Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about "Digital marking by punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

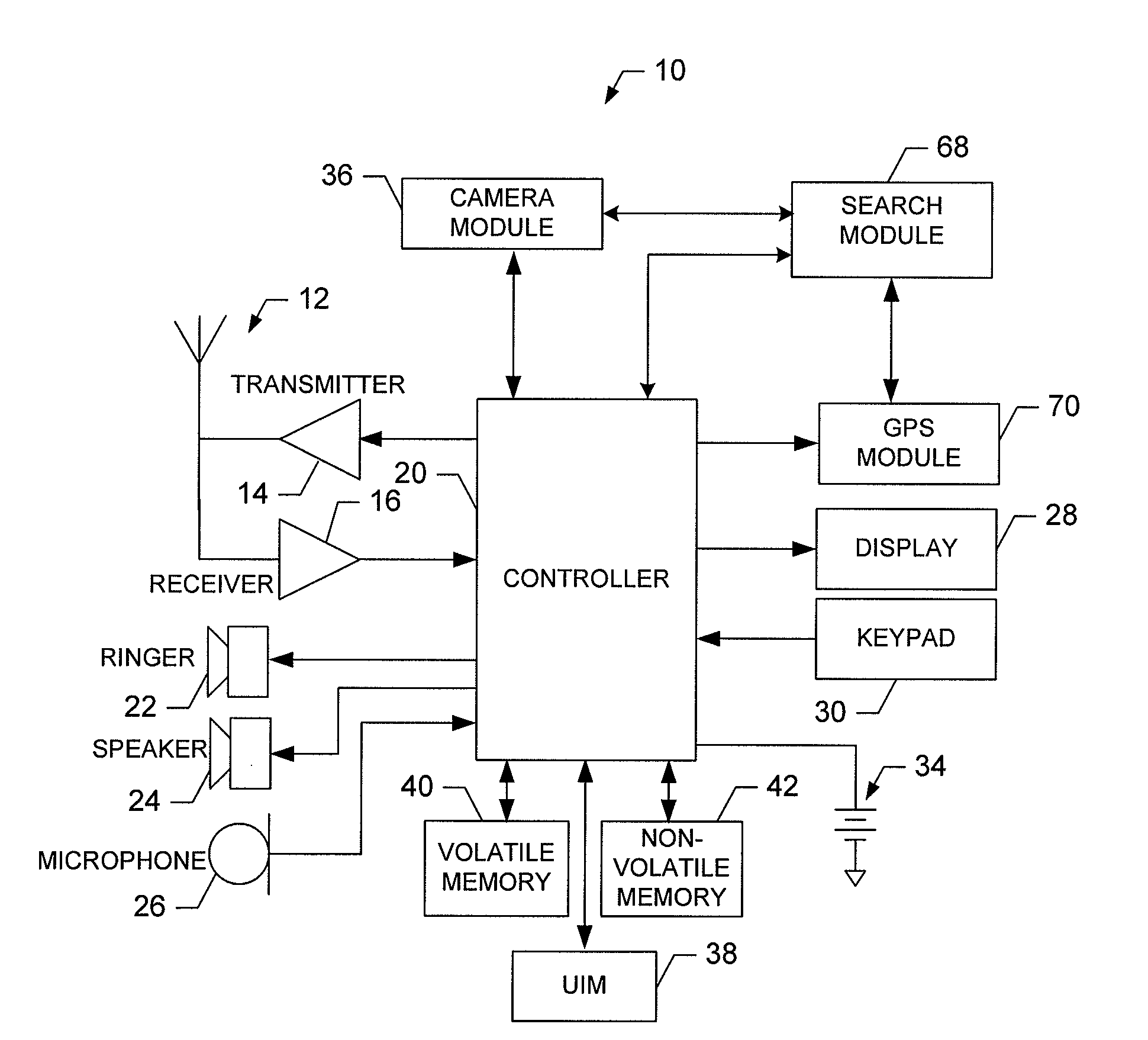

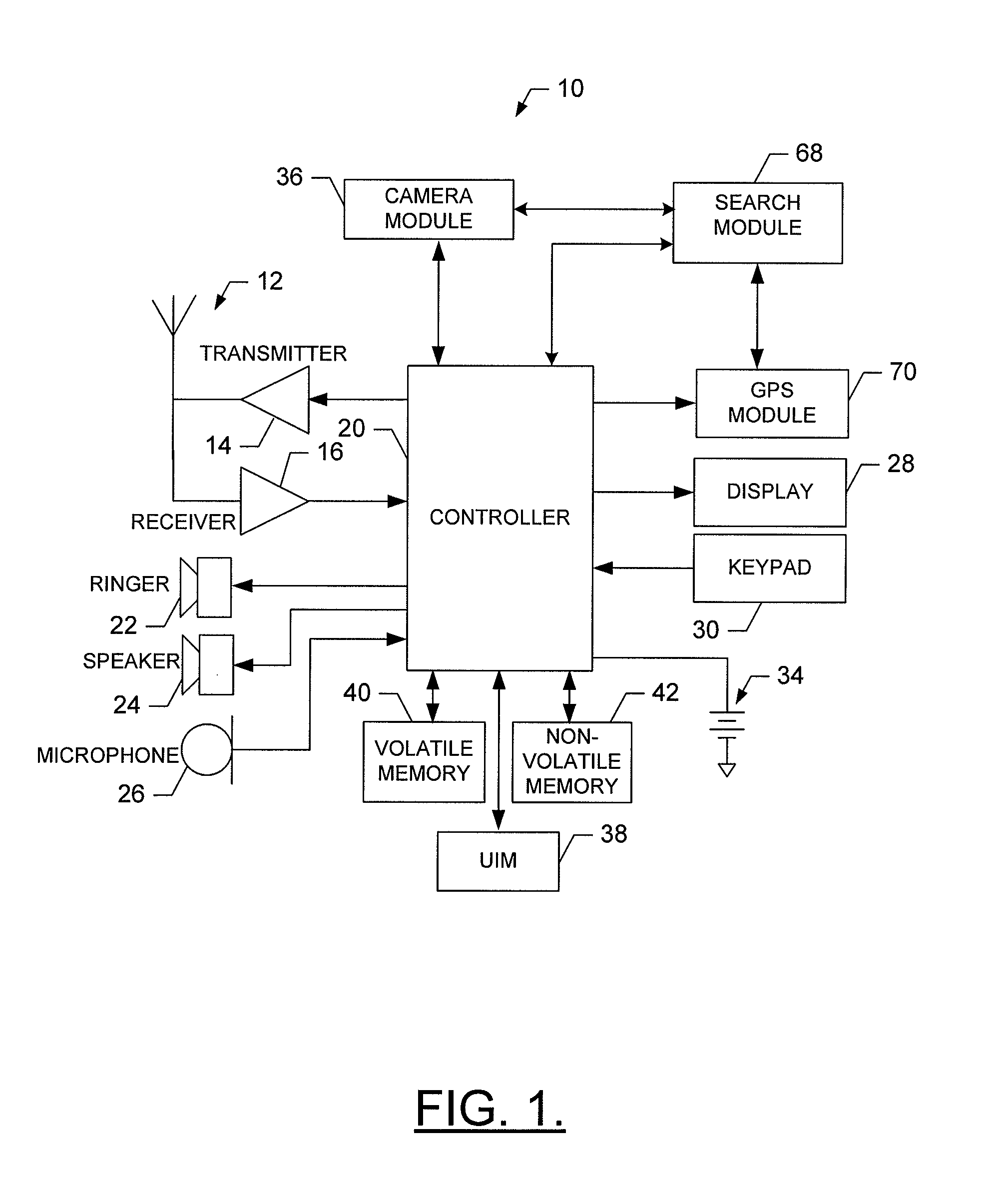

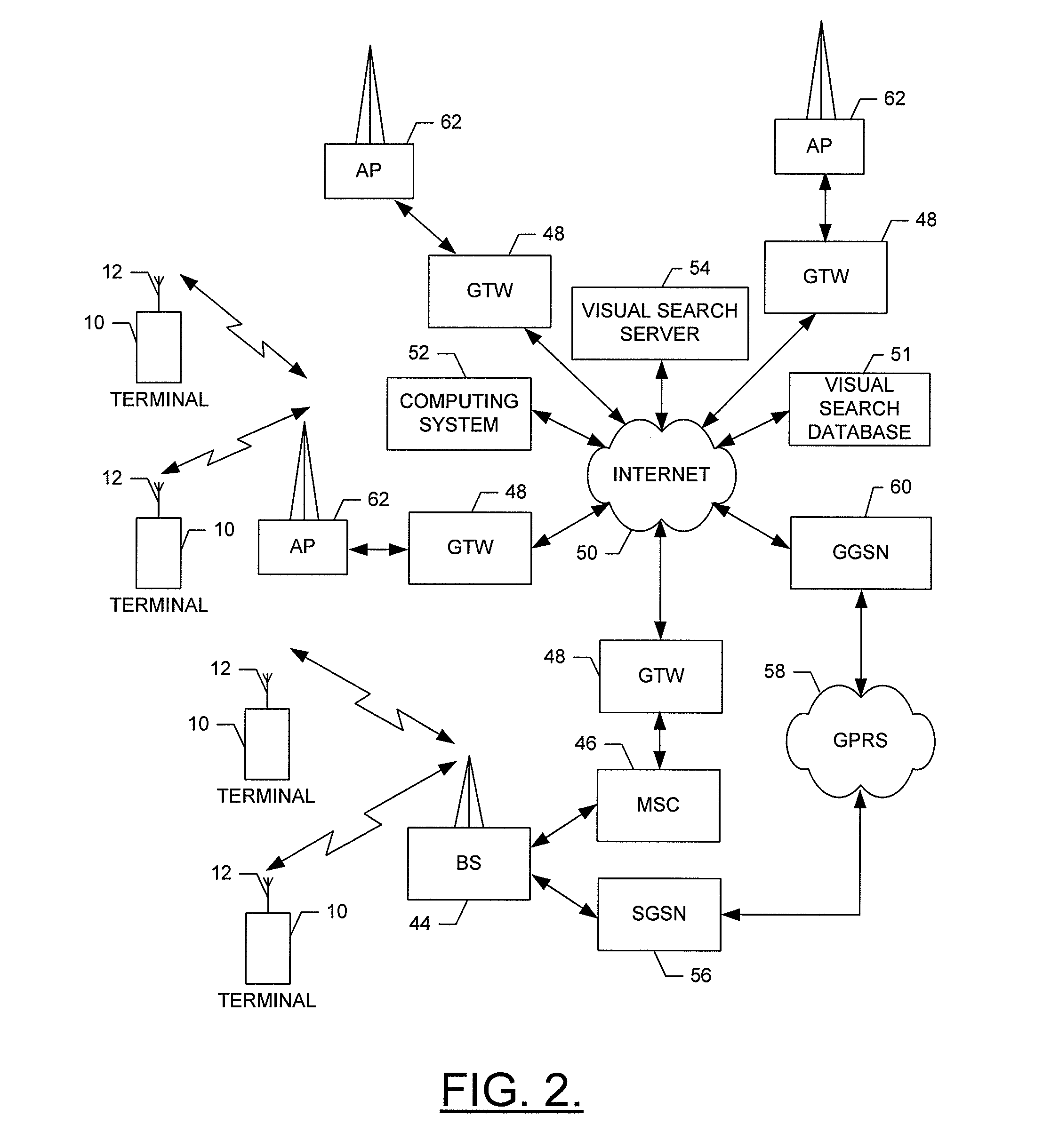

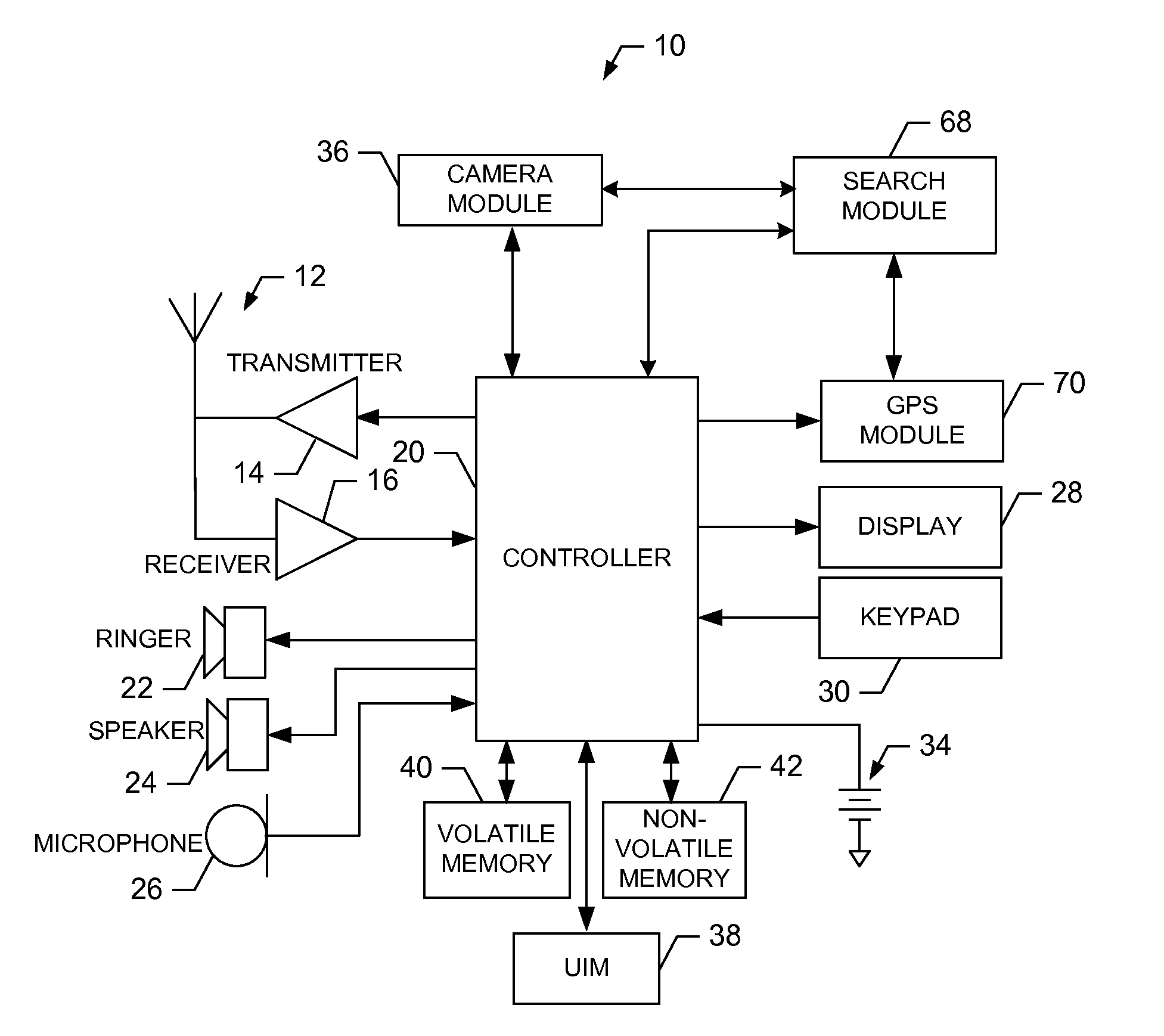

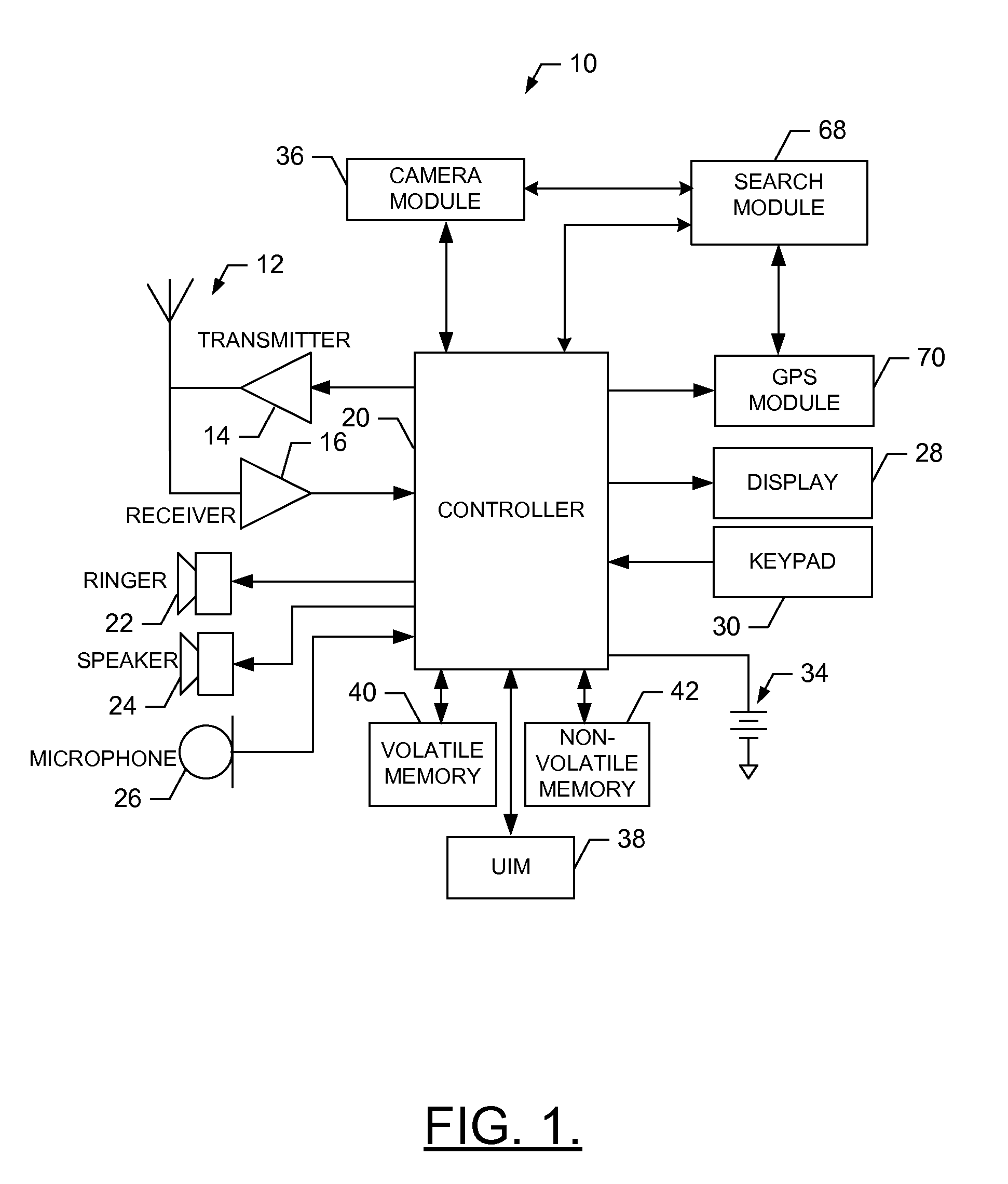

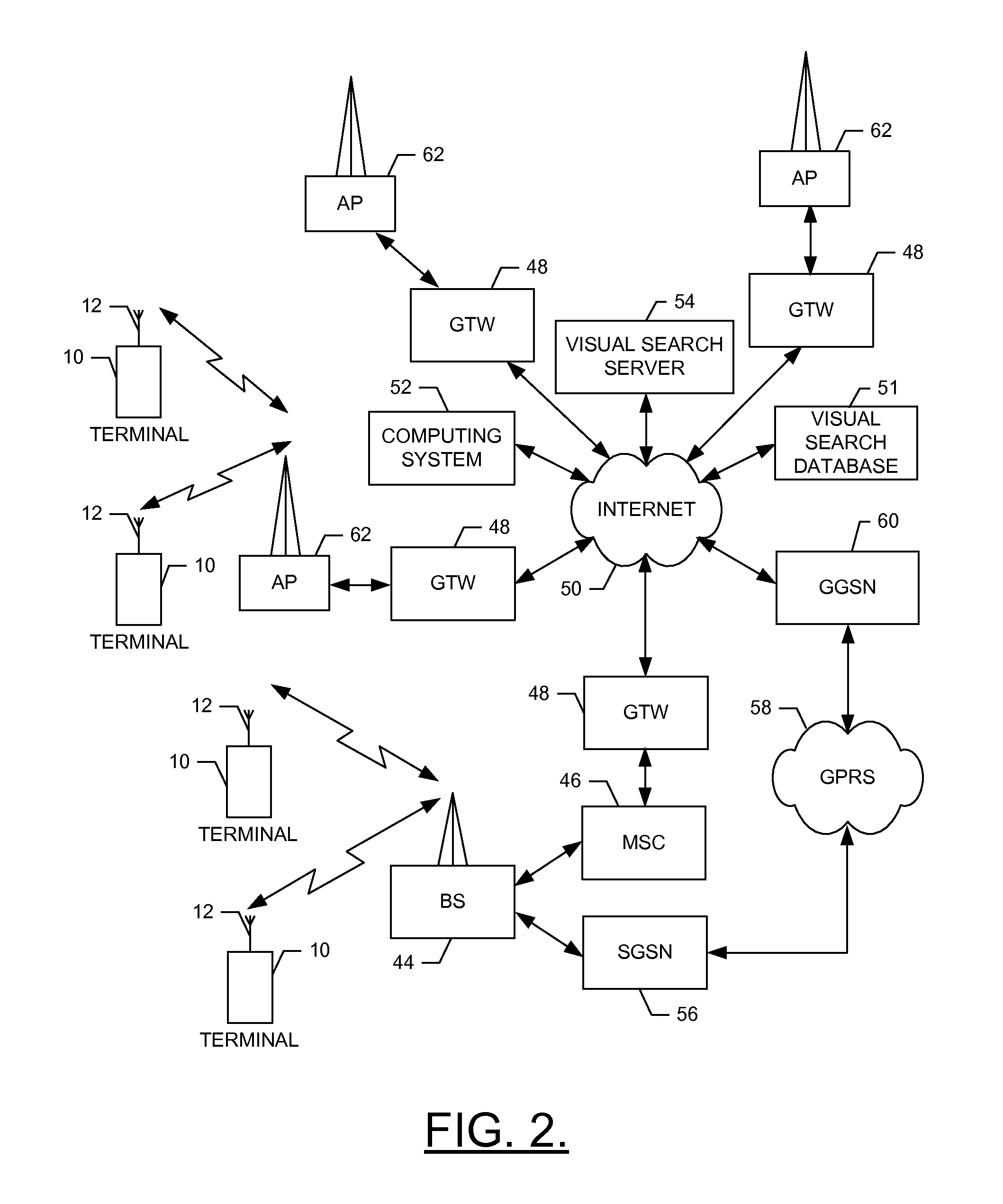

Method, device and computer program product for integrating code-based and optical character recognition technologies into a mobile visual search

InactiveUS20080267504A1Digital data information retrievalCharacter and pattern recognitionComputer scienceMobile vision

A device for switching between code-based searching, optical character recognition (OCR) searching and visual searching is provided. The device includes a media content input for receiving media content from a camera or other element of the device and transferring this media content to a switch. Additionally, the device includes a meta-information input capable of receiving meta-information from an element of the device and transferring the meta-information to the switch. The switch is able to utilize the received media content and the meta-information to select and / or switch between a visual search algorithm, an OCR algorithm and a code-based algorithm.

Owner:NOKIA CORP

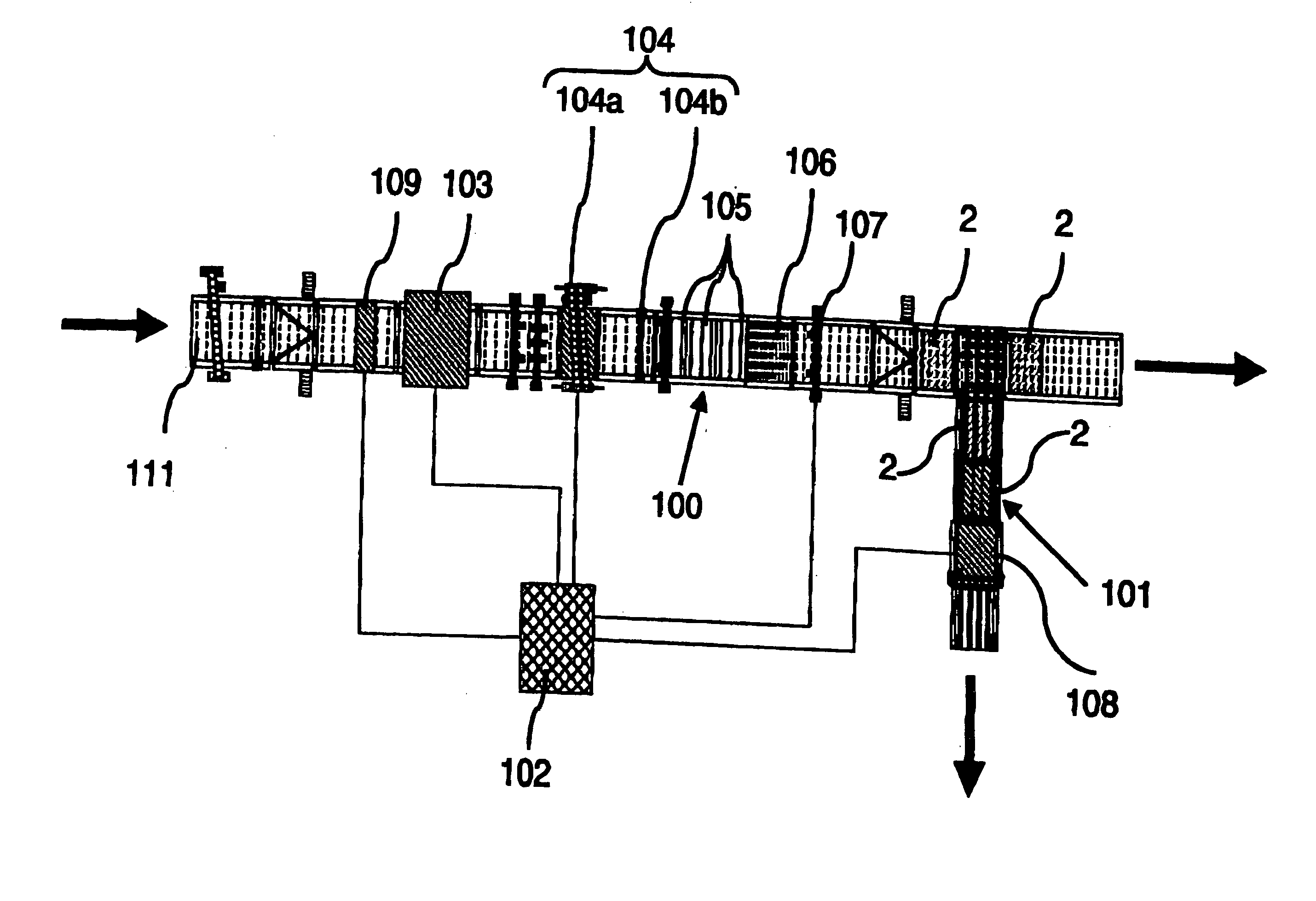

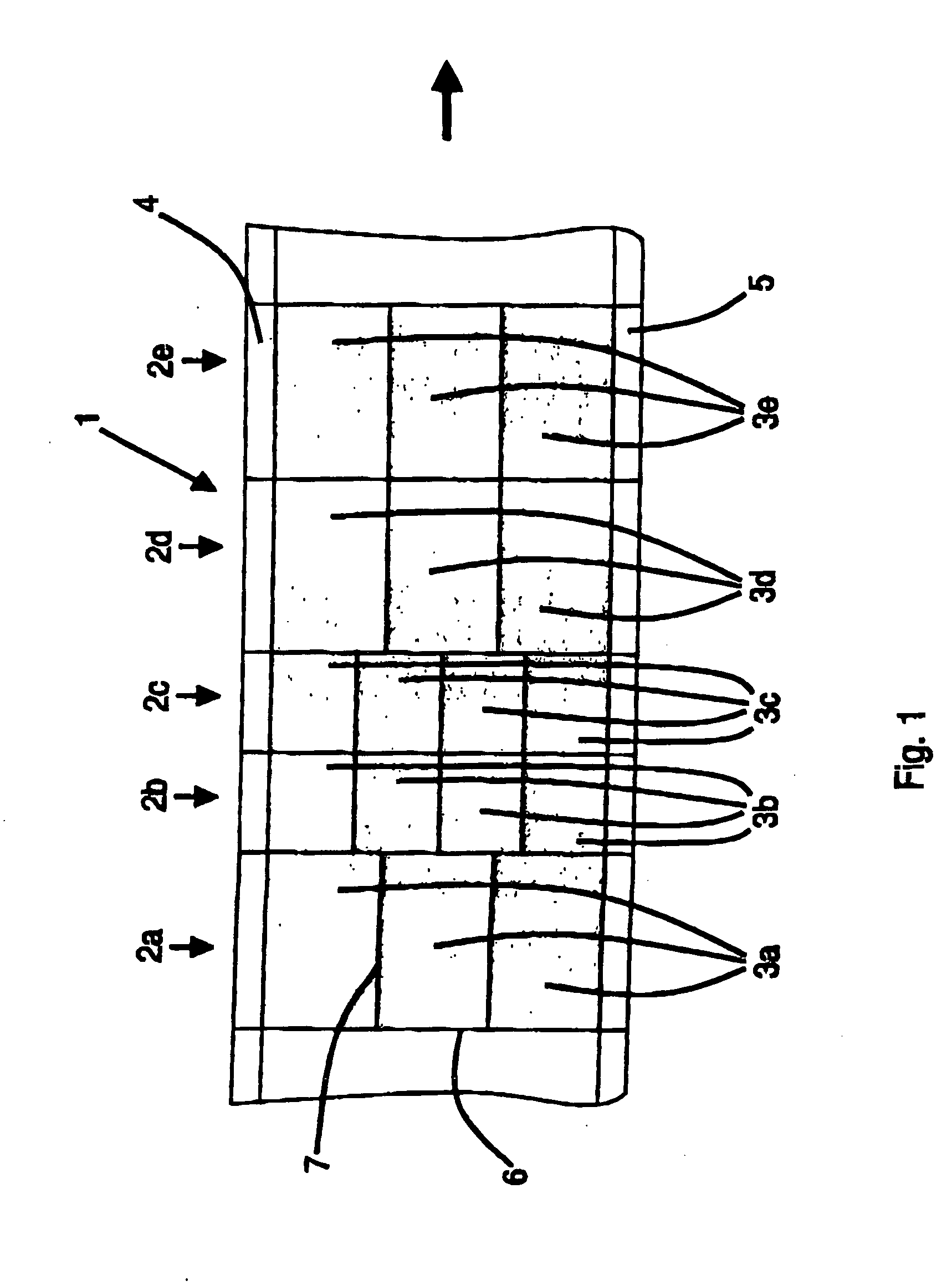

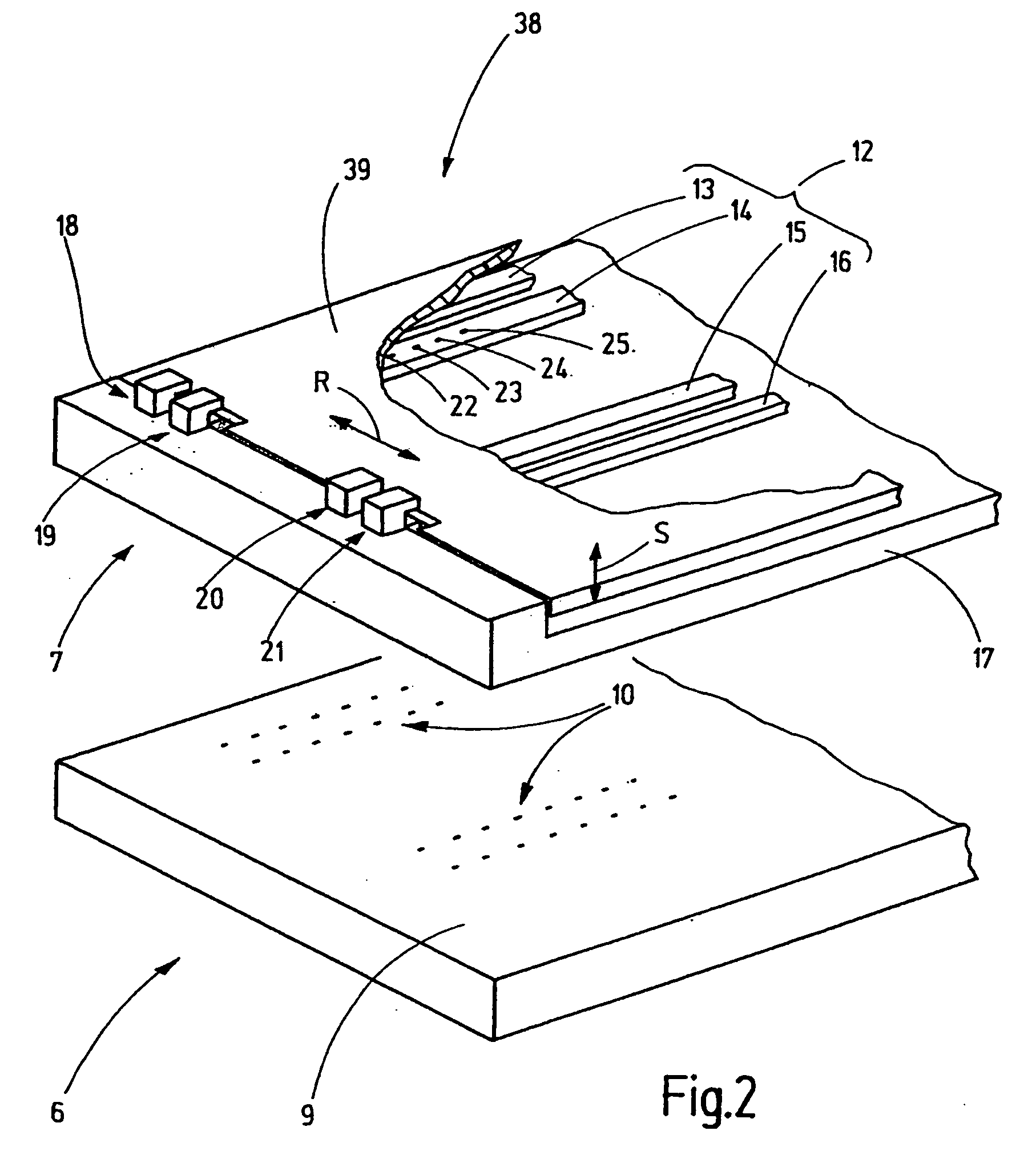

Method and apparatus for cutting off glass panes from a continuously produced glass sheet

InactiveUS20050023337A1High yieldWidth minimizedProgramme controlMaterial testing goodsEngineeringGlass sheet

The method for cutting off glass panes from a continuously produced glass sheet includes continuously testing the glass sheet for glass faults prior to the cutting off process and determining glass sheet regions to be discarded containing the glass faults. Based on the test results for the glass faults an optimized cutting pattern for a predetermined glass sheet section is calculated in a cutting optimization device, which is a plan for cutting the glass sheet section into crosscut pieces, in which glass panes of respective sizes are arranged next to each other in corresponding crosscut pieces. In order to reduce waste, the cutting lines for the glass panes to be cut away within each crosscut piece are placed sufficiently close to the fault-containing glass sheet regions, so that widths (BS) of the glass sheet regions to be discarded are minimized or the glass sheet regions to be discarded are minimized, while accounting for a largest possible number of usable glass panes. The crosscut pieces are subsequently cut according to the optimized cutting pattern and the glass panes are formed. An appropriate apparatus for performing the method is described.

