Waste packaging box crushing equipment for medicine packaging

A technology for shredding equipment and packaging, applied in the field of shredding equipment for waste packaging boxes for medical packaging, can solve the problems of affecting the working environment, destroying the air quality of the working environment, and collecting debris from splashing, and achieving the effect of preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

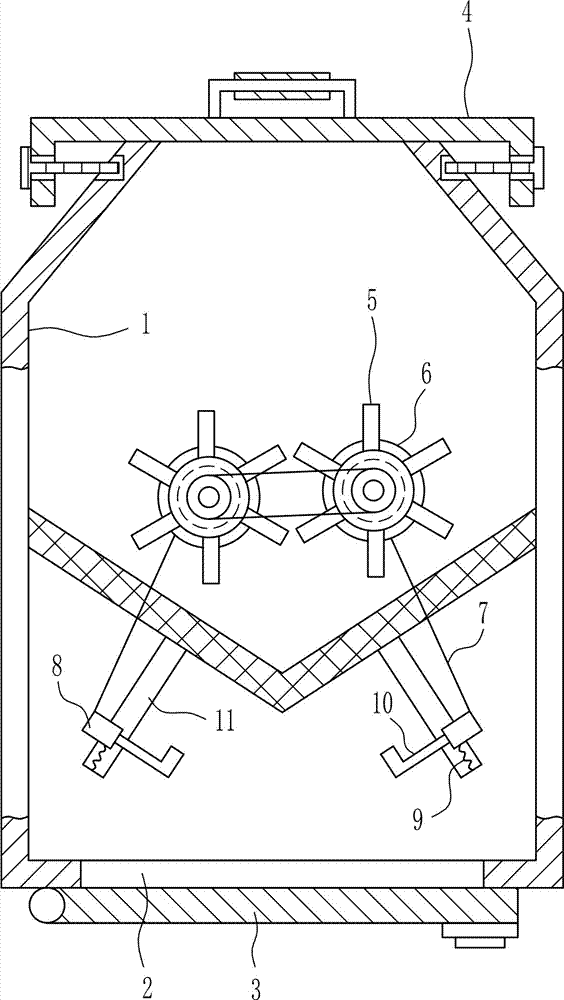

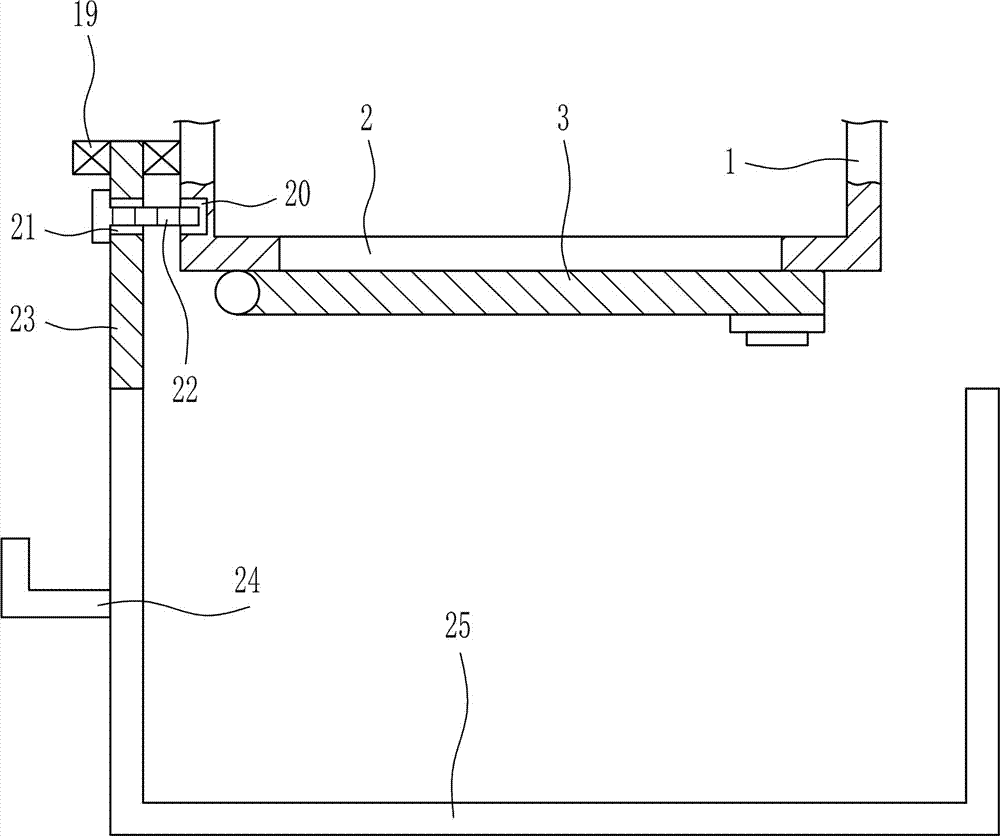

[0040] A waste packaging box crushing equipment for medical packaging, such as Figure 1-7 As shown, it includes a crushing box 1, a baffle plate 3, a capping mechanism 4 and a crushing mechanism 5, a first through hole 2 is opened in the middle of the bottom wall of the crushing box 1, and a baffle plate 3 is connected to the left side of the crushing box 1 in a rotating manner. The right side of the bottom of the baffle plate 3 is fixed on the right side of the bottom of the crushing box 1 by means of bolts, the top of the crushing box 1 is provided with a cover tightening mechanism 4, and the middle part of the crushing box 1 is provided with a crushing mechanism 5.

