Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Achieve the purpose of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

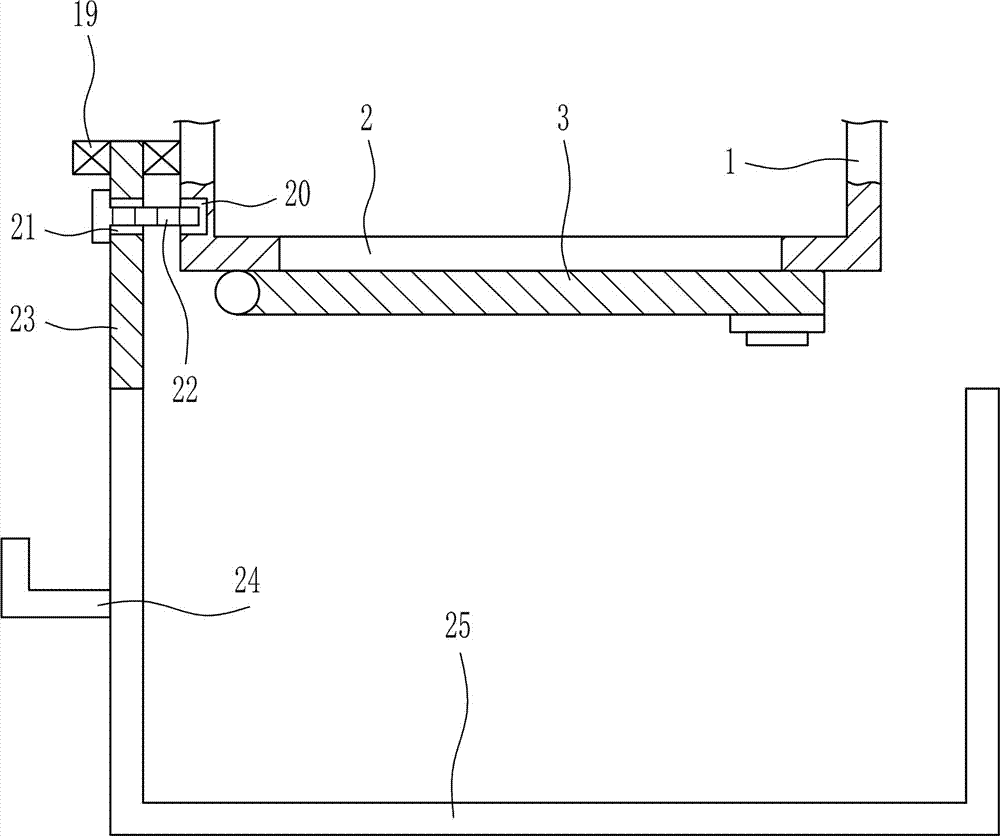

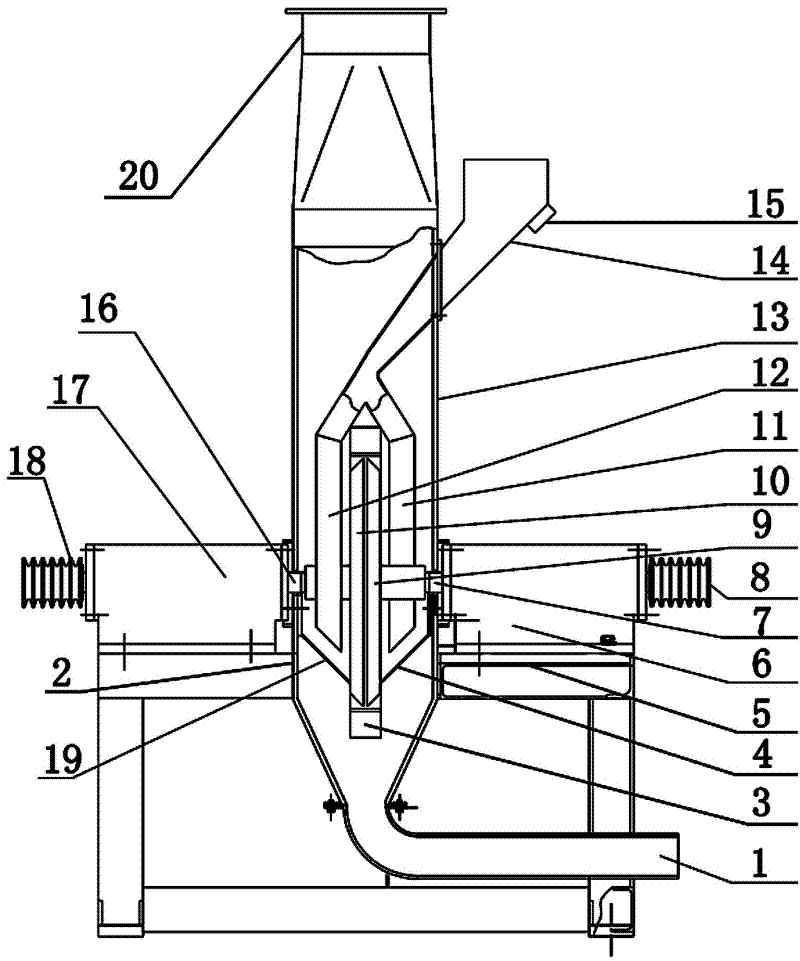

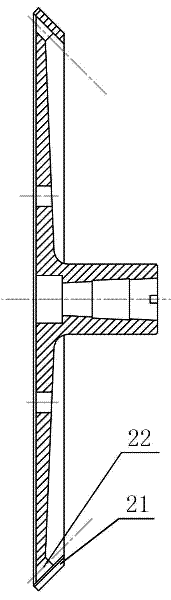

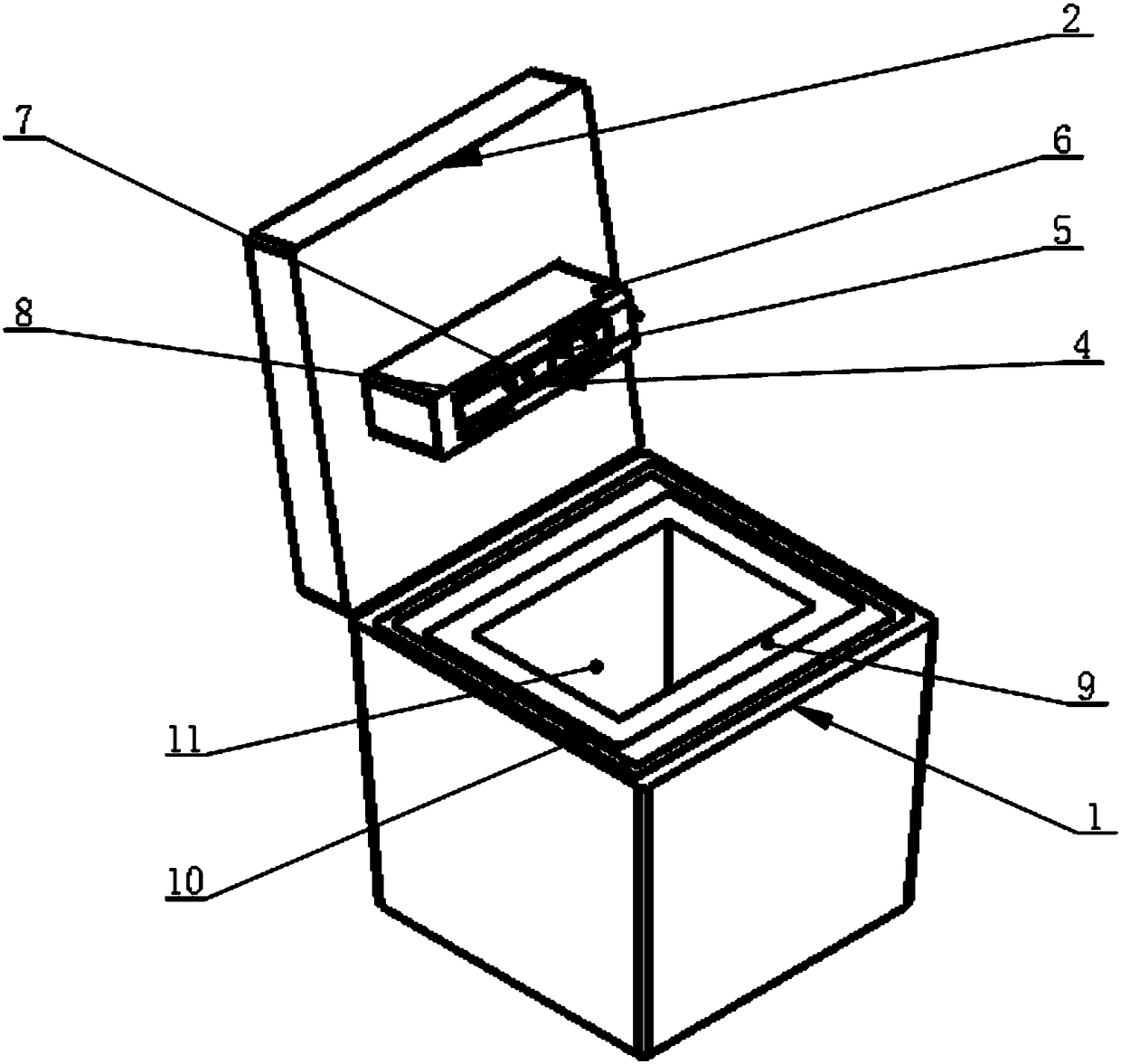

Waste packaging box crushing equipment for medicine packaging

The invention relates to crushing equipment, in particular to waste packaging box crushing equipment for medicine packaging. The waste packaging box crushing equipment for medicine packaging has the advantages that crushing can be carried out under a closed condition, and chippings can be prevented from spilling out and can be convenient to collect. The waste packaging box crushing equipment for medicine packaging comprises a crushing box and the like; a first through hole is formed in the middle of the bottom wall of the crushing box; a baffle is connected to the left side of the bottom of the crushing box in a rotating mode; the right side of the bottom of the baffle is fixed to the right side of the bottom of the crushing box through bolts; a cover tightening mechanism is arranged at the top of the crushing box; and a crushing mechanism is arranged in the middle of the crushing box. According to the waste packaging box crushing equipment, the cover tightening mechanism and the crushing mechanism are arranged so that the chippings can be prevented from spilling out, meanwhile, the purpose of carrying out crushing under the closed condition can be achieved, and the illumination angle of an illumination lamp can be adjusted by a worker through a second rotating rod so as to improve the practicability of the equipment.

Owner:谢阳萍

Method for storing color and luster and flavor of Chinese chestnut-lotus root composite ultramicro whole powder with easy gelatinization

The invention relates to a method for storing the color and luster and flavor of Chinese chestnut-lotus root composite ultramicro whole powder with easy gelatinization, and belongs to the field of the food processing of fruits and vegetables. The method comprises the following main processes of: peeling Chinese chestnuts and fresh lotus roots, cutting into slices, and keeping colors by using a composite color fixative prepared from citric acid, ascorbic acid and N-acetylcysteine; freeze-drying by microwave to prepare dried slices; and crushing the dried slices of the Chinese chestnuts and thelotus roots coarsely, mixing, and performing airflow type ultramicro full crushing to prepare the Chinese chestnut-lotus root composite ultramicro whole powder with the easy gelatinization. In the processing process, the change of the color and luster in the drying and crushing processes in the later period can be controlled by color-keeping processing; in the drying process, the change degree ofthe color and luster and flavor in the conventional hot-air drying process is reduced obviously by the microwave freeze-drying technology; and in the crushing process, the loss of excessive heat generated by the mechanical shearing crushing technology on the color and luster and flavor is prevented effectively by the airflow type ultramicro full crushing technology, and the flavor and nutrition of the Chinese chestnuts and the lotus roots can be better mixed by high-pressure air combination in the ultramicro full crushing process.

Owner:杭州建德天堂食品有限公司 +1

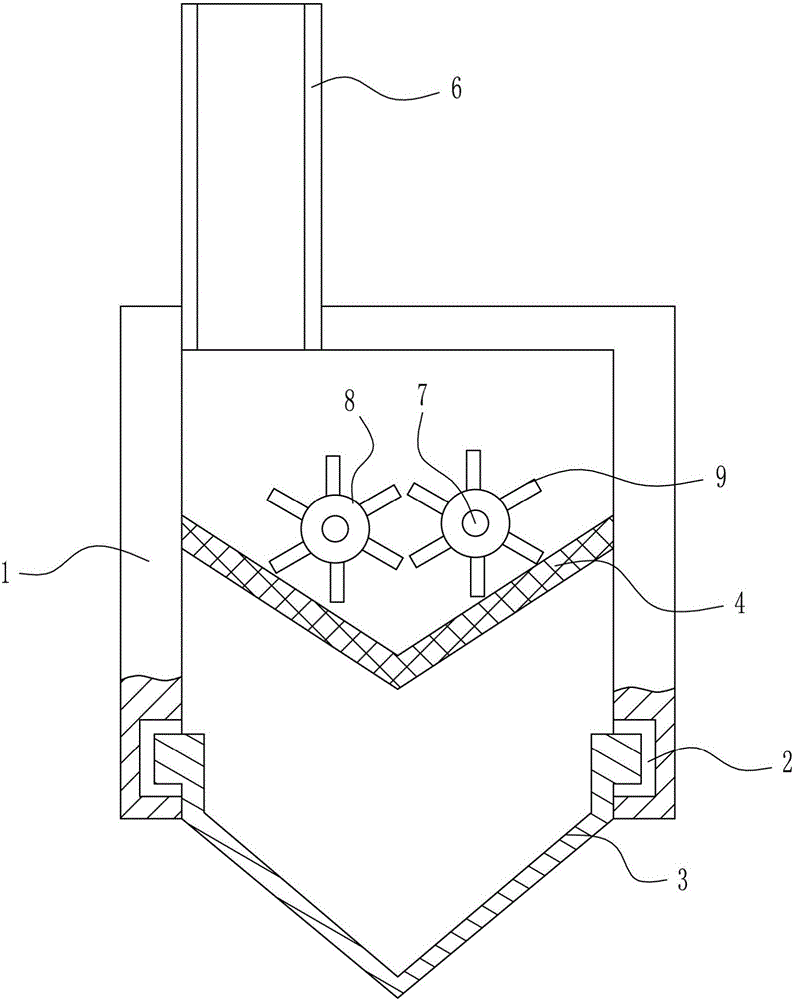

Mixing device integrating screening and crushing

ActiveCN110404640AStrong shearStrong impactRotary stirring mixersTransportation and packagingEngineeringLarge particle

The invention relates to the technical field of architectural coating mixing, and discloses a mixing device integrating screening and crushing. In order to solve the problem that existing stirring andmixing equipment has poor processing quality, the following scheme is proposed, the mixing device comprises an outer cylinder, an inner cylinder is arranged in the outer cylinder, a U-shaped plate arranged in a handstand manner is arranged on the top of the outer cylinder, a rotating shaft is rotatably mounted between the bottom of the U-shaped plate and the bottom inner wall of the inner cylinder, the bottom of the rotating shaft extends into the inner cylinder and is fixedly provided with a stirring rod, a horizontally-arranged vibrating plate is installed in the inner cylinder in a slidingmanner, the vibrating plate is located below the stirring rod, the vibrating plate is slidably connected with the rotating shaft, the inner wall of the inner cylinder is provided with a flow guide plate, and the rotating shaft is fixedly provided with a baffle arranged in an inclined manner. The mixing device can achieve mixing, dissolving, dispersing and refining of coating and has the screeningfunction, larger particles in the coating are screened out to be chiseled and chopped, refinement of the large particles is realized, the quality of the coating is improved, and promotion is easy toachieve.