Owner:SCHOTT AG

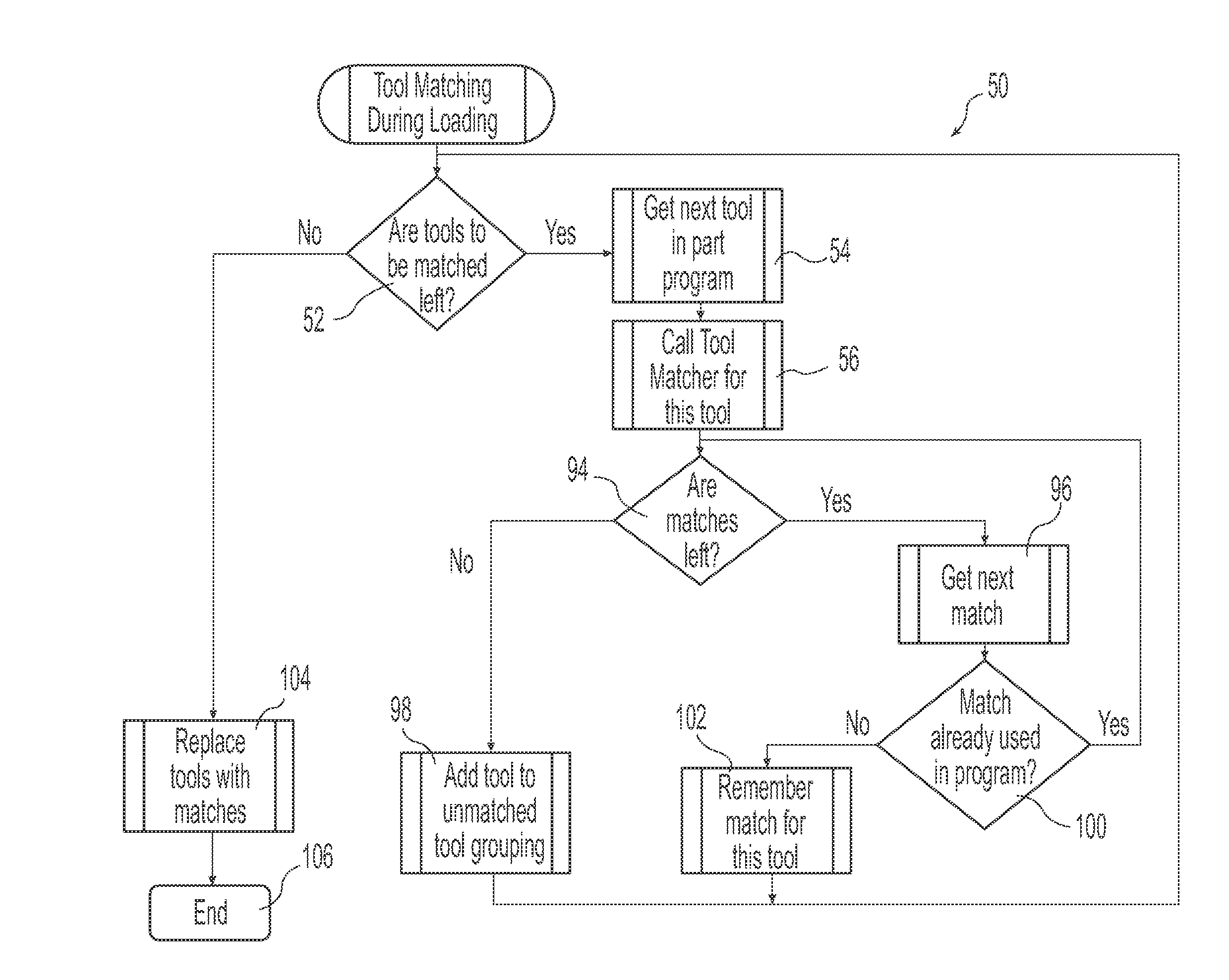

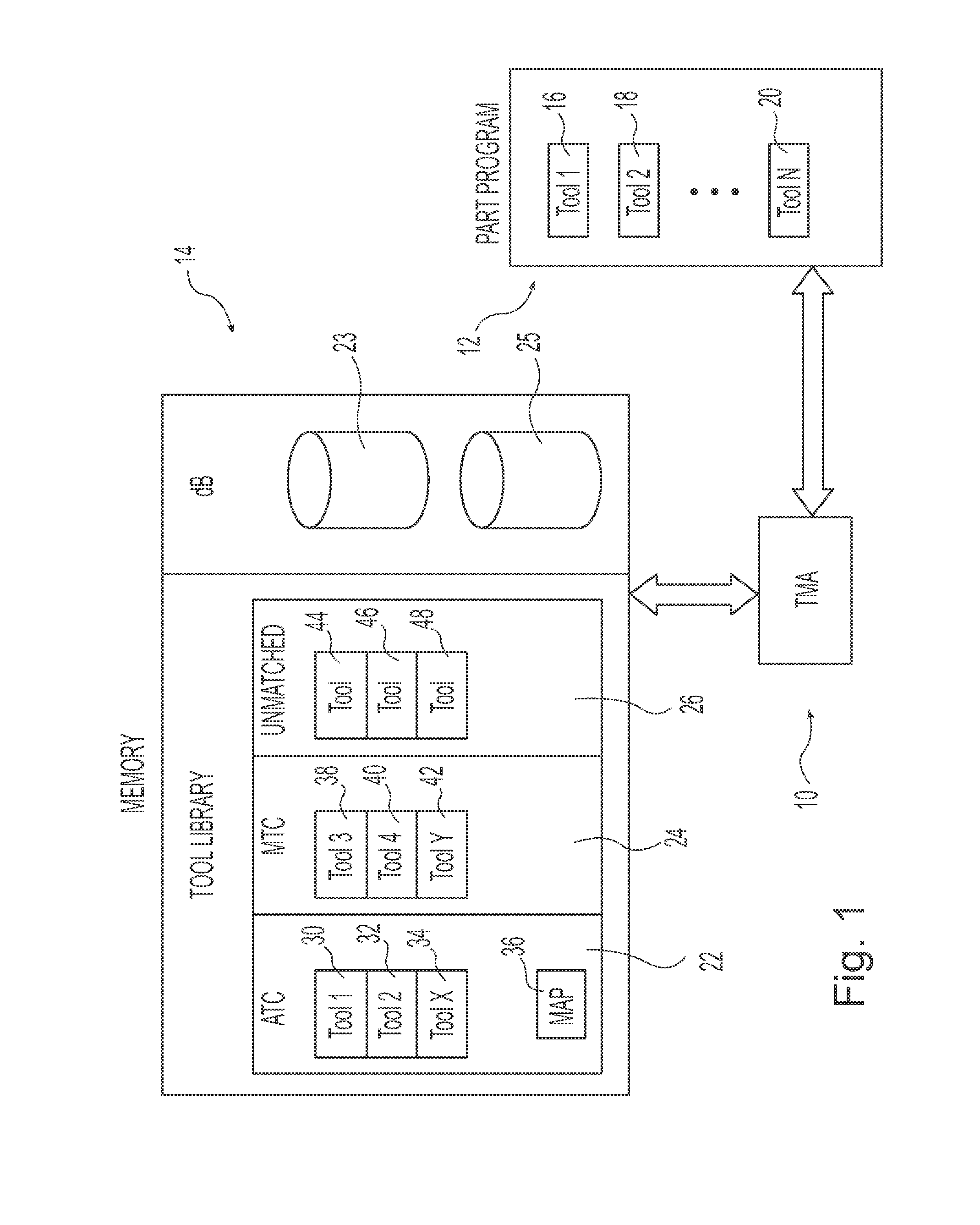

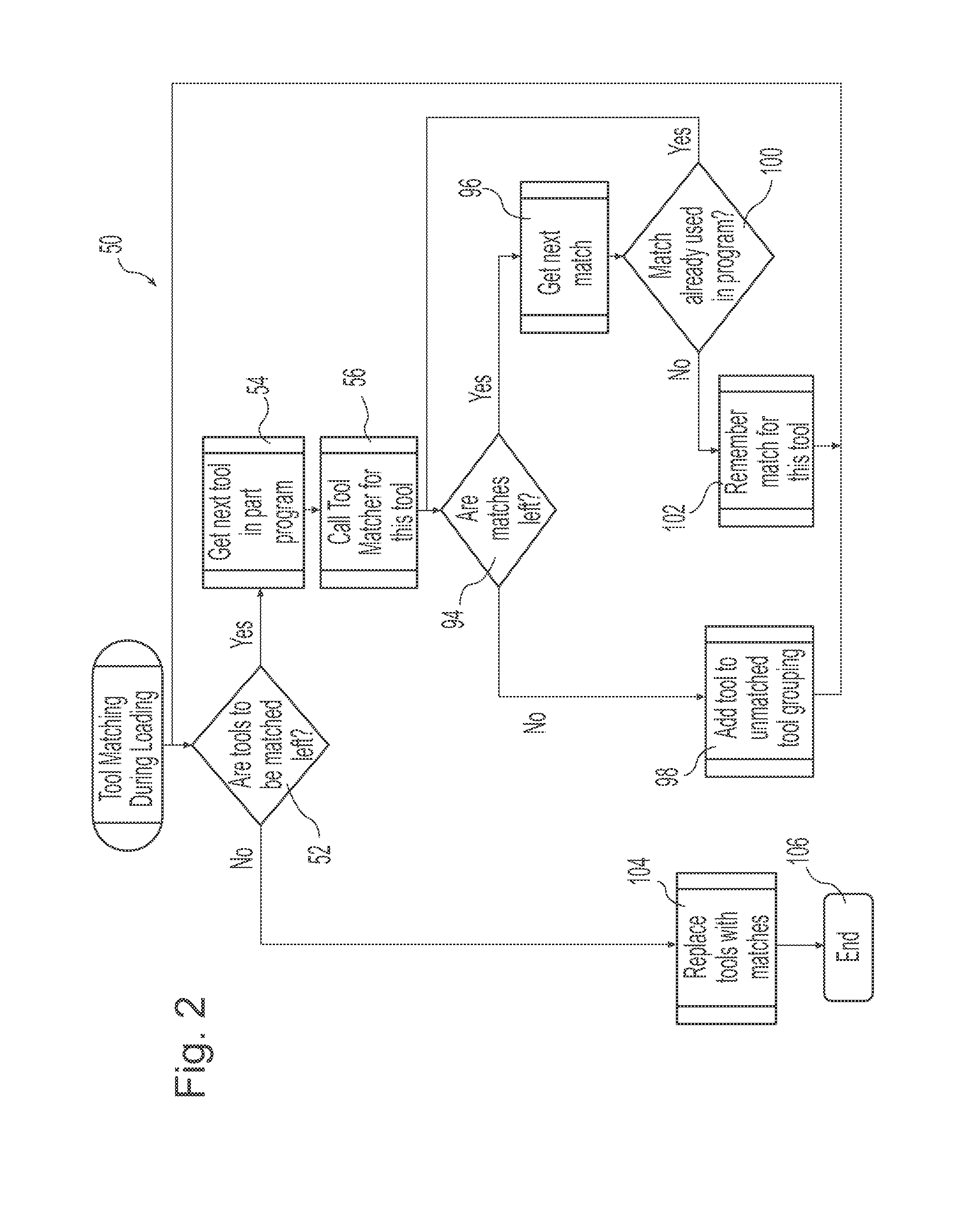

System and method for tool use management

The present invention provides a system and method for tool use management wherein a CNC machine retains information identifying the tools associated with the machine as well as their current locations (if any), and executes an algorithm for determining the source tools needed by a part program and matching the source tools with the available tools.

Owner:HURCO

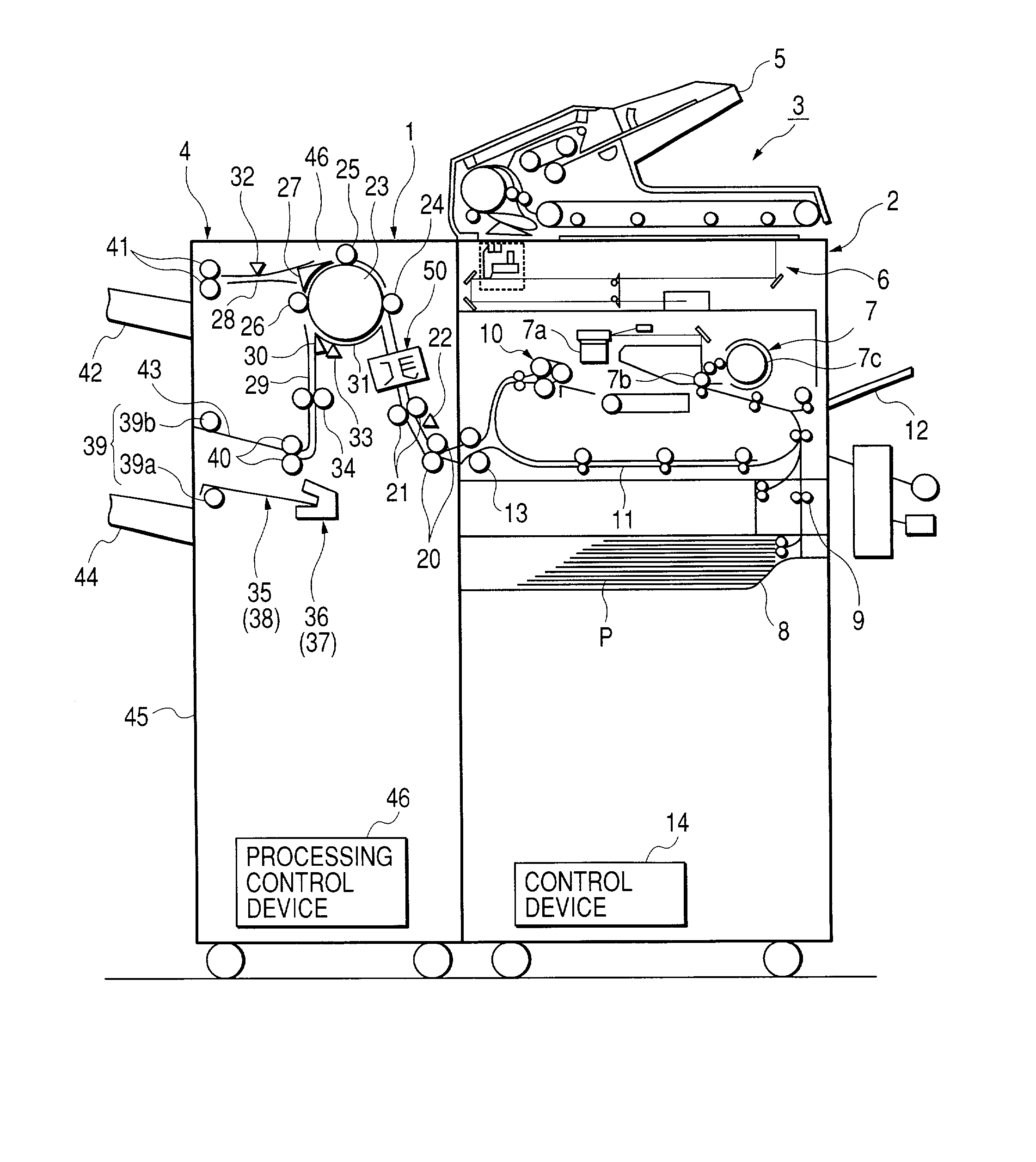

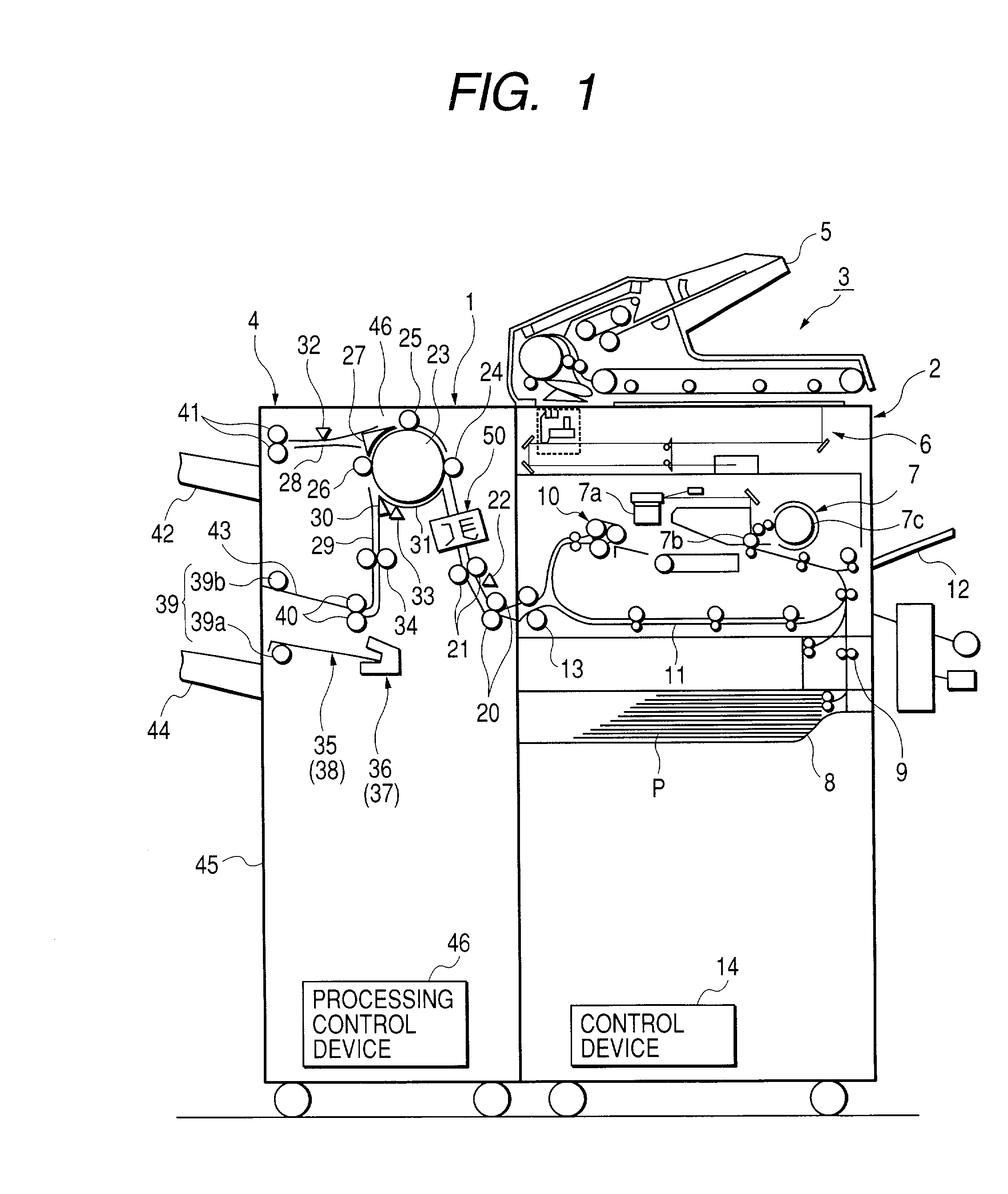

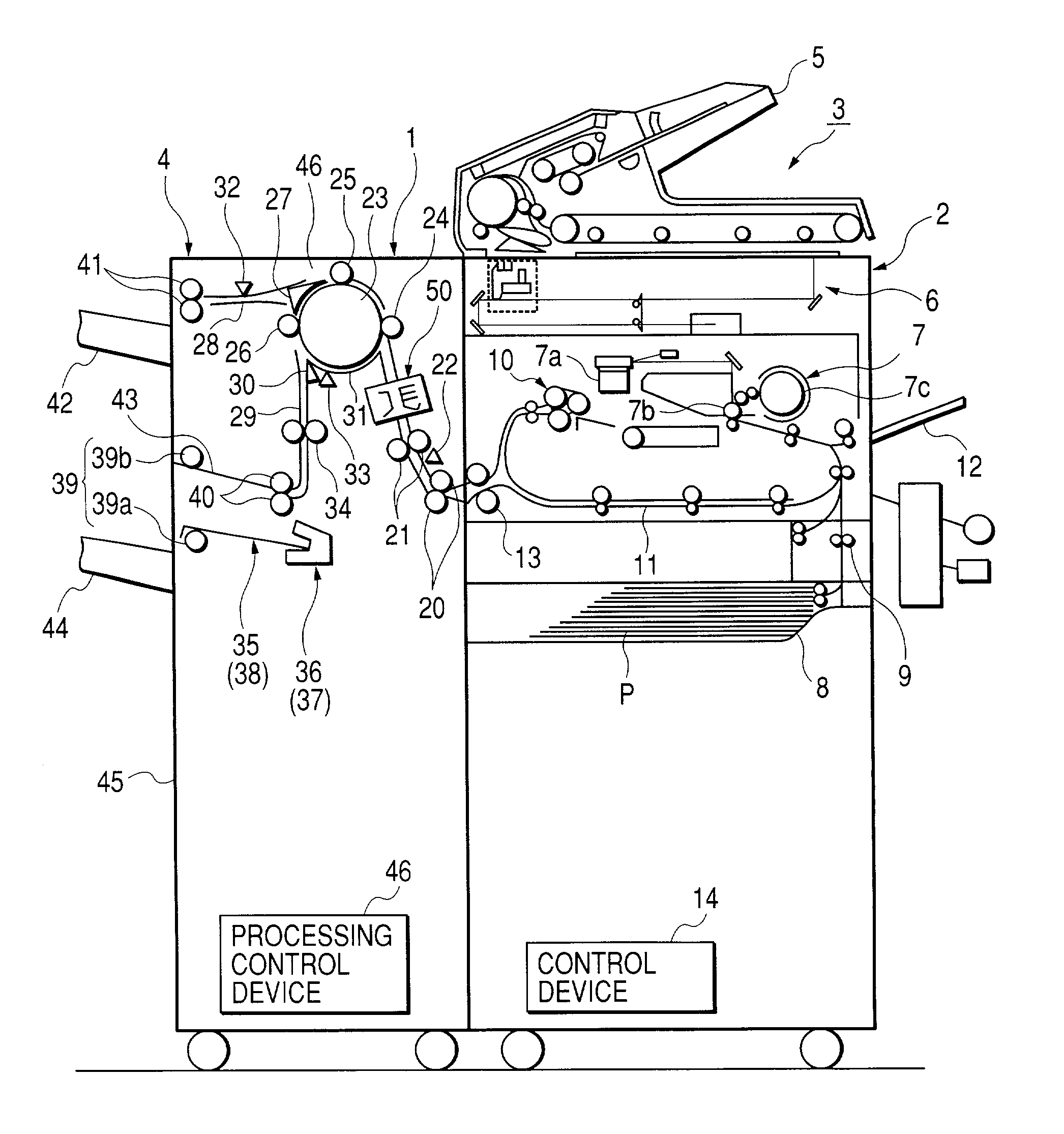

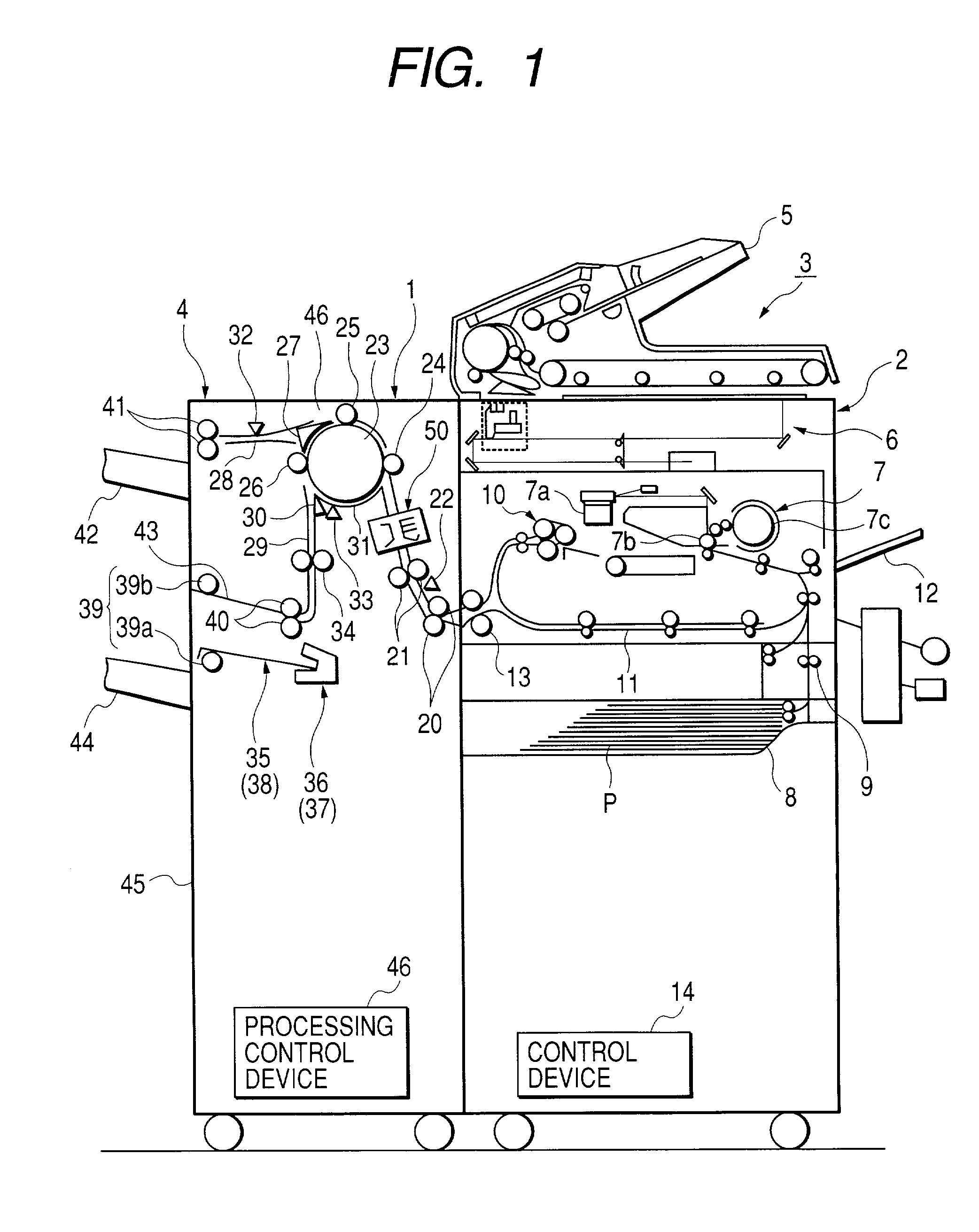

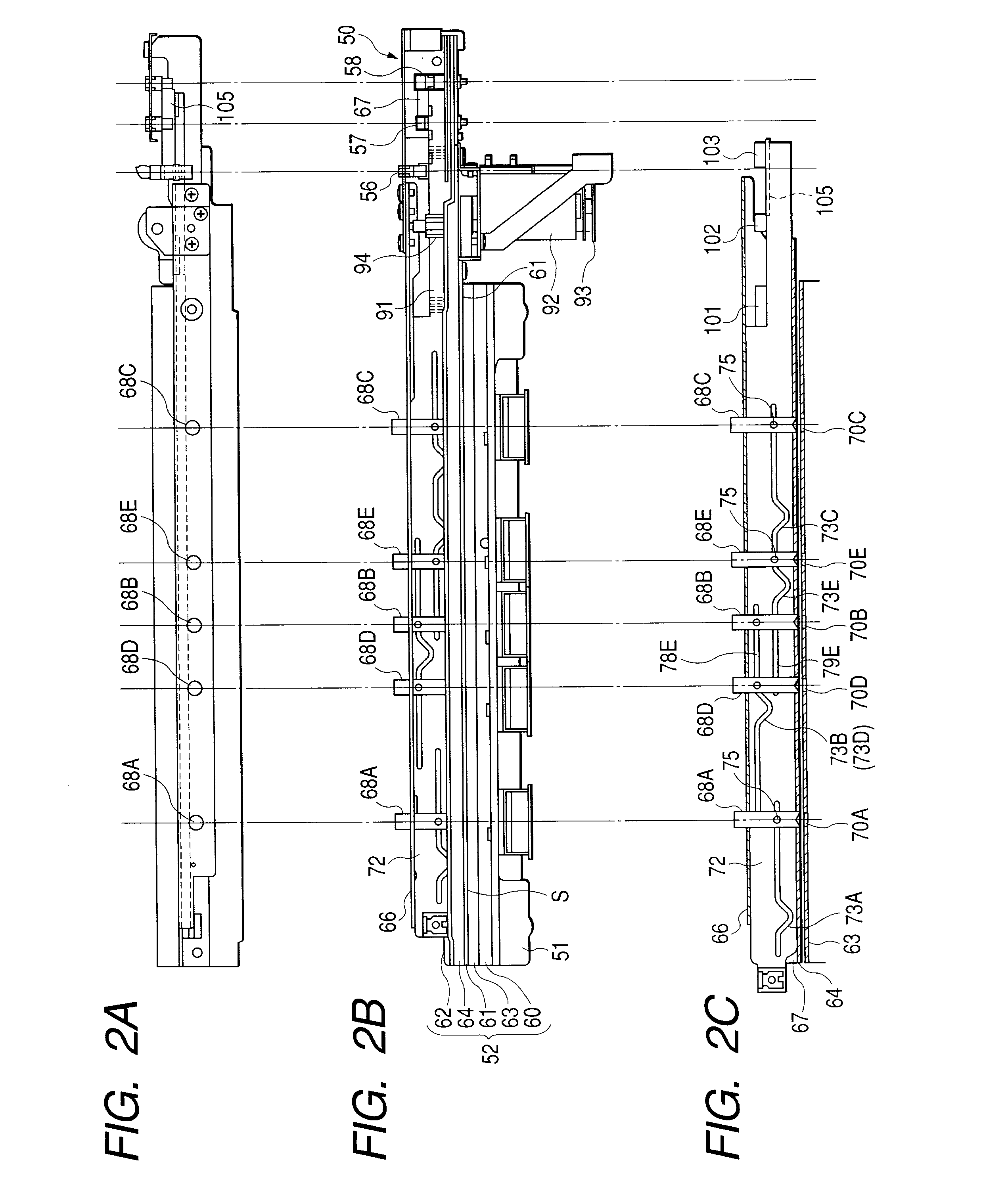

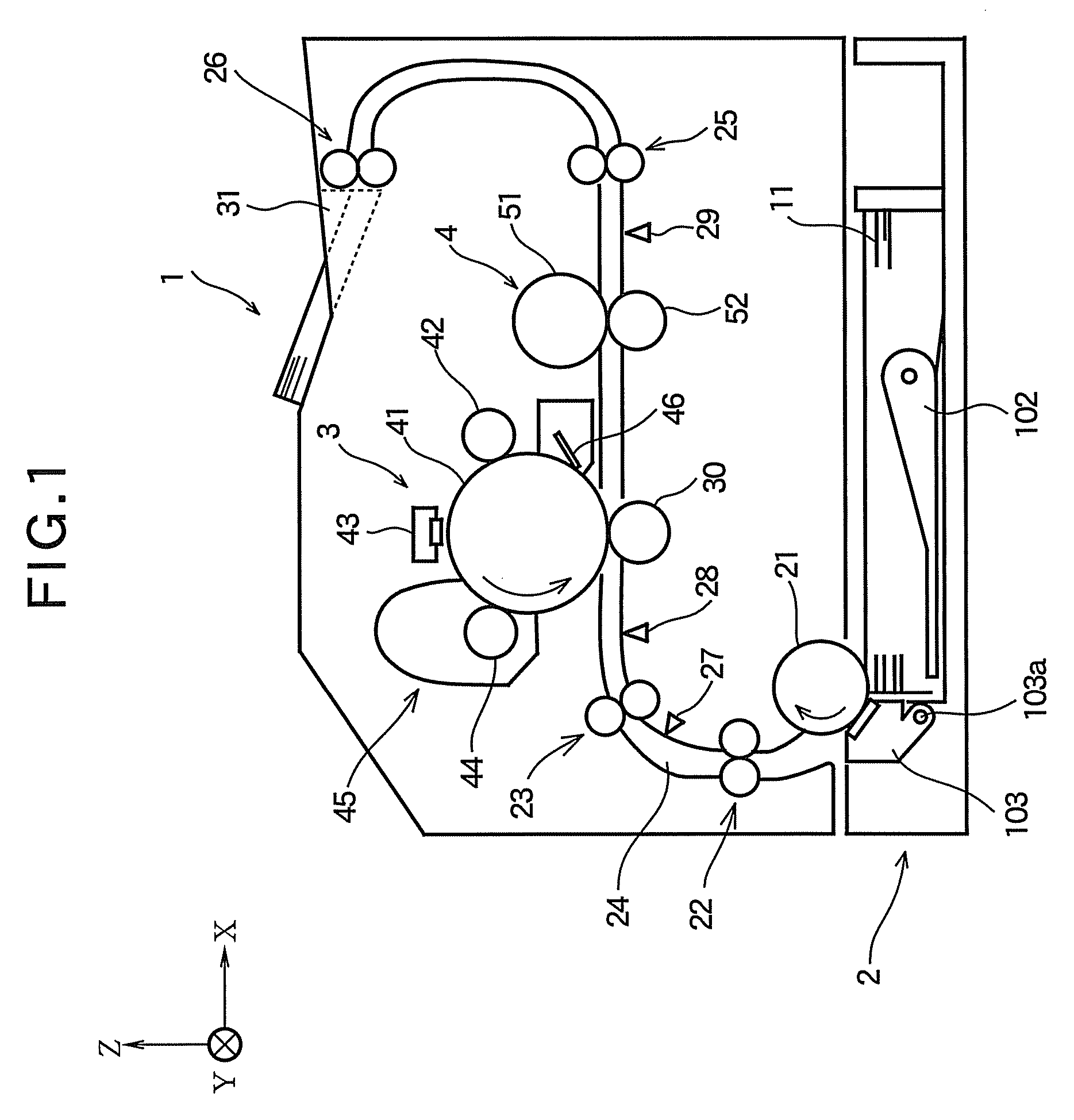

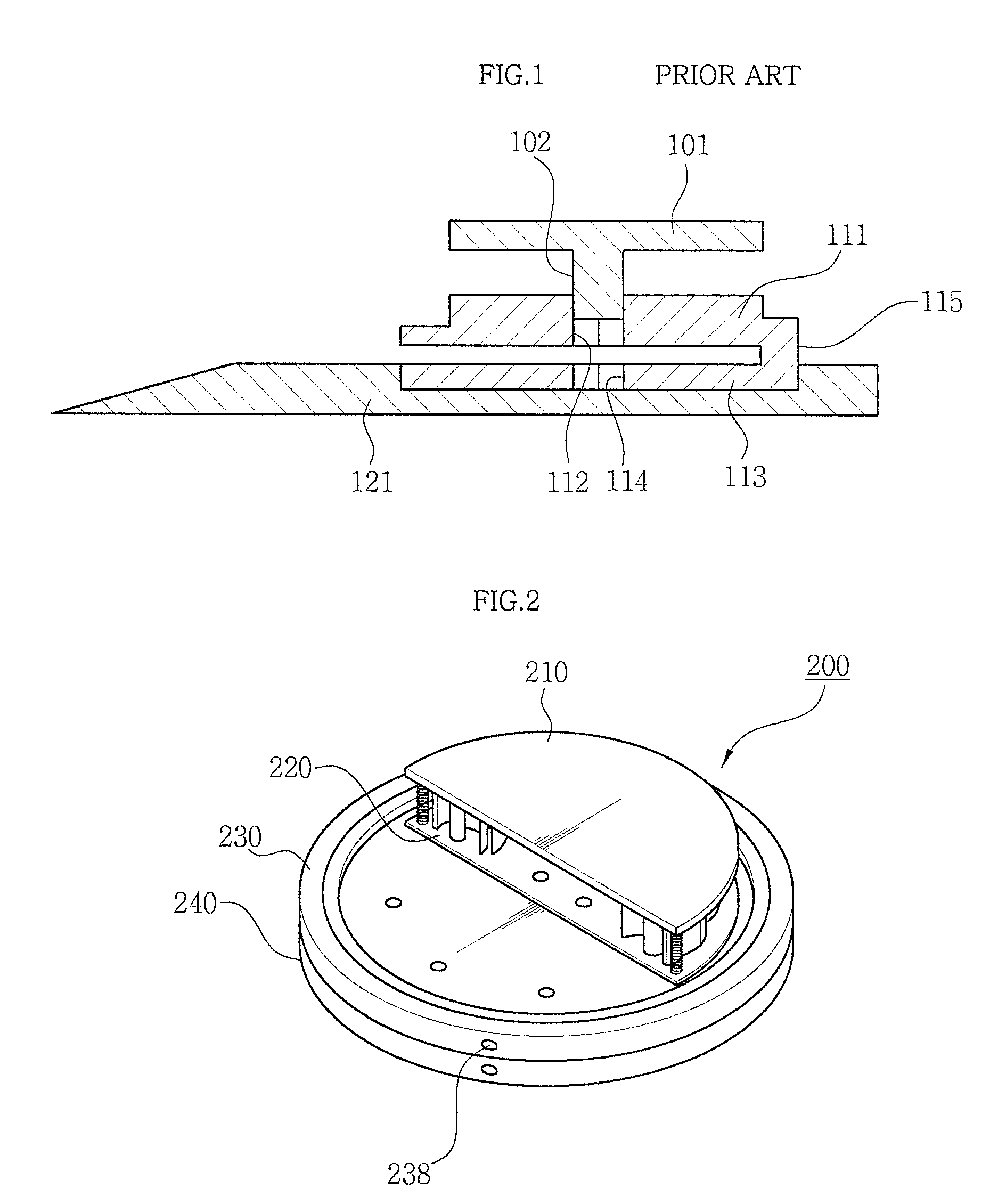

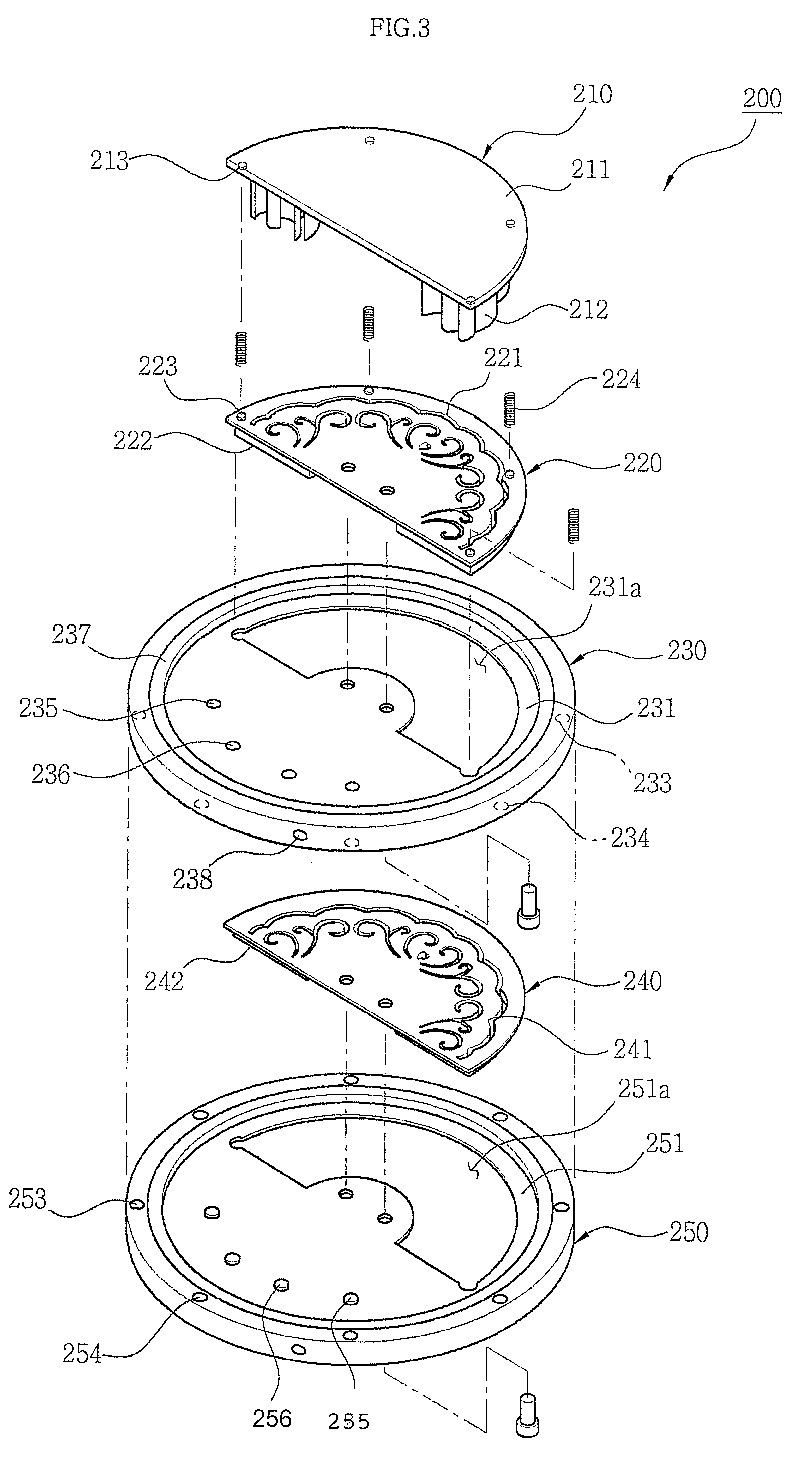

Punching device, sheet processor having the punching device, and image forming apparatus having the punching device

InactiveUS20020129690A1Reliable stopEasy to operateElectrographic process apparatusMetal working apparatusPunchingCam

There is provided a punching device including: a die member having a plurality of die holes formed therein; a plurality of punch members which are caused to advance into the die holes to punch holes in a member to be punched; an operating member having cam portions formed along a direction intersecting the direction of advancement of the punch members, the operating member being moved along the direction intersecting the direction of advancement of the punch members to cause by a conversion function of the cam portions the punch members to advance into the die holes; and a drive unit for selectively causing advancement of the plurality of punch members by changing the direction of movement of the operating member. In the punching device, each of the cam portions has a straight groove and a cam groove for performing the conversion function, and when the operating member is moved in one of opposite directions, at least one of the cam grooves of the cam portions acts on one of the punch members to selectively cause the same to advance.

