedures.

Owner:SPECTRANETICS

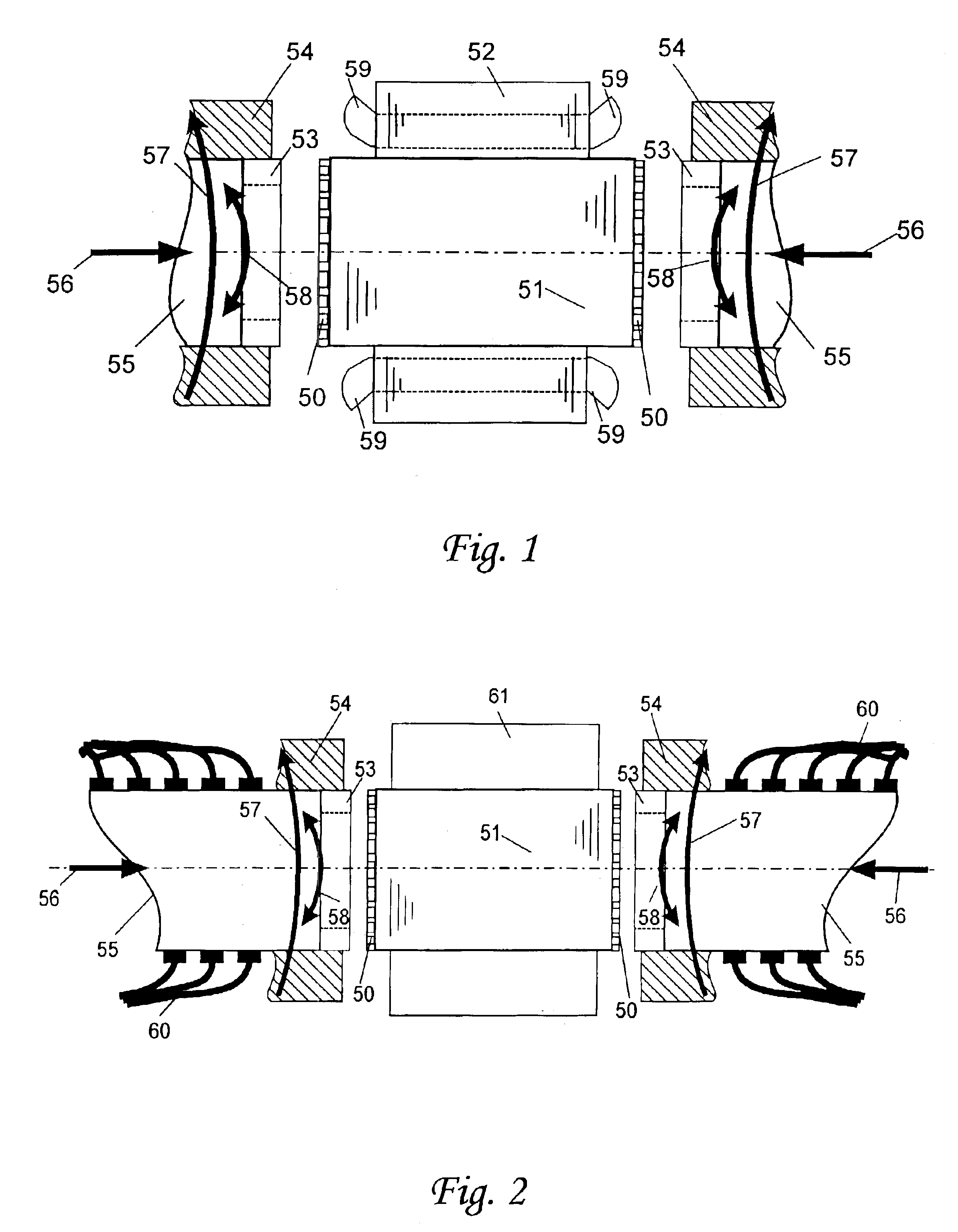

Electrofriction method of manufacturing squirrel cage rotors

InactiveUS6877210B2Smooth connectionReduce area of smallWindingsMagnetic circuitEngineeringConductive materials

A method of making a squirrel cage rotor of copper material for use in AC or DC motors, includes forming a core with longitudinal slots, inserting bars of conductive material in the slots, with ends extending out of opposite ends of the core, and joining the end rings to the bars, wherein the conductive material of either the end rings or the bars is copper. Various methods of joining the end rings to the bars are disclosed including electrofriction welding, current pulse welding and brazing, transient liquid phase joining and casting. Pressure is also applied to the end rings to improve contact and reduce areas of small or uneven contact between the bar ends and the end rings. Rotors made with such methods are also disclosed.

Owner:UT BATTELLE LLC

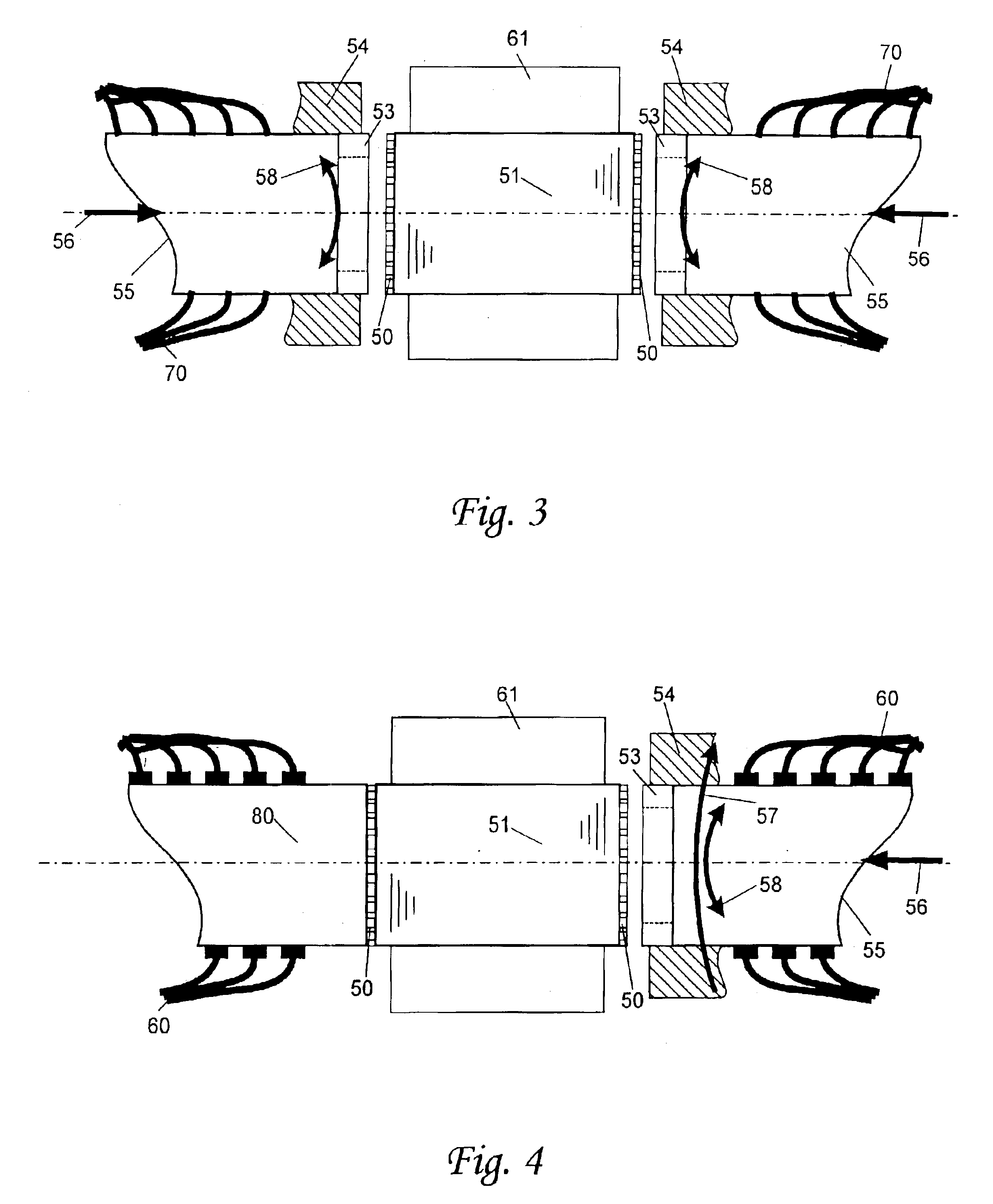

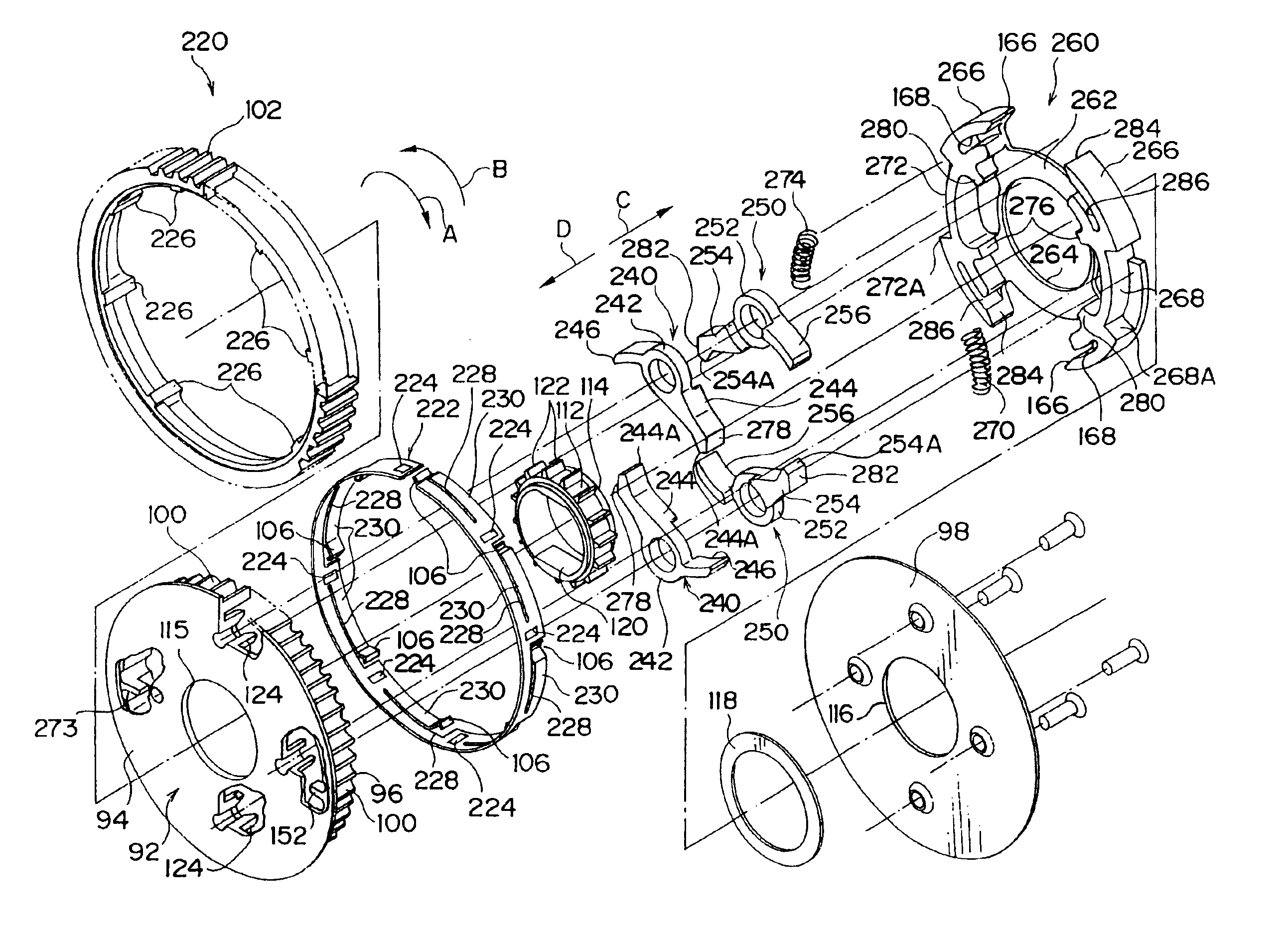

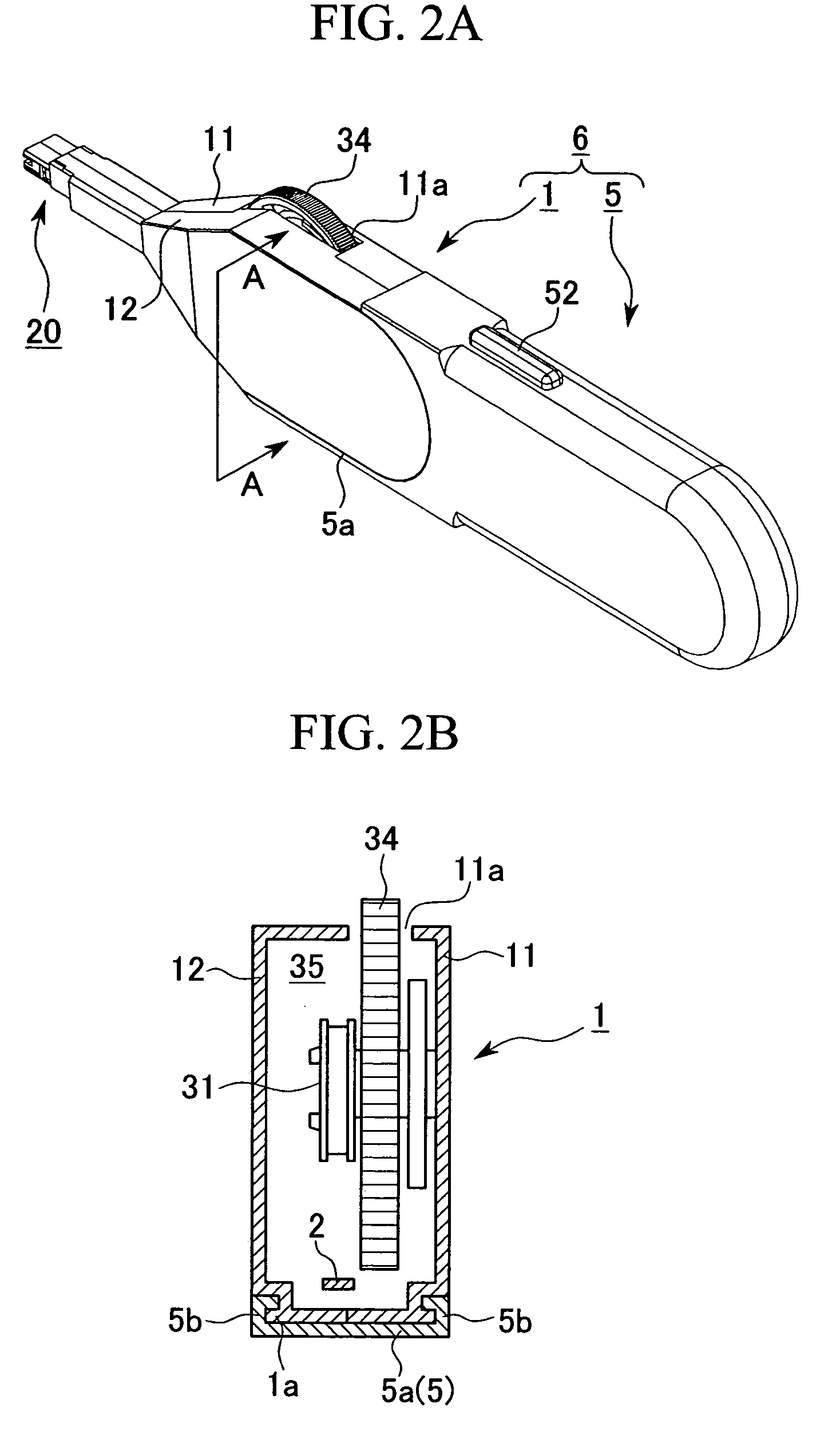

Webbing winding device

InactiveUS6857594B2Optimization mechanismAvoid using forceBelt retractorsBelt control systemsEngineeringConductor Coil

In a webbing winding device, when an external gear of a clutch receives driving force of a motor and rotates in a winding direction, a pressing portion of an inertial plate pushes a pawl and meshes the pawl with outward teeth of an adaptor. Consequently, the winding shaft rotates in the winding direction. When the external gear receives rotating force of the motor and rotates in a drawing out direction, another pushing portion of the inertial plate pushes another pawl and meshes the pawl with the outward teeth of the adapter. Consequently, the winding shaft rotates in the drawing out direction. Thus, by providing these pawls, in this webbing winding device it is possible to transmit both forward-rotation and reverse-rotation of the motor for rotating the winding shaft.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Low friction hole punch element

InactiveUS20070044623A1Reduce punching effortMinimize return spring forceMetal working apparatusElectroless nickelCutting force

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create a bend in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. The pin and / or other components optionally include electroless nickel plating to reduce friction and wear at the component or pin sliding and cutting surfaces.

Owner:WORKTOOLS

Hole punch element

InactiveUS20070044624A1Reduce punching effortMinimize return spring forceMetal working apparatusEngineeringCutting force

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create an angle in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. The punch elements and punch pins may be configured so that the punch pins cut into the sheet media sequentially.

Owner:MARKS JOEL S

Cleaning unit for optical connector and cleaning tool for optical connector

InactiveUS7243390B2Easy to cleanEasy to implementLiquid processingReconditioning/cleaning record carriersRelative motionOptical connectors

A join end face of an optical connector is easily and reliably cleaned when the optical connector has been inserted into a connector housing, by using an optical connector cleaning unit comprising a cleaning member which wipes clean a join end face of an optical connector inside a connector housing by relative motion against the join end face, a drive mechanism which drives the cleaning member, and a connection section which enables a drive auxiliary mechanism for applying a moving force to the drive mechanism to be connected, and an optical connector cleaning tool in which a drive auxiliary unit comprising the drive auxiliary mechanism has been connected to the connection section of the optical connector cleaning unit.