Owner:阜阳市广联普惠自动化技术有限公司

Cement smashing device

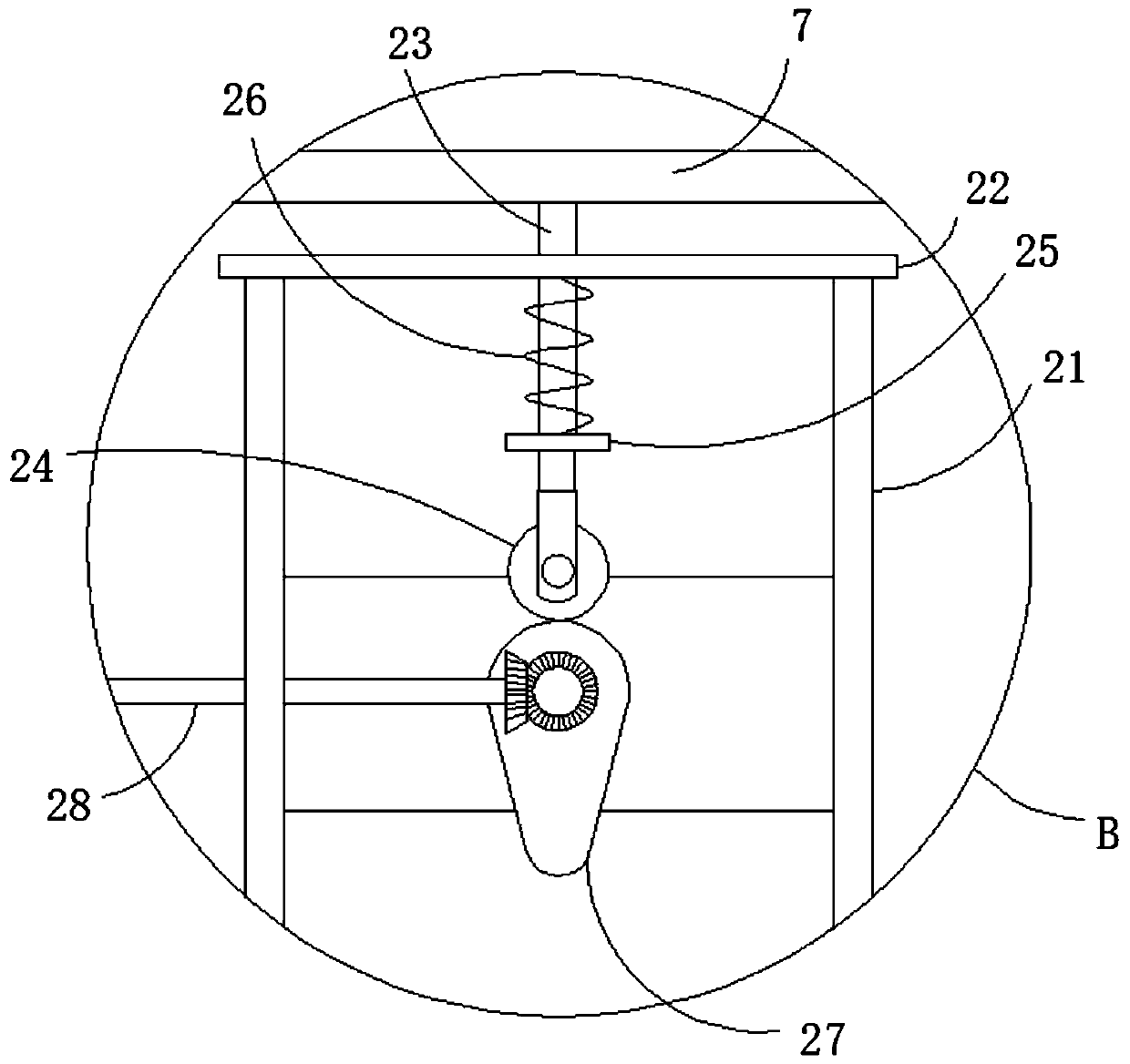

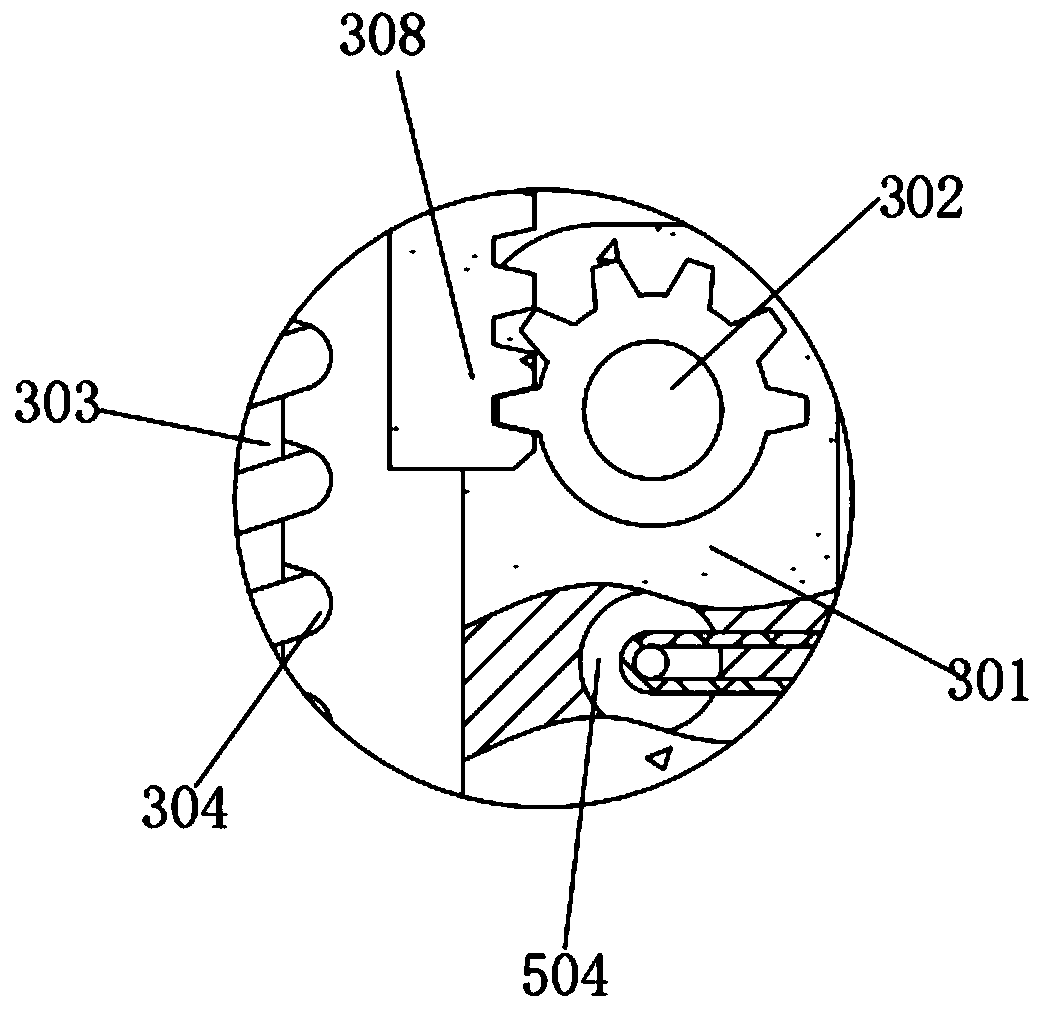

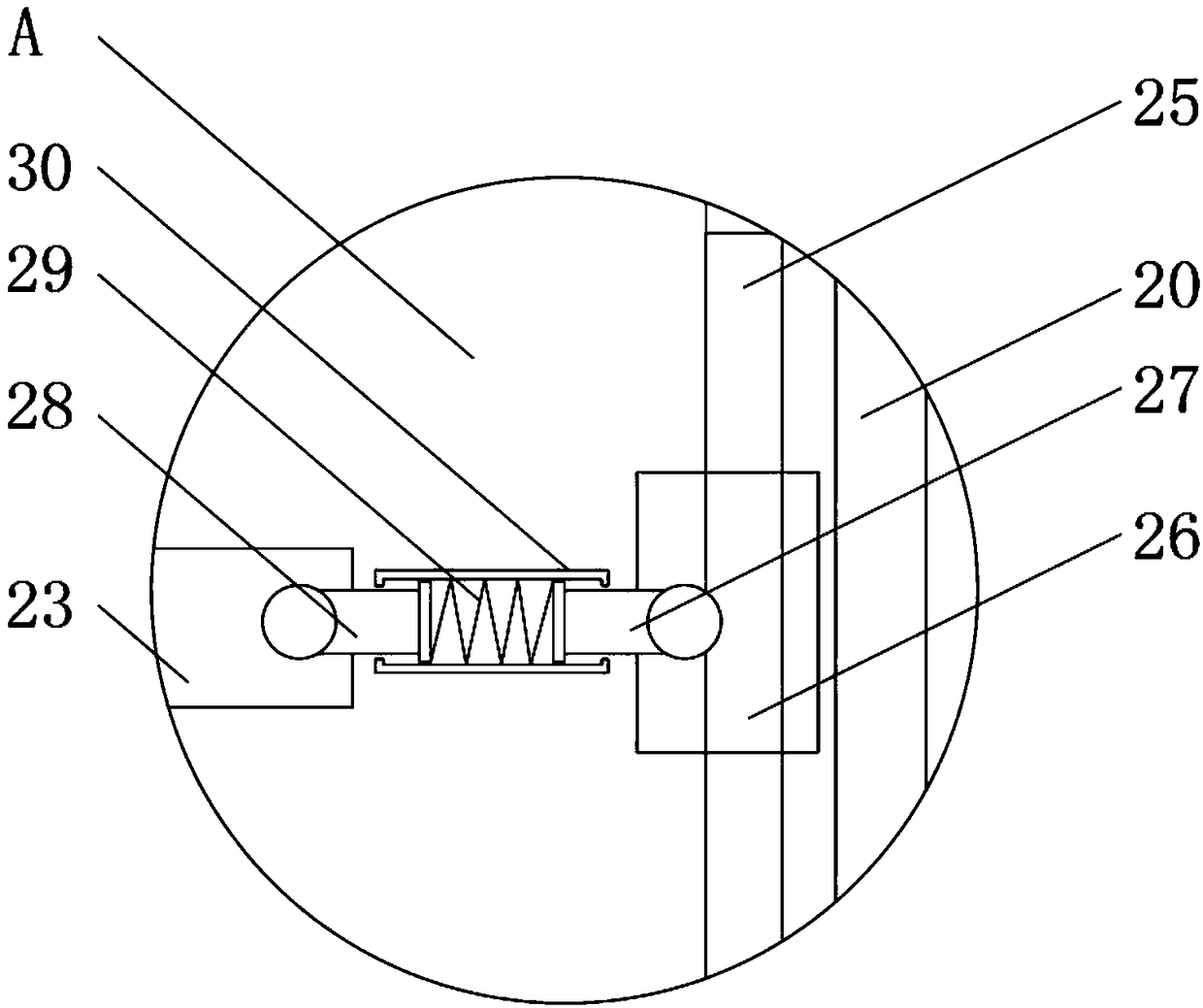

ActiveCN111151339AReduce vibrationExtended service lifeNon-rotating vibration suppressionDirt cleaningVibration amplitudeGear wheel

The invention discloses a cement smashing device comprising a first cross plate and bases fixedly connected with the lower surface of the first cross plate. A damping device is installed on the uppersurface of the first cross plate. According to the cement smashing device, by means of mutual cooperation of vertical rods, first half-ring gears, first tooth plates, second cross plates, first springs, L-shaped plates and other structures, the vibration amplitude can be lowered when the cement smashing device works, so that the service life of the cement smashing device is prolonged. By means ofmutual cooperation of a second motor, a second half-ring gear, a second toothed plate, a second spring, a pipe and other structures, a material blockage phenomenon is avoided, the work efficiency is improved and the labor cost is reduced; by means of mutual cooperation of a filtering net, a third cross plate, a pipe, a fan, the first cross plate and other structures, dust generated during smashingcan be sucked for centralized treatment, and therefore the health of operation personnel is protected.

Owner:承德冀东水泥有限责任公司

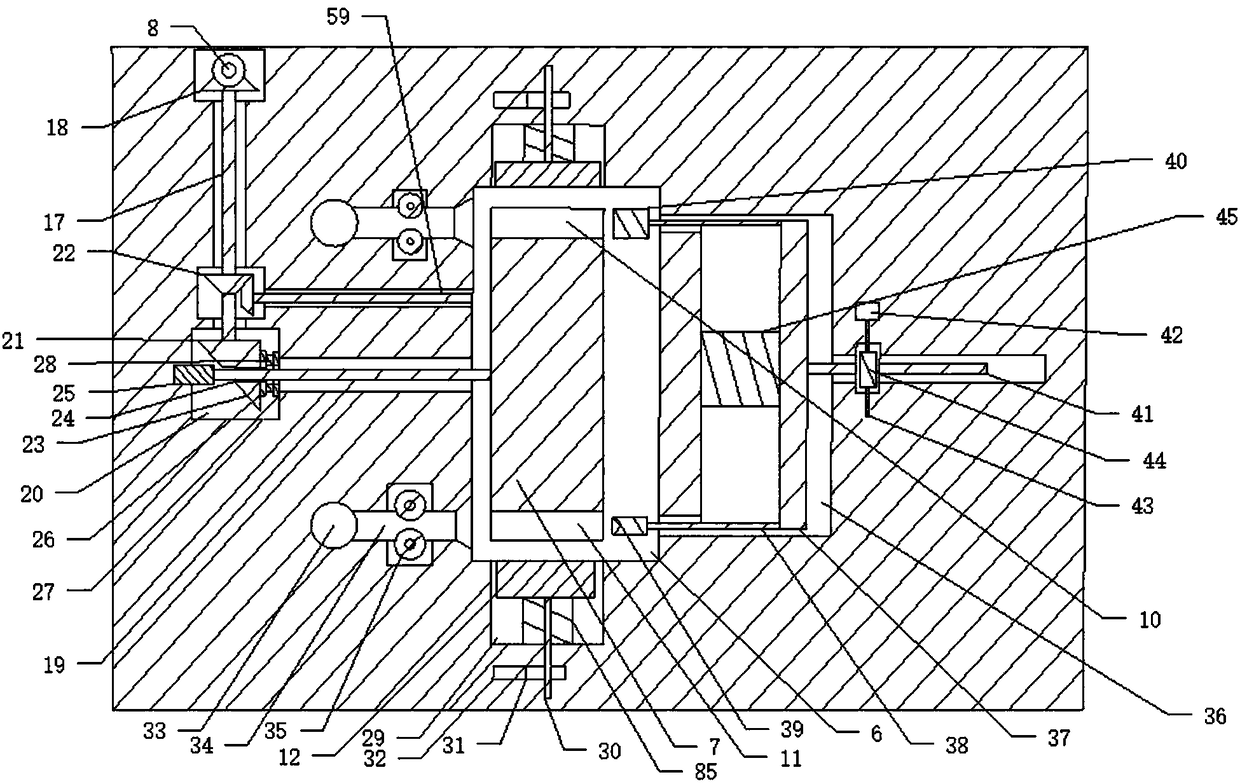

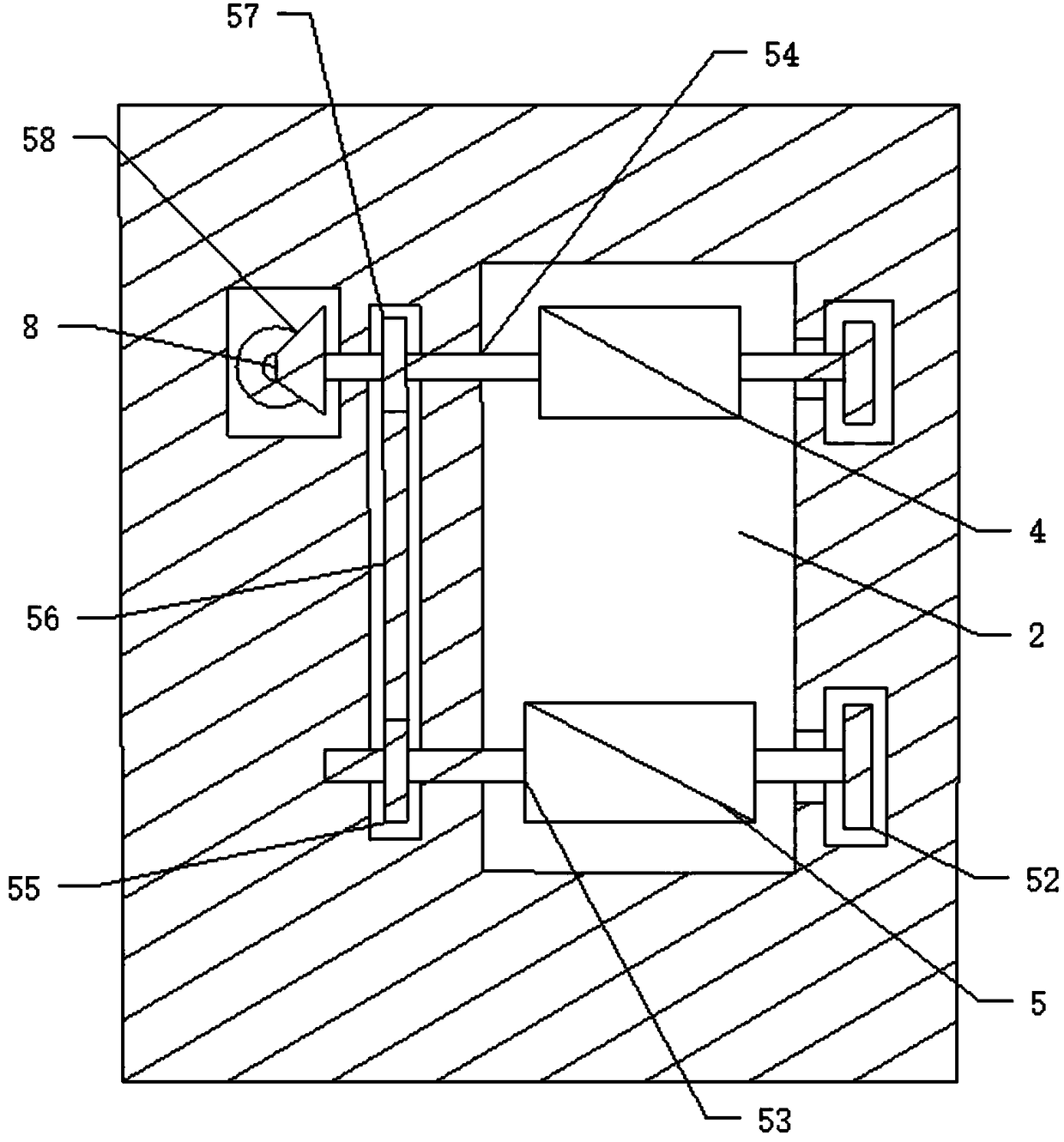

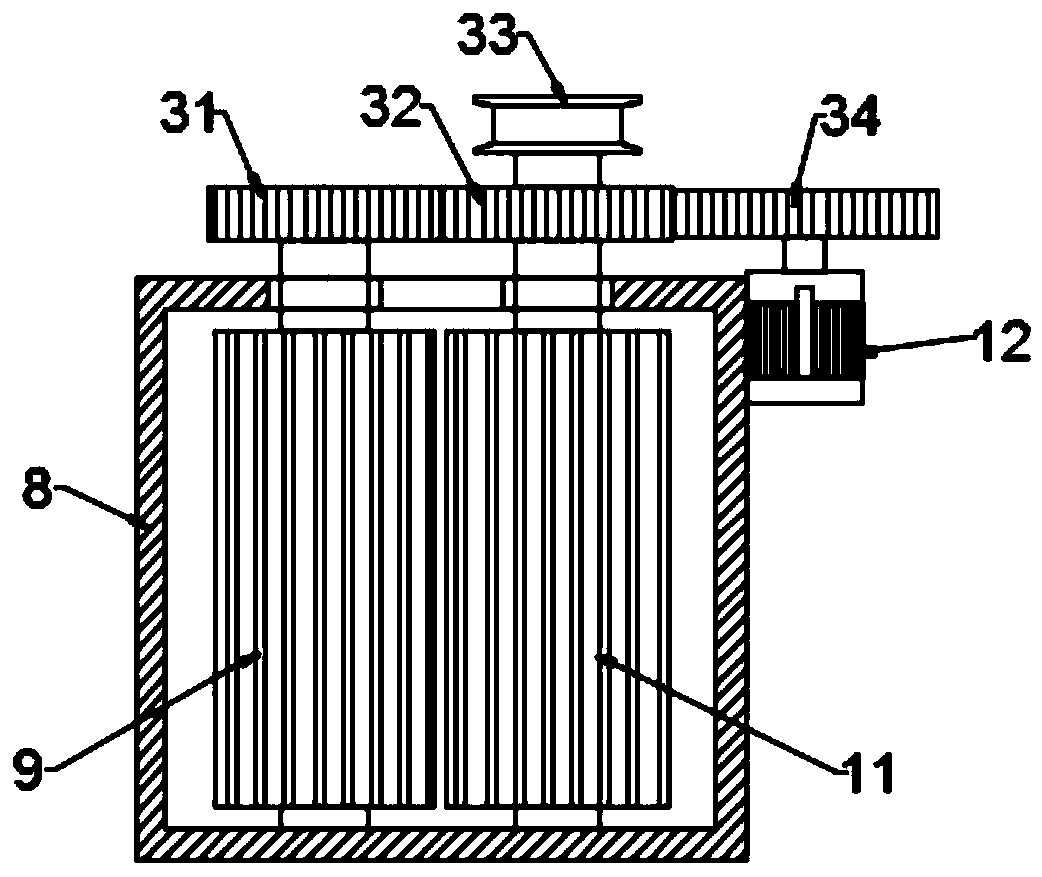

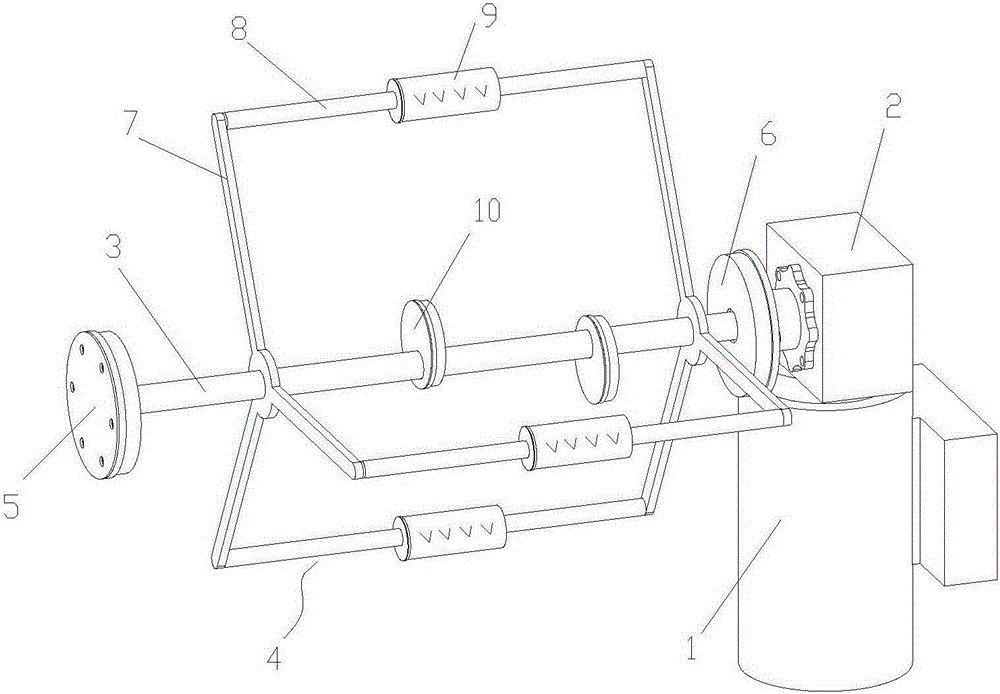

Double-disc refining pulverizer

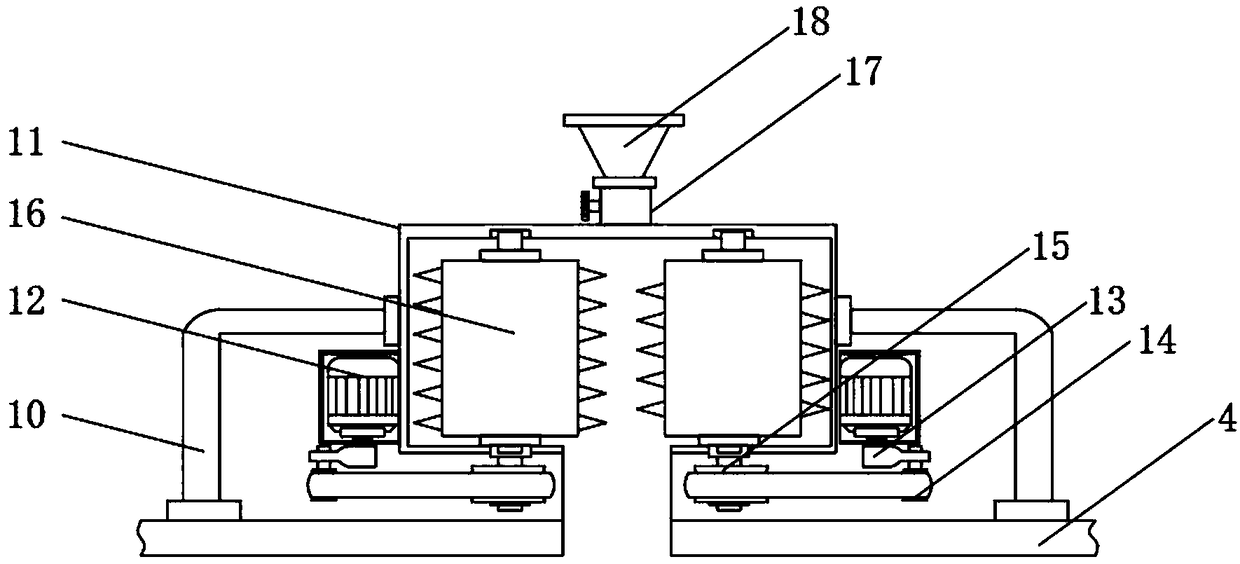

ActiveCN102371200AAchieve the purpose of crushingAchieve the goal of energy saving and production increaseCocoaGrain treatmentsShortest distanceElectric machinery

The invention discloses a double-disc refining pulverizer, which comprises a machine base and a machine box, wherein the upper part of the machine box is provided with a discharging hole; the lower part of the machine box is provided with an air outlet; one side of the machine box is provided with a feeding hopper; the feeding hopper is communicated with a first distributing pipe and a second distributing pipe; a first diversion groove is formed on the lower part of the first distributing pipe; a second diversion groove is formed on the lower part of the second distributing pipe; a first throwing disk is connected with a first main shaft arranged on a first bearing base; a second throwing disk is connected with a second main shaft arranged on a second bearing base; and the first polishing disk and the second polishing disk are arranged oppositely in the machine box. In the invention, a double-disc refining structure is adopted, and a motor is directly used for driving two throwing disks to throw materials out by rotating positively and negatively at high speeds, so that the materials are collided, sheared and decomposed within a short distance, the aim of pulverizing is fulfilled, the structure of an air current pulverizer is simplified, and the production cost and the energy consumption are lowered.

