Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Achieve a buffering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Buffering structure, falling protection device, falling protection control method and mobile terminal

ActiveCN107566586AImprove protectionSolve problems such as damageTravelling carriersHoldersGround contactStress concentration

The invention provides a buffering structure. The structure comprises a connecting rod, a balancing weight and a buffering component, wherein the balancing weight is rotationally connected with the connecting rod; and the buffering component is connected with the balancing weight. The balancing weight automatically rotates according to a falling direction when an object to be protected is in a falling state, the buffering component can be come into contact with the ground vertically when falling in any direction, and instantaneous impact stress on the object to be protected is reduced under the action of the buffering component at a ground contacting moment, so that the aim of protecting the object to be protected is fulfilled, and the phenomenon of stress concentration is avoided.

Owner:BOE TECH GRP CO LTD +1

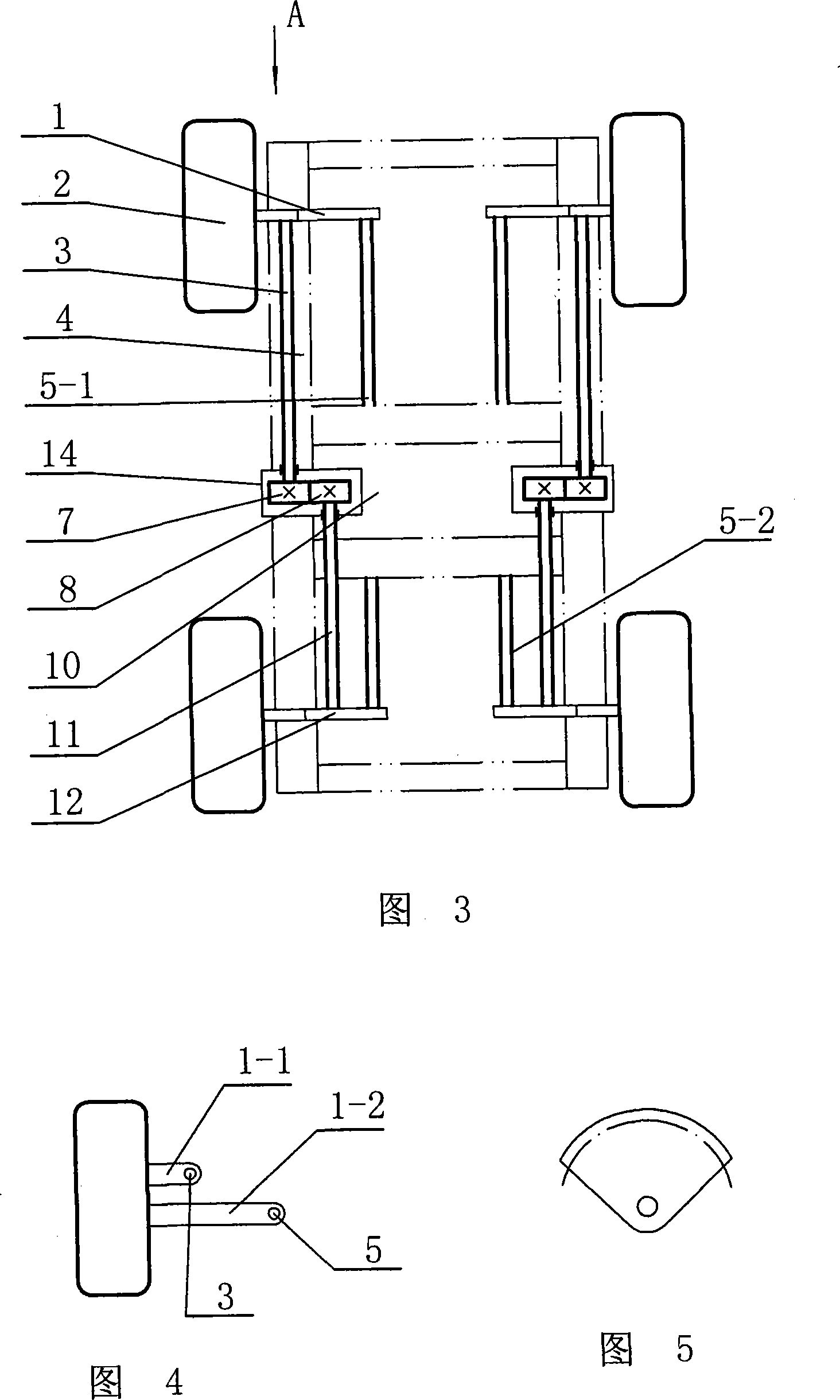

Torsion bar type automobile suspension arrangement

InactiveCN101229764AReduce horizontal vibrationGood vibration reduction effectInterconnection systemsResilient suspensionsVehicle frameRoad surface

The invention which relates to a device for hanging cars, in particular to a twisted bar type device for hanging cars comprises a front twisted bar spring installed in the front hanging of the car and is characterized in that a back twisted bar spring is installed in the hang at the back of the car; the corresponding ends of the front and the back twisted bar spring in the same side are mutually connected through a connection mechanism and connected with a car frame through a location device. As the connection mechanism is arranged between the front and the back twisted bar spring on the same side, a linkage relation is built between the front and the back twisted bar spring on the same side, which can improve effectively the vibration situation in an uneven road surface in the driving process of the car; at the same time, the car frame and a body frame receive no twisted force so that the service life of the car can be prolonged.

Owner:李志东

Method of continuous pigment dyeing for fabric

InactiveCN101509184AWell mixedDyeing firmDrying solid materials with heatTextile treatment machine arrangementsSURFACTANT BLENDPigment

The invention relates to a continuous pigment dyeing method for fabrics, in which the fabrics during travelling are subjected to the steeping of a composite dye solution in a steeping tank that is continuously supplemented with the composite dye solution, and then to the rolling of rollers, and the time the fabrics are subjected to the composite dye solution by the fabrics is 2.5-5 seconds. The composite dye solution comprises the components having the following concentrations: 10g / L-50g / L of a pigment paste, 1g / L-8g / L of a cation modifying agent, 3g / L-5g / L of a surfactant and 5g / L-20g / L of a cation bonding agent. The padding fabrics are continuously subjected to an infrared pre-drying apparatus for drying, a hot-air pre-drying tank for drying and a steam drying cylinder apparatus for drying. The inventive method has superior stability of the dyeing effect and is free from agglomeration.

Owner:常州市东高染整有限公司

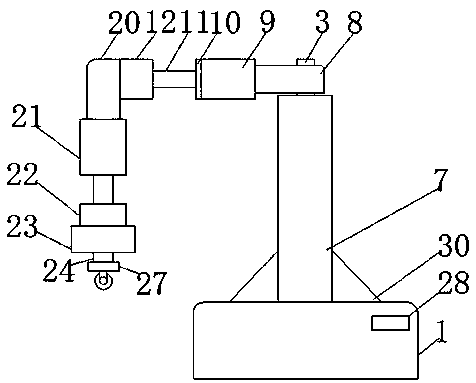

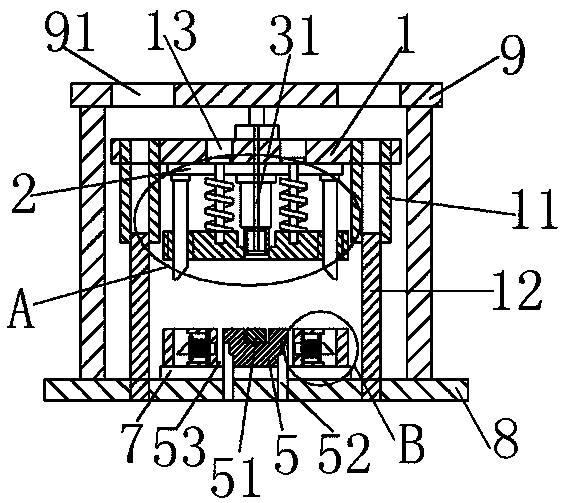

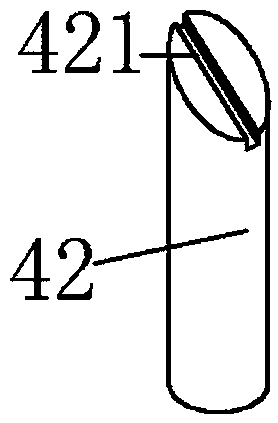

Simple industrial mechanical arm for teaching

InactiveCN108015757AImprove scalabilitySimple structureProgramme-controlled manipulatorEducational modelsGear wheelDrive shaft

The invention discloses a simple industrial mechanical arm for teaching, and relates to the technical field of teaching tools. The simple industrial mechanical arm for teaching comprises a base box; abearing block is arranged at the bottom of the inner wall of the base box; a transmission shaft matched with the bearing block is arranged in the bearing block; the end, close to the bearing block, of the transmission shaft is sleeved with a first bevel gear; weighting blocks are symmetrically and fixedly connected to the bottom of the inner wall of the base box and are located on the two sides of the bearing block; a rotating shaft motor is fixedly connected to the top of the weighing block on the right side of the bearing block; and an output shaft of the rotating shaft motor is fixedly connected with a second bevel gear. According to the simple industrial mechanical arm for teaching, the overall structure of the mechanical arm can be simplified through an electromagnetic telescopic device, use can be more convenient, the size is small, carrying by teachers and explaining to students can be facilitated so that the students can better understand and master related knowledge, and therefore the learning interests of the students can be increased, and the classroom life can be enriched.

Owner:黄静

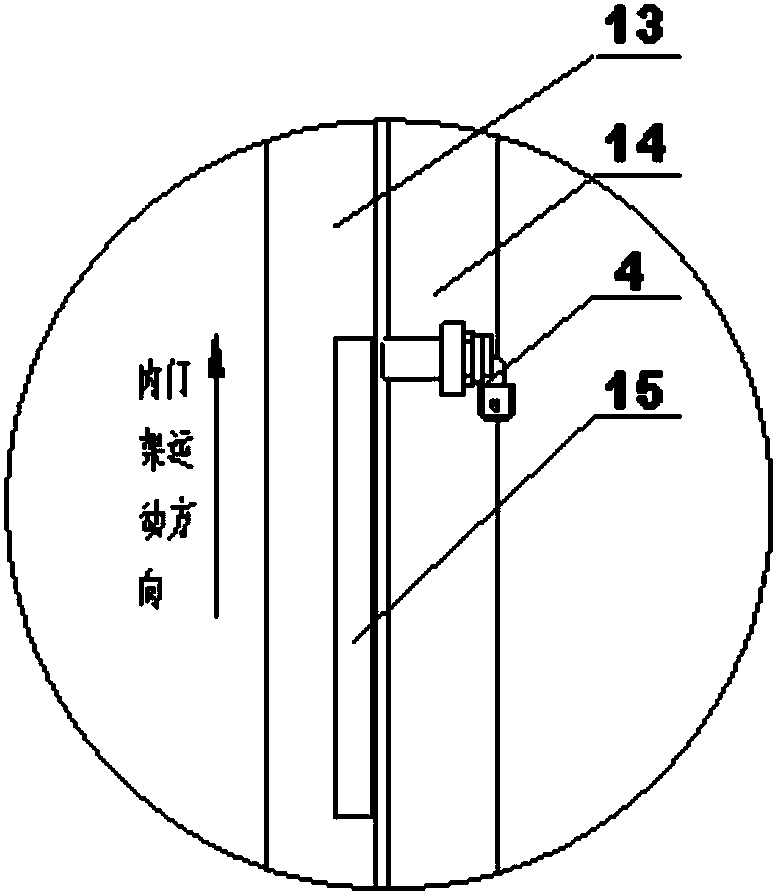

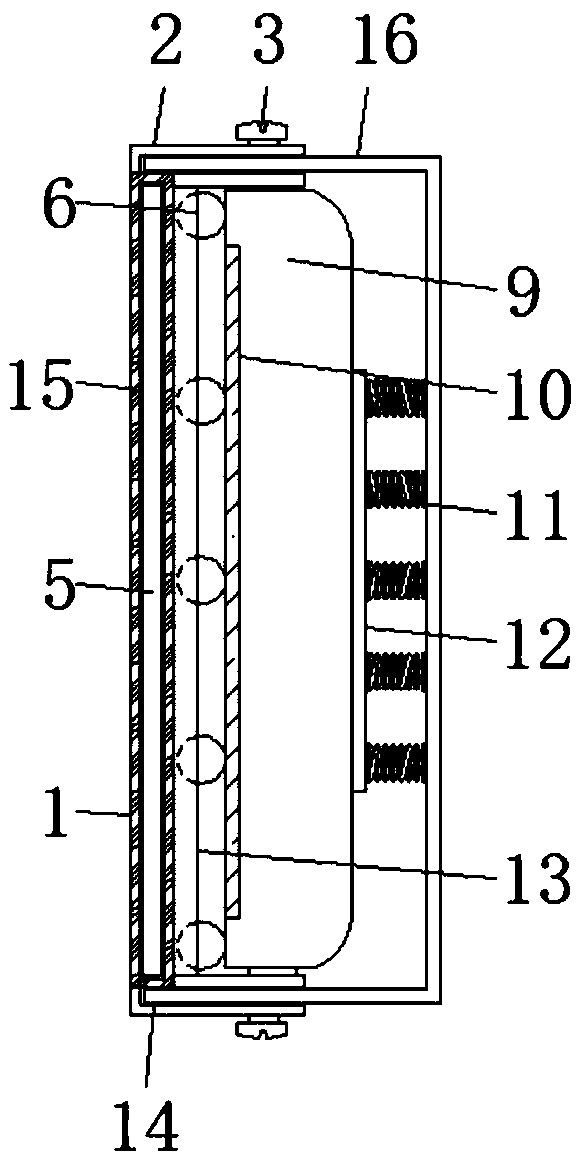

Telescopic type pulling hole packer

ActiveCN101457654AImprove compactnessPrevent simultaneous rotationDust removalFire preventionReusabilityEngineering

The invention discloses a telescopic drainage hole sealer which comprises a drainage pipe; wherein, at least two coaxial hole seal pipes are sheathed on the drainage pipe, the drainage pipe is longer than the hole seal pipes, both ends of each hole seal pipe are respectively provided with a closure plate, and a coaxial cylindrical air sac is arranged between the hole seal pipes; the drainage pipe penetrates through and is connected with the closure plate and the air sac through rotation fit, and a holding apparatus outside the closure plates on the ends of the hole seal pipes is arranged on the drainage pipe. The telescopic drainage hole sealer has the advantages of simple structure, easy production and installation and convenient operation, can be suitable for draining or injecting liquid into holes of different hole diameters through the dimension change of the components of the telescopic drainage hole sealer, solves the fault problems of pipeline cracking, ventilation and liquid leakage and even breakage, prolongs the service life of the main device, shortens the working time, increases the working efficiency, reduces the drainage times and the maintenance workload and cost, has high drainage or liquid injection speed, high reusability and easy maintenance, and guarantees the quality and the safety of liquid drainage or injection.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