Owner:THE FUJIKURA CABLE WORKS LTD

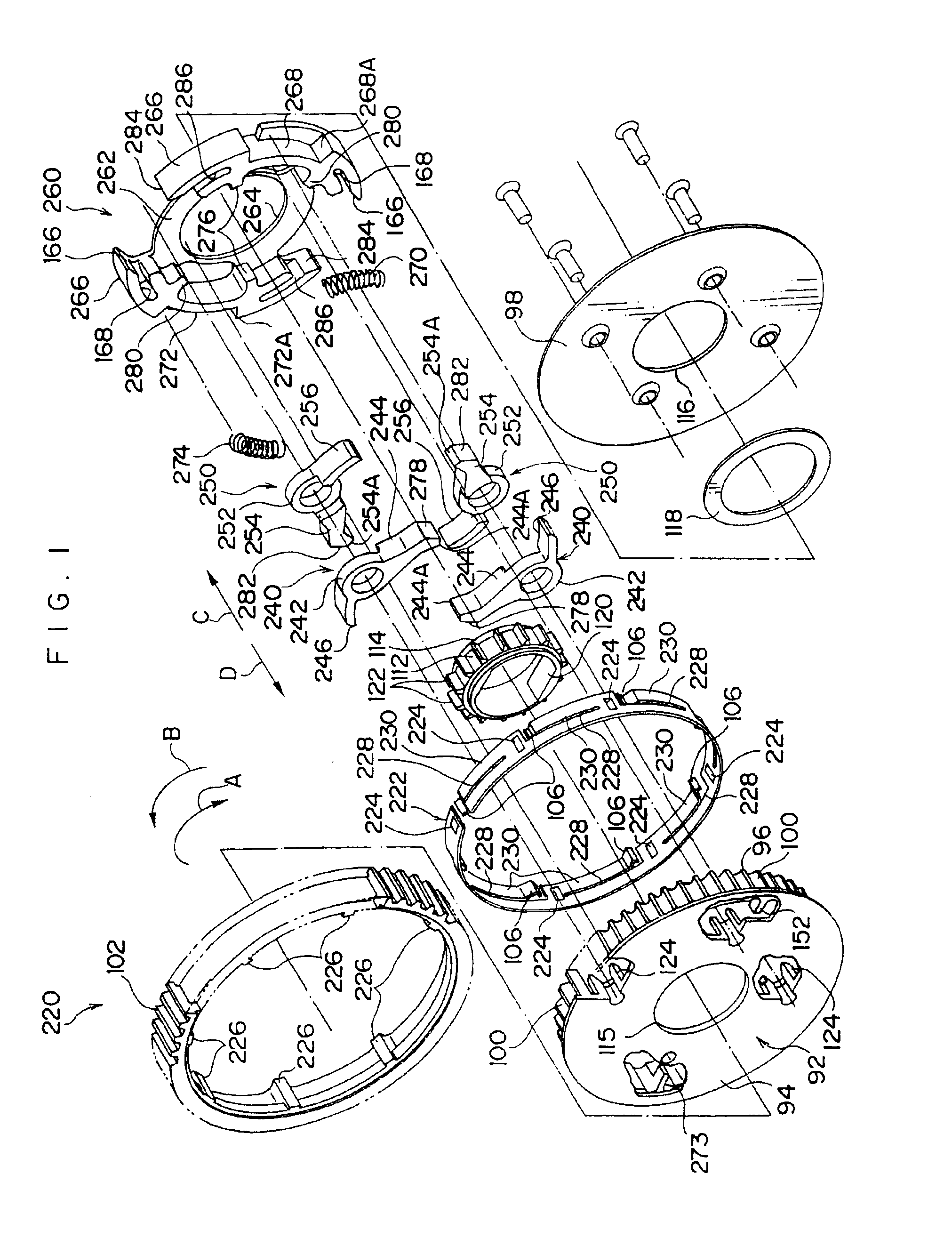

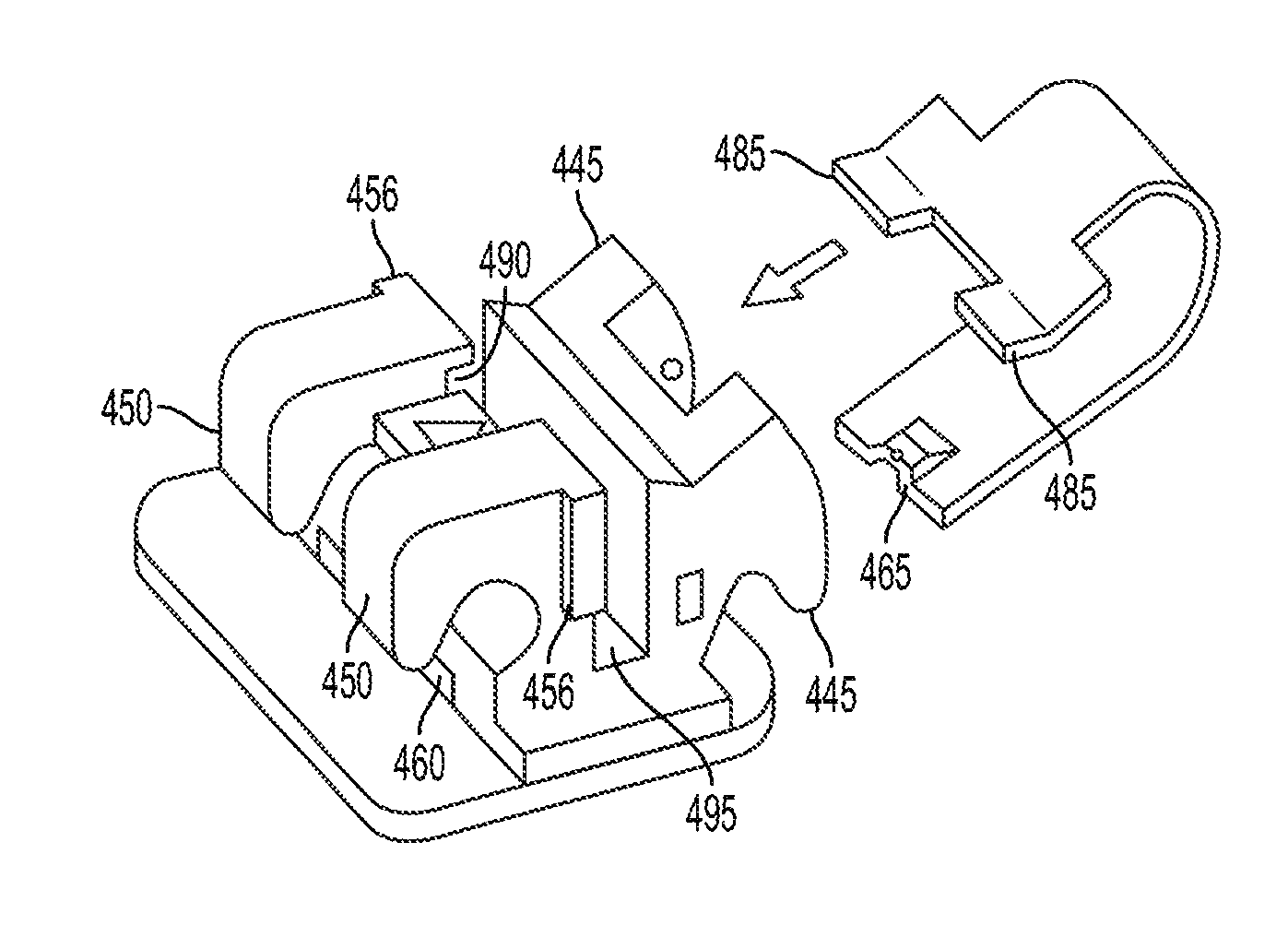

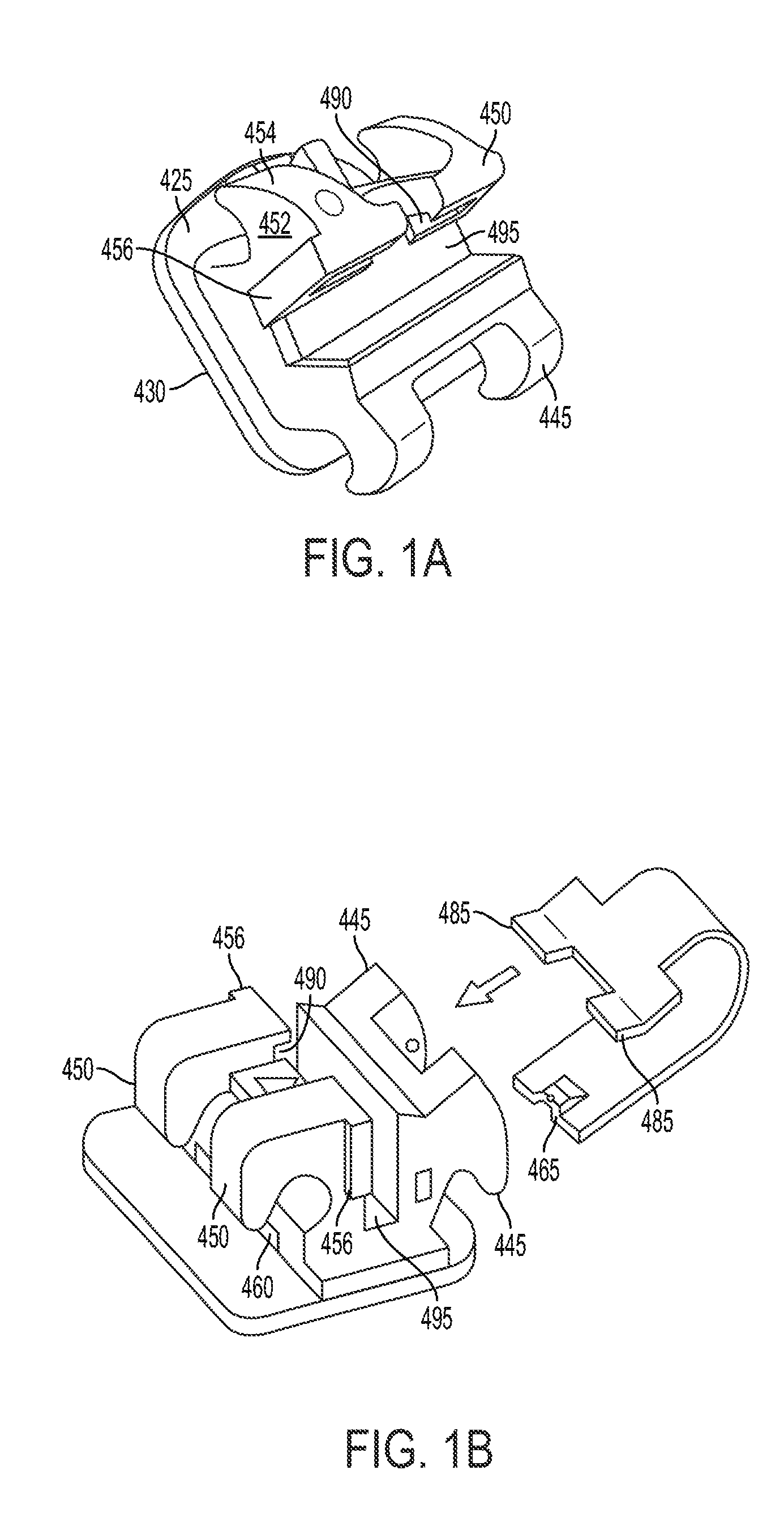

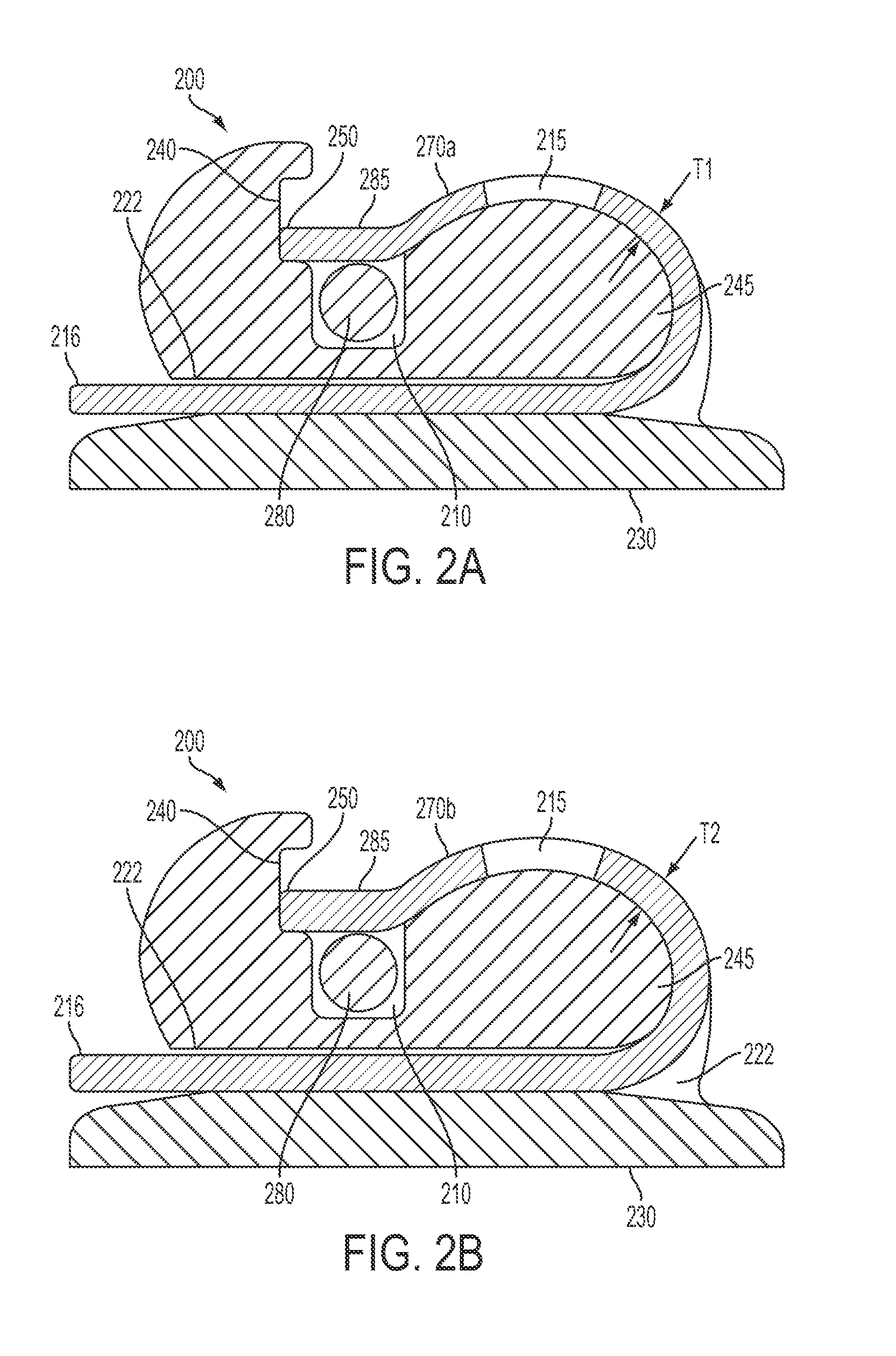

Biocompatible self-ligating brackets

InactiveUS20140134563A1Less complicatedAvoid heavy forceArch wiresBracketsEngineeringOrthodontic brackets

A plurality of self-ligating orthodontic brackets for use in orthodontic treatment comprising at least one first bracket, at least one second bracket, and at least one third bracket. Each of the first, second and third brackets include a first, second and third locking shutter, respectively, for applying a force onto an archwire to effect orthodontic treatment. The first locking shutter applies a first force, the second second locking shutter applies a second force and the third locking shutter applies a third force such that the first, second and third forces differ from each other.

Owner:ORTHOARM

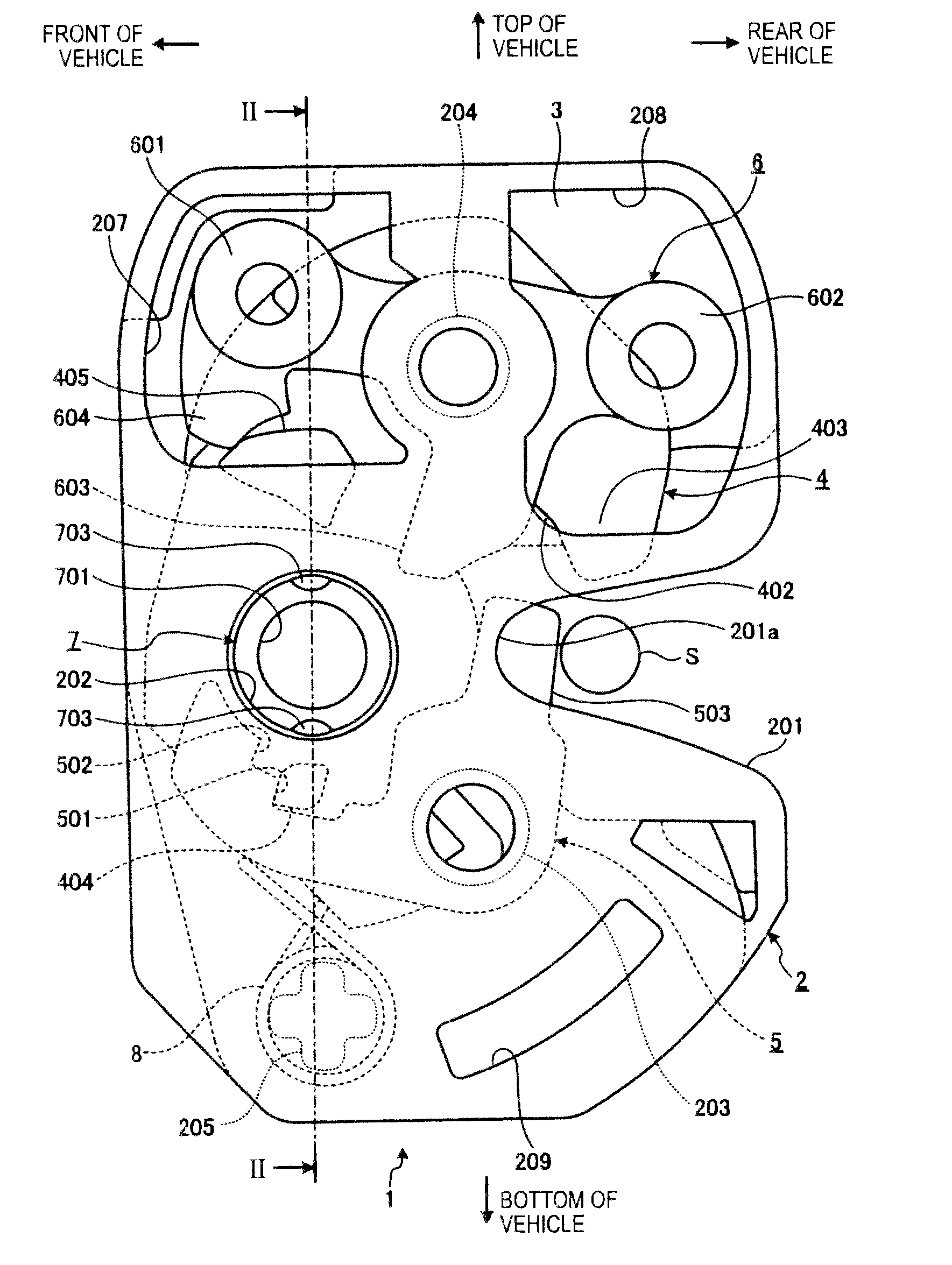

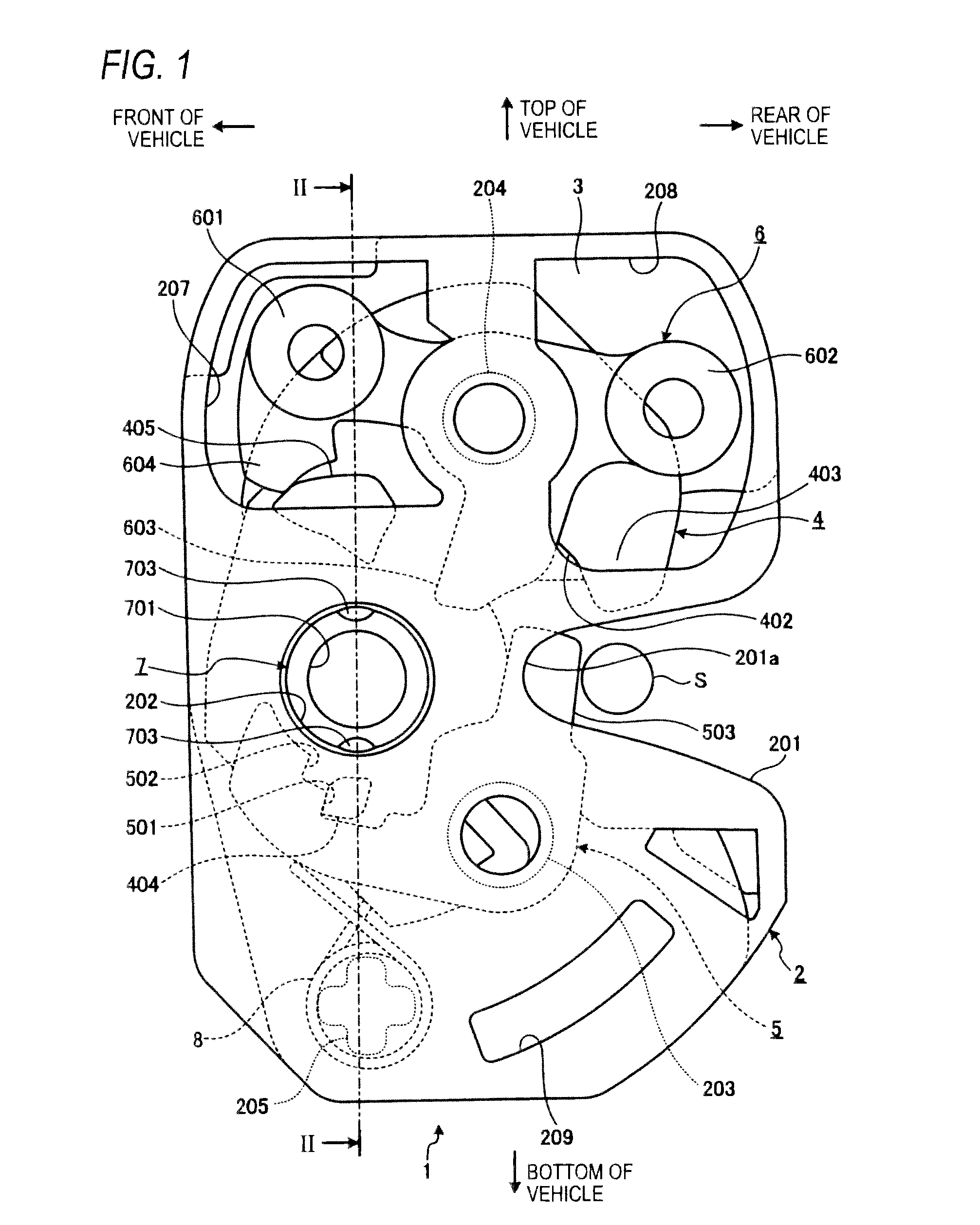

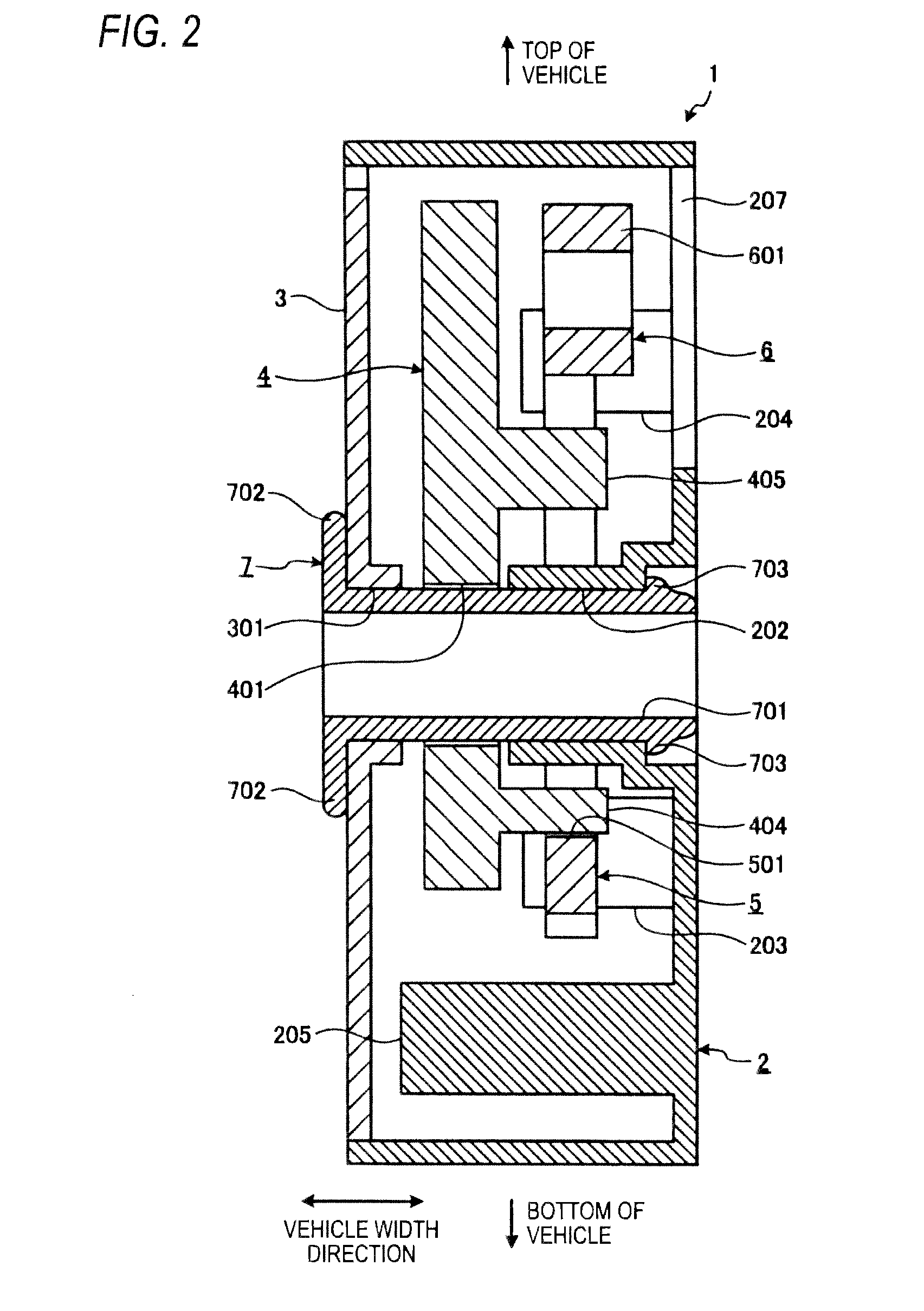

Seat lock apparatus

InactiveUS20140117698A1Avoid heavy forceAvoid it happening againMovable seatsMonocoque constructionsEngineeringMechanical engineering

A seat lock apparatus includes a guide lever having a waiting hook engagement portion and a striker abutment portion and a hook having a guide engagement portion which, when the hook reaches a waiting position which lies further in a striker releasing direction than a striker releasing position, engages with the waiting hook engagement portion to hold the hook in the waiting position and is disengaged from the waiting hook engagement portion so that the hook restrains the striker. The guide lever has a halfway hook engagement portion which, when the hook is in a halfway position between the releasing position and a restraining position and the striker is not in a position to be restrained by the hook, engages with the guide engagement portion to hold the hook in the halfway position.