Owner:宜昌慧龙科技开发有限公司

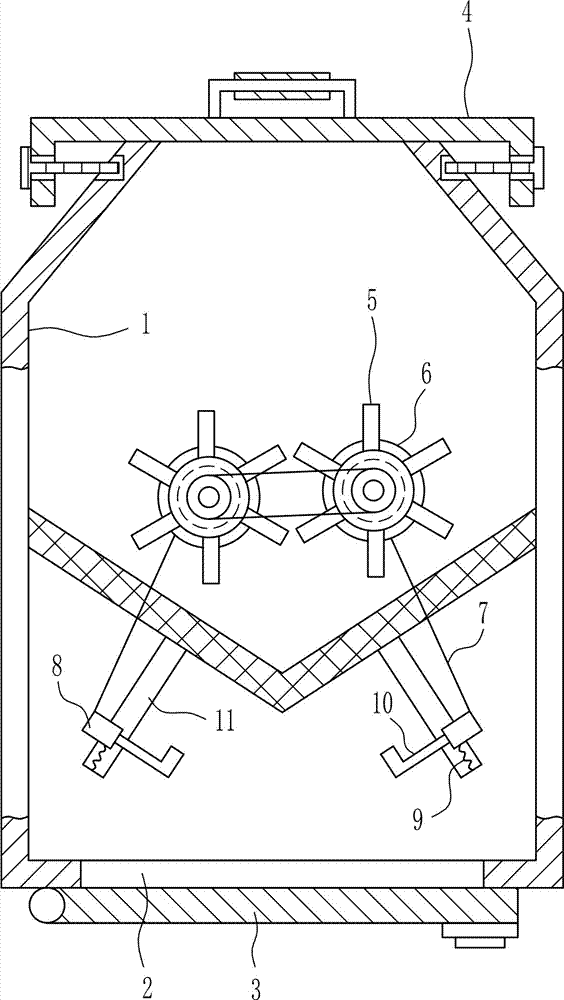

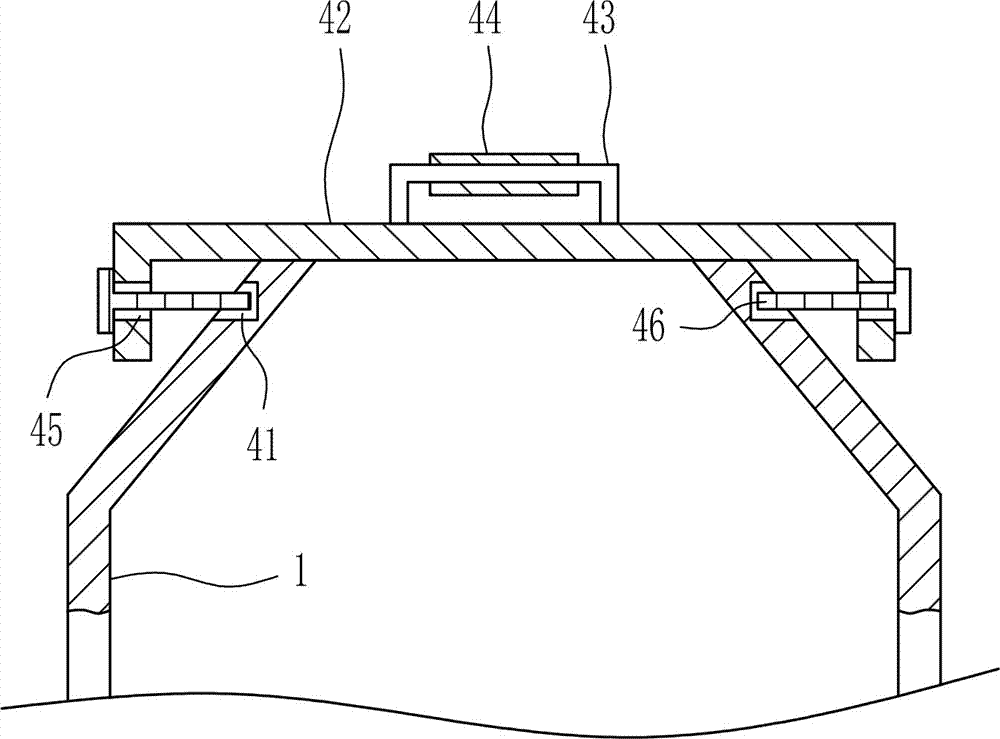

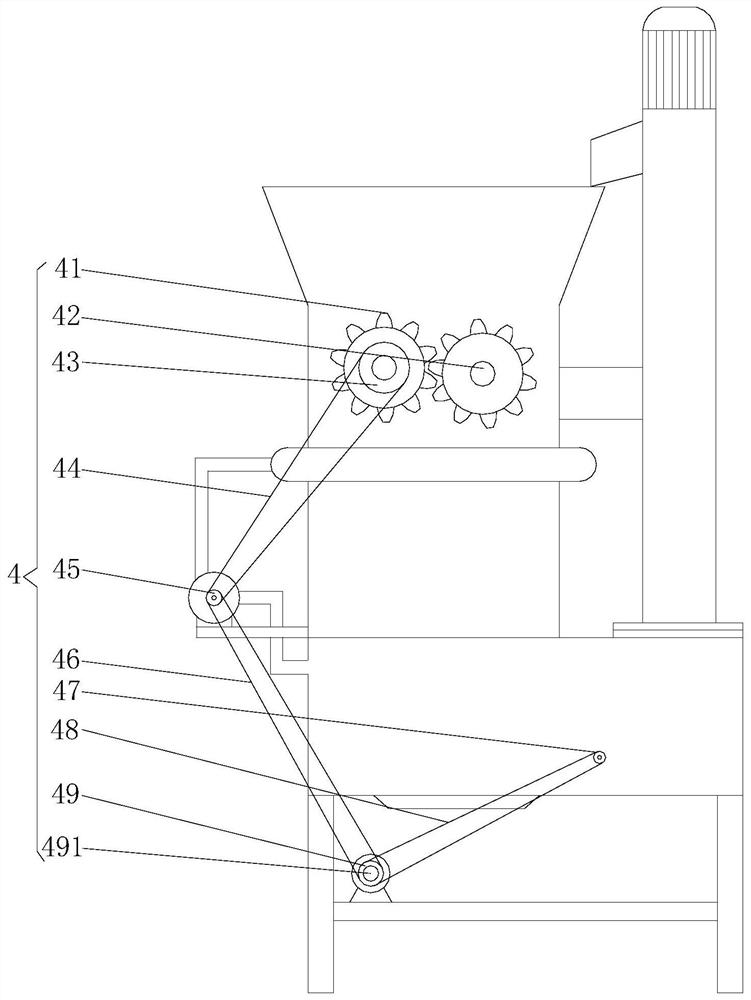

Completely smashing device for character design drawing for cartoon game development

ActiveCN106669922ATo achieve the purpose of crushingTo achieve dredging effectSievingScreeningCharacter designElectric machinery

Owner:NINGBO KAKU CARTOON MAKING

Combustion furnace realizing complete combustion of coal

PendingCN109268877AAchieve the purpose of crushingAchieve the purpose of separationSievingDomestic stoves or rangesAutomotive engineeringCoal

The invention provides a combustion furnace realizing complete combustion of coal. The combustion furnace comprises a shell, a crushing device and a vibrating screen. The shell is internally providedwith a first combustion chamber and a second combustion chamber; the crushing device is used for crushing incompletely combusted coal in the first combustion chamber; a plurality of water spray nozzles for spraying water mist to combusted coal in the first combustion chamber are arranged in a tank; the vibrating screen is used for bearing the crushed incompletely-combusted coal and separating thecoal from coal cinder. The combustion furnace has advantages that by arrangement of the crushing device, crushing of the incompletely combusted coal can be crushed; by arrangement of the water spray nozzles, dust reduction in crushing of the incompletely combusted coal is realized; by arrangement of the vibrating screen, separation of the crushed coal and the coal cinder is realized; by arrangement of the second combustion chamber, complete combustion of separated coal is realized.

Owner:芜湖天火新能源科技有限公司

Drug intermediate reaction device and using method thereof

InactiveCN110496583AAchieve the purpose of crushingAchieve the purpose of cleaningHollow article cleaningChemical/physical/physico-chemical stationary reactorsArchitectural engineering

The invention discloses a drug intermediate reaction device and a using method thereof. The device includes a shell, a partition plate is fixedly connected to the upper end of the inner cavity of theshell, the outer side of the bottom of the partition plate is fixedly connected with an annular tube, the bottom of the annular tube is communicated with a spray head, a scraping mechanism is fixedlyconnected to the bottom of the partition plate and located at the inner side of the annular tube, the scraping mechanism comprises an annular sliding base, a slider, a supporting plate, an electric telescopic rod and a scraping plate, a crushing motor is fixedly mounted at the middle end of the top of the shell, and crushing teeth are fixedly connected to the output shaft of the crushing motor through a crushing shaft. The scraping mechanism is fixedly connected to the bottom of the partition plate and located at the inner side of the annular tube, and the annular sliding base, the slider, thesupporting plate, the electric telescopic rod, the scraping plate, the crushing motor, the crushing shaft and the crushing teeth make the device additionally have crushing and cleaning functions on the existing basis, so the device is greatly convenient for people to use.

Owner:ANHUI PROVINCE YIFAN SPICE

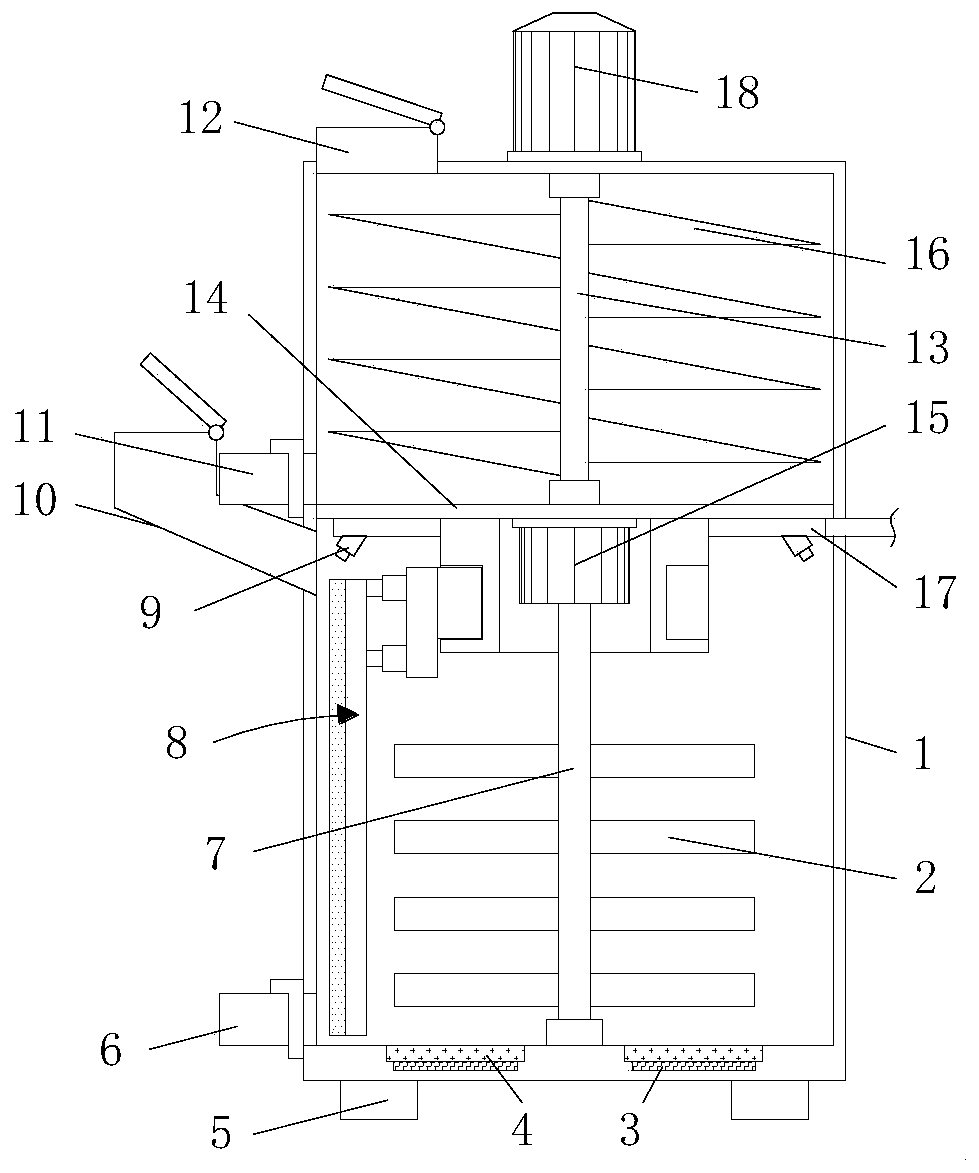

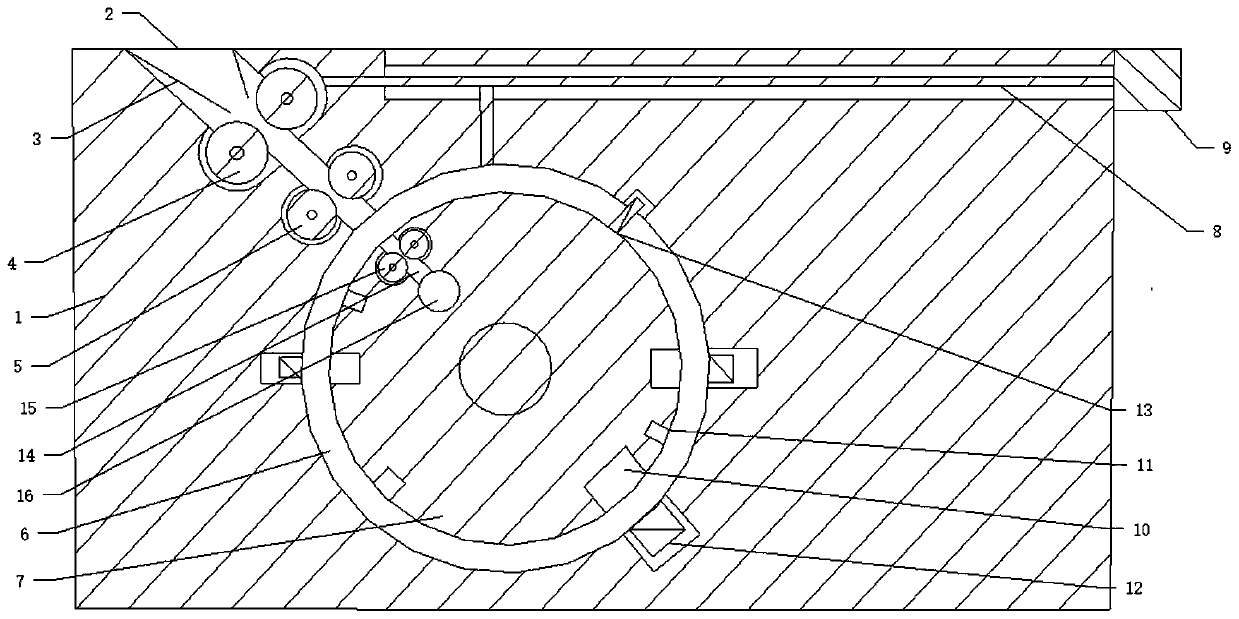

Infusion apparatus automatic splitting recovery device

InactiveCN108465143AAvoid harmAchieve the purpose of crushingInfusion needlesEngineeringControl switch

The invention discloses an infusion apparatus automatic splitting recovery device. The device includes a machine body, a first inlet is formed in the machine body, corresponding elastic pressing plates are arranged on the two sides of the first inlet respectively, a first clamping roller and a second clamping roller which are correspondingly clamped with each other during rotation are arranged onthe two sides of the first inlet respectively, a first rotating cavity correspondingly communicated with the first inlet is formed in the machine body, and a rotary splitting disc is arranged in the first rotating cavity; multiple cutting slide grooves are formed in the rotary splitting disc, cutting blocks which synchronously conduct protrusion and sliding in the corresponding cutting slide grooves are arranged in the machine body separately, and a jacking and pressing slide groove which is formed in the rotary splitting disc is positioned between every two cutting slide grooves. A control switch and other parts on an infusion pipe can be cut separately through sliding of the cutting blocks, the purpose of separate recovery is correspondingly achieved, and the recycling rate is further increased.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

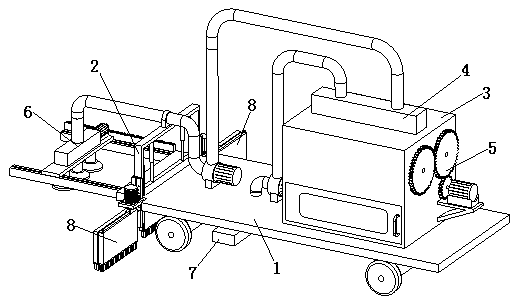

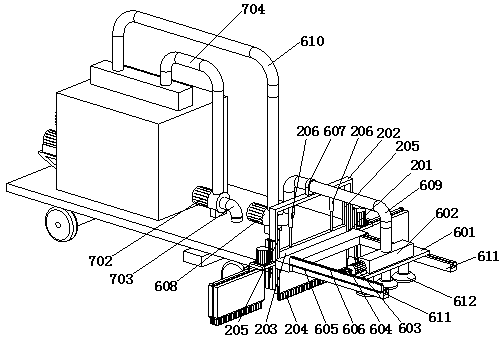

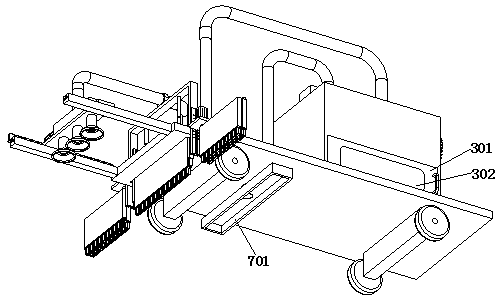

Road surface leaf automatic collecting equipment for environmental sanitation

ActiveCN110644404AEasy to reuseImprove cleaning efficiencyRoad cleaningGrain treatmentsAgricultural engineeringEnvironmental engineering

The invention provides road surface leaf automatic collecting equipment for environmental sanitation, and belongs to the technical field of environmental sanitation equipment. The road surface leaf automatic collecting equipment for environmental sanitation comprises a vehicle body, a first cleaning assembly, a collecting box, a discharging box, a crushing assembly, a first suction assembly, a second suction assembly and two second cleaning assemblies, wherein the first cleaning assembly is installed at the front end of the vehicle body; the two second cleaning assemblies are symmetrically arranged at the front end of the vehicle body; the collecting box is installed at the top and the bottom of the vehicle body; the discharging box is installed at the top of the collecting box, and the discharging box communicates with the collecting box; the crushing assembly is installed on the collecting box; the first suction assembly is installed at the front end of the vehicle body; and the second suction assembly is installed at the bottom of the vehicle body. According to the road surface leaf automatic collecting equipment for environmental sanitation, the problem that the cleaning rangecannot be adjusted, the cleaning efficiency is influenced, and the collected leaves cannot be treated in time so that the secondary utilization of the leaves can be extremely inconvenient is solved.

Owner:CHANGDE DINGCHENG LINYU AUTOMOTIVE PARTS

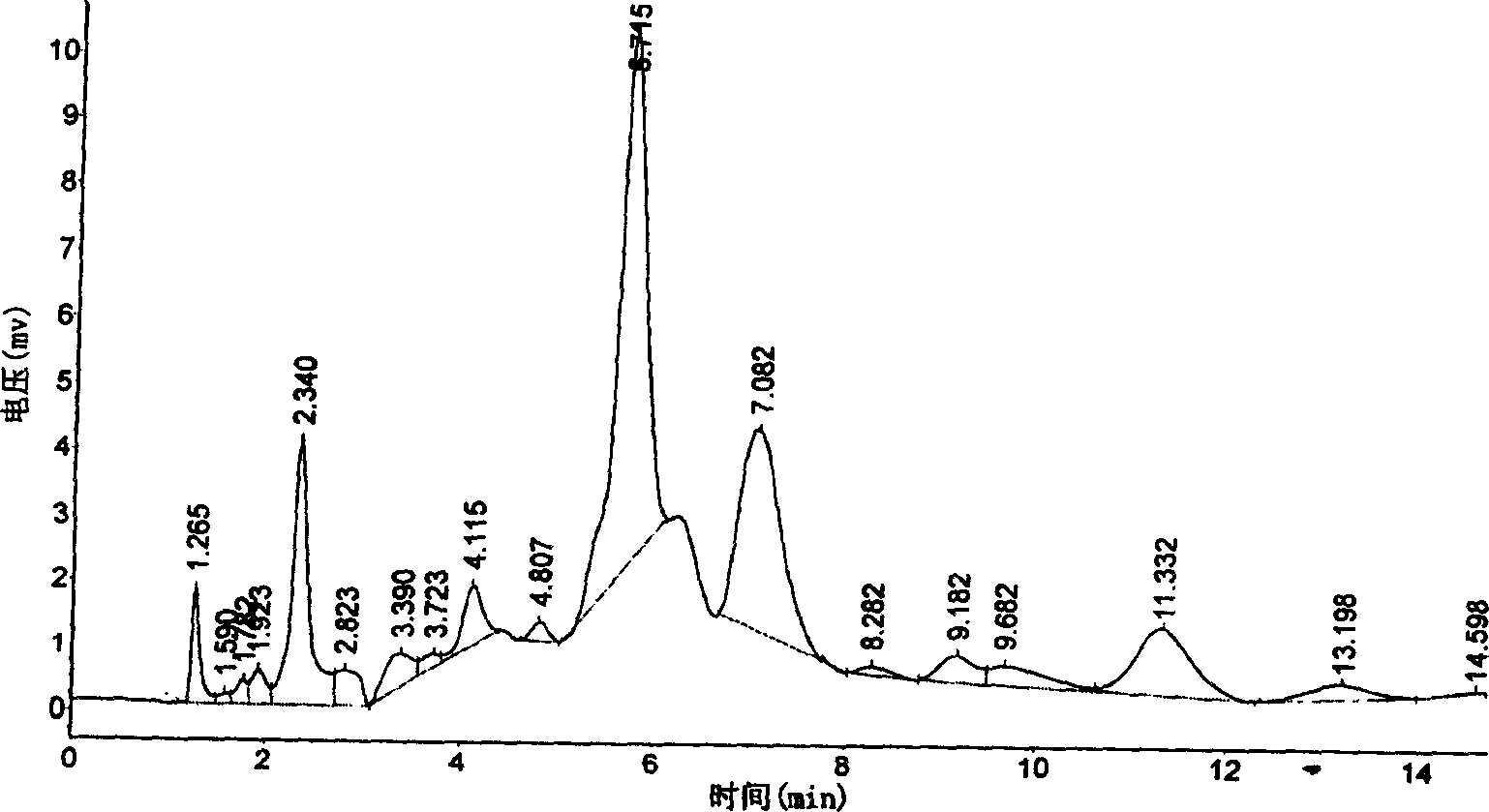

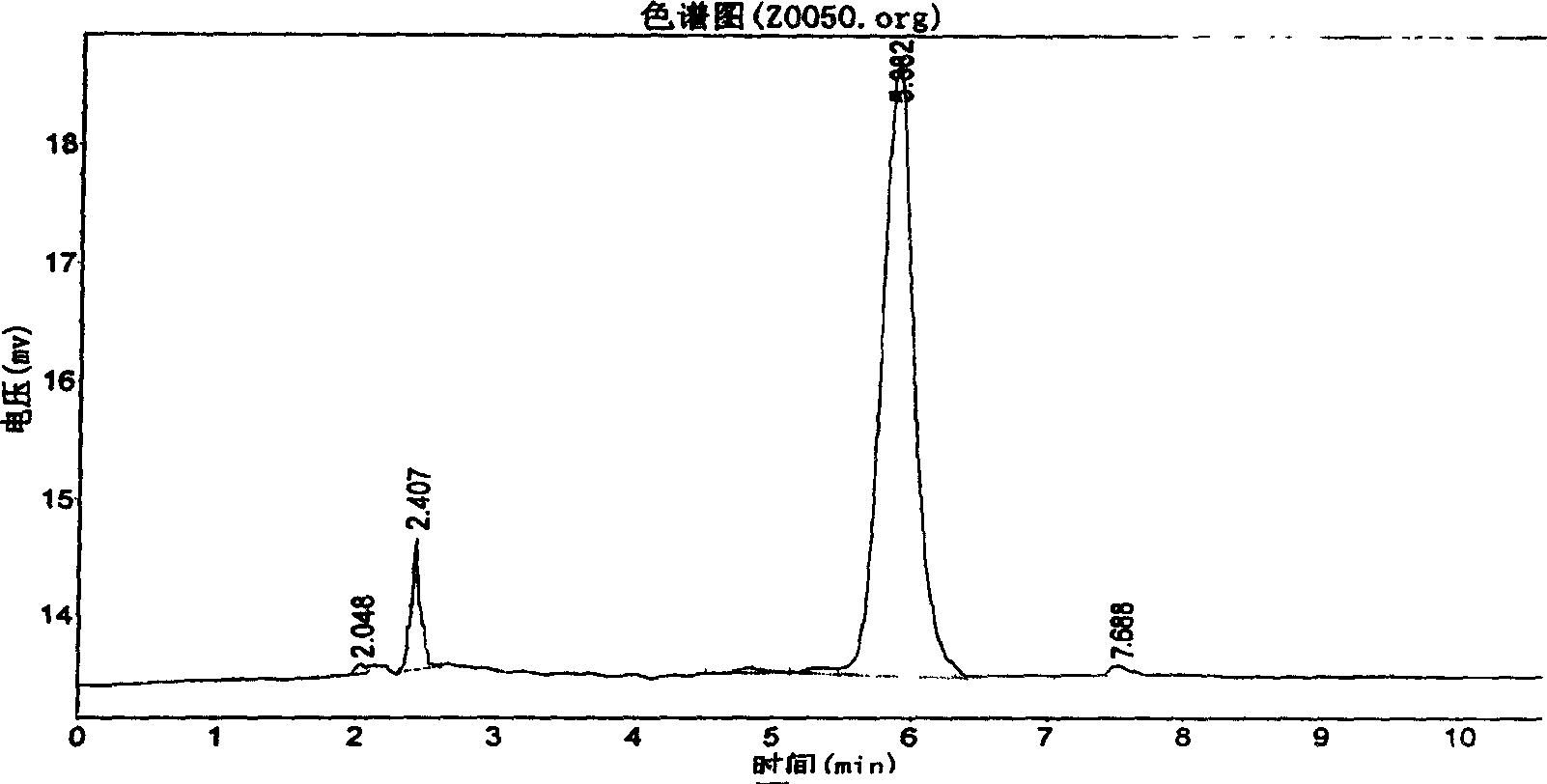

Method for extracting nimbin

InactiveCN1907986AOvercoming the disadvantage of lossReduce wasteOrganic chemistryOrganic solventExtraction methods

The invention discloses an extracting method of melicitrin, which comprises the following steps: first, immersing peeled melicit seed as 3-5 times organic solvent as melicitrin for 6-12 h; second, adopting high-speed blade to extract; filtering to obtain extract and filter cake; third, removing polarity organic solvent to obtain the product under 40 deg.c.