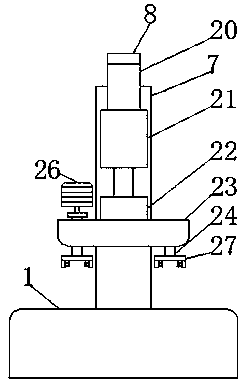

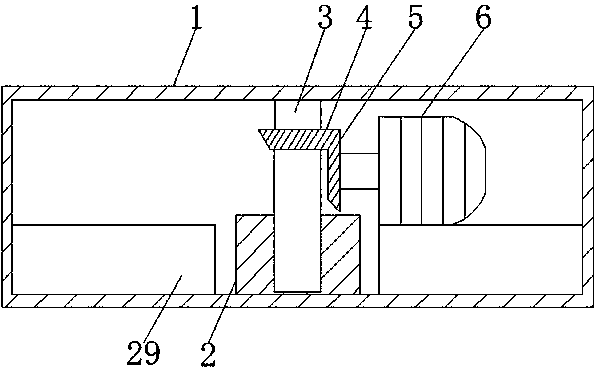

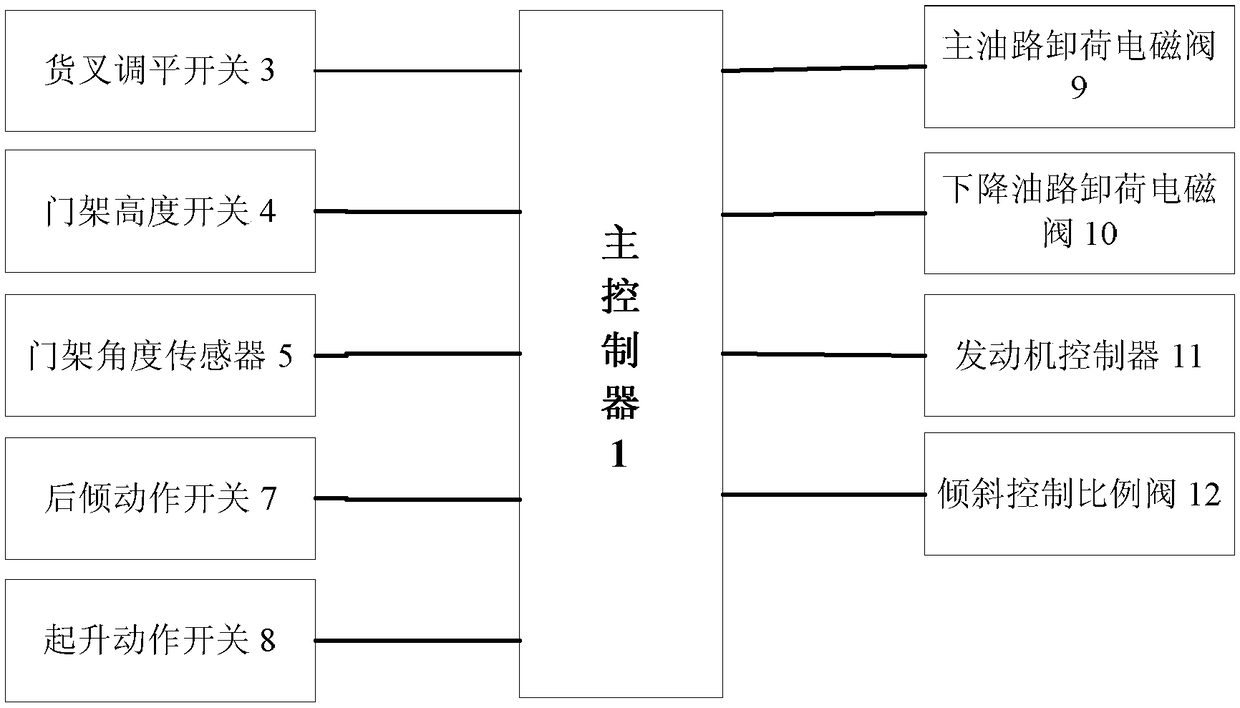

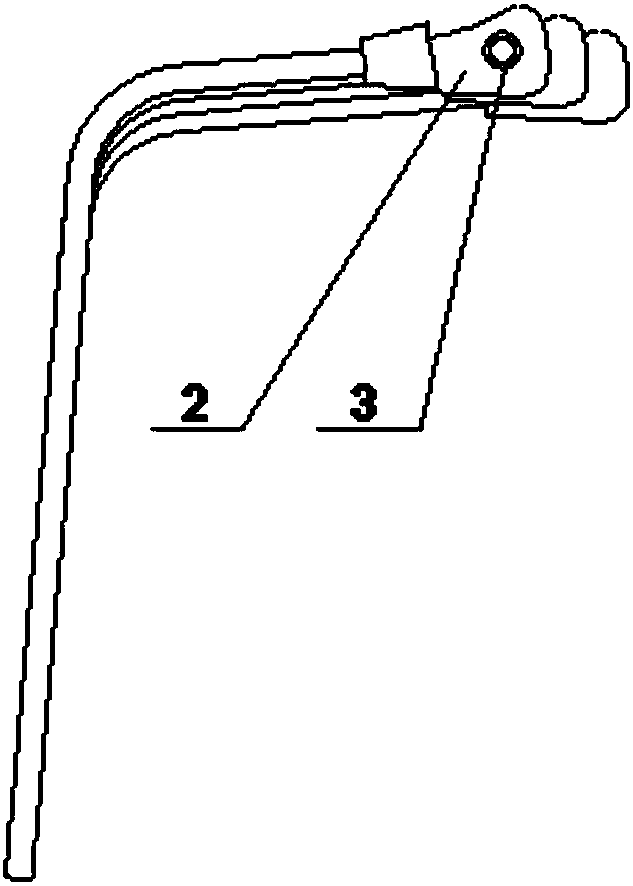

Forklift working safety control device and control method

ActiveCN108516505AImprove stabilityProtection securitySafety devices for lifting equipmentsVehicle frameEngineering

The invention discloses a forklift working safety control device. The control device comprises a master controller, a fork leveling switch, a gantry height switch, a gantry angle sensor, a backward inclination action switch, an ascending action switch, a main oil circuit unloading electromagnetic valve, a descending oil circuit unloading electromagnetic valve, an engine controller and a pluralityof forklift fixing structures, wherein the master controller is arranged on a forklift center console, the fork leveling switch is arranged on an operation handle of a multi-way valve inclined linkagevalve rod, the gantry height switch is arranged on a gantry, the gantry angle sensor is arranged on an inclined oil cylinder, the backward inclination action switch is arranged on a multi-way valve assembly, the ascending action switch is arranged on the multi-way valve assembly, the main oil circuit unloading electromagnetic valve is arranged on the multi-way valve assembly, the descending oil circuit unloading electromagnetic valve is arranged on the multi-way valve assembly, the engine controller is arranged in the center console, and the multiple forklift fixing structures are arranged atthe bottom of a frame. The control device has the advantages that the working efficiency and the stability of a forklift can be effectively improved, and the safety of operators and cargoes can be protected.

Owner:HANGCHA GRP

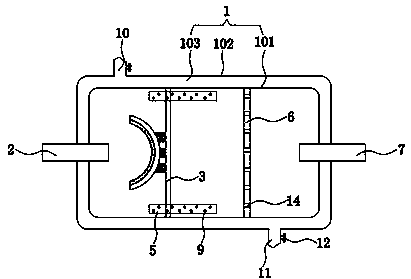

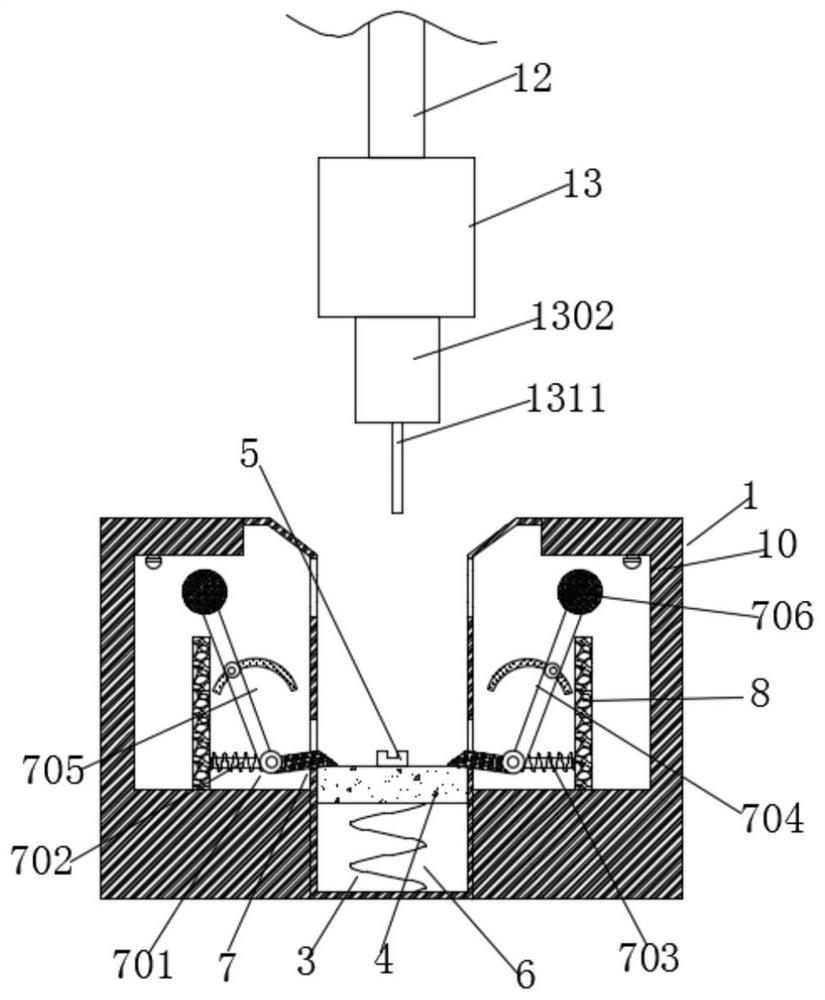

A television set with screen shield for household use

InactiveCN109167949ATo achieve the protective effectAchieve a buffering effectTelevision system detailsColor television detailsArchitectural engineeringProtective glasses

The invention discloses a television set with screen shield for household use, include a first front guard frame, Second front guard frame, A television body and a rear guard frame, the first front protective frame and the second front protective frame are arranged at the front end of the television body, the first front protective frame and the second front protective frame are both provided withinsertion grooves, the two insertion grooves are inserted with protective glass, the inner sides of the first front protective frame and the second front protective frame are provided with fixing plates, balloon balls are evenly arranged on the inside of the fixing plate, the balloon ball is attached to the outer frame of the television body, the outer sides of the first front protective frame and the second front protective frame are both provided with fixed frames, A meshing groove is formed between the fixing frame and the first and second front protective frames, and the rear protective frame is inserted into the meshing groove. A spring is fixed on the inner surface of the rear protective frame, and a shock absorbing plate is fixed on the spring. The shock absorbing plate is attachedto the rear end of the television body. The invention has the advantages of screen protection, external shock absorption buffering and dustproof performance.

Owner:长沙洲源智能科技有限公司

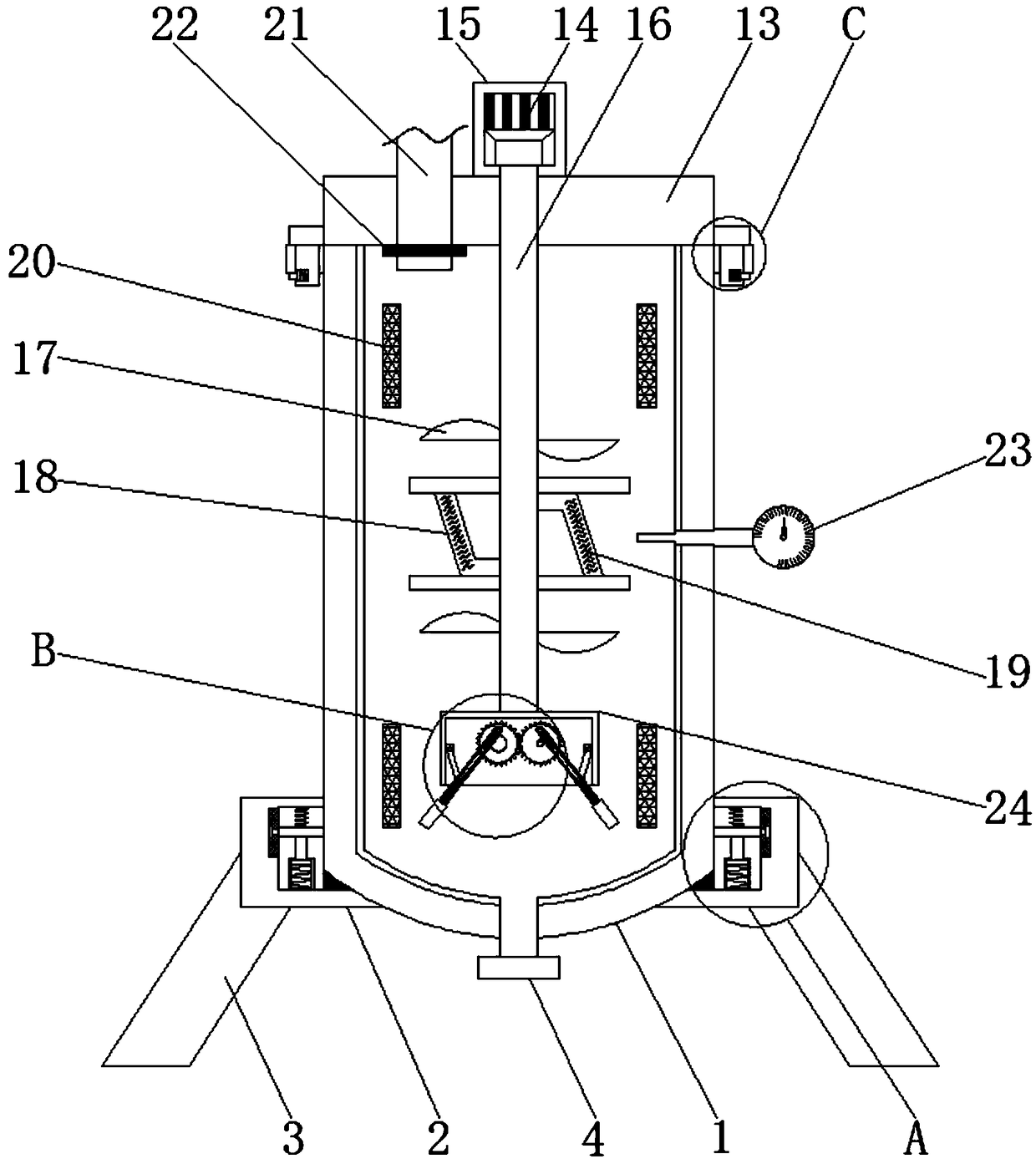

Stirring machine for producing cleaning agent

InactiveCN108636168AAvoid Stirring Dead AnglePerformance impactRotary stirring mixersTransportation and packagingPistonMotor drive

The invention provides a stirring machine for producing a cleaning agent and relates to the field of stirring equipment. The stirring machine for producing the cleaning agent comprises a stirring box,wherein a bearing plate is inserted into the bottom of the stirring box; supporting legs are fixedly mounted at four corners of the bottom of the bearing plate; a valve is communicated with the bottom of the stirring box; baffle plates are fixedly mounted at two sides of the stirring box and are located in the bearing plate; sleeves are fixedly mounted at the bottom of an inner wall of the bearing plate; pistons are arranged in the sleeves. According to the stirring machine for producing the cleaning agent, a first motor drives stirring blades to rotate and the aim of stirring is realized; asecond motor drives a gear to rotate so that a transverse rod shakes leftward and rightward; meanwhile, a rotary rod drives a box body to rotate, and liquid at the bottom of the stirring box is stirred so that the uniform stirring effect is realized; a condition that the bottom of the stirring machine is not sufficiently stirred is avoided and conditions that a stirring dead angle is formed and the utilization performance of the cleaning agent is influenced are avoided.

