Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about "Transducers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

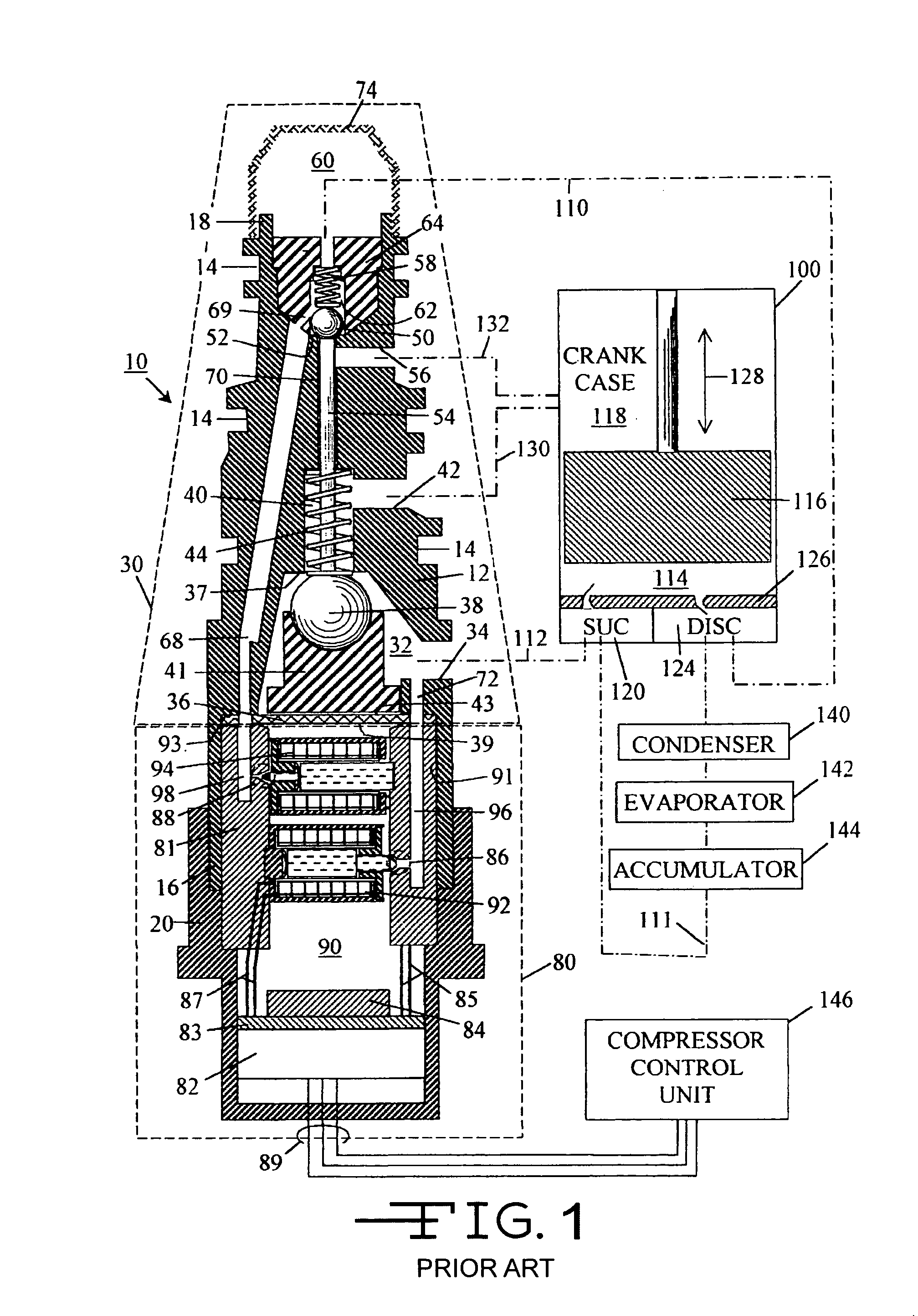

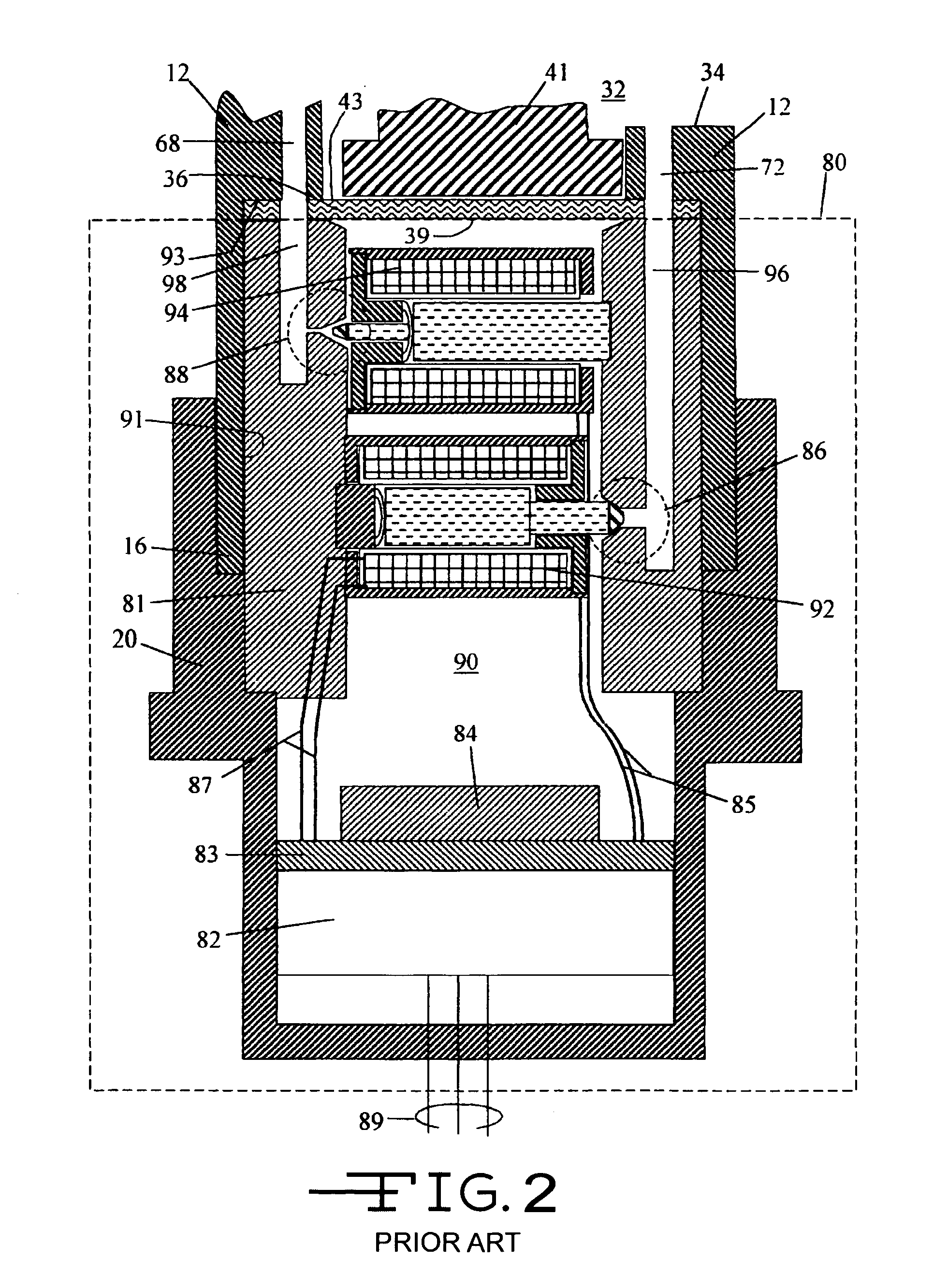

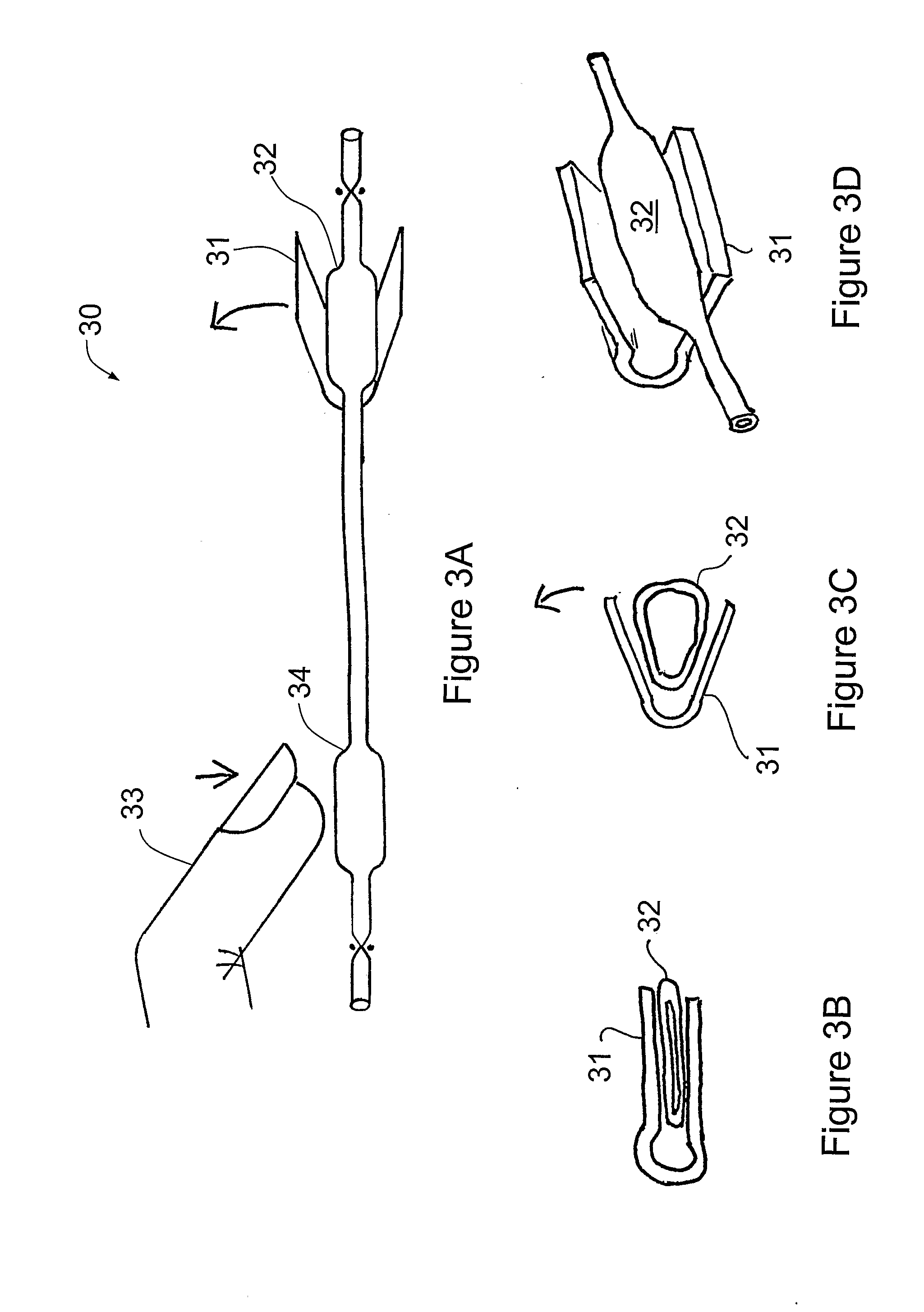

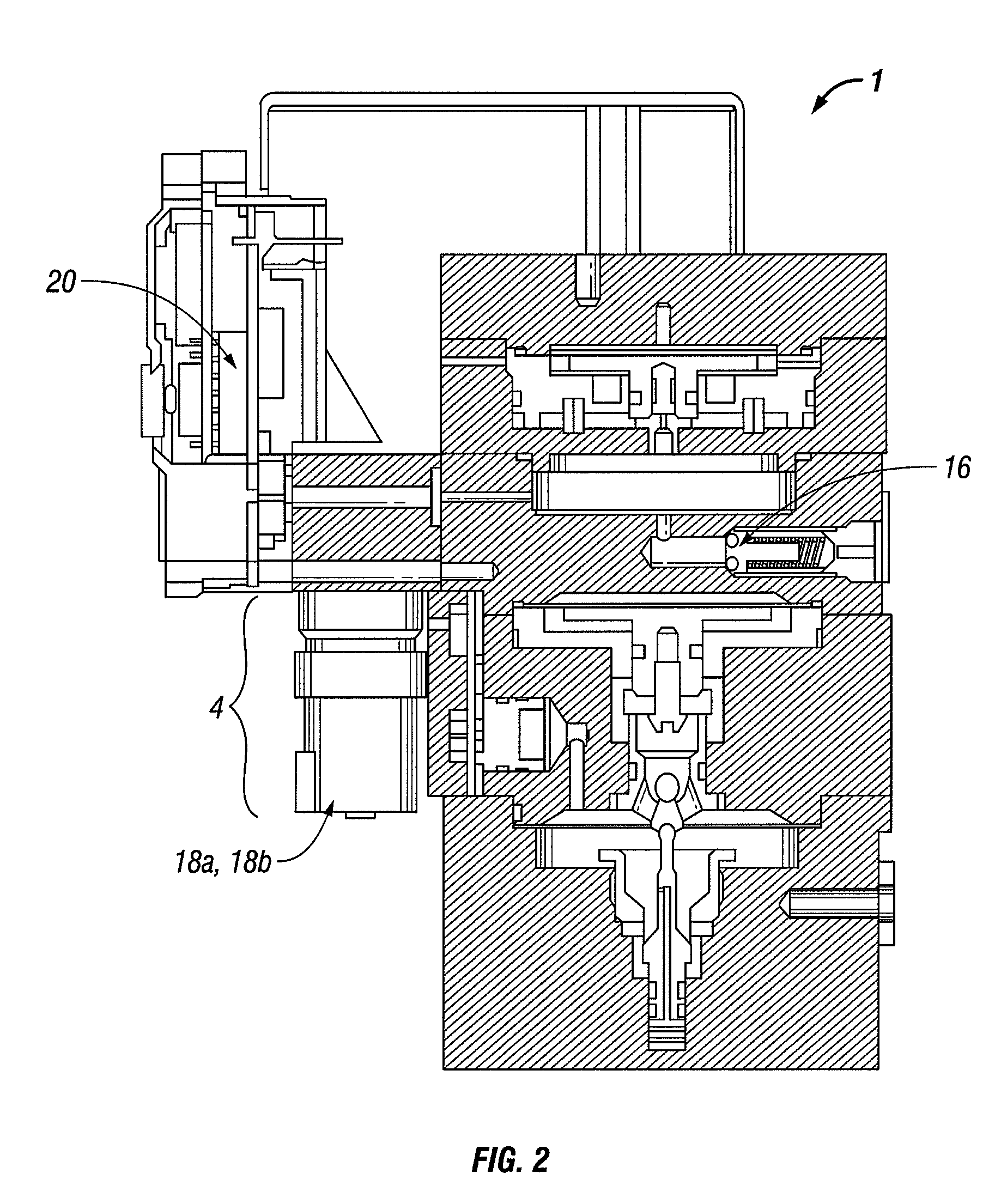

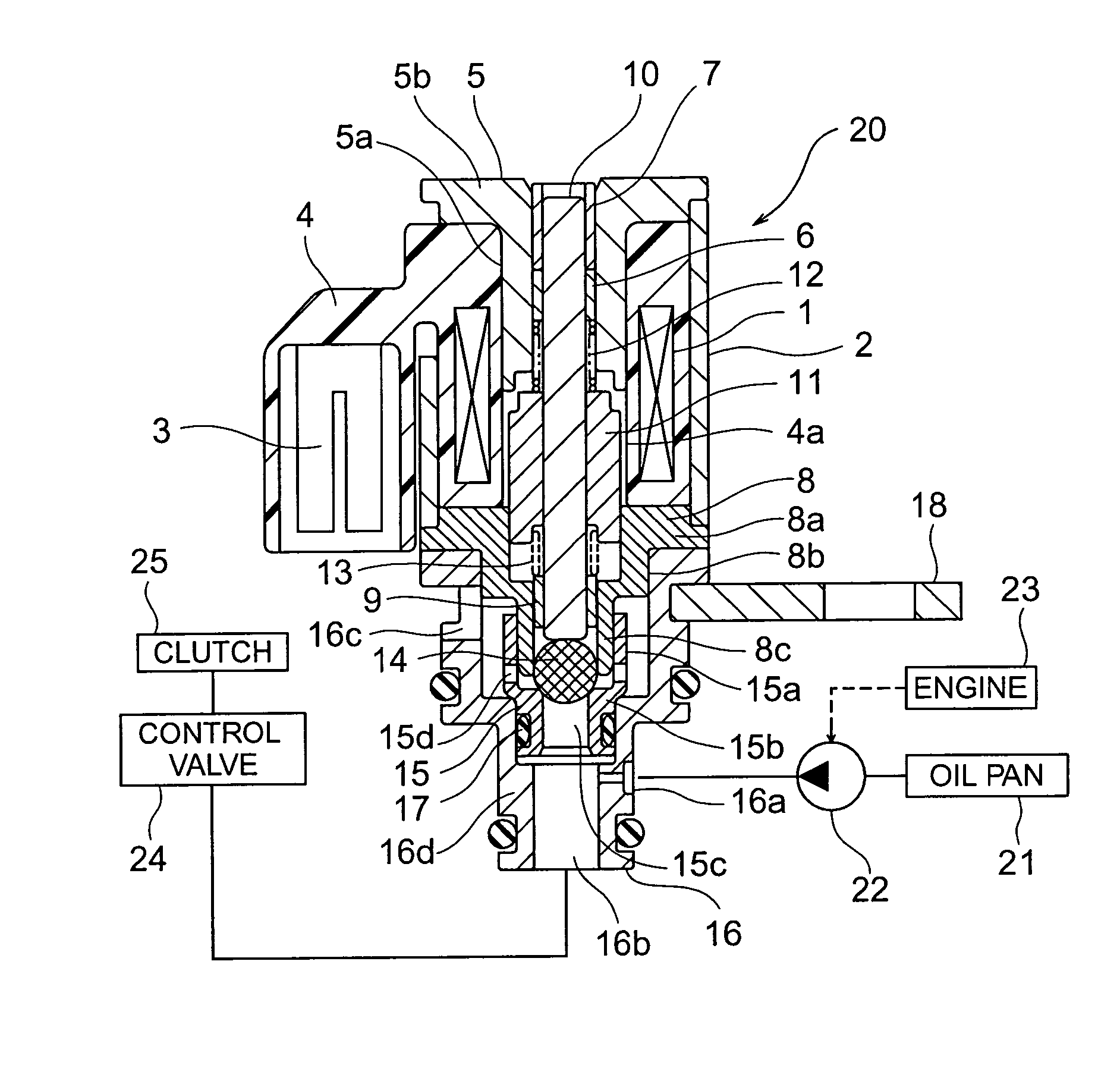

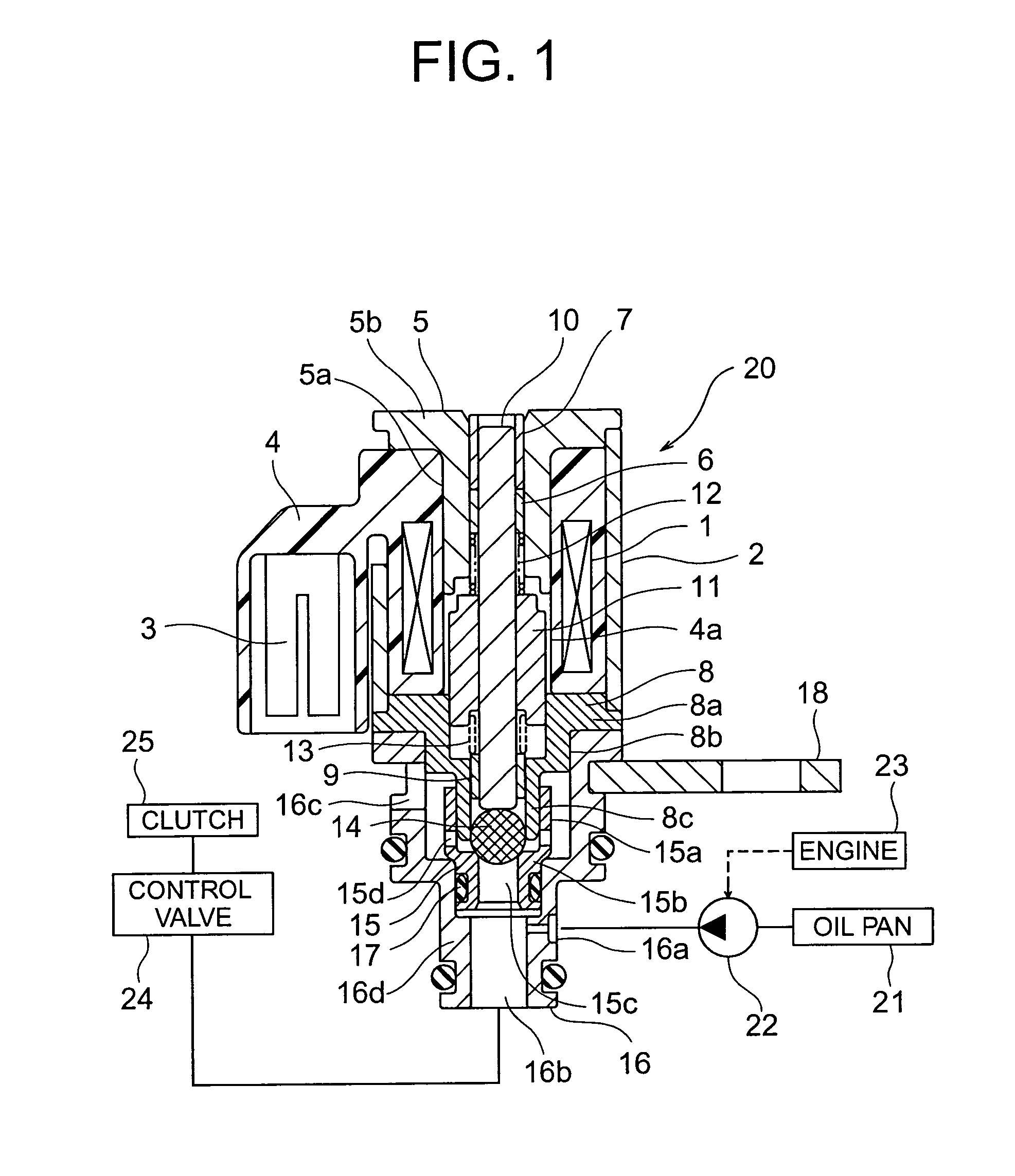

Microvalve device suitable for controlling a variable displacement compressor