Owner:JIANGSU QIANGLIN BIO ENERGY

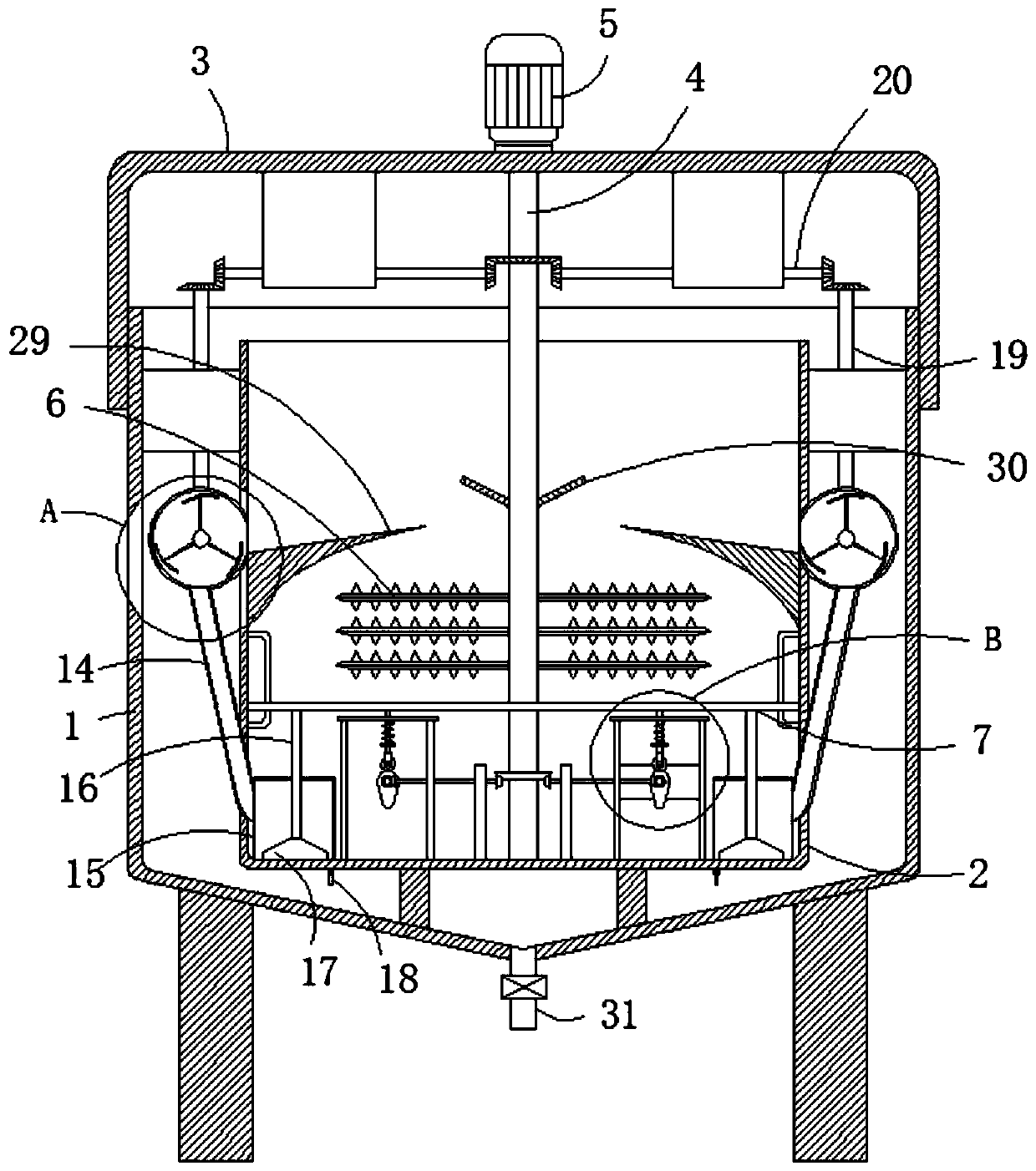

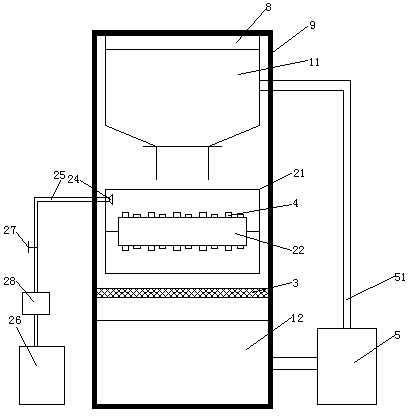

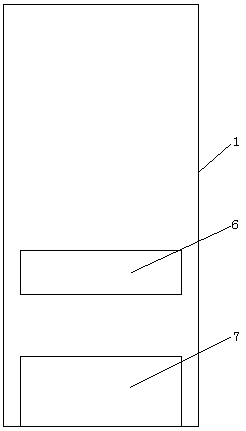

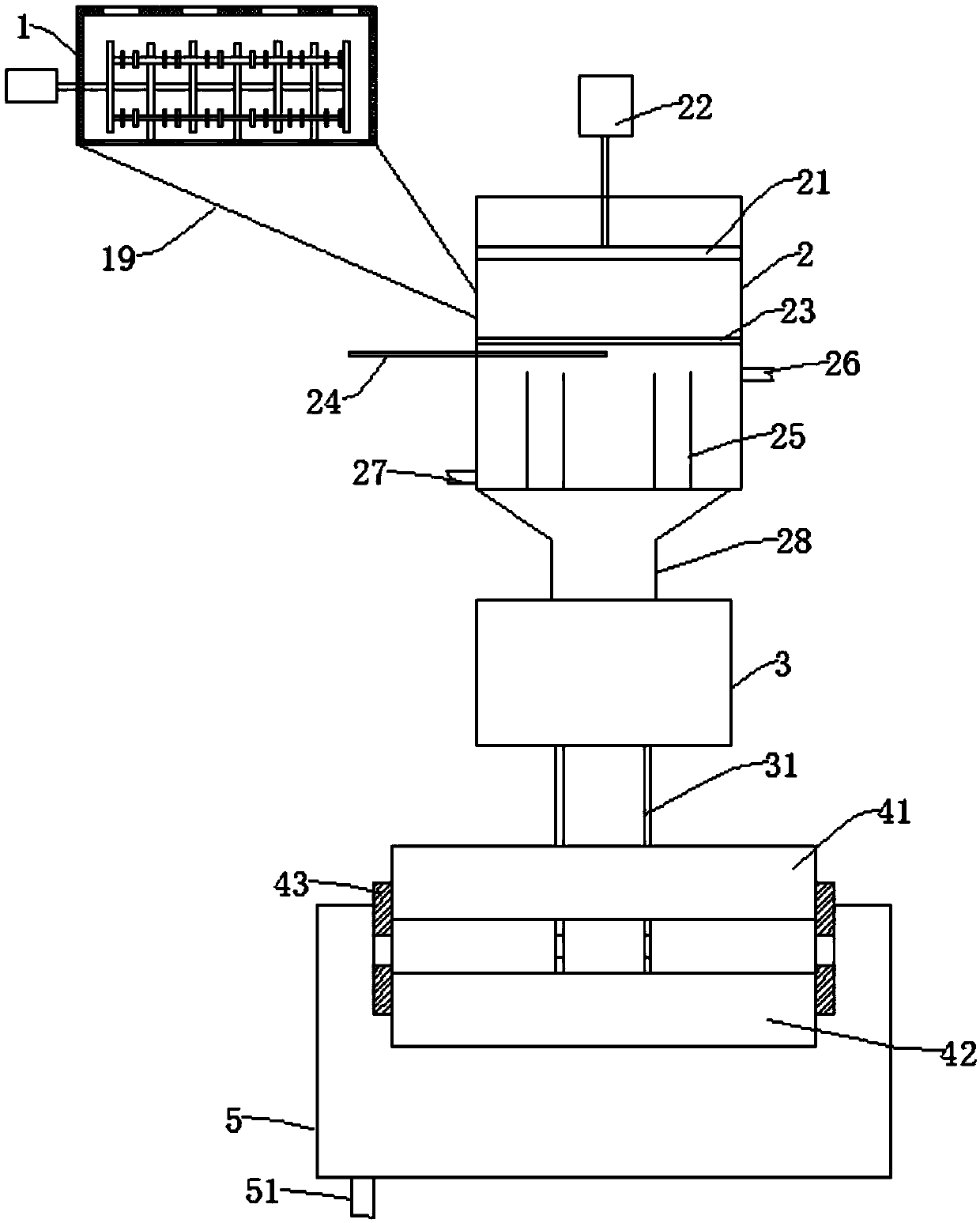

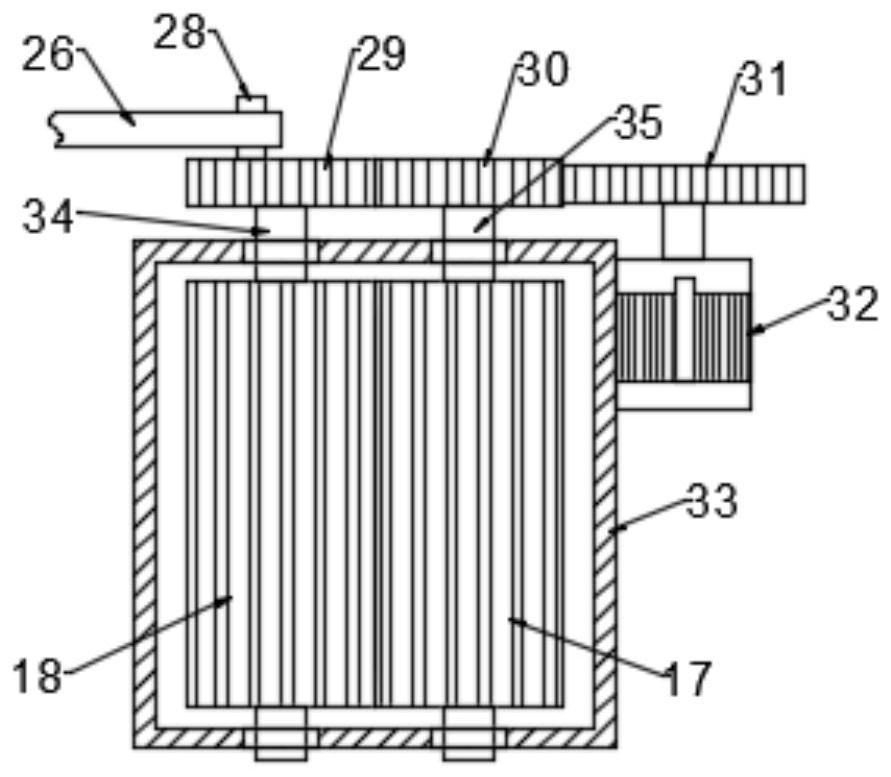

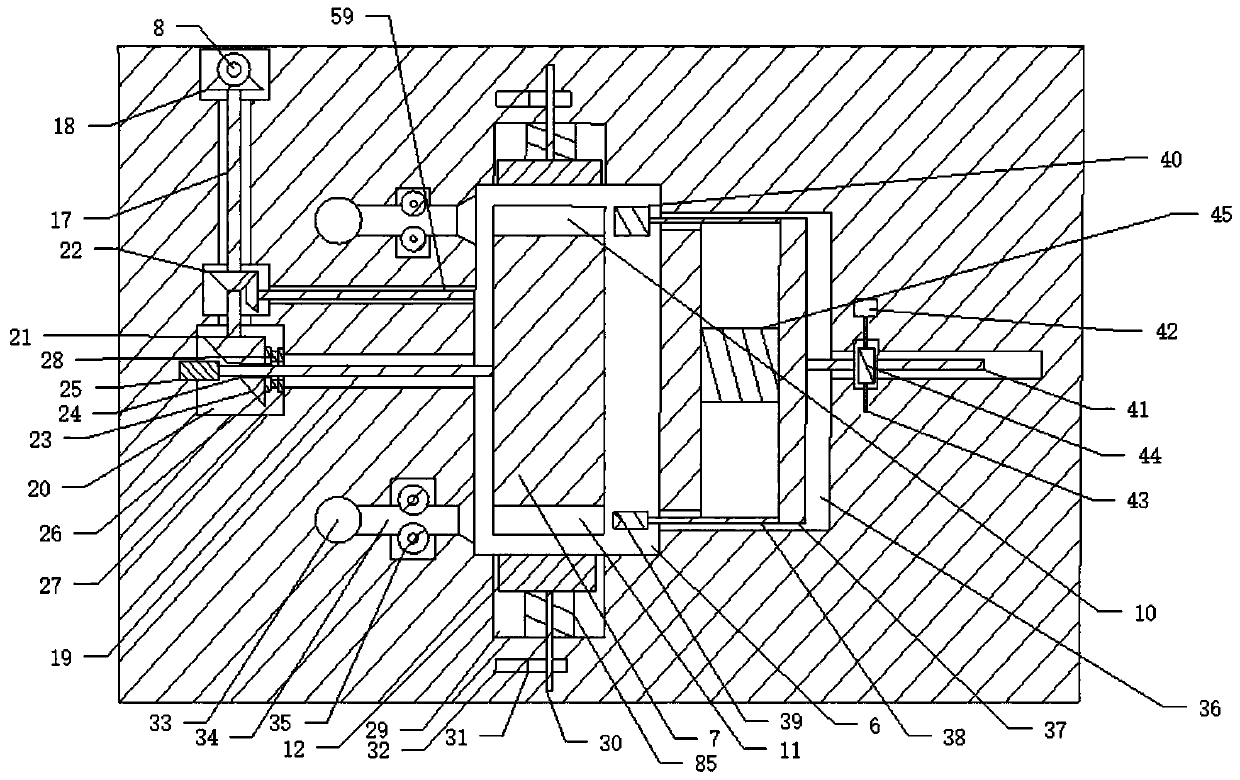

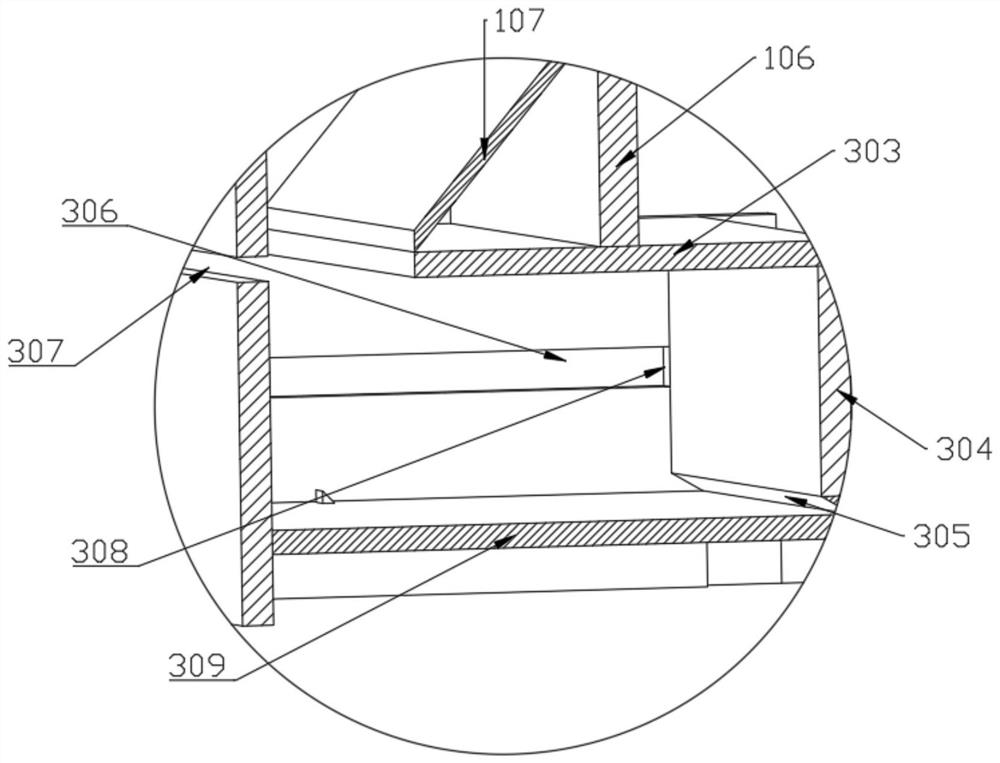

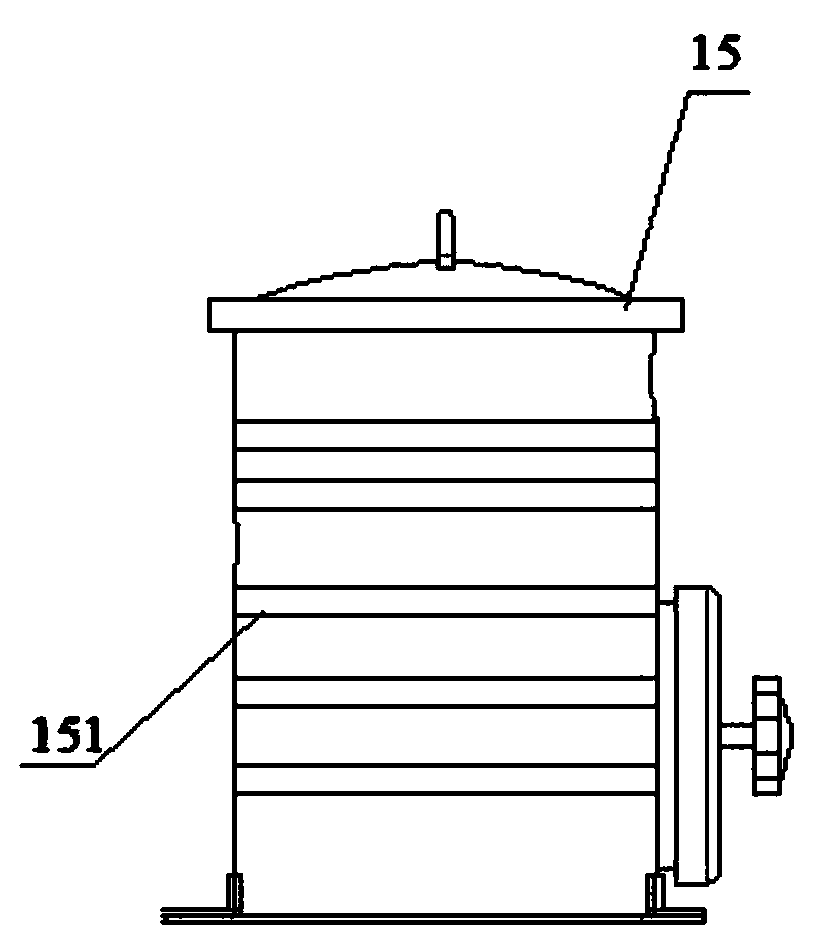

Multiple high-efficiency pulverizing device for tea leaves and pulverizing method

ActiveCN109530060ACrushed fullyImprove crushing efficiencyPre-extraction tea treatmentCocoaEngineeringMechanical engineering

The invention provides a multiple high-efficiency pulverizing device for tea leaves. The multiple high-efficiency pulverizing device comprises a first pulverizing box, a second pulverizing box, a drying box, a grinding mechanism and a material gathering box; a plurality of first partitions are arranged at the bottom of the first pulverizing box at intervals, the first partitions divide an internalspace of the first pulverizing box into a plurality of first cavities, each first cavity is internally vertically provided with a rotary cutter disc, a rotating rod sequentially passes through the rotary cutter discs and the first partitions and is connected with a motor rotating shaft located outside the first pulverizing box, the two ends of each of a plurality of connecting rods are connectedwith the rotary cutter disc on the outermost side, a plurality of hammer sheets are arranged at the positions, located in any first cavity, of the connecting rods, first discharging ports are arrangedat the positions, corresponding to the first cavities, of the bottom of the first pulverizing box, the bottom of the first pulverizing box communicates with a first discharging pipe; the drying box is located below the second pulverizing box, and a third discharging pipe is arranged at the lower end of the drying box; and the lower end of the material gathering box is provided with a second discharging port. By means of the multiple high-efficiency pulverizing device for the tea leaves, multi-stage pulverization and grinding on the tea leaves can be carried out, so that the tea leaves are pulverized more sufficiently, and the pulverization efficiency is high.