Owner:MITSUI KINZOKU ACT

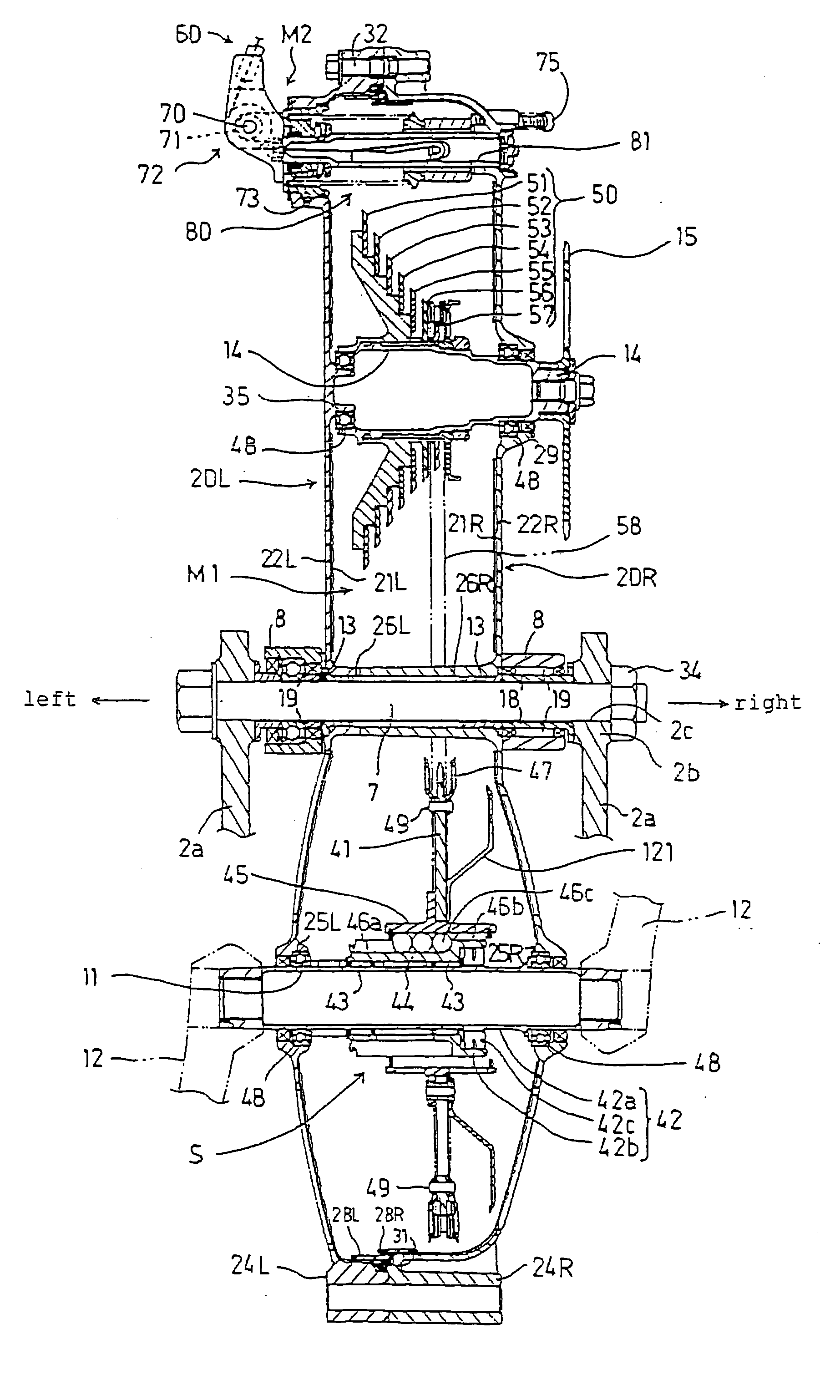

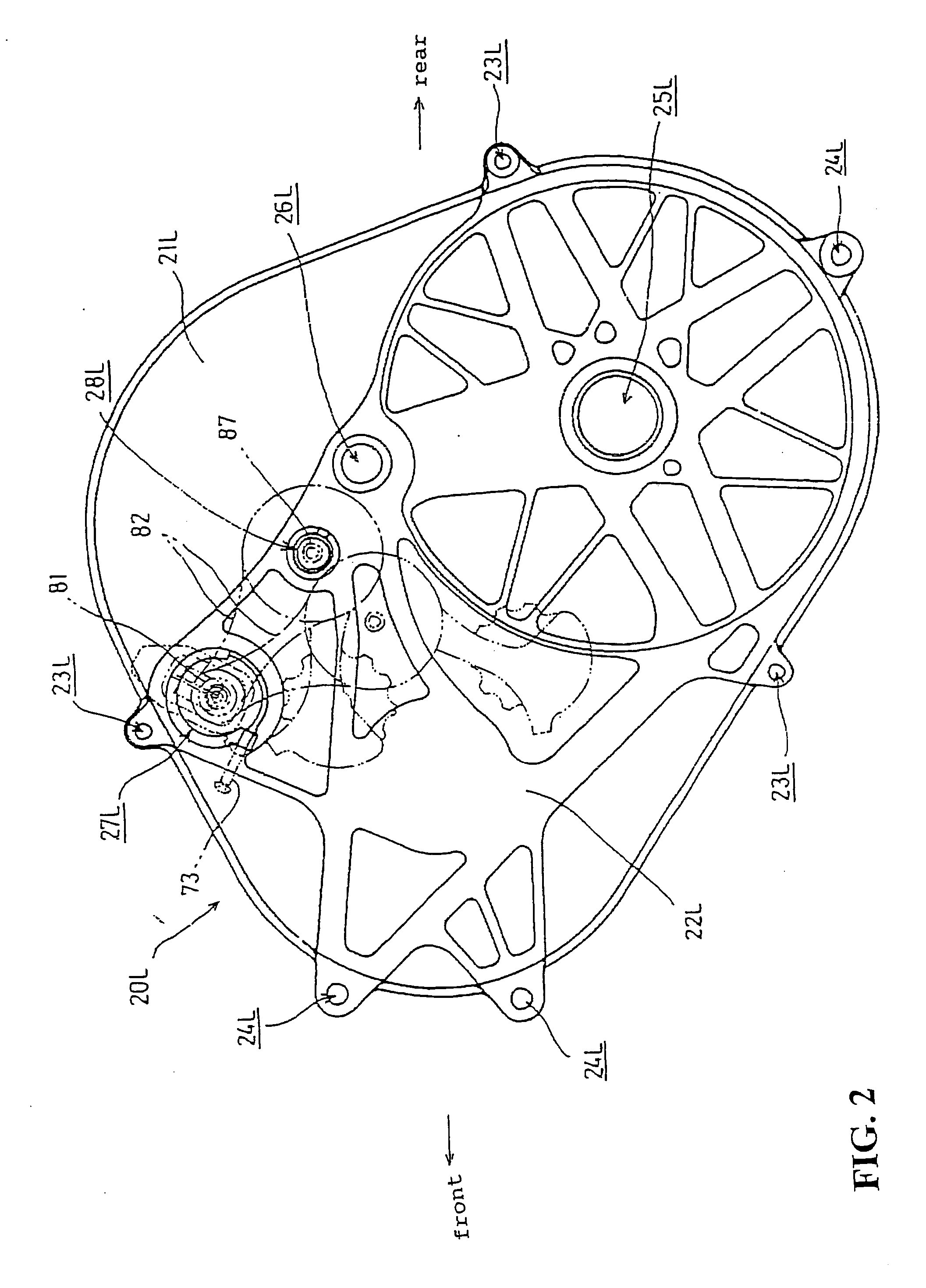

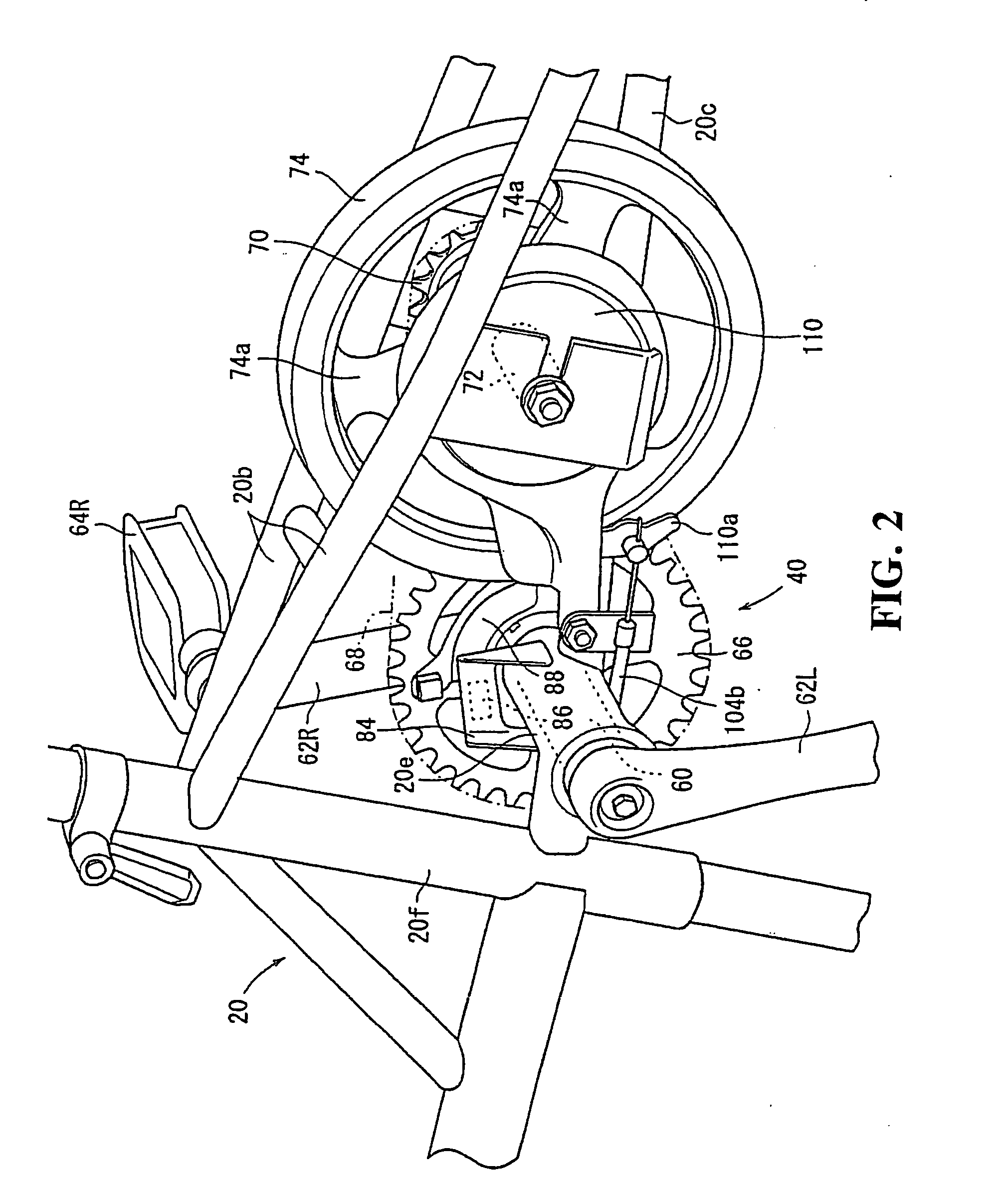

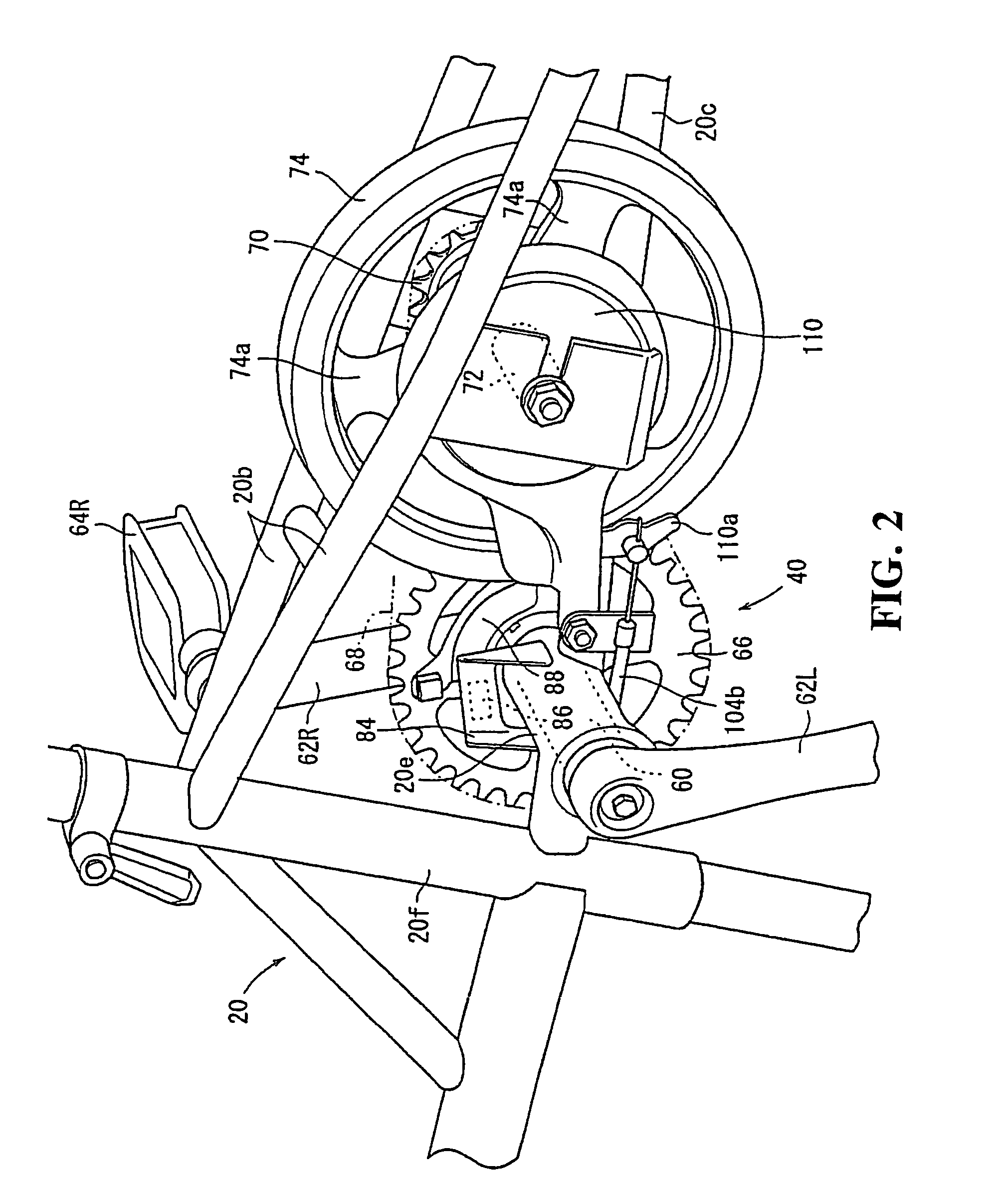

Drive sprocket wheel slide restricting structure of bicycle transmission

InactiveUS20050176536A1High precisionSmooth changeWheel based transmissionChain/belt transmissionSprocketPower transmission

A transmission for a bicycle includes a derailleur shaft supported by a case member. A derailleur arm is movably journaled by the derailleur shaft. A guide rotational body is rotatably supported by the derailleur arm and an endless power transmission belt is wound therearound. The endless power transmission belt is shifted among a plurality of rotational body elements which constitute a speed-change rotational body for changing the speed-change ratio. An operating pin is connected to a wire which moves in the fore-and-aft direction in accordance with the speed-change operation so that the derailleur arm is rotated with respect to the derailleur shaft and translated toward the center axis of the derailleur shaft by the operating pin being moved while being guided through the guide hole by the speed-change operation via the wire. A roller is rotatably journaled by the operating pin is rotatably fitted in the guide hole.