ActiveUS7210502B2Fluid-pressure actuator safetyOperating means/releasing devices for valvesSpool valveEngineering

A device is disclosed for controlling a variable displacement compressor. The device comprises a microvalve operated control valve. A microvalve device for controlling fluid flow and a micro spool valve for use as a microvalve are also disclosed.

Owner:DUNAN MICROSTAQ

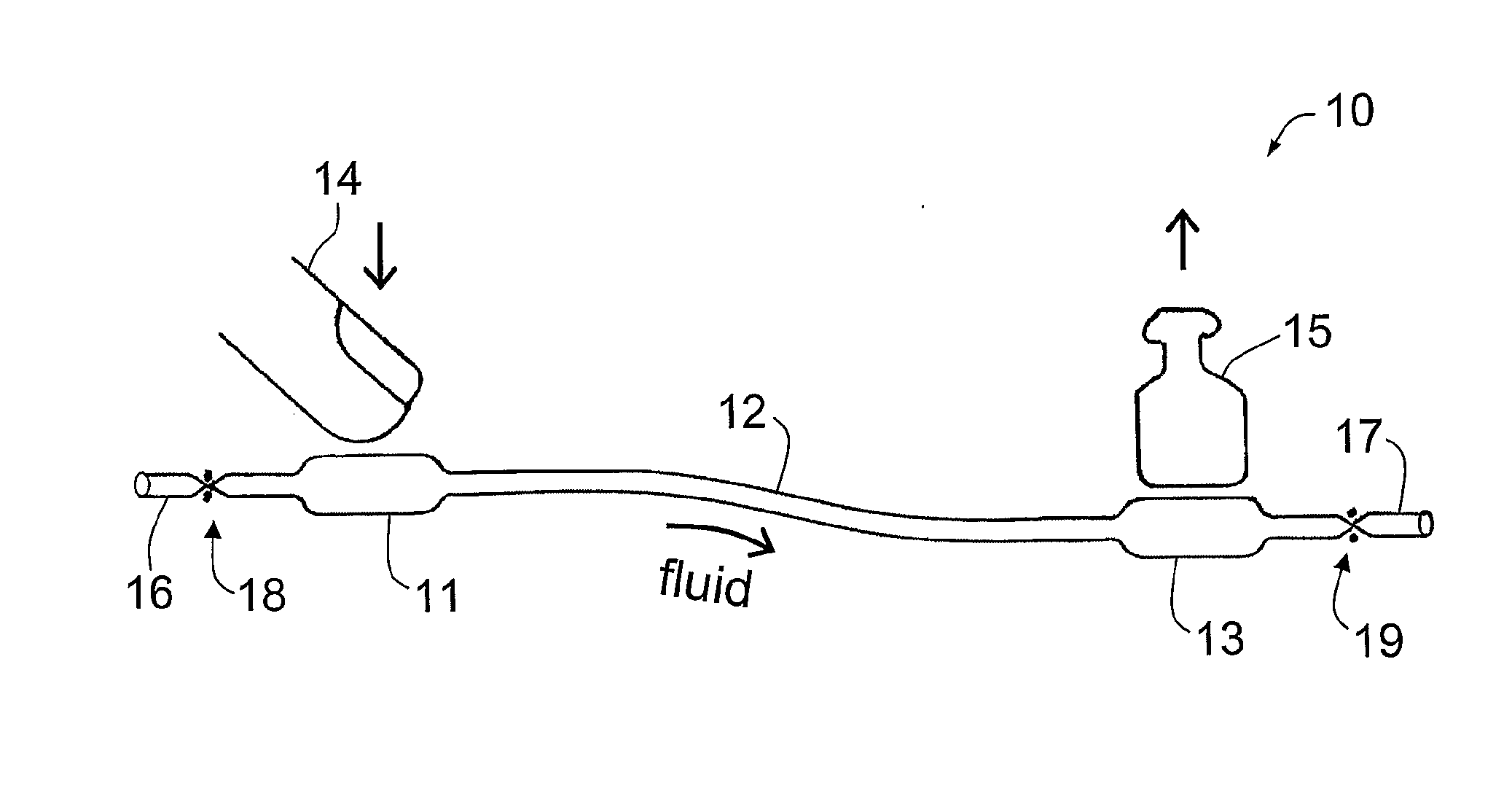

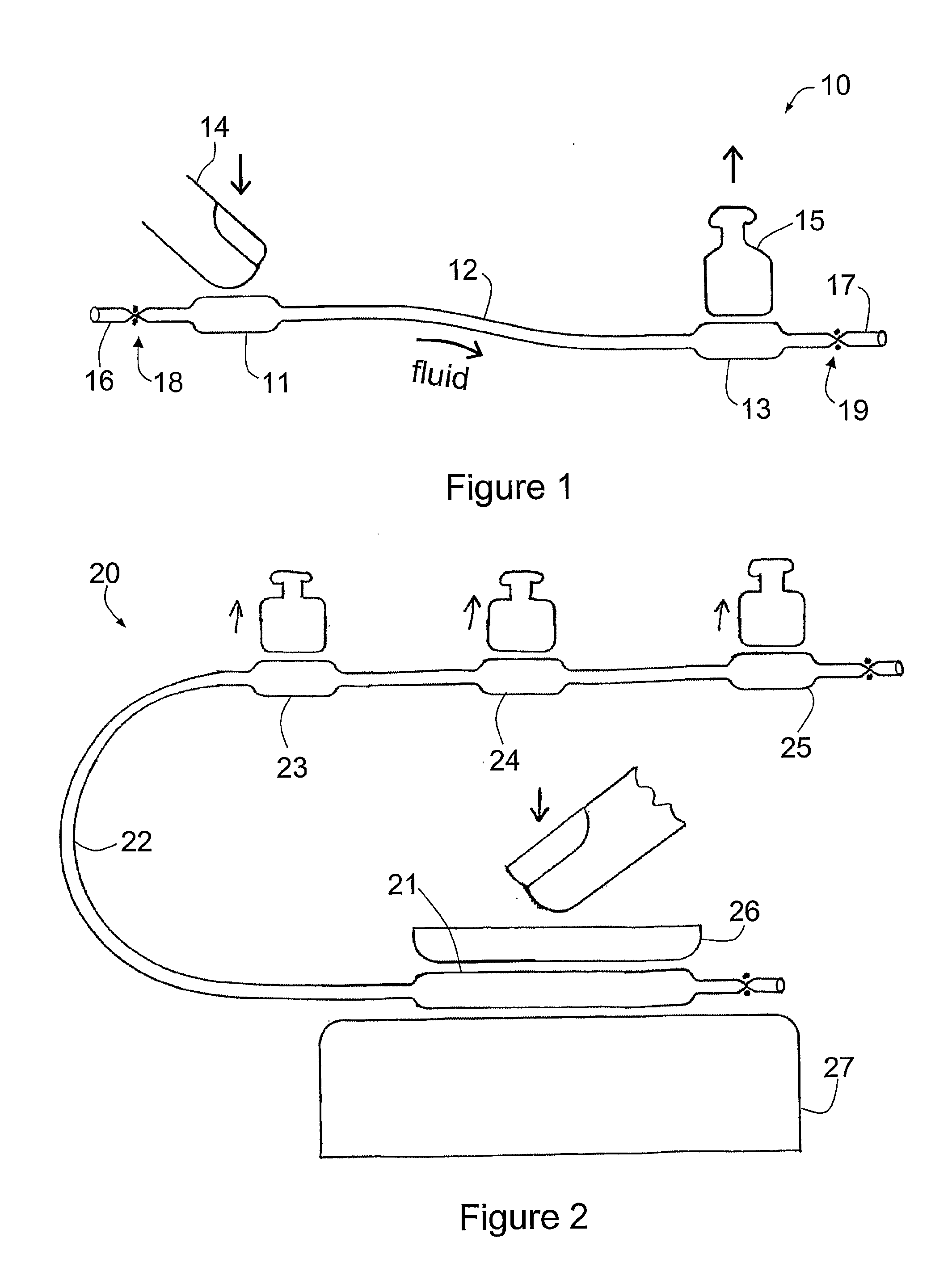

Fluid transmission

InactiveUS20090071137A1Transfer size reductionReduce forceDollsSelf-moving toy figuresEngineeringActuator

A fluid transmission that employs a fluid to transmit a force, comprising a conduit for the fluid made from heat shrink polymer tubing, wherein at least a portion of the heat shrink polymer tubing is shrunken, whereby the force can be transmitted by the fluid from a first or proximal end of the conduit to a second or distal end of the conduit. Also, an actuator and methods for manufacturing the transmission and actuator.