Owner:胡依芸 +1

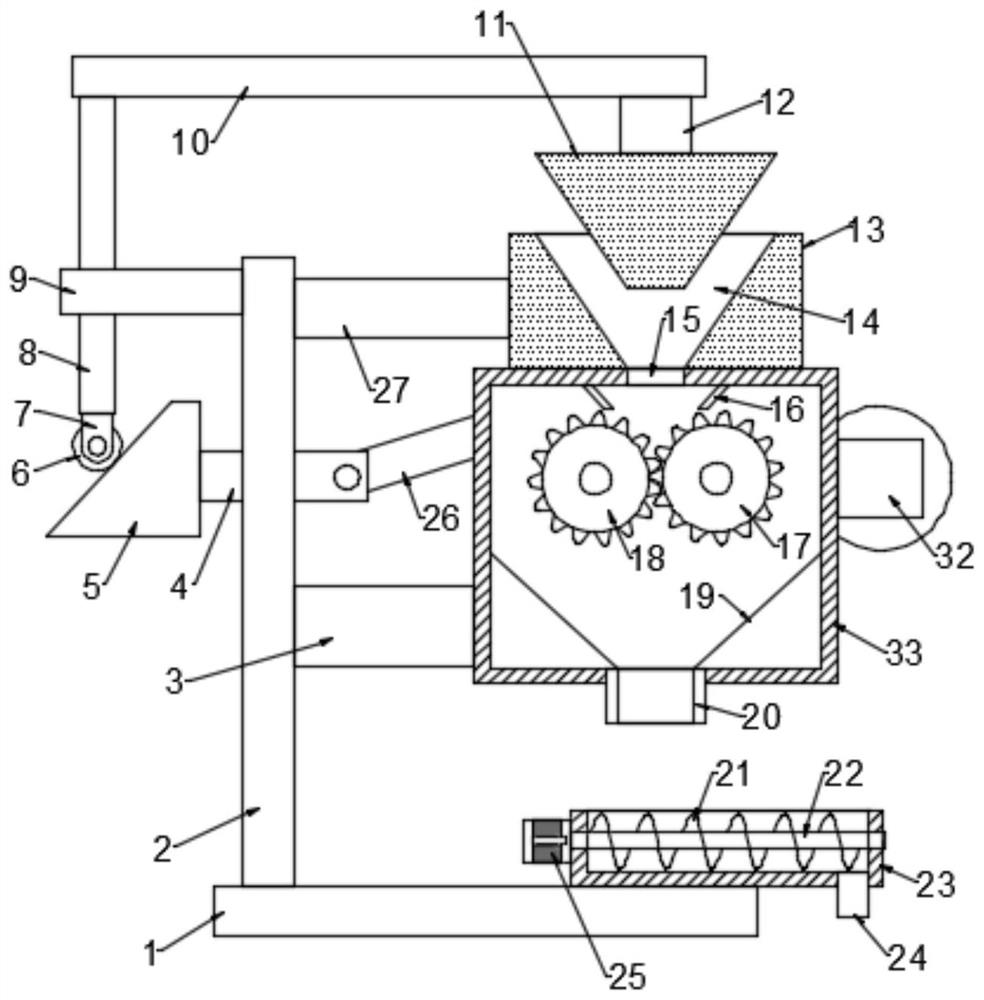

Multi-stage crushing device for building processing

InactiveCN112473973AAchieve the purpose of crushingRealization of multi-stage crushingGrain treatmentsArchitectural engineeringElectric machinery

The invention is applicable to the technical field of crushing devices, and provides a multi-stage crushing device for building processing. The device comprises a bottom plate, a first supporting plate and a second supporting plate are arranged on a vertical plate, a crushing box is arranged on the first supporting plate, a crushing seat is arranged on the second supporting plate, the crushing seat is arranged on the crushing box, a crushing groove is formed in the crushing seat, a discharging port communicating with the crushing groove is formed in the top wall of the crushing box, a discharging pipe is connected to the bottom wall of the crushing box, a hammering assembly is arranged on the crushing seat, and a crushing assembly is arranged in the crushing box. According to the multi-stage crushing device for building processing, materials in the crushing groove are continuously beaten through a conical pressing hammer to be primarily crushed, and a first crushing roller and a secondcrushing roller are driven by a second motor to operate to crush the primarily crushed materials to achieve further crushing, so that multi-stage crushing is achieved, the crushing efficiency is improved, the crushing effect is good, and the crushed materials are discharged from the discharging pipe.

Owner:李海英

Novel grinding and crushing equipment always dipped in ultralow-temperature liquid nitrogen environment

PendingCN108212421AIncreased durabilityAchieve the purpose of crushingGrain treatmentsFreezing chamberEngineering

The invention relates to novel grinding and crushing equipment always dipped in a ultralow-temperature liquid nitrogen environment. The equipment comprises a freezing chamber, a freezing cover and human-computer interaction equipment; the freezing cover is rotationally connected to the freezing chamber; an insulation box with liquid nitrogen is arranged in the freezing chamber; a grinding mountingcylinder is arranged on the inner side surface of the freezing cover; a grinding tank is arranged in the grinding mounting cylinder; a steel collider is arranged in the grinding tank; a grinding mounting cylinder cover is arranged on the grinding mounting cylinder; an electromagnetic coil is arranged on the peripheral side of the grinding tank; and the electromagnetic coil is connected with the human-computer interaction equipment. The equipment can completely extract needed effective components in ultralow-temperature state, enables substance characteristics to change under the ultralow-temperature environment to achieve the crushing purpose within the shortest time of ten seconds, and improves the material durability; and in addition, due to use of ultralow-temperature characteristics of the liquid nitrogen, the grinding and crushing efficiency is greatly improved.

Owner:TAHE ELECTROMECHANICAL TECH SHANGHAI

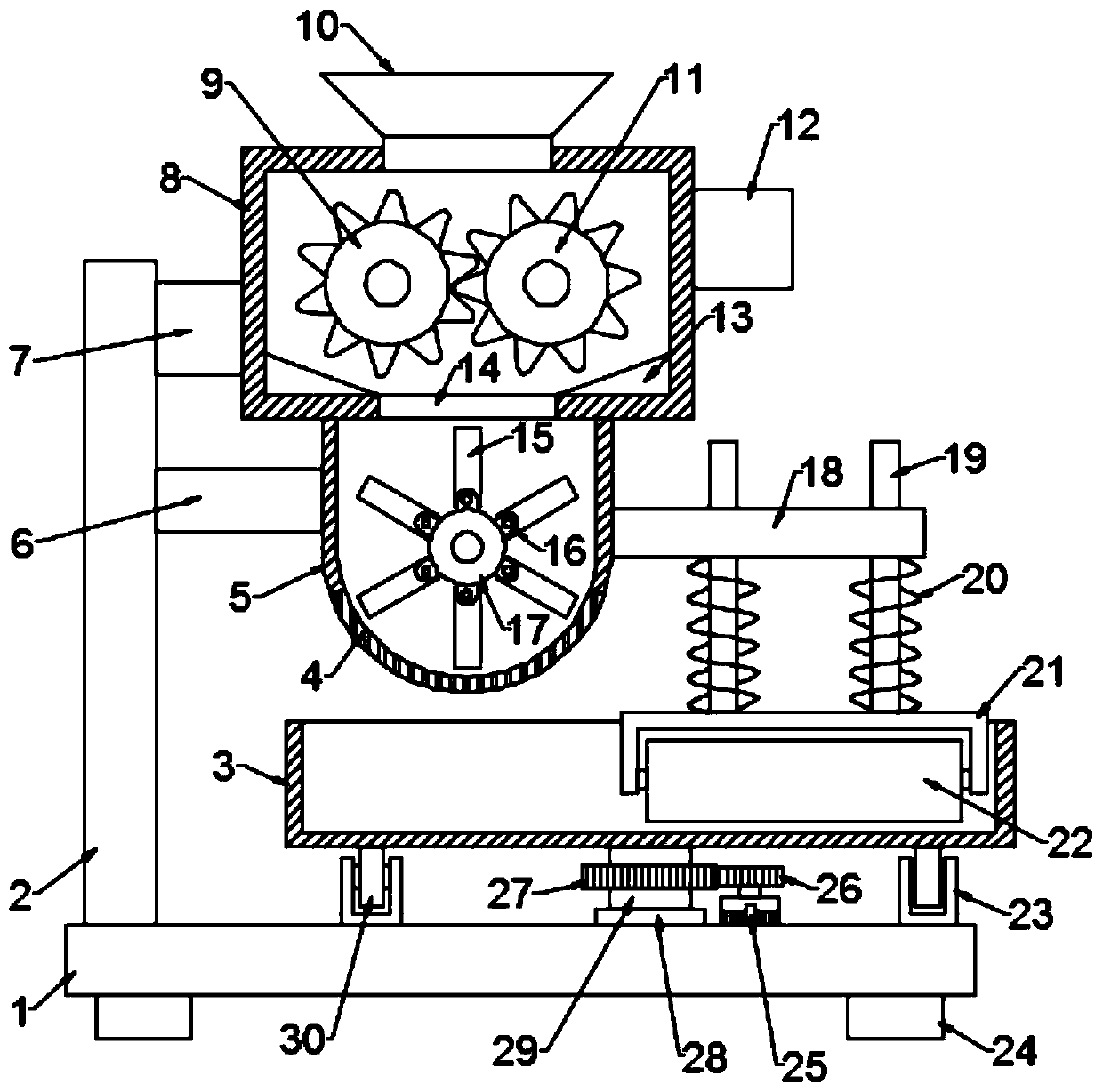

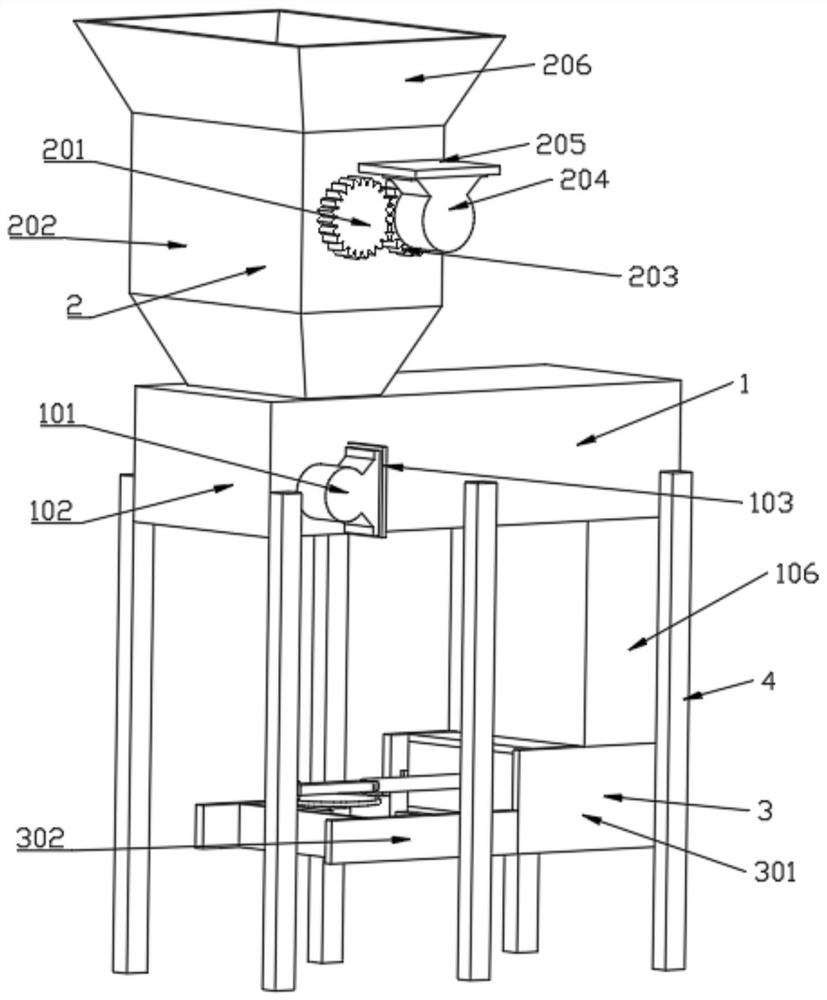

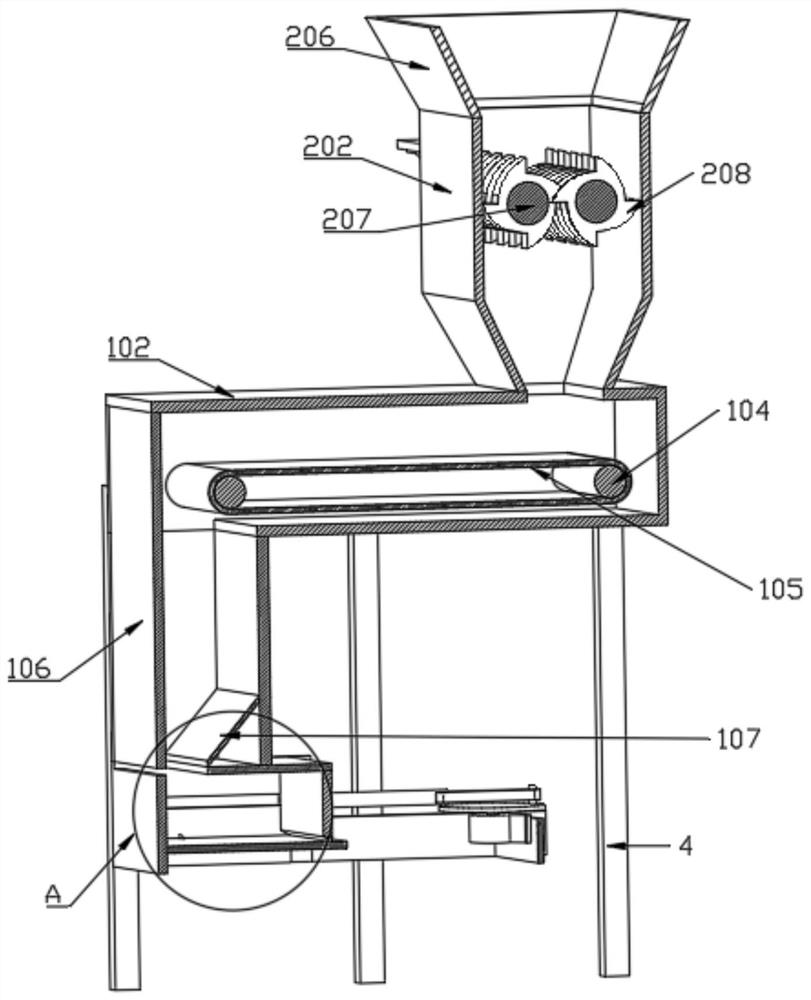

Graded crushing device for corn processing

InactiveCN111097573AAchieve the purpose of crushingImprove crushing efficiencyGrain treatmentsAgricultural engineeringStructural engineering

The invention relates to the technical field of corn processing, and particularly relates to a graded crushing device for corn processing. The graded crushing device comprises a bottom plate, whereinan upper crushing box is arranged on the upper side of the bottom plate; a lower crushing box is mounted at the bottom of the upper crushing box; a feeding hopper is mounted on the top wall of the upper crushing box; a blanking opening is formed in the bottom wall of the upper crushing box; a discharging hole is formed in the bottom wall of the lower crushing box; a first crushing roller and a second crushing roller which are matched with each other are arranged in the upper crushing box; the first crushing roller and the second crushing roller are connected with rotating shafts which are connected with side wall bearings of the upper crushing box; a driving assembly which is used for driving the first crushing roller and the second crushing roller to operate is arranged on the upper crushing box; a crushing assembly which is used for improving the crushing effect is arranged in the lower crushing box; and a grinding mechanism is arranged on the lower side of the lower crushing box. According to the graded crushing device for corn processing, a graded crushing mode is adopted, so that the crushing efficiency is improved, and the crushing effect is also improved.