Owner:CANON KK

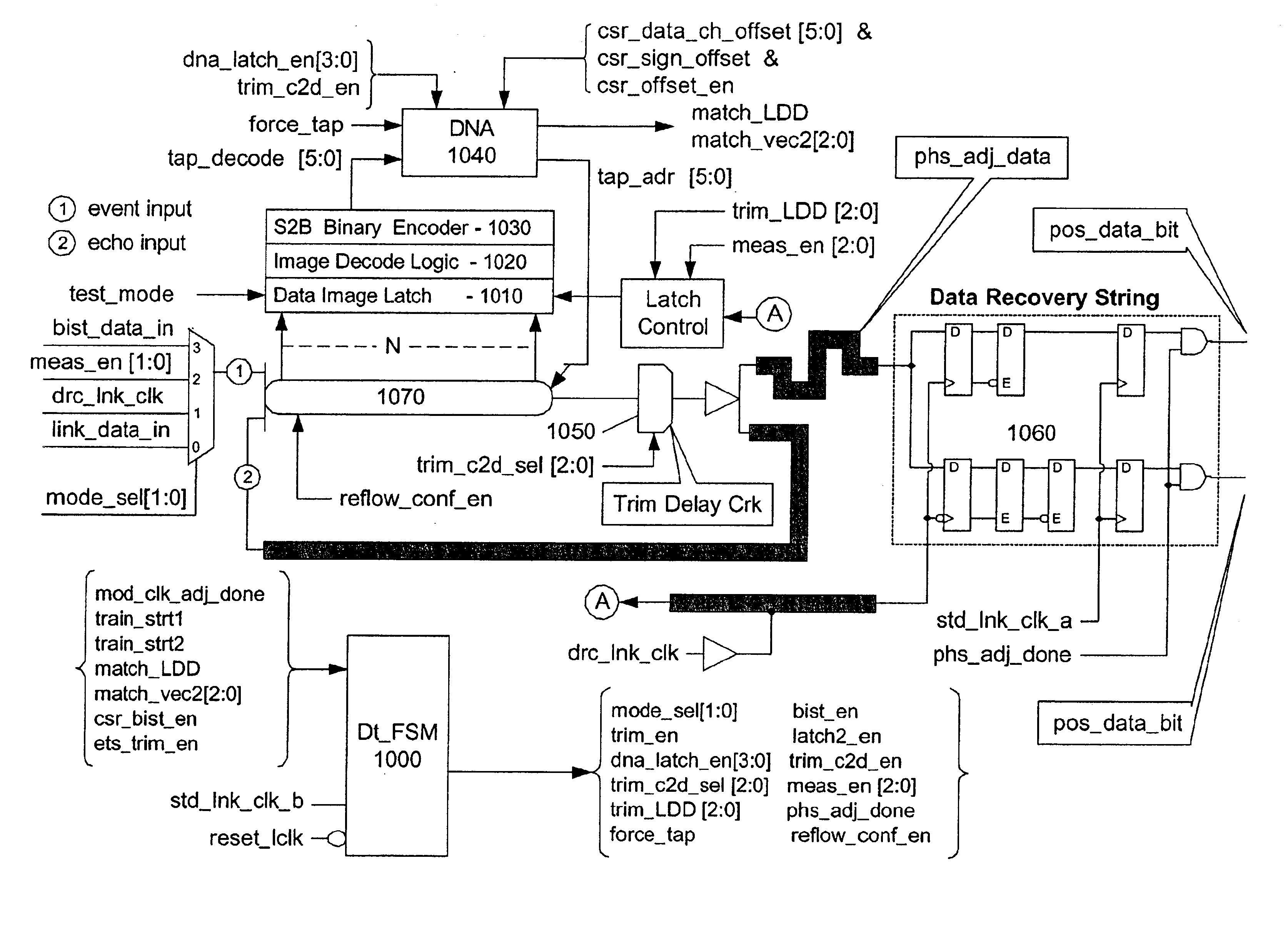

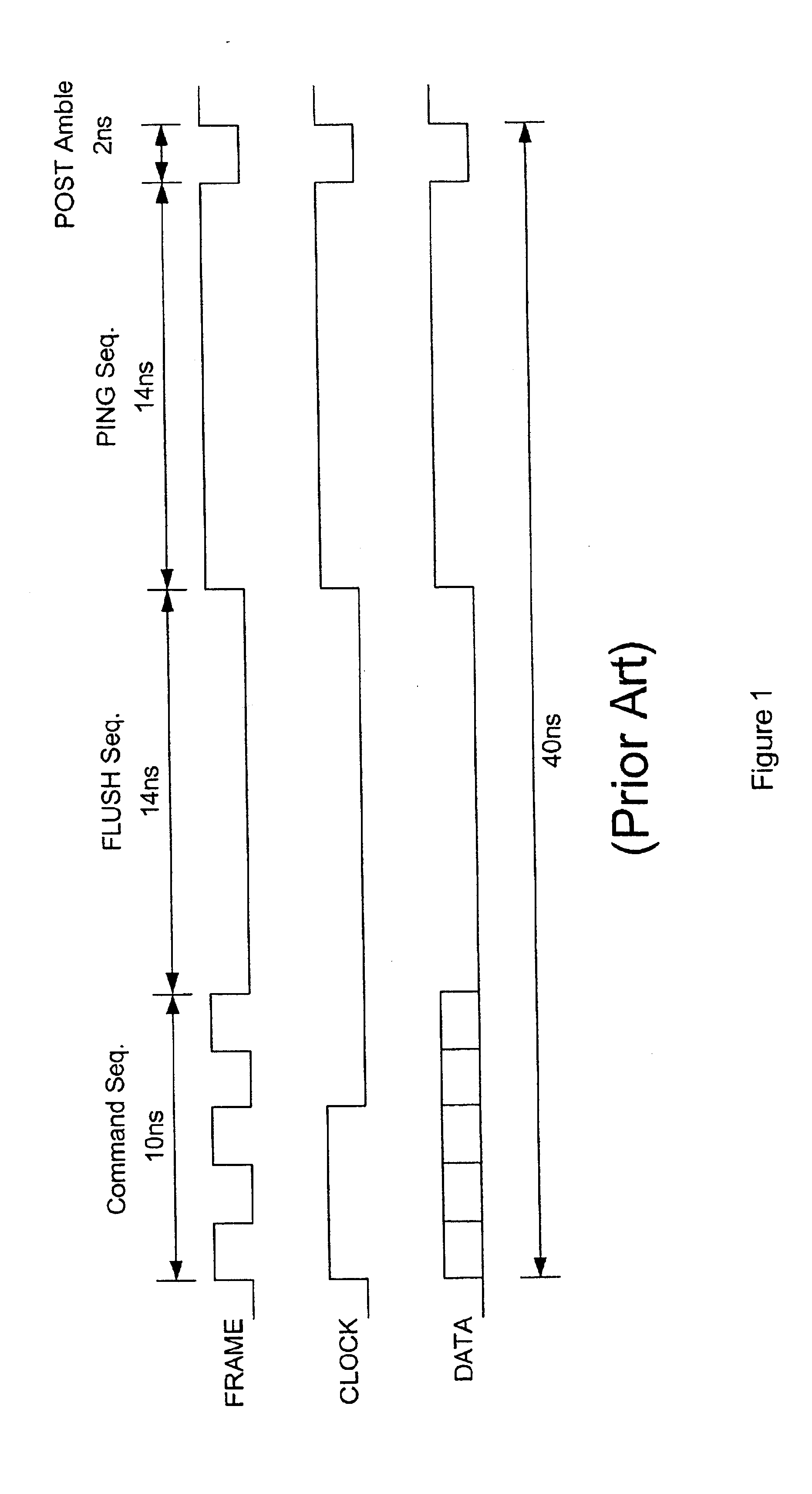

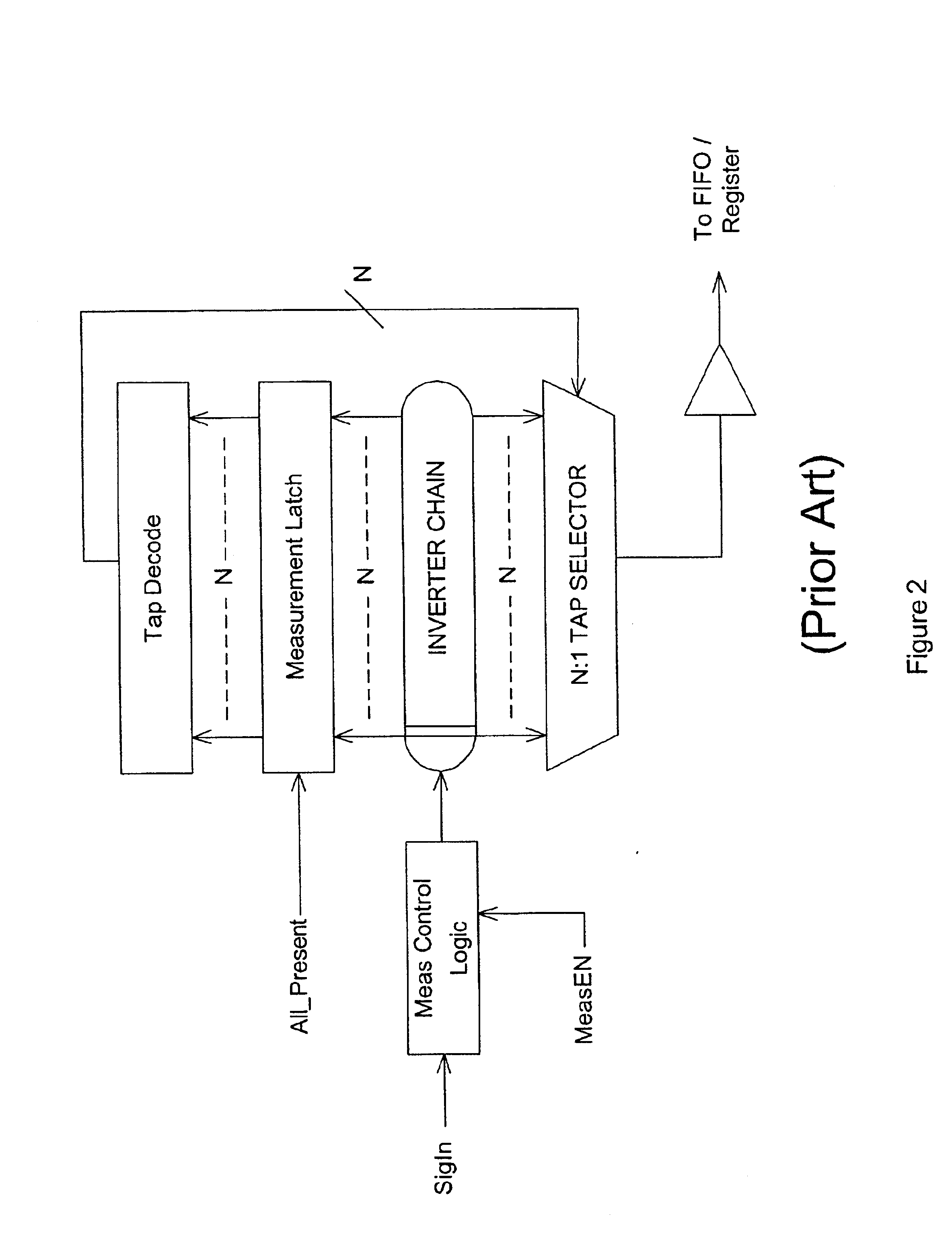

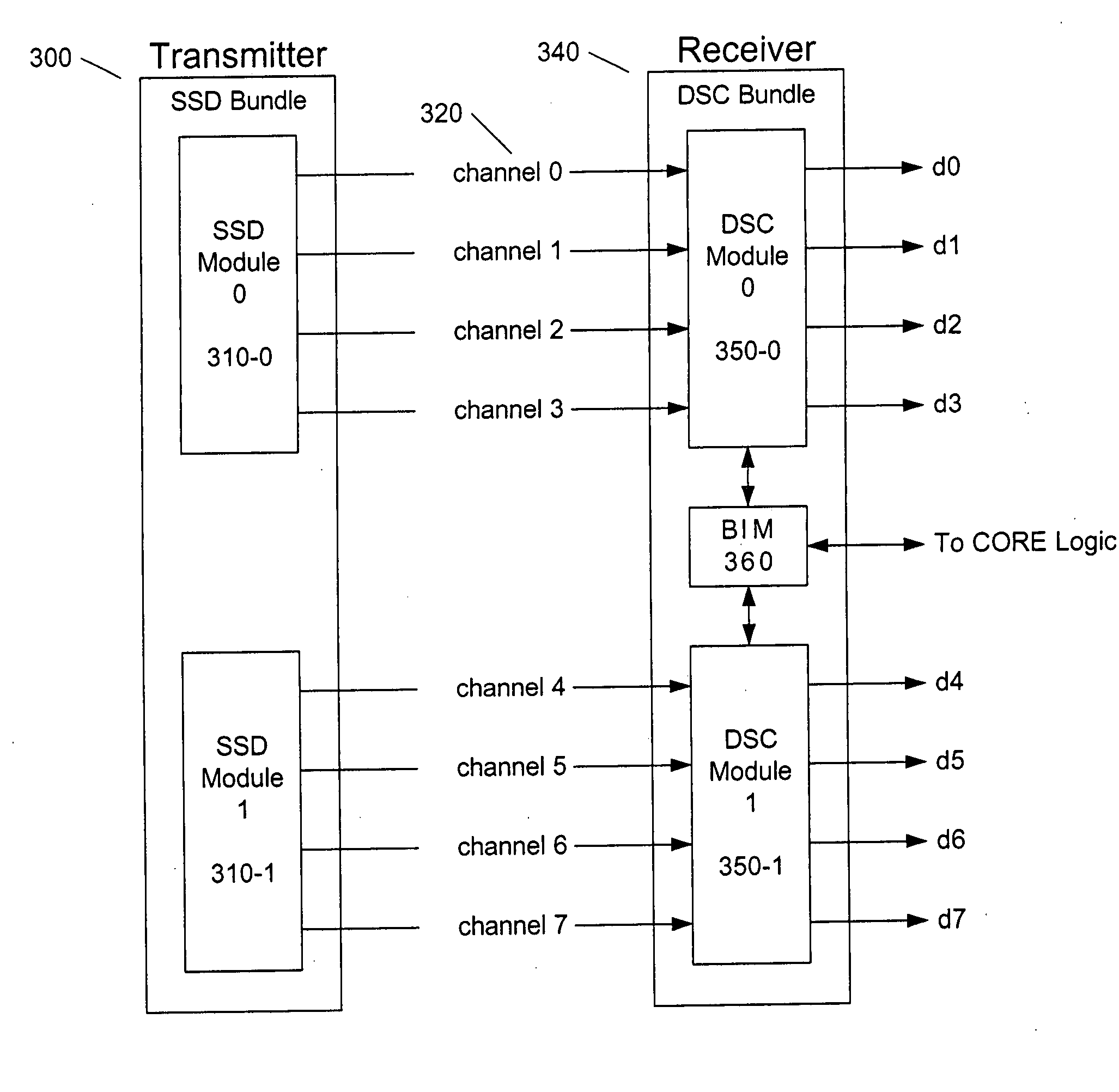

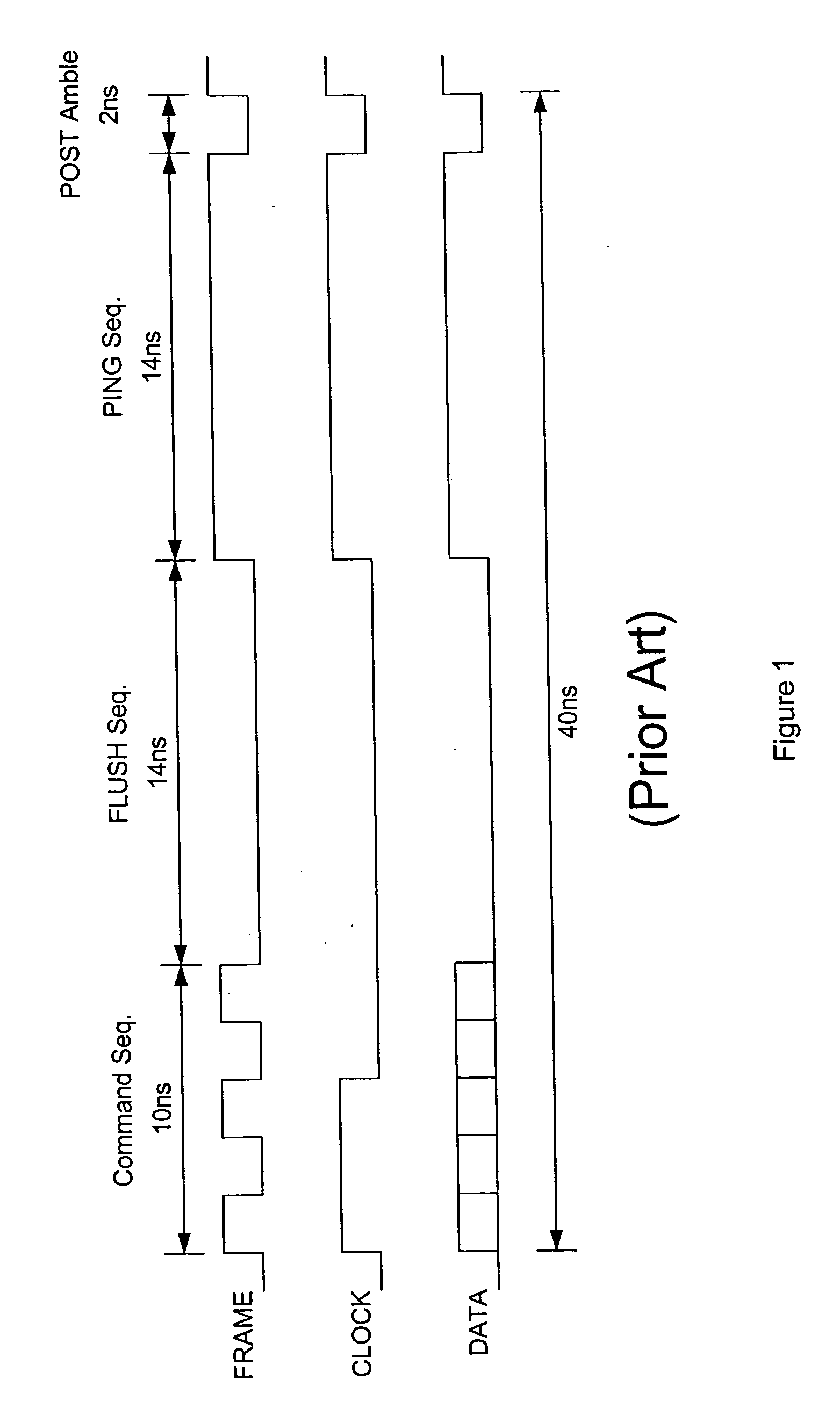

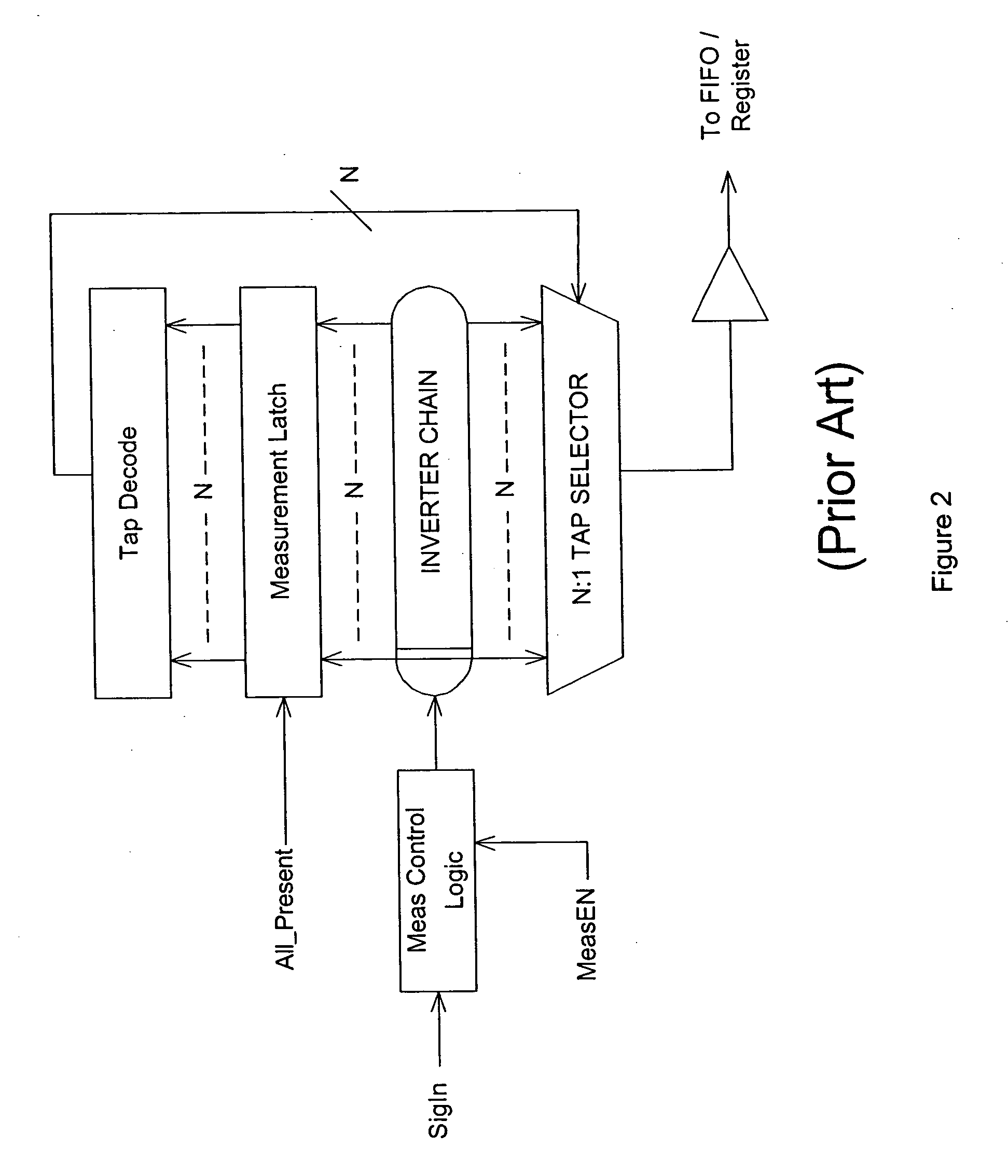

Relative dynamic skew compensation of parallel data lines

InactiveUS6907552B2Add supportDelay powerChannel dividing arrangementsError detection/correctionData signalSignal edge

A system performs a two-step skew compensation procedure by first correcting for any phase error alignment between a parallel link clock and data signal edges of each data channel, thereby allowing the received data bits to be correctly sampled. Then, a second step is performed to “word-align” the bits into the original format, which is accomplished with a Skew Synchronizing Marker (SSM) byte in a data FIFO of each data channel. The SSM byte is transmitted on each data channel and terminates the skew compensation procedure. When the SSM byte is detected by logic in the data FIFO of each data channel, the data FIFO employs the SSM byte to initialize the read and write pointers to properly align the output data.

Owner:SYNOPSYS INC

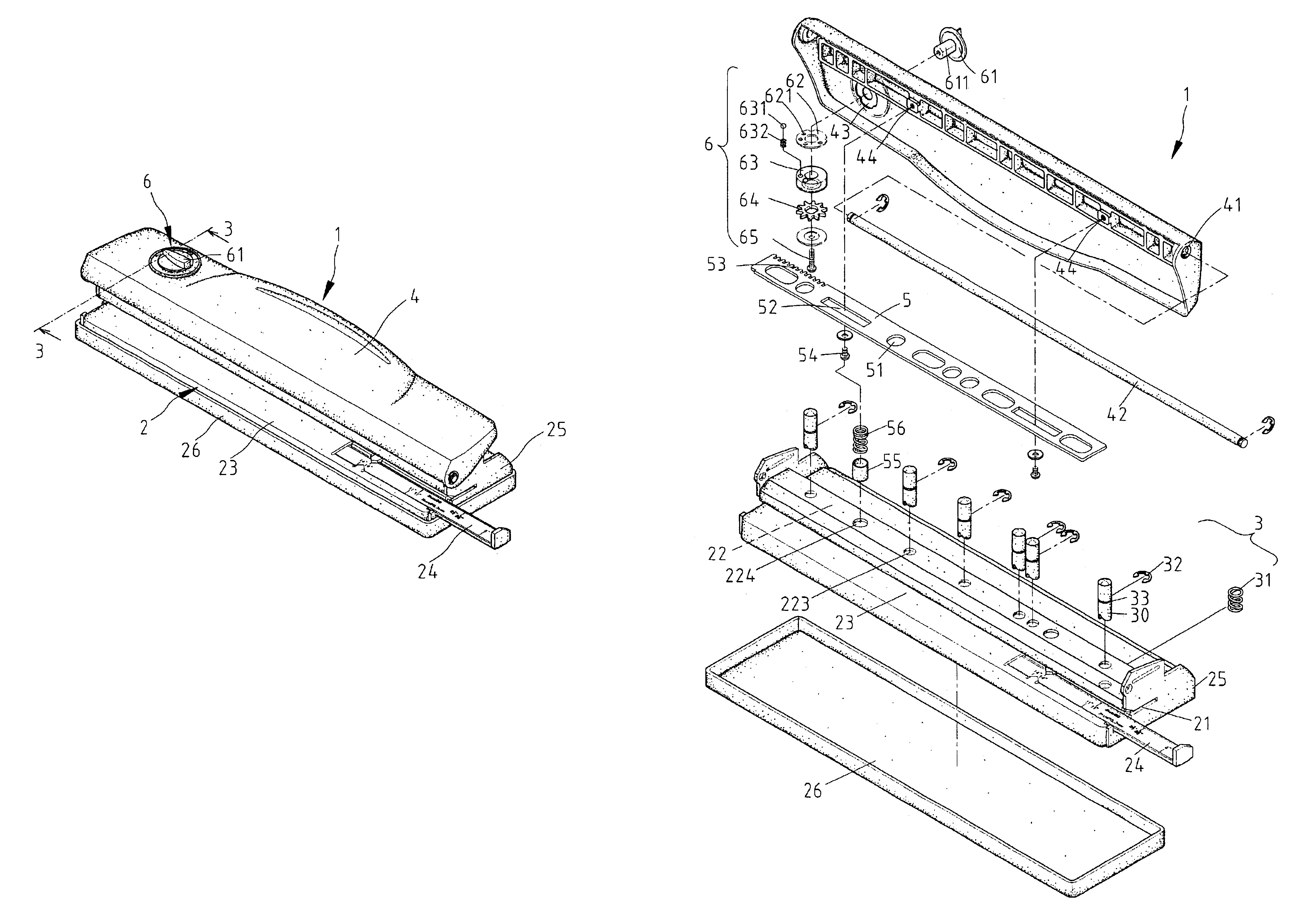

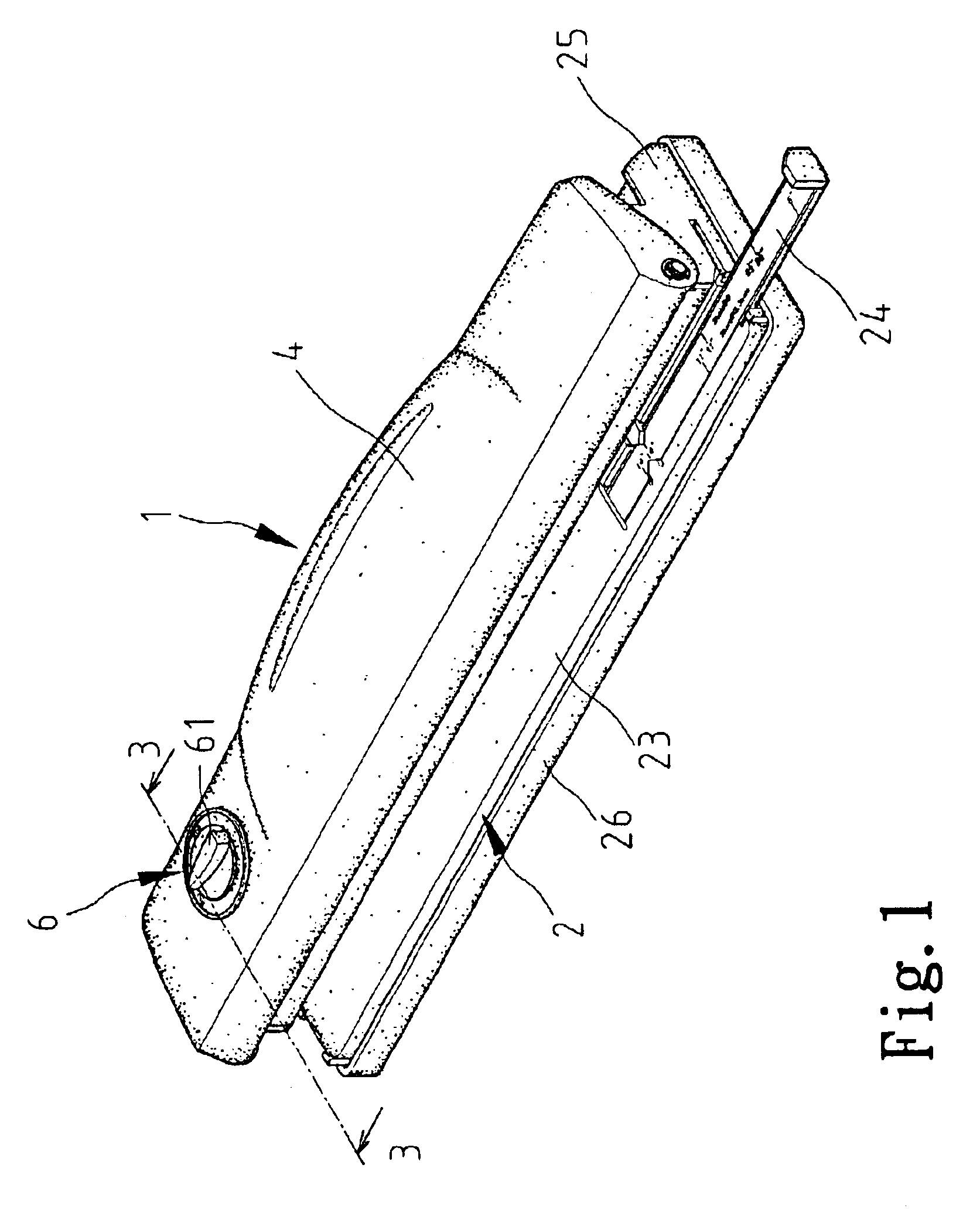

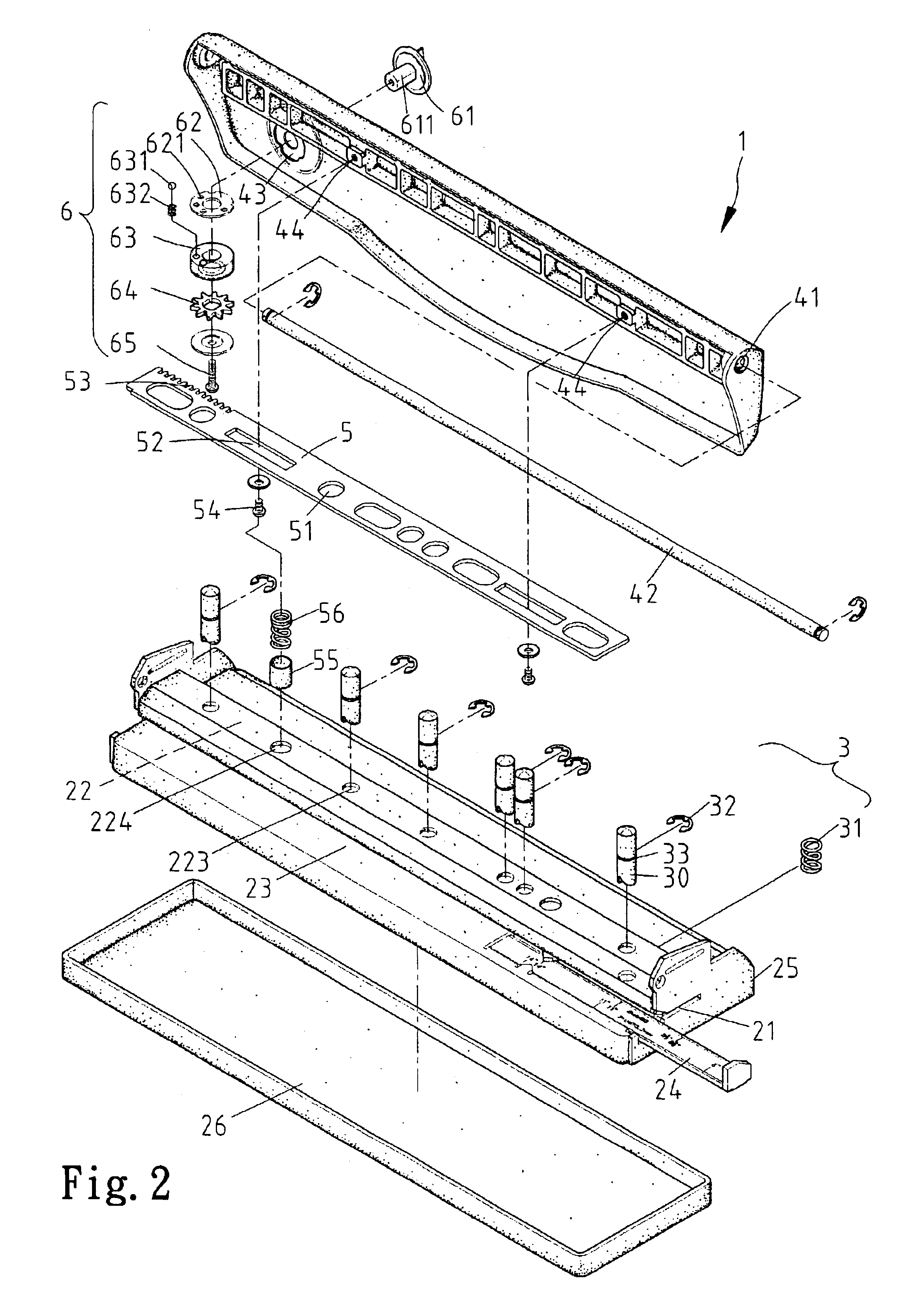

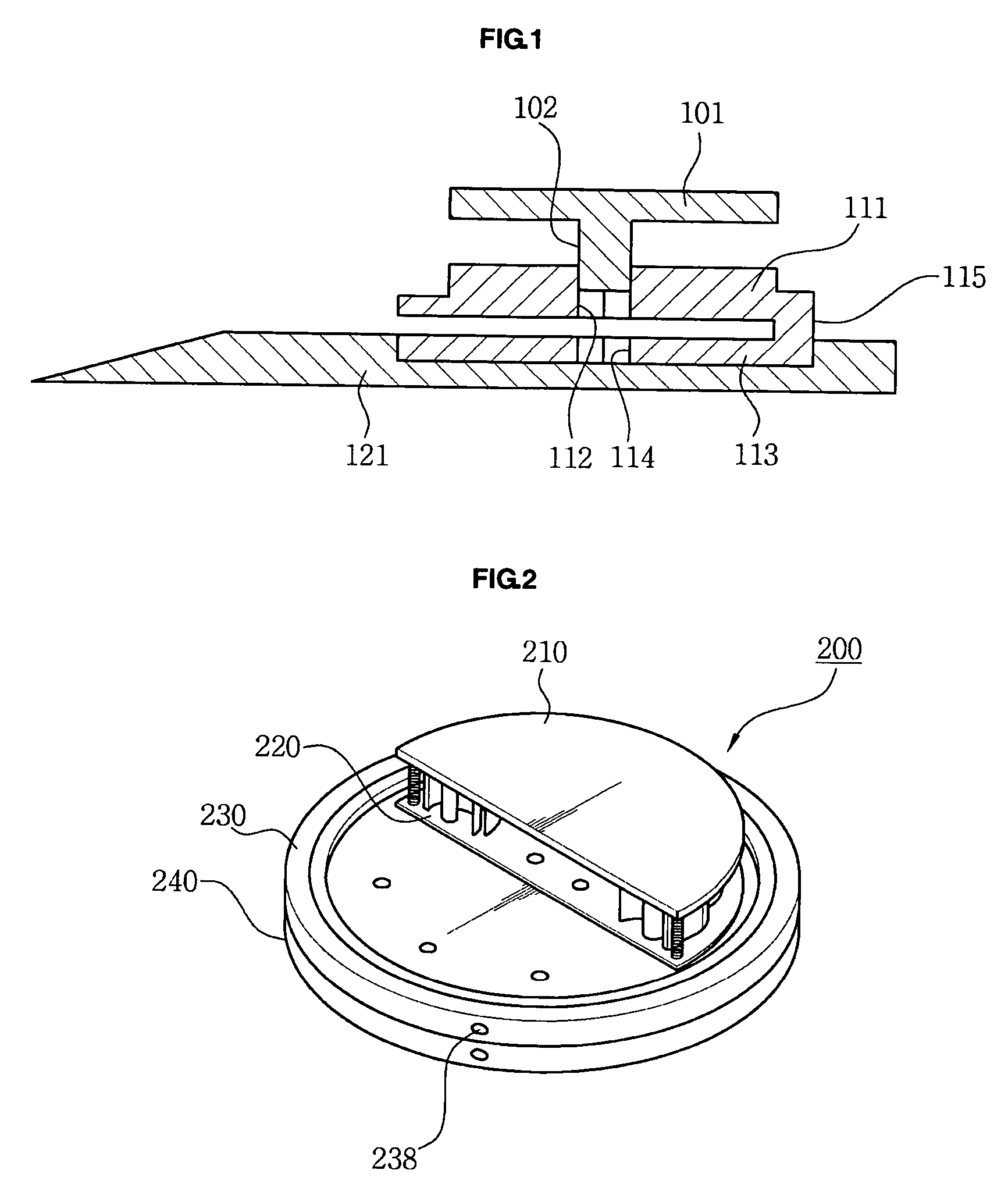

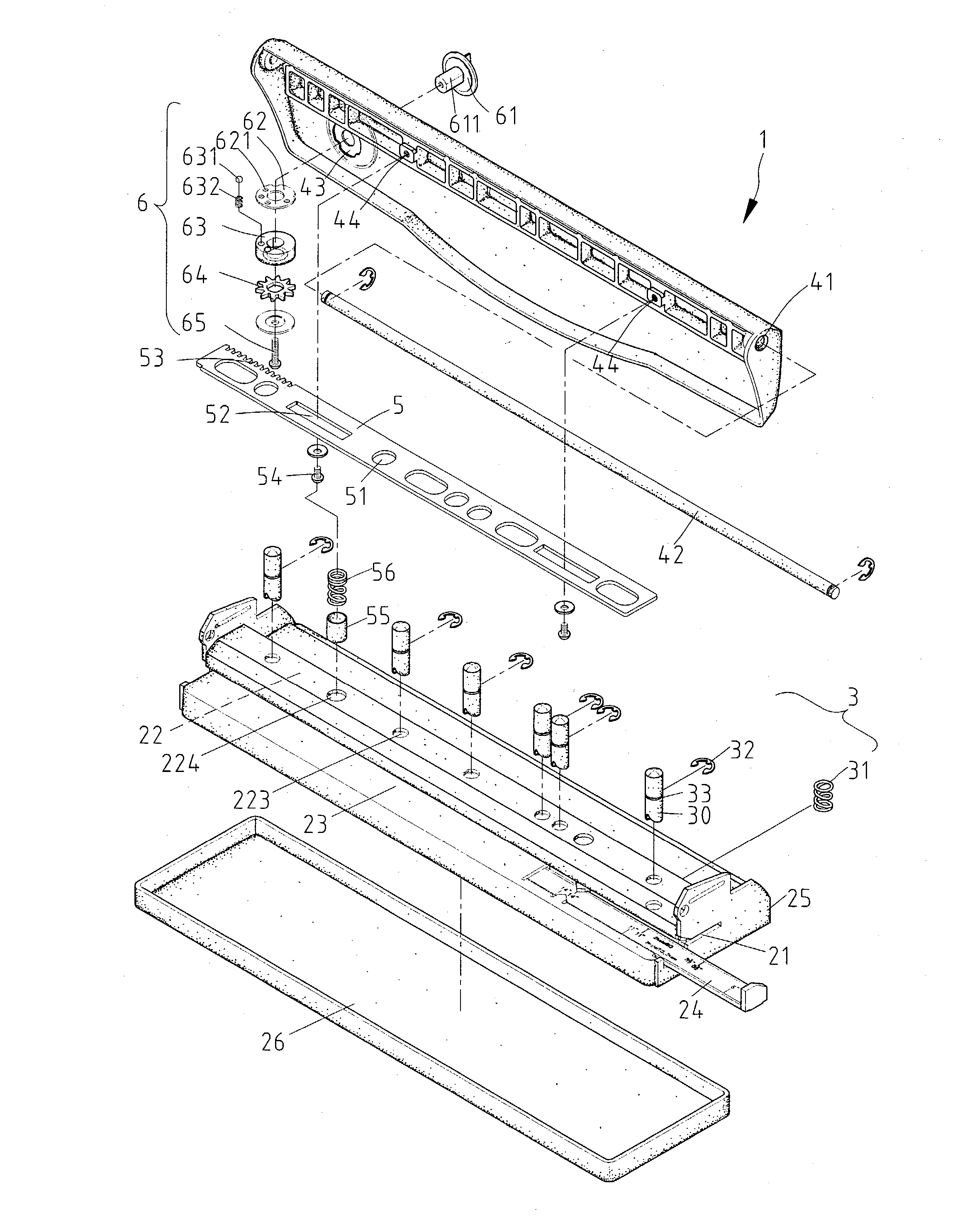

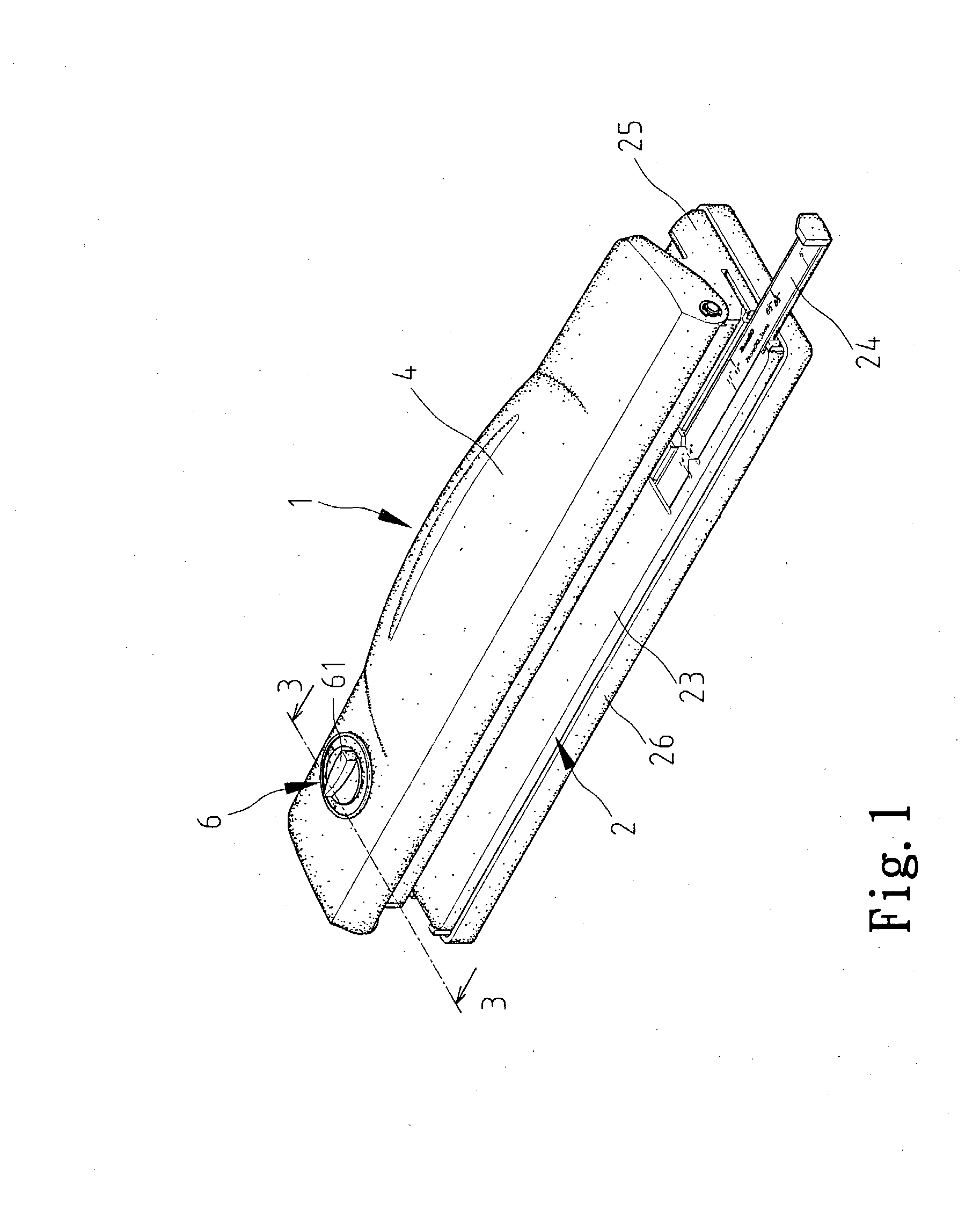

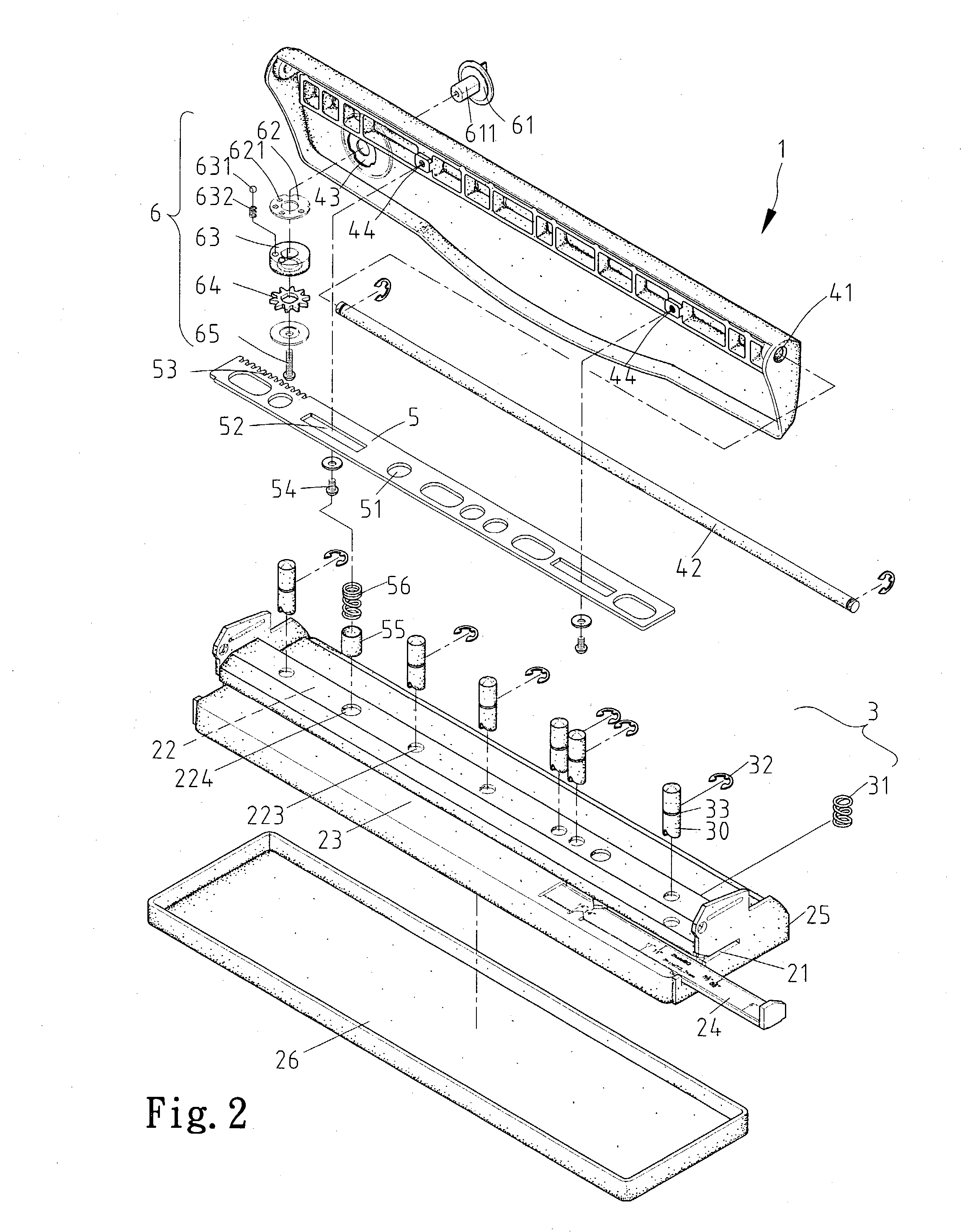

Punch with punch elements in adjustable positions

InactiveUS6786395B1Easy to adjustMetal working apparatusDigital marking by punchingPunch pressEngineering

A punch includes a base, a plurality of punch pins, a lever and a plank. The base includes a lower member defining a plurality of holes and an upper member defining a plurality of holes corresponding to the holes defined in the lower member. Each of the punch pins is for insertion through one of the holes defined in the upper member and one of the holes defined in the lower member. The lever is pivotally mounted on the base. The plank defines a plurality of holes. The plank is movably attached to the lever between several positions in each of which it pushes a different set of the punch pins when the lever is operated.