Owner:HARRIS MARTIN RUSSELL

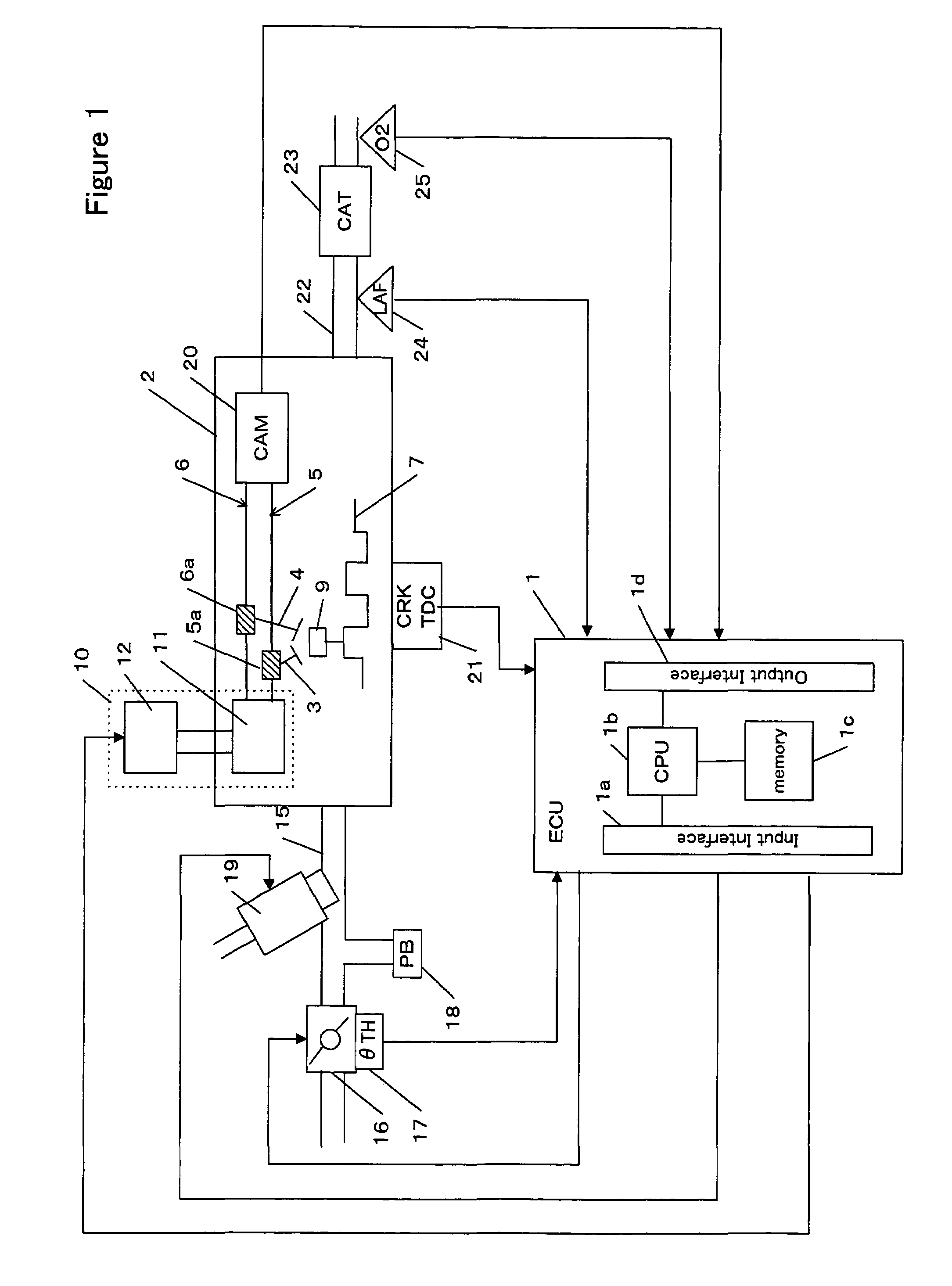

Control apparatus for controlling a plant by using a delta-sigma modulation algorithm

InactiveUS7133763B2Not to damageAccurate outputAnalogue computers for vehiclesElectric signal transmission systemsControl theoryControl equipment

The invention provides a control apparatus comprising a controller for determining a manipulated variable for manipulating a controlled object so that an output of the controlled object converges to a desired value and a modulator for modulating the manipulated variable by using one of a delta-sigma modulation algorithm, a sigma-delta modulation algorithm and a delta modulation algorithm to generate a modulated signal to be applied to the controlled object. The modulator generates the modulated signal so that a center value of an amplitude of the modulated signal follows a change of the manipulated variable. Thus, the modulated signal in which the manipulated variable is reflected without any loss can be generated even when the manipulated variable changes.

Owner:HONDA MOTOR CO LTD

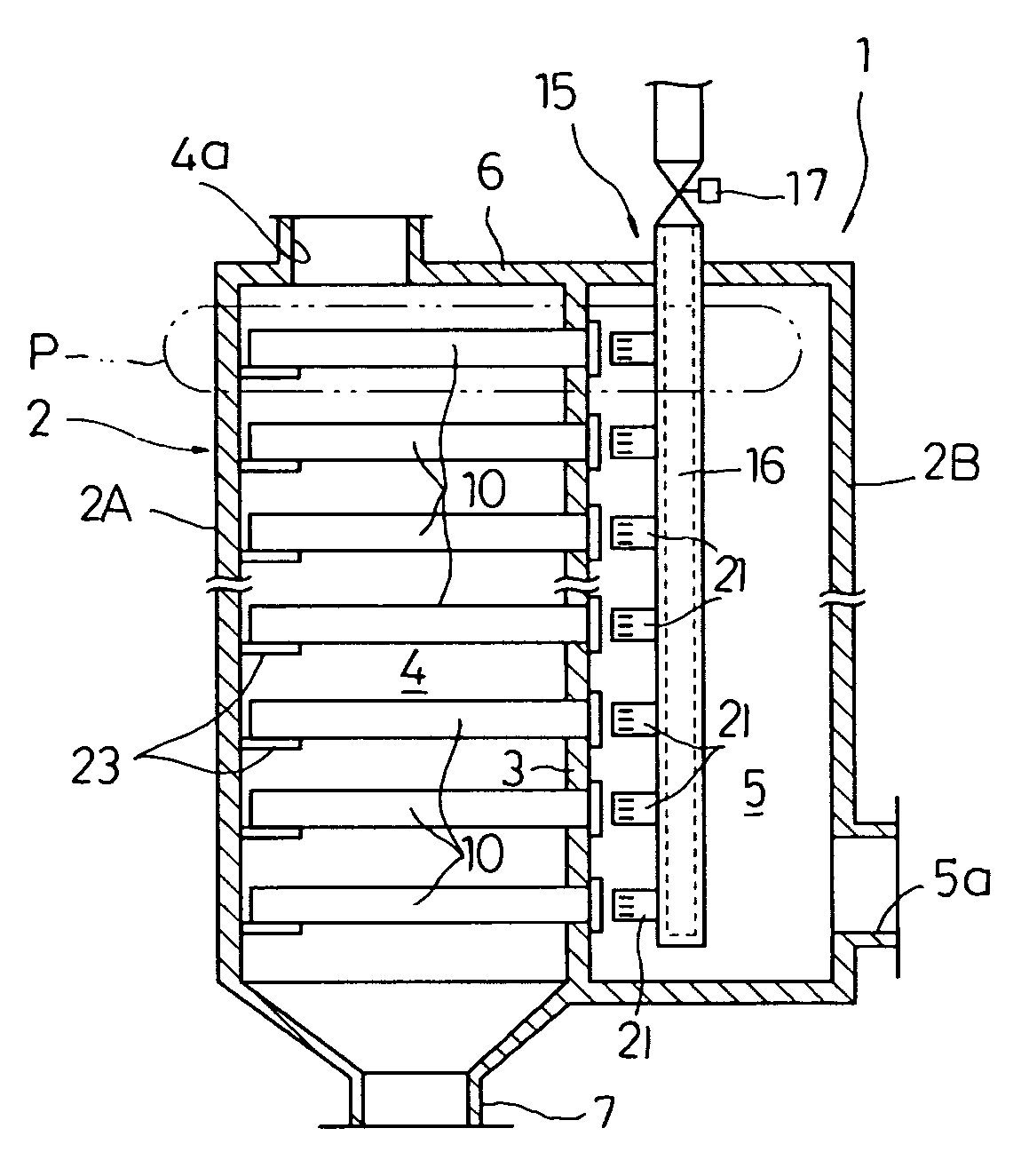

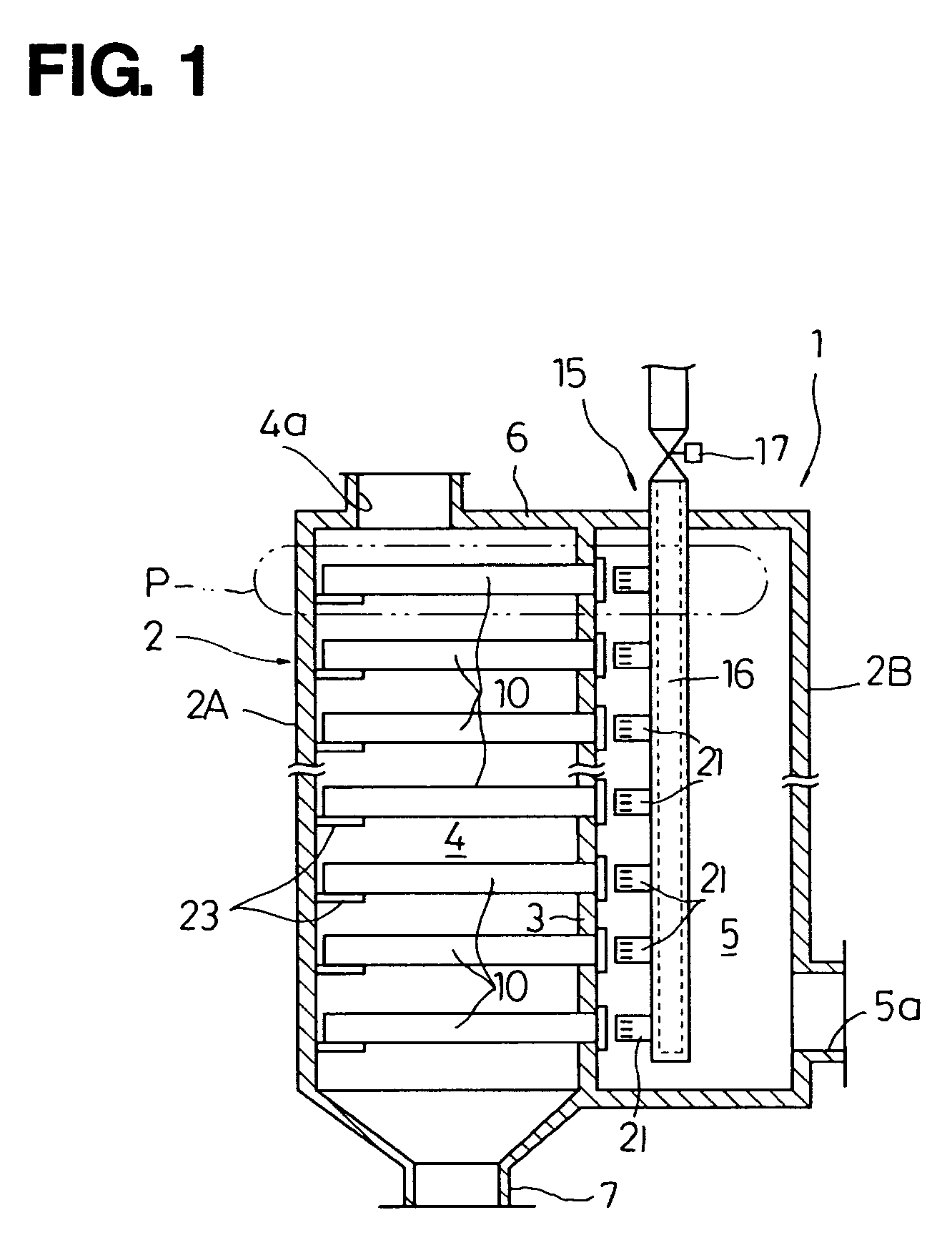

Nozzle and filter-type dust collector

InactiveUS20060075726A1Low running costReduce adverse effectsCombination devicesBurnersDust collectorNozzle