Owner:新昌县盛南建材有限公司

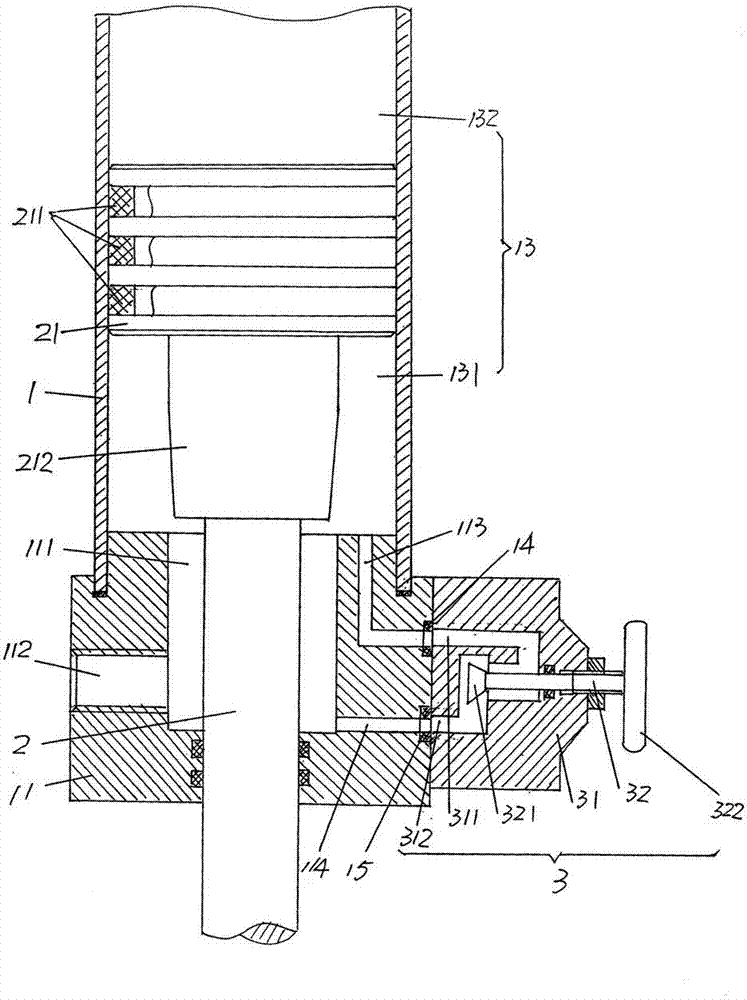

Hydraulic buffer

ActiveCN106763438AAdjustable buffer forcePerformance maximizationSpringsShock absorbersPulp and paper industryPiston

The invention discloses a hydraulic buffer. The hydraulic buffer comprises an oil cylinder seat, a buffering cylinder, a piston and a rotary sleeve; the buffering cylinder is installed in the oil cylinder seat and comprises a fixed buffering cylinder body and a movable buffering cylinder body, the fixed buffering cylinder body is installed in the movable buffering cylinder body in a sleeved mode, and throttling holes and reflowing holes are formed in the surfaces of the fixed buffering cylinder body and the movable buffering cylinder body; the fixed buffering cylinder body is used for storing oil liquid, a hollow portion formed between the fixed buffering cylinder body and the piston is an inner cavity, and a certain space is formed between the movable buffering cylinder body and the oil cylinder seat and used as a oil returning cavity to form an outer cavity; and the rotary sleeve and the movable buffering cylinder body are connected to control rotating of the movable buffering cylinder body and adjust the number and size of the aligned throttling holes of the movable buffering cylinder body and the fixed buffering cylinder body, when being subjected to the action of force, the piston moves inwards the buffering cylinder, and the oil liquid is compressed, flows to the outer cavity from the inner cavity through the throttling holes and then flows back to the inner cavity through the reflowing holes to achieve circulation of the oil liquid.

Owner:JIANGSU ELECTRIC POWER RES INST +3

Shock-proof shock absorber based on spiral sheet

InactiveCN107906157AAdapt to spatial changesPlay a shock absorbing effectSprings/dampers design characteristicsShock absorbersElectricityEngineering

The invention belongs to the technical field of shock absorbers, and particularly relates to an shock-proof shock absorber based on a spiral sheet. The shock-proof shock absorber comprises an upper supporting plate, a damping spring, a buffering mechanism, a lower supporting plate, a motor air inlet, a motor air outlet, a motor support, a pneumatic motor, an electric generator and electric generator supports; when the upper supporting plate is impacted, the upper supporting plate can be compressed and move downwards, the damping spring can be compressed when the upper supporting plate moves downwards so that the damping effect can be achieved through the damping spring, meanwhile, the lower supporting plate moves downwards to drive a push rod to move downwards, the push rod moves downwardsto drive tan upper piston plate to move downwards, a lower piston plate is driven to move downwards through the buffer spring, high-pressure helium between the lower piston plate and a correspondingpiston shell can flow into the pneumatic motor through a piston air outlet pipe and the motor air inlet in the downward moving process of the lower piston plate, the gas flowing into the pneumatic motor can enable the pneumatic motor to work, and the pneumatic motor enables the electric generator to generate electricity.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Air inlet structure of electric propulsion engine

ActiveCN109404240ASealed and compactSimple and convenient detachableMachines/enginesUsing plasmaElectricityWorking temperature

The invention provides an air inlet structure of an electric propulsion engine, relates to the problem of propellant supply of the electric propulsion engine, and belongs to the field of electric propulsion. The volume of the electric propulsion engine body is greatly reduced, and a propellant supply structure of the engine becomes more complicated. Because an engine gas distributor air inlet pipeline has a high discharge voltage and is in a relatively high working temperature range, a propellant supply pipeline outside the engine is difficultly in direct connection with a gas distributor, otherwise the engine is short-circuited. In order to solve the problem, an electric propulsion engine air inlet structure with sealing and insulating functions is designed. Conical surface extrusion is carried out on a gas distributor pipeline-sealing ring, and an air inlet cavity is formed between an air inlet flange and an engine body flange, so that the one-to-four connection mode between an external propellant pipeline and the engine gas distributor pipeline is achieved, and simultaneously the sealing and insulation requirements on the outer wall surface of the gas distributor pipeline and the engine body flange are met.

Owner:BEIHANG UNIV

Buffer oil cylinder for plastic product forming machinery

InactiveCN102852904AAchieve a buffering effectThere will be no impact on the cylinder headFluid-pressure actuatorsThermodynamicsCylinder head

The invention relates to a buffer oil cylinder for plastic product forming machinery and belongs to the technical field of power sources of plastic product forming machinery. The buffer oil cylinder comprises an oil cylinder body and an oil cylinder column, wherein the oil cylinder body with an oil cylinder head at one end and a tail seat at the other end is provided with an oil cylinder head buffer oil cavity and an oil inlet and outlet hole, and the oil cylinder column is arranged in an oil cavity of the oil cylinder body. The tail seat is provided with a tail seat oil inlet and outlet hole, an oil cylinder column piston head is additionally arranged at one end of the oil cylinder column towards the tail seat, and a piston head sealing ring is arranged on the oil cylinder column piston head. The buffer oil cylinder for plastic product forming machinery is characterized in that a buffer column is formed on the surface of the oil cylinder piston head, the oil cylinder head is provided with an oil outlet hole and an oil return hole , a pressure oil flow adjusting mechanism is arranged on the outer wall of the oil cylinder head and communicated with the oil outlet hole and the oil return hole at the same time and controls flow of pressure oil entering the oil return hole from the oil outlet hole. Accordingly, the oil cylinder head is protected from being collided by the oil cylinder column piston head, no damage to the oil cylinder body is caused, and the buffer oil cylinder is simple in structure, easy to manufacture and mount.

Owner:SUZHOU TONGDA MACHINERY

Reinforcing device for narrow coal pillar between roadways

InactiveCN107060811ANo deformation and collapseEasy to installUnderground chambersTunnel liningResource recoveryEngineering

The invention discloses a reinforcement device for a narrow coal pillar between roadways, which comprises a narrow coal pillar, a top plate and a bottom plate, a top plate is fixed above the narrow coal pillar, a bottom plate is fixed below the narrow coal pillar, and The column includes an anchor cable and a guard member plate, and an anchor hole is opened on the narrow coal pillar, and the guard plate member plate is fixedly installed on both sides of the narrow coal pillar, and the upper and lower parts of the guard plate member plate are provided with connecting devices, The anchor cable is located in the anchor hole, and the anchor cable passes through the anchor hole, and both ends of the anchor cable extend to the guard plate member, and both ends of the anchor cable are provided with fixed locks, and the anchor hole There are five anchor holes in the upper part of the narrow coal pillar symmetrically, one anchor hole in the middle part and two symmetrically in the lower part. The first grouting layer and the second grouting layer are arranged on the narrow coal pillar layer, the first grouting layer is located on the inner wall of the anchor hole. The invention has the advantages of simple structure, convenient and fast installation, reliable support, material saving and improved resource recovery rate.