Owner:应元芬

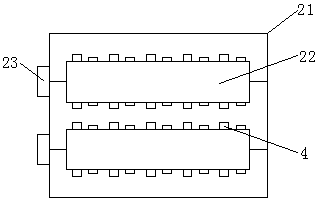

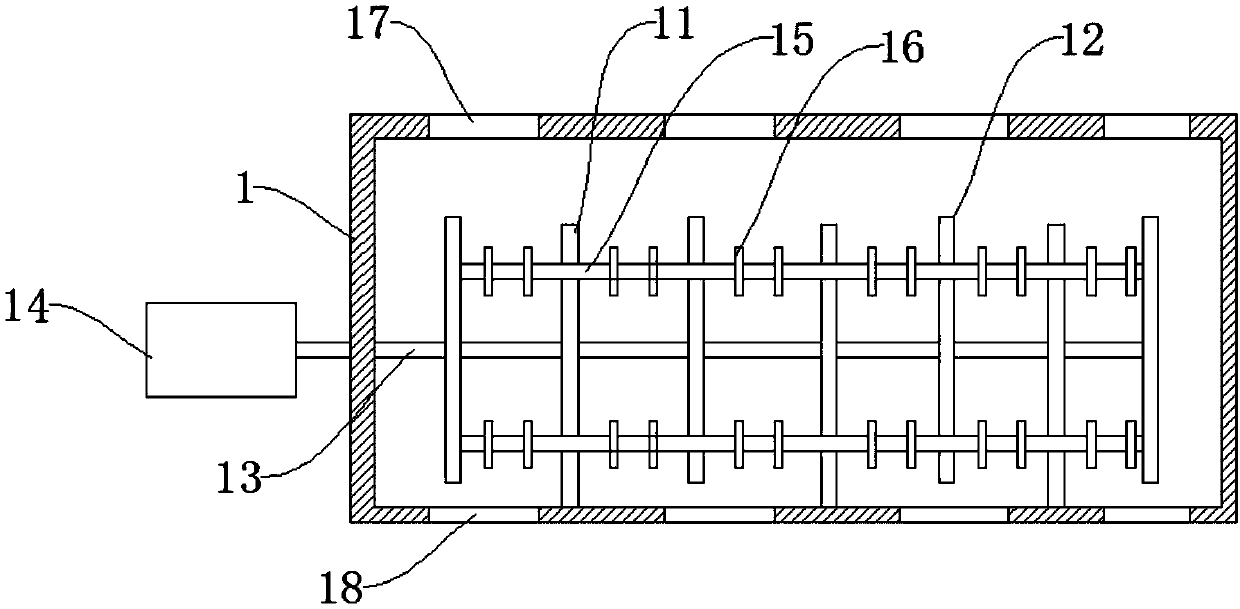

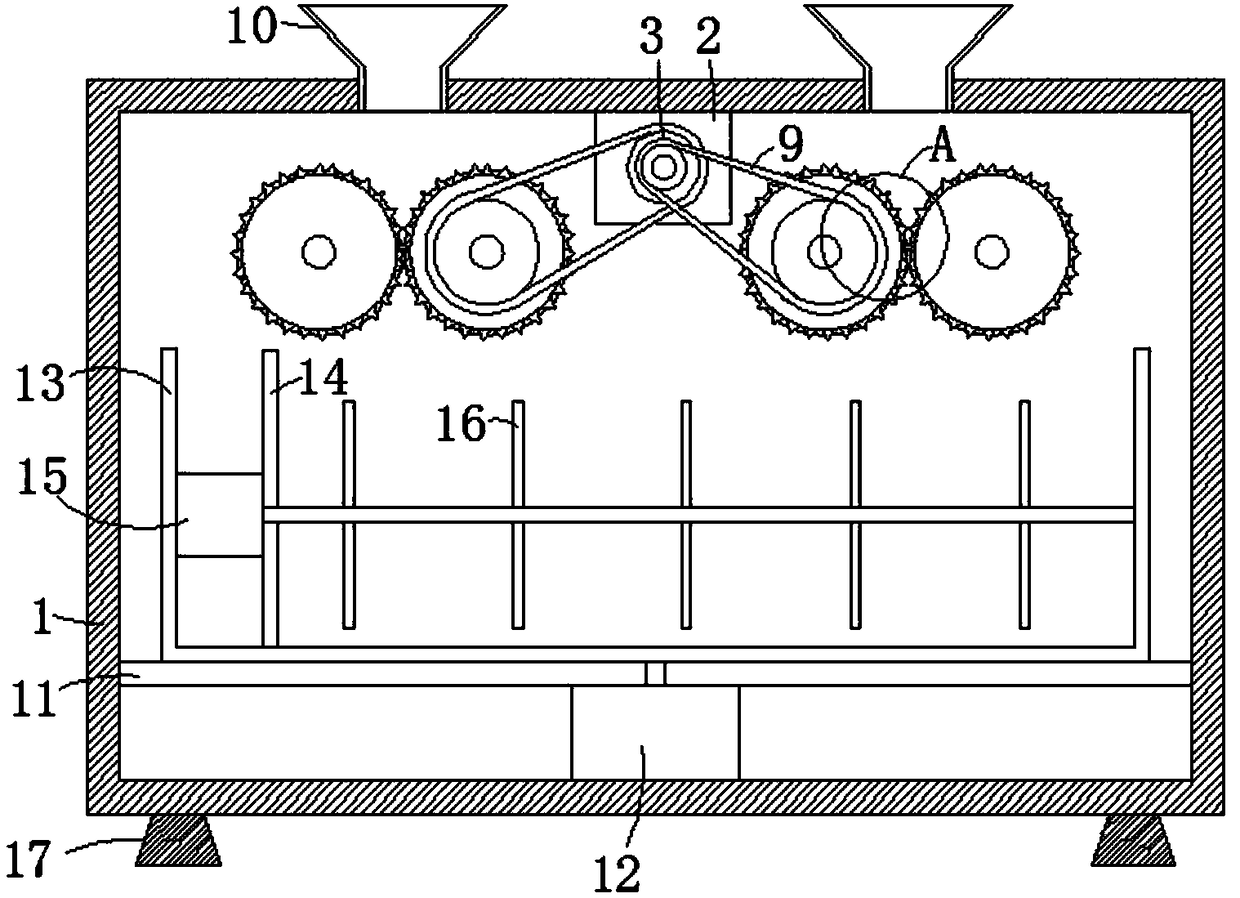

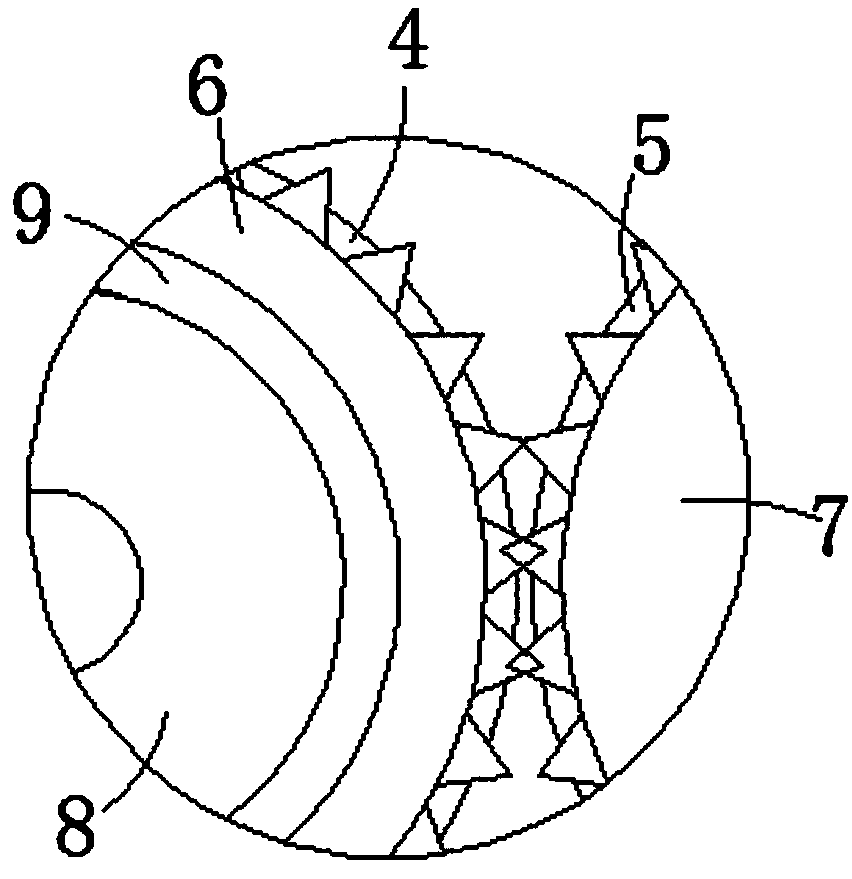

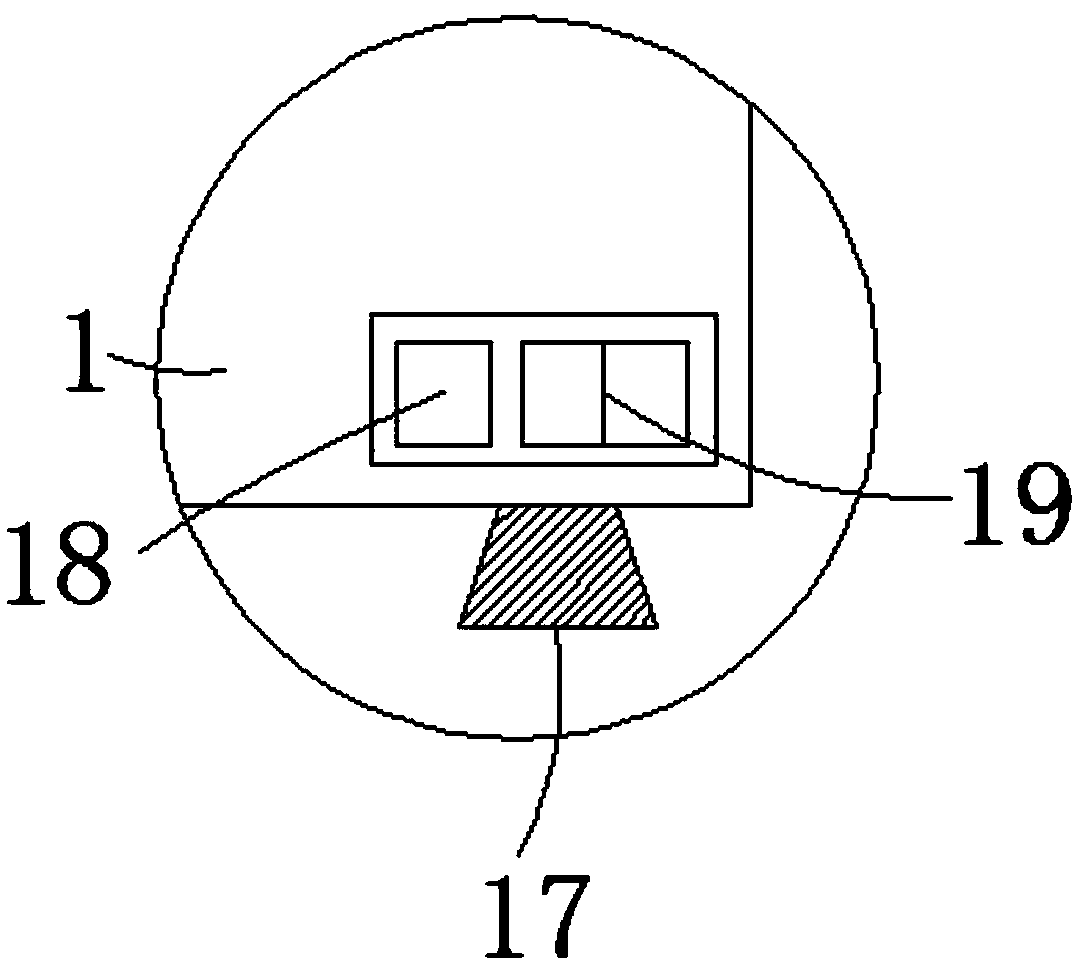

Amino acid powder mixing equipment

InactiveCN108144499AAchieve the purpose of stirringAchieve the purpose of crushingRotating receptacle mixersTransportation and packagingBiochemical engineeringAmino acid

The invention discloses amino acid powder mixing equipment, which comprises a box body. The amino acid powder mixing equipment is characterized in that the lower surface of the top plate of the box body is fixedly connected with a first motor; the output shaft of the first motor is fixedly connected with a first belt pulley; the inner side of the box body is provided with a plurality of pulverizing units; each pulverizing unit comprises a driving pulverizing roller and a driven pulverizing roller, wherein the driving pulverizing roller and the driven pulverizing roller are both rotatably connected into the box body; the driving pulverizing roller is fixedly connected with a rotation driving gear; the driven pulverizing roller is fixedly connected with a driven gear; the driven gear and thedriving gear are meshed; the driving gear is fixedly provided with a second belt pulley; the second belt pulley is connected with the first belt pulley through a belt; the upper side of the driving gear is provided with a feeding funnel. According to the amino acid powder mixing equipment, a purpose of massive amino acid pulverization is realized, meanwhile, different amino acids are mixed, and therefore, the amino acid powder mixing equipment is worth popularizing.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

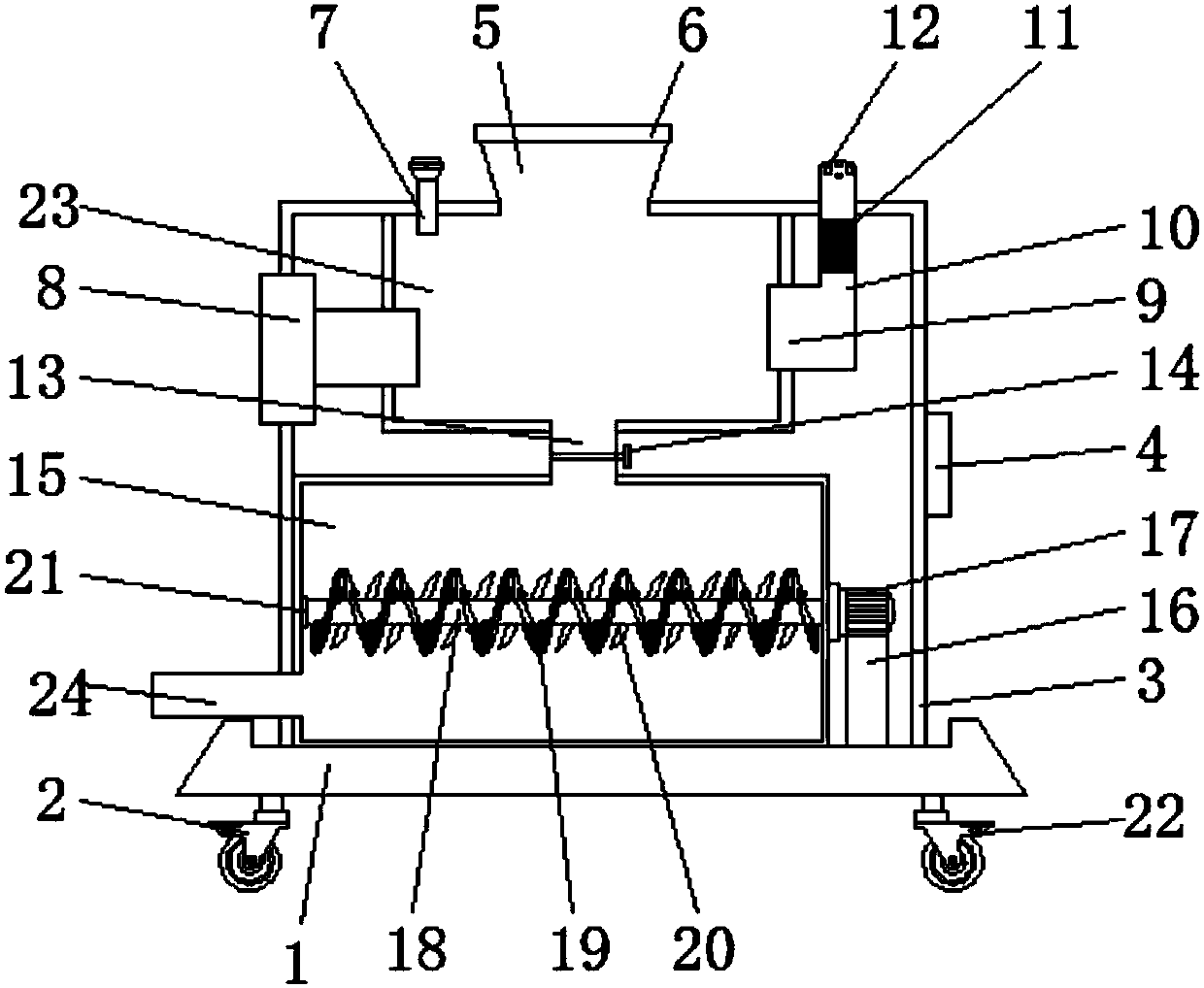

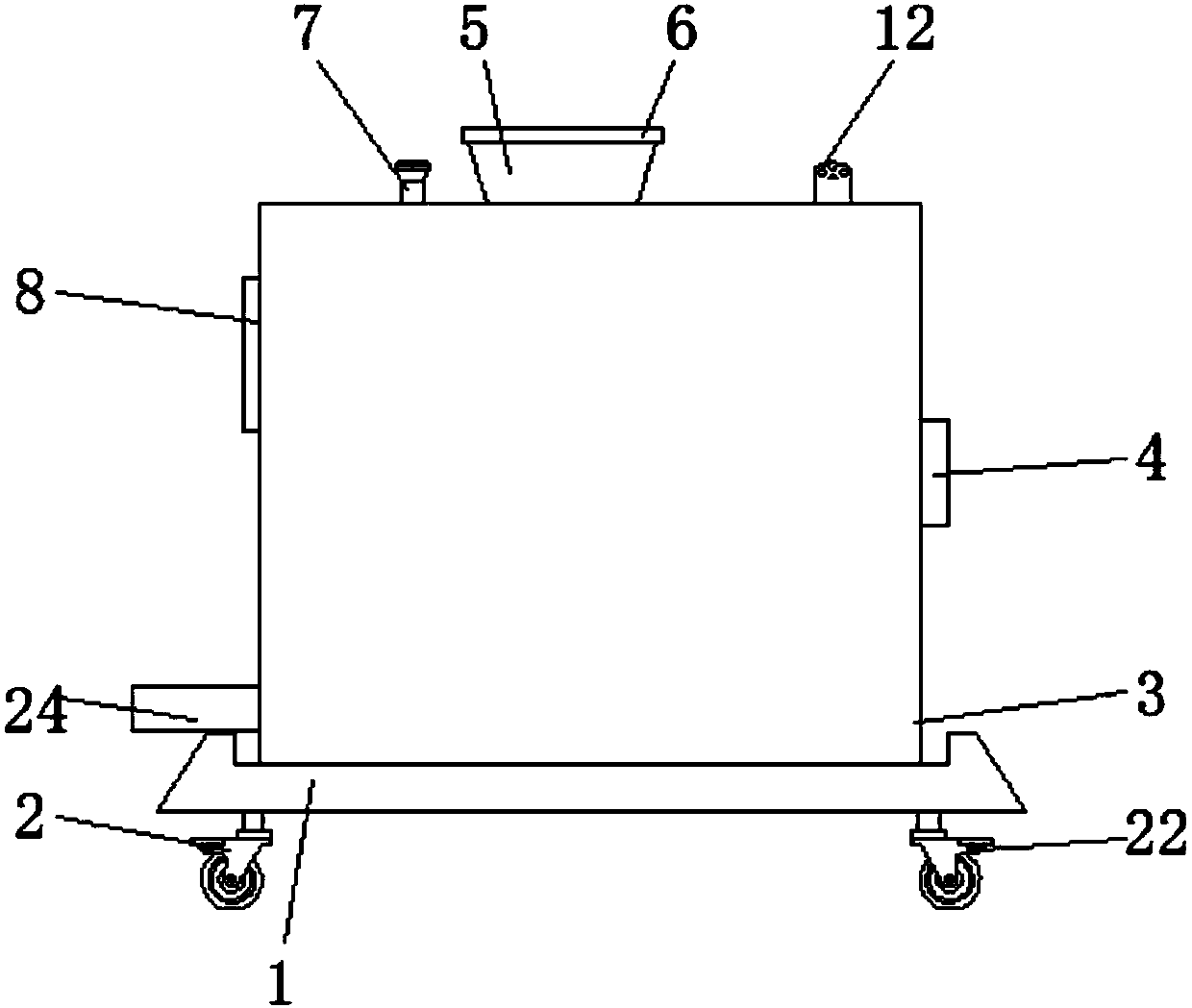

Garbage crushing mechanical equipment special for garbage yard

PendingCN107583938AEasy to moveGuaranteed tightnessSolid waste disposalDrying gas arrangementsWaste dumpDisinfectant

The invention provides garbage crushing mechanical equipment special for a garbage yard. The garbage crushing mechanical equipment comprises a base, an air heater, a crushing chamber and a mixing chamber, wherein truckles are arranged at four corners of the top end of the base; a shell is arranged at the top end of the base; a controller is mounted on the right wall of the shell; a material feeding hopper is arranged at the top of the shell; an upper cover is arranged at the top end of the material feeding hopper; a liquid feeding pipe is also arranged at the top of the shell; the liquid feeding pipe is arranged on the left side of the material feeding hopper; the mixing chamber is formed inside the shell; the air heater is arranged on the left wall of the shell; the right end of the air heater extends into the mixing chamber. Garbage can be directly poured into the mixing chamber through the material feeding hopper on the device, and a disinfectant can be poured into the mixing chamber through the liquid feeding pipe, so that the garbage can be fully disinfected in the mixing chamber to further enhance the garbage disinfection effect, and the arrangement of the upper cover keeps the airtightness of the mixing chamber.

Owner:沈燕

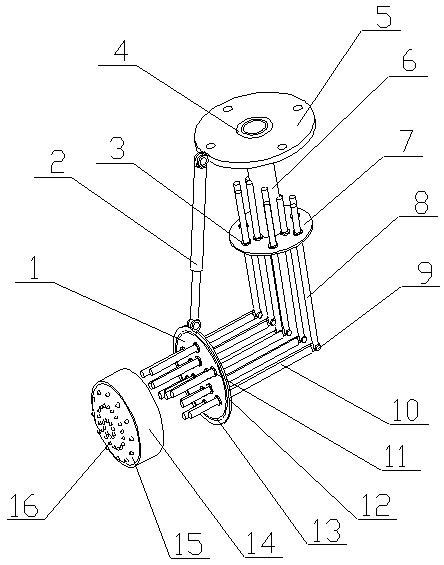

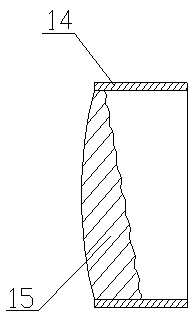

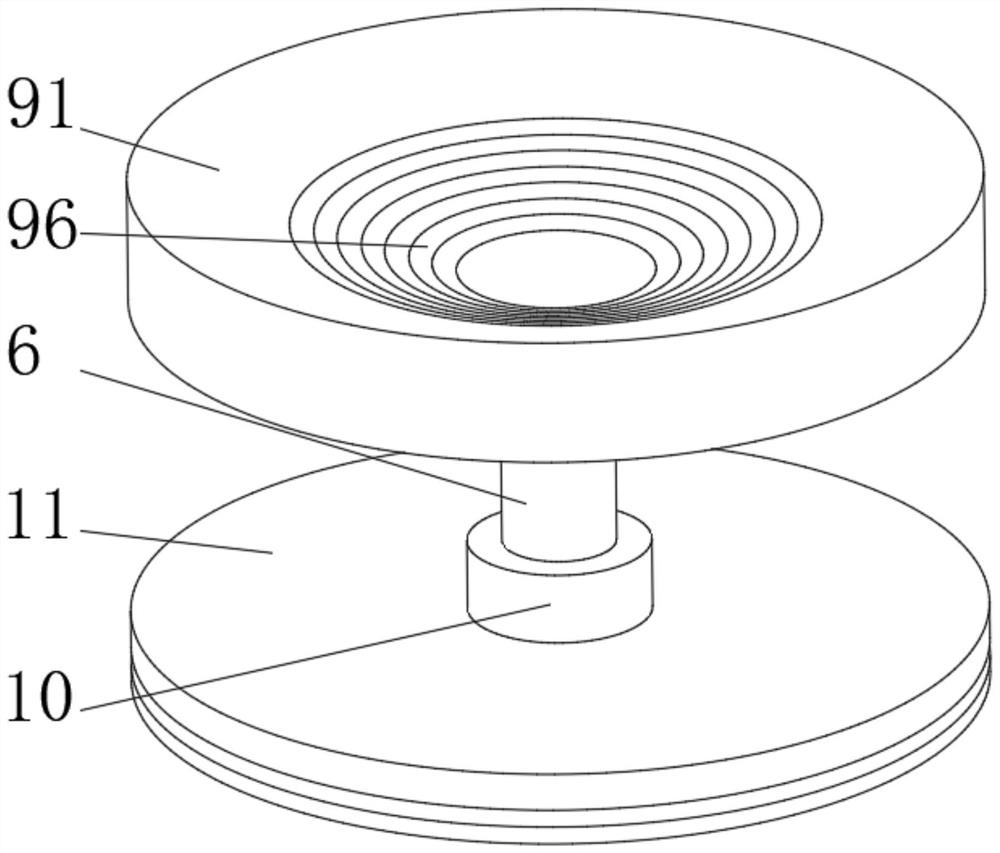

Beef steak processing device of food processing

The invention relates to a beef steak processing device of food processing, and discloses a beef fiber pulverizing device through which multipoint pressing is performed on the surface of beef steaks through the cooperation of driven rods and a silica gel cushion and through which multi-direction pressing is performed through the expanding and contracting of an oil cylinder. Through the adoption ofthe beef steak processing device disclosed by the invention, extruding of juice in the beef steaks can be reduced, the edible mouth feel of the beef steaks is improved, the compaction degree of the beef steaks is reduced, and the effect of pulverizing fibers in the beef steaks is improved. The beef steak processing device is characterized in that one end of a rotating barrel is arranged in the middle part of a fixing plate through a fixing bearing; a plurality of mounting holes are formed in the fixing plate; the fixing plate adopts a circular plate structure; the middle part of a driving disk is arranged at the other end of the rotating barrel; the driving disk adopts a circular plate structure, and is manufactured from rigid materials; one end of the oil cylinder is arranged on the outer side of the fixing plate in a hinging manner; the outer side of the fixing plate is arranged at one end of a piston rod on the oil cylinder in a hinging manner; and a driven disk is arranged in thefixing ring through a bearing bush, adopts a circular plate structure and is manufactured from rigid materials.

Owner:广西都安嘉豪实业有限公司

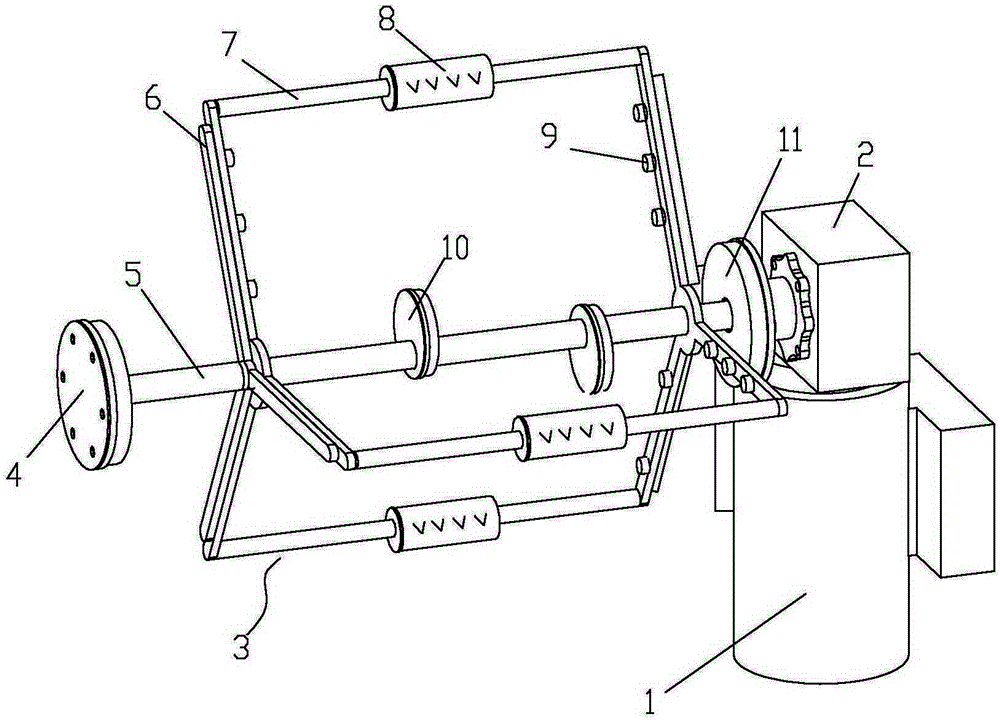

Rotation stirring rack

ActiveCN105233747ASimple structureAchieve the purpose of crushingRotary stirring mixersSolid waste disposalEngineeringCam

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

Crushing and screening device for biological medicinal materials

InactiveCN108176451ACrushing precisionAchieve the purpose of crushingGrain treatmentsScreening effectFiltration

The invention discloses a crushing and screening device for biological medicinal materials. The crushing and screening device comprises a base, the top of the base is fixedly connected with a supporting rack, the top of the supporting rack is fixedly connected with a support platform, the inner side of the support platform is fixedly connected with a crushing box, and one side of the top portion of the support platform is fixedly connected with a first motor; an output shaft of the first motor is rotatably connected with a first belt pulley, the first belt pulley is rotatably connected with asecond belt pulley through a belt, the second belt pulley is rotatably connected with a first crushing wheel through a rotating shaft, and the first belt pulley is connected with a second crushing wheel through a rotating shaft; and the invention relates to the technical field of biological medicine. The crushing and screening device for the biological medicinal materials solves the problem of incomplete crushing, uneven particle sizes, low filtration efficiency and low precision at the same time, and is high in crushing precision, good in crushing effect and screening effect, and is convenient to screen and produce for enterprises, thus improving the production efficiency.