Owner:CHAU LIH RONG ENTERPRISE

Method, device and computer program product for integrating code-based and optical character recognition technologies into a mobile visual search

InactiveUS20120027301A1Digital data information retrievalCharacter and pattern recognitionMobile visionVisual perception

A device for switching between code-based searching, optical character recognition (OCR) searching and visual searching is provided. The device includes a media content input for receiving media content from a camera or other element of the device and transferring this media content to a switch. Additionally, the device includes a meta-information input capable of receiving meta-information from an element of the device and transferring the meta-information to the switch. The switch is able to utilize the received media content and the meta-information to select and / or switch between a visual search algorithm, an OCR algorithm and a code-based algorithm.

Owner:NOKIA CORP

Boring device

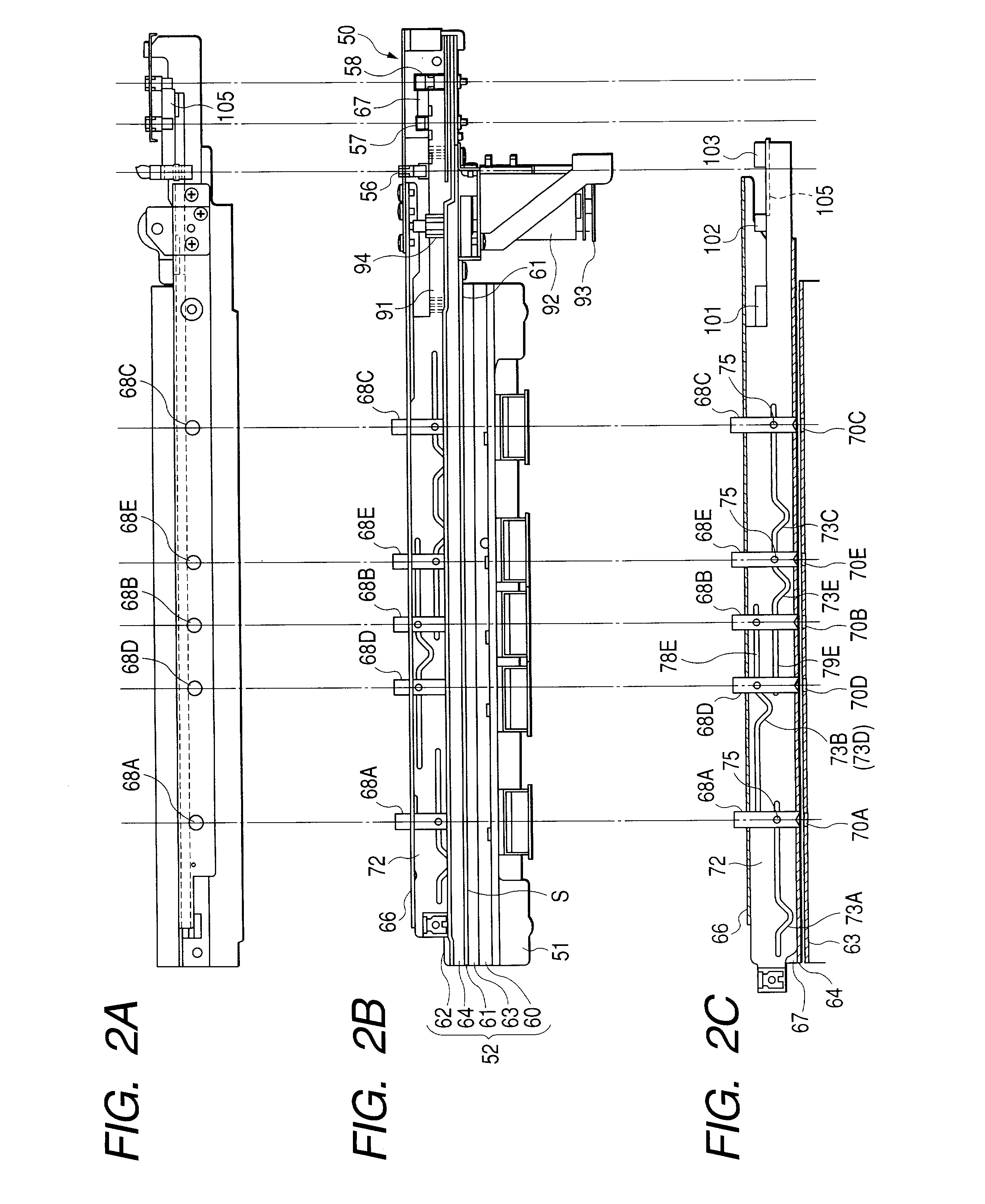

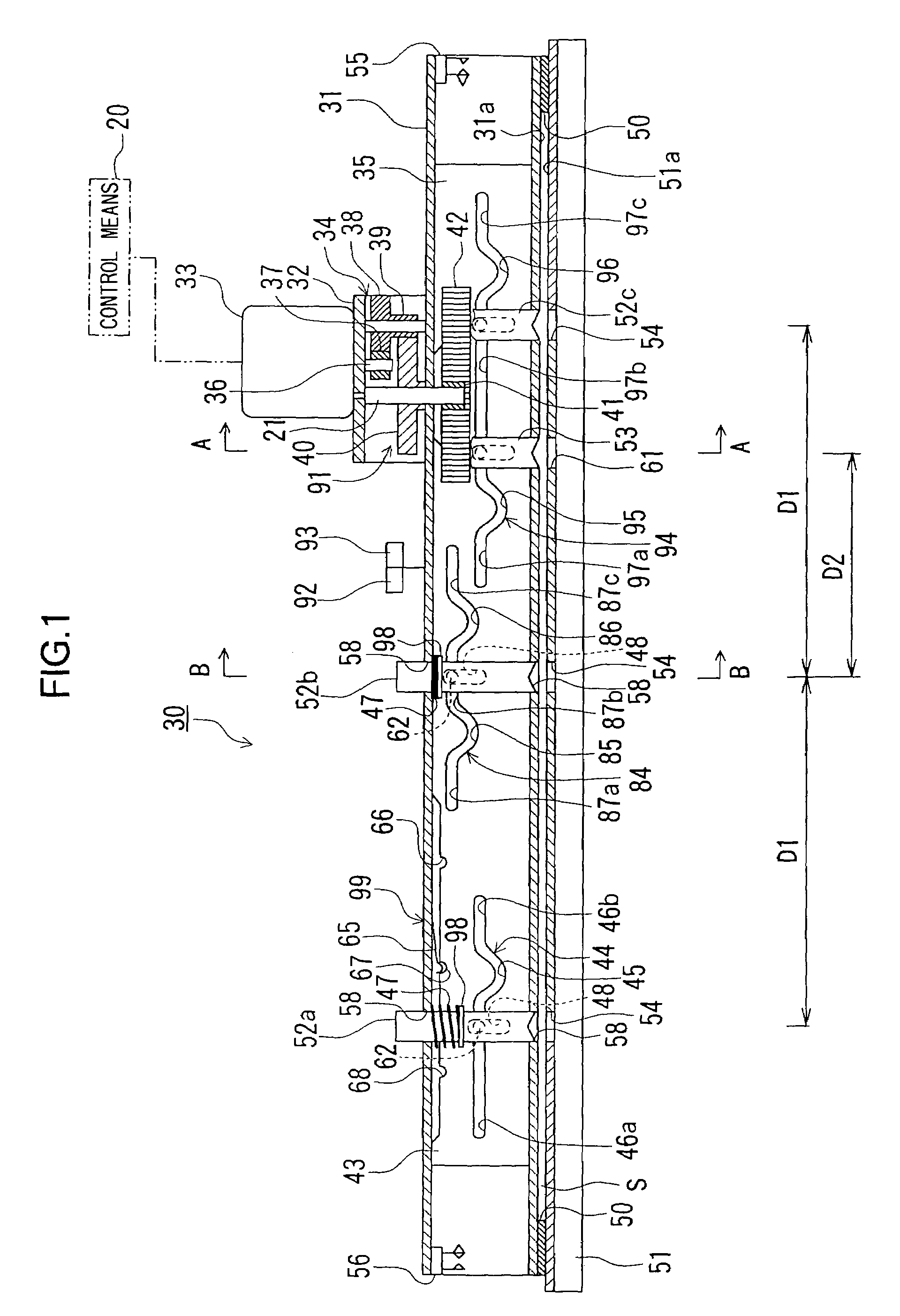

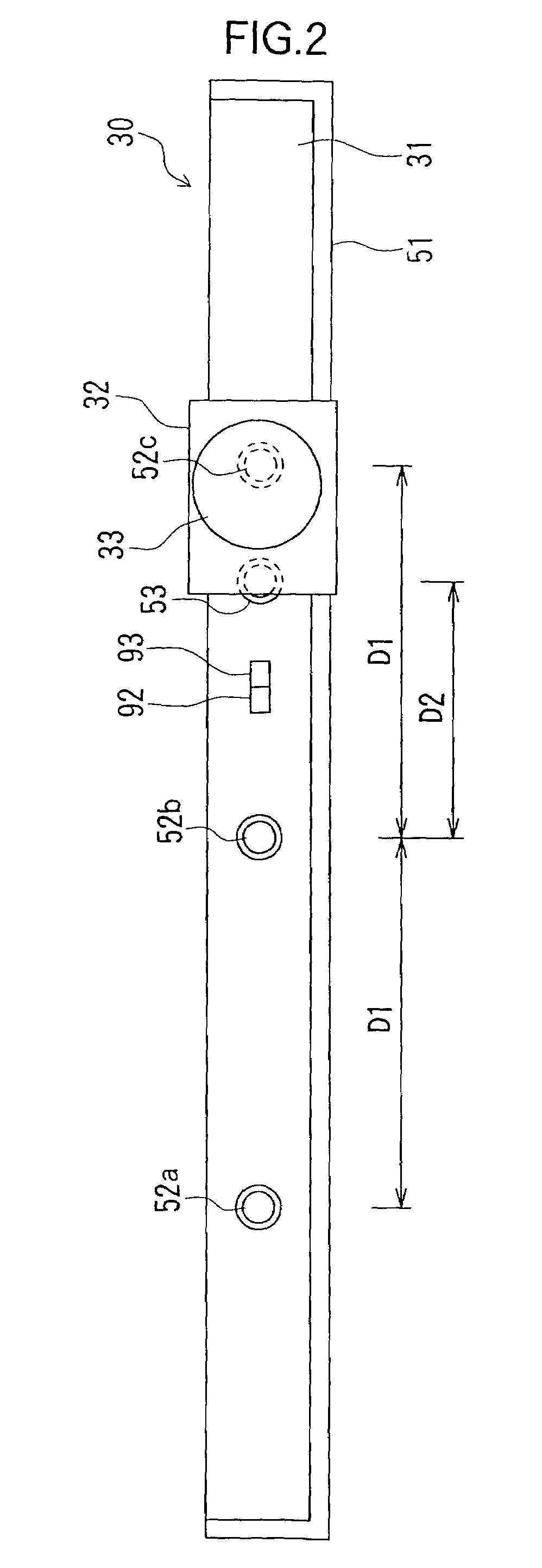

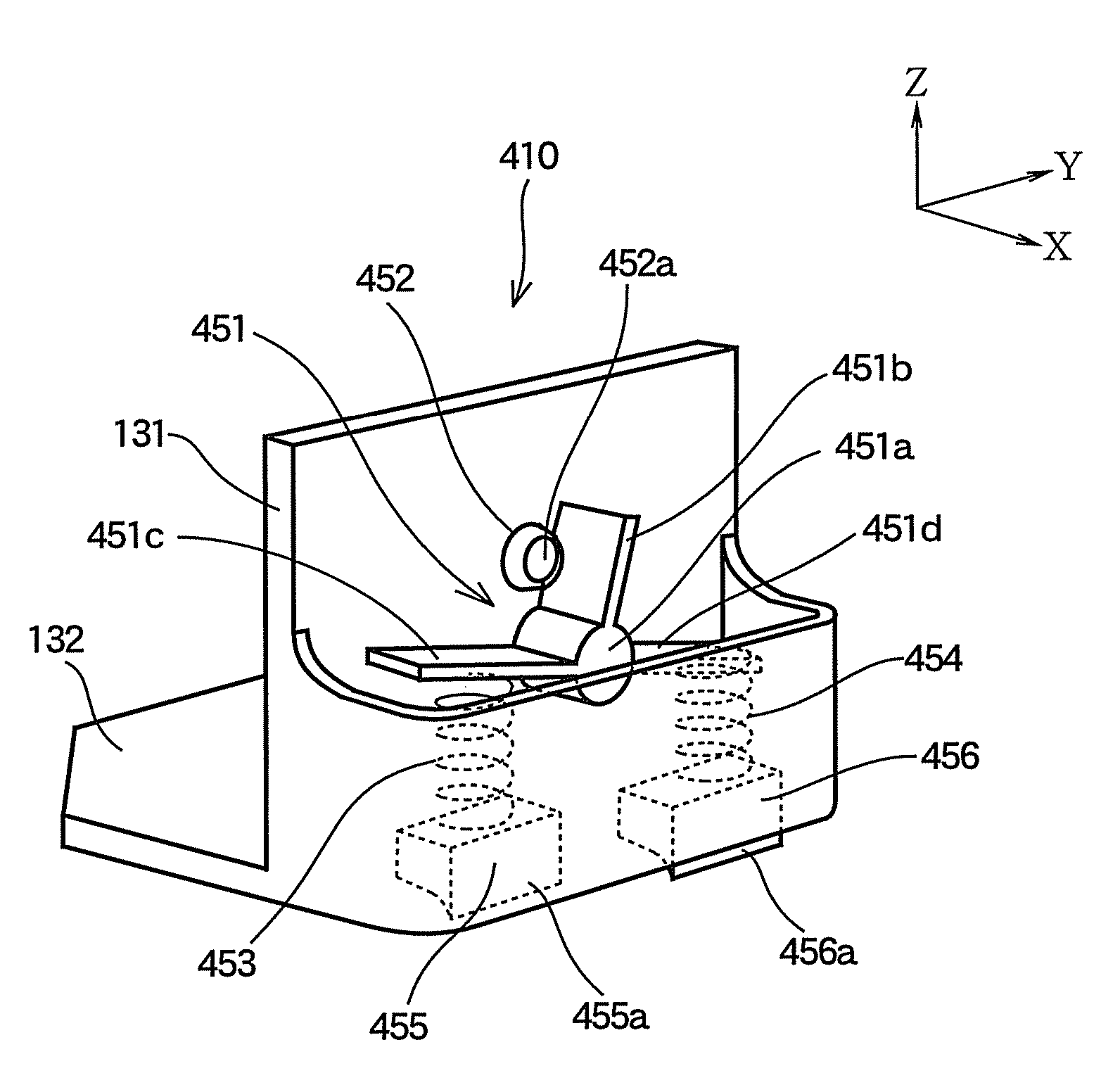

InactiveUS7458505B2Reduce the number of partsSimple structureMetal working apparatusDigital marking by punchingPunchingReciprocating motion

A punching unit is arranged so that a plurality of punches is grouped into a first group having a predetermined number of punches and a second group containing any one of the punches in the first group and having a smaller number of punches. A punching state of the predetermined number of punches is produced by reciprocating a reciprocating member within a first range and by vertically moving the punches of the first group through the intermediary of cams and followers corresponding to the first group and another punching state of the smaller number of punches is reached by reciprocating the reciprocating member within a second movable range and vertically moving the punches of the second group through the intermediary of cams and followers corresponding to the second group. This arrangement allows the number of punches and dies to be reduced as compared to the prior art.

Owner:DAIDO KOGYO CO LTD

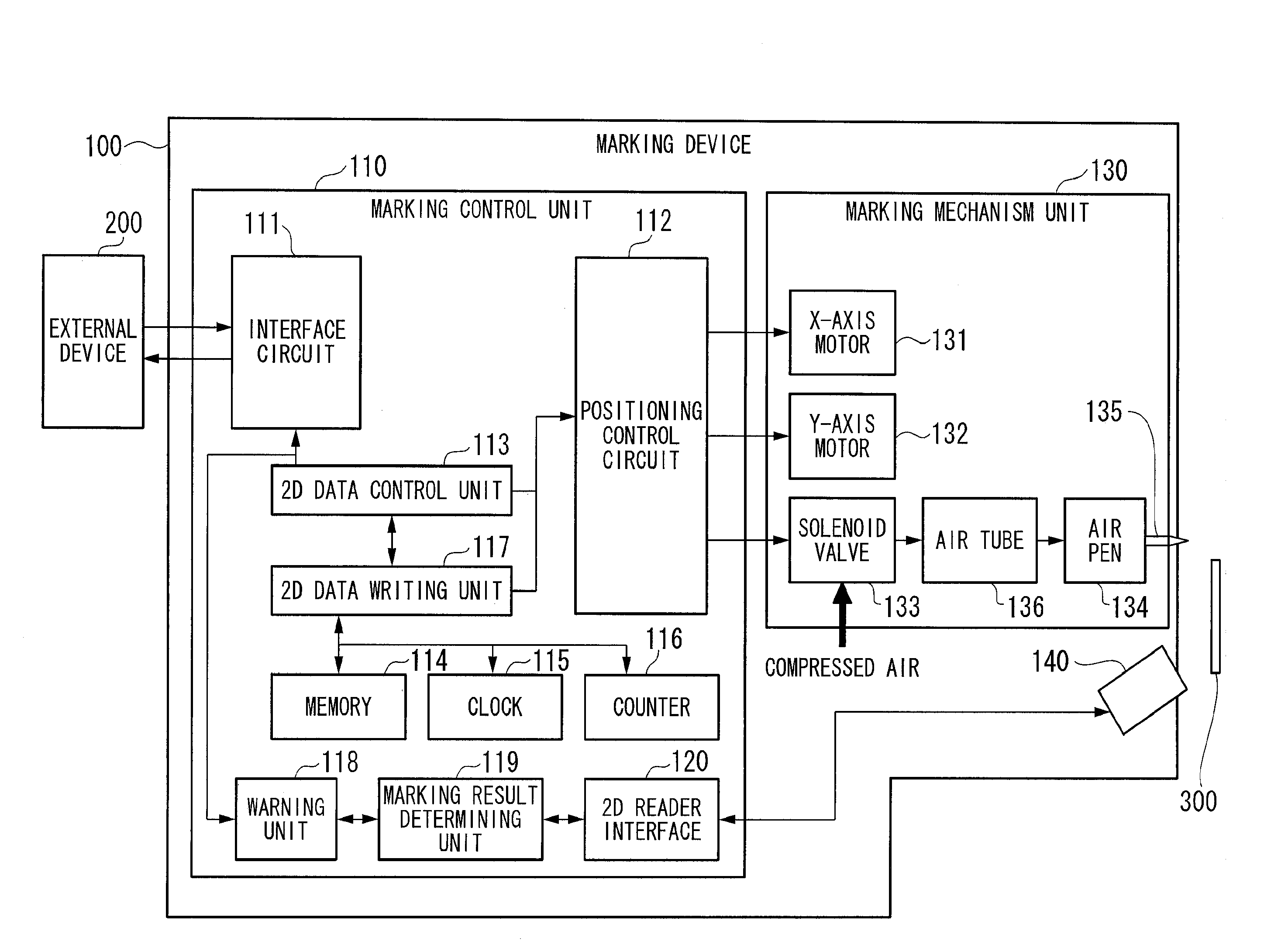

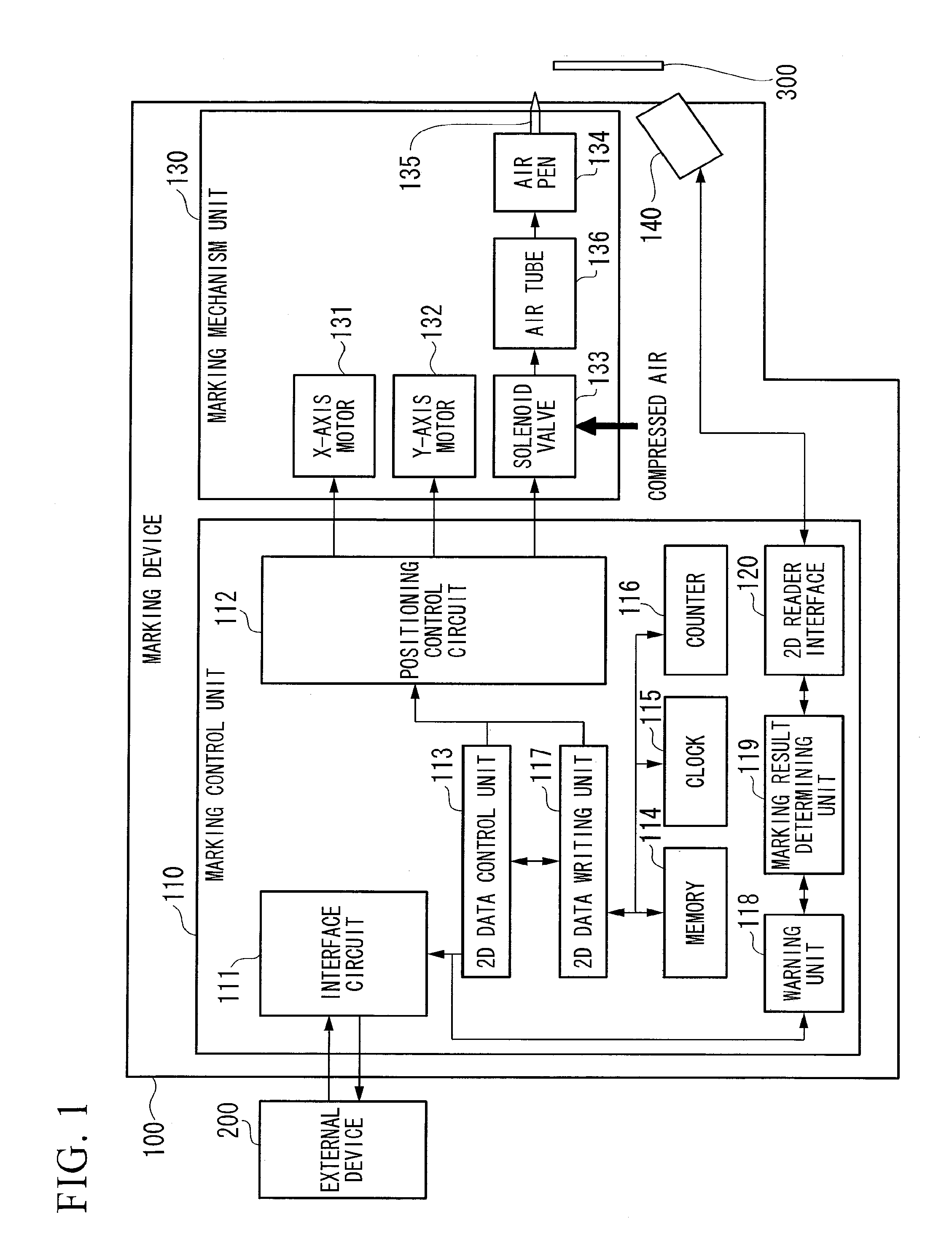

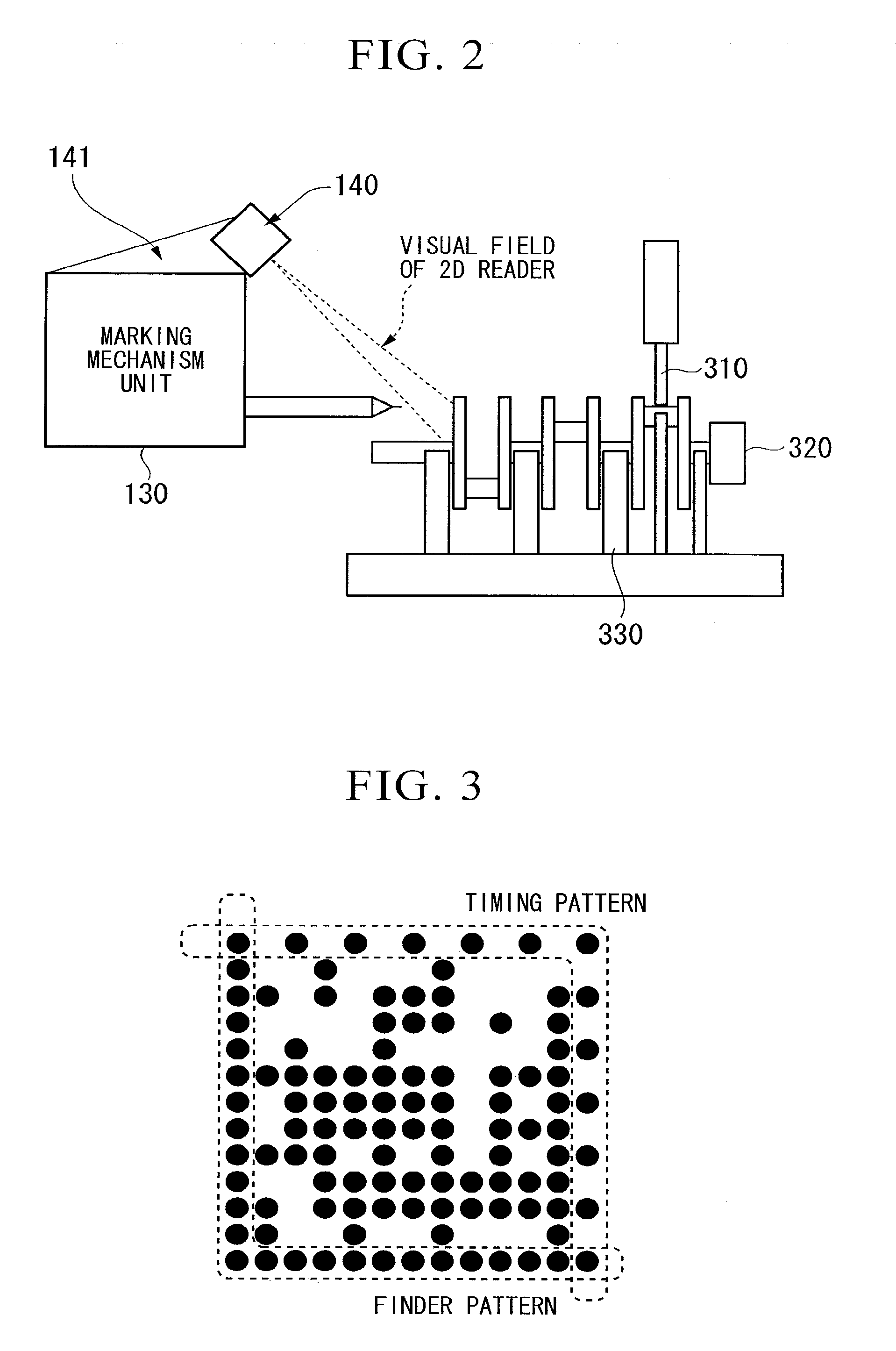

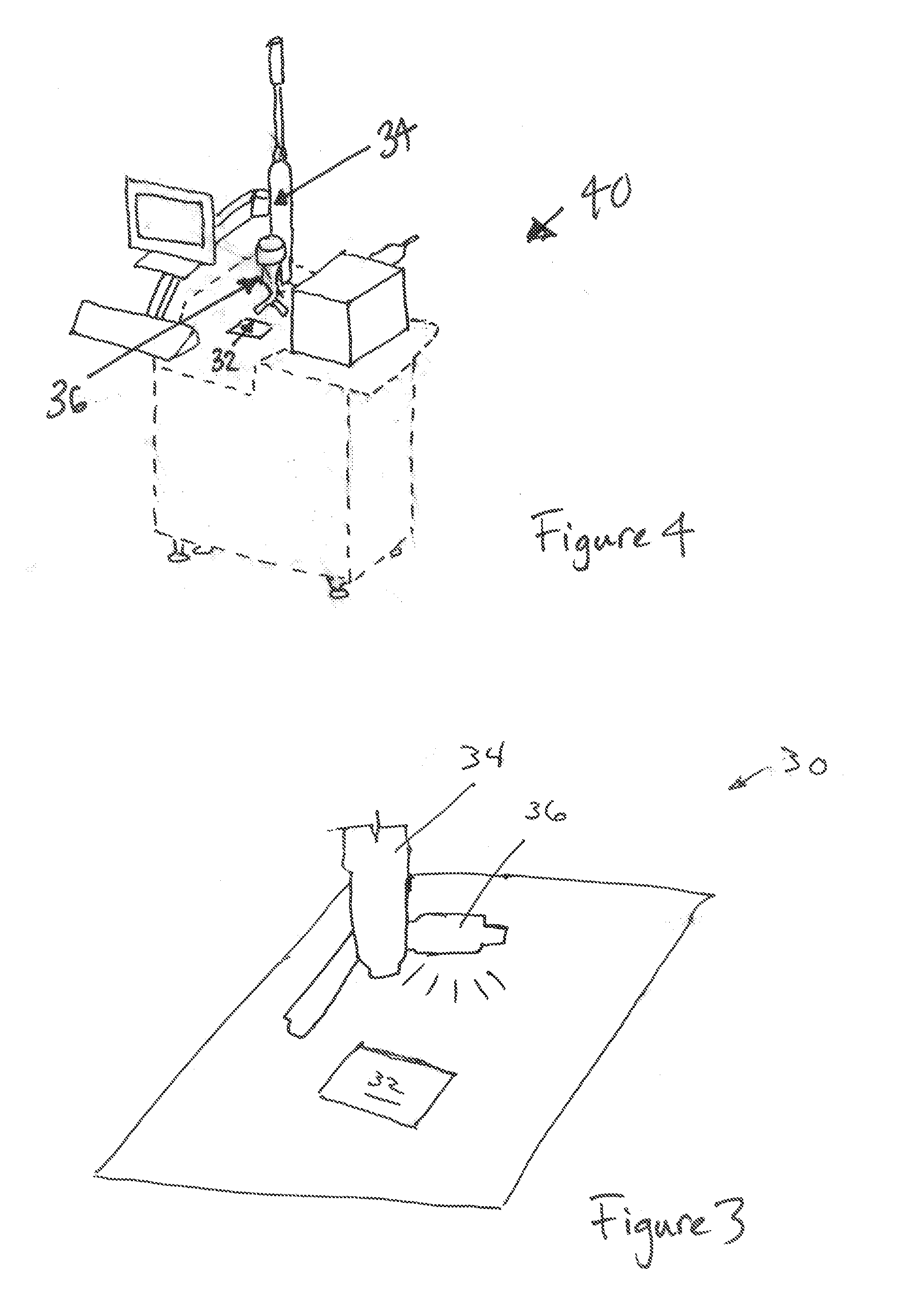

Marking Device

InactiveUS20100051683A1Digital marking by photographic/thermographic registrationSpecial data processing applicationsObject basedComputer engineering

A marking device includes a two-dimensional code forming unit converting first identification information into two-dimensional code information in accordance with a predetermined standard and forming a two-dimensional code on an object based on the two-dimensional code information, a two-dimensional code reading unit reading the two-dimensional code and generating second identification information in accordance with the standard, and a determination unit determining whether or not the first identification information matches the second identification information.

Owner:VECTOR LIMITED

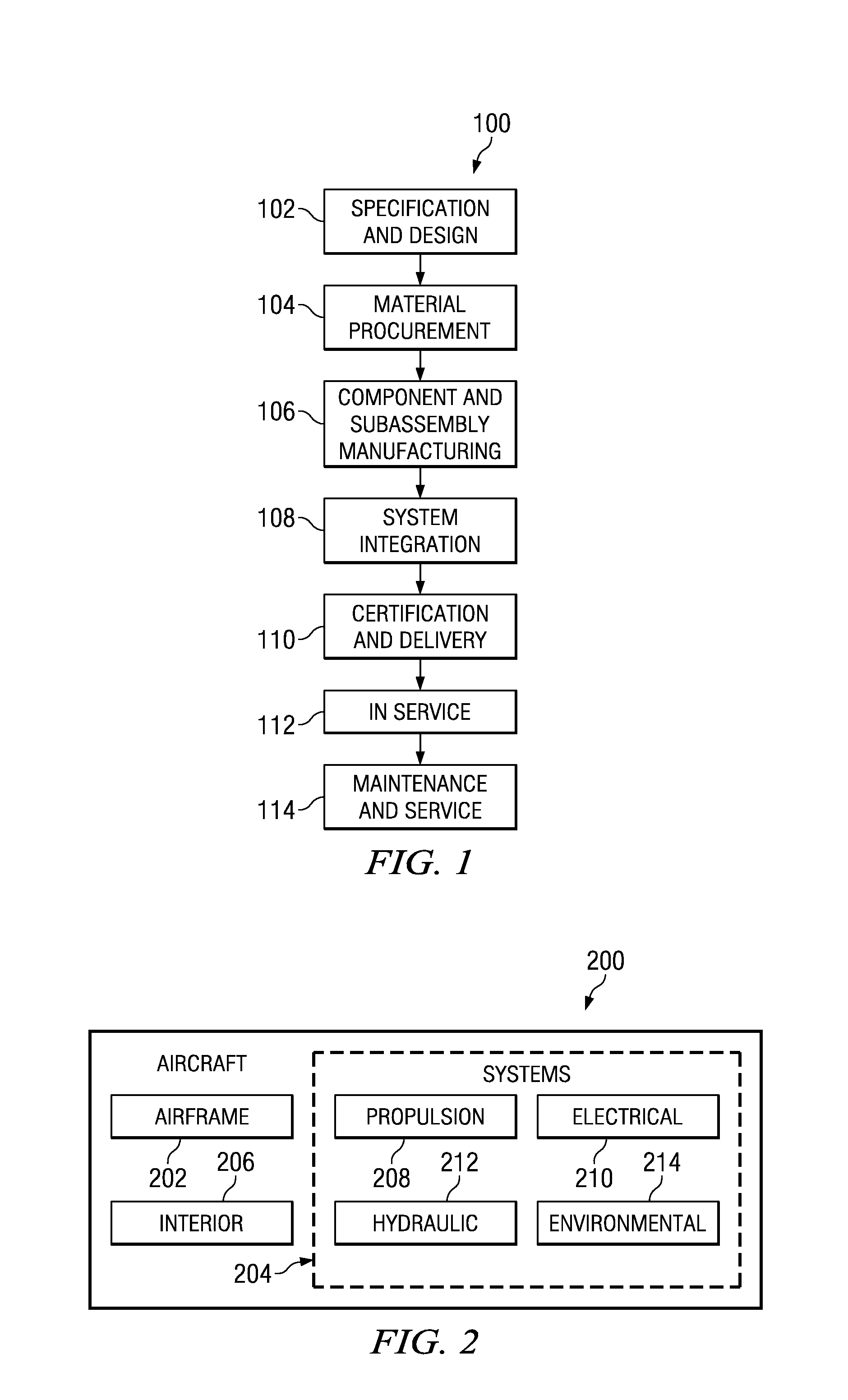

Method and apparatus for generation of datamatrix barcodes utilizing numerical control drilling patterns

InactiveUS20090125143A1Thread cutting auxillary apparatusPlaning/slotting machinesDigital dataNumerical control

The illustrative embodiments provide a method, apparatus, and computer usable program product for generating datamatrix barcodes on parts. A digital datamatrix code associated with a machined part on a numerically controlled machine tool is converted into an x-y drilling pattern contained in a numerically controlled program. A drill cycle associated with a numerically controlled program defines a pattern of dots to be drilled in the machined part to form a dot pattern. A dot pattern is drilled as a series of partially drilled holes on a surface of the machined part to form a datamatrix barcode mark.