Owner:JIAXING UNIV

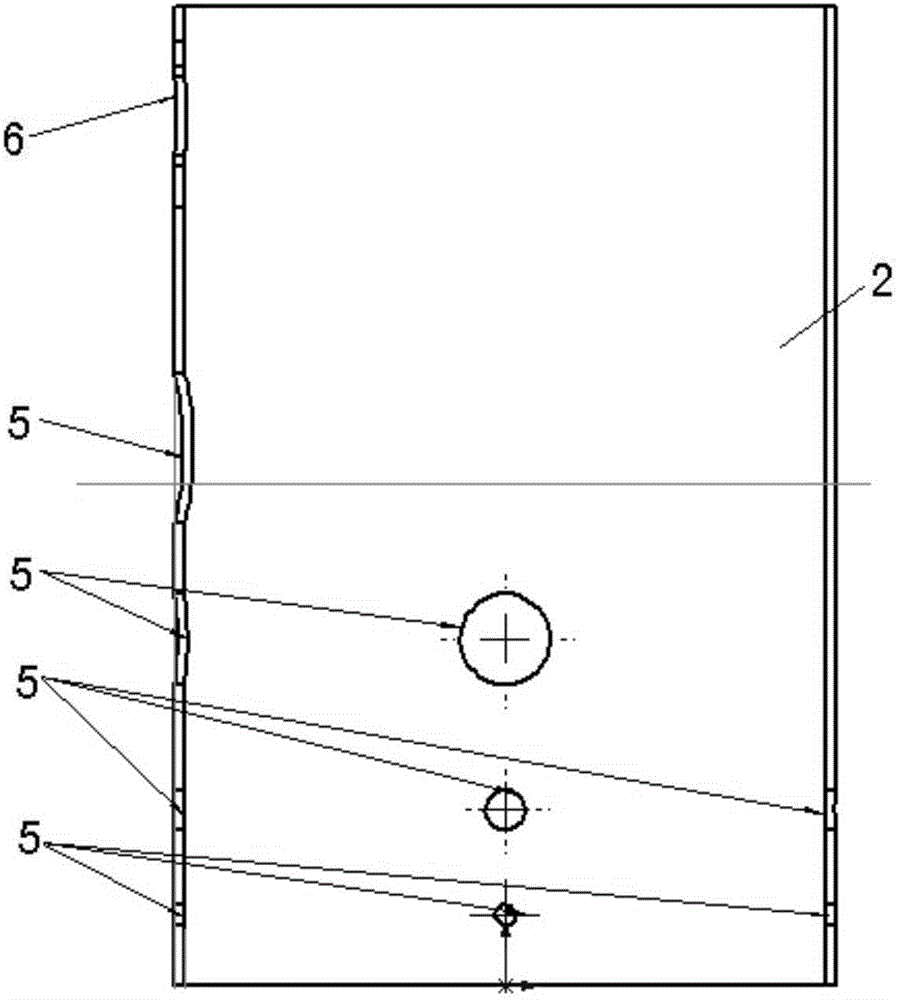

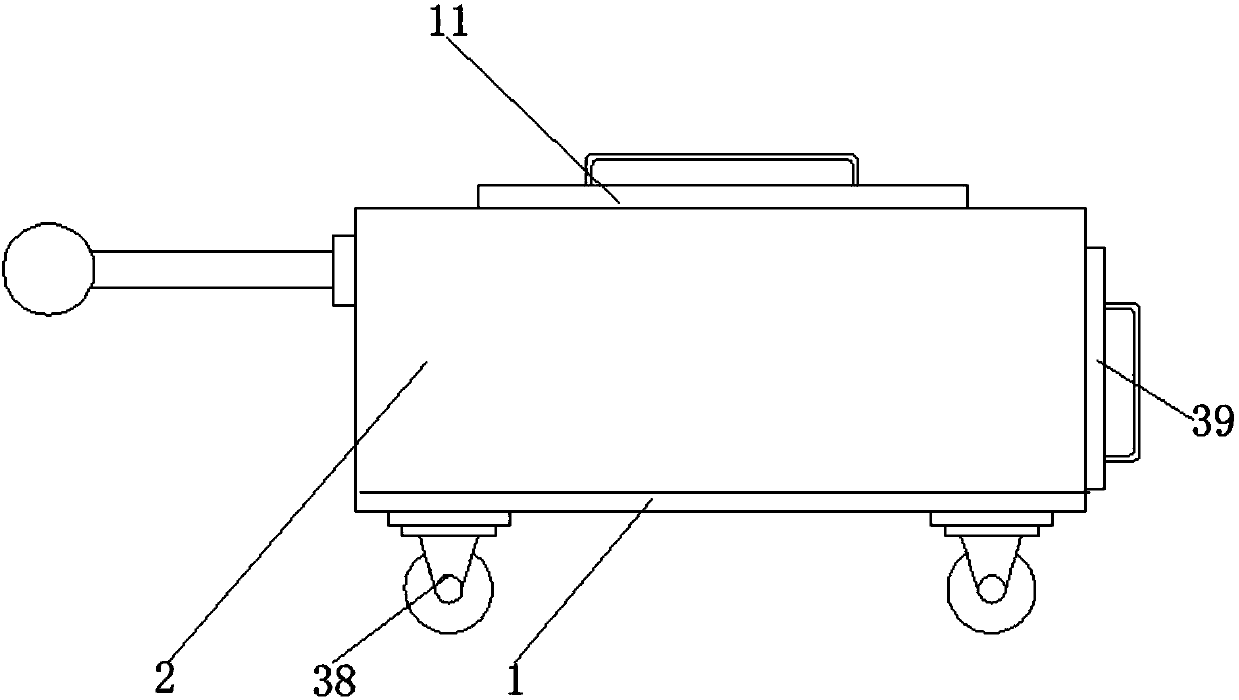

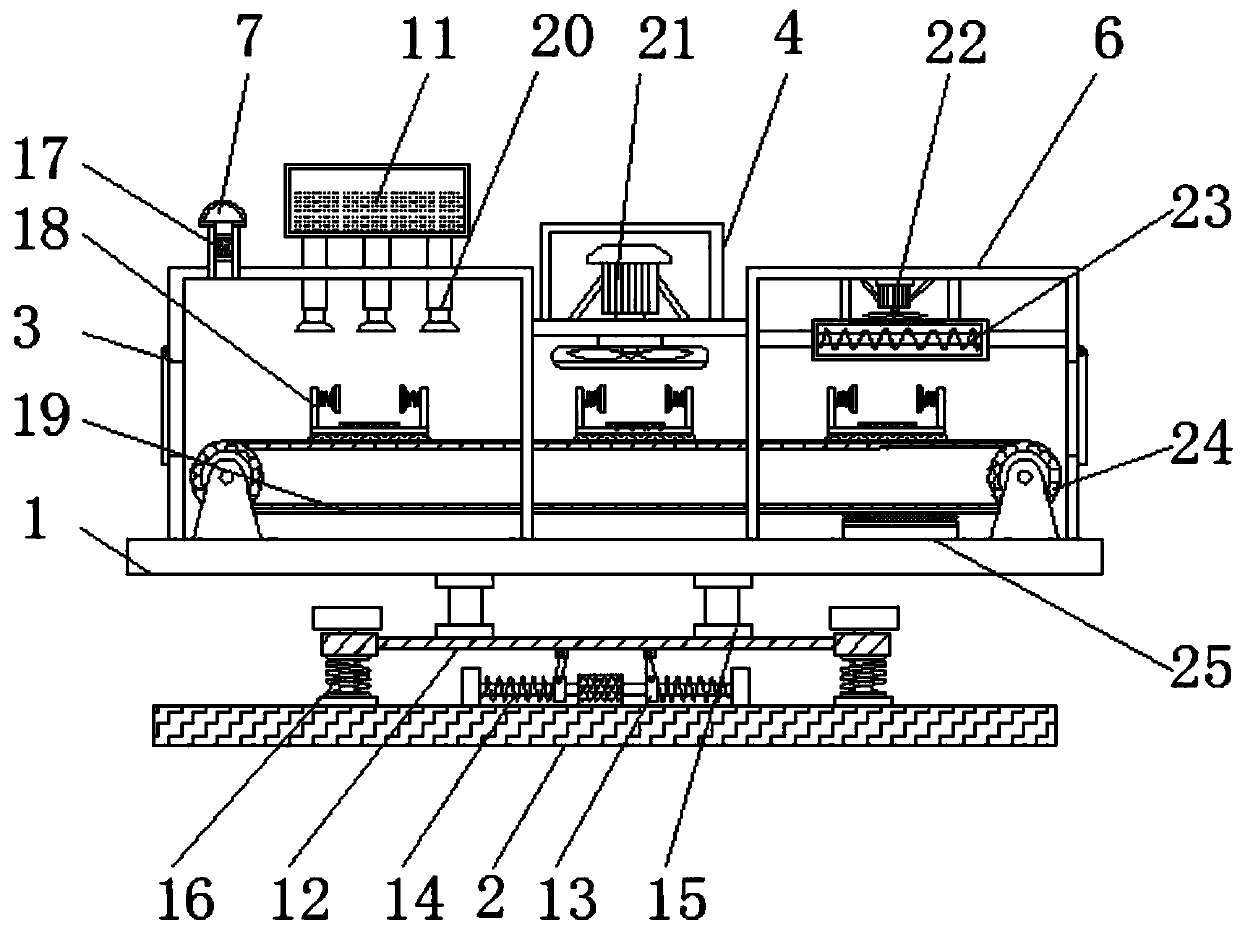

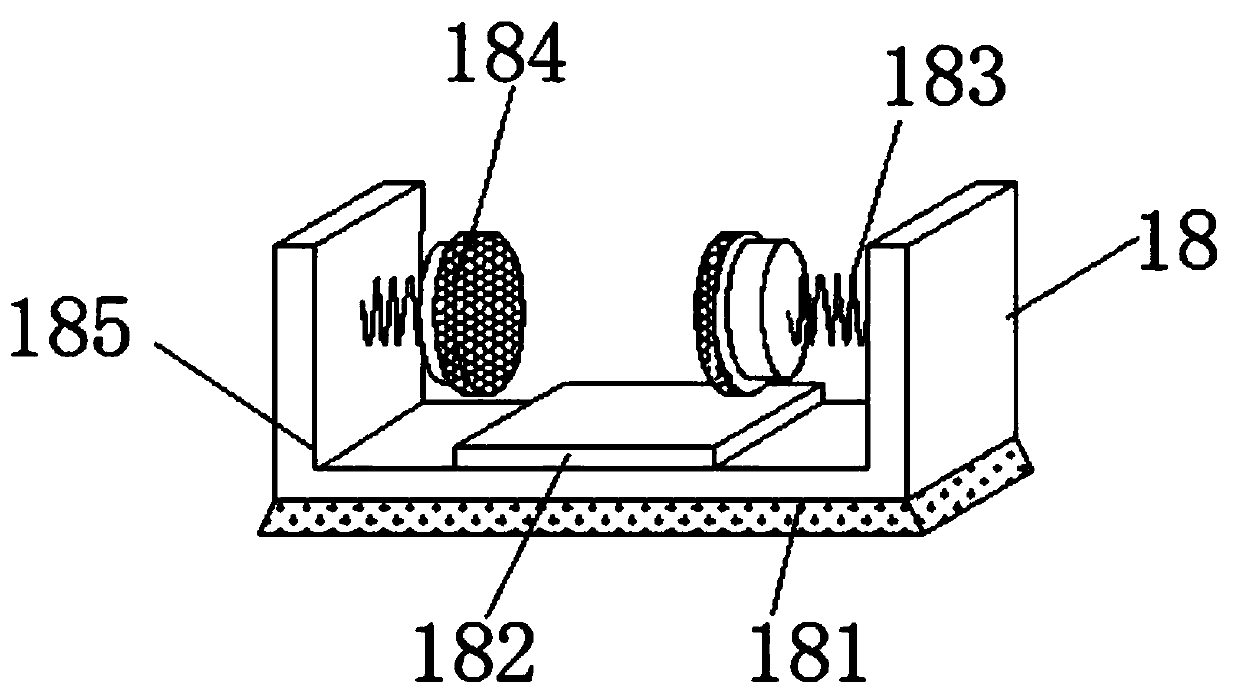

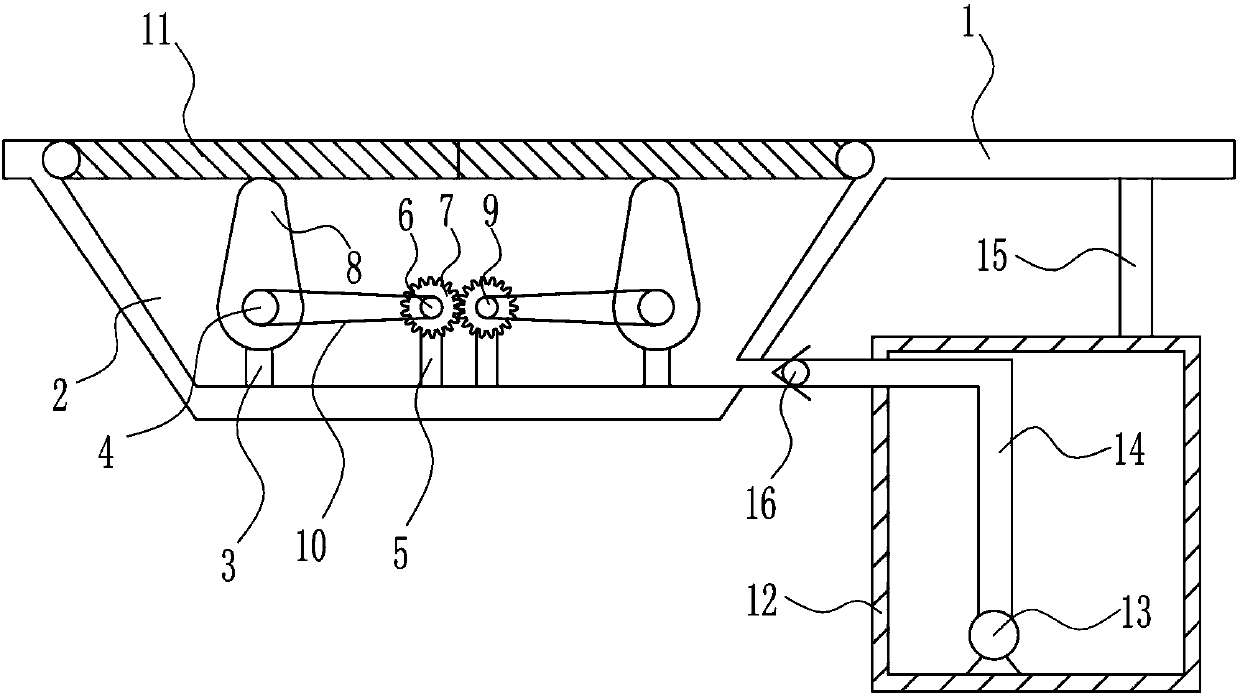

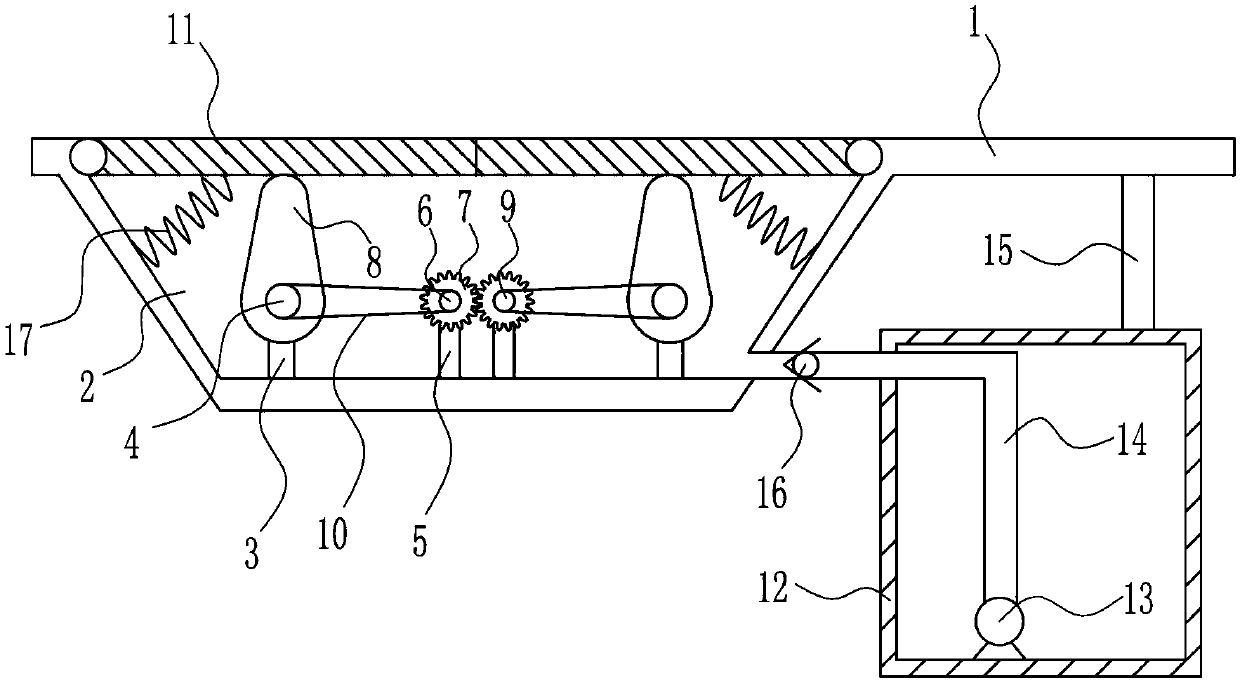

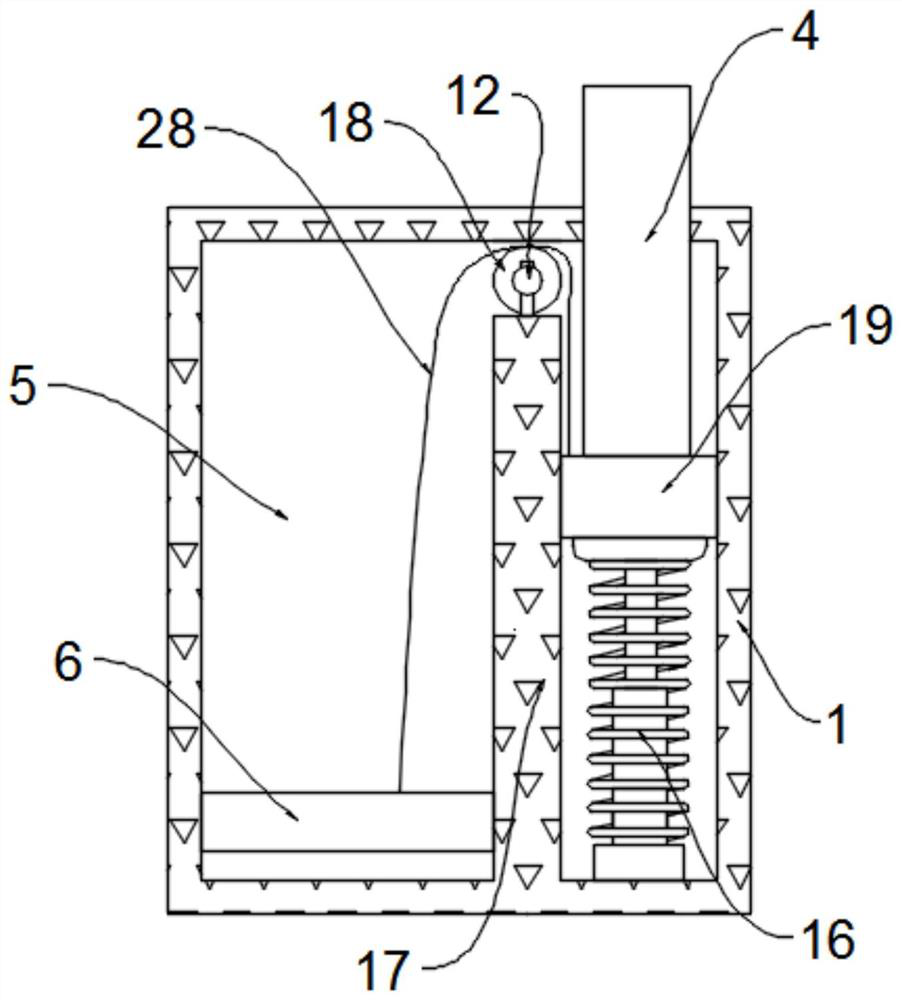

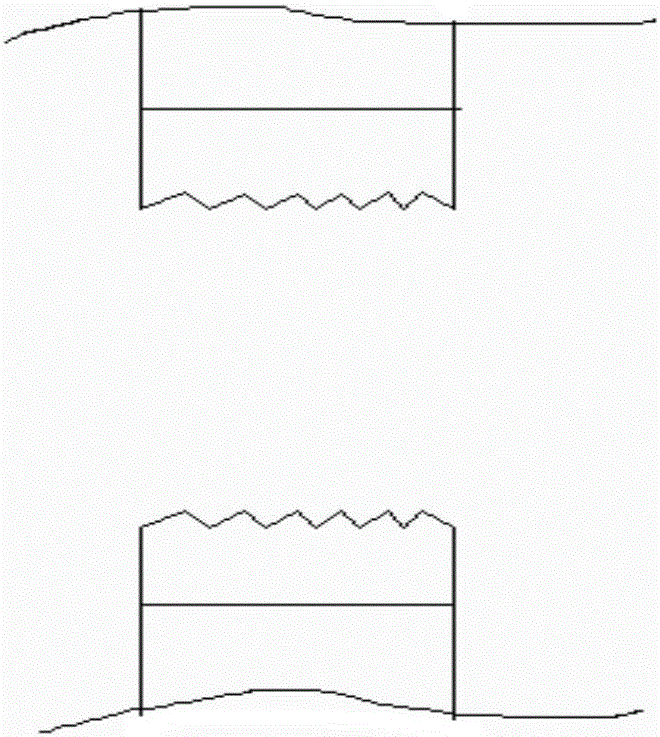

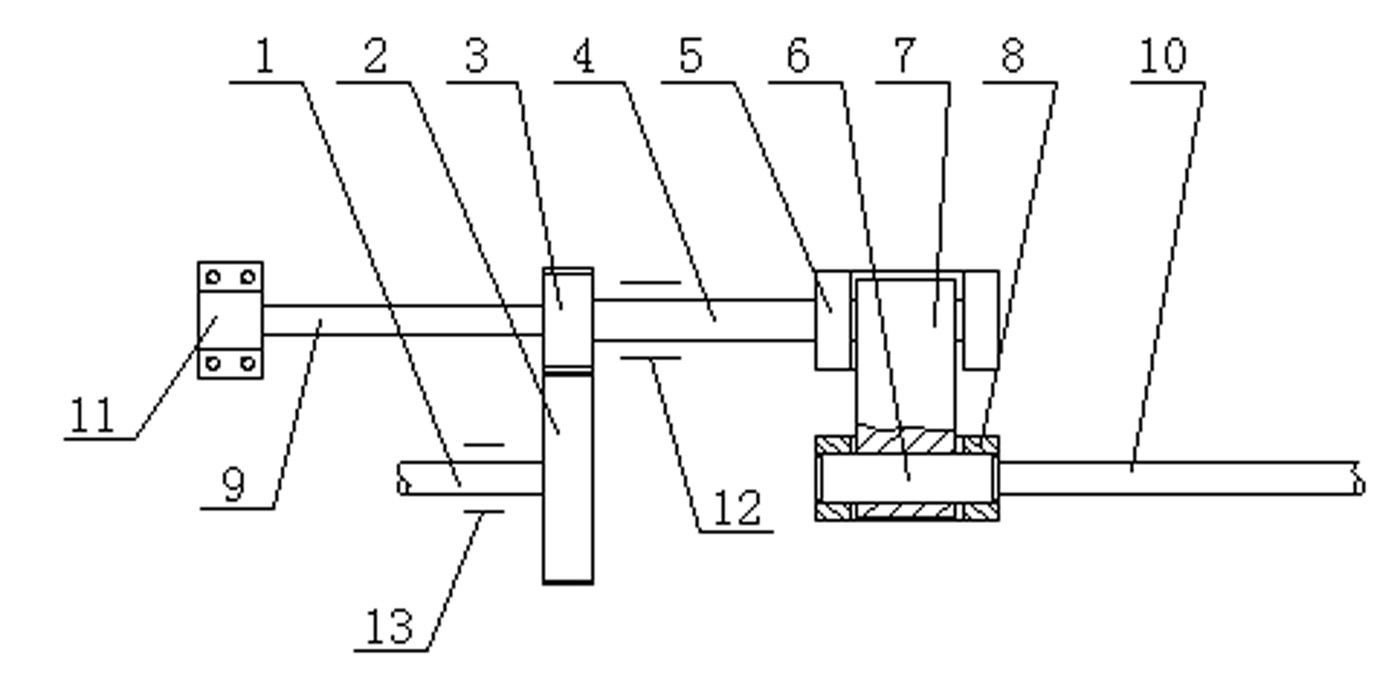

Textile reeling roller transporting device

ActiveCN107826152AImprove shock absorptionAchieve a buffering effectHand carts with multiple axesHand cart accessoriesRoad surfaceMechanical engineering

The invention discloses a textile reeling roller transporting device, and relates to the technical field of textile transporting equipment. The textile reeling roller transporting device comprises a base, a box body is fixedly connected to the top of the base, one side of the box body is fixedly connected with a first threaded block, a hollow screw rod is in threaded connection with the interior of the first threaded block, one end of the hollow screw rod penetrates through the box body and extends to the interior of the box body, one end, extending to the interior of the box body, of the hollow screw rod is fixedly connected with a mounting hopper, and one end, away from the mounting hopper, of the hollow screw rod is fixedly connected with a second threaded block, and a screw rod is in threaded connection with the interior of the second threaded block. The textile reeling roller transporting device can achieve that a clamping device and a damping device in the box body can be startedup after reeling rollers are carried from textile equipment to a transporting vehicle, in the transporting process, the transporting vehicle cannot jolt in the transporting process due to the fact that the road surface is uneven, the reeling rollers are relatively stable, and cannot collide with one another, and accordingly the quality of textile cloth materials can be well protected.