Owner:佛山杰致信息科技有限公司

Water surface garbage cleaning device

InactiveCN113463597ATo achieve the purpose of collectionReduce work intensityWater cleaningFiltration separationWater flowOutfall

The invention discloses a water surface garbage cleaning device, and relates to the technical field of environmental protection. The water surface garbage cleaning device comprises a shell, wherein a filter screen is fixedly connected to the bottom of the shell; a collecting frame is fixedly connected to the side, away from the shell, of the filter screen; foam floating plates are evenly installed at the position, away from the collecting frame, of the outer side of the shell; a telescopic air cylinder is installed on the outer side of the bottom of the collecting frame; a piston rod of the telescopic air cylinder is fixedly connected with a telescopic rod; the end, away from the telescopic air cylinder, of the telescopic rod penetrates the collecting frame to be fixedly connected with a fixing block; water outlets are evenly formed in the position, close to the telescopic air cylinder, of the bottom of the collecting frame; a material suction device is fixedly connected to the inner wall of the shell; and a rubber sealing ring is installed at the position, away from the fixing block, of the outer side of the telescopic rod. According to the water surface garbage cleaning device, the aim of collecting floating objects on the water flow surface is achieved, the work intensity of environmental protection persons is reduced, and the device is suitable for small river water areas, and is flexible and light.

Owner:何钧健

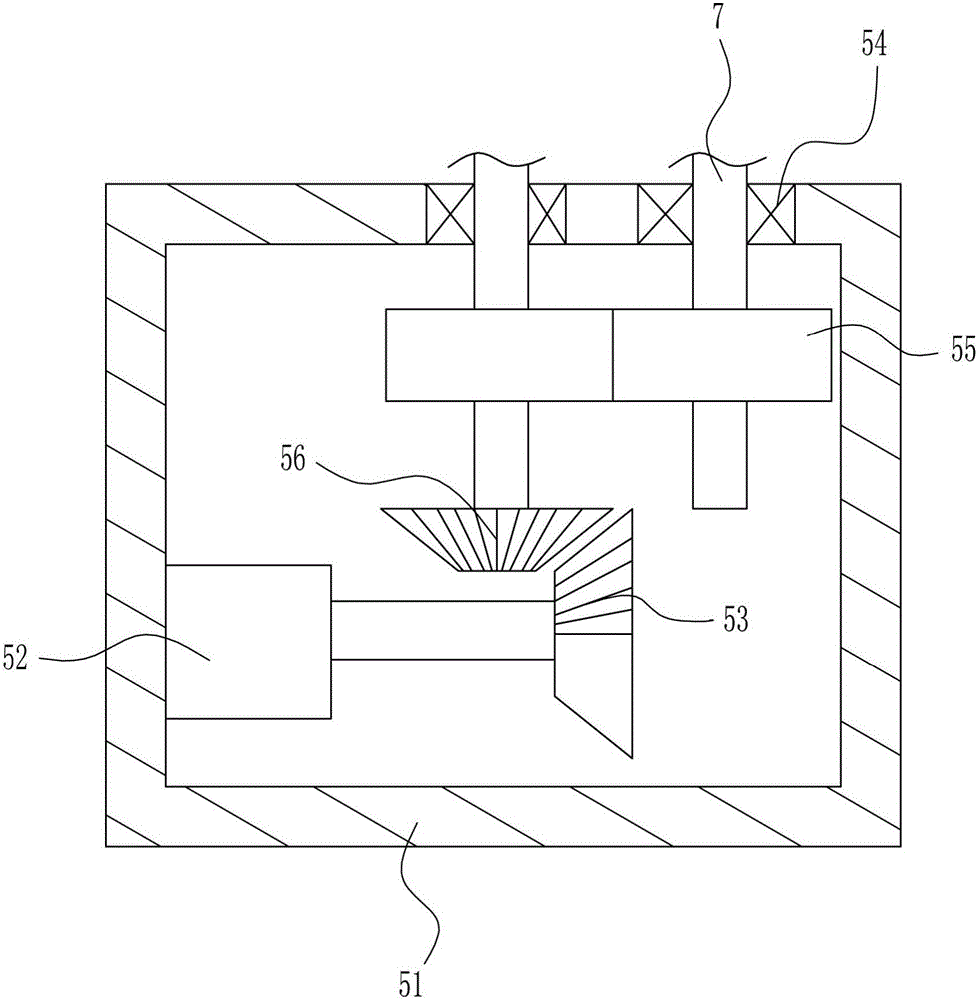

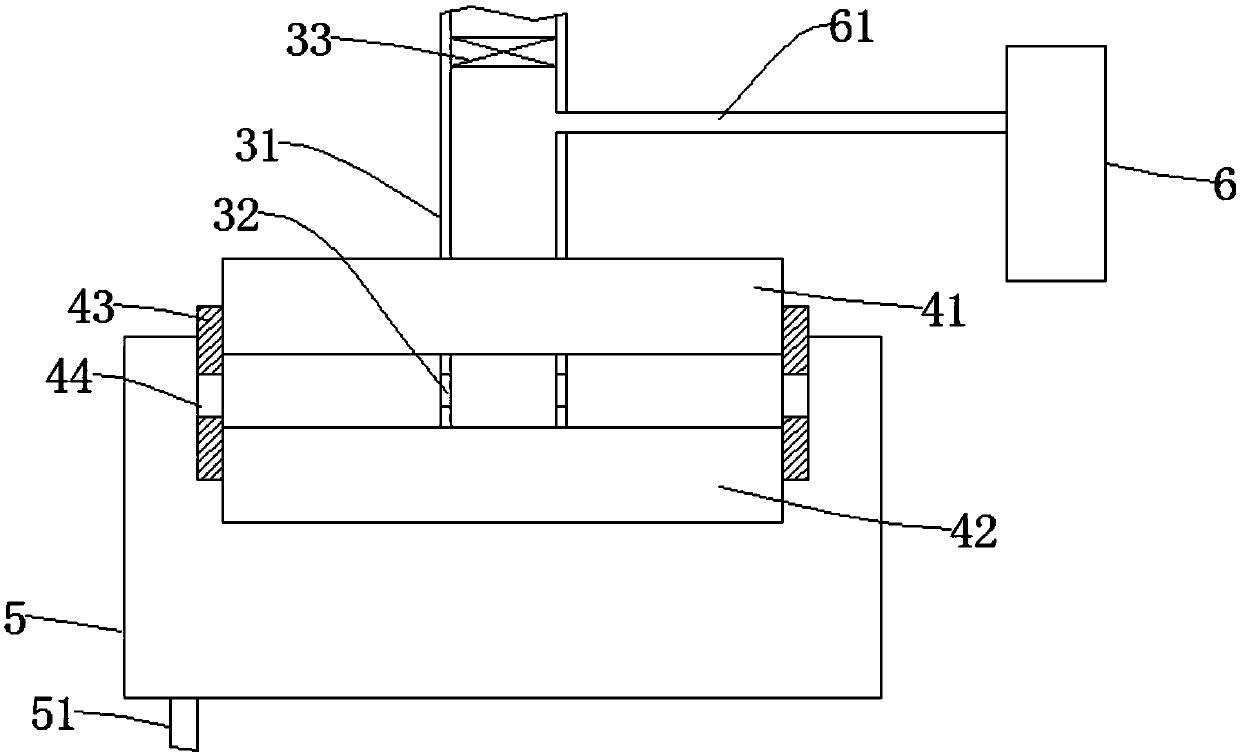

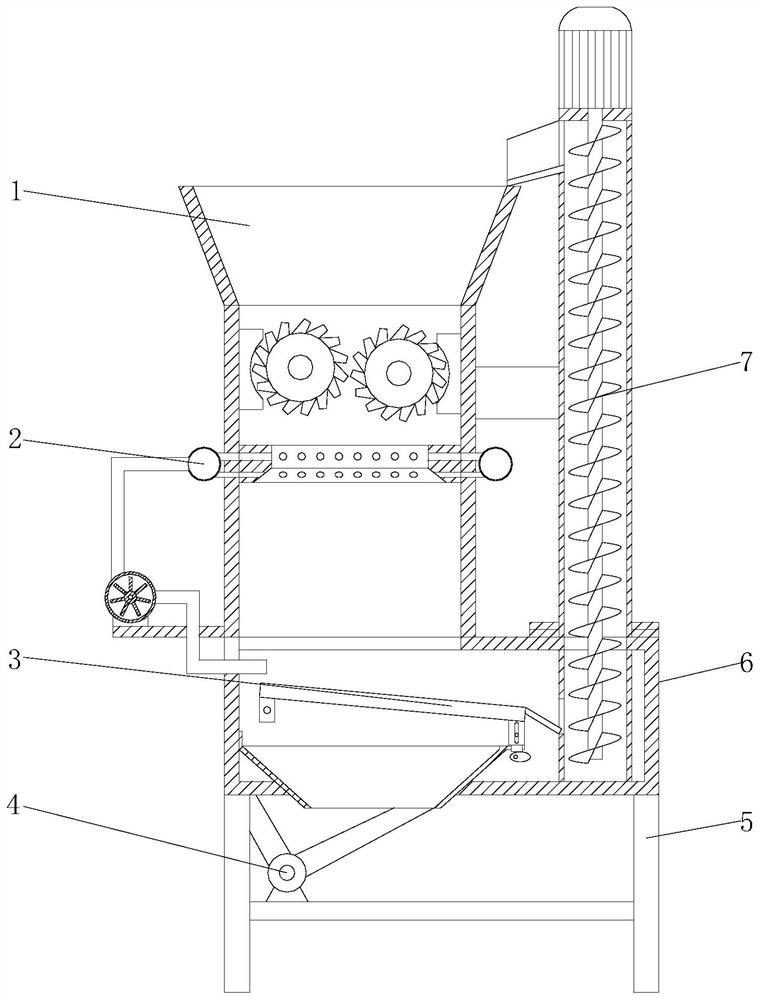

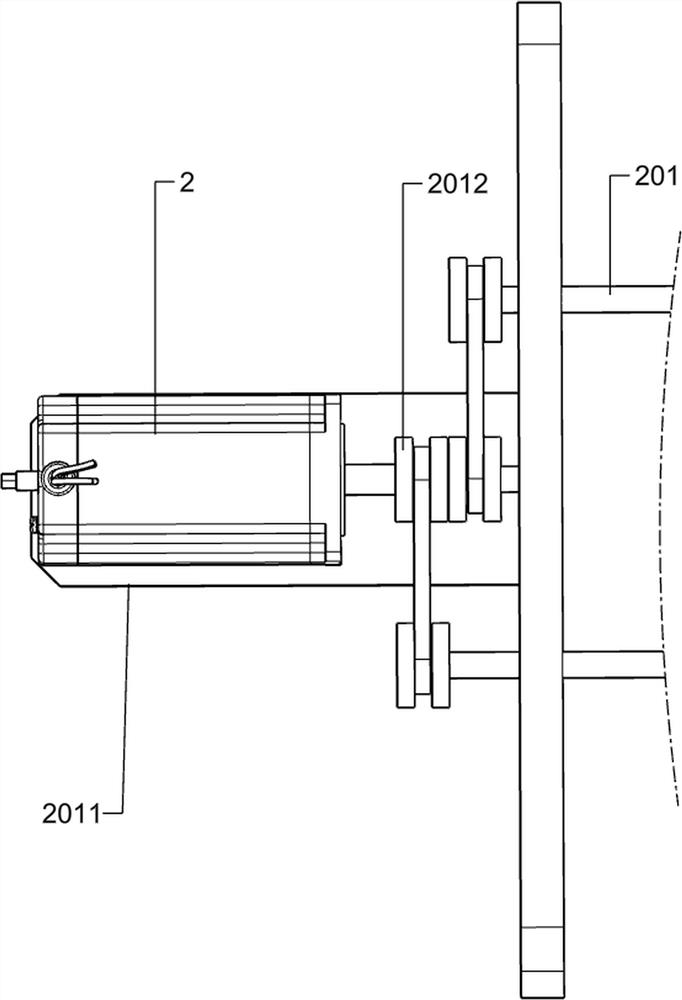

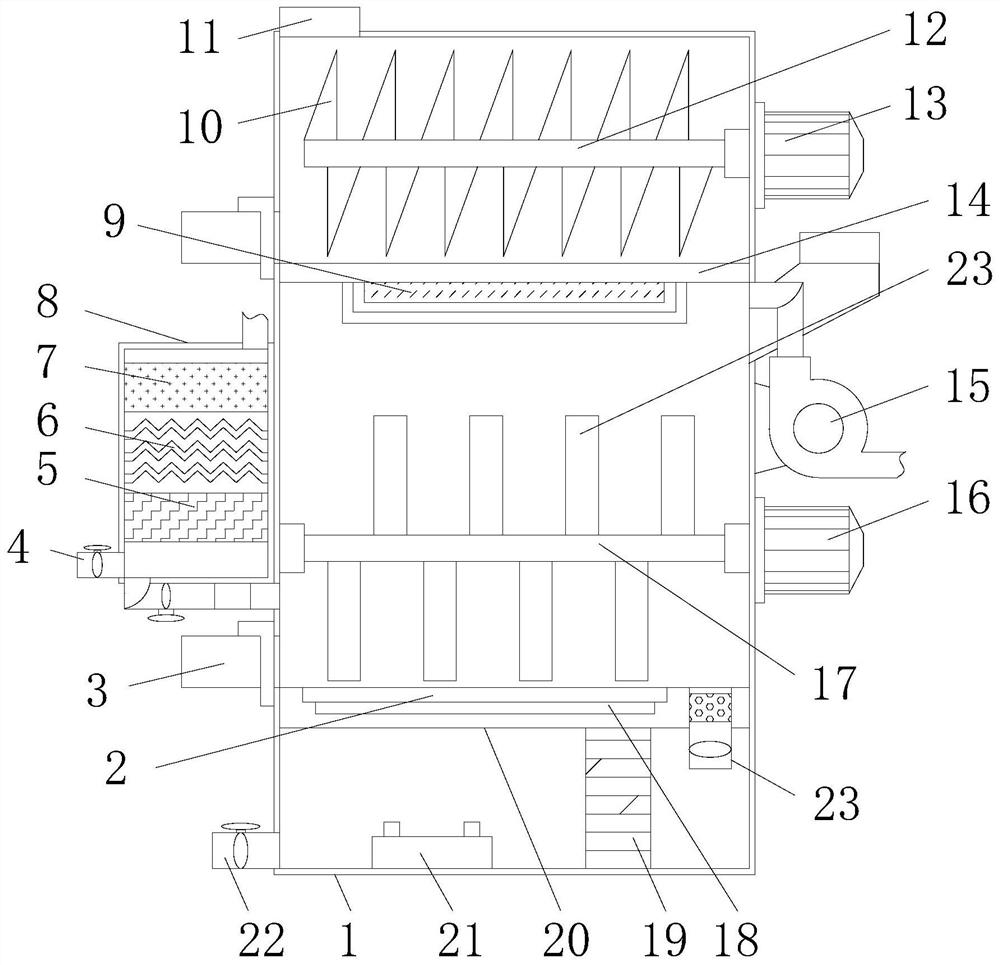

Raw material grinding device with dust collection and recovery functions for mortar production

InactiveCN112371230AEasy to handleAchieve the purpose of crushingSievingScreeningProcess engineeringEnvironmental geology

The invention discloses a raw material grinding device with dust collection and recovery functions for mortar production. The raw material grinding device comprises a smashing shell, a dust collectionmechanism, a vibration separation mechanism, a power mechanism, a support, a box body and a lifting mechanism, wherein the left side and the middle part of the smashing shell are fixedly connected with the right side of the dust collection mechanism, the bottom of the smashing shell is fixedly connected with the left side of the top of the box body, the right side of the top of the box body is fixedly connected with the bottom of the lifting mechanism, and the middle part of the interior of the box body is fixedly connected with the front side and the rear side of the vibration separation mechanism. According to the raw material grinding device with the dust collection and recovery functions for mortar production, after raw materials are smashed through a first smashing roller and a second smashing roller, a large amount of dust is generated by the smashing shell falling into the box body, suction force is generated through the rotation of conveying blades, the generated dust is sucked into a dust collection annular pipe through a top washing pipe and a bottom suction pipe, then the sucked dust is conveyed into the box body through a first conveying pipe and a second conveying pipe, and then the dust is discharged out of the box body through a discharging groove in a centralized mode, so that the generated dust can be effectively treated.

Owner:浙江古思建筑科技有限公司

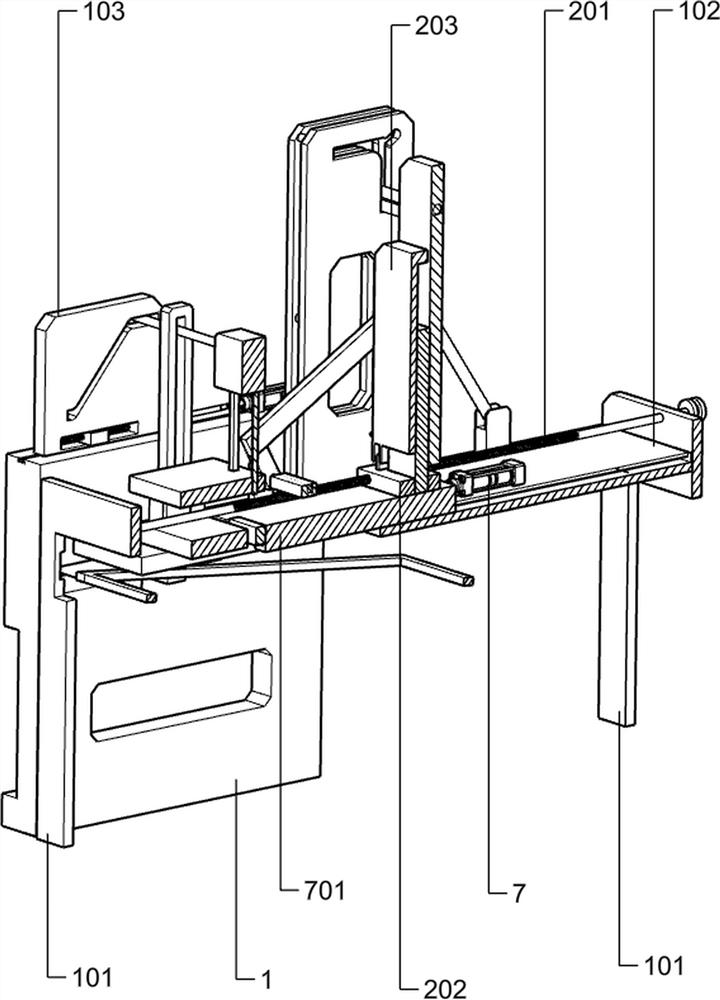

Silicon-manganese alloy crushing equipment for metallurgical smelting

ActiveCN112371218AEasy first time crushingAchieve the purpose of crushingGrain treatmentsMangalloyEngineering

The invention relates to crushing equipment, in particular to silicon-manganese alloy crushing equipment for metallurgical smelting. The technical problem is to provide the silico-manganese alloy crushing equipment for the metallurgical smelting that can reduce the labor intensity of works, has high processing efficiency, and is safe and simple. According to the technical scheme, the silicon-manganese alloy crushing equipment for the metallurgical smelting comprises side supporting plates, supporting legs, a transverse plate and the like; the two side supporting plates are symmetrically arranged; the transverse plate is fixedly connected to the inner sides of the two side supporting plates; and the two supporting legs are symmetrically arranged along one center line of the transverse plate, and the other two sides of the transverse plate are fixedly connected to the two supporting legs. According to the silico-manganese alloy crushing equipment for the metallurgical smelting provided by the invention, a knocking assembly I can crush vertical silicon-manganese alloy plates successively, small chippings can directly fall off from a linear through groove on the transverse plate, largechippings can be pushed to the bottom of a knocking assembly II and crushed again through the knocking assembly II, and therefore the purpose of replacing manpower to crush silicon-manganese alloy isachieved.