Owner:THE BOEING CO

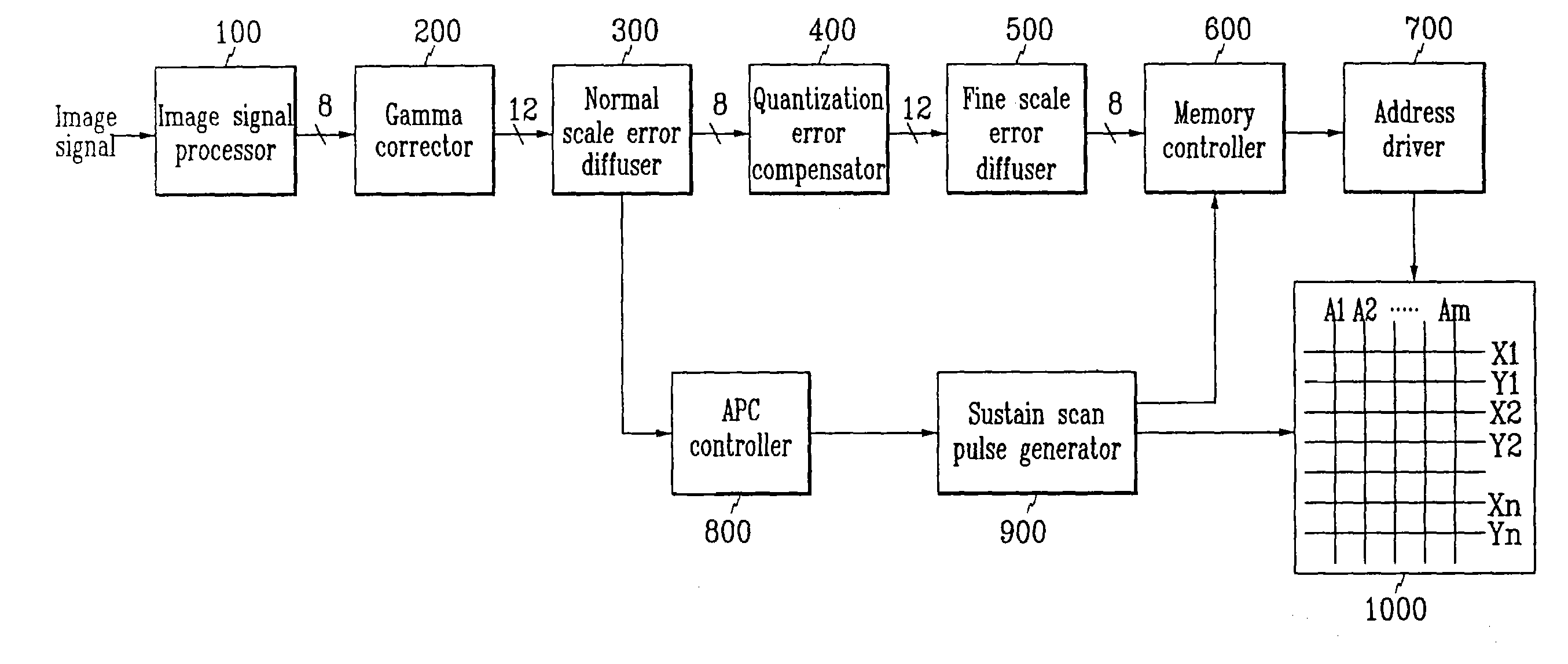

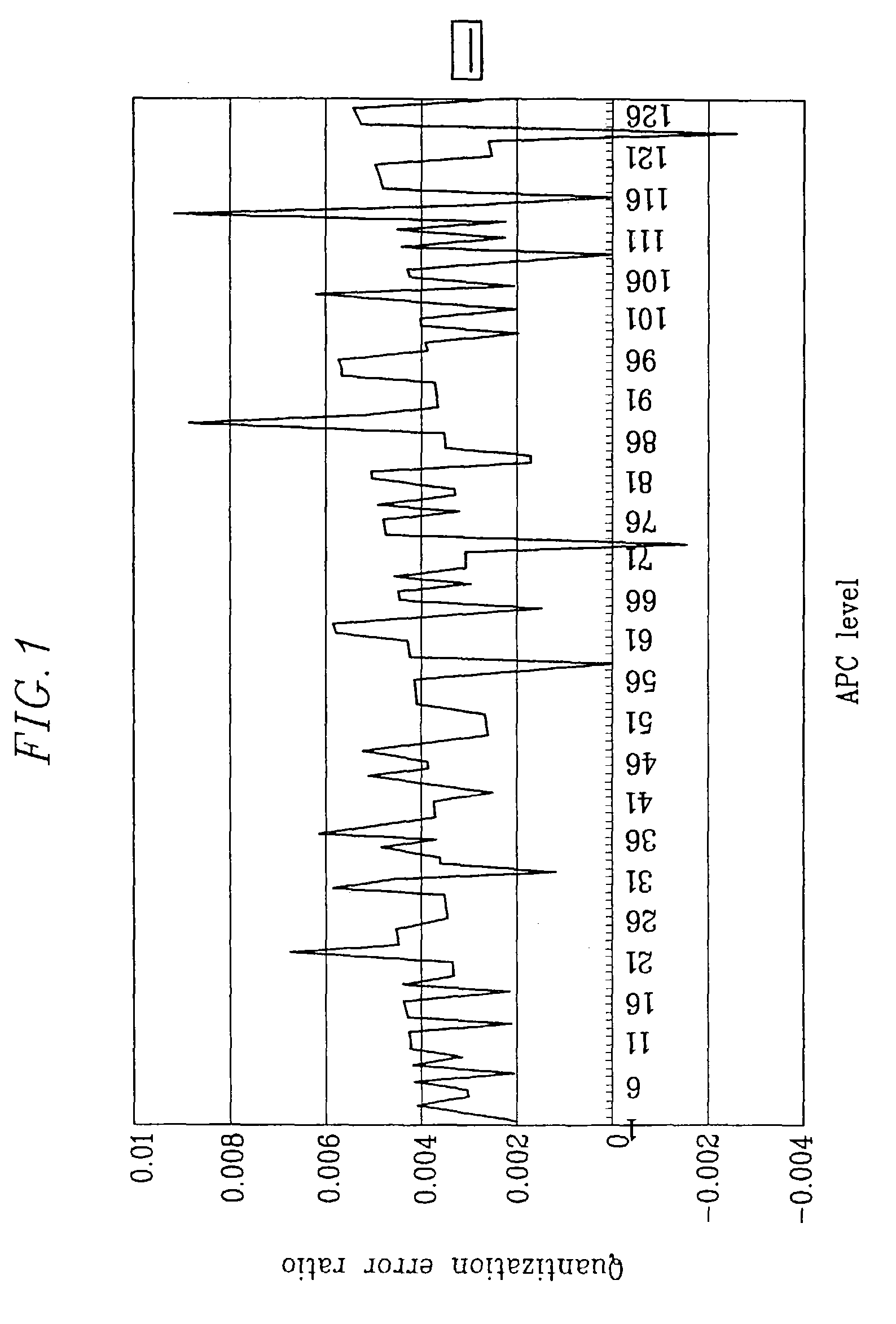

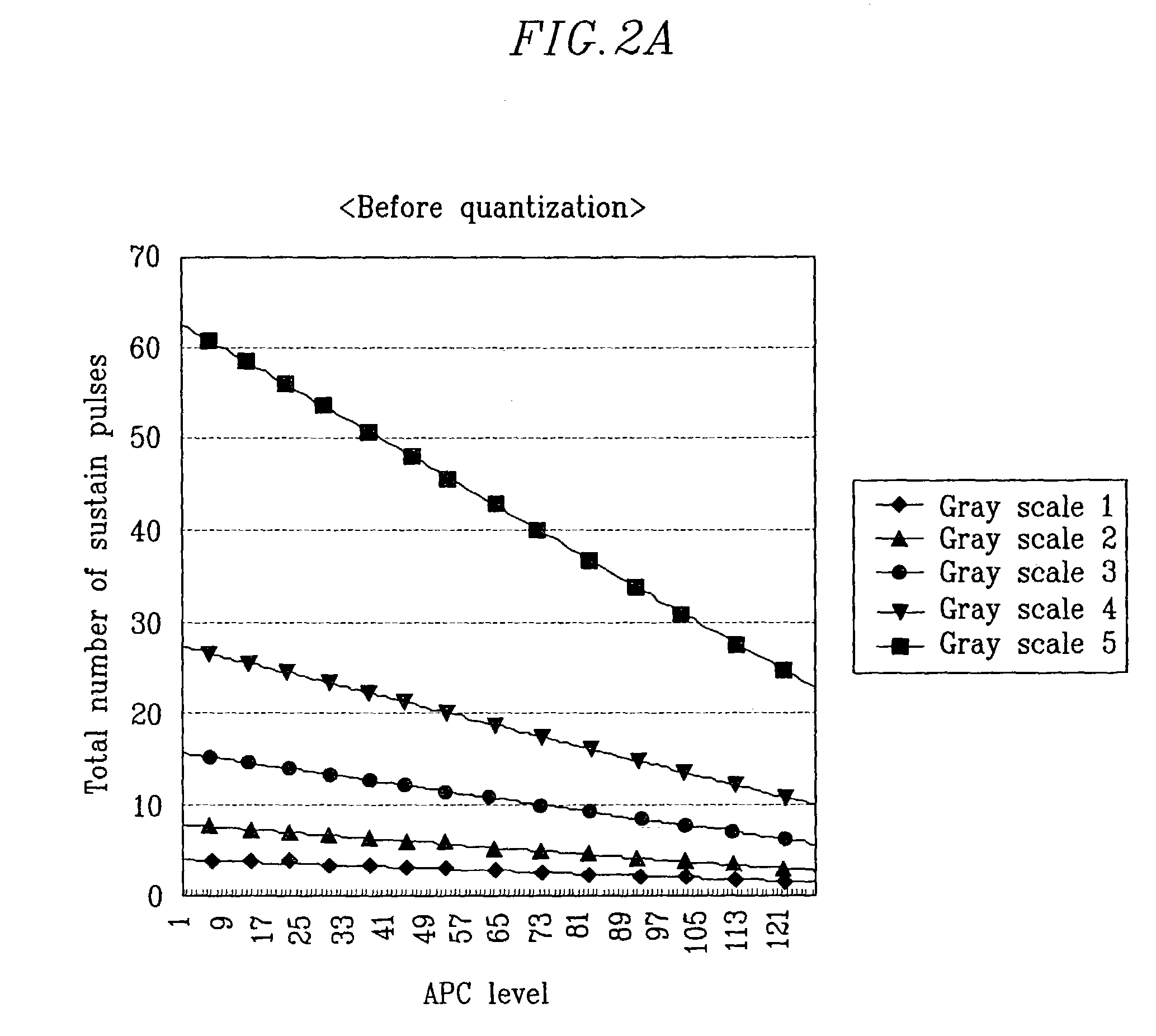

Apparatus and method for driving plasma display panel to enhance display of gray scale and color

InactiveUS7025252B2Improve the display effectDisplay moreTelevision system detailsCathode-ray tube indicatorsControl signalError diffusion

The present invention relates to an apparatus and method for driving a PDP (plasma display panel). An image signal processor of the apparatus performs gamma correction and error diffusion processes of input image signals. A quantization error compensator compensates quantization errors with respect to an automatic power control (APC) level of image data output from the image signal processor. An error diffuser sets part of the image data output from the quantization error compensator as display errors and diffuses the display errors to peripheral pixels. A memory control and address driver generates sub-field and address data corresponding to image data that have undergone error diffusion by the error diffuser, and applies the data to the PDP. An APC and sustain / scan pulse generator generates a sub-field arrangement structure according to the APC level, generates control signals based on the generated sub-field arrangement, and applies the control signals to the PDP.

Owner:SAMSUNG SDI CO LTD

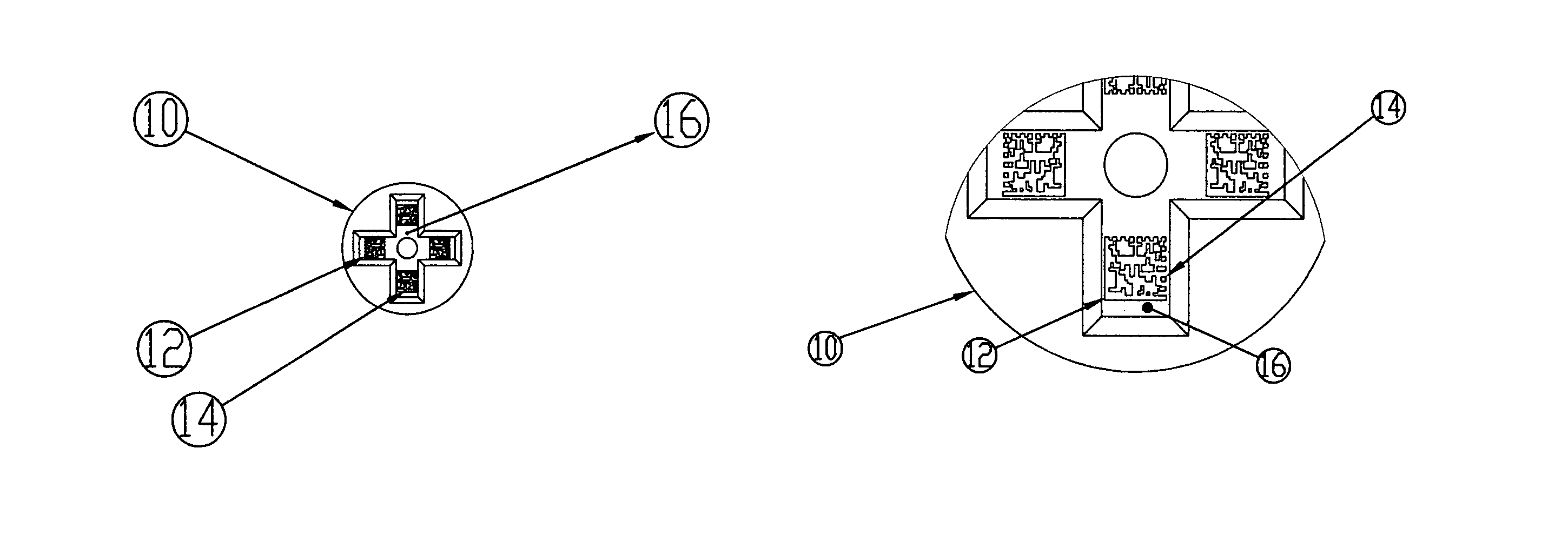

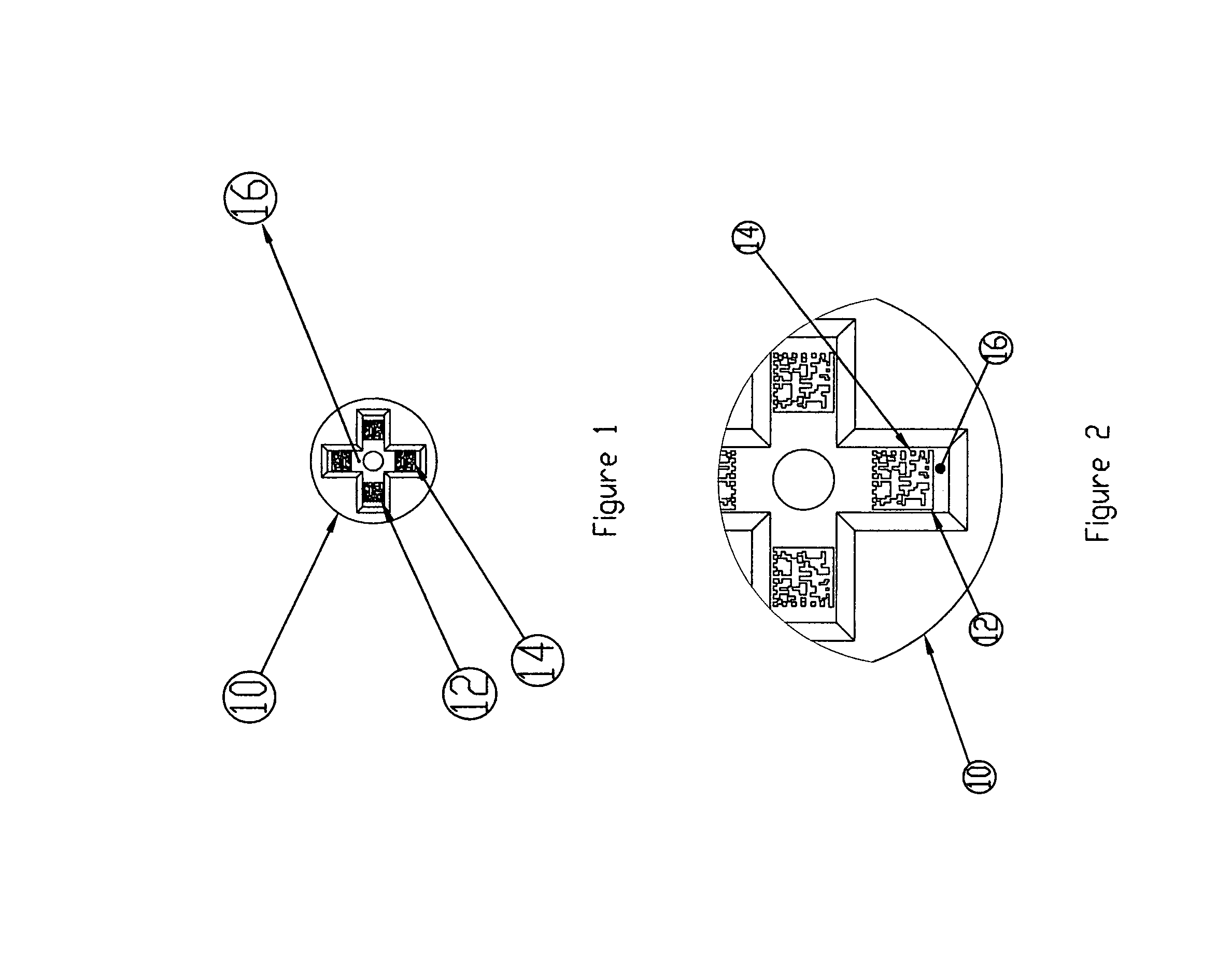

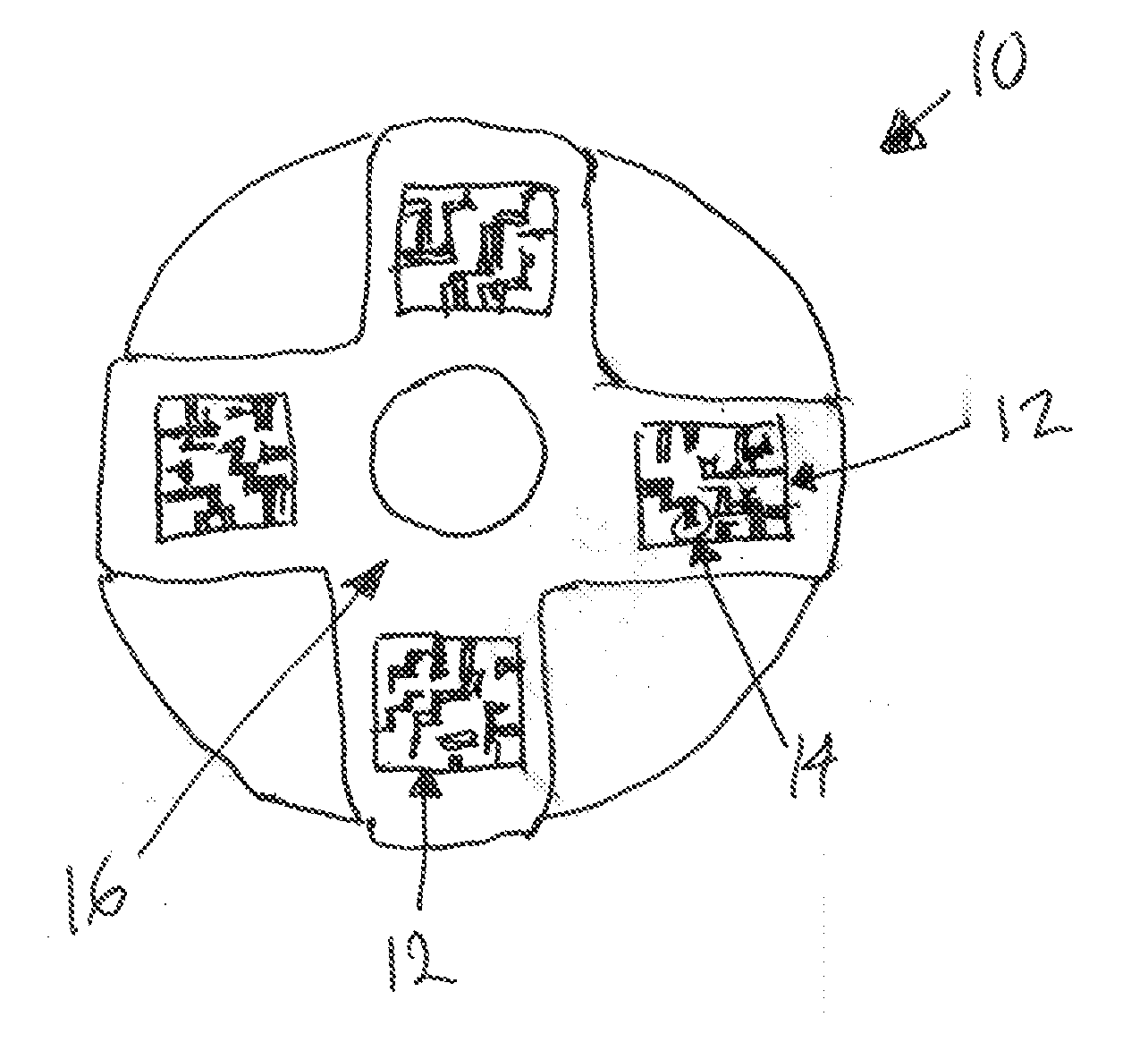

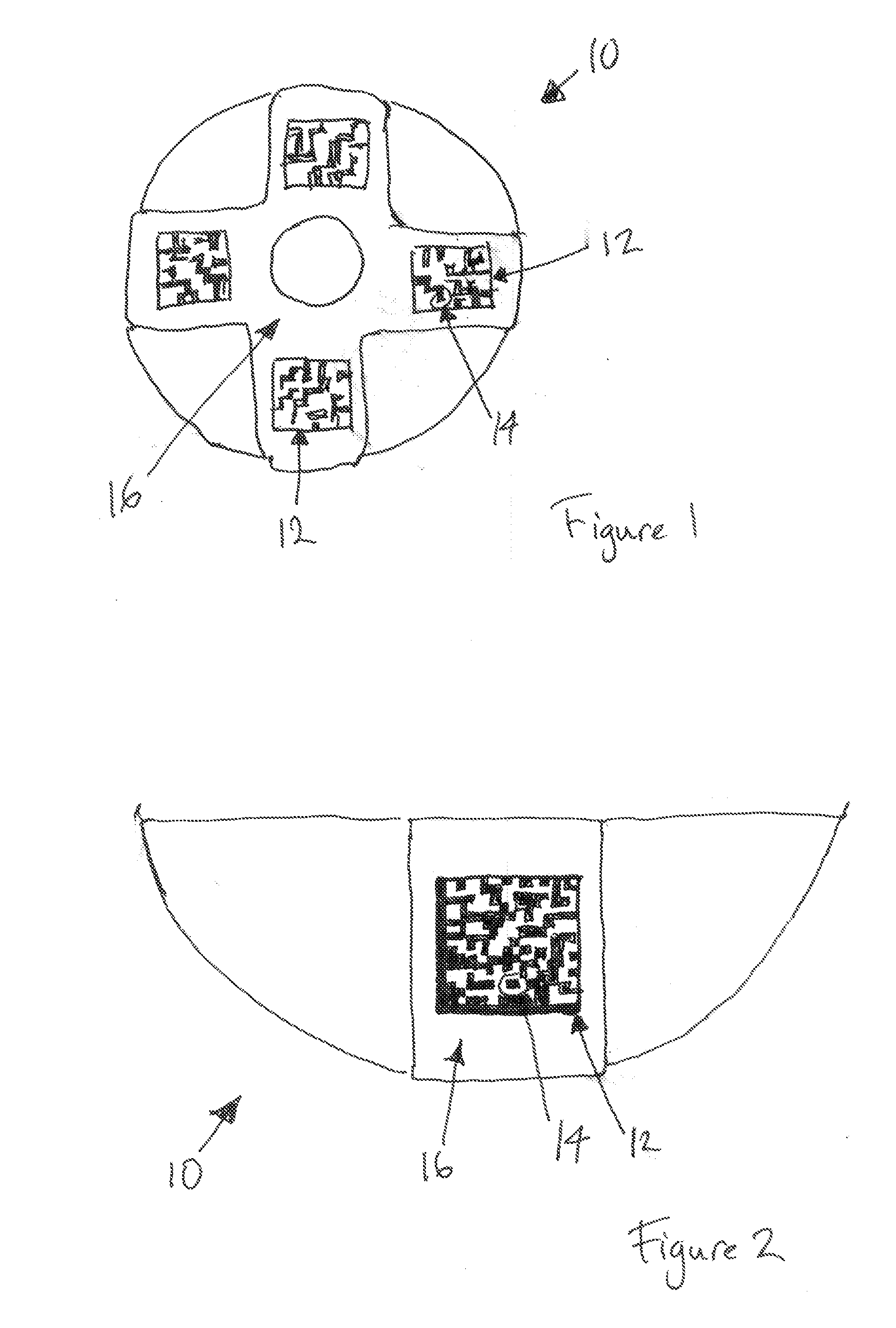

Micro matrix data marking

InactiveUS8552336B2Increased data marking capacityImprove clarityAblative recordingSensing record carriersComputer scienceCell size

The invention provides methods and systems for the application and reading of micro markings for coding of information for placement on the surfaces of individual very small devices. In preferred embodiments, a two dimensional micro matrix of markings or dots is realized on a scale of a 25 um cell size and smaller.

Owner:TRIUNE IP

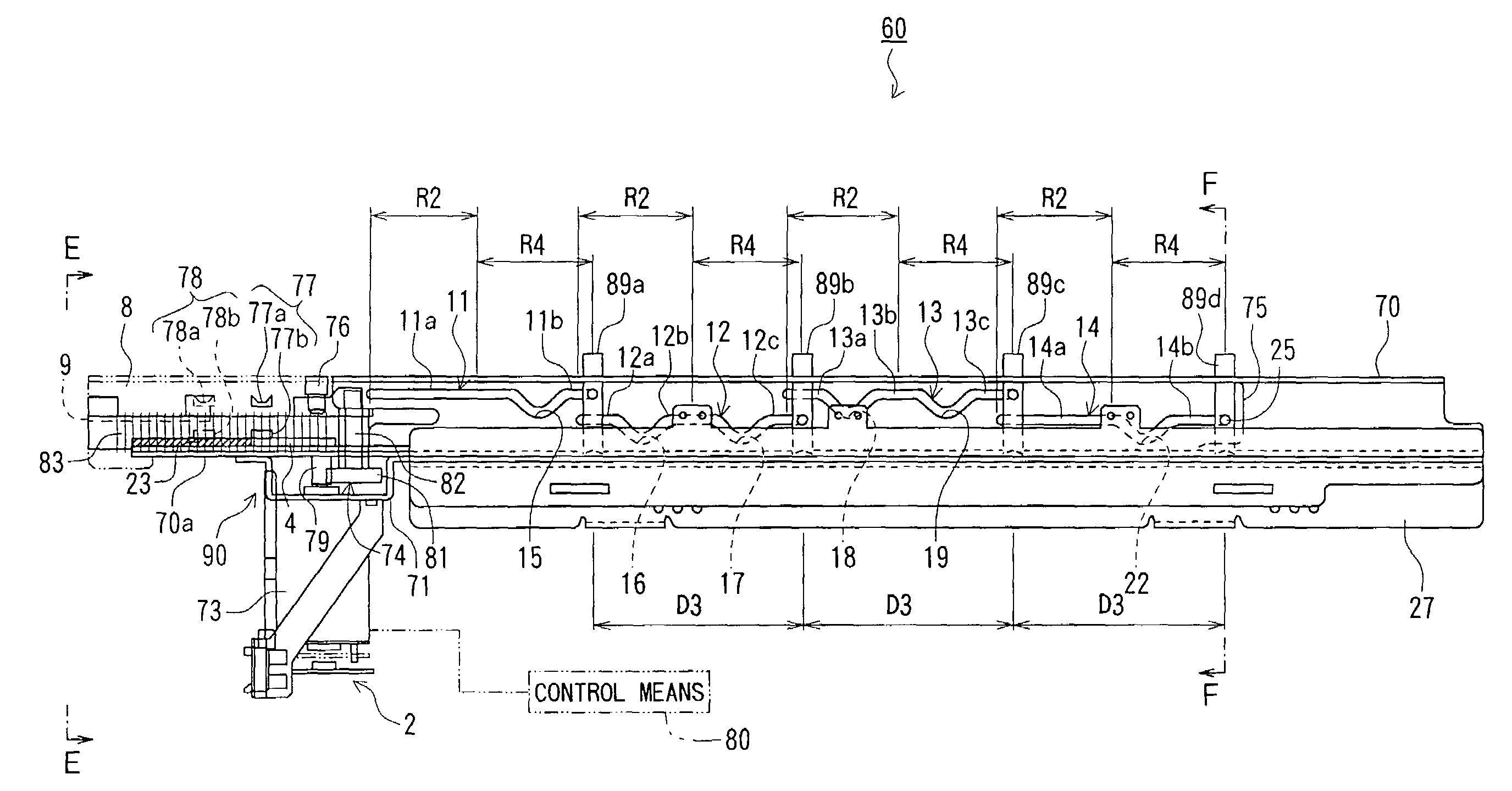

Punching device, sheet processor having the punching device, and image forming apparatus having the punching device

InactiveUS7073706B2Smoothly punching holeQuick changeElectrographic process apparatusMetal working apparatusPunchingCam

There is provided a punching device including: a die member having a plurality of die holes formed therein; a plurality of punch members which are caused to advance into the die holes to punch holes in a member to be punched; an operating member having cam portions formed along a direction intersecting the direction of advancement of the punch members, the operating member being moved along the direction intersecting the direction of advancement of the punch members to cause by a conversion function of the cam portions the punch members to advance into the die holes; and a drive unit for selectively causing advancement of the plurality of punch members by changing the direction of movement of the operating member. In the punching device, each of the cam portions has a straight groove and a cam groove for performing the conversion function, and when the operating member is moved in one of opposite directions, at least one of the cam grooves of the cam portions acts on one of the punch members to selectively cause the same to advance.

Owner:CANON KK

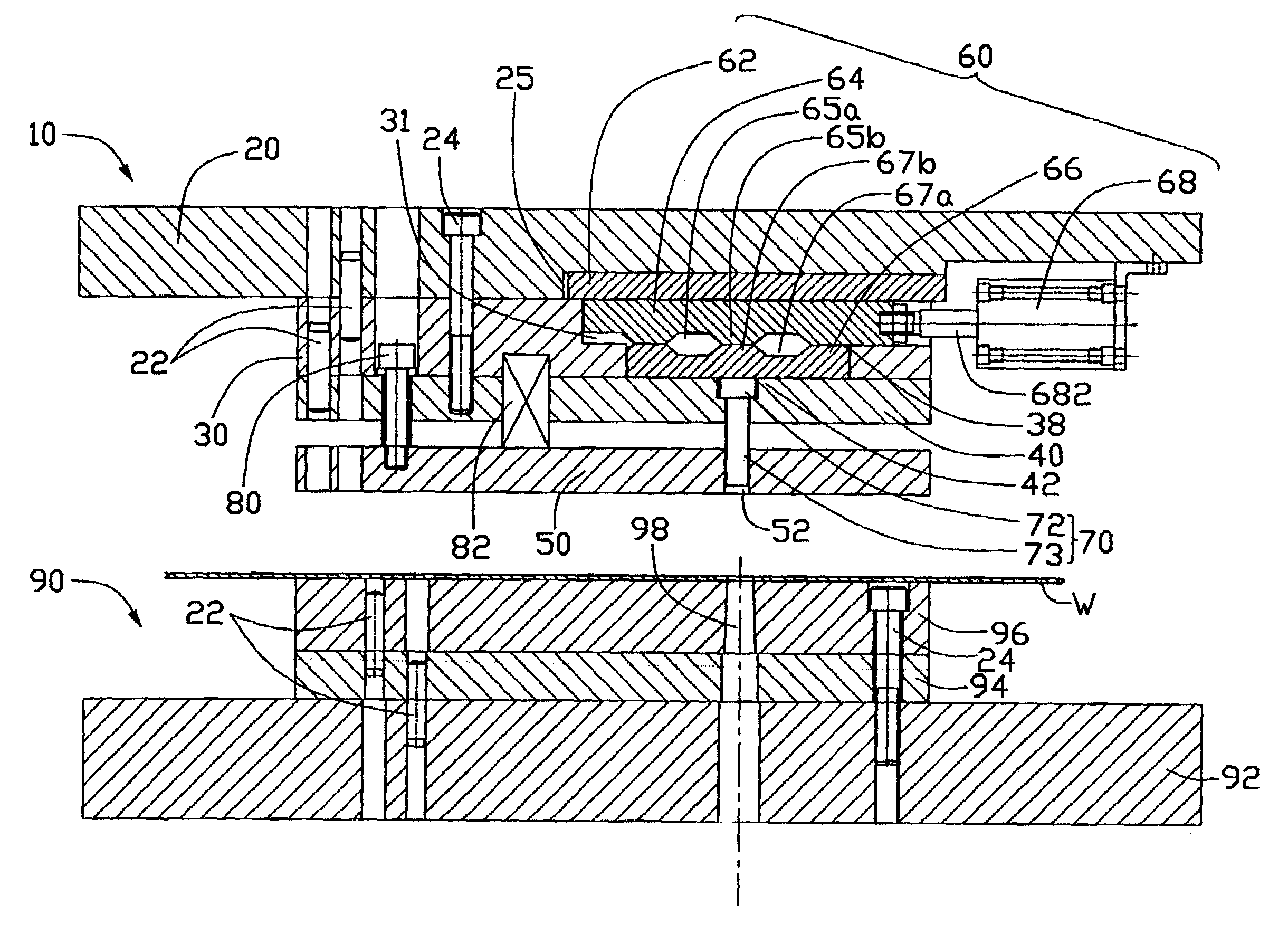

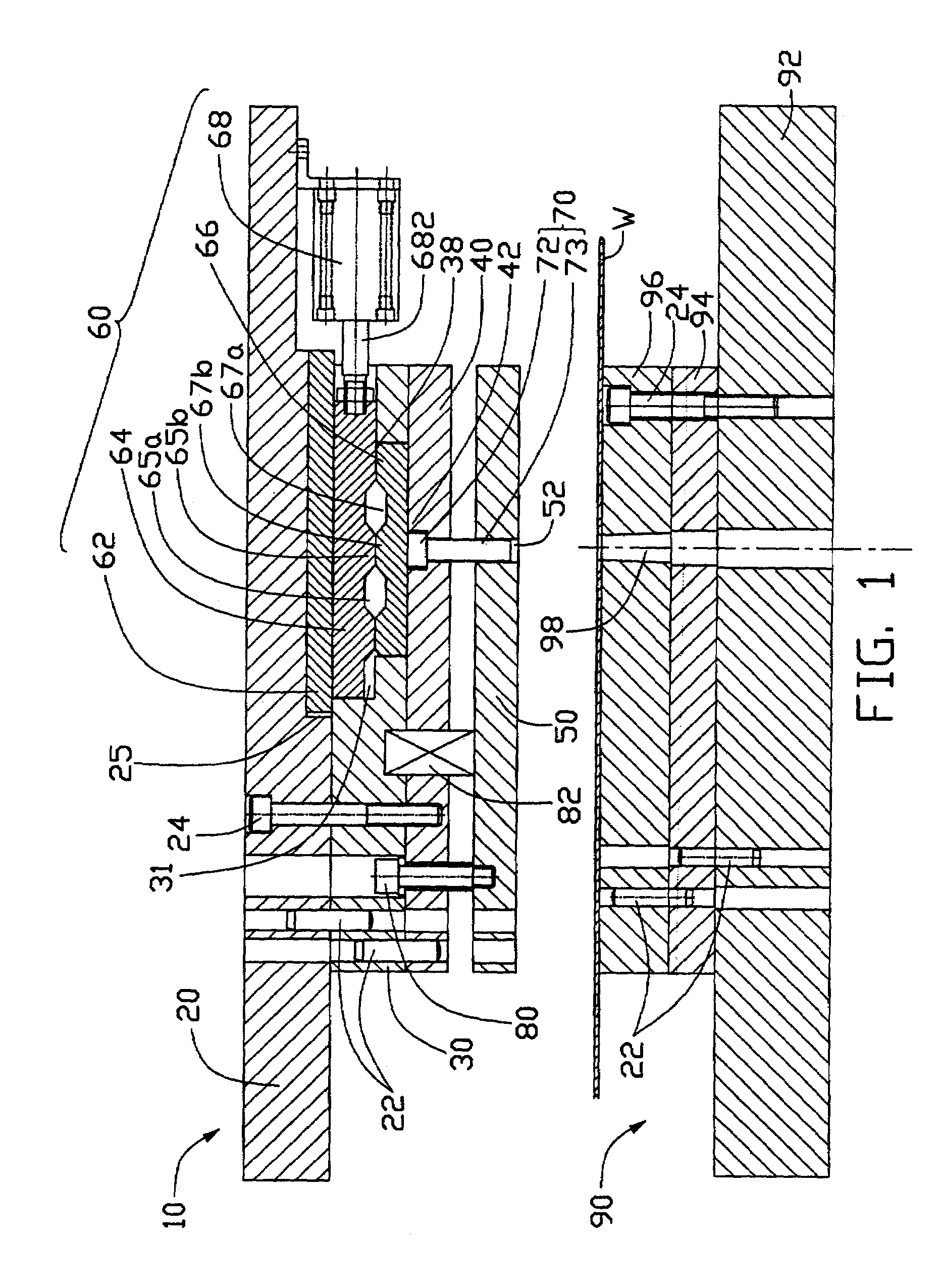

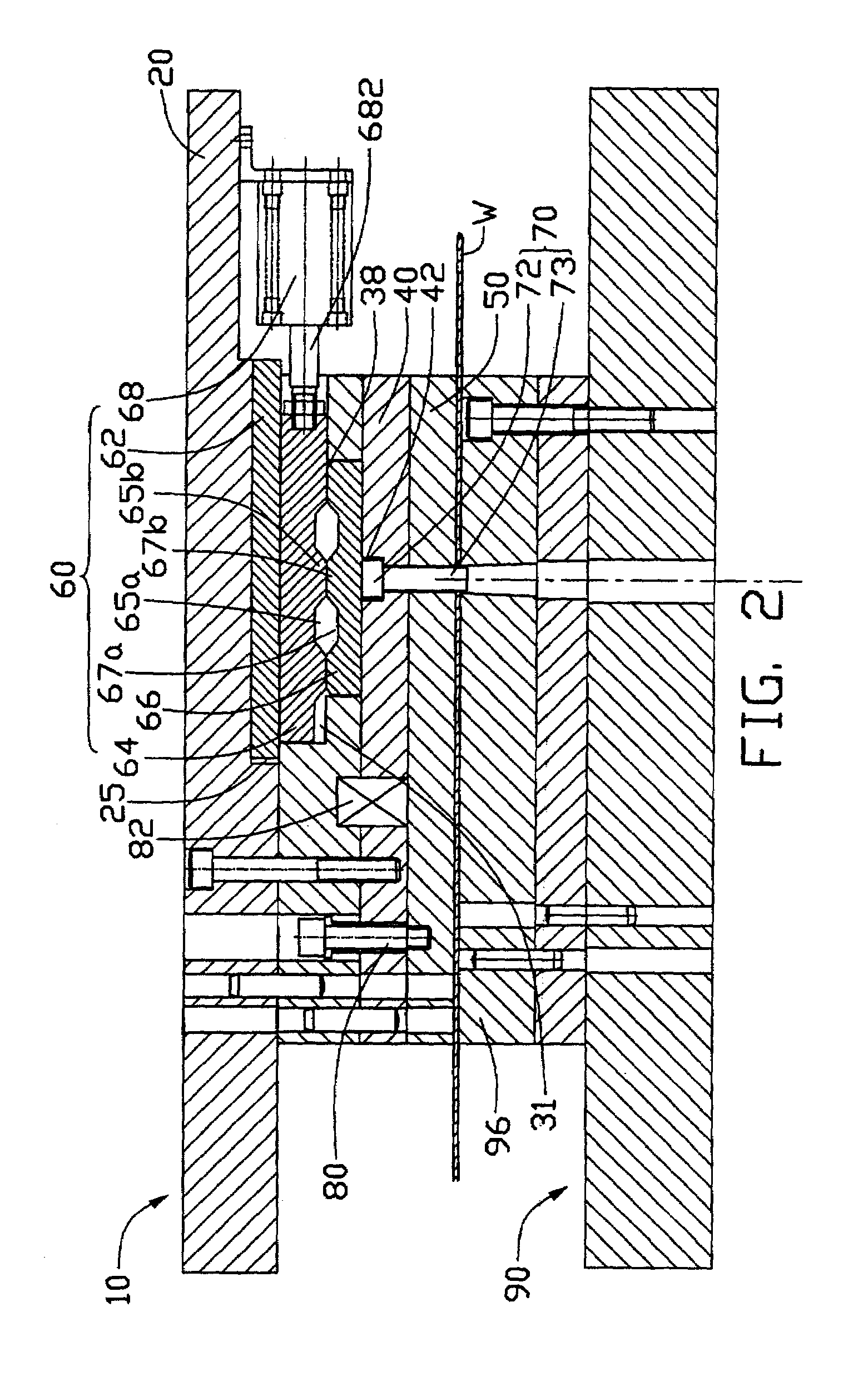

Sequential punch press with complementary sliding plates

InactiveUS7086582B2Readily and efficiently machineMetal working apparatusDigital marking by punchingPunch pressSlide plate

A sequential punch press includes an upper die (10), a lower die (90), and an adjusting device (60) in the upper die. The upper die sequentially includes a punch set (20), a punch pad (30), a punch holder (40), and a stripper (50). A punch (70) is vertically and movably secured in the punch holder and received in the stripper. The adjusting device includes first and second sliding plates (64, 66) respectively having protrusions (65b, 67b), a piston cylinder (68) having a piston rod (682) fixedly connected with the first sliding plate, and a programmable controller for causing the piston rod to slidingly move the first sliding plate. When the first protrusions opposingly abut the second protrusions, the punch can extend beyond the stripper to punch a workpiece. When the first protrusions do not opposingly abut the second protrusions, the punch cannot extend beyond the stripper to punch the workpiece.