Owner:安徽省伊贝雅纺织股份有限公司

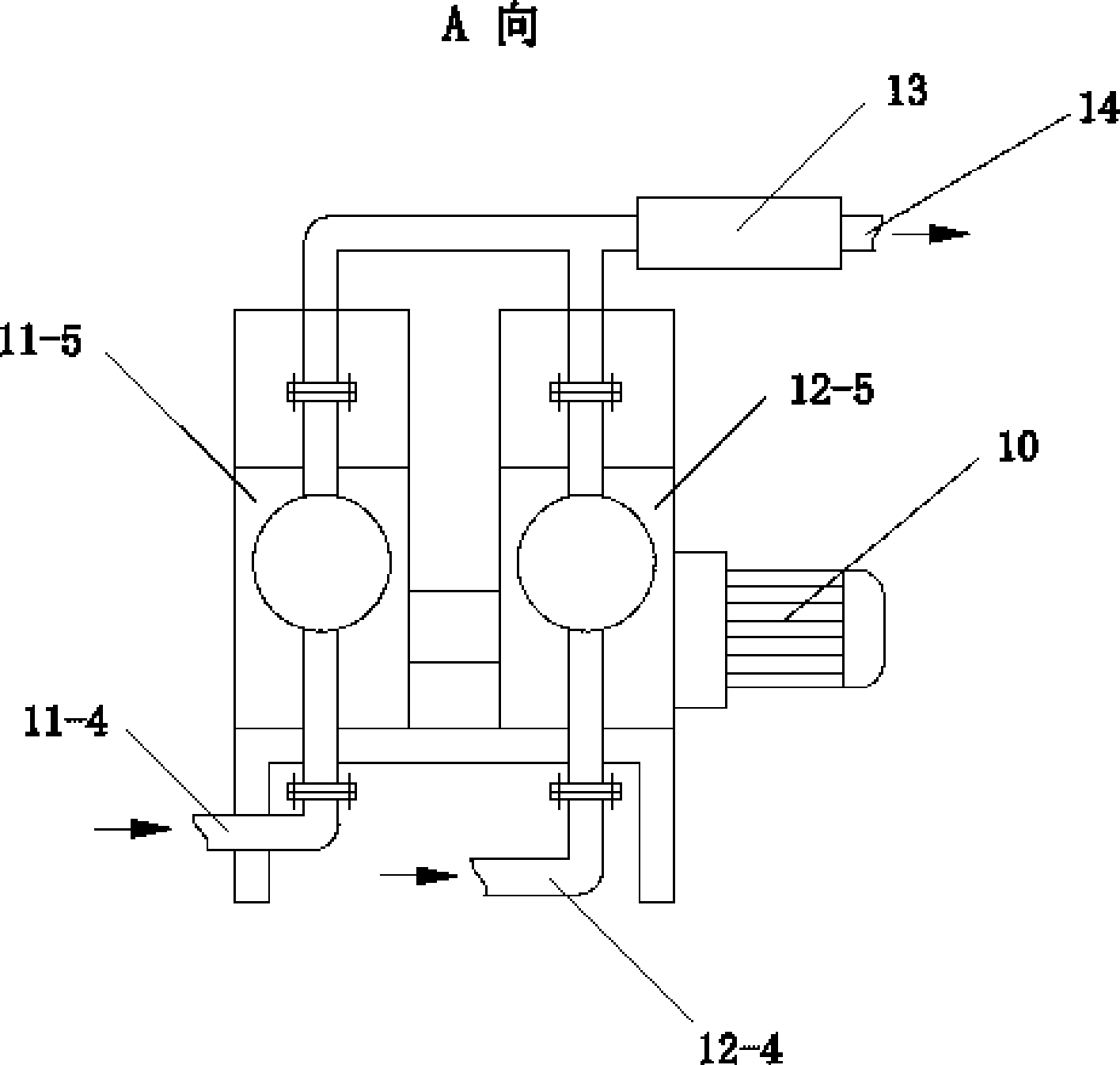

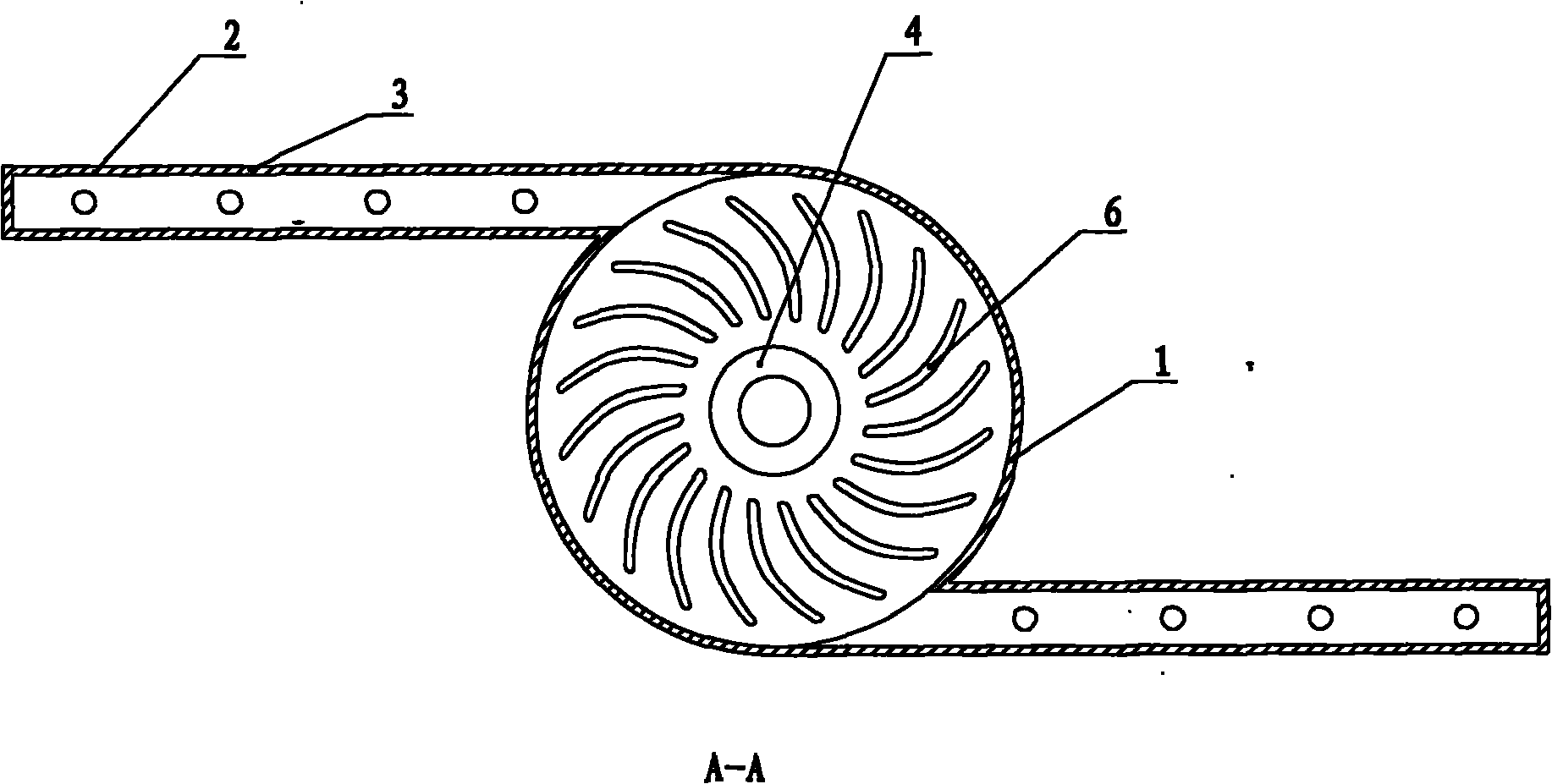

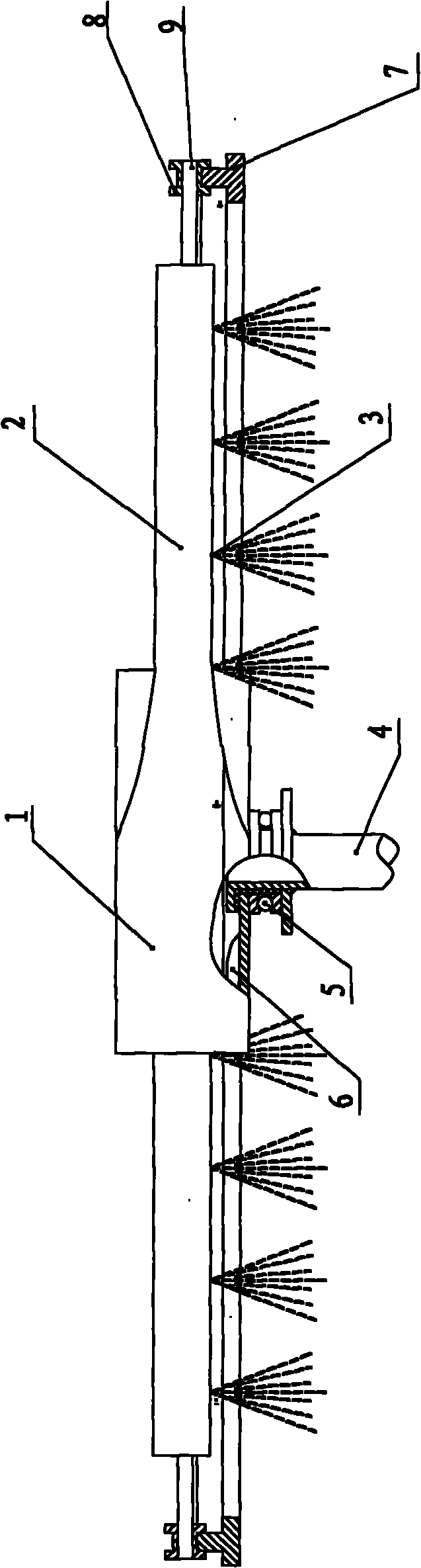

Automatically-rotating flusher for wet desulfurization demister

ActiveCN101804295AReduce impactAchieve a buffering effectDispersed particle separationRotation functionEngineering

The invention discloses an automatically-rotating flusher for a wet desulfurization demister. The flusher comprises a vertical shaft tube and a rotary sprinkler, wherein the rotary sprinkler comprises a middle round driving box body and spray tubes symmetrically connected around the driving box body; at least two spray tubes are arranged; spray holes or spraying devices are uniformly distributed below the spray tubes; the free ends of the spray tubes are enclosed; the vertical shaft tube is arranged in the middle of the lower wall of the driving box body through a bearing; the inner surface of the upper wall or lower wall of the driving box body is provided with a certain number of projecting rotary raised lines which rotate leftwards or rightwards; and the spray tubes are tangentially arranged along the cylindrical surface of the round driving box body and the rotation directions of the spray tubes are matched with those of the rotary raised lines in the box body. The device has the advantages of simple structure, clean flushing and automatic rotation function. If roller guide rail supports and auxiliary driving mechanisms are arranged at the two ends of the spray tubes, rotation of the flusher can be further ensured.