Owner:HONDA MOTOR CO LTD

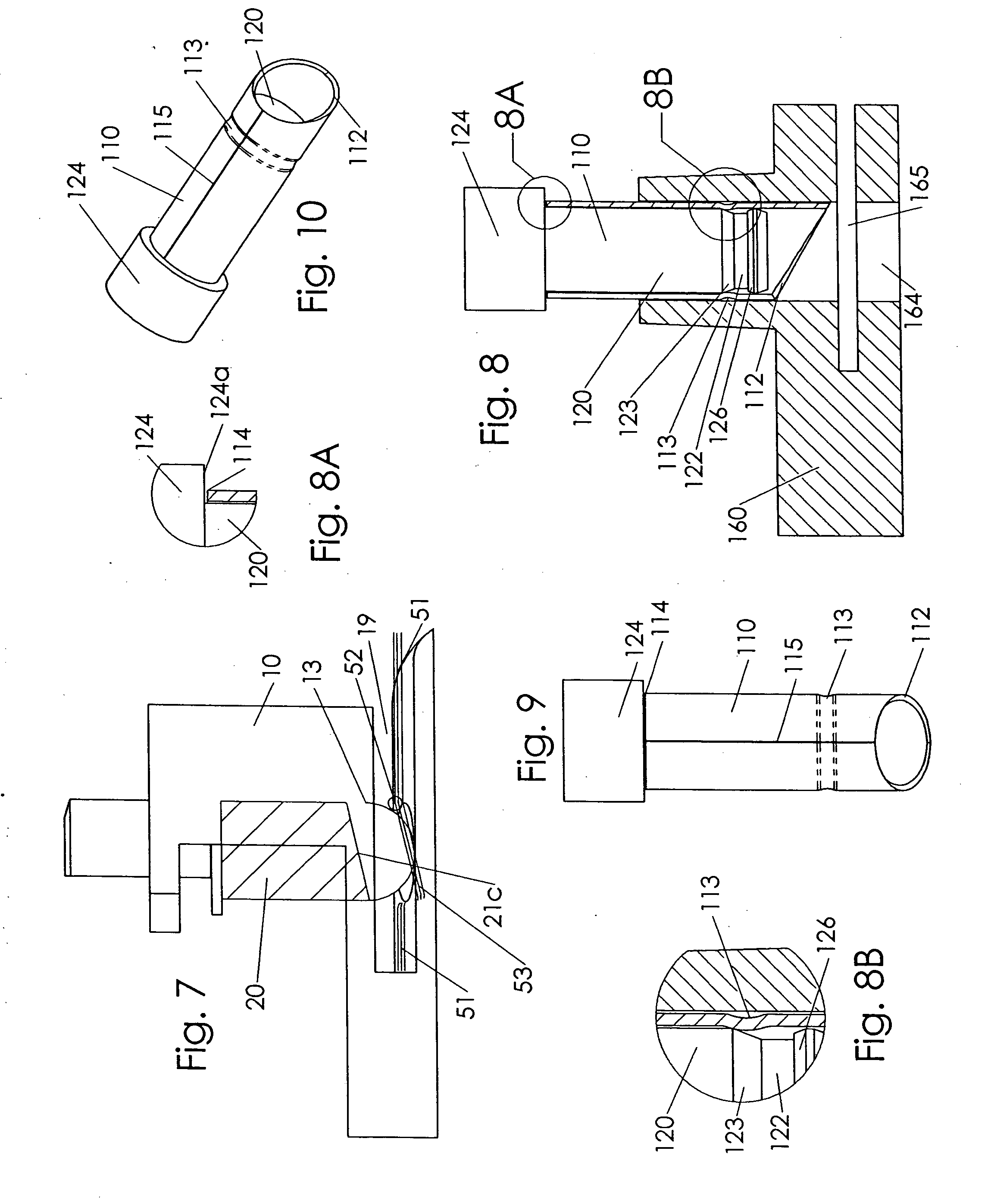

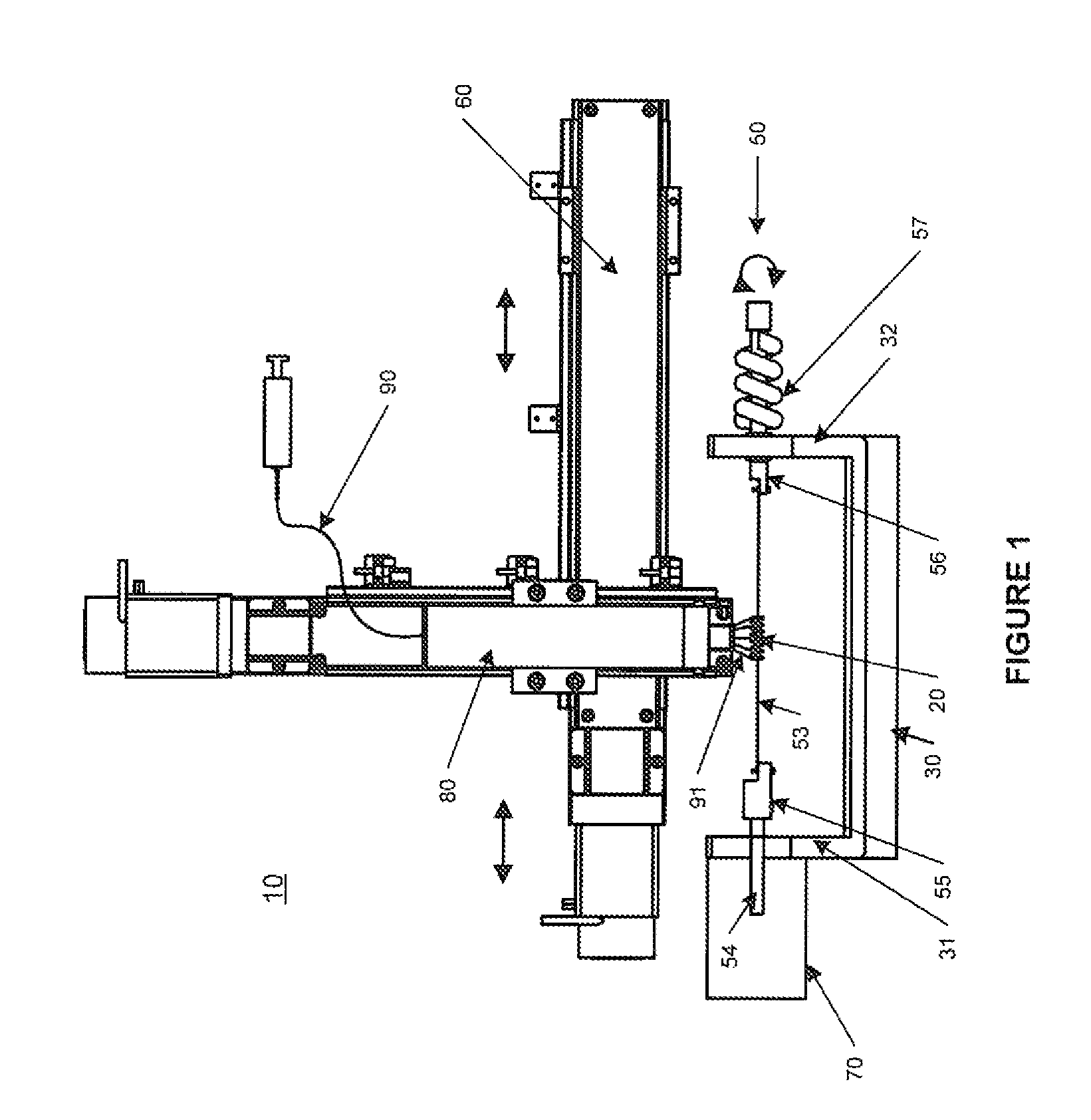

Apparatus for Holding a Medical Device During Coating

InactiveUS20090090299A1Remove shadowsInexpensive and robustLiquid surface applicatorsSpraying apparatusInsertion stentMedical device

The present invention is directed towards the holding of medical devices during manufacture to enable the application of therapeutic and / or protective coatings. More specifically, the present invention provides medical device holders that securely retain stents and other medical devices during the application of a coating while minimizing compressive and tensile forces applied to the stents. The invention avoids disruptions to coating quality due to holder blockage during coating deposition. The invention discloses an improved device containing a mandrel and frame that may improve coating uniformity by eliminating shadowing from the frame of the medical device holder when applying coatings to stents and other medical devices.

Owner:ADOLFO MENENDEZ +4

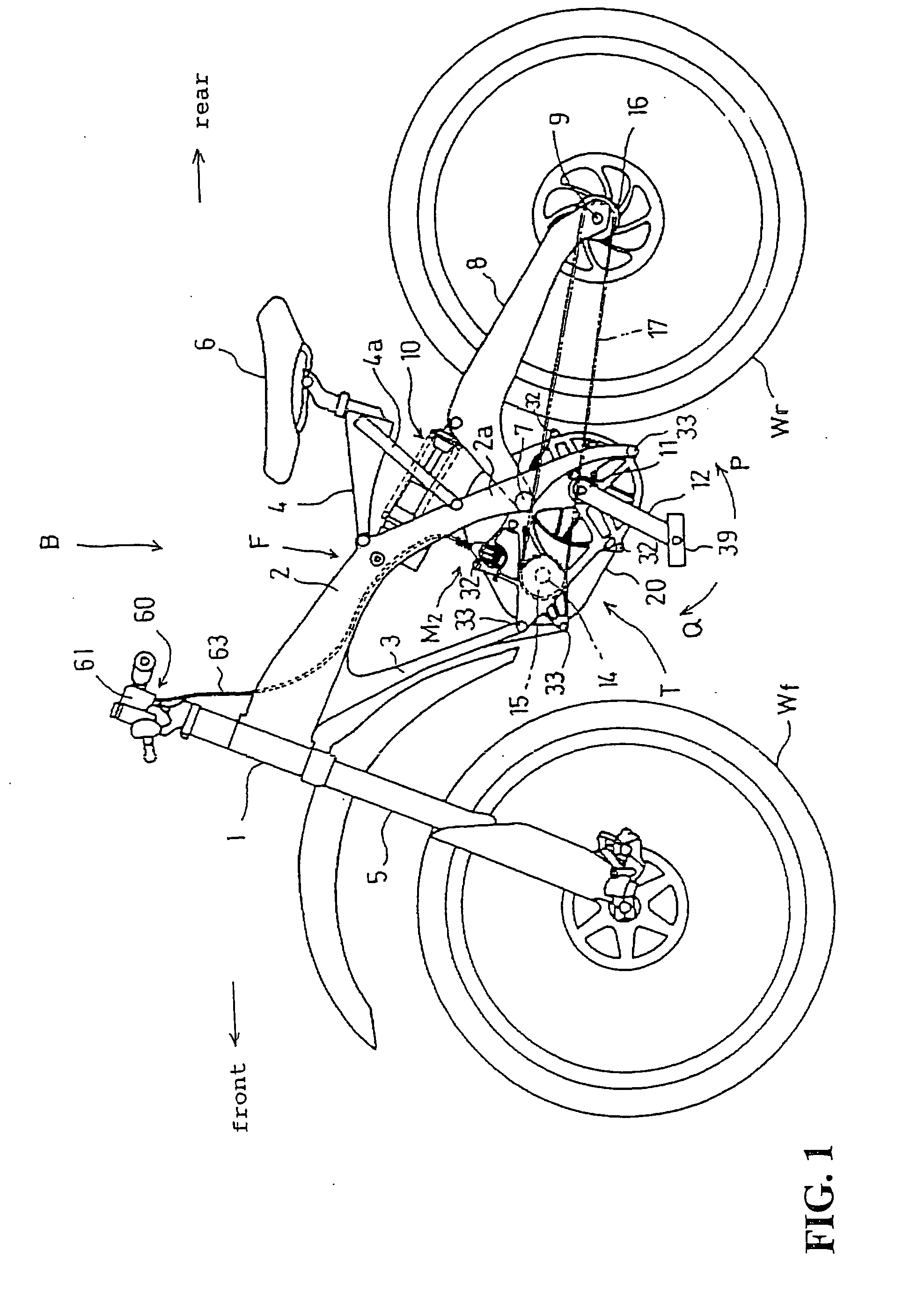

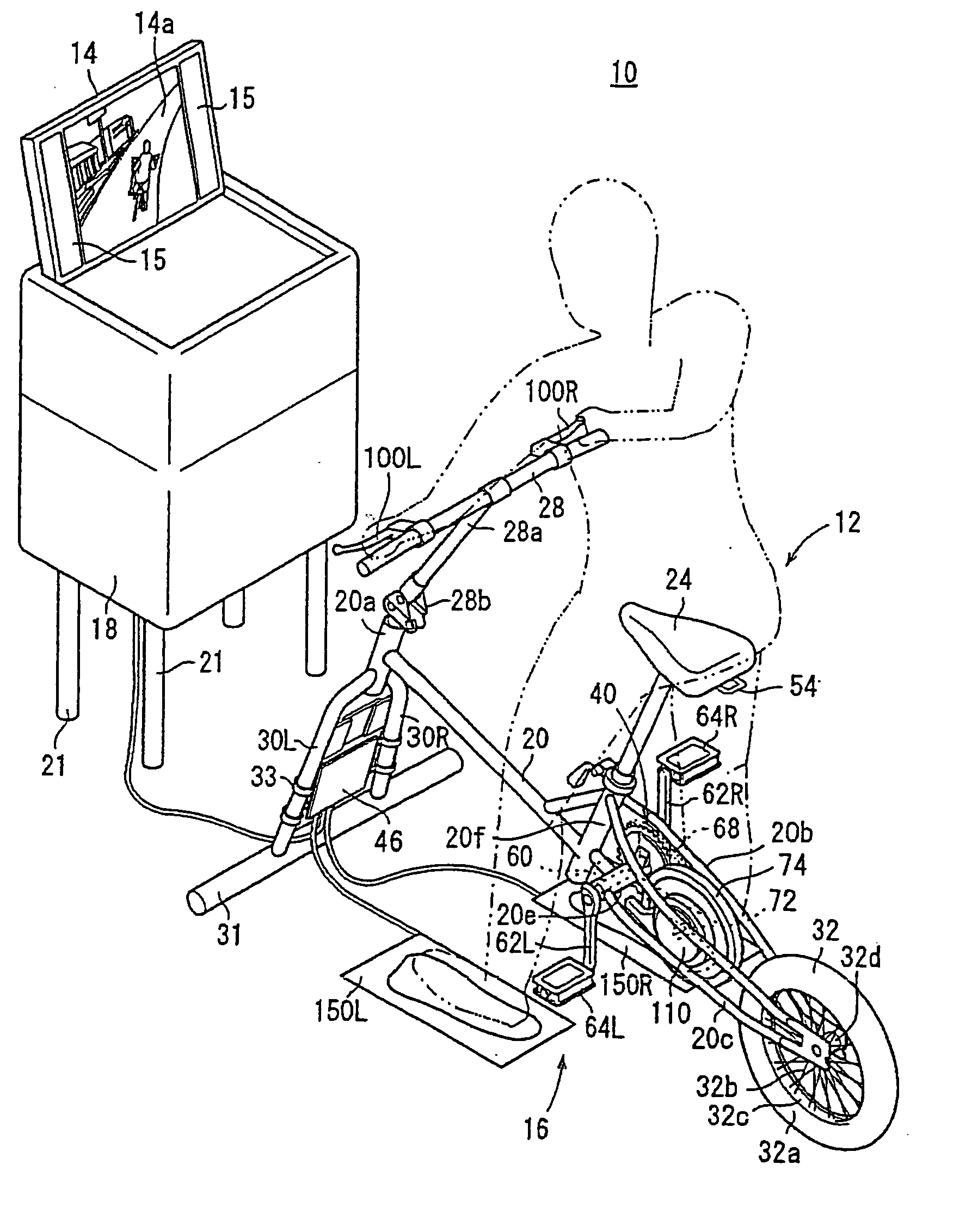

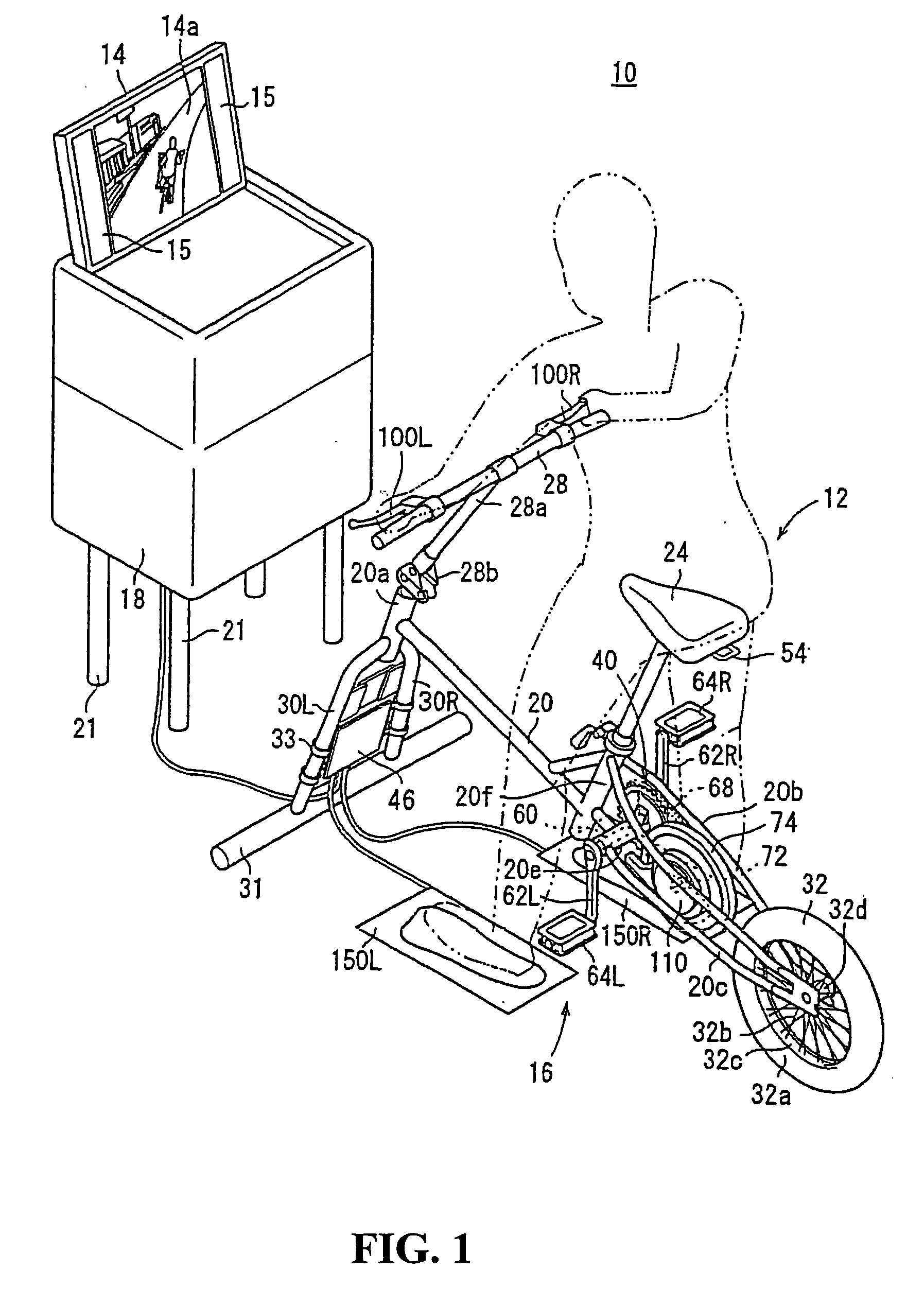

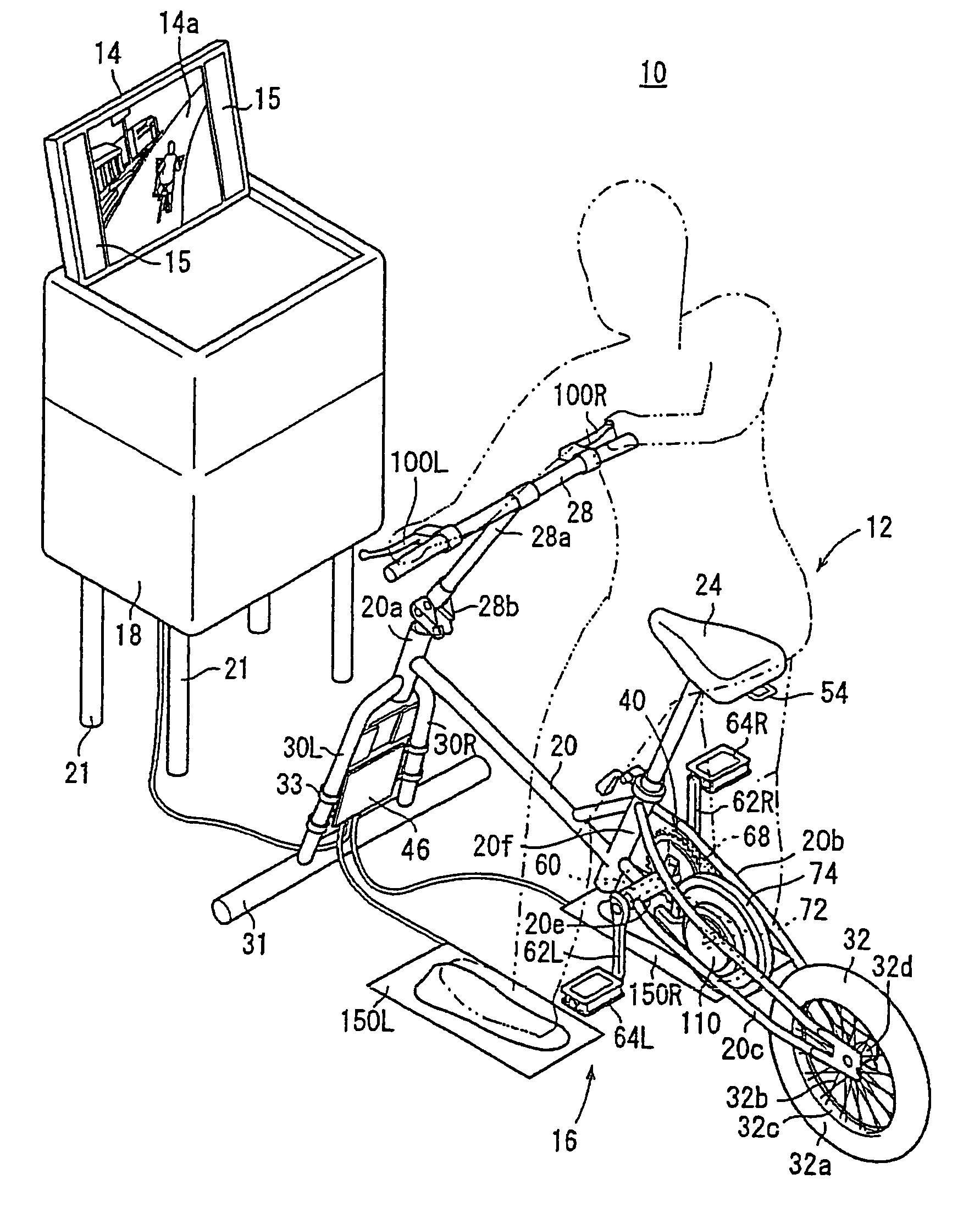

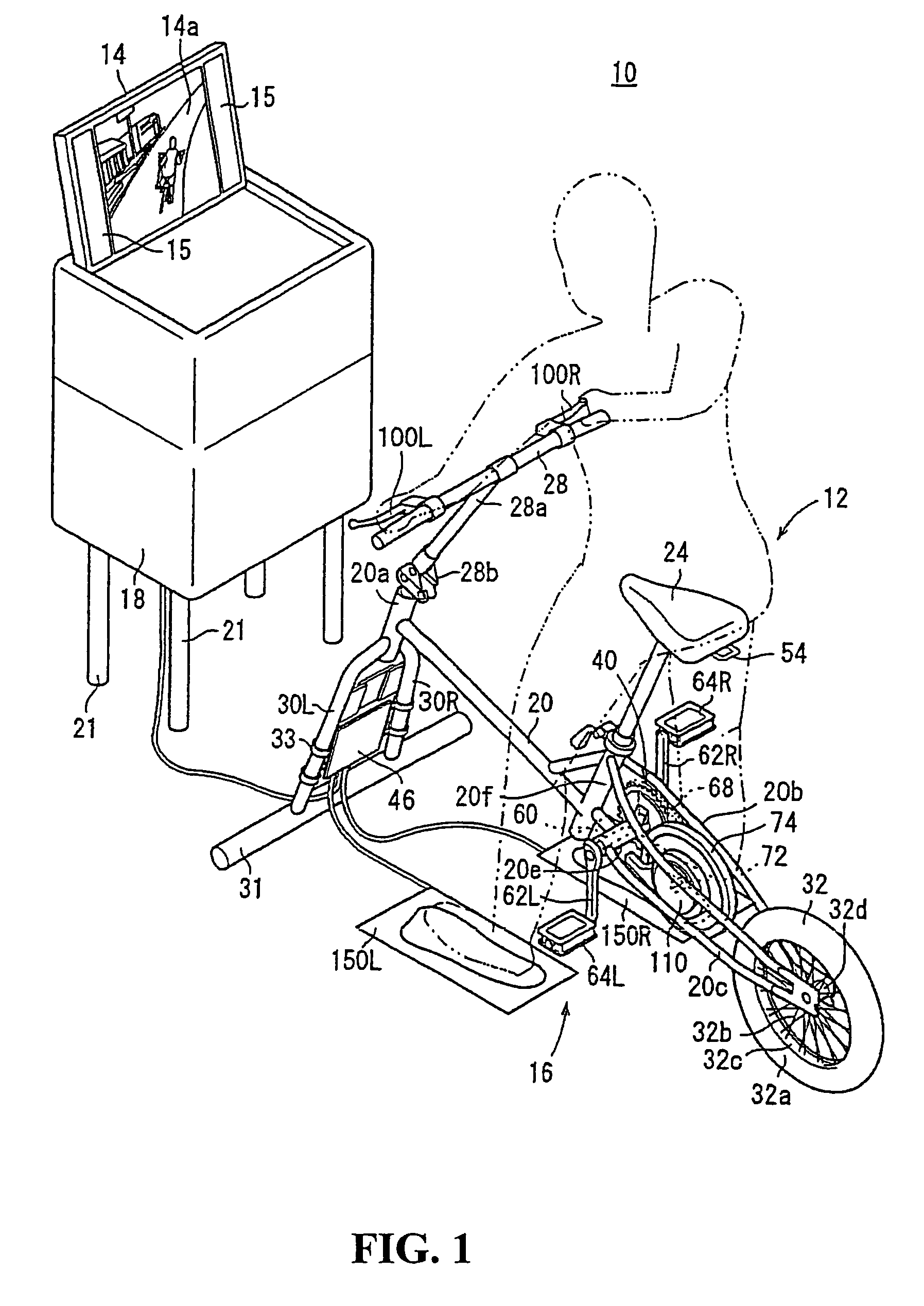

Bicycle simulation system

InactiveUS20060270527A1Easily conveyedEasy to transportSpace saving gamesSimulatorsVehicle frameEngineering

