Forklift working safety control device and control method

A safety control and forklift technology, applied in the direction of lifting equipment safety device, hoisting device, etc., can solve the problems of improper operation, engine flameout, low stability, etc., to increase stability, protect safety, and prevent engine flameout effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

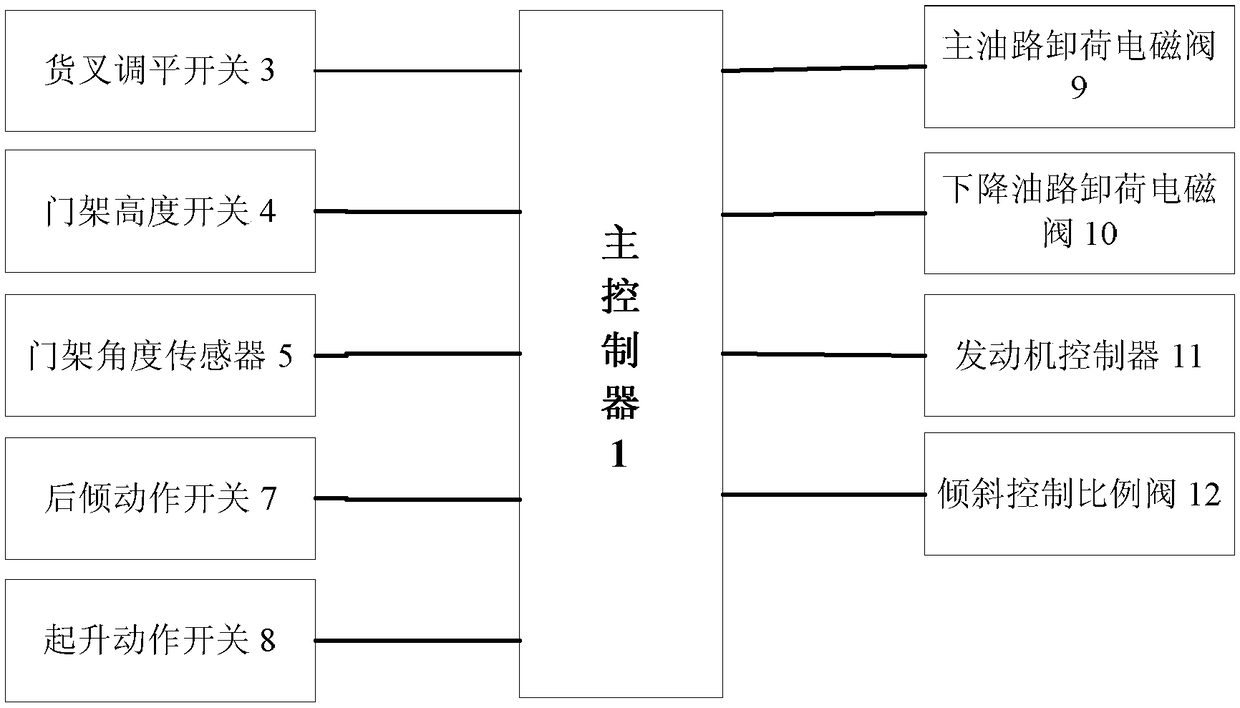

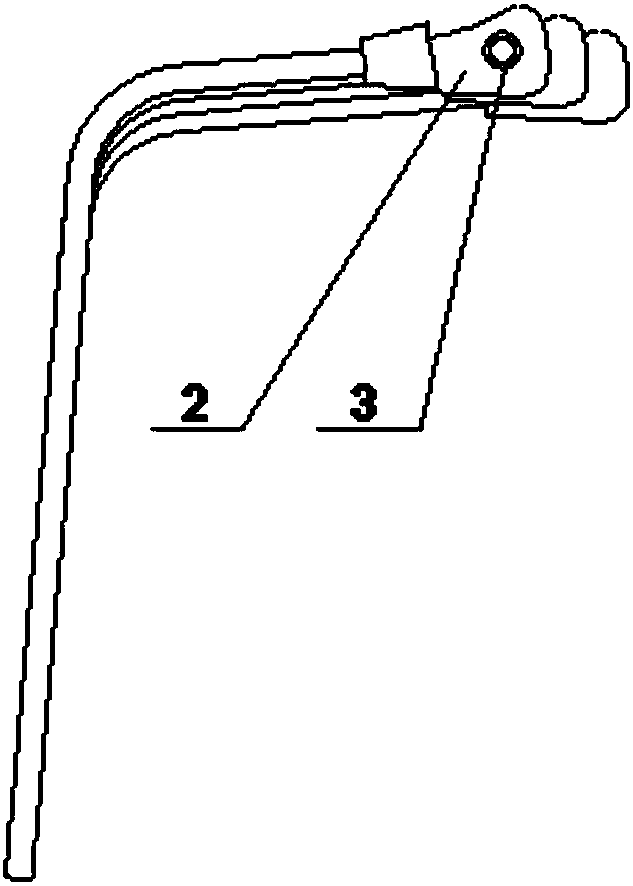

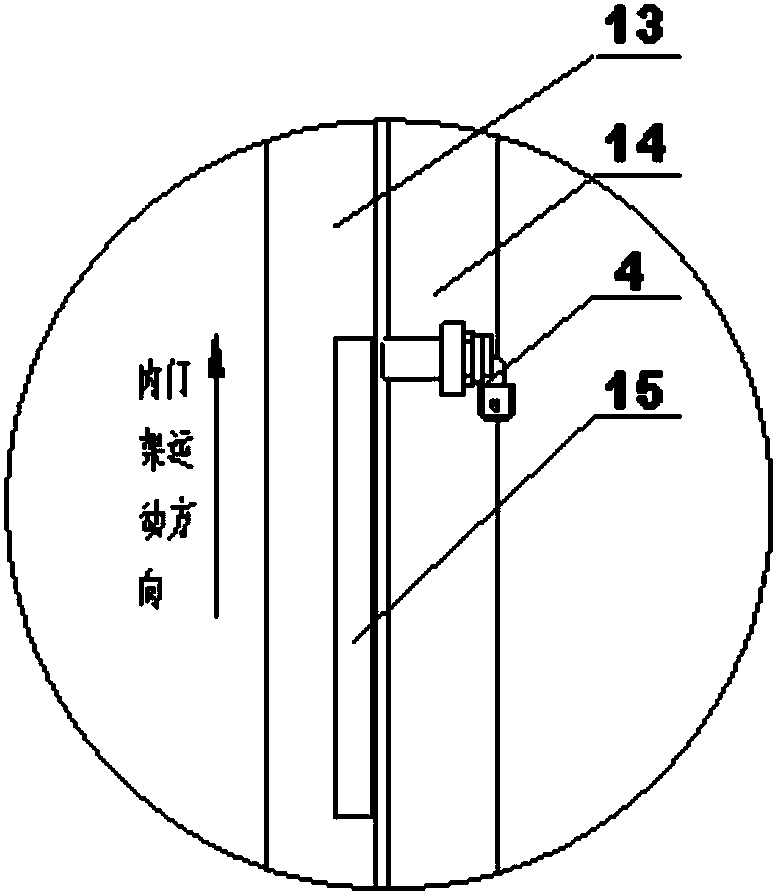

[0035] Such as figure 1 The illustrated embodiment is a work safety control device for a forklift. The forklift includes a frame, a door frame connected to the frame on the frame, a shelf on the door frame, and a shelf on the shelf. The connected cargo fork, the center console set in the frame, the multi-way valve assembly set on the frame, the multi-way valve tilting valve stem connected with the multi-way valve assembly, and the multi-way valve assembly The multi-way valve control lever is set on the tilting cylinder and lifting cylinder at the rear of the mast; including the main controller 1 set on the center console of the forklift, and the operating handle 2 set on the multi-way valve tilting valve stem The fork leveling switch 3, the mast height switch 4 on the mast, the mast angle sensor 5 on the tilt cylinder, the backward tilting act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com