Owner:DATANG ENVIRONMENT IND GRP

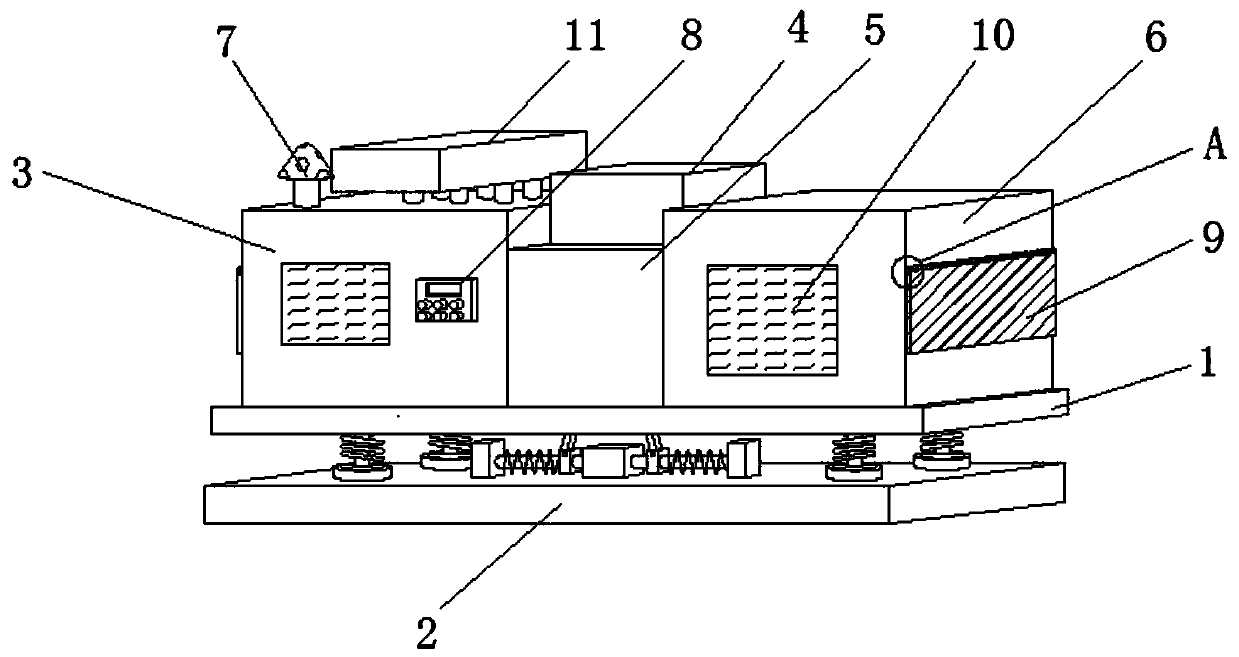

Electrophoresis spraying machine device for automobile accessories

InactiveCN110548633AEasy to compressEasy to disassemble and useSpray boothsElectrophoresisEngineering

The invention discloses an electrophoresis spraying machine device for automobile accessories. The device comprises a supporting plate, wherein a base is arranged at the lower end of the supporting plate, and a painting chamber is arranged at the upper end of the supporting plate; an air blowing chamber is arranged at one side of the painting chamber, and a control panel is arranged on the front surface of the painting chamber; a vent hole is formed in the upper end of the painting chamber, and a fixing device is arranged in the painting chamber; and an electric spray gun is arranged at the upper end of the fixing device, and a conveying belt is arranged at the lower end of the fixing device. According to the device, a damping spring and a compression spring are arranged, and the damping spring can be conveniently compressed through an adjusting rod, so that the vibration of the device in use is buffered; and meanwhile, the adjusting rod is capable of compressing the compression springwhile a transverse slide connection sleeve forwards and backwards swings, and thus the device in use can be buffered again; double-buffer reduces the loss of inner original parts in work, and thus the service life of the device is greatly prolonged.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

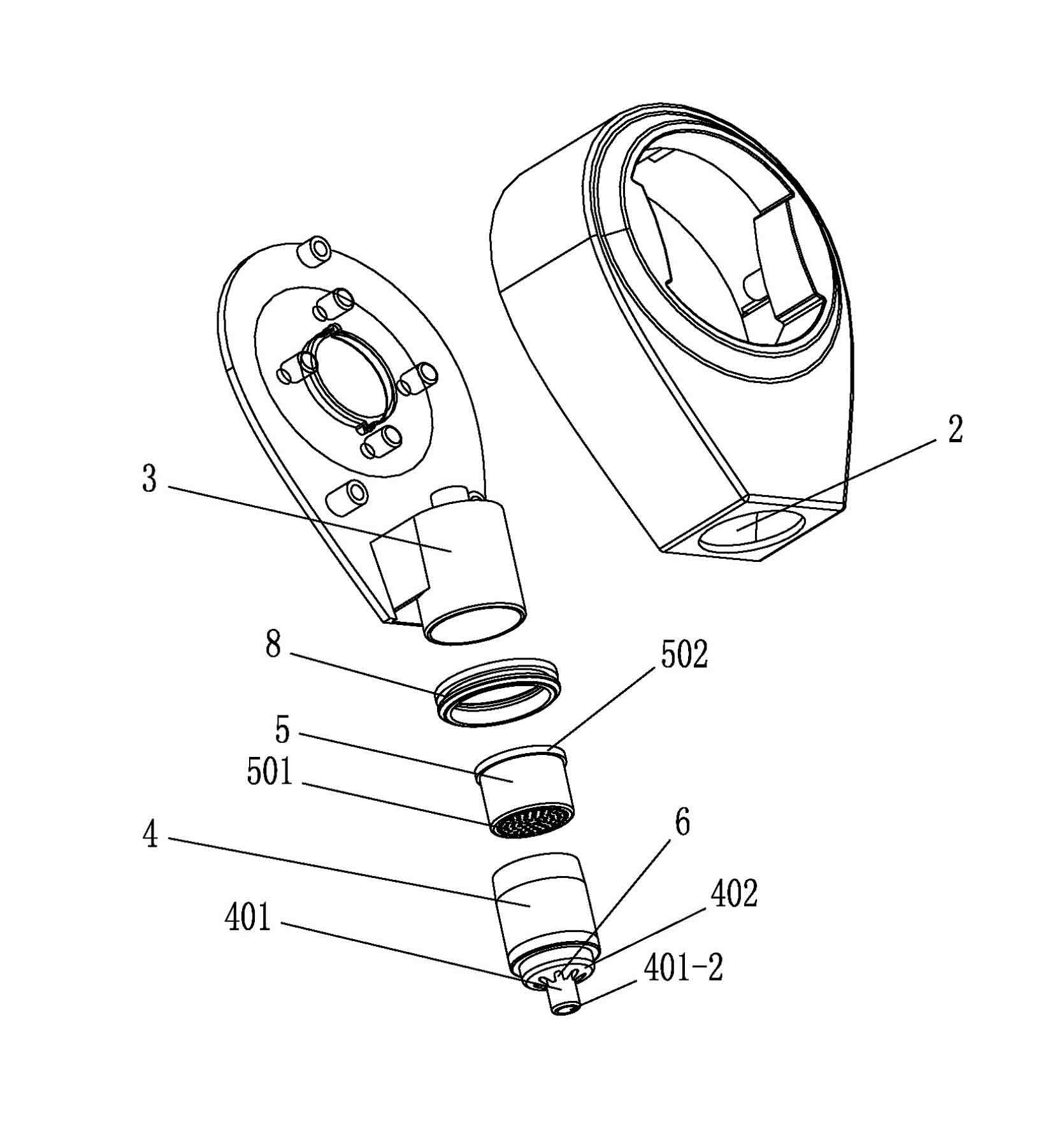

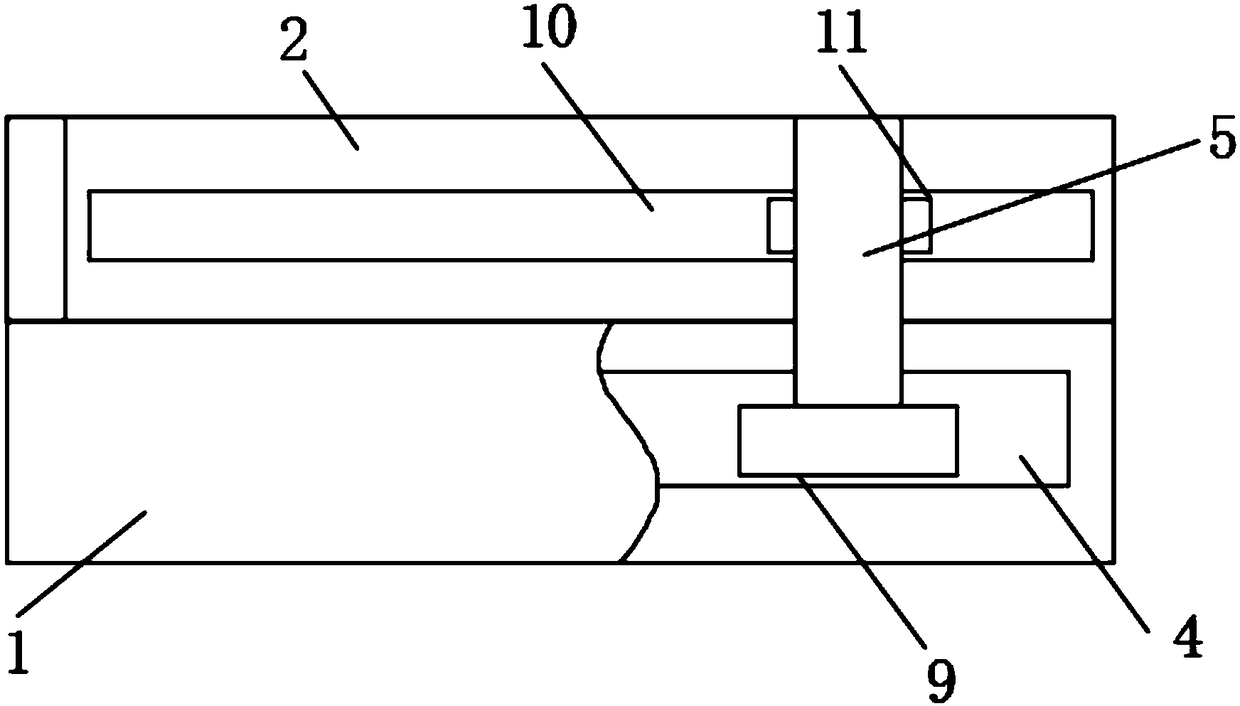

Water outlet port structure for water dispenser

The invention relates to a water outlet port structure for a water dispenser, which comprises a water outlet control box, wherein the bottom end of the water outlet control box is provided with a connection hole. The water outlet port structure is characterized in that a water inlet hood is sleeved in the connection hole; the water inlet hood is tightly connected with a water outlet sleeve; an upper end and a lower end corresponding to the water inlet hood and the water outlet sleeve are respectively connected with a water inlet pipe and a water outlet pipe which are communicated with each other; a buffer type pressure relief sleeve communicated with the water inlet pipe is further sleeved in the water outlet sleeve; the bottom surface of the buffer type pressure relief sleeve is providedwith a plurality of buffer discharge holes; the top end of the water outlet pipe extends into the cavity of the water outlet sleeve and abuts on the buffer discharge holes; the bottom end of the water outlet sleeve is provided with an obconical inclined surface; the bottom end of the water outlet pipe extends out of the inclined surface; and the inclined surface close to the outer wall of the water outlet pipe is provided with a plurality of water outlet holes communicated with the cavity of the water outlet sleeve in the circumferential direction. The invention has a simple and reasonable structure, can smoothly supply cool / hot water, is safe and reliable, and can relieve pressure during water supply.

Owner:广东昌盛电器有限公司

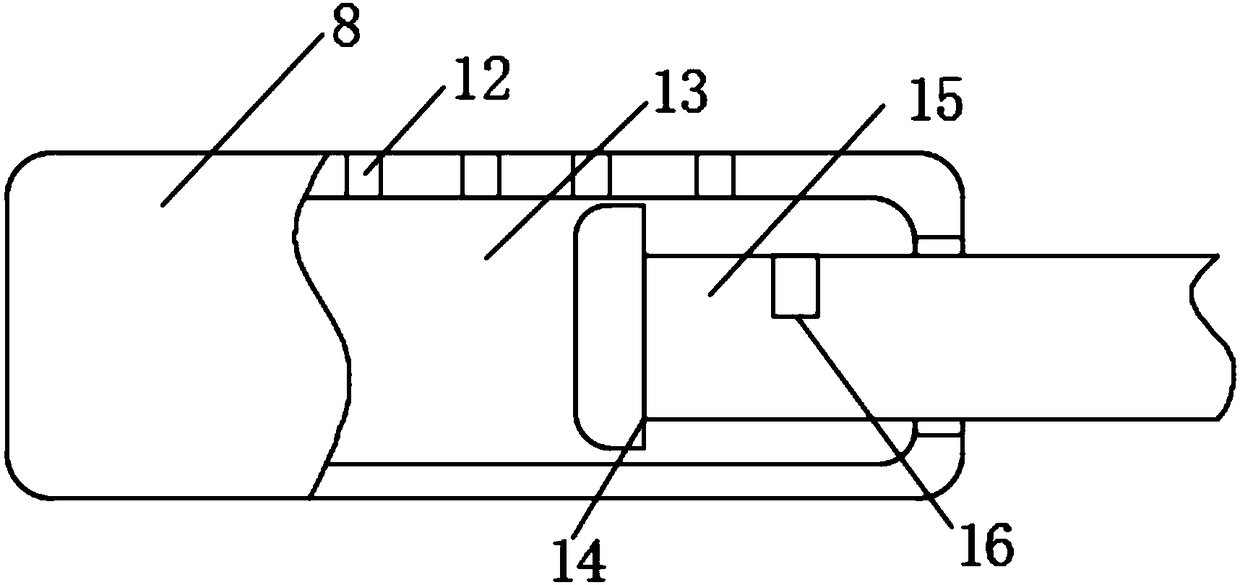

Noise eliminating device for reducing exhaust noise of internal combustion engine

InactiveCN108979816ATo achieve the effect of noise reductionAchieve a buffering effectExhaust apparatusSilencing apparatusComing outExternal combustion engine

The invention discloses a noise eliminating device for reducing the exhaust noise of an internal combustion engine. The noise eliminating device comprises a shell, wherein the shell comprises an innershell and an outer shell, a cavity is formed between the inner shell and the outer shell, an air inlet pipe is arranged on the left side of the shell, the air inlet pipe extends into the inner cavityof the shell, a first baffle is arranged in the inner cavity of the shell, a buffer groove is formed in the middle of the left side of the first baffle plate, the buffer groove and the air inlet pipeare located on the same horizontal plane, and noise eliminating pipes are arranged on the periphery of the buffer groove. Through the arrangement of the buffer groove, the airflow can play a role inbuffering when coming out of the air inlet pipe, and the air flow can circularly flow on the left side of the first baffle to reduce the noise; sound absorbing cotton is arranged on the inner surfaceof the buffer groove, so that when the air flow is transmitted to the buffer groove, the effect of absorbing noise is achieved; the noise eliminating pipes are arranged, so that air flow is transmitted to the right side of the first baffle from the left side of the first baffle; and first noise eliminating holes are formed, so that the energy of the air flow in the noise eliminating pipes is prevented from being attenuated, and the effect of noise eliminating is achieved.