A bicycle simulation system that can be easily transported includes a frame, a steering handle operated by a rider, a left-right pair of pedals to be operated by the rider for rotating a flywheel, two front forks for supporting the head tube and a rotatable rear wheel. The rear wheel is grounded on a floor so that it supports the frame, together with the front forks. The bicycle simulation system ensures that the operations of a brake lever are accompanied with the same feeling as that in operating a real bicycle. A brake lever is operated by the rider with a drum brake for frictionally braking the rotation of the flywheel in conjunction with the brake lever. A brake wire extending from the brake lever and is branched into two brake wires, one connected to the drum brake, and the other connected to the rotational sensor.

Owner:HONDA MOTOR CO LTD

Hole punch element

ActiveUS20070267472A1Improve scalabilityImprove pore forming efficiencyMetal working apparatusDigital marking by punchingEngineeringCutting force

Owner:WORKTOOLS

Apparatus for holding a medical device during coating

InactiveUS8689728B2Solve the lack of tensionMinimizing creationSpraying apparatusPharmaceutical containersInsertion stentMedical device

Owner:ADOLFO MENENDEZ +4

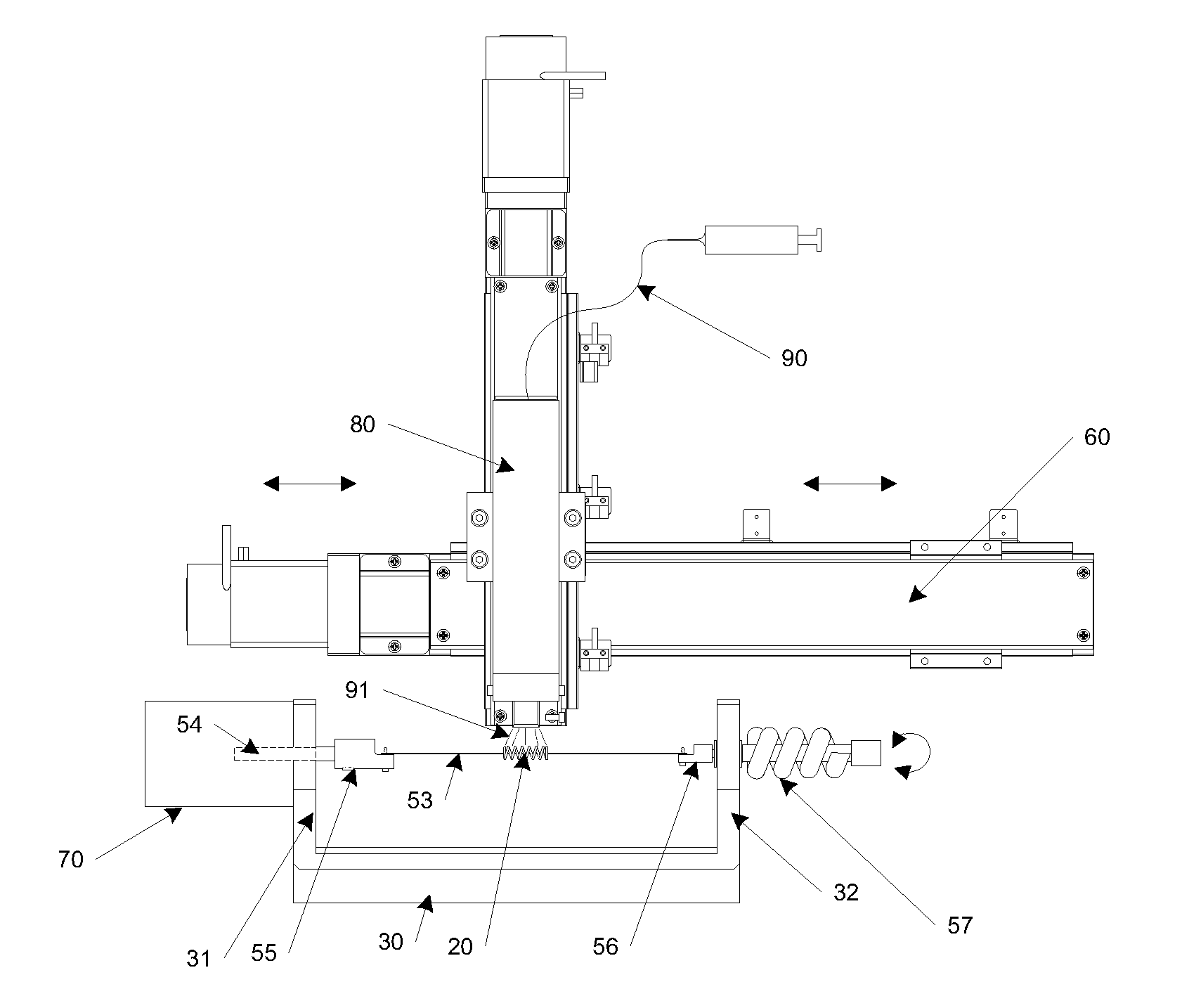

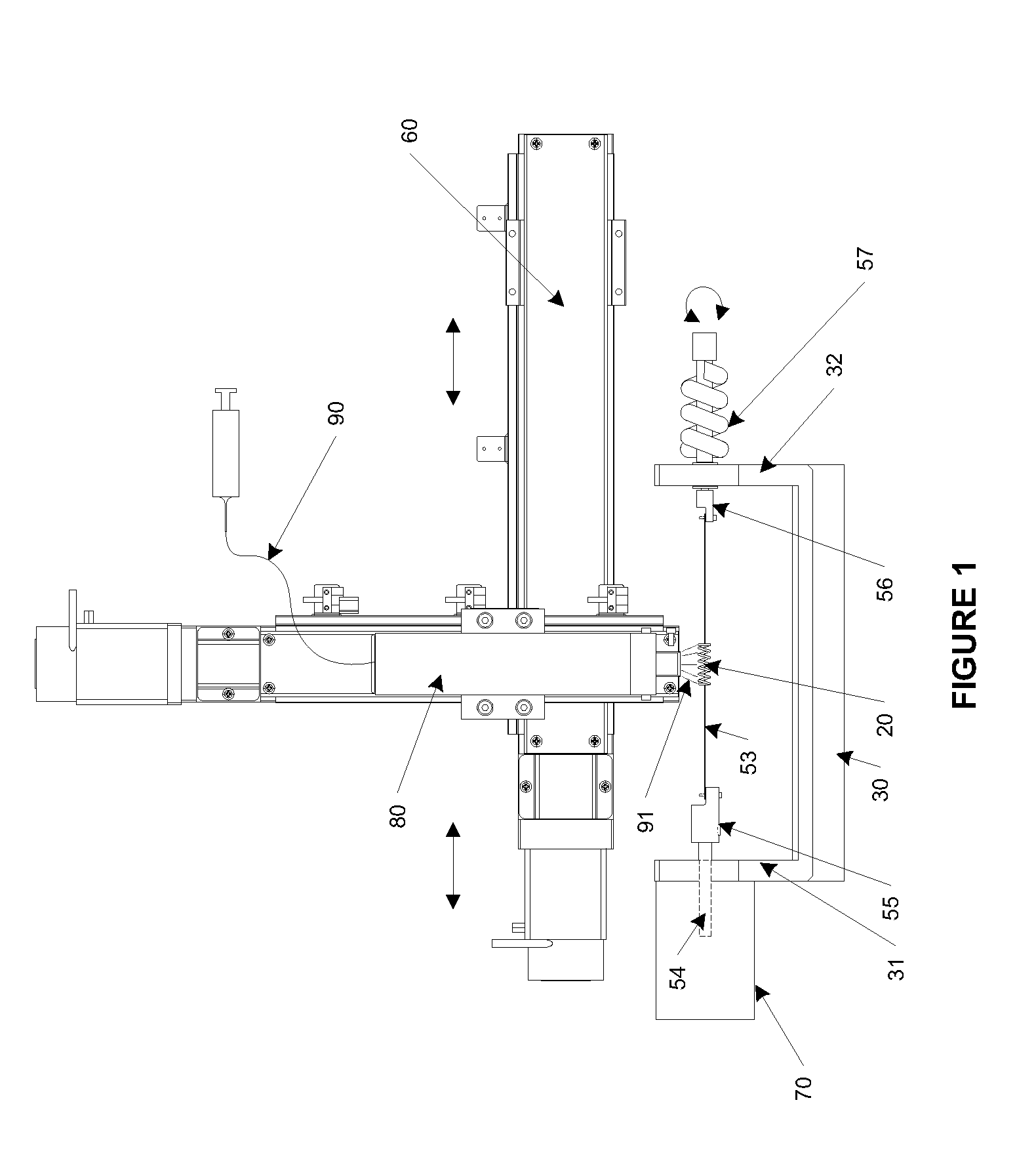

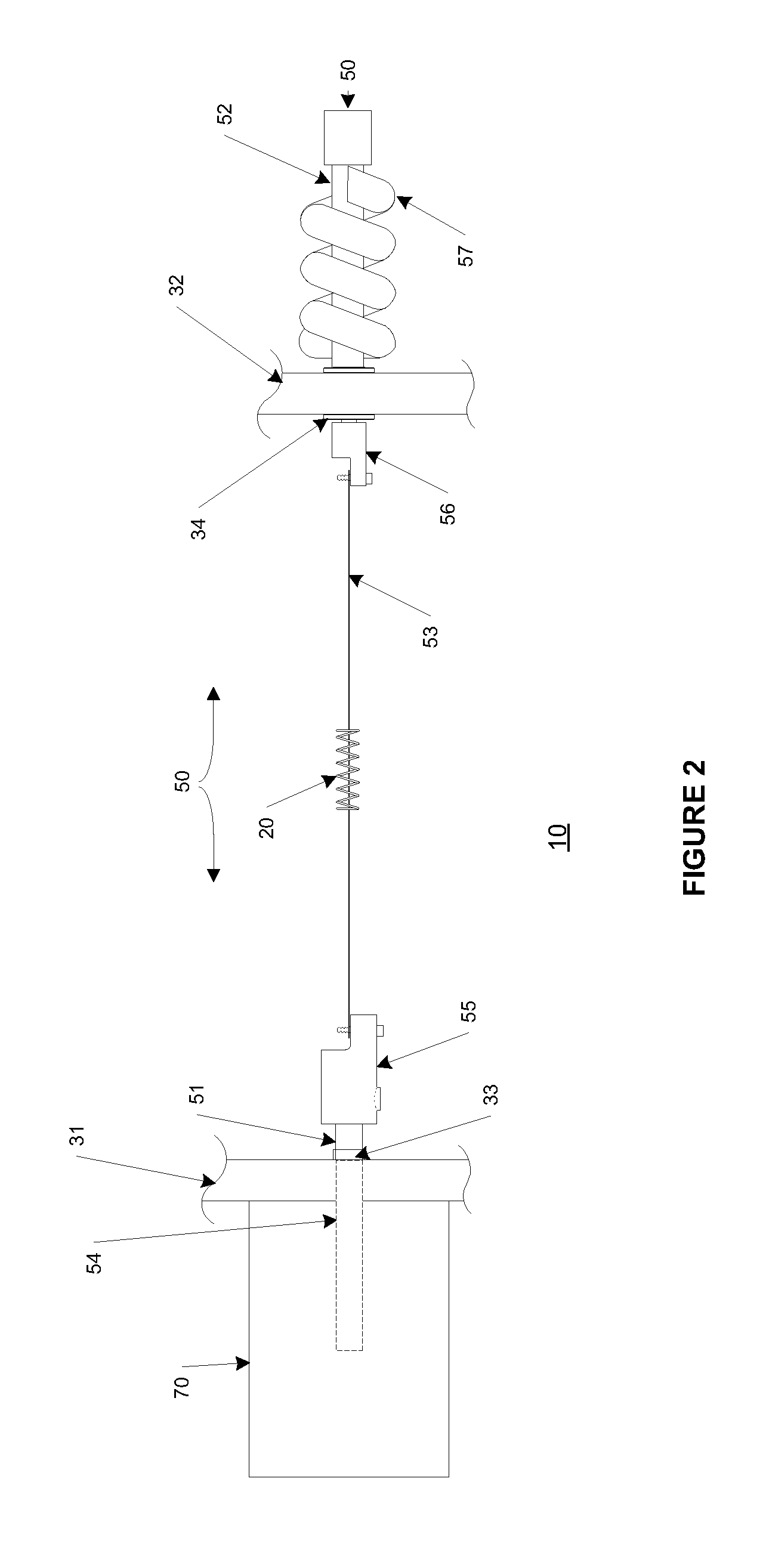

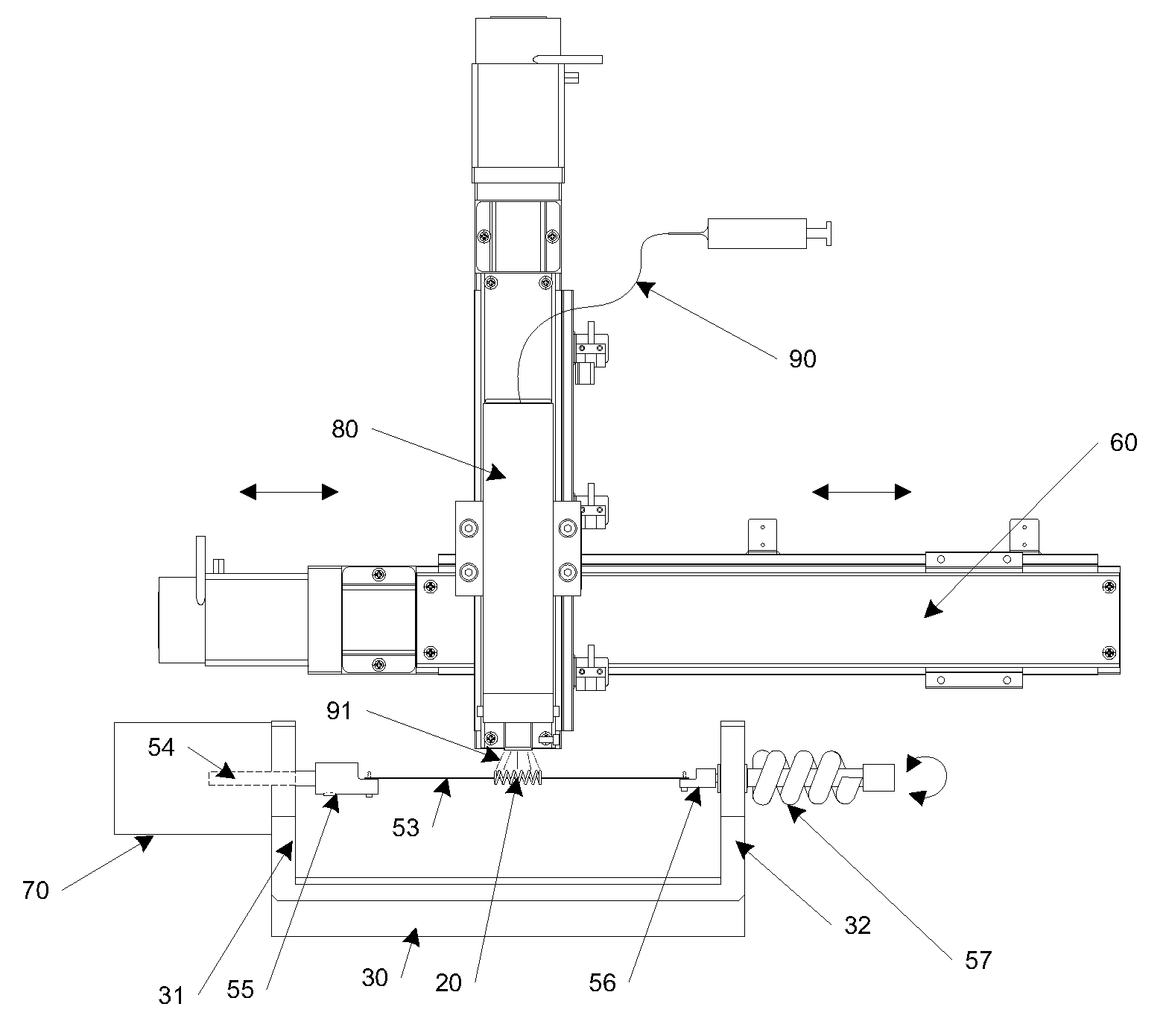

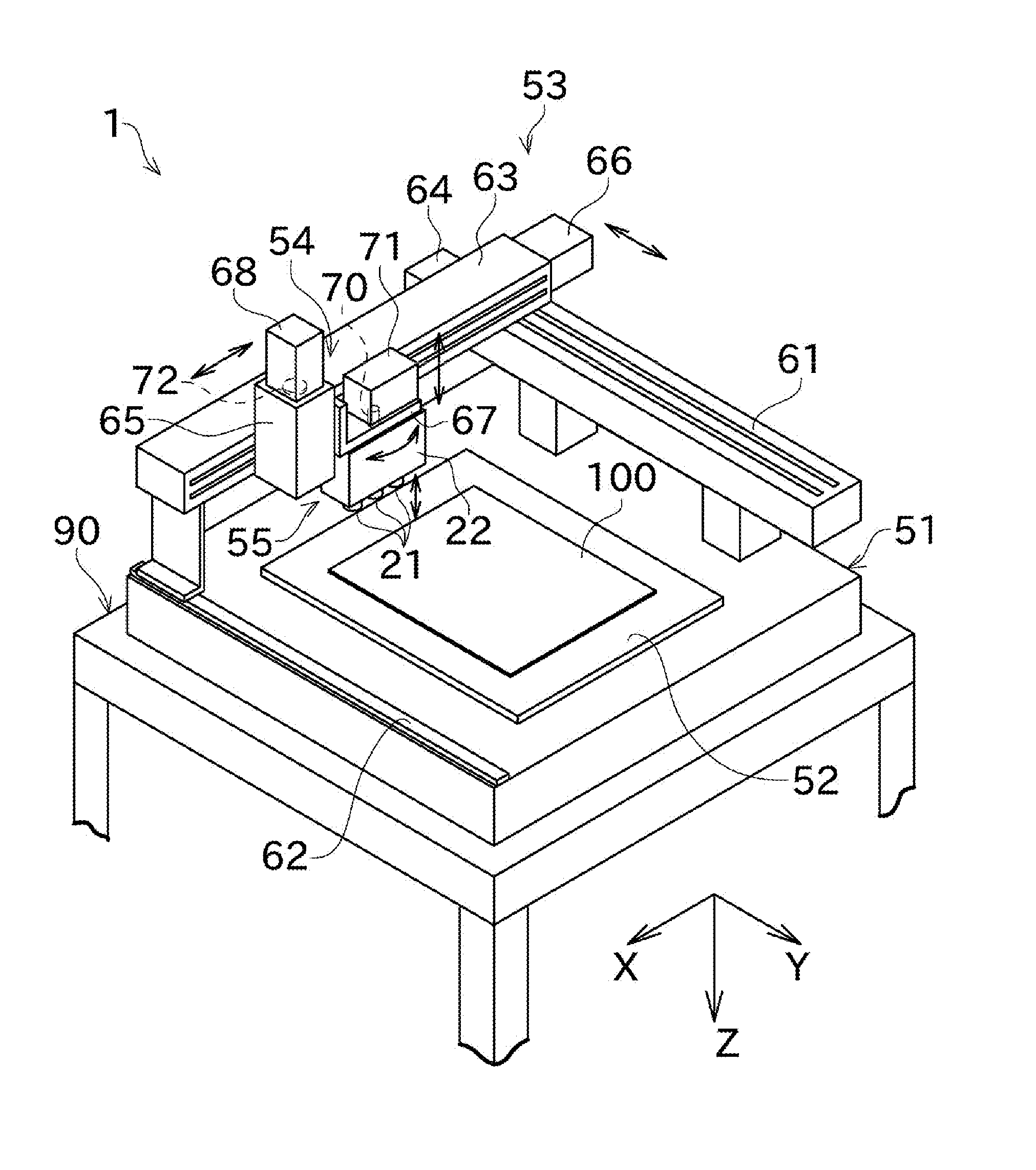

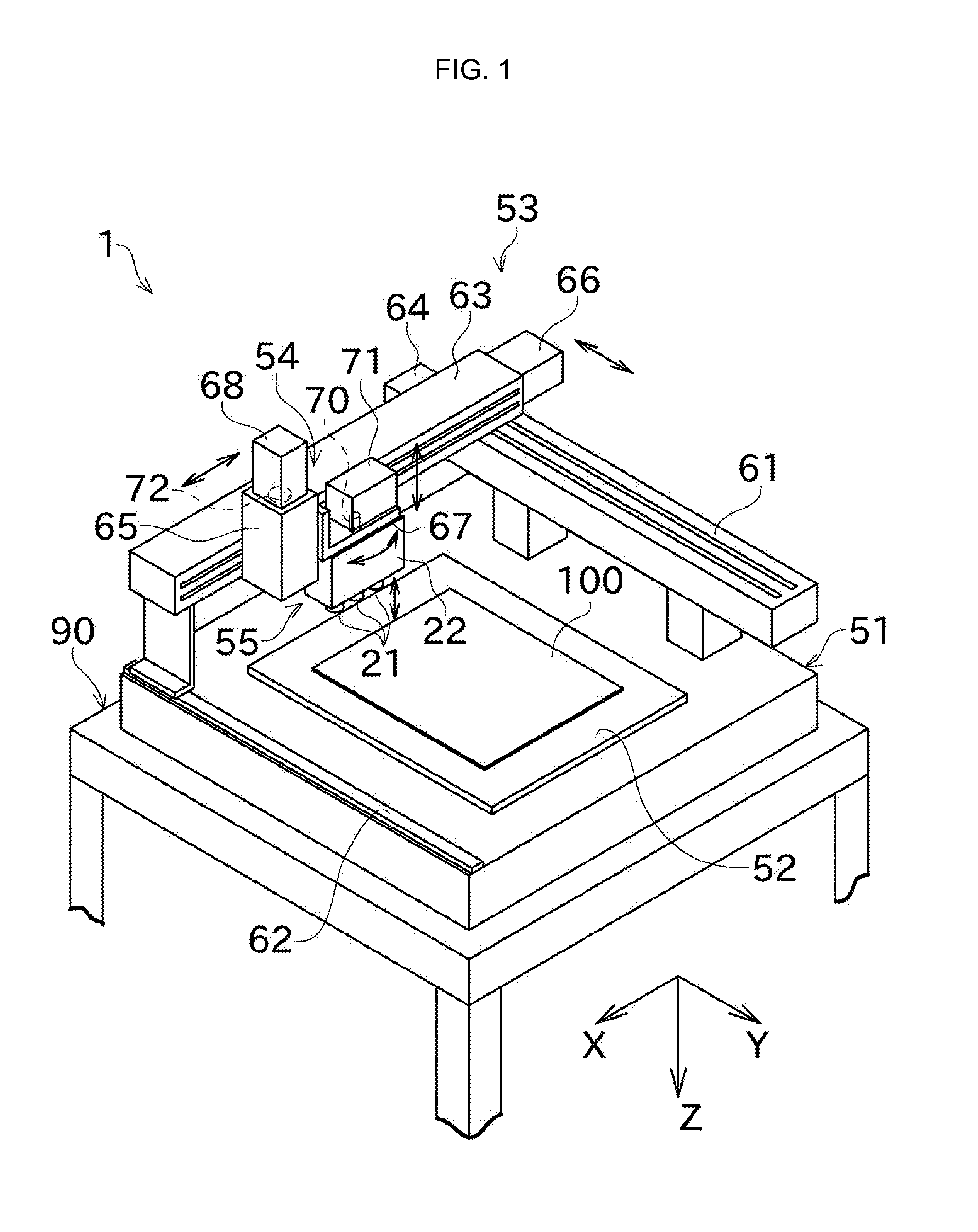

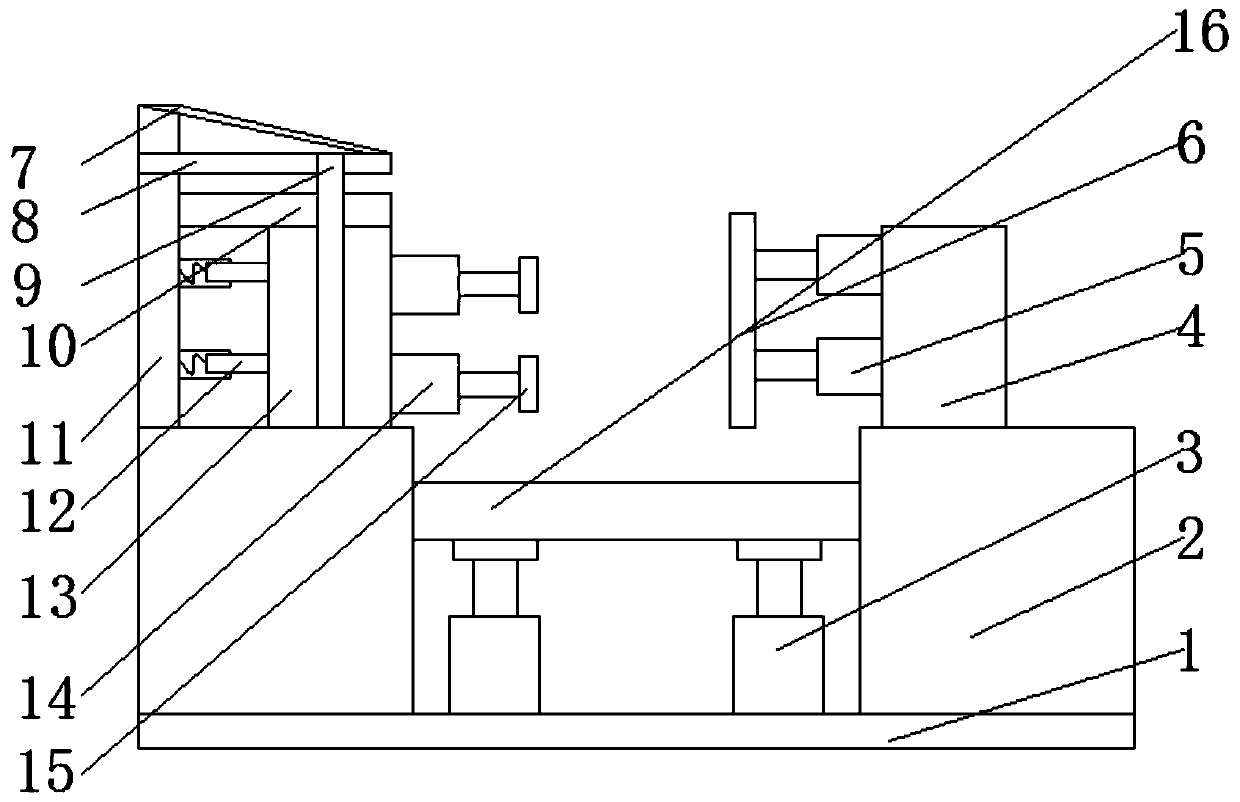

Touch panel inspecting apparatus

InactiveUS20150212625A1Flexible and easy to changeImprove inspection efficiencyError detection/correctionInput/output processes for data processingEngineeringTouchscreen

A touch panel inspecting apparatus includes a workpiece holder, a pseudo finger, an X-Y movement mechanism, a memory part, an electric pneumatic regulator, and a panel signal acquiring part. The workpiece holder allows a touch panel, which is an inspection target, to be set thereon. The pseudo finger is contactable with the touch panel set on the workpiece holder. The X-Y movement mechanism moves the pseudo finger relative to the touch panel. The memory part stores therein a set value of pressing force of the pseudo finger, in a changeable manner. The electric pneumatic regulator regulates the pressing force to bring the pseudo finger into contact with the touch panel, based on the set value stored in the memory part. The panel signal acquiring part acquires an electric signal output from the touch panel.