Embodiment 2

[0042] A waste packaging box crushing equipment for medical packaging, such as Figure 1-7 As shown, it includes a crushing box 1, a baffle plate 3, a capping mechanism 4 and a crushing mechanism 5, a first through hole 2 is opened in the middle of the bottom wall of the crushing box 1, and a baffle plate 3 is connected to the left side of the crushing box 1 in a rotating manner. The right side of the bottom of the baffle plate 3 is fixed on the right side of the bottom of the crushing box 1 by means of bolts, the top of the crushing box 1 is provided with a cover tightening mechanism 4, and the middle part of the crushing box 1 is provided with a crushing mechanism 5.

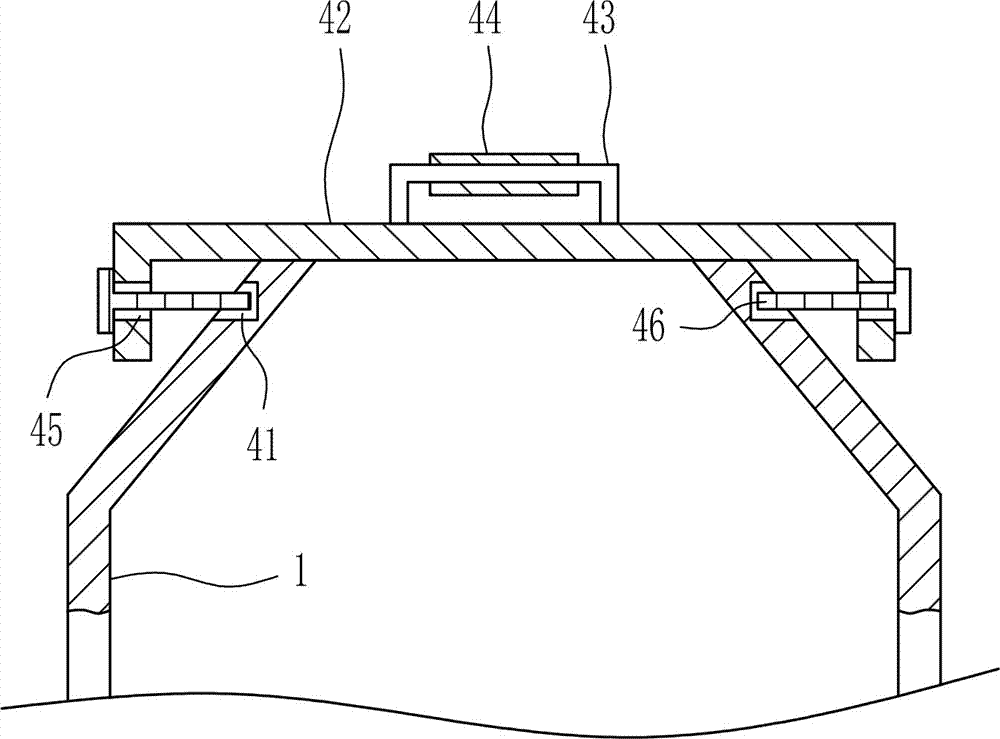

[0043] Cover tight mechanism 4 comprises cover plate 42, first handle 43, rubber pad 44 and first screw rod 46, and cover plate 42 is placed on the top of crushing box 1, and cover plate 42 left and right two wall middle parts all have the first threaded hole 45, pulverize The upper part of the left and right ...

Embodiment 3

[0045] A waste packaging box crushing equipment for medical packaging, such as Figure 1-7 As shown, it includes a crushing box 1, a baffle plate 3, a capping mechanism 4 and a crushing mechanism 5, a first through hole 2 is opened in the middle of the bottom wall of the crushing box 1, and a baffle plate 3 is connected to the left side of the crushing box 1 in a rotating manner. The right side of the bottom of the baffle plate 3 is fixed on the right side of the bottom of the crushing box 1 by means of bolts, the top of the crushing box 1 is provided with a cover tightening mechanism 4, and the middle part of the crushing box 1 is provided with a crushing mechanism 5.

[0046] Cover tight mechanism 4 comprises cover plate 42, first handle 43, rubber pad 44 and first screw rod 46, and cover plate 42 is placed on the top of crushing box 1, and cover plate 42 left and right two wall middle parts all have the first threaded hole 45, pulverize The upper part of the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com