Owner:全椒县全动机械有限公司

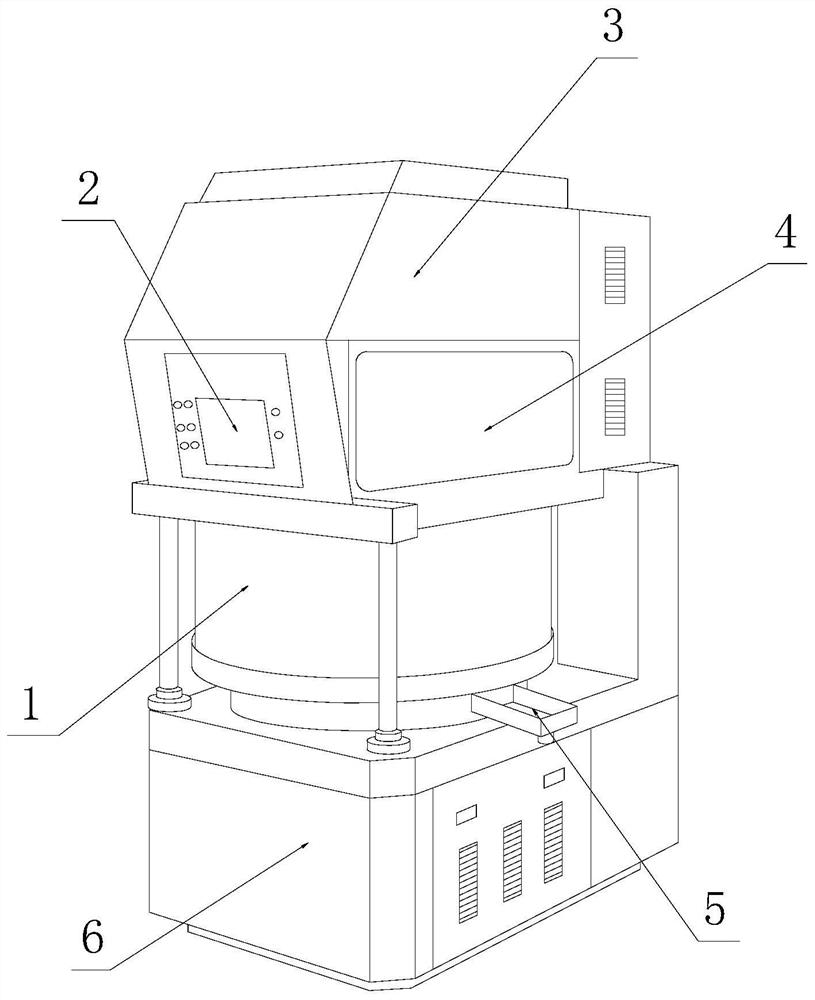

Semiconductor ceramic protection equipment

InactiveCN112571197AAchieve a buffering effectGuaranteed fitEdge grinding machinesPolishing machinesStructural engineeringCentrifugal force

The invention discloses semiconductor ceramic protection equipment. The equipment structurally comprises a machining center, a controller, a driving box, observation windows, a powder discharging groove and an equipment box. The upper end of the machining center is movably matched with the driving box, the upper end of the driving box is fixedly connected with the controller in an embedded mode, the observation windows are fixed to the left end and the right end of the driving box through bolts, and the lower end of the machining center is in clearance fit with the upper end of the equipment box; and the powder discharging groove is connected with the right end of the machining center in a nested mode, the powder discharging groove is connected with the upper end of the equipment box in awelded mode, and the machining center comprises a polisher, a protective cover, a rotating sleeve column, a construction bin and a fixing base. According to the equipment, through the centrifugal force generated during rotation, a powder scattering groove is moved, a displacement rod is expanded upwards through the action of centrifugal force under the cooperation of a thrust block and a rolling wheel, and internal hot air and ceramic dust are divided from a flow-dividing block and finally discharged from the discharging groove, so that the internal ceramic dust is effectively discharged out of a construction barrel, meanwhile, the internal hot air is discharged, and the problem that a grinding block adsorbs the dust due to heating is avoided.

Owner:李三源

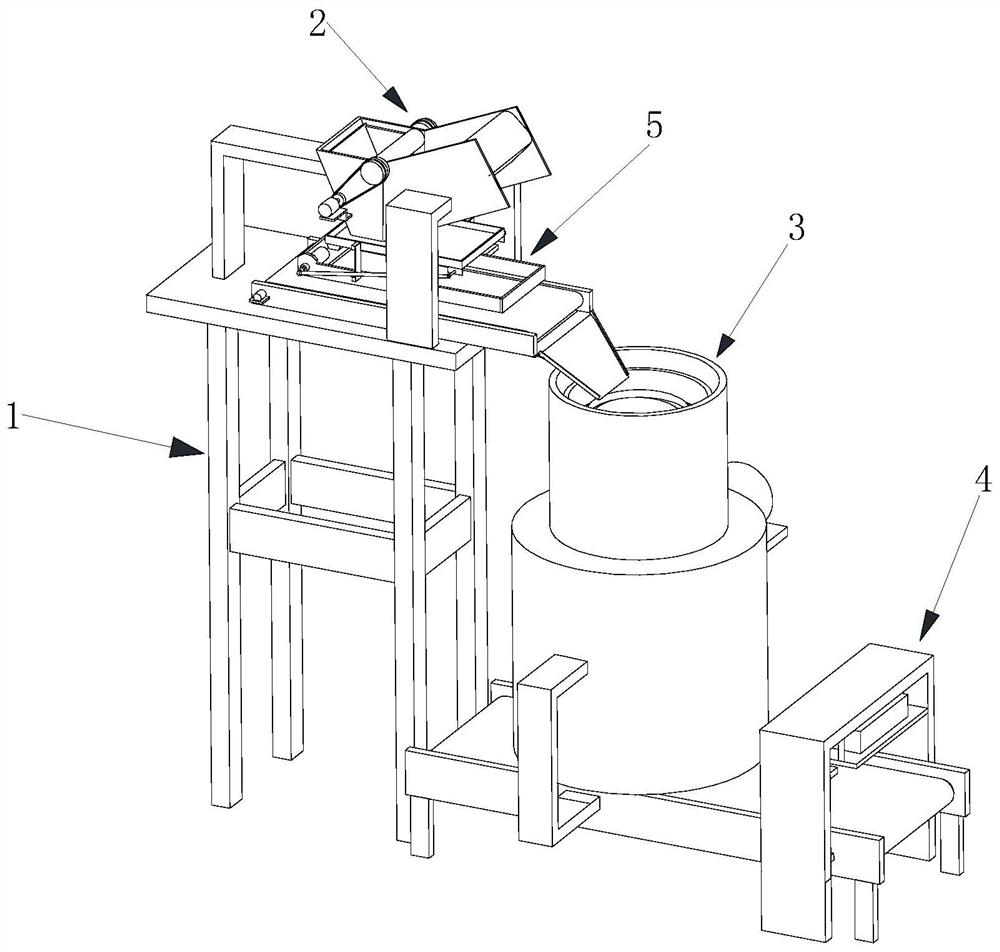

Construction waste crushing device

The invention relates to the technical field of construction waste treatment equipment, in particular to a construction waste crushing device. The construction waste crushing device comprises a rack,a primary crushing device, a screening device, a secondary crushing device and an iron removing device, wherein the screening device is assembled above the rack, the primary crushing device is assembled above the screening device, the secondary crushing device is located on one side of the rack and used for crushing coarse aggregate crushed by the primary crushing device again, and the iron removal device is located on one side of the secondary crushing device and used for adsorbing and removing iron in fine aggregate crushed by the secondary crushing device. The construction waste treatment equipment can screen and refine the construction waste and effectively avoids reduction of the recovery rate due to crushing of steel bars and other metals.

Owner:安徽黎搏装饰工程有限公司

An efficient surface water sampling device used for water quality detection, and manufacturing and sampling methods thereof

PendingCN108036970AImprove bearing strengthNot easy to wearWithdrawing sample devicesGeneral water supply conservationDrive wheelSurface water

Owner:南京萃智水利科技有限公司

Buffer device for garment processing

InactiveCN112943855ATo achieve the buffer effectImprove buffering effectConveyorsNon-rotating vibration suppressionPulleySupport plane

The invention discloses a buffer device for garment processing. The buffer device comprises a buffer base, ventilation pipes are fixedly connected to the two sides of the buffer base, air bags are slidably connected to the outer side walls of one ends of the ventilation pipes, rubber sleeves fixedly sleeve the outer side walls of the air bags, a first cavity, a second cavity and a supporting frame are arranged in the buffer base, a fixed pulley support is fixedly connected to the top of the supporting frame, and a driving fixed pulley is rotationally connected with the inner side wall of the fixed pulley support. According to the buffer device for garment processing, by arranging the ventilation pipes, the air bags and the rubber sleeves, the air bags expand due to inflation of air, so that a garment processing outer frame obtains a good buffering effect, and strenuous vibration generated in the processing process of a garment processing device is effectively reduced; and meanwhile, a plurality of springs is avoided, and errors caused by displacement generated in the garment processing process when the springs exceed the elastic limit range of the springs are avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Bidirectional-protection automobile front bumper

ActiveCN105922957AReduce two-way damageImprove buffering effectPedestrian/occupant safety arrangementBumpersEngineeringAirbag

The invention provides a bidirectional-protection automobile front bumper which comprises a front bumper body. The front bumper body comprises a first bumper and a second bumper which are in front-rear arrangement and are identical in radian, a buffering device is arranged between the first bumper and the second bumper, multiple upper buffering pads are arranged on the rear side of the first bumper, lower buffering pads corresponding to the upper buffering pads are arranged on the front side of the second bumper, the upper buffering pads and the lower buffering pads are in coaxial fit, gaps exist between the upper buffering pads and the lower buffering pads, maximum compression distance of the buffering device is greater than the gaps between the upper buffering pads and the lower buffering pads, and a protection device is arranged on the second bumper and comprises a safety airbag and a distance sensor. Buffering effect of the front bumper is improved through multilayer buffering, damage to passengers and impacted objects is reduced as much as possible during strong impact, damaged degree of an automobile is lowered, and property loss is reduced.

Owner:TIANJIN ZHONGSHENG IND

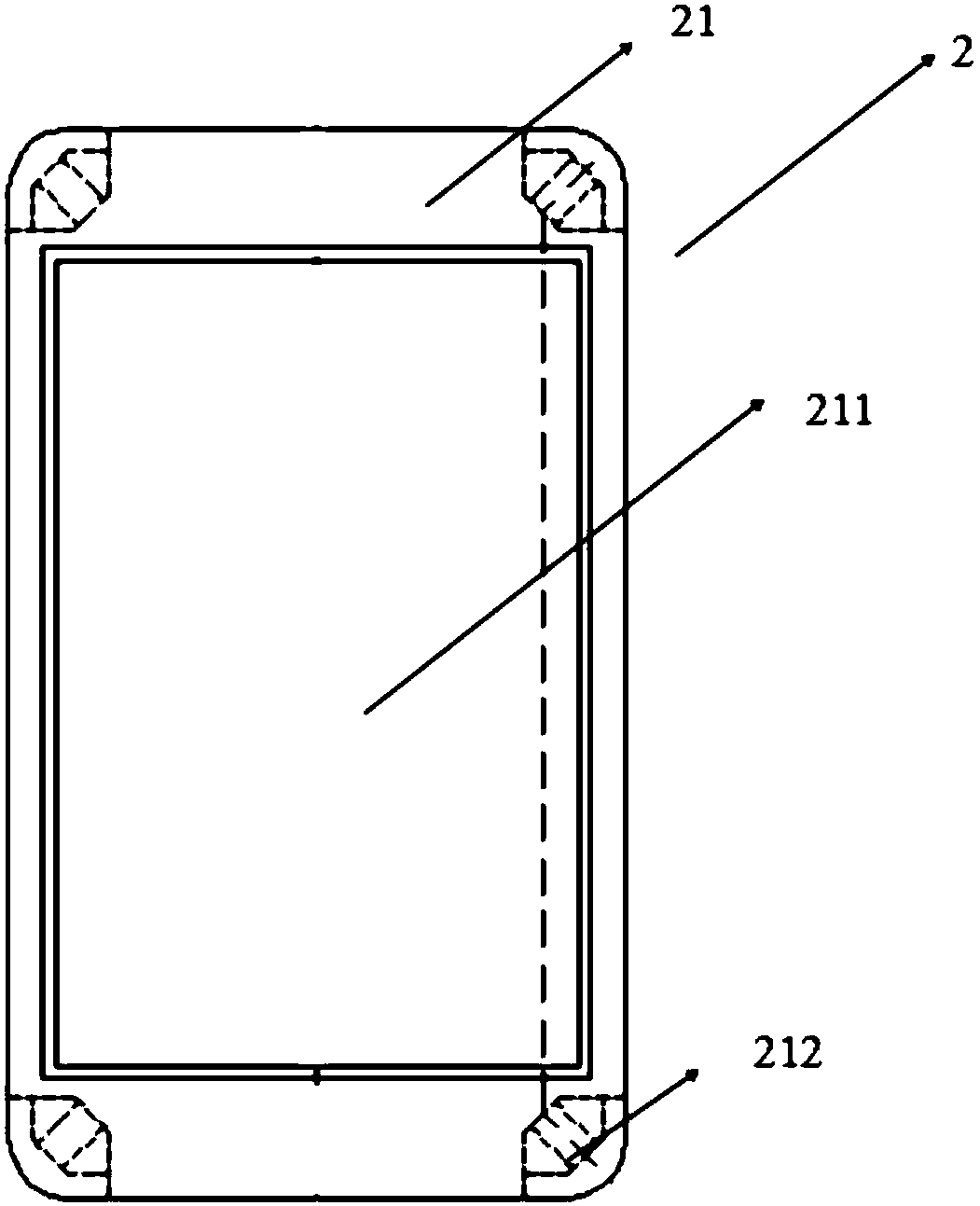

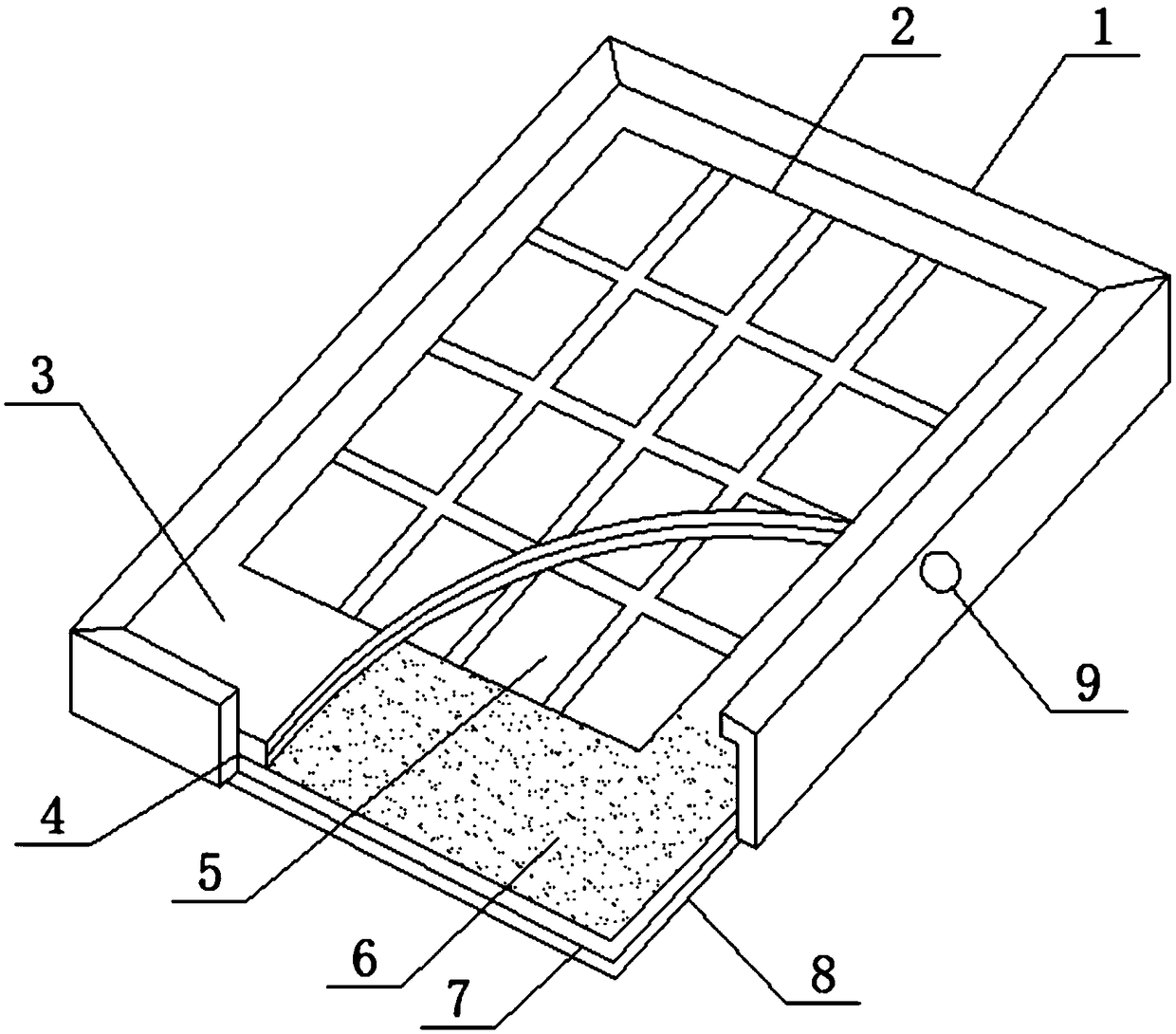

Solar panel module

PendingCN109301014AAvoid damageNo fragmentationPhotovoltaicsPhotovoltaic energy generationGlass coverSolar module

The present invention discloses a solar panel module. The solar panel module comprises a solar energy frame and an upper glass cover plate, the solar energy frame is internally provided with the upperglass cover plate which sleeves and is connected with the internal portion of the solar energy frame, the solar energy frame sleeves and is connected with the upper glass cover plate, and the internal portion of the upper glass cover plate is provided with an installation groove in an embedding mode. Compared to a current solar energy module rain-proof method, the solar panel module is very convenient for later maintenance and replacement and enough to cover the solar energy module, rainwater is exhausted from a rain-proof groove to prevent the solar cell panel from being damaged, when the solar energy module is suffered from the load of the external force, the force is transmitted to a spring ring at the lower end when the solar panel is suffered from the load so as to prevent the solarpanel from being damaged caused by the action of the rigid force and improve the service life of the solar energy module.