There are provided a nozzle capable of enhancing the straight-advancing capability of jetted fluid to increase the back wash effect of a filter member, and a filter-type dust collector capable of effectively carrying out dust removal from a filter member with such a nozzle. To this end, the nozzle has a Laval nozzle section secured to the inside of an outer tube at its proximal end and a fluid guide section disposed at the leading end of the outer tube. The fluid guide section has a plurality of suction holes elongated in the flowing direction of the pressurized fluid. This nozzle is mounted on a pulse header tube of a dust removal device.

Owner:TAKUMA

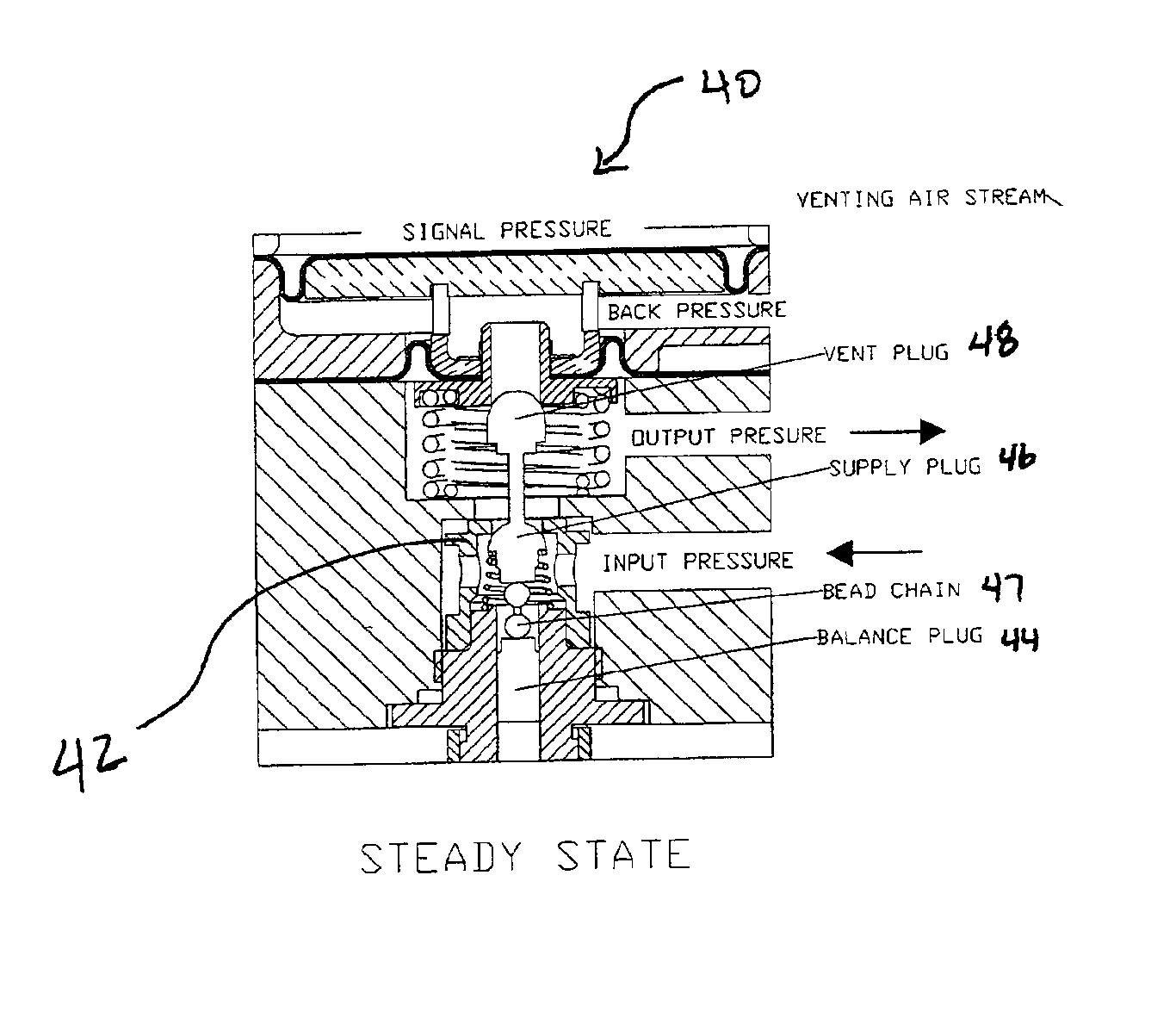

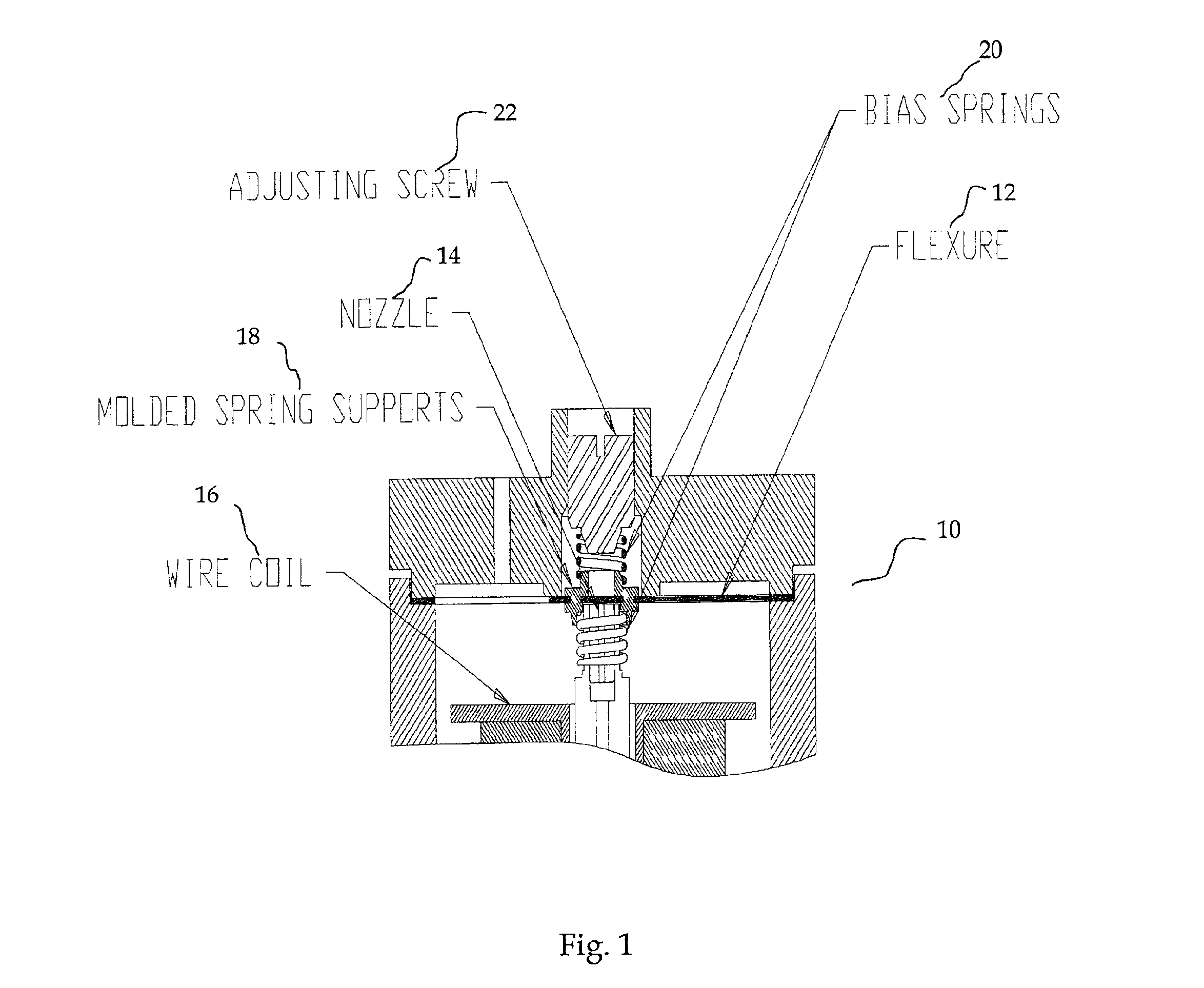

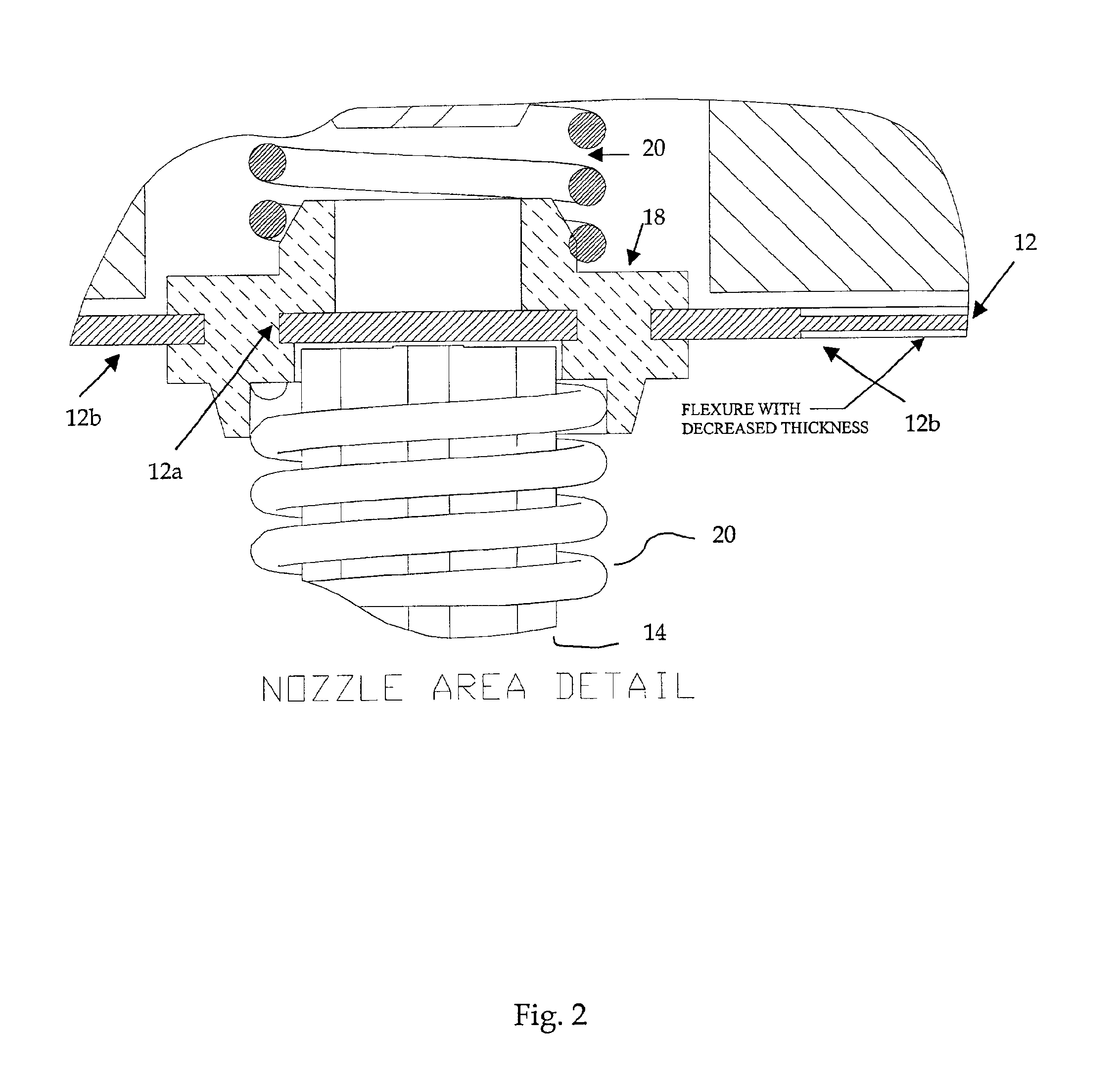

Dynamic current-to-pneumatic converter and pneumatic amplifier

InactiveUS6957127B1Reliable steady state amplifier performanceAvoid flowFluid-pressure actuator testingLevel controlAudio power amplifierEngineering

A dynamically balanced pneumatic relay amplifier and a current-to-pneumatic converter are disclosed. The relay has a balance plug, a supply plug positioned on top of the balance plug, a bead chain connecting the balance plug and the supply plug, and a vent plug positioned on top of the supply plug. The relay also includes a baffle positioned on top of the vent plug. The converter, used in an electro-pneumatic positioner, comprises a flat strip made of magnetic material located in proximity to a nozzle, and a flow regulator having a flat spring securing a plug in a seat within the regulator. The converter also includes a cantilevered flexure integrally secured to a molded spring support, a first bias spring positioned on a first side of the flexure, and a second bias spring positioned on a second side of the flexure. The thickness of the flexure is locally reduced in an area not integrated into the molded spring support.

