Stirring frame for garbage disposable

A technology of garbage disposal and agitation frame, which is applied in the direction of grain treatment, mixer with rotating agitation device, chemical/physical process, etc. It can solve the problems that it is difficult to achieve thorough crushing and further decomposition of garbage, so as to save energy, promote agitation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

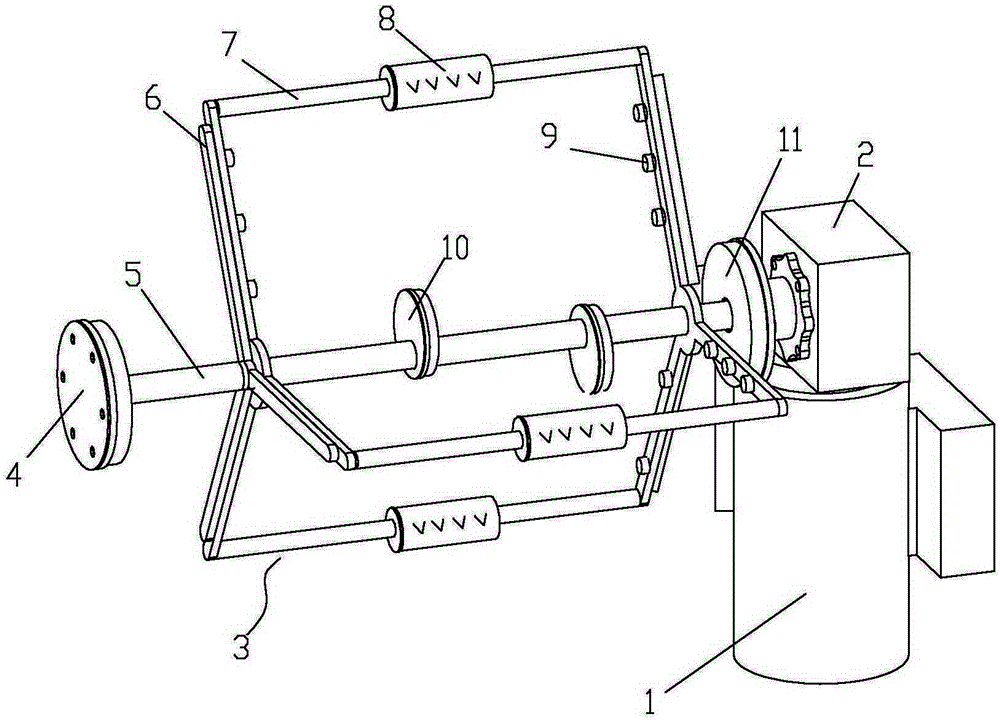

[0011] Please refer to the attached figure 1 , the embodiment of the present invention includes:

[0012] A stirring frame for garbage disposal, comprising a motor 1, a gearbox 2, a tripod 3 and a shaft end cover 4; the tripod 3 includes a rotating shaft 5, two tripod forks 6, a connecting rod 7; two tripod forks 6 Oppositely, the connecting rod is used to connect the opposite forks on the tripod fork 6; the connecting rod 7 is also fitted with a roller 8; the surface of the roller 8 is also provided with a raised portion; The tripod fork 6 is set on the rotating shaft 5; the rotating shaft 5 and the tripod fork 6 are internal hollow cavity stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com