Owner:HON HAI PRECISION IND CO LTD

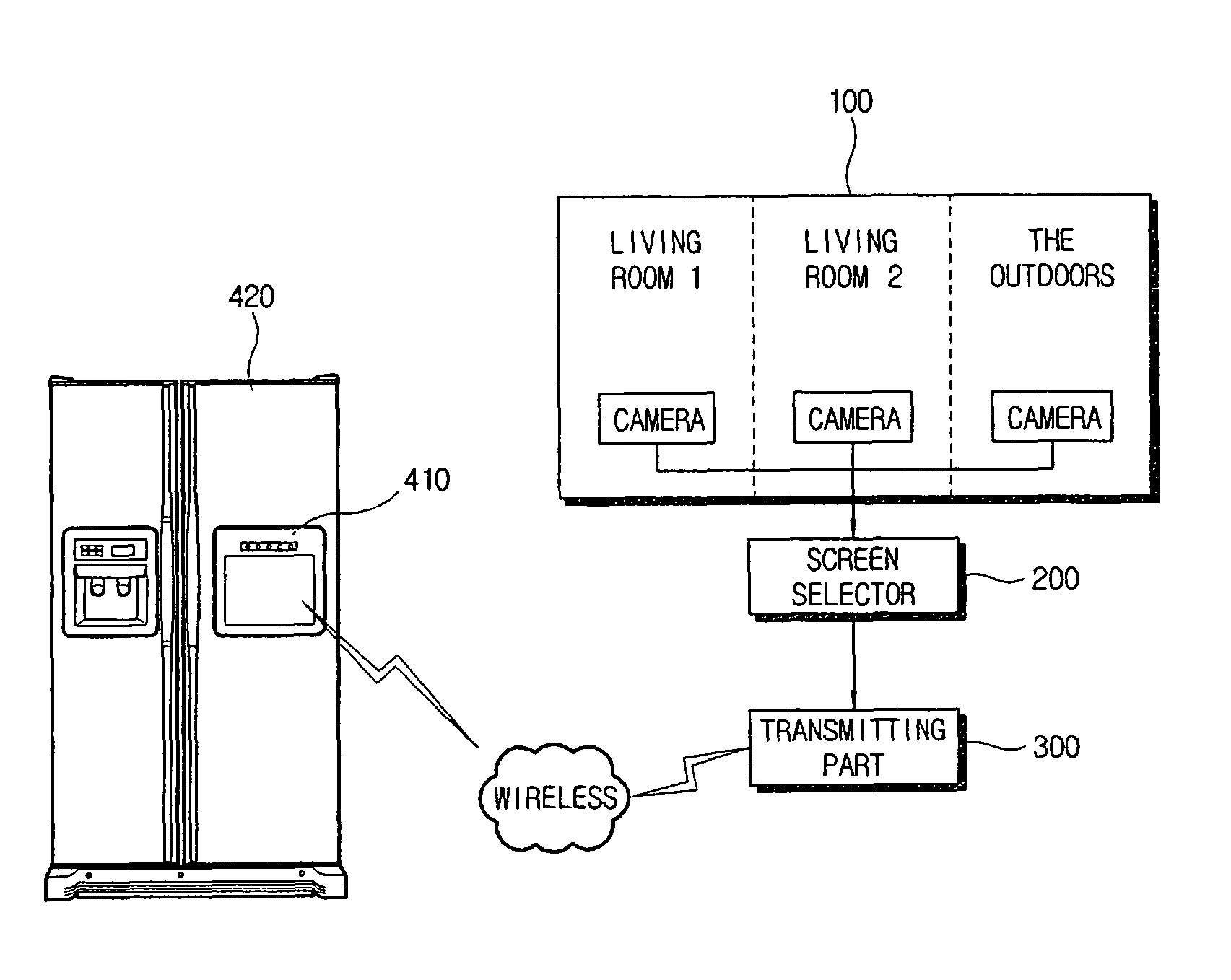

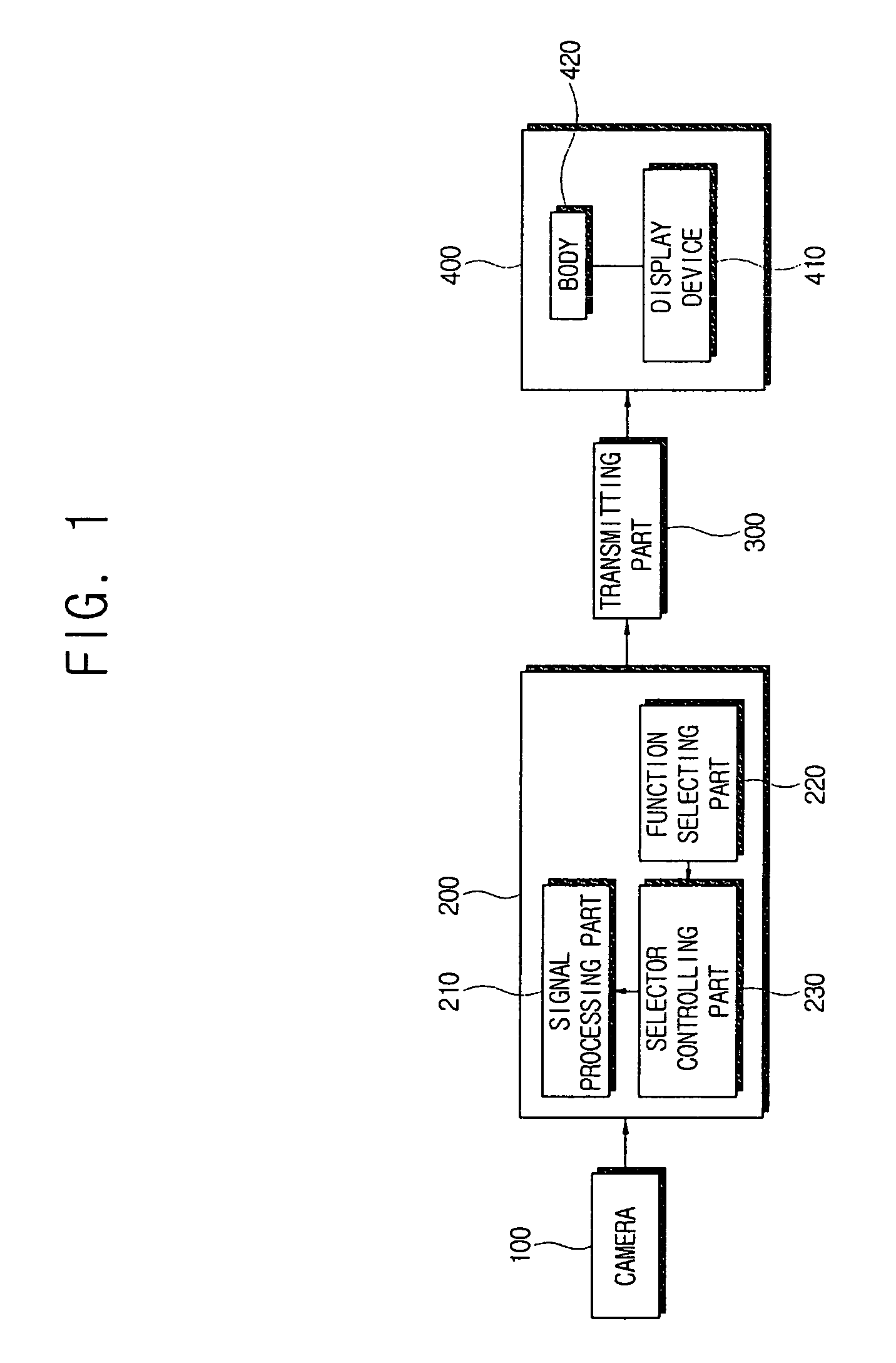

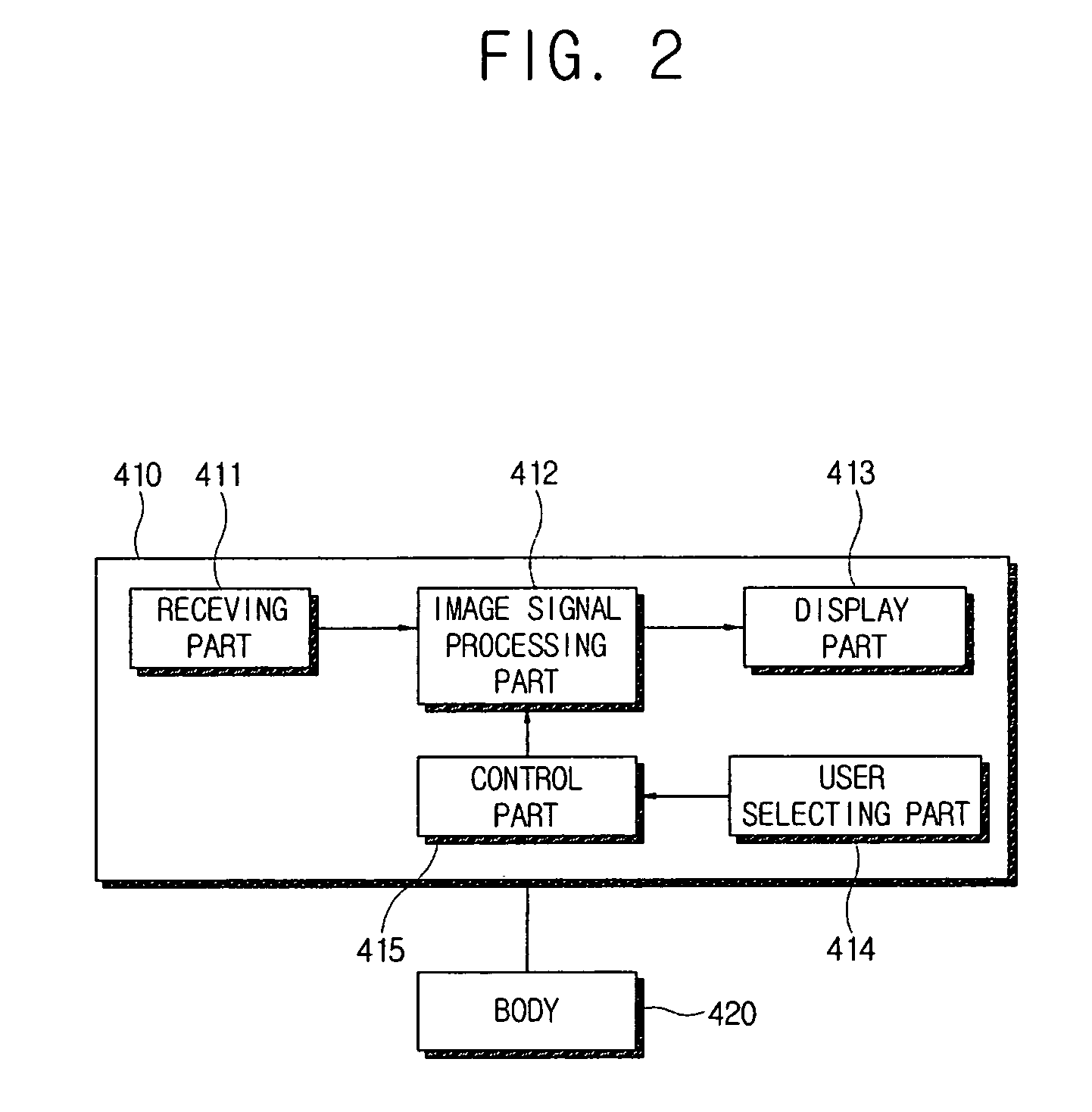

Refrigerator, monitoring system having refrigerator and control method thereof

A refrigerator for monitoring the status of another space by means of a display device mounted to the refrigerator, a monitoring system having the refrigerator and a control method thereof. The refrigerator includes a body which is formed with a storage chamber, a door for opening and closing the storage chamber, and a display device which is mounted to a front side of the door, the display device having a receiving part for receiving a monitoring image signal from a predetermined outside signal supply source, an image signal processing part for processing the received monitoring image signal, a display part for displaying the monitoring image signal and a control part for controlling the image signal processing part so that the received monitoring image signal is displayed on the display part.

Owner:SAMSUNG ELECTRONICS CO LTD

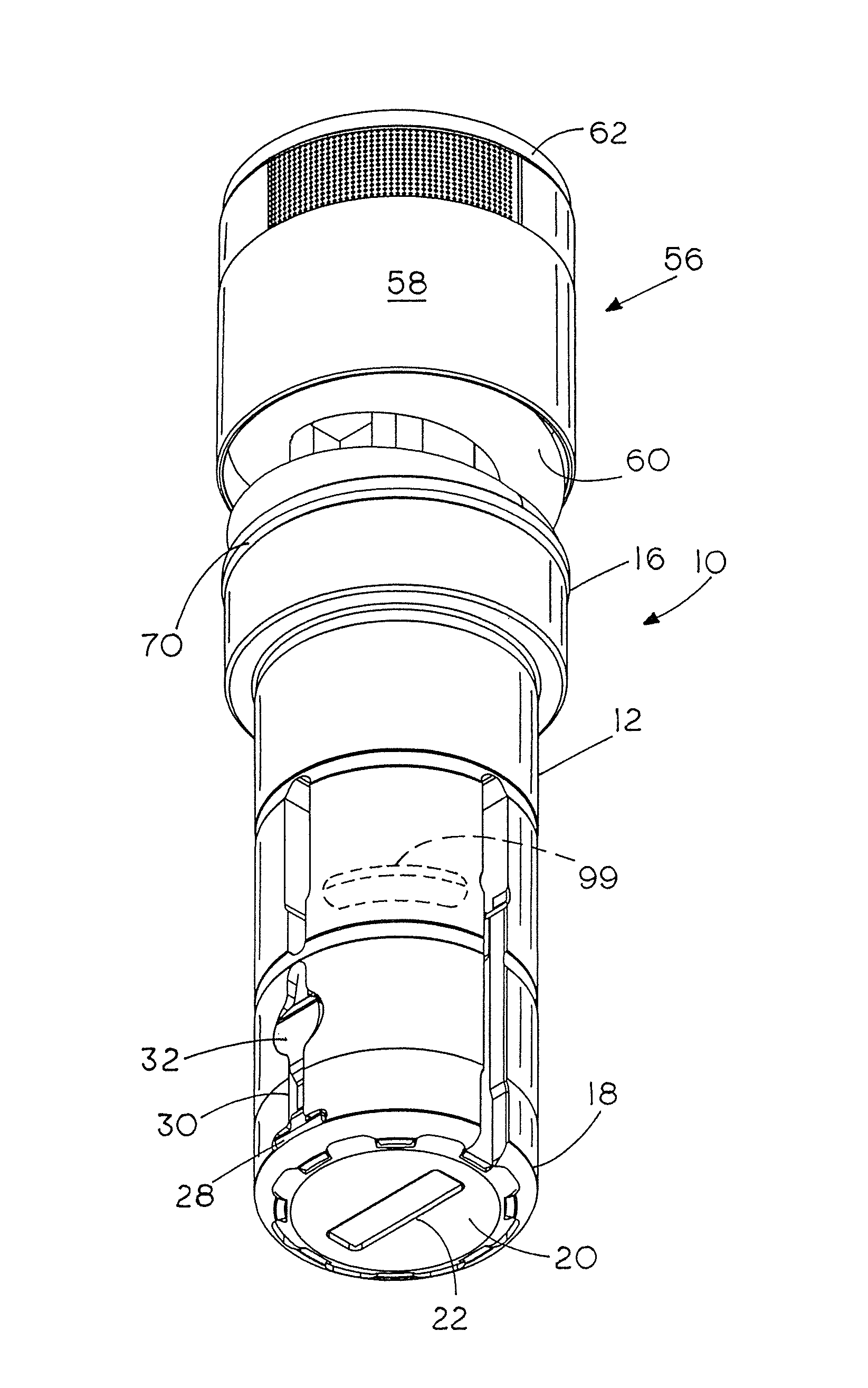

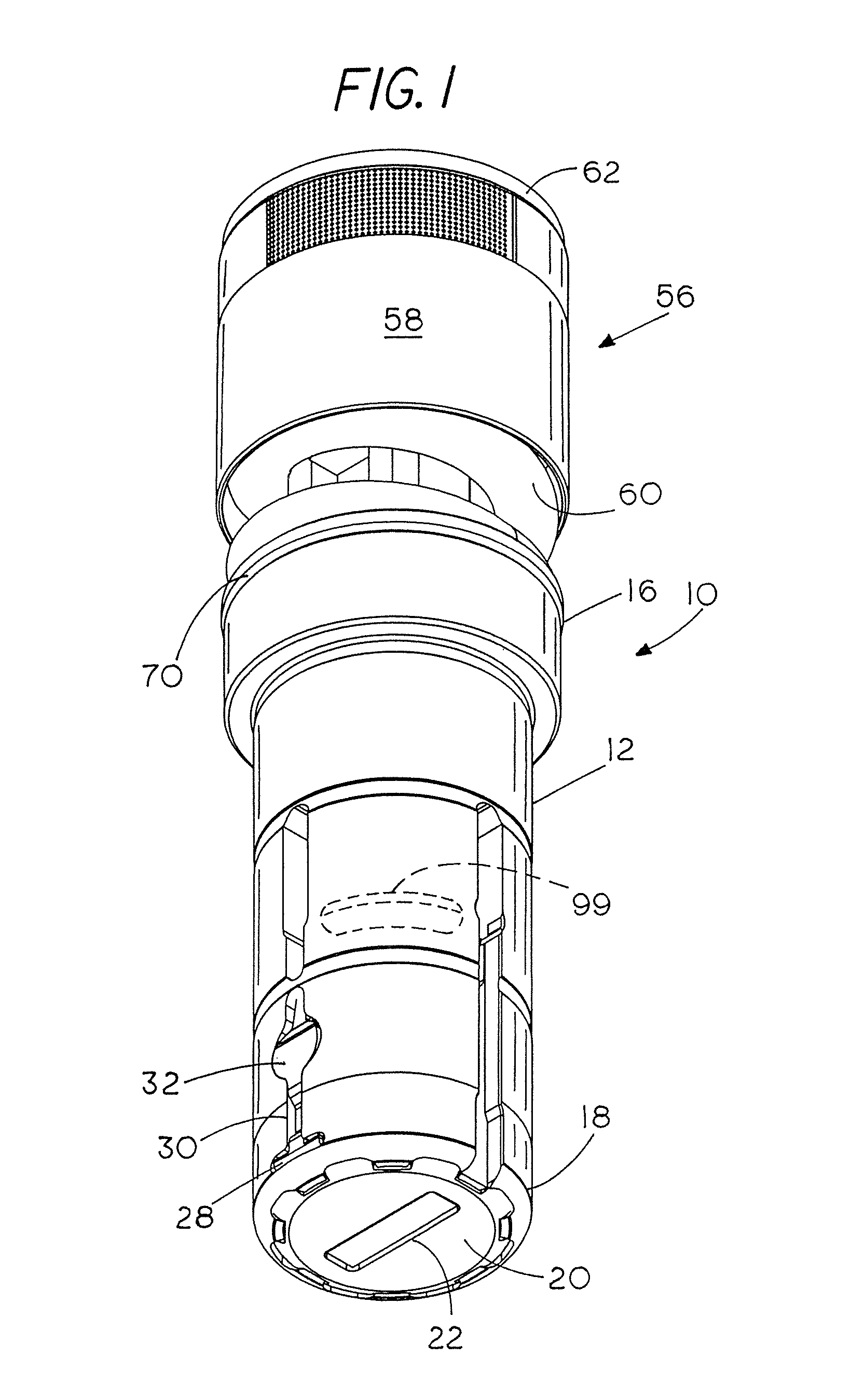

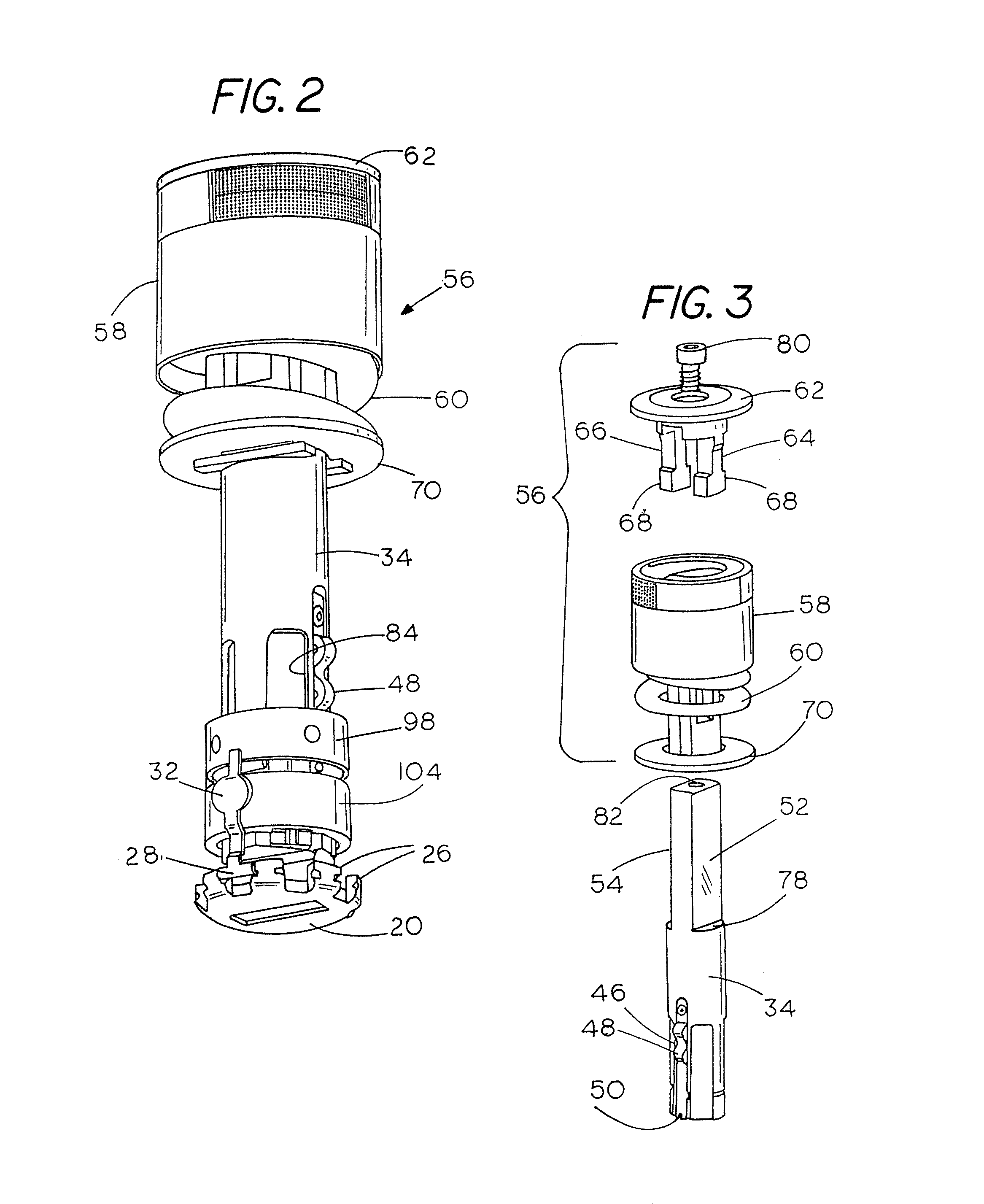

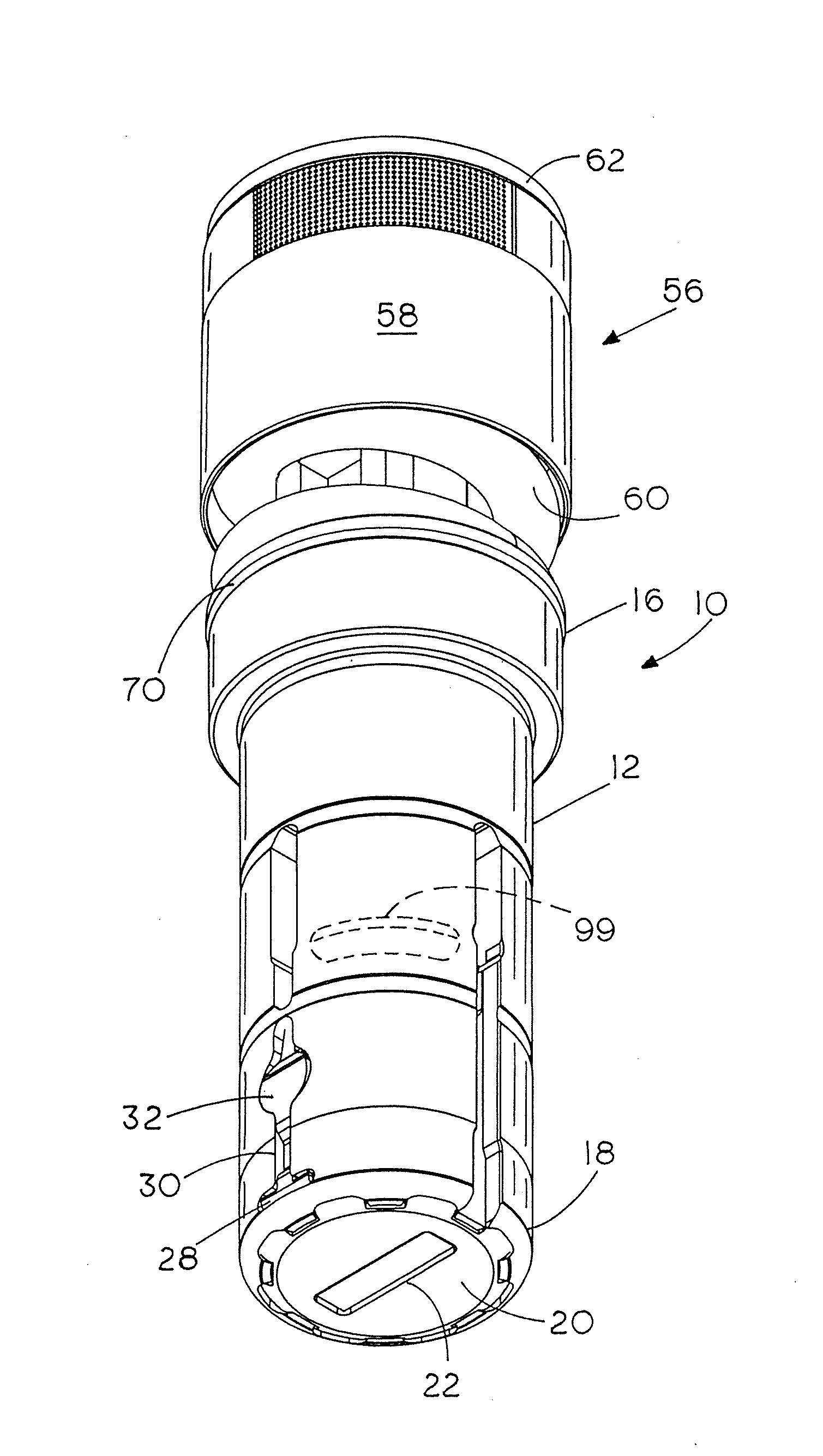

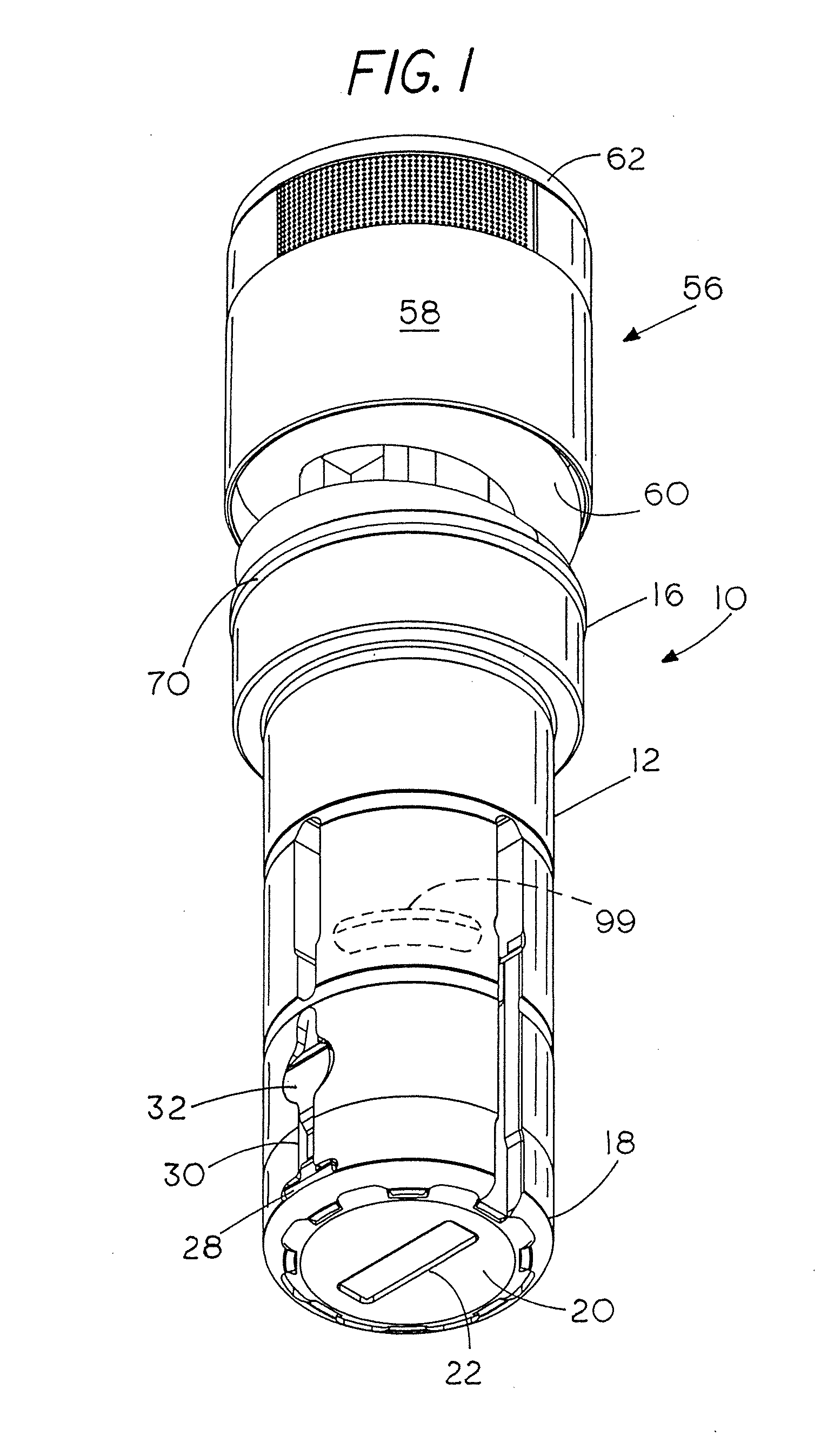

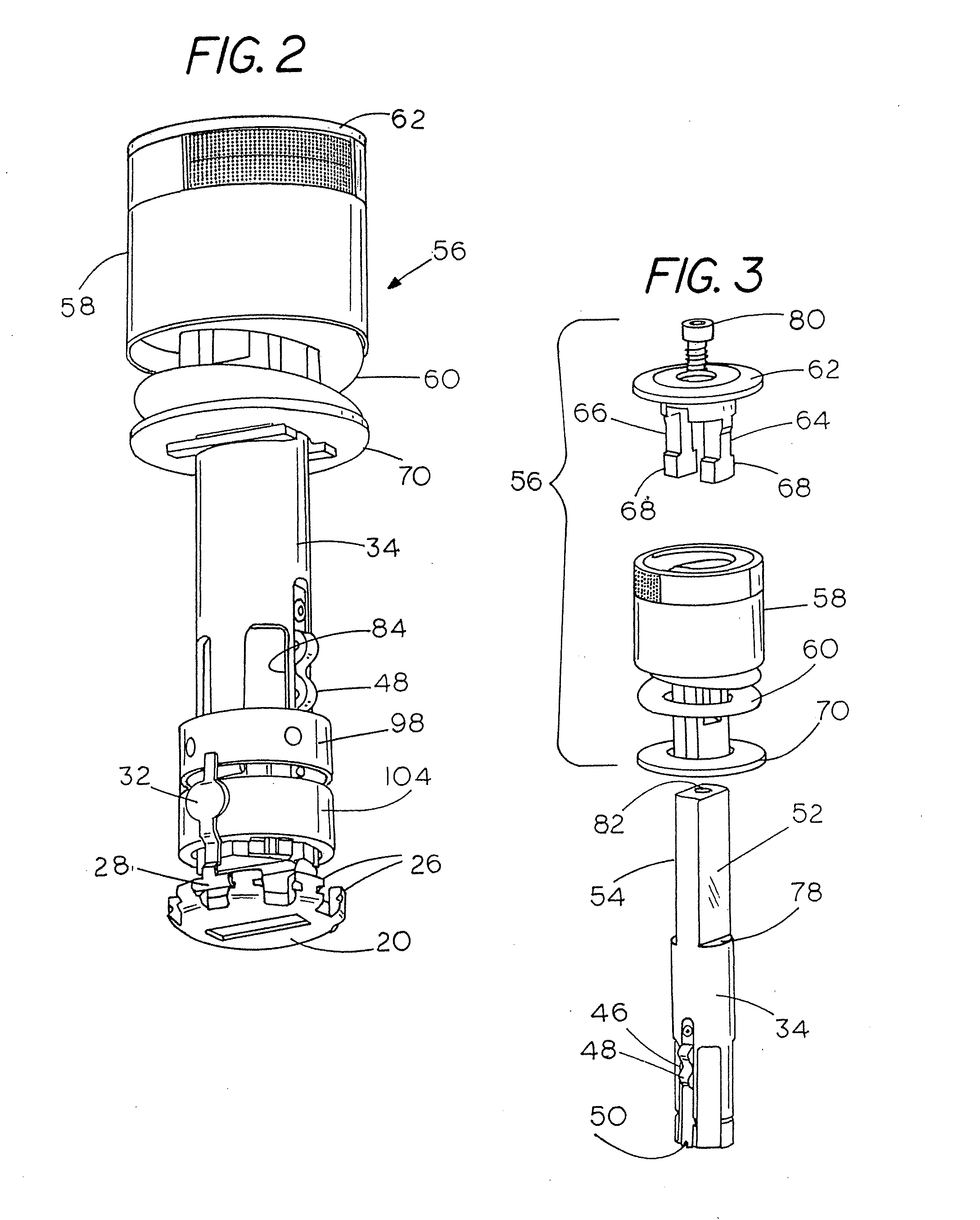

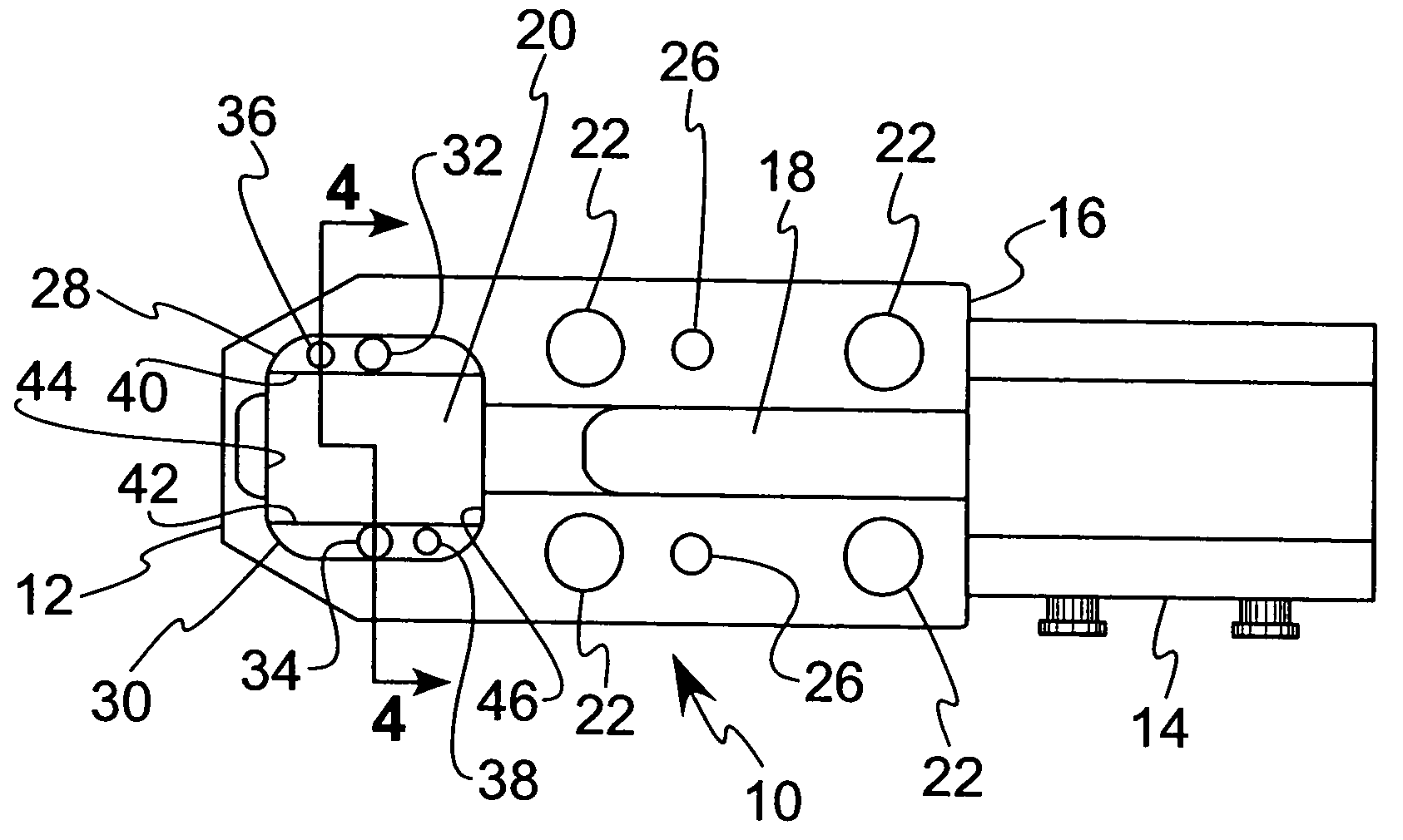

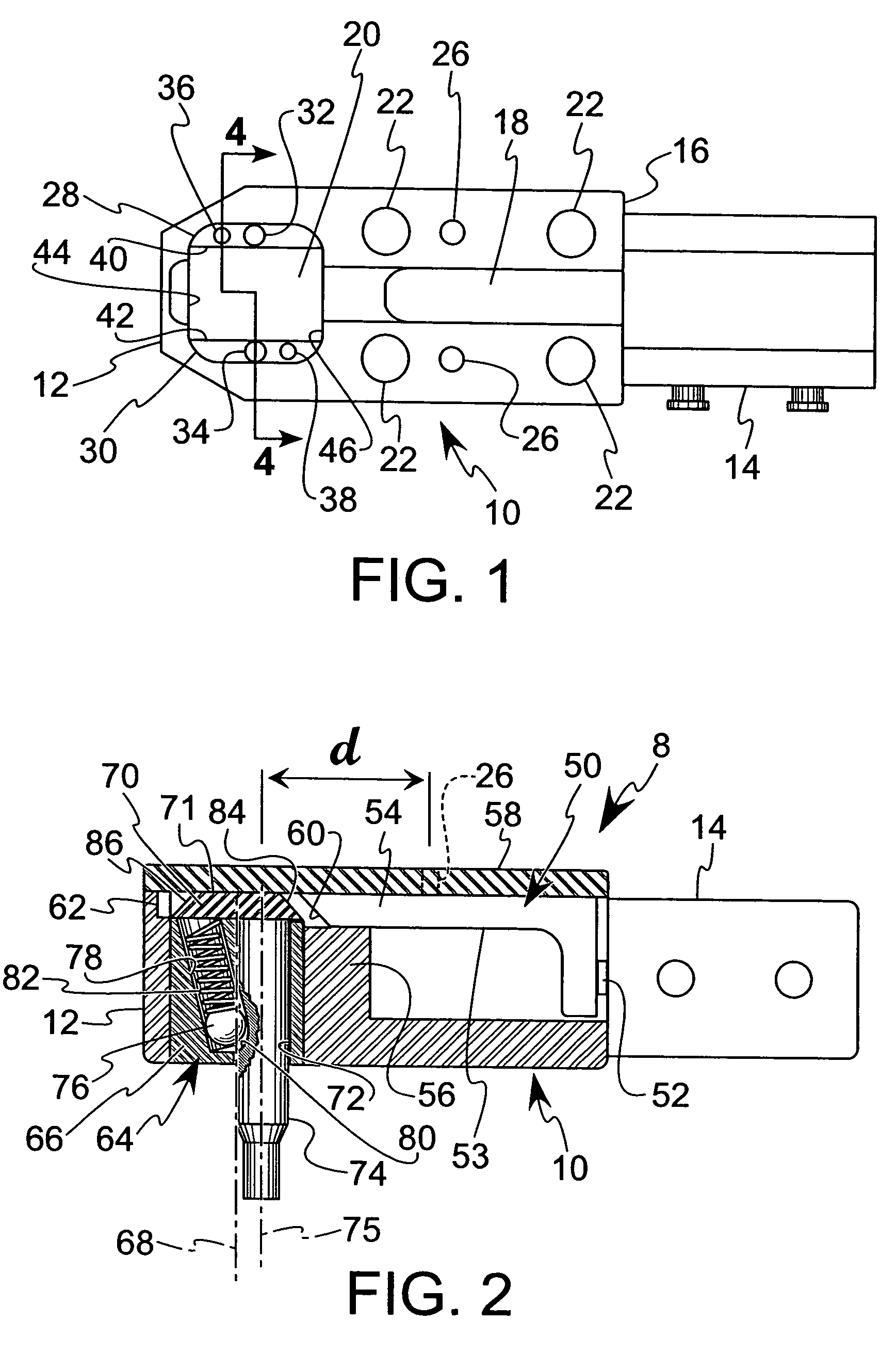

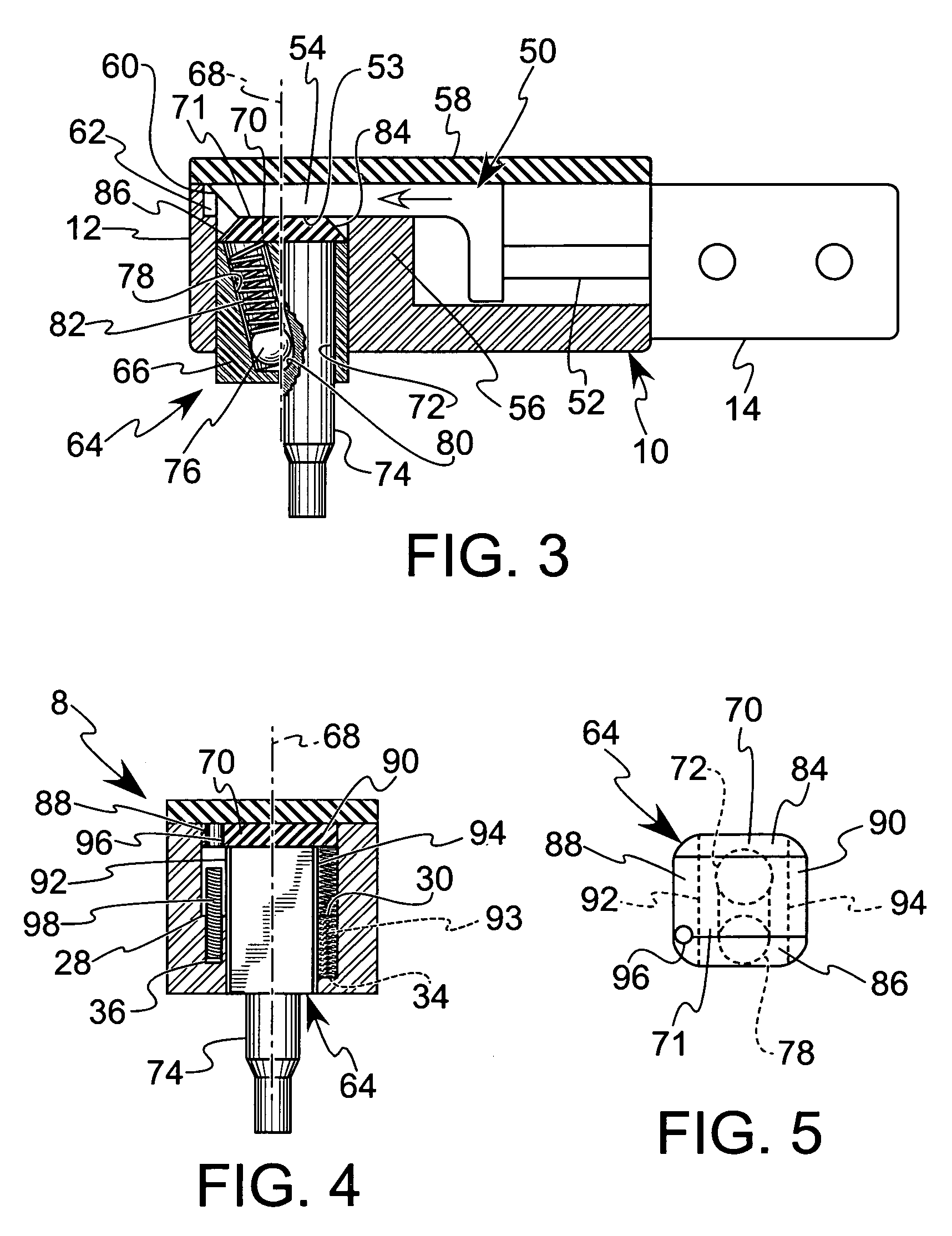

Punch assembly with quick attach punch point and stripper plate removably secure thereon

A punch assembly for a turret punch press having a two piece reciprocally movable punch member that has a punch point insert removably attached to a punch driver that allows replacement of the punch point insert without the need to extract the punch member from its punch guide. A locking assembly having four vertical guideways containing slider strips for coupling the punch point insert to the punch driver ensures precision registration of the punch point insert with its driver.

