Reinforcing device for narrow coal pillar between roadways

A reinforcement device and narrow coal pillar technology, applied in tunnels, tunnel linings, bolt installation, etc., can solve the problems of waste of resources, difficulties in safe production, low compression capacity, etc., to facilitate installation and disassembly, and improve resource extraction The effect of efficiency and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

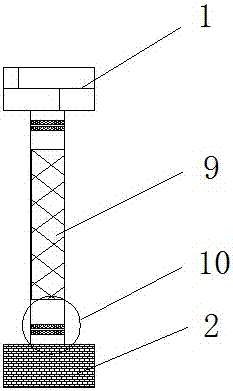

[0020] refer to Figure 1-4 , the present embodiment proposes a reinforcement device for narrow coal pillars between roadways, including a narrow coal pillar 3, a top plate 1 and a bottom plate 2, a top plate 1 is fixed above the narrow coal pillar 3, and a bottom plate 2 is fixed below the narrow coal pillar 3 , the narrow coal pillar 3 includes an anchor cable 4 and a watch member plate 8, an anchor hole 14 is provided on the narrow coal pillar 3, and the guard plate member plate 8 is fixedly installed on both sides of the narrow coal pillar 3, and the upper part of the guard plate member plate 8 and the The lower part is provided with connecting device 10, the anchor cable 4 is located in the anchor hole 14, and the anchor cable 4 runs through the anchor hole 14, both ends of the anchor cable 4 extend to the guard plate member plate 8, and both ends of the anchor cable 4 are provided with The fixed lockset 7 has five anchor holes 14, two anchor holes 14 are symmetrically ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com