Owner:NIDEC-READ CORPORATION

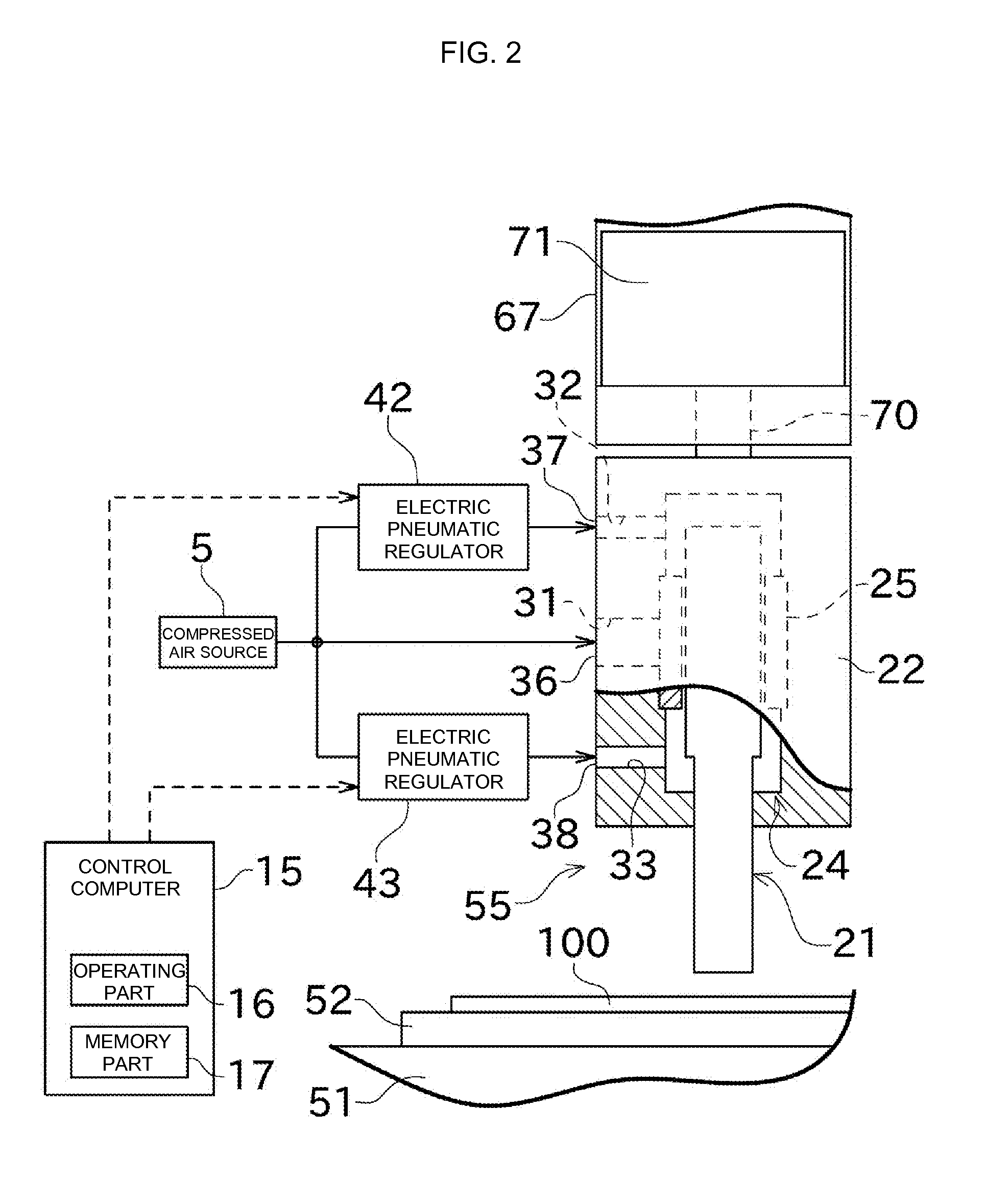

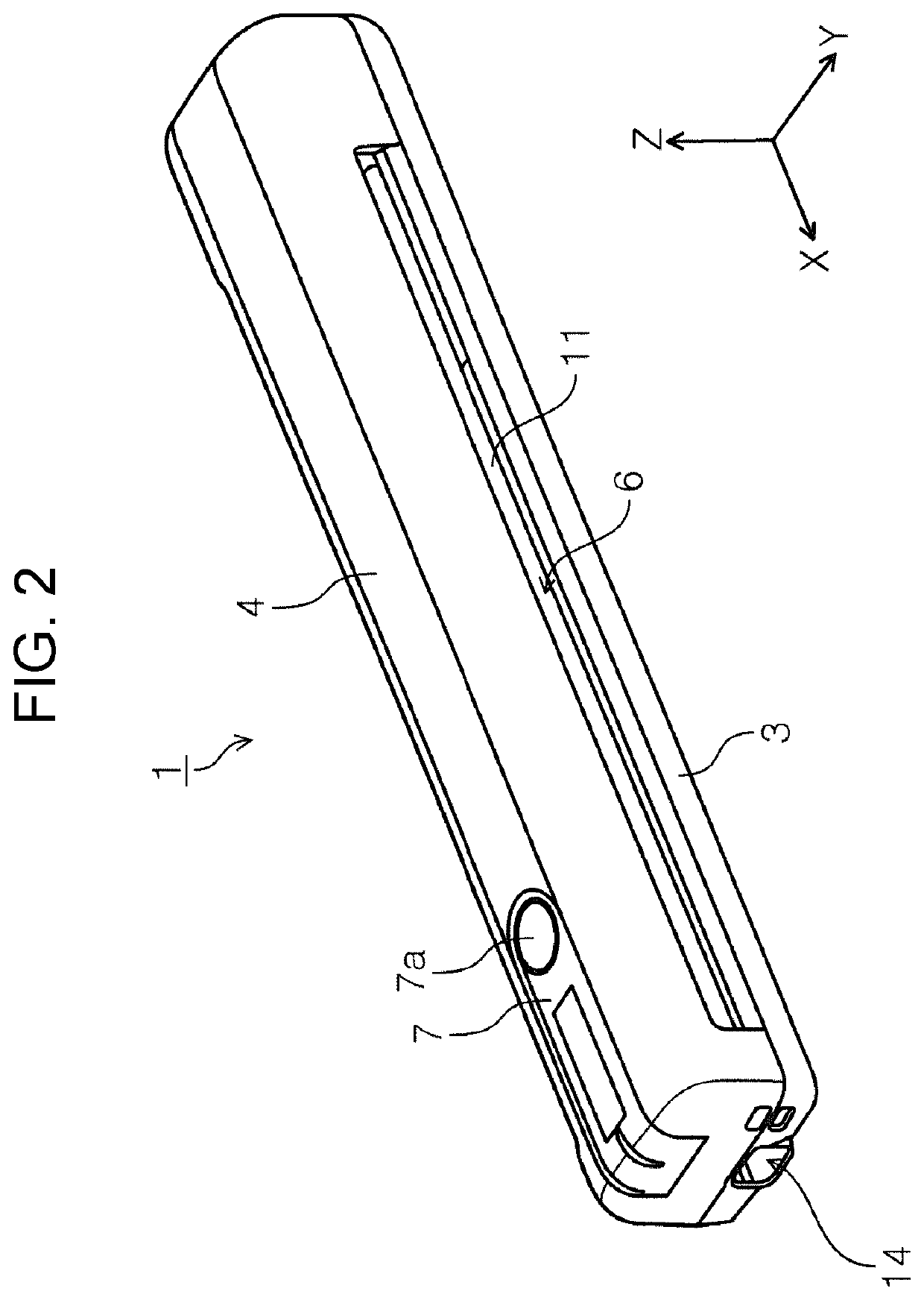

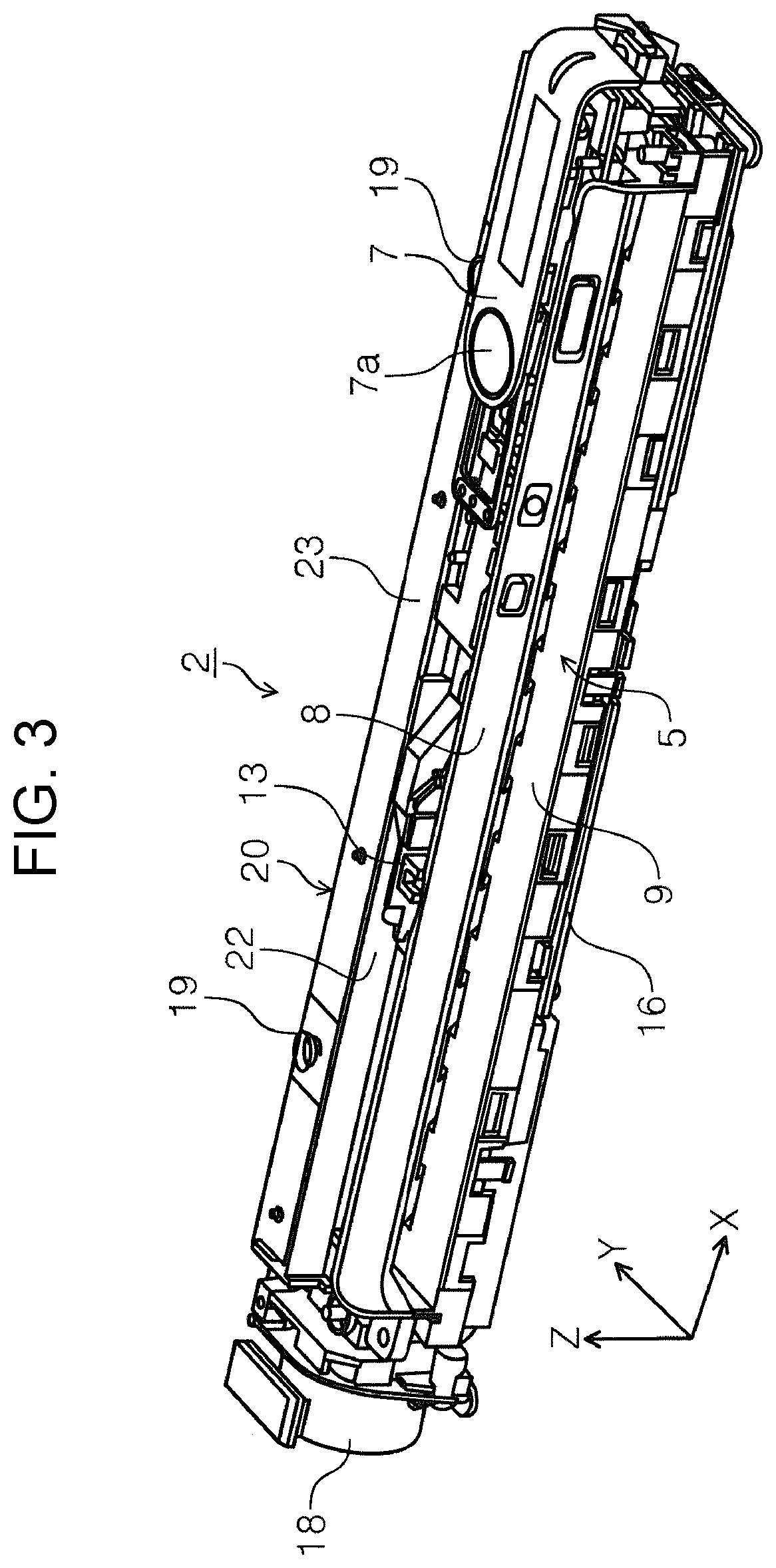

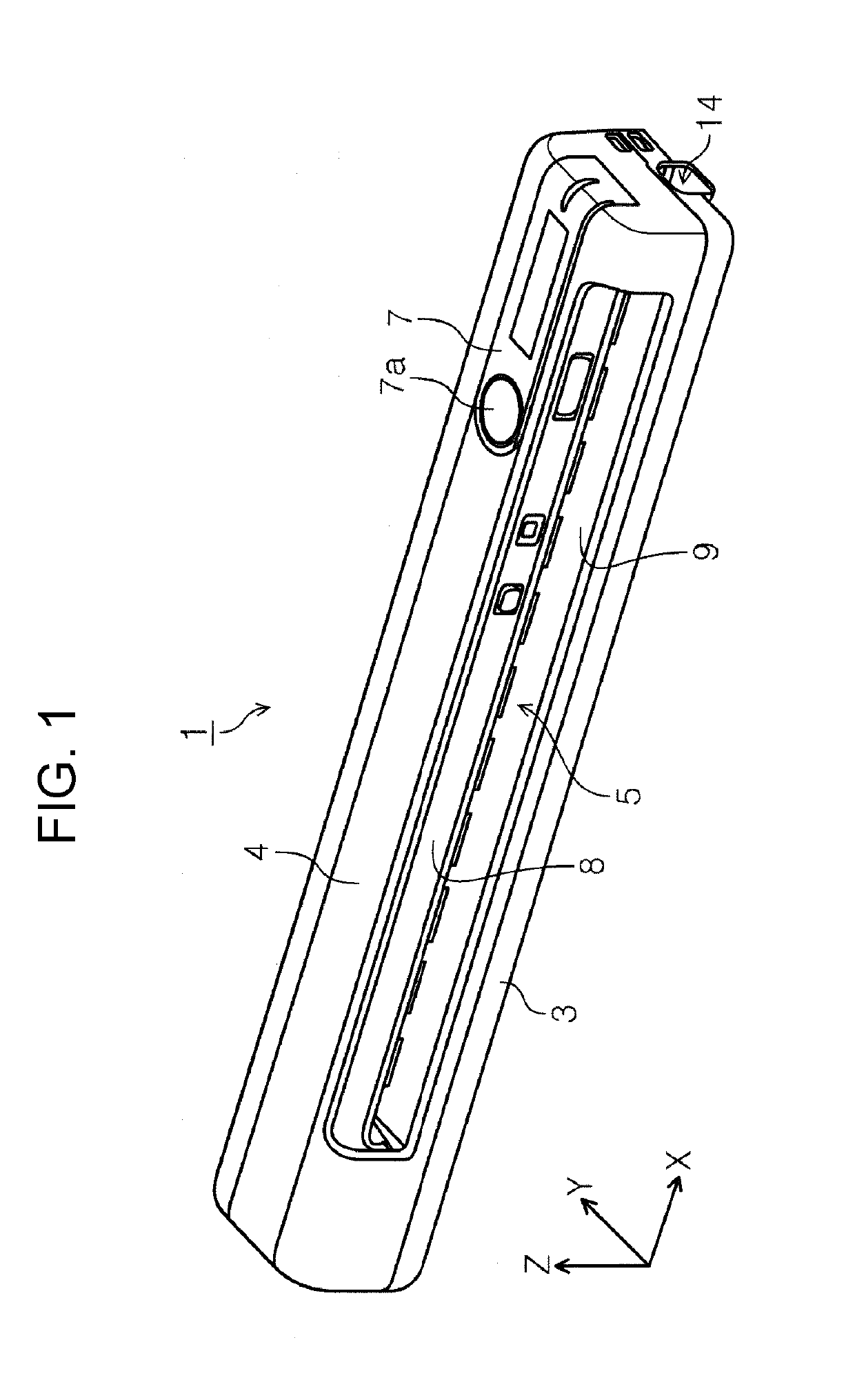

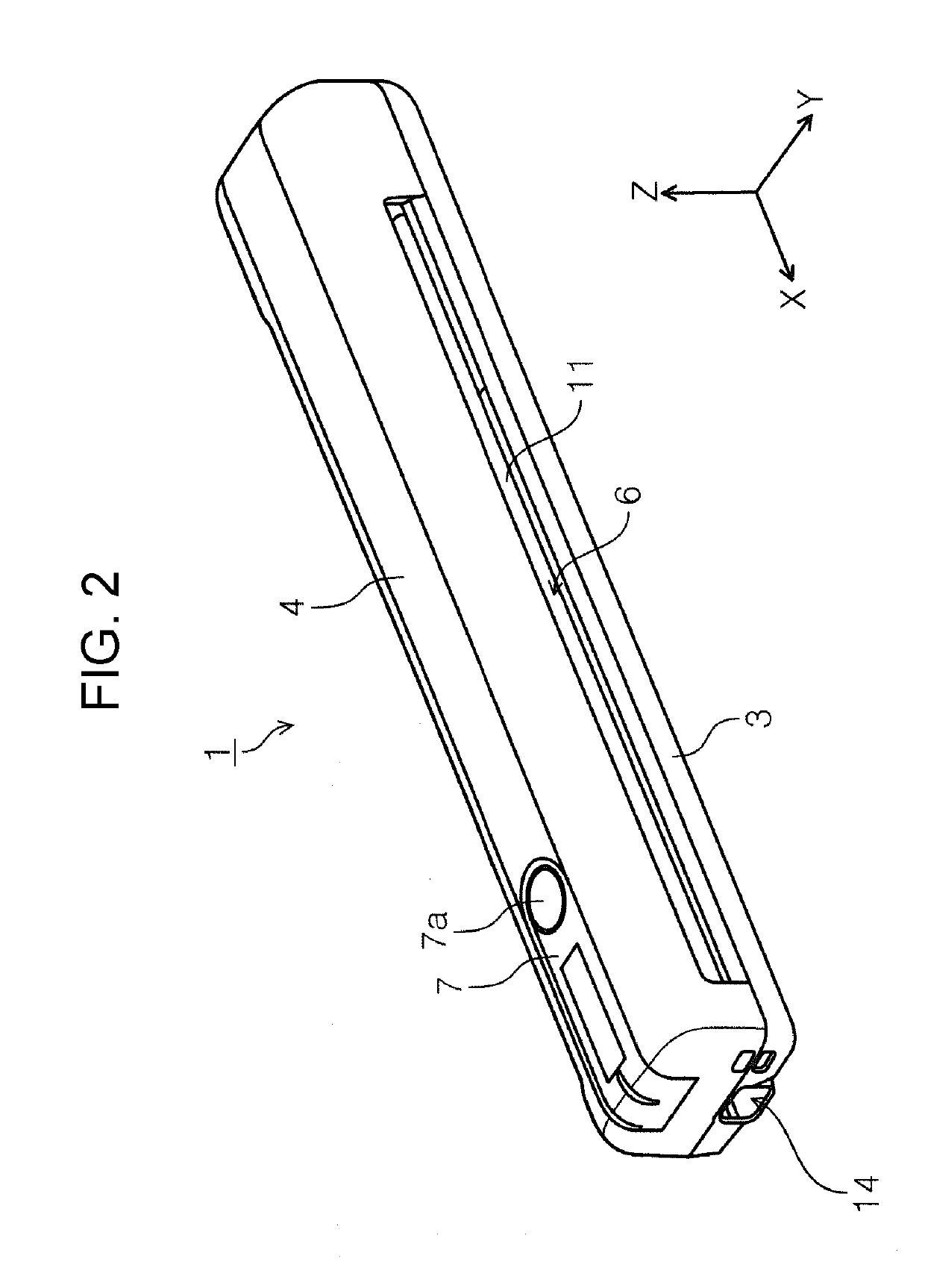

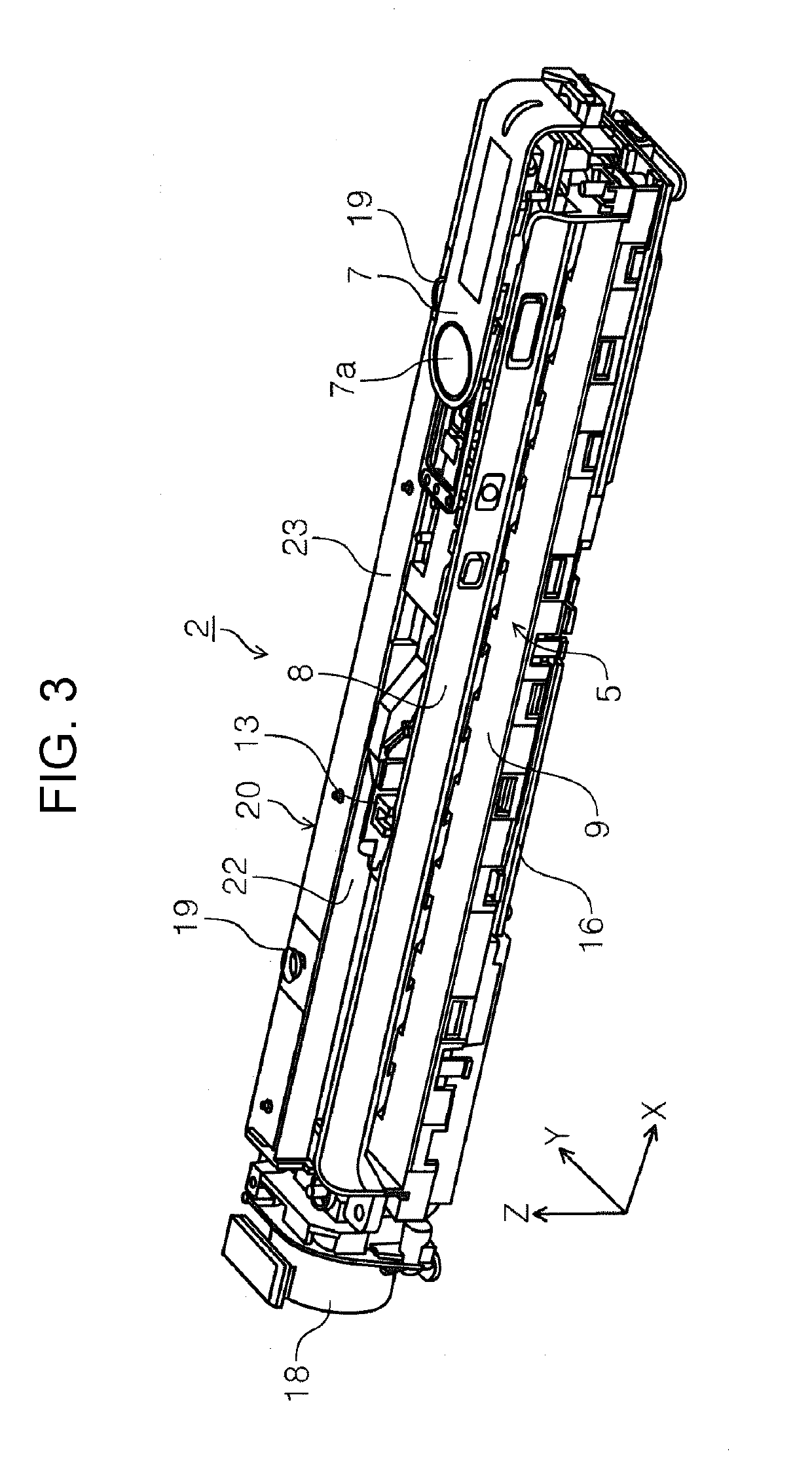

Image reader

ActiveUS10594881B2Reduce weightAvoid heavy forcePictoral communicationEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

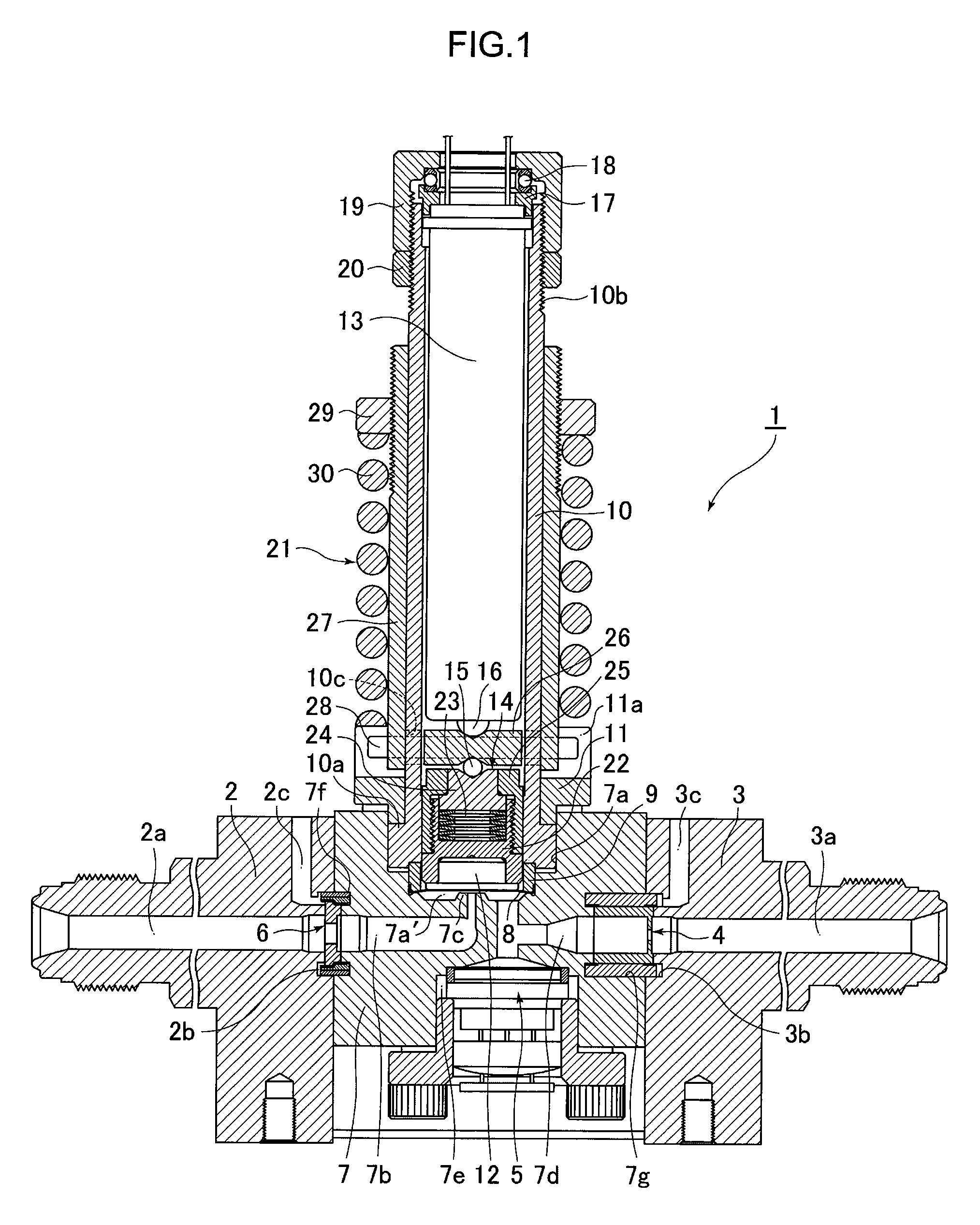

Piezoelectric element driven metal diaphragm control valve

ActiveUS20110042595A1Good effectPrecise flow controlDiaphragm valvesOperating means/releasing devices for valvesElectricityEngineering

A control valve has a body that forms a valve chamber and a valve seat, a metal diaphragm installed inside the valve chamber and making contact with and departing from the valve seat, an actuator box fixed to the side of the body, a piezoelectric element installed inside the actuator box to thrust the metal diaphragm through mediation of a metal diaphragm presser by elongating downward when voltage is applied, a conical spring mechanism that absorbs elongation of the piezoelectric element at the time when the metal diaphragm makes contact with the valve seat and a prescribed thrust is applied to the valve seat and the like, and a preload mechanism that applies upward compressive force to the piezoelectric element all the time wherein the compressive force applied to the piezoelectric element is externally adjustable.

Owner:FUJIKIN INC

Bicycle simulation system

InactiveUS7806810B2Easy to transportEasily conveyedSpace saving gamesFrictional force resistorsFreewheelTurning frames

A bicycle simulation system that can be easily transported includes a frame, a steering handle operated by a rider, a left-right pair of pedals to be operated by the rider for rotating a flywheel, two front forks for supporting the head tube and a rotatable rear wheel. The rear wheel is grounded on a floor