Owner:MATE PRECISION TOOLING

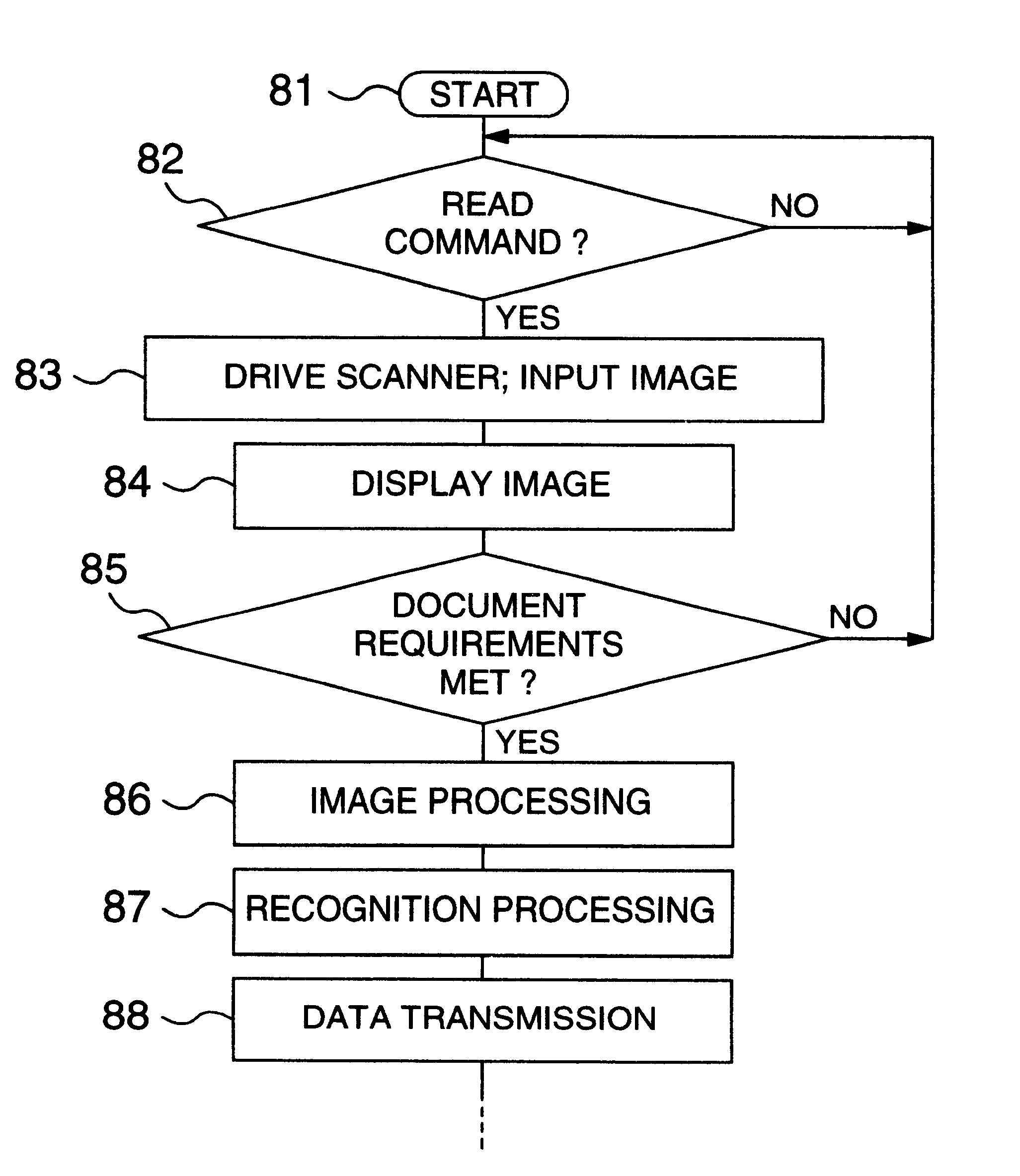

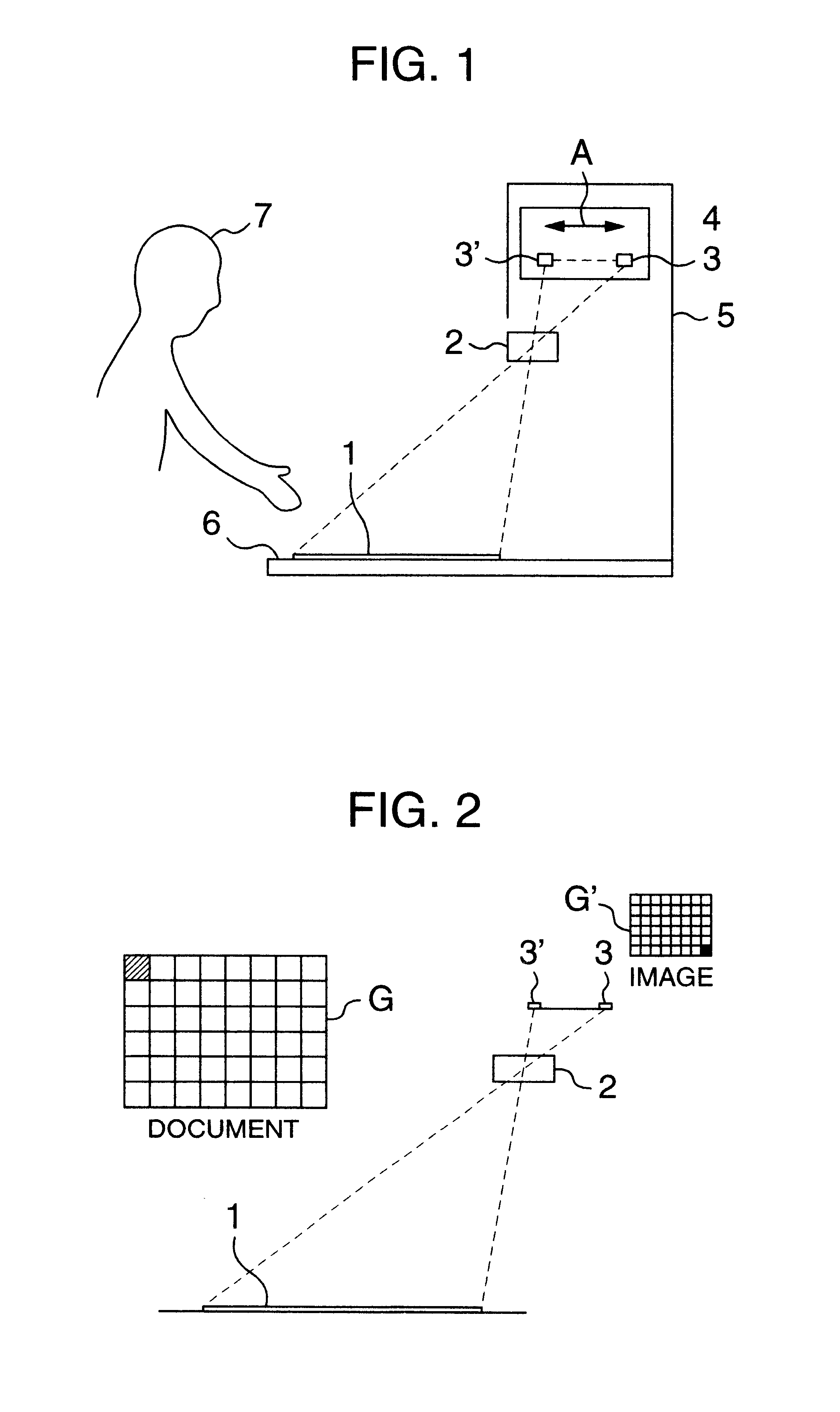

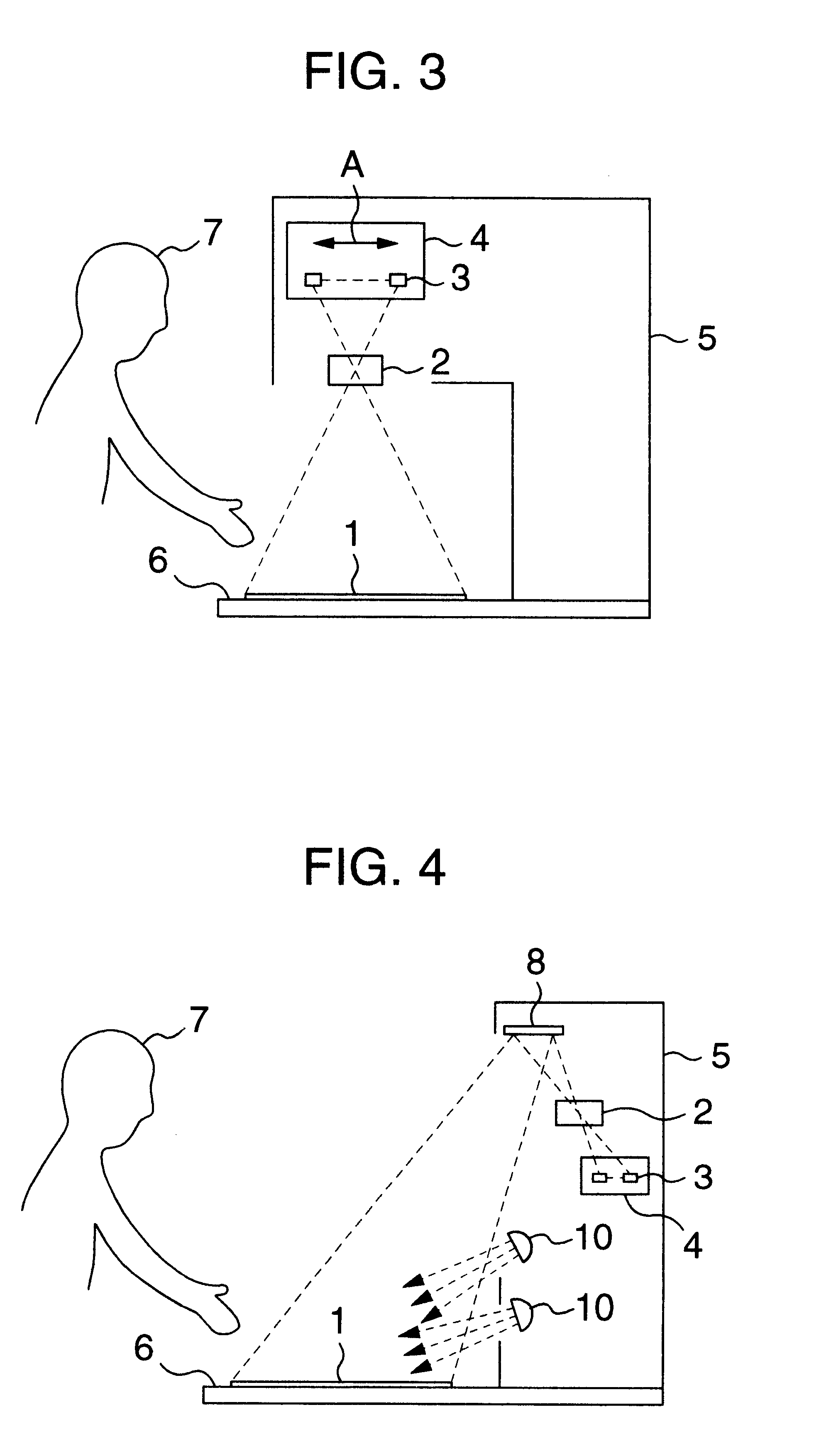

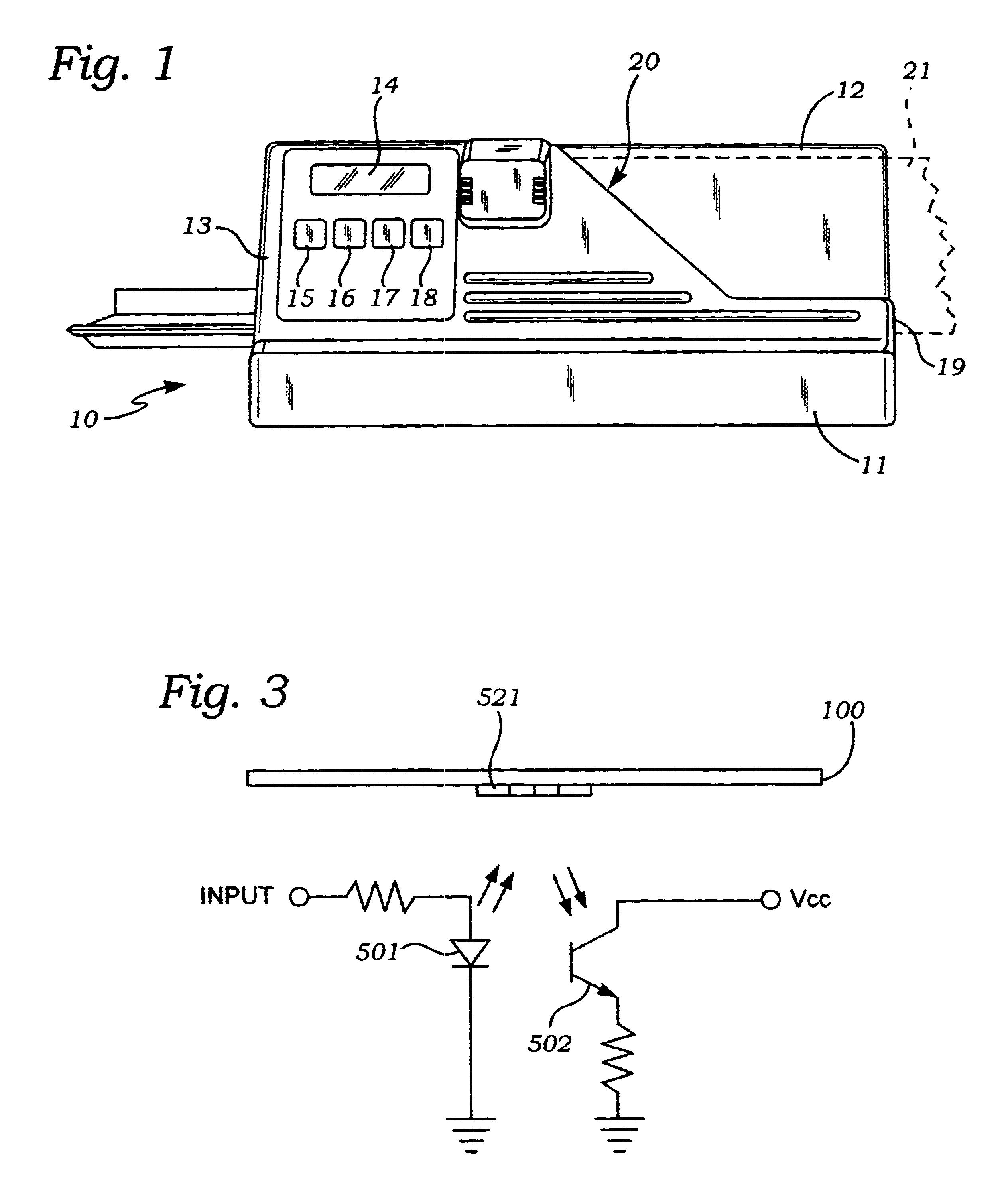

Document reading apparatus

InactiveUS6738166B1Easy to operateImprove securityGeometric image transformationImage data processing detailsComputer graphics (images)Image correction

In reading an image of the document, the CCD sensor reads the image of the document through the image reading lens. The reading head including the image reading lens and the CCD sensor is arranged deviated from the center of the document reading area so that the reading head is removed from above the document. The image of the document read in is corrected by the image correction device, and the corrected image is displayed on the display.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

Relative dynamic skew compensation of parallel data lines

InactiveUS20050229049A1Add supportDelay powerChannel dividing arrangementsError detection/correctionData signalSignal edge

A system performs a two-step skew compensation procedure by first correcting for any phase error alignment between a parallel link clock and data signal edges of each data channel, thereby allowing the received data bits to be correctly sampled. Then, a second step is performed to “word-align” the bits into the original format, which is accomplished with a Skew Synchronizing Marker (SSM) byte in a data FIFO of each data channel. The SSM byte is transmitted on each data channel and terminates the skew compensation procedure. When the SSM byte is detected by logic in the data FIFO of each data channel, the data FIFO employs the SSM byte to initialize the read and write pointers to properly align the output data.

Owner:SYNOPSYS INC

Micro Matrix Data Marking

InactiveUS20100155380A1Improve clarityReduced micro matrix marking sizeAblative recordingSensing record carriersComputer scienceCell size

The invention provides methods and systems for the application and reading of micro markings for coding of information for placement on the surfaces of individual very small devices. In preferred embodiments, a two dimensional micro matrix of markings or dots is realized on a scale of a 25 um cell size and smaller.

Owner:TRIUNE IP

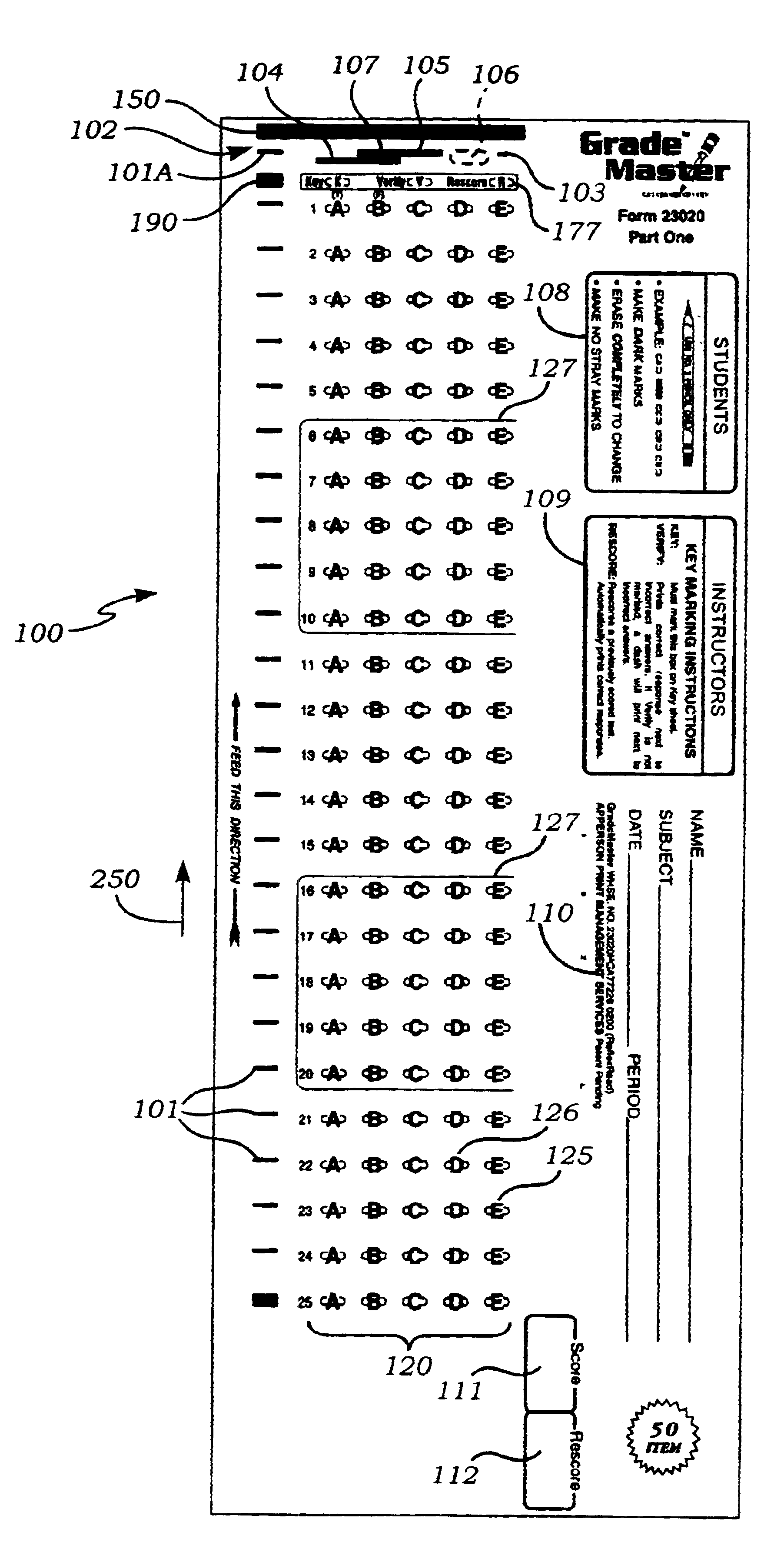

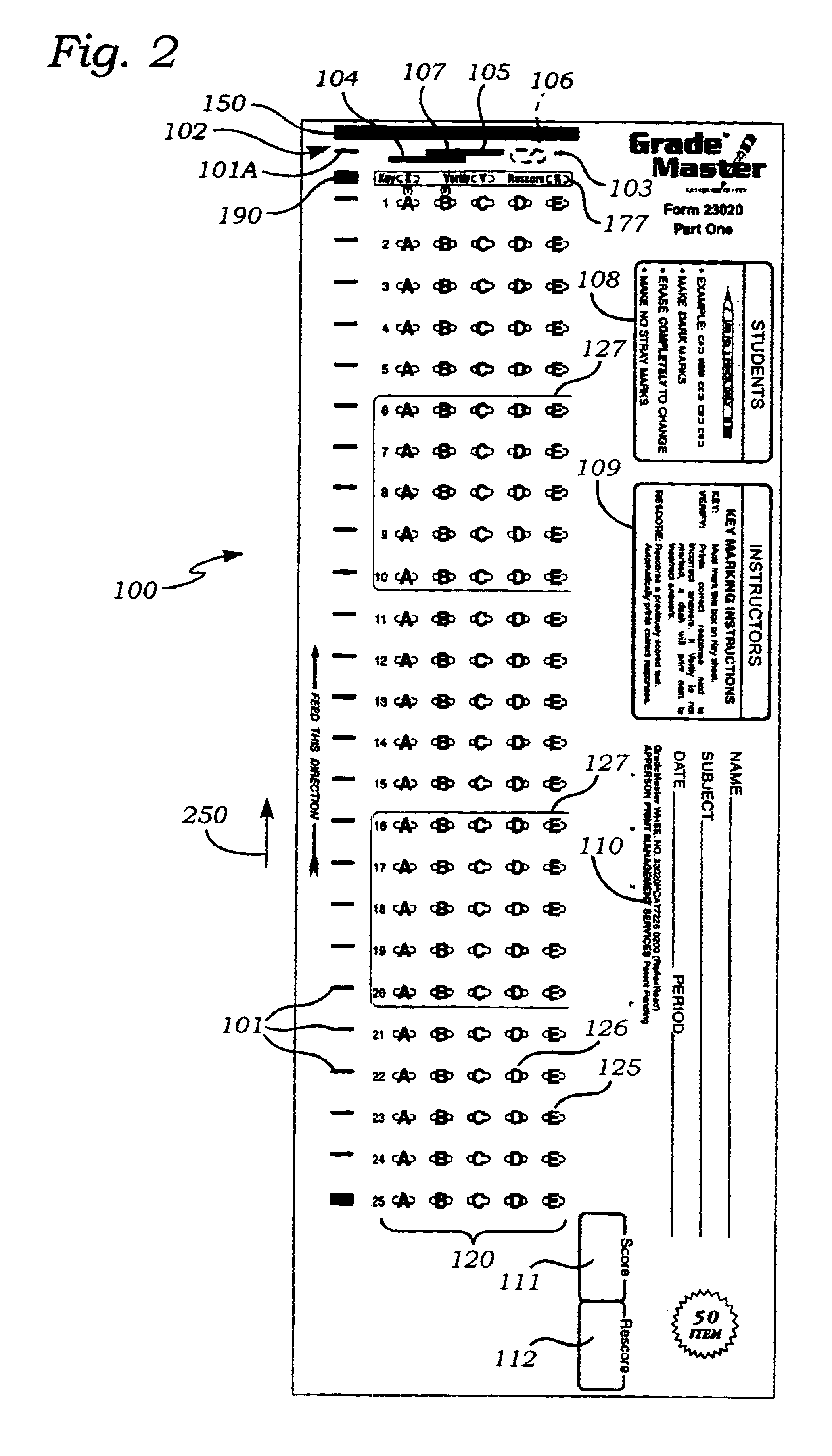

Data processing form for use with a scanning apparatus

InactiveUS6695216B2Improve versatilityConveying record carriersRecord carriers used with machinesGraphicsLeading edge

This invention is directed to a unique type of form to be used with an optical mark sensing device known as a mark read scanner for reading marks on the form. Form characteristics are defined by "graphic switches" printed near the lead edge of the form. Each "graphic switch" has four distinct settings. The expense of completely replacing the internal program of a scanner when a user requests a variation of a test form that had not been pre-programmed into the original specification of the scanner is eliminated.

Owner:APPERSON WILLIAM

Punch assembly with quick attach punch point and stripper plate removably secure thereon

A punch assembly for a turret punch press having a two piece reciprocally movable punch member that has a punch point insert removably attached to a punch driver that allows replacement of the punch point insert without the need to extract the punch member from its punch guide. A locking assembly comprising four vertical guideways containing slider strips for coupling the punch point insert to the punch driver ensures precision registration of the punch point insert with its driver.

Owner:MATE PRECISION TOOLING

Reversible floating punch retainer for punch change retainer tool

InactiveUS7204181B2Help positioningPerforating toolsMetal working apparatusEngineeringMechanical engineering

A punch change retainer for positioning a floating punch in a retracted, disengage position and an extended, engage position. The change retainer includes a change retainer body and a punch retainer receiving aperture extending upwardly through the change retainer body from a bottom surface thereof. A gagging member is located in the change retainer body and is actuable by an actuator between a retracted position distal from a nose portion of the change retainer body and an extended position adjacent the nose portion of the change retainer body. A floating punch retainer is receivable within the punch retainer receiving aperture, and includes an upper end positioned for engagement with the gagging member. A punch receiving hole is defined in the floating punch retainer; where the punch receiving hole is adapted to be rotatably positioned about a longitudinal center line of the floating punch retainer within the punch retainer receiving aperture.

Owner:DAYTON PROGRESS

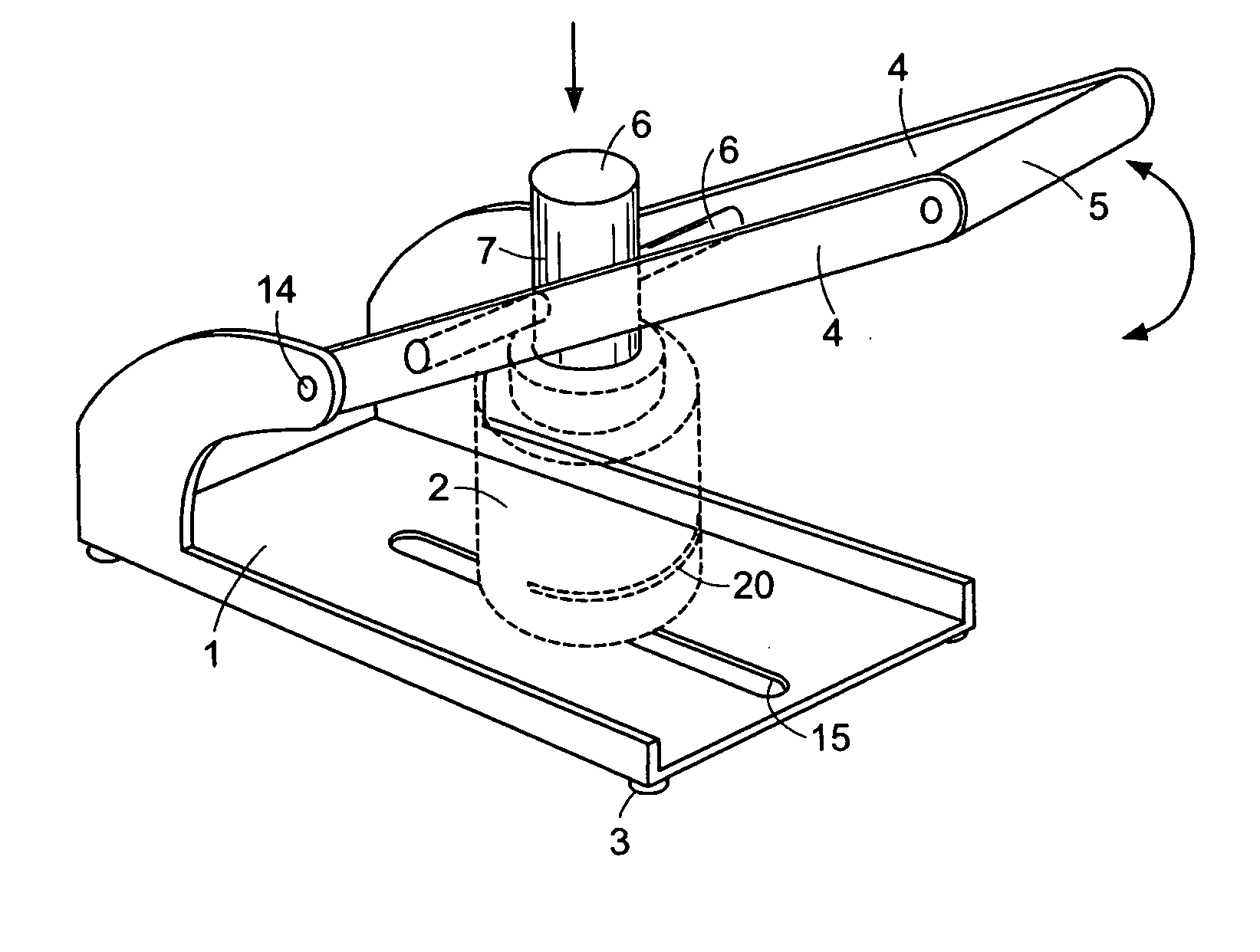

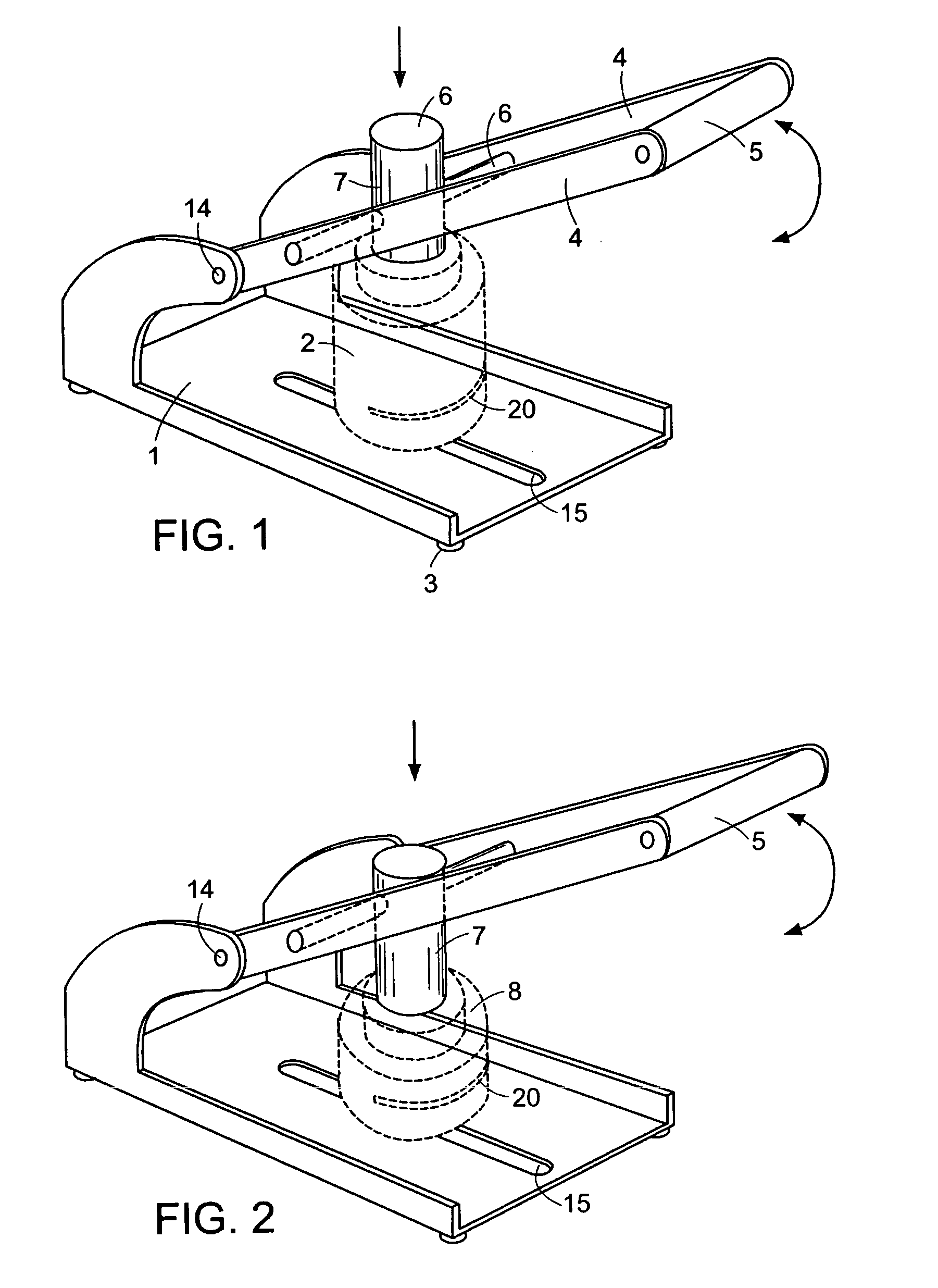

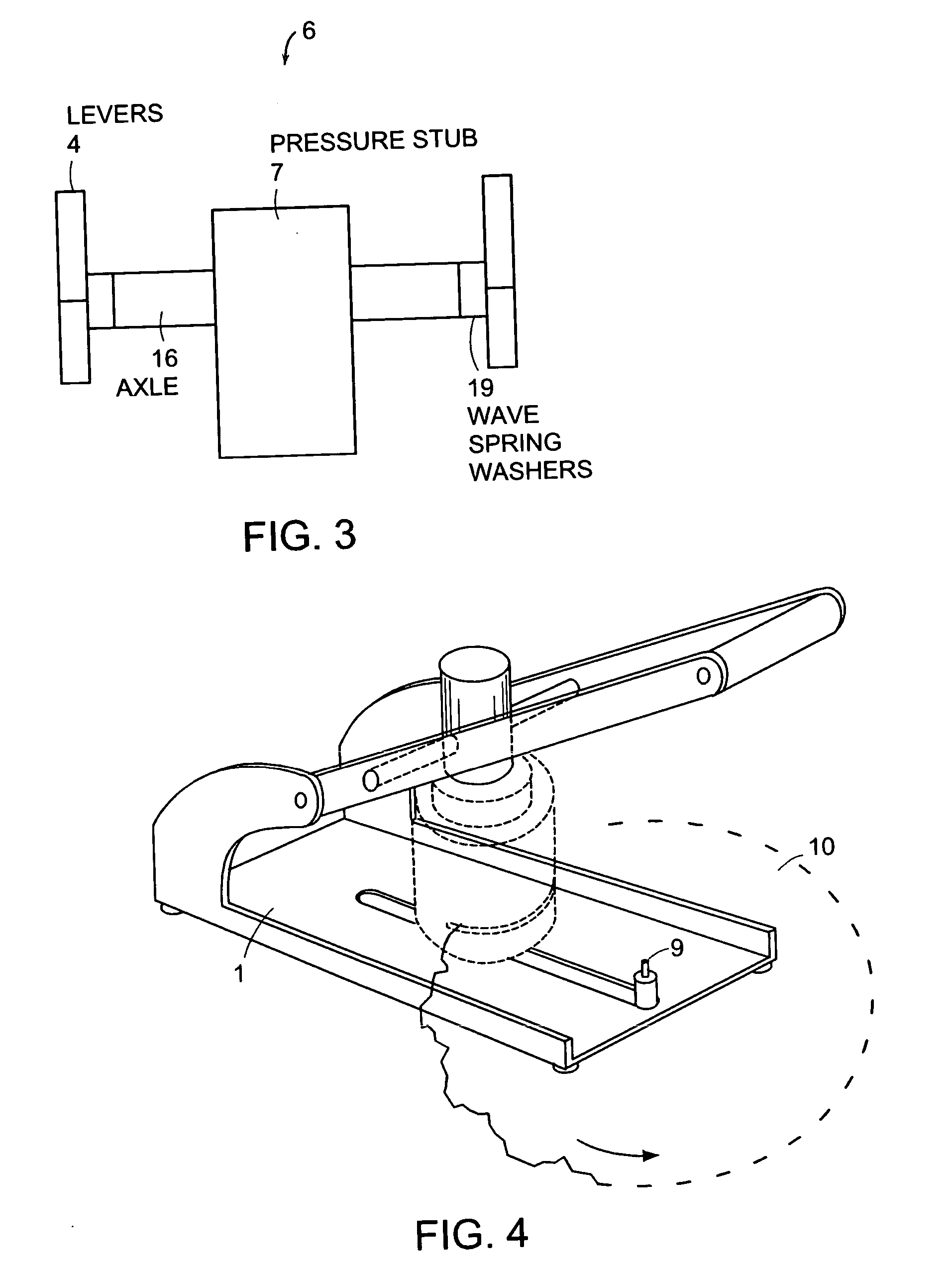

Craft punch aid

A craft punch aid includes a base portion and a lever portion pivotally attached to the base portion. A rotatable pressure head assembly is attached to the lever portion, the pressure head assembly includes a pressure stub for accommodating punches of differing heights. The base portion may include a pivot device for producing designs of differing radii on a work-piece, and the craft punch aid may include a straight guide for attachment to the base portion for enabling straight-line punching of a work-piece.

