Semiconductor ceramic protection equipment

A technology for protecting equipment and semiconductors. It is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc. It can solve the problems of low surface smoothness of semiconductor ceramics, heat generation, and the decline in the protection effect of semiconductor ceramics, so as to avoid heat generation and adsorption of dust. Avoid the effect of polishing dead corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

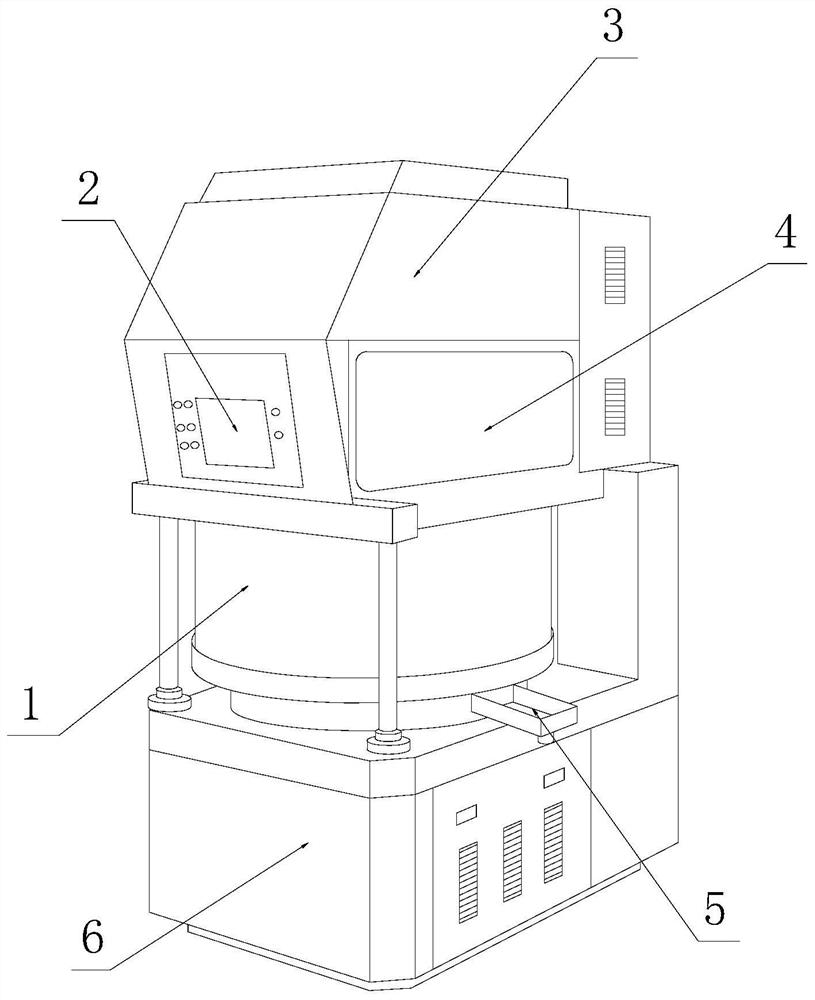

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] Its structure includes a machining center 1, a controller 2, a driving box 3, an observation window 4, an end slot 5, and an equipment box 6. The upper end of the machining center 1 is movably matched with the driving box 3, and the upper end of the driving box 3 is in cooperation with the controller. 2. Embedded connection, the observation window 4 is fixed to the left and right ends of the drive box 3 with bolts, the lower end of the machining center 1 is in clearance with the upper end of the equipment box 6, and the end row groove 5 is nested and connected to the right end of the machining center 1. The exhaust end groove 5 is welded to the upper end of the equipment box 6. The machining center 1 includes a polisher 11, a protective cover 12, a rotating sleeve 13, a construction warehouse 14, and a fixed seat 15. The polisher 11 and the rotating sleeve 13 The overall nesting fit, the bottom of the rotating s...

Embodiment 2

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the loose powder tank a4 includes a drainage bar b1, a swing frame b2, a discharge tank b3, a diverter block b4, and a clamping plate b5. The drainage bar b1 is hingedly connected to the surface of the discharge tank b3. The two sides are movable and fit, the swing frame b2 is interference fit with the inner wall of the clamp b5, the two sides of the diverter block b4 are in clearance fit with the swing frame b2, and the discharge groove b3 is fixed on the inner side of the clamp b5 to cooperate with it. The drainage bar b1 is in the shape of a long wavy strip as a whole. There are two groups, one group of three, and they are distributed on the top of the discharge groove b3 for swing hinged connection. Among them, the swing frame b2 is conducive to swinging to the left under the drive of centrifugal force so as to divert the internal wind direction from the flow. After the block b4 is inhaled, it cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com