Owner:DRESSER IND INC

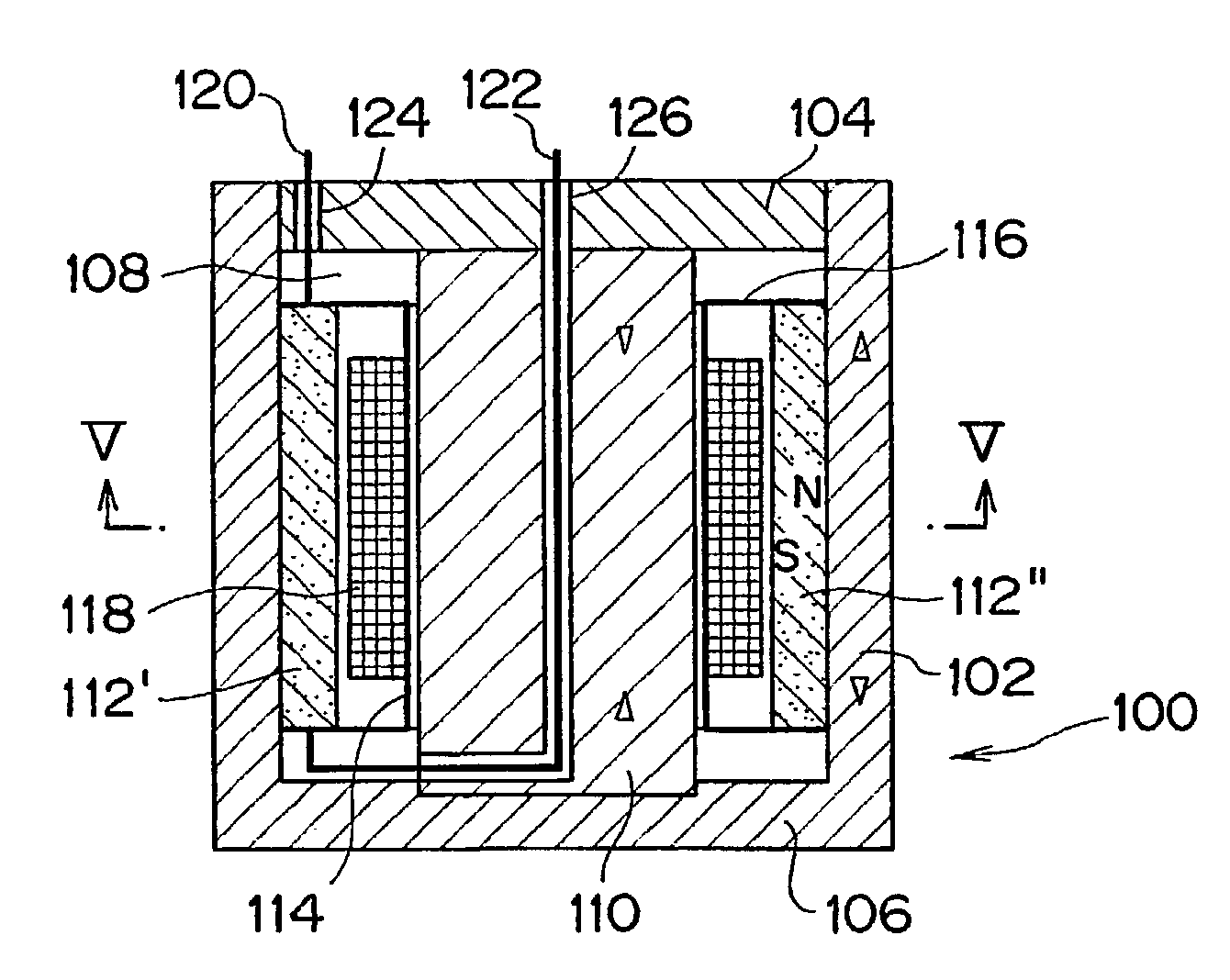

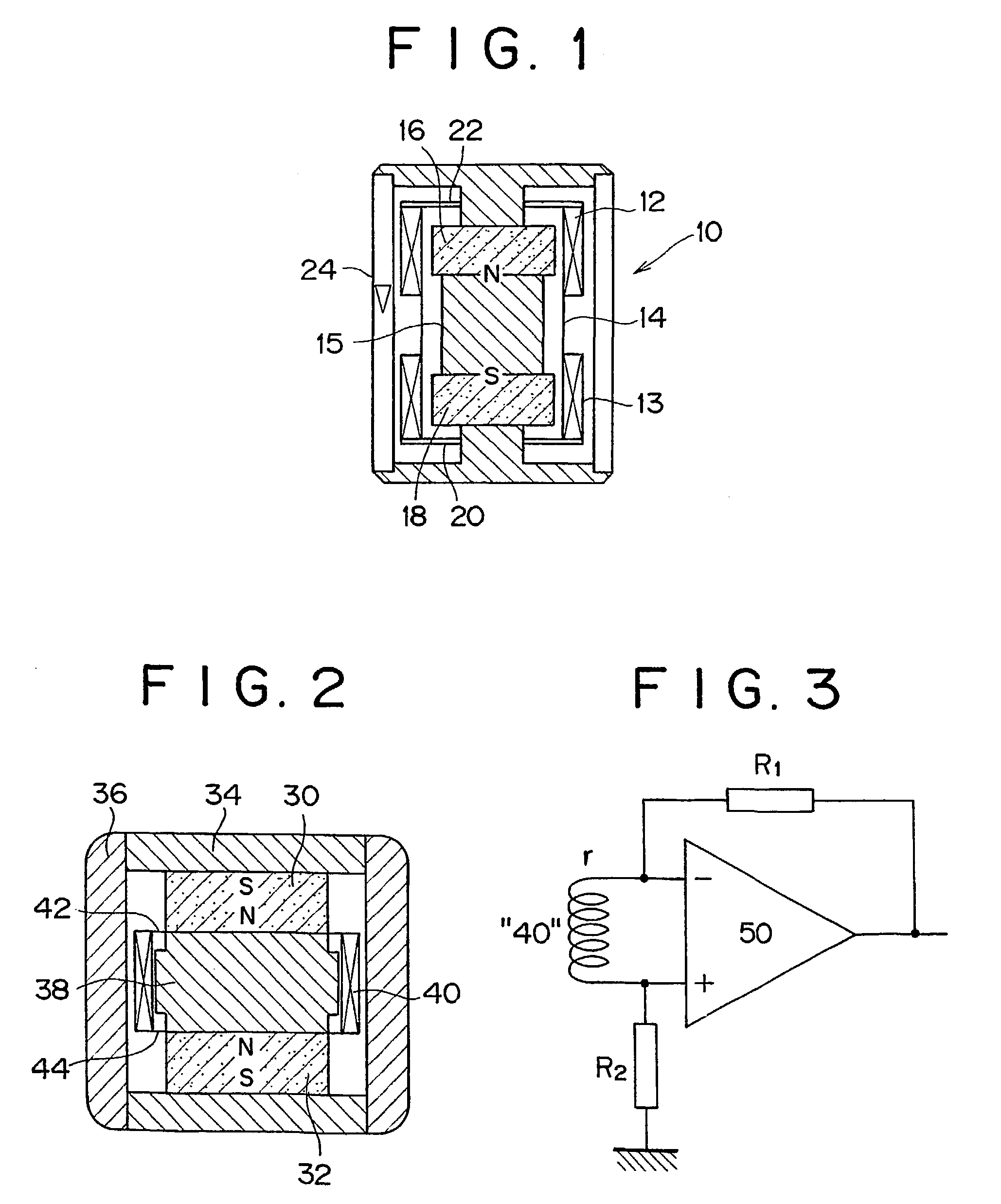

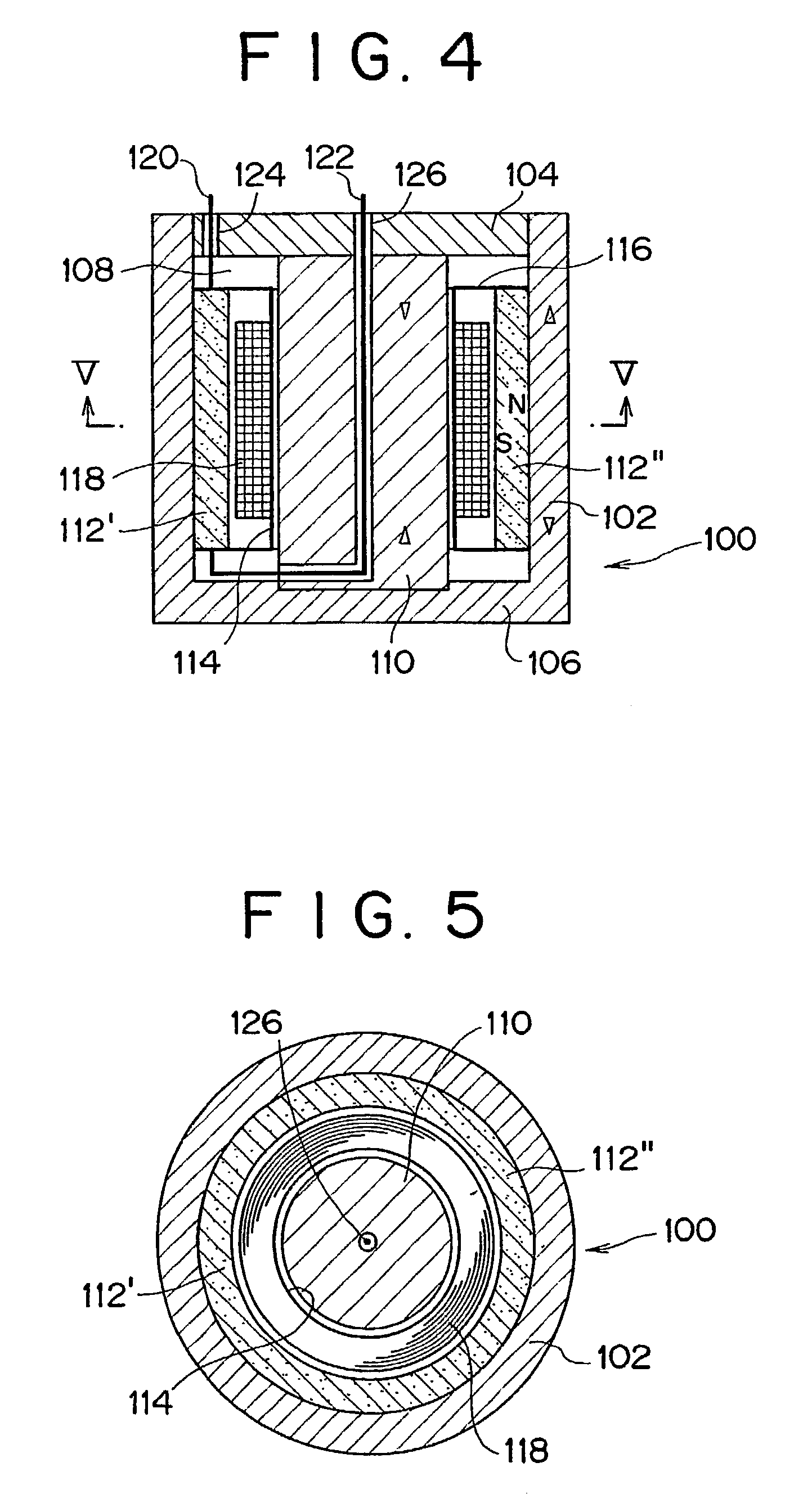

Geophone and method of manufacturing a geophone

InactiveUS7099235B2High sensitivityExpensive stepVibration measurement in solidsElectric signal transmission systemsGeophoneBobbin

A vibration transducer such as a geophone, comprising a central pole piece (110) with a magnet (112) and coil (118) concentrically arranged around it. The position of the magnet (112) is fixed relative to the pole piece (110) and the coil (118) is movable relative to the magnet (112). A method of manufacturing a vibration transducer is characterised in that a bobbin carrying the coils is formed from a substantially tubular body which is positioned on a mandrel and at least one coil is wound around its outer surface, the mandrel being removed from the bobbin when the coil is complete. Another method is characterised in that the coil is formed separately and the bobbin is formed from a substantially tubular body which is positioned inside the coil and expanded to contact the coil when in position.