so that it supports the frame, together with the front forks. The bicycle simulation system ensures that the operations of a brake lever are accompanied with the same feeling as that in operating a real bicycle. A brake lever is operated by the rider with a drum brake for frictionally braking the rotation of the flywheel in conjunction with the brake lever. A brake wire extending from the brake lever and is branched into two brake wires, one connected to the drum brake, and the other connected to the rotational sensor.

Owner:HONDA MOTOR CO LTD

Image reader

ActiveUS20190335049A1Reduce weightAvoid heavy forcePictoral communicationGravity centerComputer science

Owner:SEIKO EPSON CORP

Fixing device for installation and maintenance of mining equipment

The invention discloses a fixing device for installation and maintenance of mining equipment in the technical field of installation and maintenance. The fixing device for installation and maintenanceof the mining equipment comprises a base, wherein supports are arranged on the left side and the right side of the top of the base, a fixing support is arranged on the top of the right side support, second electric telescopic rods are uniformly arranged on the left side of the fixing support, and a round sliding block matched with a turntable is arranged on the inner wall of the outer side of thebottom of the turntable. The electric telescopic rods are arranged, so that a workbench is flexible to move and capable of adjusting different heights of objects, the workbench is provided with the turntable which can rotate at different angles of the objects, so that a person cannot run back and forth due to installation of the objects at different angles, the second electric telescopic rods canadjust the restraining force of the objects, limiting telescopic rods are arranged at the same time, a limiting effect is achieved, too much stress can be avoided, and a protection effect is achieved.