Owner:无锡英鹏新能源有限公司

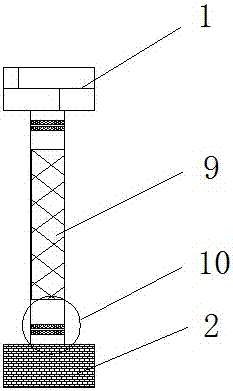

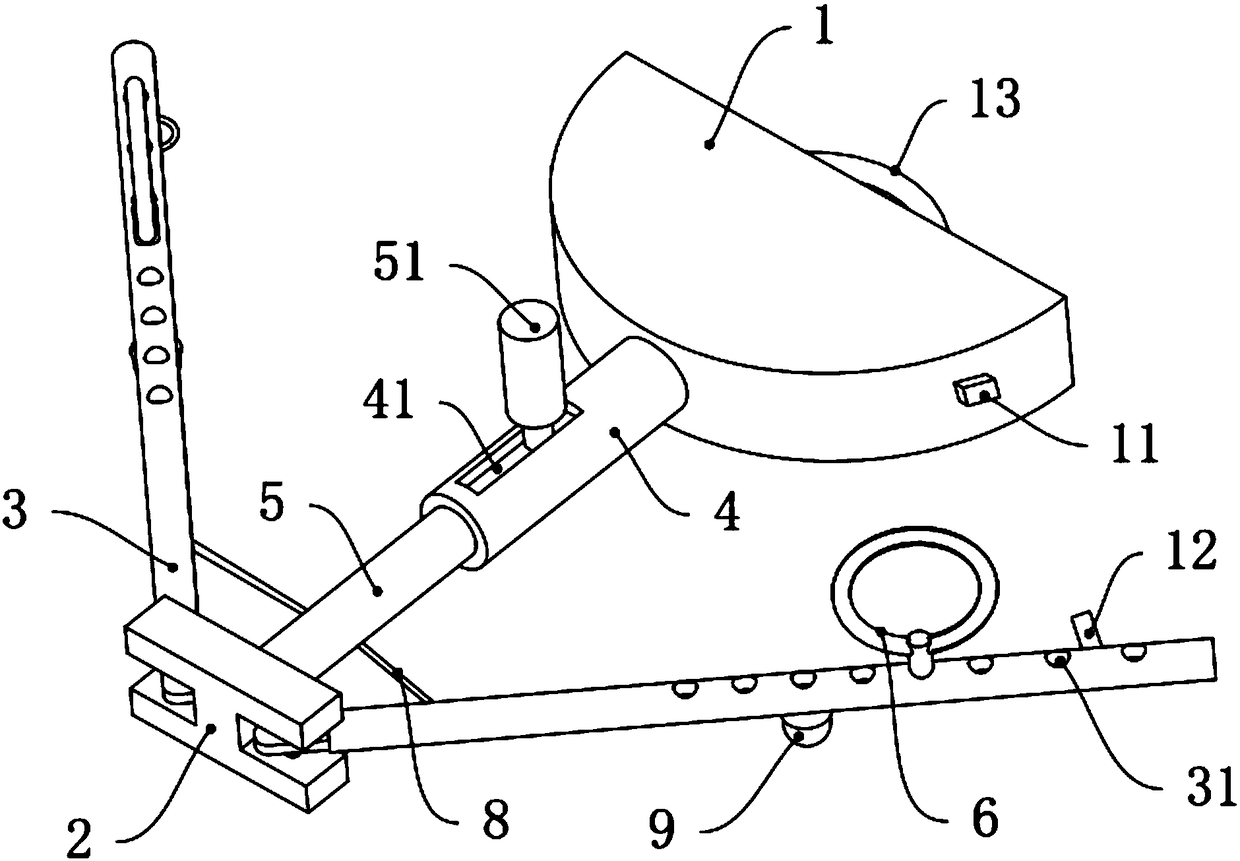

Dance assisting training device

The invention relates to the field of training auxiliary devices, in particular to a dance assisting training device which comprises a seat cushion, a telescopic device, a support and two stretching rods. The telescopic device includes a sleeve and a sliding rod, the sleeve is of a hollow barrel-shaped structure with one end provided with an opening and the other end closed, the closed end of thesleeve is connected with the seat cushion, one end of the sliding rod extends into the sleeve through the open end of the sleeve and can slide relative to the sleeve, the top side of the sleeve is provided with a strip-shaped opening in the length direction, a portion of the sliding rod extending into the sleeve is provided with a handle, and the handle passes through the strip-shaped opening andextends out of the sleeve. The support is disposed at the other end of the sliding rod. The two stretching rods are disposed on the two sides of the telescopic device respectively, one end of each ofthe two stretching rods is hinged to the support respectively, and a plurality of threaded holes are evenly formed at intervals in the top sides of the stretching rods in the length direction. The dance assisting training device also includes pedals each connected with one of the threaded holes. The dance assisting training device is simple in structure and can be adjusted and used according to the leg length of a user.

Owner:PANZHIHUA UNIV

New energy auto motor special turnover frame

InactiveCN108128551AAchieve a buffering effectEasy to movePackaging vehiclesContainers for machinesNew energyEngineering

The invention discloses a new energy auto motor special turnover frame. The new energy auto motor special turnover frame comprises a bottom plate and a locating clip, one side of the upper surface ofthe bottom plate is fixedly provided with a fixing plate, a locating groove is formed in the middle portion of the fixing plate, the end portion of the fixing plate is integrally provided with a baffle, the lower surface of the baffle is welded on the end portion of the upper surface the bottom plate, a sliding groove is formed in one side of the inner portion of the bottom plate, and the upper surface of the bottom plate is provided with a supporting plate; one sides of the fixing plate and baffle are provided with shock absorption sponge, at the same time, one side of a movable face is alsoprovided with shock absorption sponge, after the device fixes a motor, the motor can achieve a certain buffering effect by contacting with the shock absorption sponge; one end of the movable face is fixedly arranged at one side of the supporting plate, the end portion of the supporting plate is provided with a sliding block, thus the supporting plate can be slidably arranged in the sliding groovethrough the sliding block to achieve the purpose of sliding, the other end of the movable face is provided with a locating block, the locating block is slidably arranged in the locating groove, so that the structure is more stable when moving.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

Novel porous stamping mould

InactiveCN109158477AAvoid damageEasy to removePerforating toolsShaping safety devicesFixed frameEngineering

The invention provides a novel porous stamping mould. The novel porous stamping mould comprises an upper mould base and a lower mould base, wherein the bottom end of the upper mould base is fixedly connected with a convex mould fixing plate; the top end of the lower mould base is fixedly connected with a concave mould fixing plate; the two sides of the upper mould base are fixedly equipped with guide sleeves, and guide posts which are in sliding fit to the guide sleeves; the bottom end of the convex mould fixing plate is fixedly equipped with a convex mould and buffer assemblies; an unloadingpushing rod is arranged in the convex mould; the top end of the concave mould fixing plate is fixedly equipped with a concave mould and side hole stamping devices arranged at the two sides of the concave mould; a fixed frame is fixedly arranged on the lower mould base; and the top end of the fixed frame is symmetrically equipped with pressure interfaces. The convex mould is equipped with the unloading pushing rod, so that waste blocked in the convex mould can be pushed out to complete upper unloading while the convex mould upwards moves to the original position; the buffer assemblies are arranged at the two sides of the convex mould, so that material movement or convex mould damages are prevented; and the side hole stamping assemblies are arranged on the concave mould fixing plate, so thatstamping on the side surface of the material is completed.

Owner:芜湖市夯福机械模具有限公司

Suspension device with front and back torsion bars for automobile

InactiveCN102463864AImprove vibrationImprove shock absorptionInterconnection systemsResilient suspensionsVehicle frameRoad surface

Owner:李志东

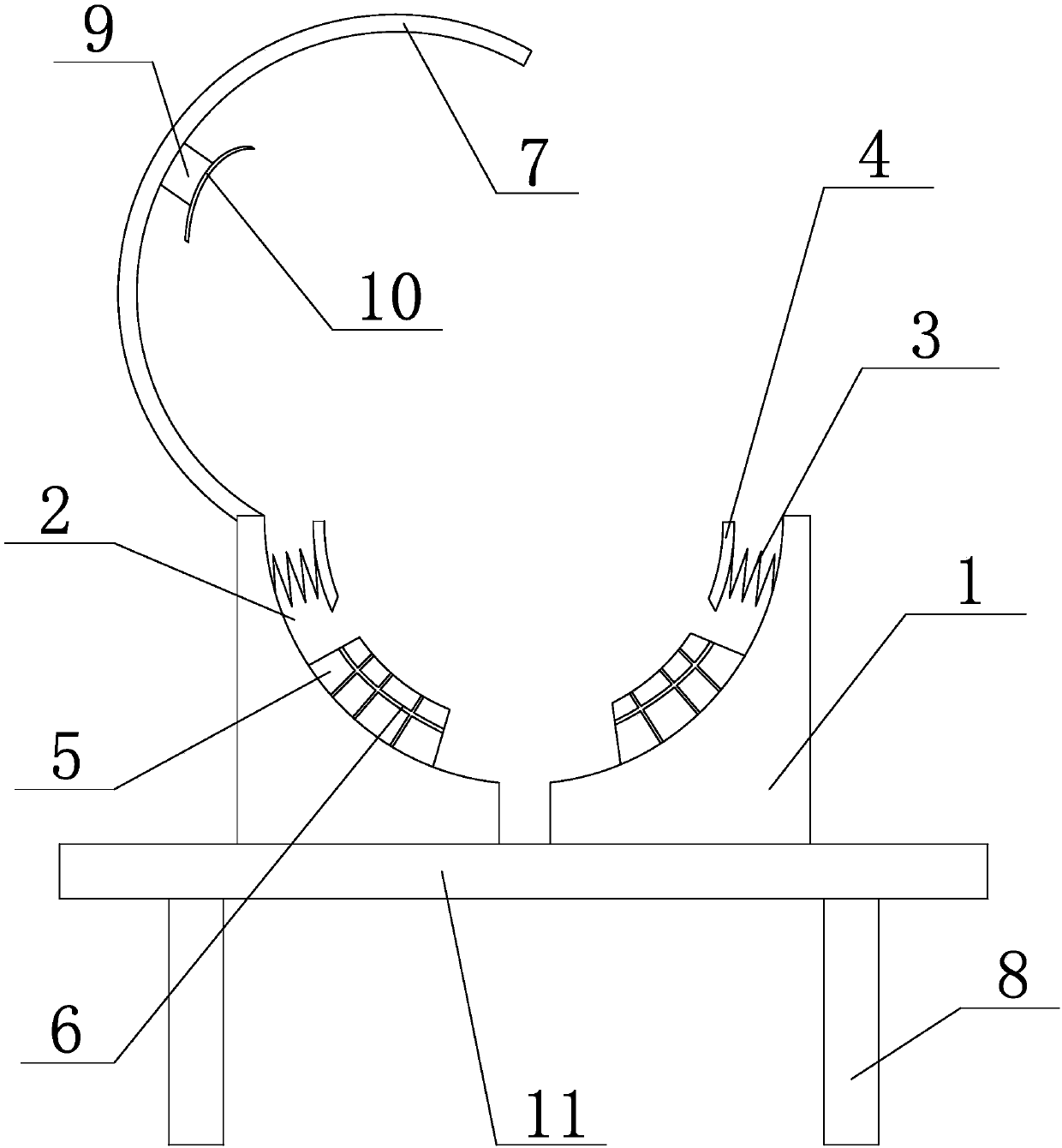

Pipeline support frame capable of switching in multiple directions

InactiveCN107781513AImprove stabilityEasy to install and disassemblePipe supportsPipe elementsEngineeringPipe support

The invention discloses a pipeline support frame capable of switching in multiple directions. The pipeline support frame support frame capable of switching in multiple directions comprises two groupsof support tables arranged on a base in parallel, wherein each group of support table comprises two support blocks; quarters of circular arc-shaped placement grooves are formed in one opposite sides of each two support blocks; support springs are perpendicularly connected onto inner walls of the placement groves; an included angle between each support spring and a horizontal line is 30 degrees; anarc-shaped support plate is connected to the top end of each support spring; a boss is arranged on the inner wall of the placement groove and under each support spring; slide blocks can move toward slide blocks under the same group of support blocks or move toward slide blocks under the other group of support blocks. The pipeline support frame provided by the invention is simple and convenient toinstall and disassembly, time and labor saving, high in stability performance, and capable of favorably buffering an impact force applied on a pipeline during petroleum transporting, keeping a position of the pipeline to be fixed, stably supporting pipelines with various sizes at the same time, and supporting pipelines in multiple directions.

Owner:CHENGDU KESHENG PETROLEUM TECH

Textile cutting equipment capable of removing fluff

InactiveCN112095329AAchieve the effect of removing lintAchieve a buffering effectSevering textilesMetal working apparatusGear wheelKnife blades

The invention relates to the technical field of textile cutting, and discloses textile cutting equipment capable of removing fluff. The equipment comprises a machine shell and a cutting device, a first notch is formed in the middle of the machine shell, a bottom block is slidably connected to the interior of the first notch, a concave block is fixedly connected to the upper end of the bottom block, a first spring is fixedly connected to the lower end of the bottom block, first stop blocks are arranged on the two sides of the bottom block, and second notches are slidably connected to the surfaces of the first stop blocks. According to the textile cutting equipment with replaceable blades, a rotating rod drives a cylinder to rotate, second stop blocks fixedly connected to the surface of thecylinder rotate on a gear, a supporting rod fixedly connected to the back surface of the gear rotates, the supporting rod drives the cutting blades to rotate, and the effect of switching the blades isachieved; and meanwhile, a screw in the surface of an inner shell slides in a fifth notch in the surface of an outer shell, and the buffering effect is achieved during cutting by the cutting blades.

Owner:梁春惠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com