Owner:CRAFTY INVENTIONS

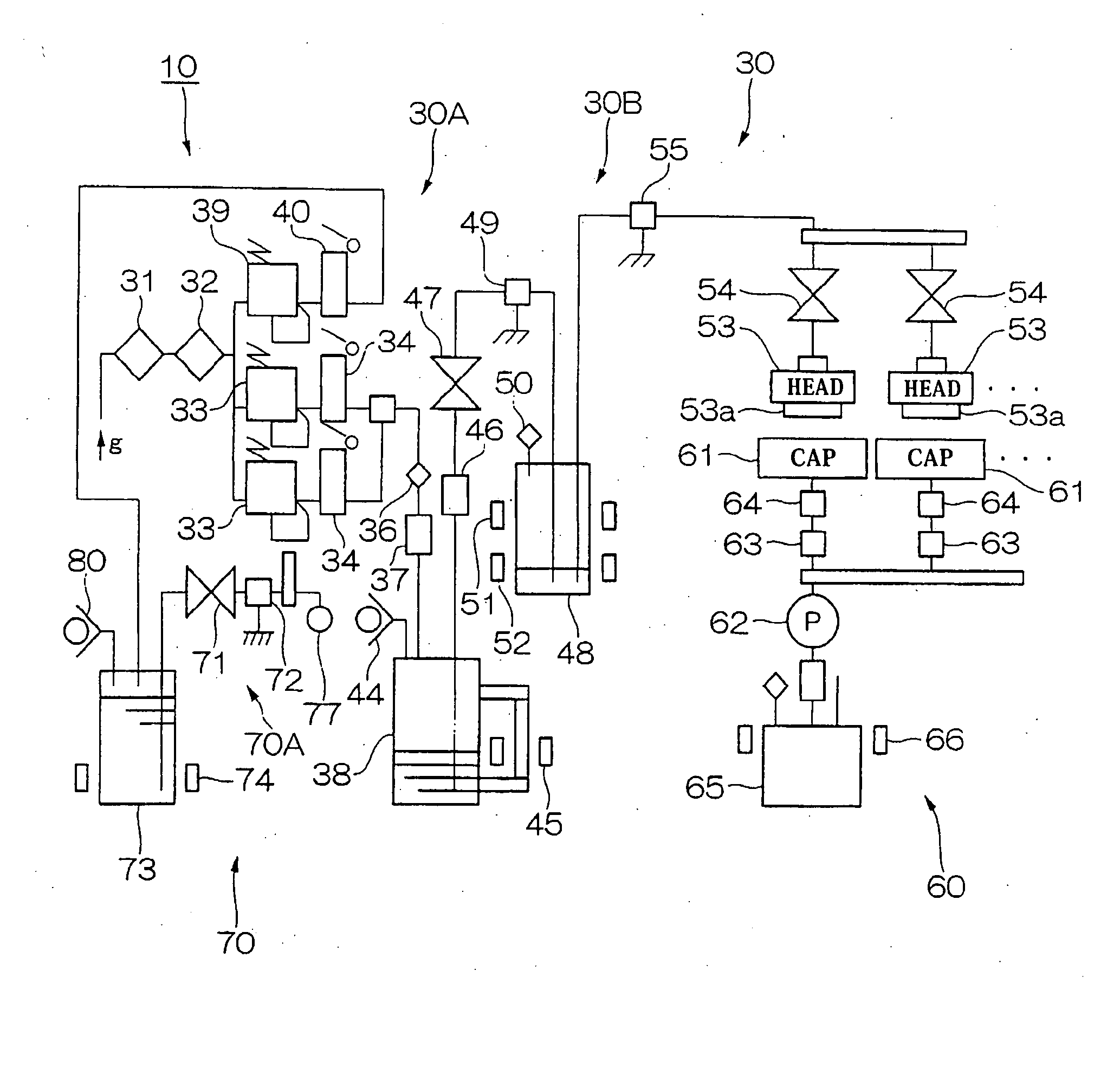

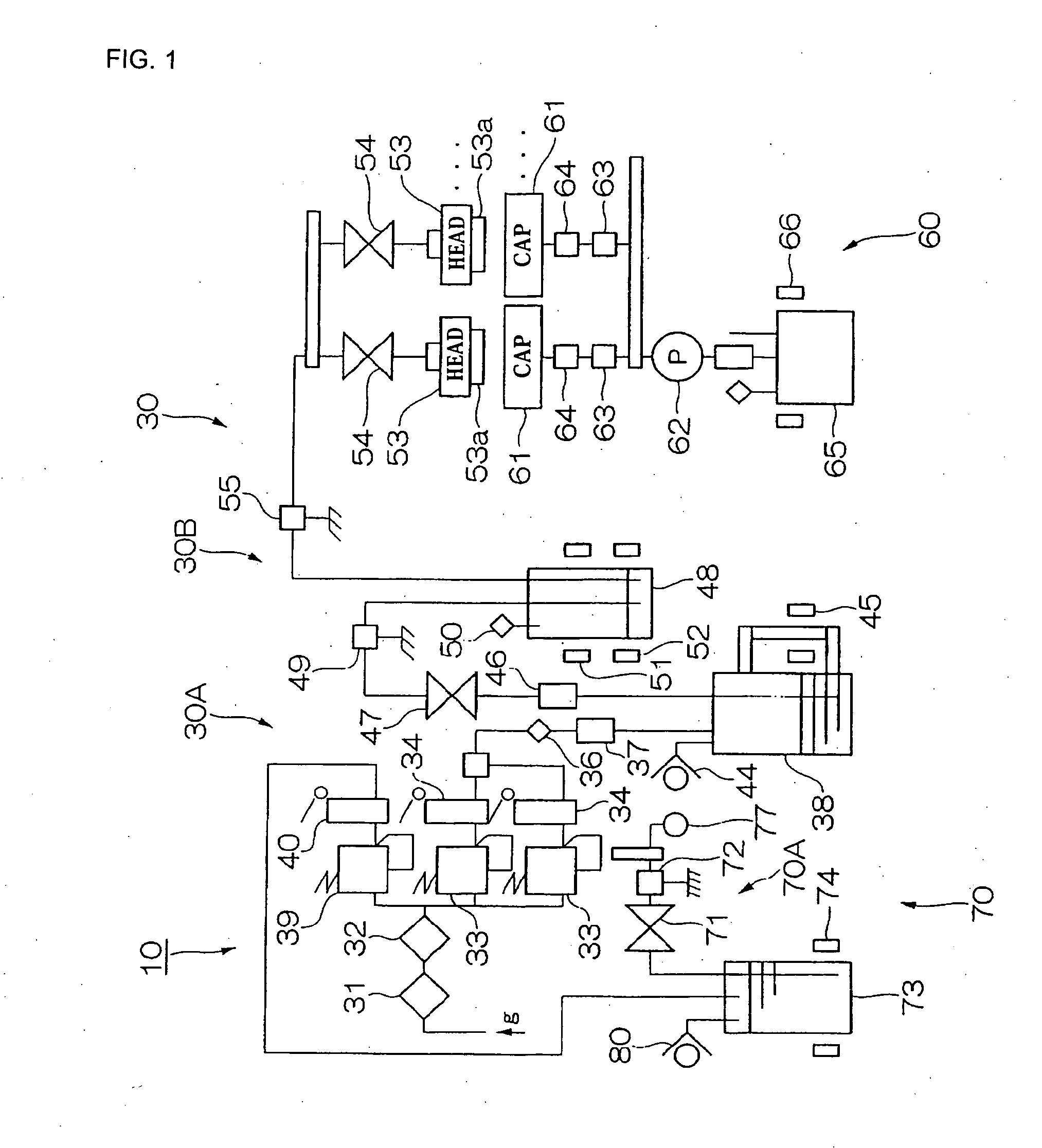

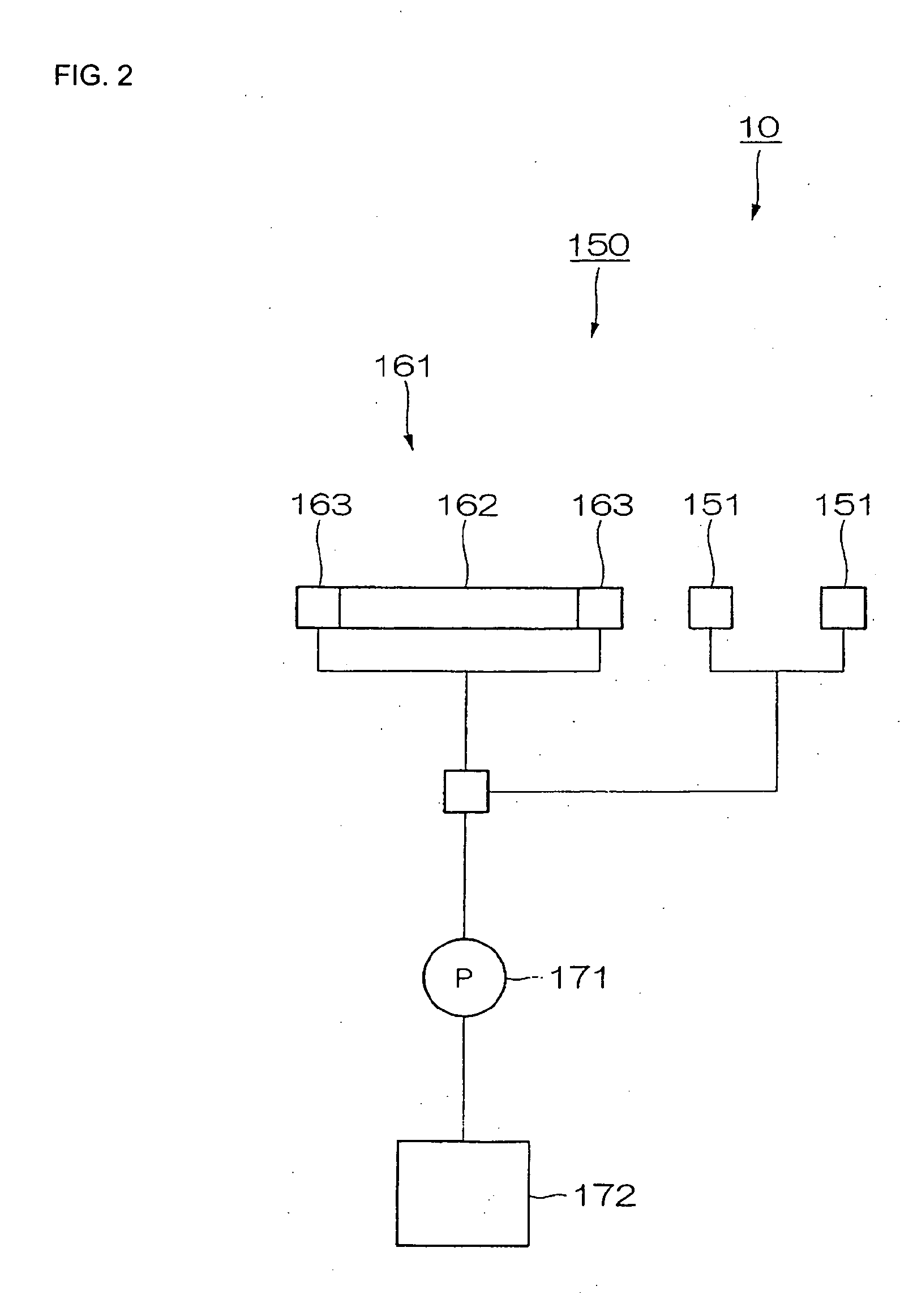

Fluid control valve and droplet ejection device

InactiveUS20050150940A1Improve performanceIncrease elasticityLiquid surface applicatorsSpray nozzlesFluid controlEngineering

Exemplary embodiments can provide a fluid control valve, which reduces or prevents any bubble from being built up in the valve itself so as to protect other hydraulic equipment placed in a downstream side from having any malfunction due to such a bubble, and a droplet ejection device using the fluid control valve. A fluid control valve includes a tank, through which a fluid passes, an inlet port, through which a fluid flows into the tank, an outlet port, through which a fluid flows out of the tank, a valve plug that opens and closes at least one of the inlet port and the outlet port, a coupler connecting part of the inlet port side, which is located in an inlet passage connected to the inlet port, and a coupler connecting part of the outlet port side, which is located in an outlet passage connected to the outlet port. Piping is connected to the coupler connecting part of the inlet port side and the coupler connecting part of the outlet port side, each by using a coupler. An annular element for the purpose of offsetting a shoulder part caused by a difference in flow passage diameter existing between each of the coupler connecting parts of the inlet port side and outlet port side and the corresponding coupler can be placed at each of the coupler connecting part of the inlet port side and the coupler connecting part of the outlet port side.

Owner:SEIKO EPSON CORP

Hole punch element

ActiveUS20070267472A1Improve scalabilityImprove pore forming efficiencyMetal working apparatusDigital marking by punchingEngineeringCutting force

Owner:WORKTOOLS

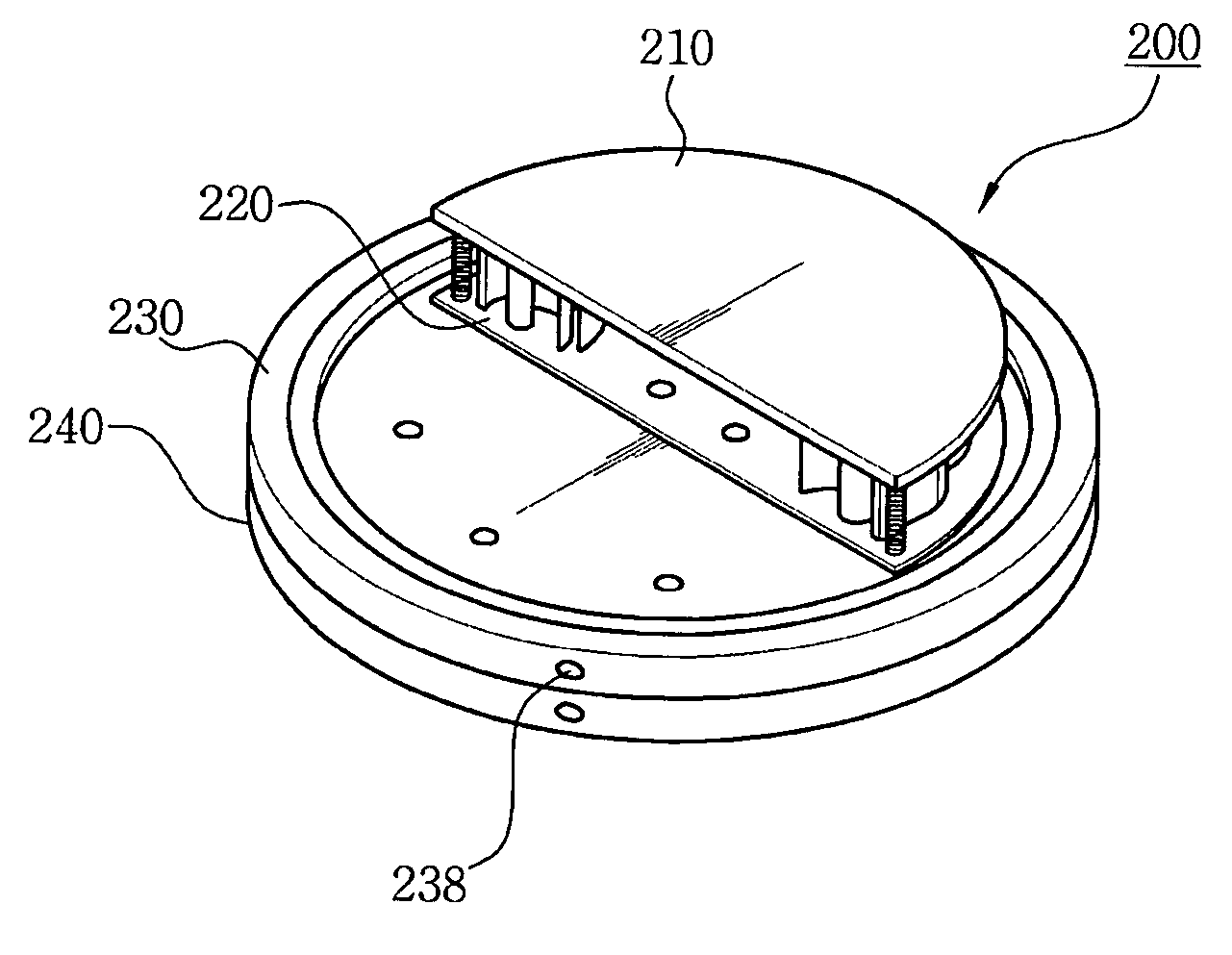

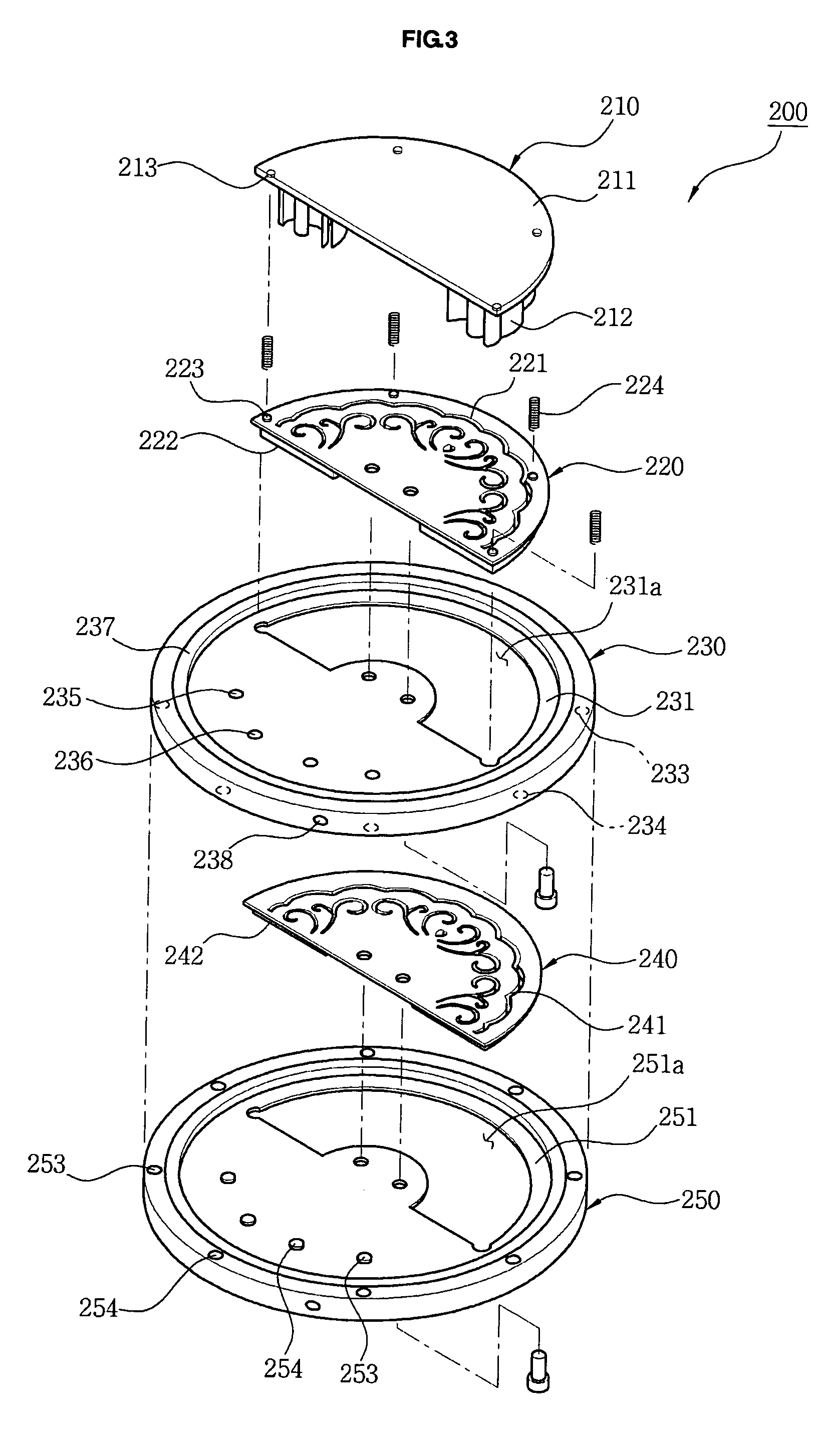

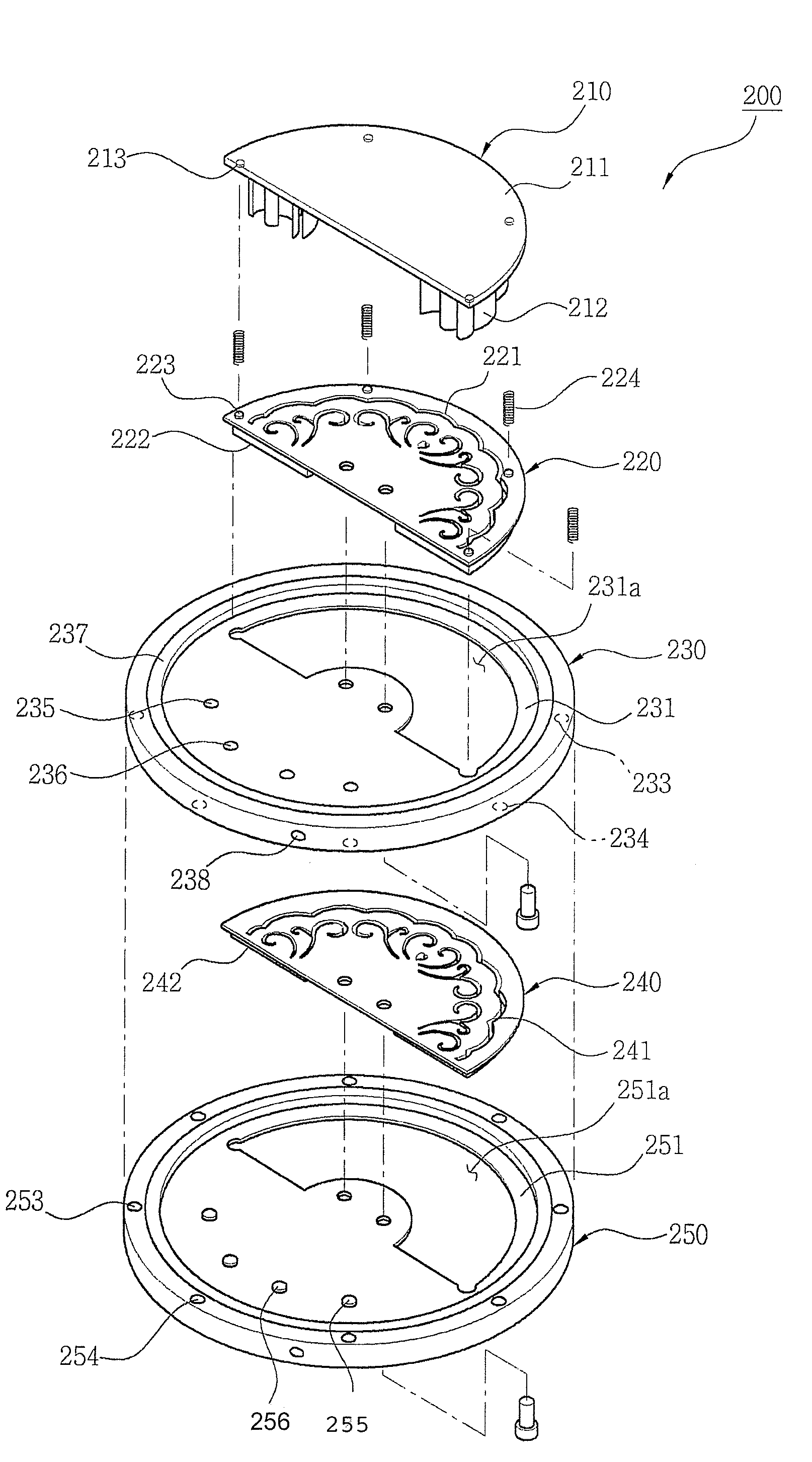

Rotary punching apparatus

Rotary punching apparatus includes: an upper rotation plate provided with punching member on which punching blade having a pattern of a specific shape is formed, and an upper jig which support elastically the punching member and forms a guide hole in the same shape as the pattern; an upper plate configured to enable the upper rotation plate to be rotated; a lower rotation plate including lower jig on which a punching hole in the same shape as the pattern is formed; and lower plate configured to enable the lower rotation plate to be rotated. The upper and the lower plate are provided with at least one magnets in a position opposite to each other and the upper and the lower rotation plate are provided with at least one or more magnets in a position opposite to each other, so that the fixed position is mutually aligned due to the magnetic force of the magnet. As a result, the present invention can freely punch a desired position irrespective of punching positions such as the seat as an object of the punching.

Owner:KIM OK HWAN +1

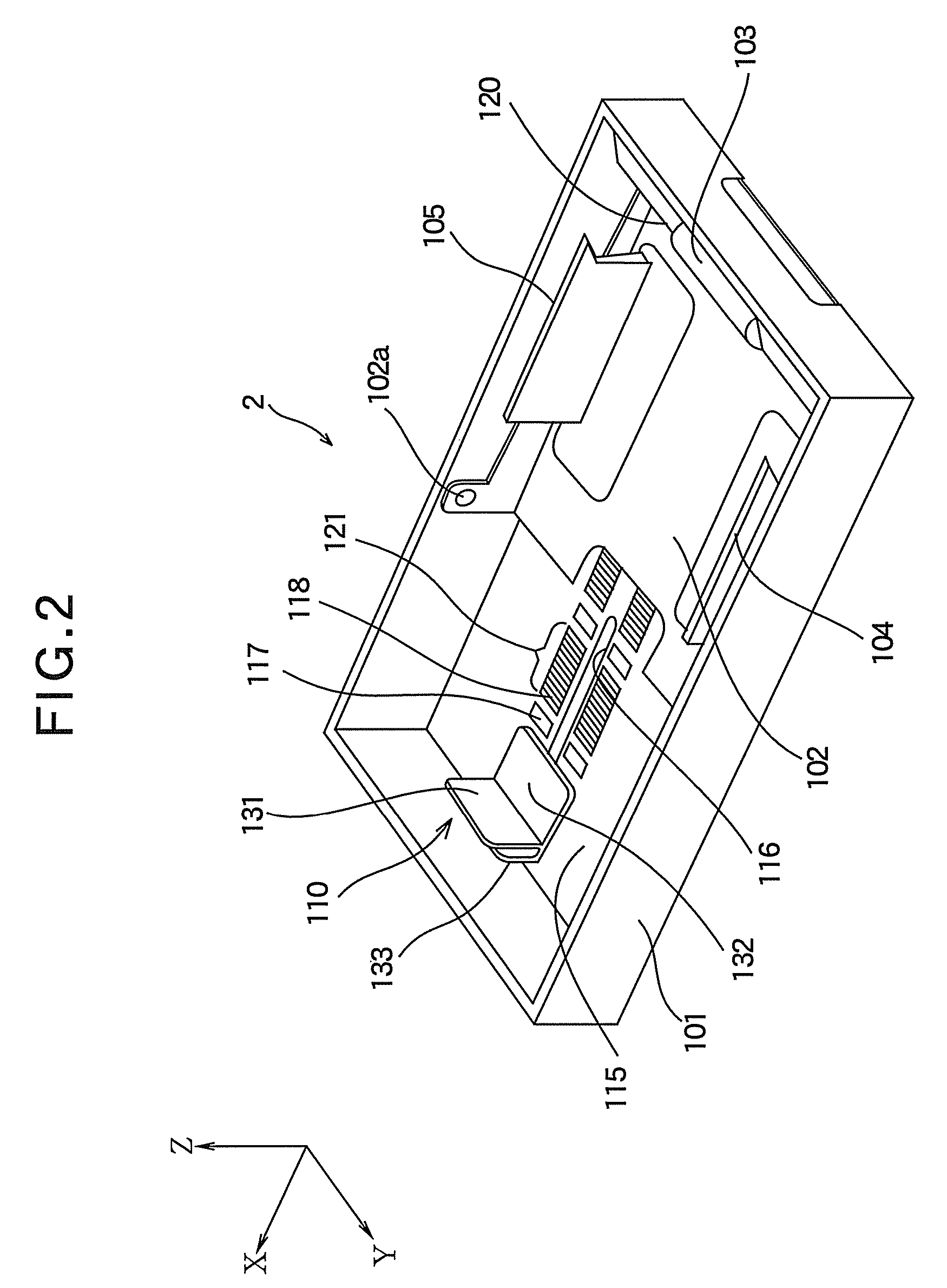

Media storage apparatus and image forming apparatus configured to operate with regular-sized recording media and irregular-sized recording media

ActiveUS8045216B2Precise positioningHigh positioning accuracyFunction indicatorsVisual presentation using printersComputer scienceRecording media

A media storage apparatus includes a media storing body that stores recording media, a guide member slidably provided in the media storing body for guiding the recording media, a first positioning portion that positions the guide member at a predetermined position where the guide member guides regular-sized recording media, and a second positioning portion that positions the guide member at a position where the guide member guides irregular-sized recording media. The first positioning portion and the second positioning portion have different shapes.

Owner:OKI DATA CORP

Rotary punching apparatus

Owner:KIM OK HWAN +1

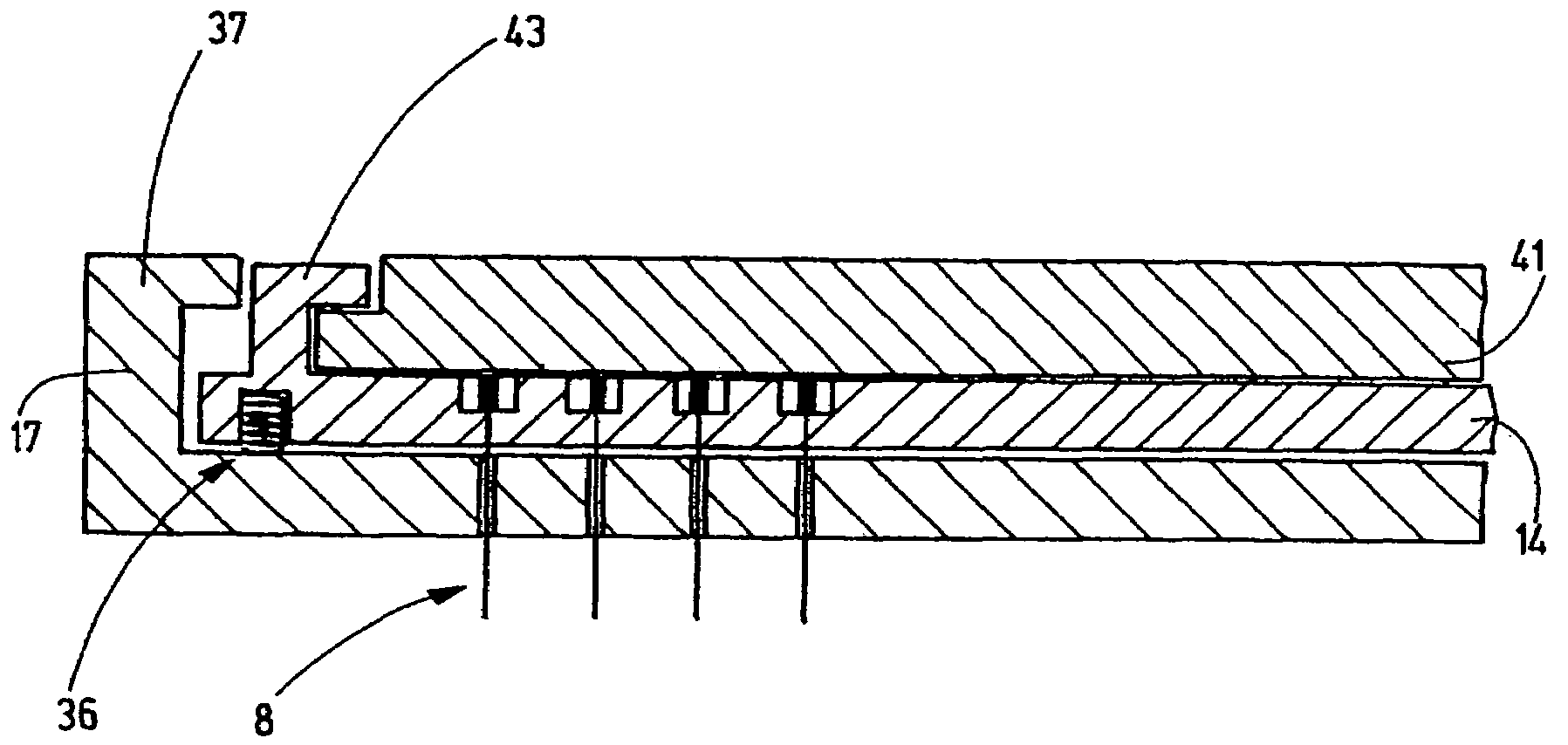

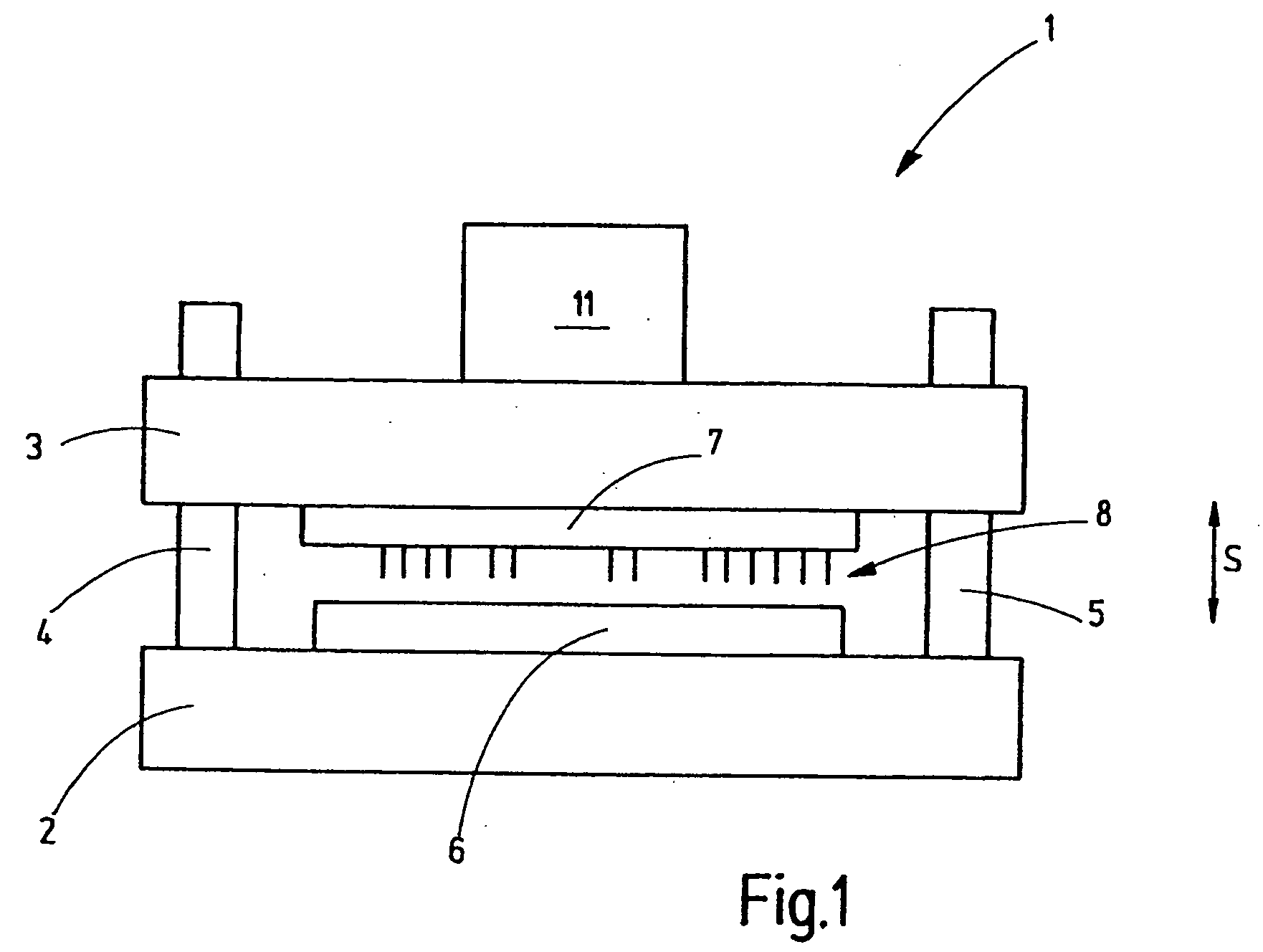

Punch device with interchangeable punch and variable punch pattern

ActiveUS20080282864A1Risk of damage to the punch is avertedPrinted circuit manufactureMetal working apparatusEngineeringMechanical engineering

A selection plate (39) is provided on a punch device (1) for activating or deactivating individual punch holding bars (13, 14). The plate has a coupling device (40) associated with a positive-locking coupling between a punch holding bar (13, 14) and the selection plate (39). Associated with the positive-locking coupling is an edge of the selection plate (39), that is provided with a recess (42), an extension (43) of the punch holding bar (13, 14) that extends around said edge, and / or a rib (41), which is located on the underside of the selection plate (39) and is associated with the punch holding bar (13, 14). As a result, it is possible to selectively establish or eliminate a positive-locking connection between the punch holding bar (13, 14) and the selection plate (39). Via the rib (41), the punch stroke of the selection plate (39) is merely transmitted to the punch holding bar (13 or 14), which is in positive-locking engagement with the lateral edge or the projections of the selection plate (39). The elongated rib (41) covers the heads (26, 27, 28, 29) of the punches (8) and transmits the stroke in a planar manner to the punch holding bar (13 or 14).

Owner:GROZ BECKERT KG

Punch with punch elements in adjustable positions

InactiveUS20040164138A1Easy to adjustMetal working apparatusDigital marking by punchingPunch pressEngineering

A punch includes a base, a plurality of punch pins, a lever and a plank. The base includes a lower member defining a plurality of holes and an upper member defining a plurality of holes corresponding to the holes defined in the lower member. Each of the punch pins is for insertion through one of the holes defined in the upper member and one of the holes defined in the lower member. The lever is pivotally mounted on the base. The plank defines a plurality of holes. The plank is movably attached to the lever between several positions in each of which it pushes a different set of the punch pins when the lever is operated.

Owner:CHAU LIH RONG ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com