Owner:SCHLUMBERGER TECH CORP

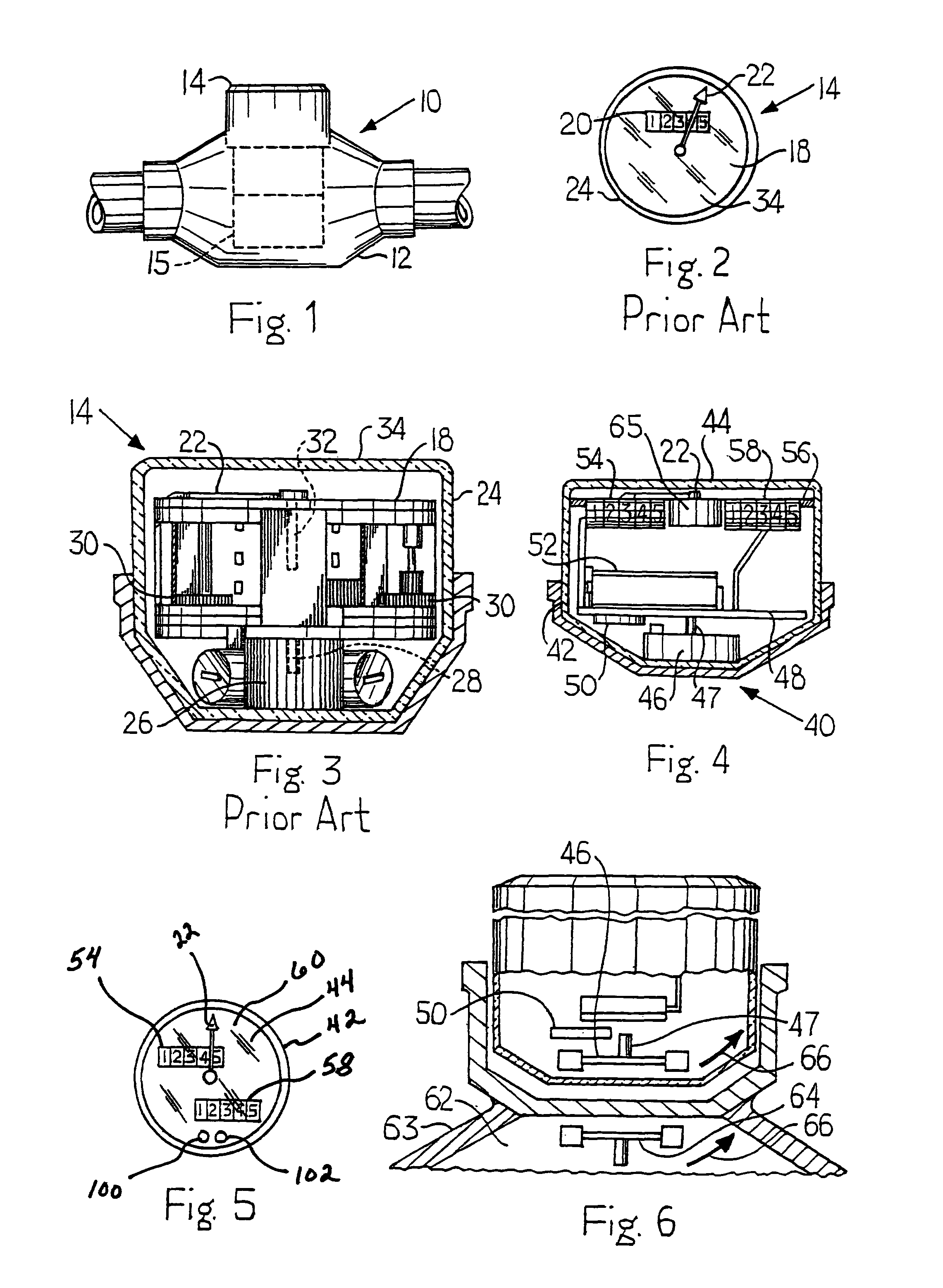

Meter register and remote meter reader utilizing a stepper motor

Owner:ARAD MEASURING TECH

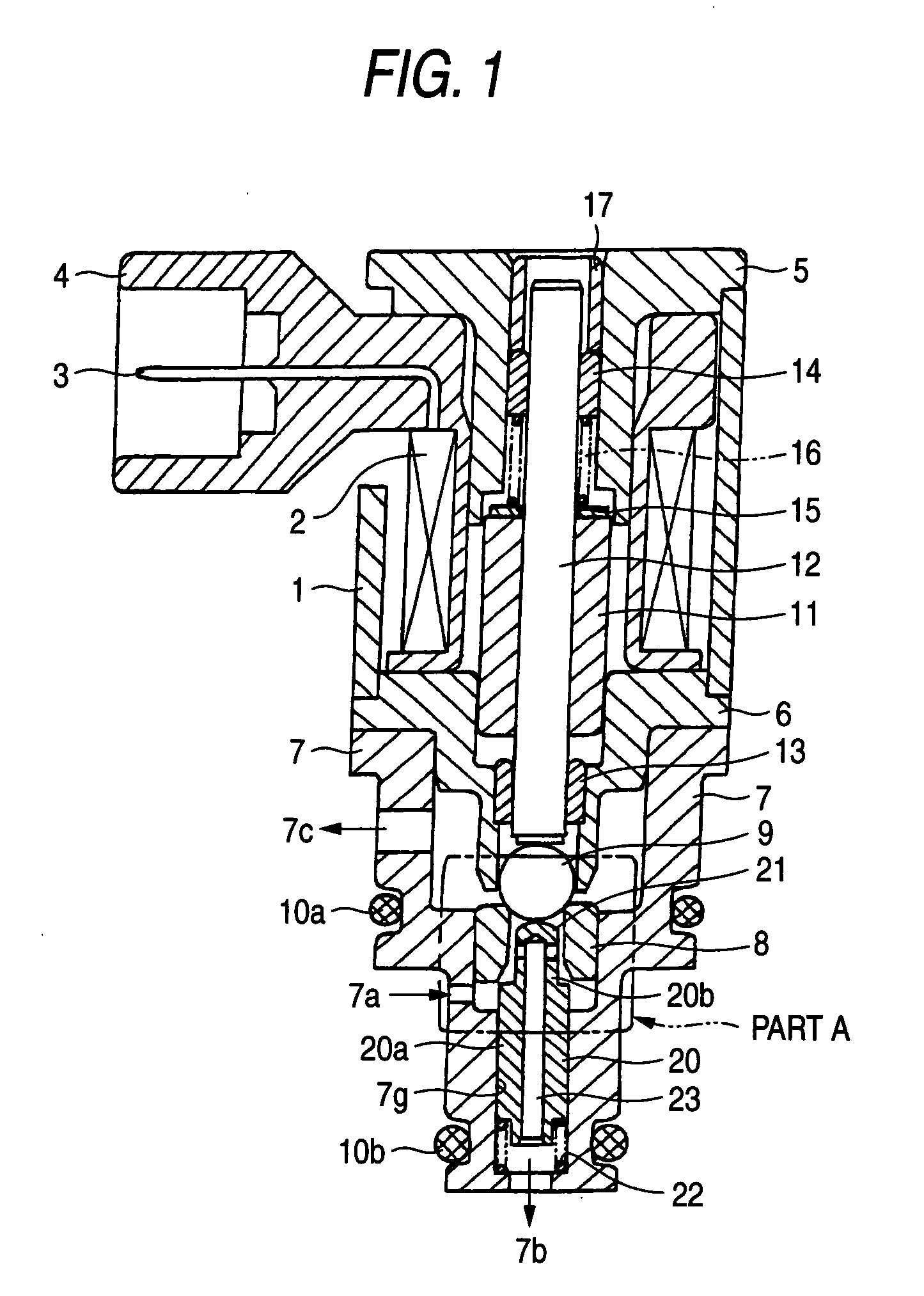

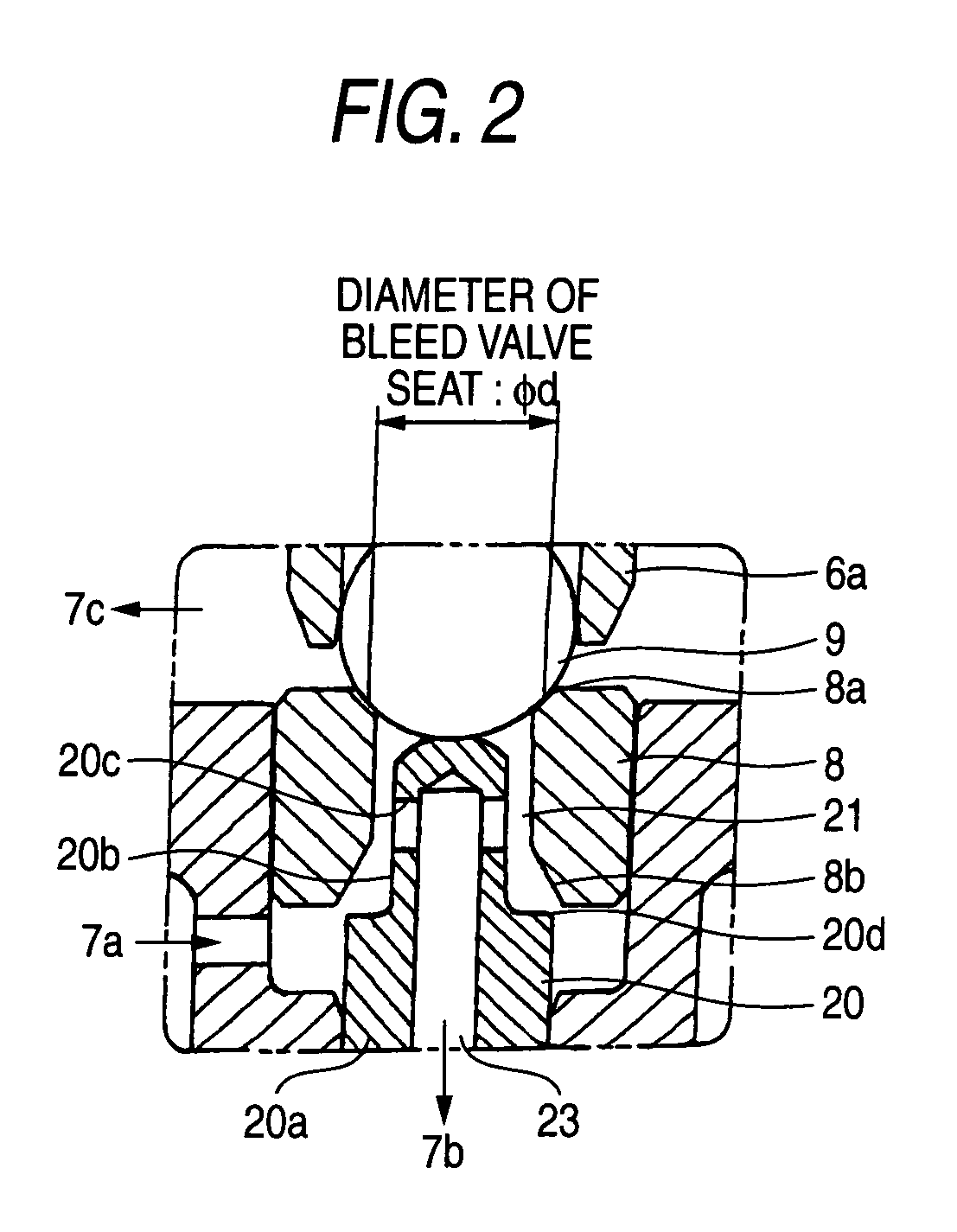

Three-way bleed type proportional electromagnetic valve

InactiveUS20050098211A1Easy to solveStable flowOperating means/releasing devices for valvesServomotor componentsSolenoid valveEngineering

A bleed-type proportional electromagnetic valve having an input port, output port, and ejection port is disclosed. Fluid force and pressing force, proportionate to an output pressure and a current flowing in a solenoid coil respectively, act on a bleed valve for controlling the output pressure, whereby the valve can obtain an