Owner:徐州奥鹏矿山设备有限公司

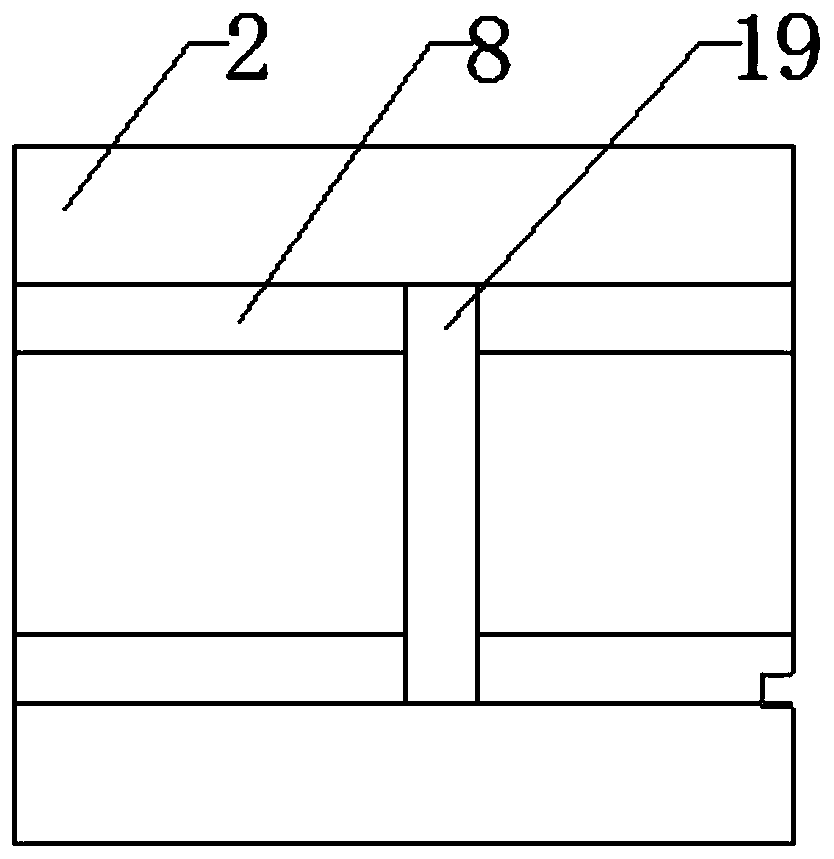

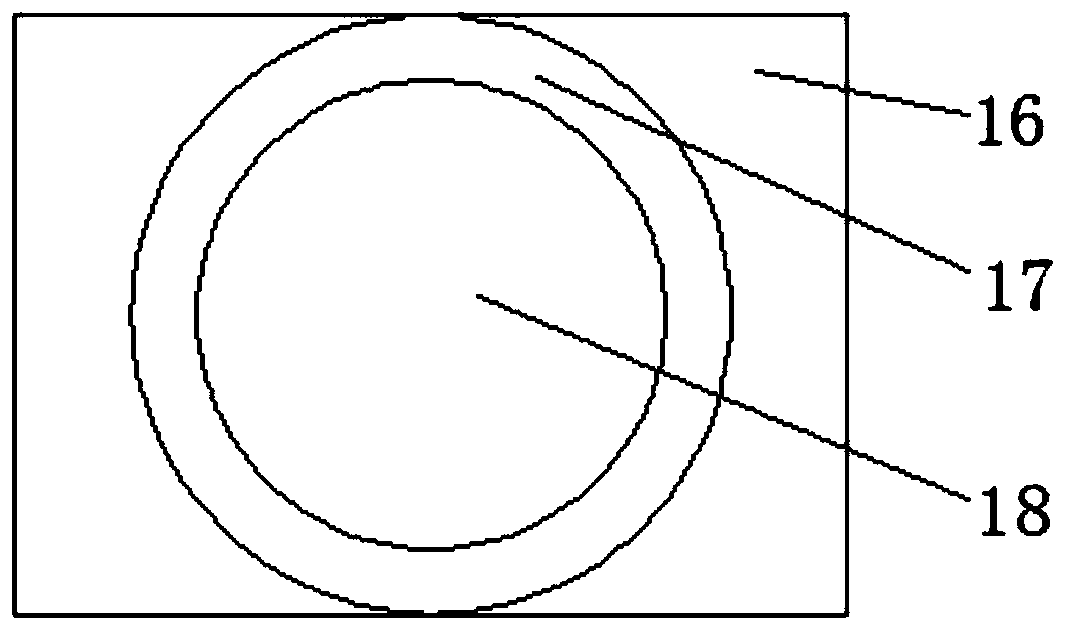

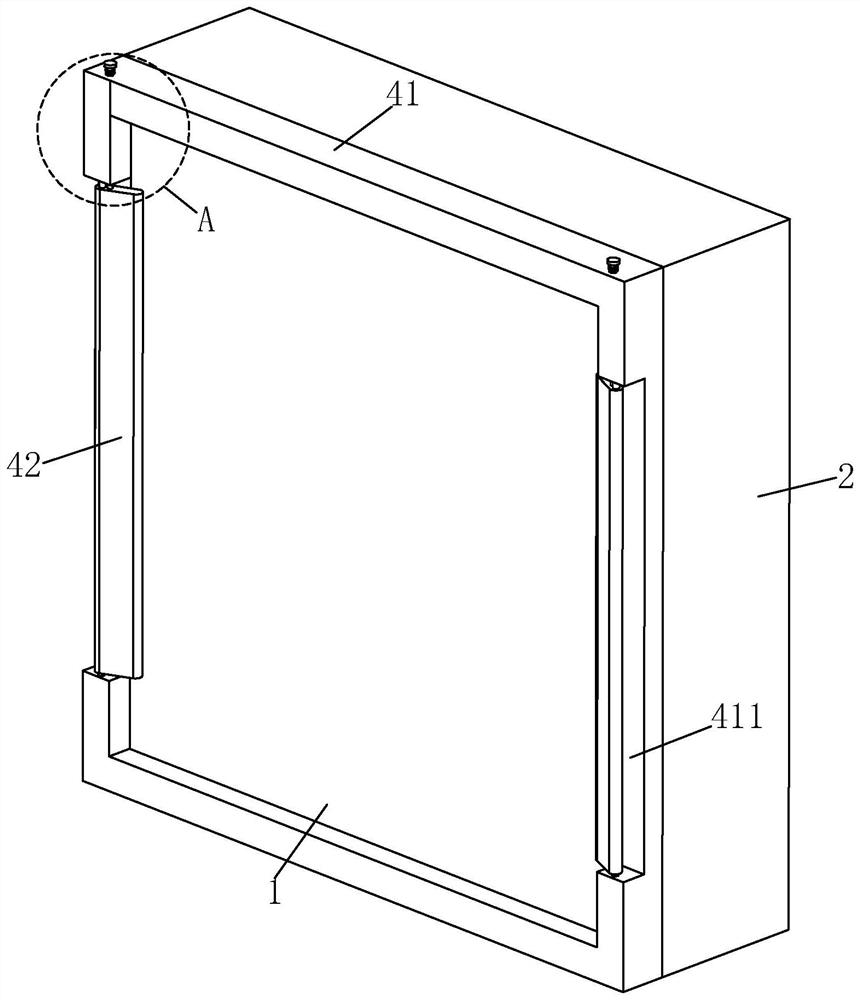

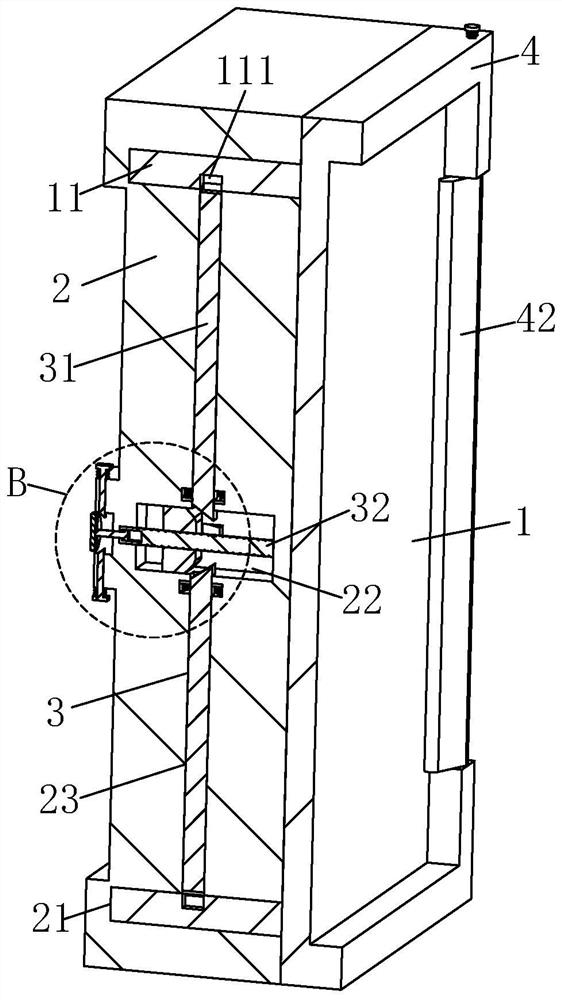

Building curtain wall mounting structure with auxiliary fixing and supporting device based on BIM (Building Information Modeling)

PendingCN114517549AAvoid the hassle of fixingImprove installation efficiencyWallsBuilding material handlingIndustrial engineeringCurtain wall

The invention belongs to the technical field of building construction, and particularly discloses a BIM-based building curtain wall mounting structure with an auxiliary fixing and supporting device, which comprises a curtain wall body, a keel frame, a fixing assembly and an auxiliary assembly, a group of insertion holes are formed in the outer side wall of the keel frame, and a cavity is formed in the keel frame; a set of first sliding grooves are formed in the inner side wall of the cavity. The first sliding groove is communicated with the insertion hole; the curtain wall body is inserted into the insertion hole; the auxiliary assembly is arranged on the outer side wall of the keel frame; the fixing assembly is arranged in the cavity and comprises a sliding rod and a rotating mechanism. The group of sliding rods are connected into the first sliding groove in a sliding manner; the rotating mechanism is arranged in the cavity, and the rotating mechanism is in sliding fit with the inner side wall of the cavity; the curtain wall body is installed by fixing the inserting rods in four directions, the trouble that the curtain wall body is fixed through fastening screws is avoided, and the installation efficiency of the curtain wall body is improved.

Owner:广东美科建工集团有限公司

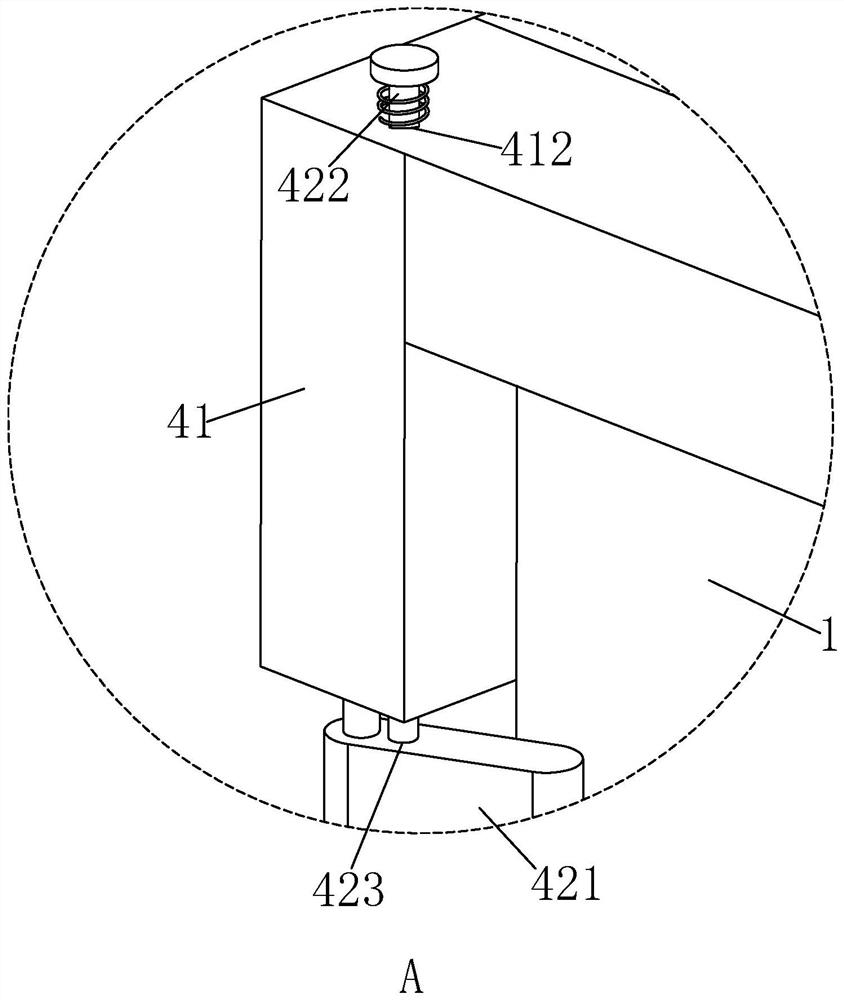

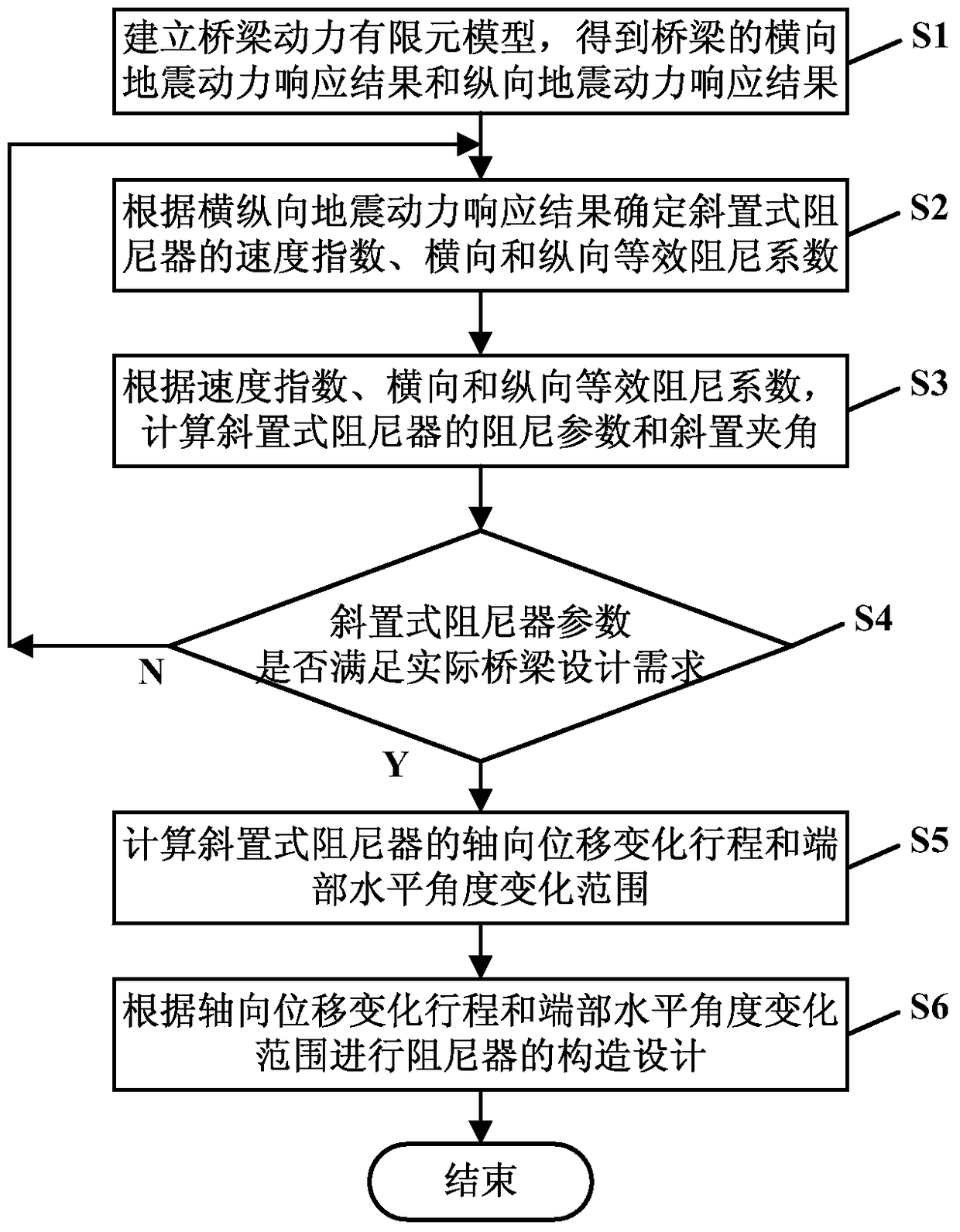

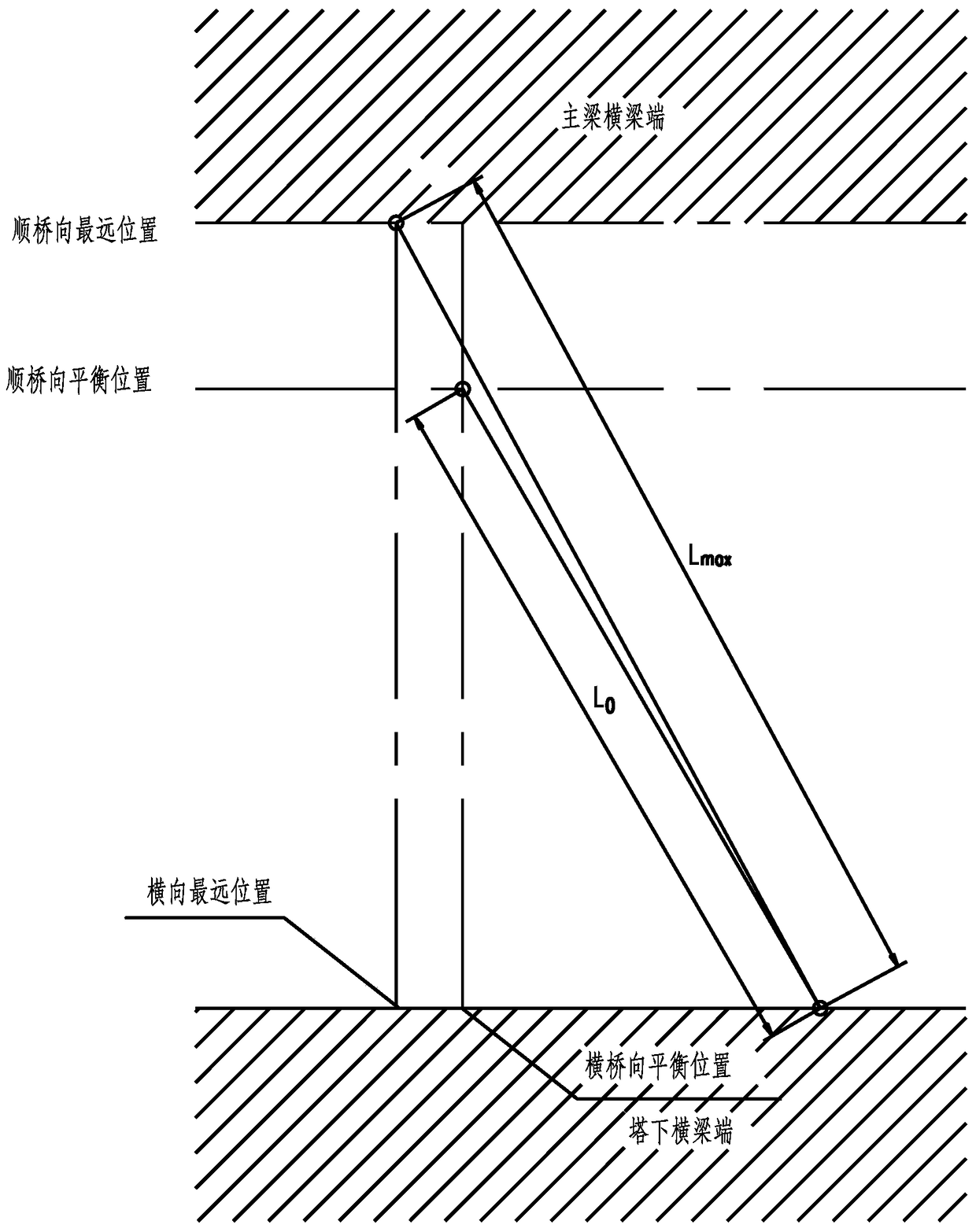

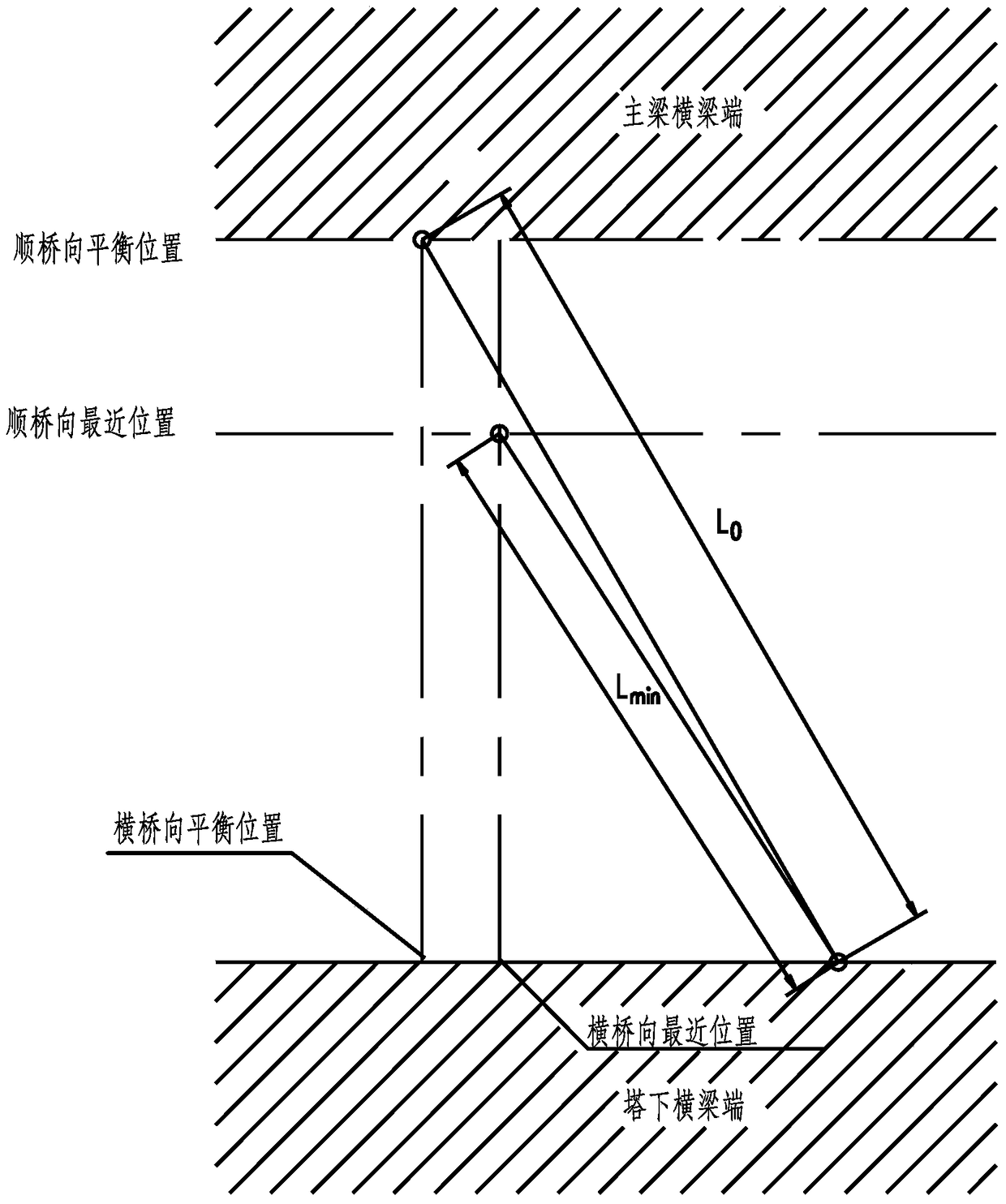

An inclined bridge seismic damper and its parameter optimization method

ActiveCN105468827BSeismic Response ControlPlay a role in damping energy consumptionBridge structural detailsDesign optimisation/simulationElement modelSnubber

The invention discloses an oblique type bridge anti-seismic damper and a parameter optimization method thereof, and relates to the technical field of bridge seismic resistance. The parameter optimization method comprises the following steps: establishing a bridge dynamic finite element model, calculating and obtaining a horizontal seismic dynamic response result and a longitudinal seismic dynamic response result of a bridge; optimizing a horizontal equivalent damping coefficient Ct, a longitudinal equivalent damping coefficient C1 and a speed index alpha of the oblique type bridge anti-seismic damper; calculating an oblique included angle beta and a damping parameter C of the oblique type bridge anti-seismic damper; and outputting the equivalent damping coefficient Ct, the longitudinal equivalent damping coefficient C1, the speed index alpha, the damping parameter C and the oblique included angle beta which satisfy the practical bridge design requirement. According to the oblique type bridge anti-seismic damper and the parameter optimization method thereof provided by the invention, when the bridge has a horizontal seismic action and a longitudinal seismic action, the oblique type bridge anti-seismic damper can play a role in damping energy dissipation, so that an effect of using only one set of oblique type bridge anti-seismic damper to control the longitudinal and horizontal seismic actions synchronously can be achieved.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com