Owner:新疆西部合盛硅材料有限公司

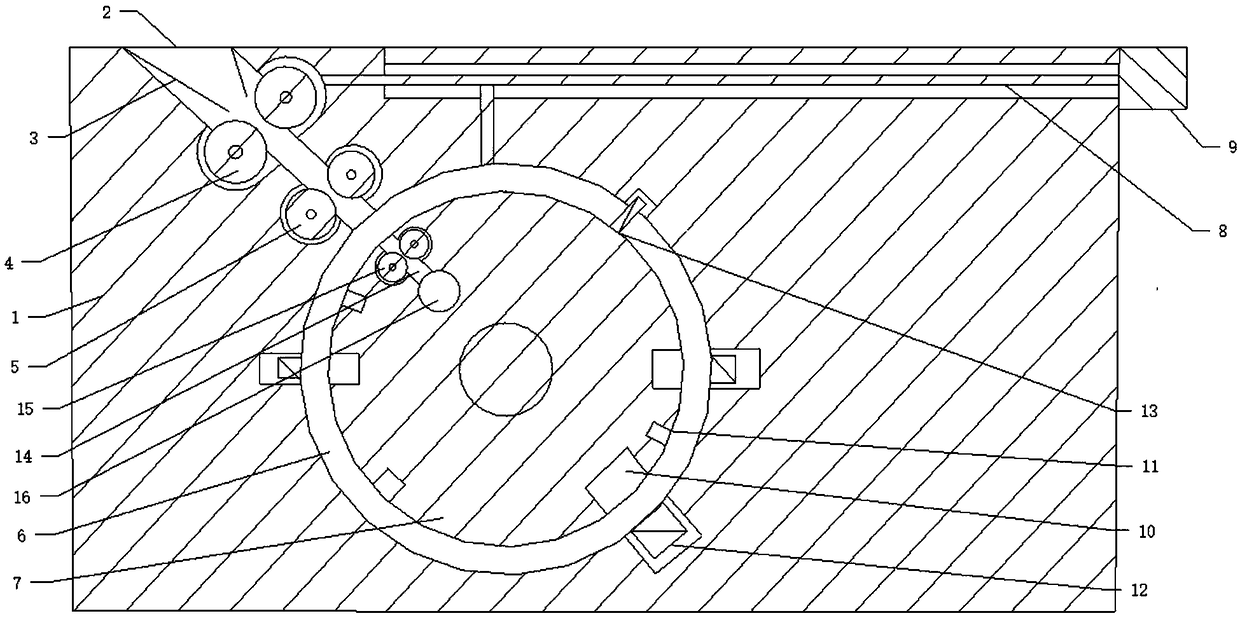

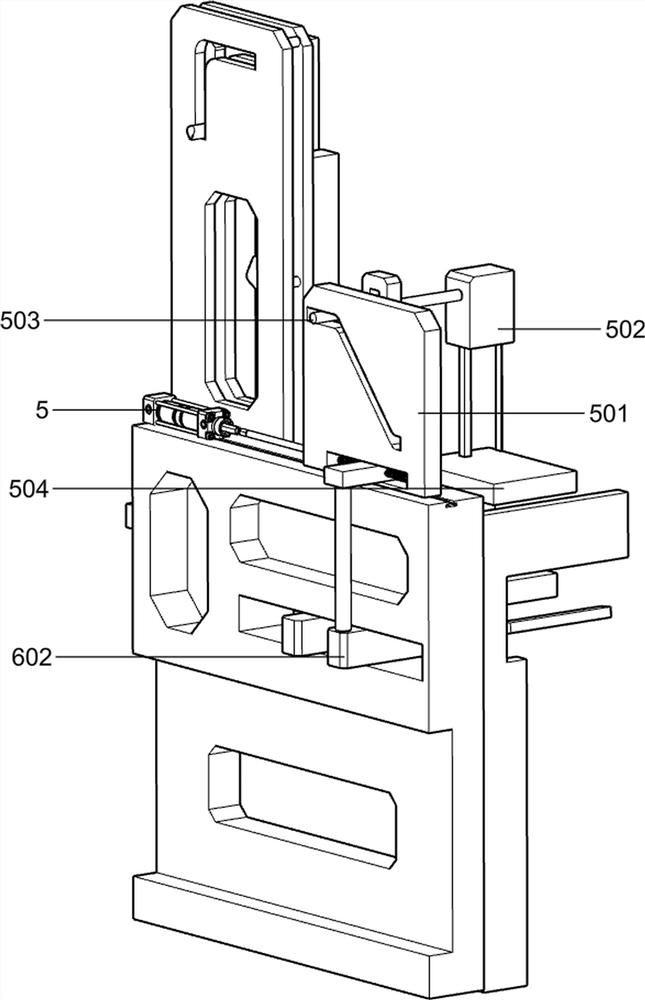

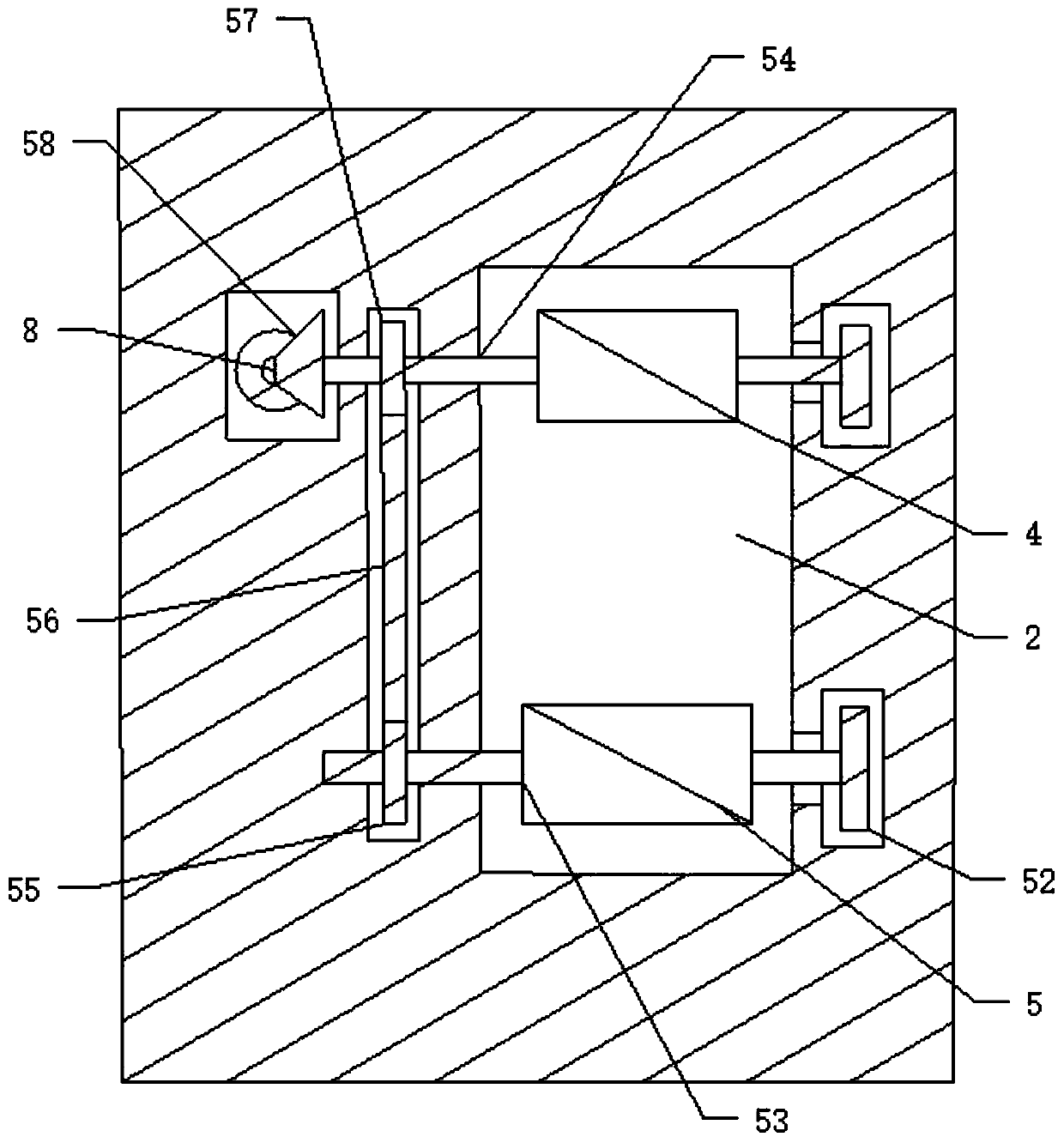

Automatic recovery device of medical waste infusion apparatus

InactiveCN111529831AAvoid harmAchieve the purpose of crushingInfusion needlesControl engineeringMedical waste

The invention discloses an automatic recovery device of medical waste infusion apparatus. The device comprises a body, wherein a first inlet is formed in the body, corresponding ejecting plates are arranged on two sides of the first inlet respectively, and two first clamping rotating wheels and two second clamping rotating wheels, which perform corresponding clamping rotation, are arranged on twosides of the first inlet respectively; a first rotary chamber in corresponding communication with the first inlet is arranged in the body, a rotary cutting plate is arranged in the first rotary chamber, and a plurality of cutting chutes are arranged on the rotary cutting plate; and cutting blocks performing synchronous extrusion sliding in the cutting chutes are arranged in the body, and a pressing chute which is arranged on the rotary cutting plate is arranged between every two adjacent cutting chutes, and components such as control switches on infusion tubes can be further cut by sliding ofthe cutting blocks. Therefore, the purpose of recovery is achieved, and the recovery rate is further increased.

Owner:左言好

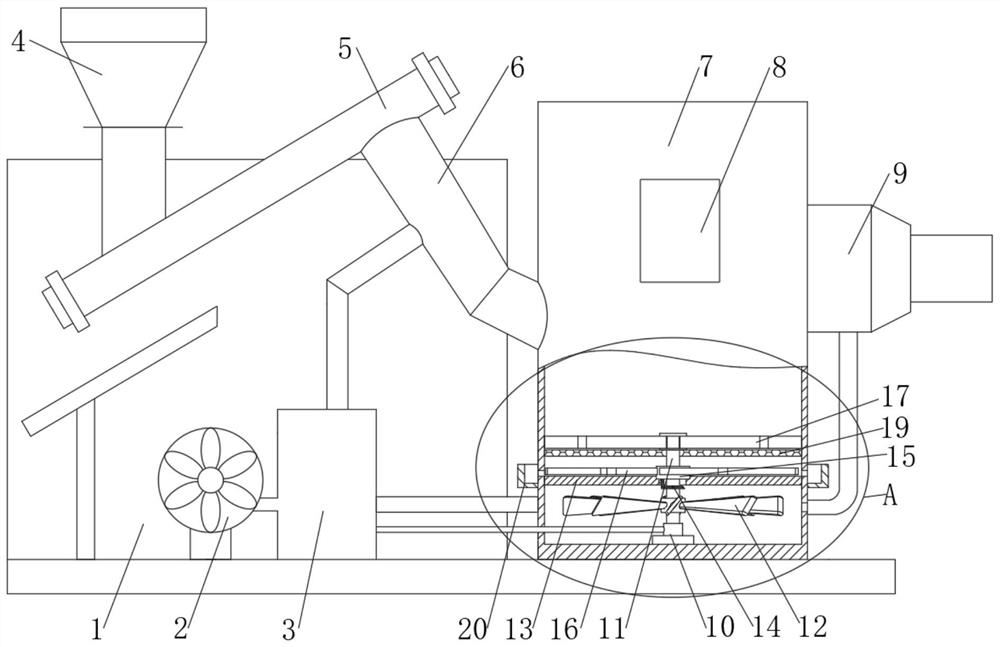

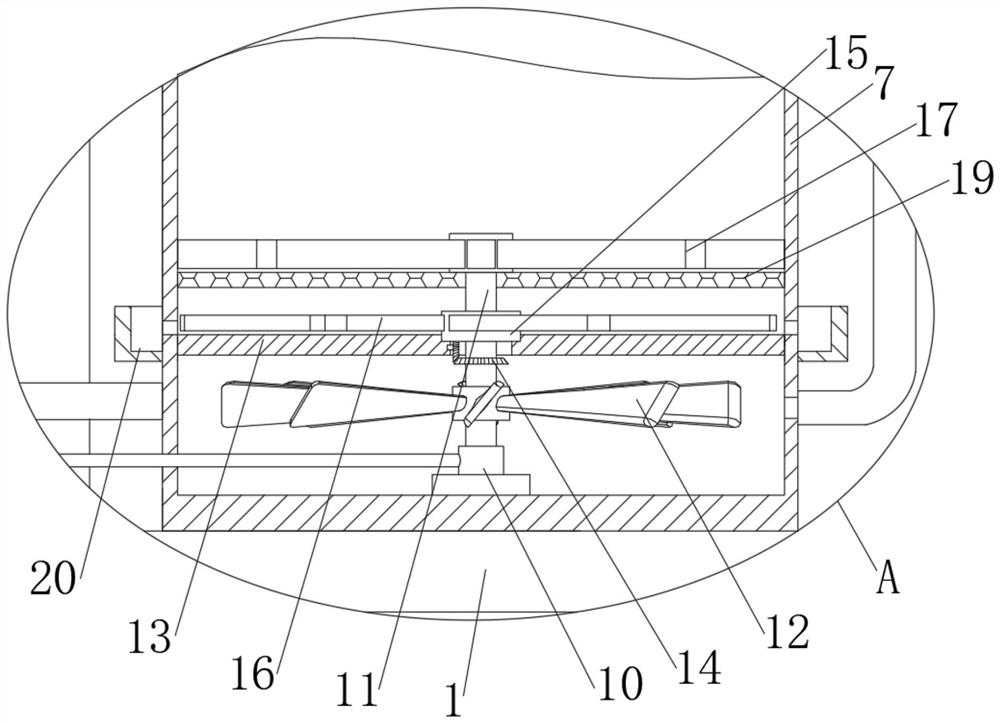

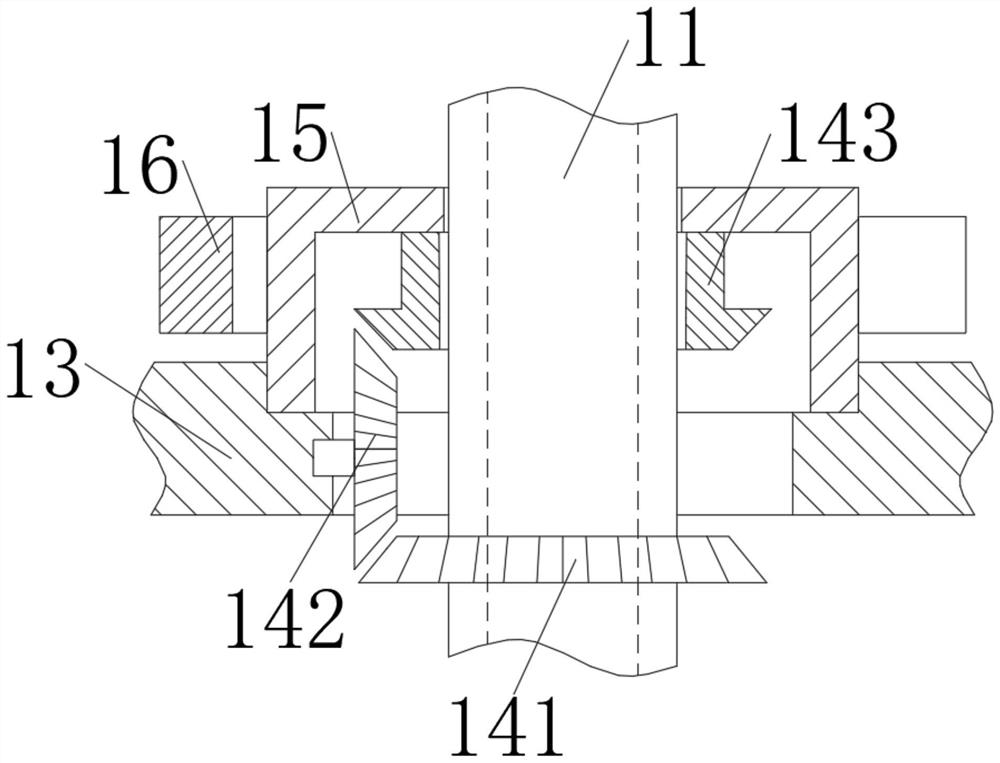

Biomass particle burner capable of improving burning rate

PendingCN111981468AAvoid cokingImprove combustion efficiencySolid fuel combustionBlast-producing apparatusFan bladeWind power

The invention relates to the technical field of burning equipment, and discloses a biomass particle burner capable of improving the burning rate. The biomass particle burner comprises an equipment body, wherein a fan, an air box and a burning furnace are sequentially installed at the bottom of the equipment body; a feeding hopper is fixedly installed on the upper portion of the equipment body; anda feeding screw is fixedly connected to the bottom of the feeding hopper. Through the arrangement of a cleaning plate and an air supply device, air rushing to fan blades from the air box drives the cleaning plate to rotate, burning ash above a metal filter screen is smashed, the purpose of smashing the burning ash before coking is achieved, and coking is prevented; the air passing through a rotary joint and a hollow shaft enters an air supply channel, a wedge block is jacked open under the air pressure for ventilation, the smashed ash is blown to a fire spraying opening through wind power forsecondary burning, and coking is prevented while the burning efficiency is improved; and the wedge block is in a closed state under the action of a spring under the non-ventilation condition, and thesituation that burning particles, impurities and the like enter the air supply channel, and consequently the air supply channel is blocked is avoided.

Owner:徐守文

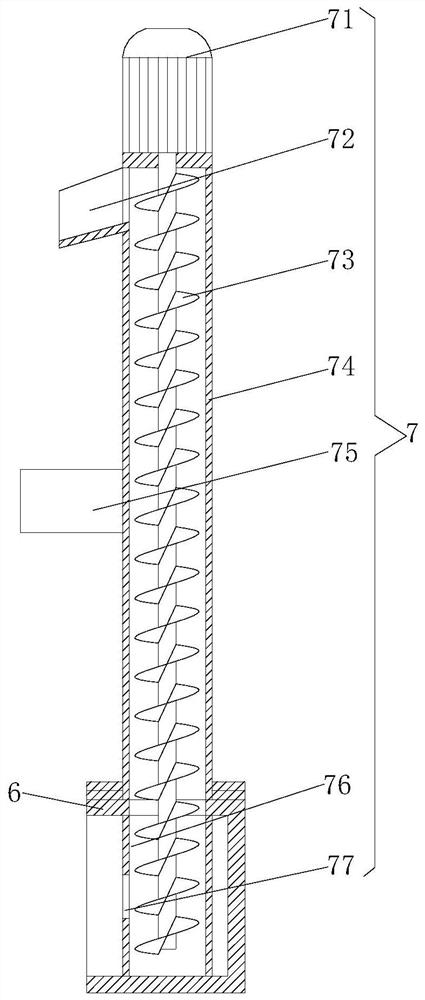

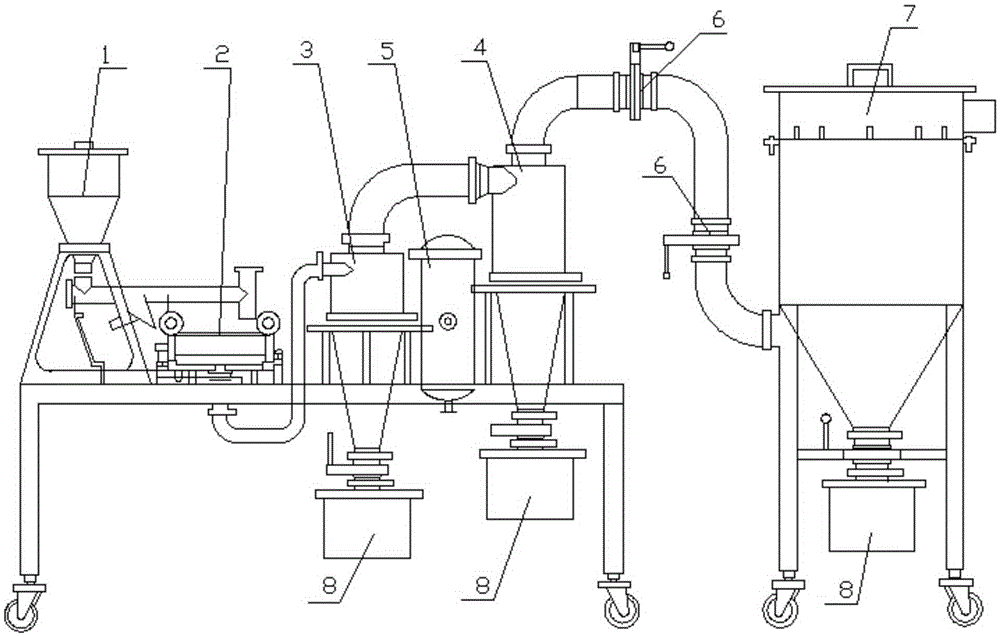

Processing technology for powder of white lotus seeds without plumule and device

InactiveCN105249381ARapid impactRapid frictionClimate change adaptationFood shapingTemperature controlOlder people

The invention discloses a processing technology for powder of white lotus seeds without plumule. The processing technology comprises the following steps: (1) planting white lotus, harvesting the lotus after maturity; (2) airing the white lotus seeds without plumule to dehydrate the white lotus seeds without plumule for 24-38 hours; (3) cutting up the white lotus seeds without plumule with the length of 1-4 cm; (4) airing the white lotus seeds without plumule to dehydrate the white lotus seeds without plumule for 12-30 hours; (5) drying the material when the inlet temperature controls at 60-75 DEG C and the outlet temperature controls at 92-120 DEG C; and (6) performing crushing and pulverizing by using a spiral gas flow pulverizer. The invention also discloses the spiral gas flow pulverizer. The powder of white lotus seeds without plumule has no additive, is pure natural high-quality food, has good dissolvability, adsorptivity and dispersibility, is easy to assimilate, and can be used as diet food, special food for diabetic patients, food for middle aged and old people, health food, enriched food and special nutritious food. The processing technology is simple and has high efficiency, and the prepared powder of white lotus seed has good quality.

Owner:JIANGXI SHICHENG QINGXIN FOOD CO LTD

Stirring frame for garbage disposable

ActiveCN105234153AAchieve the purpose of crushingQuality improvementTransportation and packagingSolid waste disposalElectric machineryEngineering

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

Diatomite recycling device

ActiveCN111921644APromote circulationAchieve the purpose of crushingDispersed particle filtrationTransportation and packagingFiberActivated carbon filtration

The invention discloses a diatomite recycling device. The diatomite recycling device comprises a shell, wherein the upper end of an inner cavity of the shell is fixedly connected to a first partitionplate, the bottom of which is fixedly connected to an ultraviolet lamp tube; the lower end of the inner cavity of the shell is fixedly connected to a second partition plate, the bottom of which is fixedly connected to a KDF filtering layer; and a heating plate is embedded on the top of the second partition plate. The diatomite recycling device is provided with a first motor, a crushing shaft and crushing teeth, so that the purpose of crushing diatomite waste can be achieved; the diatomite recycling device is provided with a second motor, a stirring shaft and a stirring blade, so that the purpose of stirring and cleaning the diatomite waste can be achieved; the diatomite recycling device is provided with the heating plate, so that the purpose of drying the diatomite waste on the top of thesecond partition plate can be achieved; the diatomite recycling device is provided with an activated carbon filter layer, a polyimide fiber needled felt layer, a drying box, a pipeline and a draught fan; the draught fan is used for sucking air in the shell into the drying box through the pipeline; and the air is subjected to two-stage physical filtration through the polyimide fiber needled felt layer and the activated carbon filter layer, and then is conveyed into the shell through the pipeline.

Owner:杭州止距智能技术有限公司

Machining waste treatment device for mechanical field

InactiveCN112044551AAchieve the purpose of crushingAchieve the purpose of deliveryGrain treatmentsPressesGear wheelElectric machinery

The invention discloses a machining waste treatment device for the mechanical field, and belongs to the field of machining waste treatment in the mechanical field. The machining waste treatment devicecomprises a crushing device, the crushing device comprises a crushing box, the upper end of the crushing box is fixedly connected with a feeding port, the side end of the crushing box is fixedly connected with a second fixing plate, the lower end of the second fixing plate is fixedly connected with a second motor, a second gear is fixedly connected to the side end of the second motor and engagedwith a first gear, a rotating shaft is fixedly connected to the side end of the first gear, blades are fixedly connected to the circumferential surface of the rotating shaft, the lower end of the crushing box is fixedly connected with a conveying device, the conveying device comprises a transverse conveying box, the lower end of the transverse conveying box is fixedly connected with a vertical conveying box, the lower end of the vertical conveying box is fixedly provided with an extrusion device, the extrusion device comprises an extrusion box, and a first guide groove is formed in the extrusion box. According to the machining waste treatment device, the structure is simple, the manufacturing cost is low, integration of waste treatment can be achieved only through simple operation, and continuous extrusion can be achieved.

Owner:郑东

Pesticide composition based on niclosamide ethanolamine salt and preparation method thereof

The invention discloses a pesticide composition based on niclosamide ethanolamine salt and a preparation method thereof, and relates to the technical field of molluscacidal preparations. The pesticidecomposition is prepared from niclosamide ethanolamine salt, a wetting agent, hyperbranched polyesteramide, a defoaming agent, an antifreeze agent and filler; a dry suspending agent type is obtained through the working procedures of premixing, airflow crushing, spray drying and granulation; on the basis of the prior art, the hyperbranched polyesteramide is used as a dispersant, and the dispersanthas a special branched molecular structure, more functional groups on the surface of a molecule can firmly wrap and adsorb the niclosamide ethanolamine salt, the bridging effect cannot occur, and thesolid content of a dry suspending agent system is effectively improved. The agricultural composition has good suspension rate and qualified high-low temperature stability, a suspending agent can be formed after the agricultural composition is mixed with water; the molluscicidal effect and the drug effect maintenance time of the composition are improved under the slow-release synergistic effect ofthe tea saponin after being sprayed and applied, and the agricultural composition is suitable for industrial application.

Owner:ANHUI TOPSUN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com