output pressure commensurate to the flowing current by displacing the valve to a position that those forces counterbalance, wherein the valve is provided with a stop valve disposed so as to be in sliding contact with a passage between the input and output port, and in contact with or separated from a valve seat. This enable the stop valve to contact with the valve seat so as to close the input port and communicate the output port with the ejection port when controlling the output pressure to be minimum.

Owner:MITSUBISHI ELECTRIC CORP

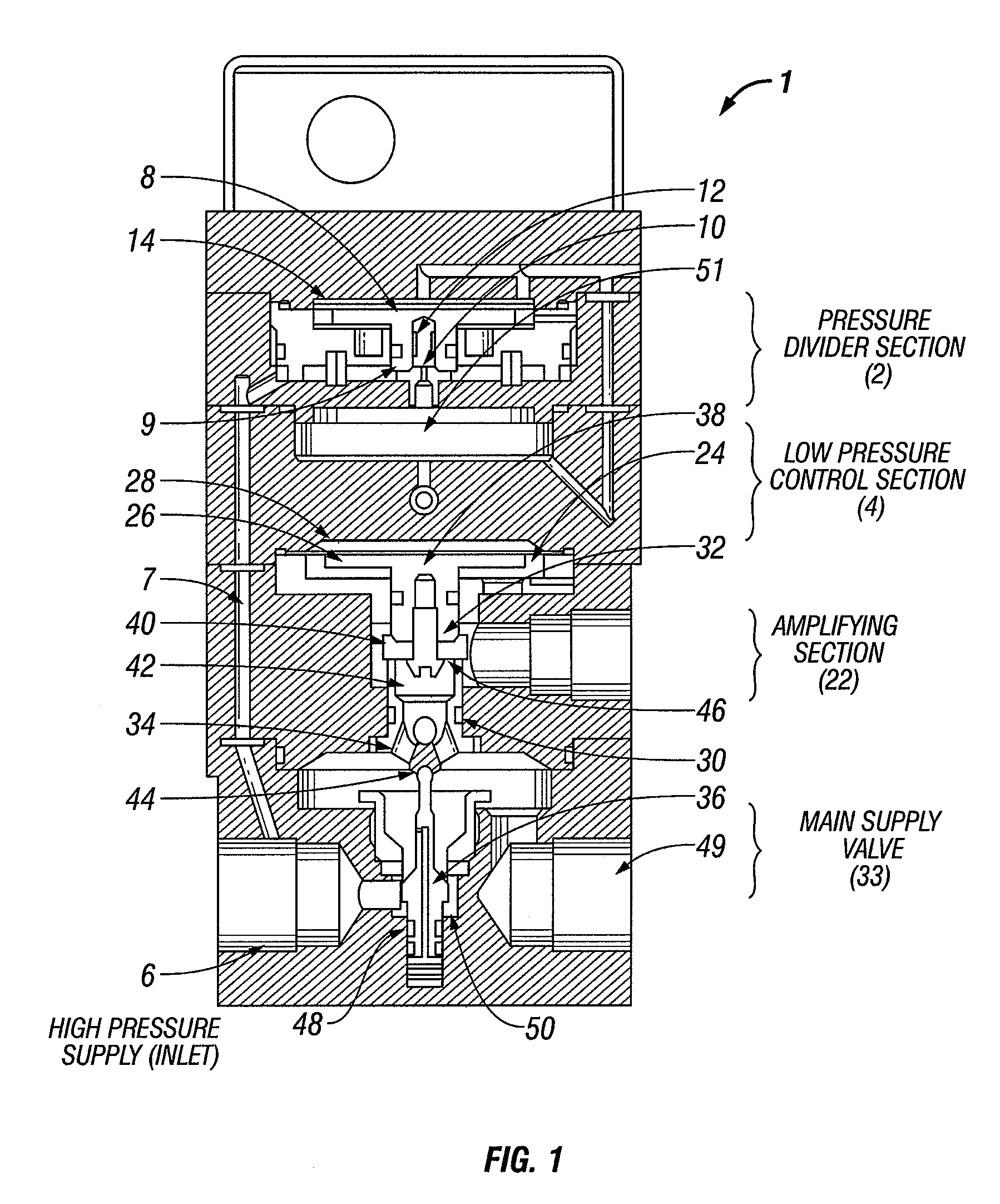

High pressure transducer

InactiveUS7766030B2InhibitionShorten the timeOperating means/releasing devices for valvesTransducersTransducerEngineering

A high pressure transducer is disclosed. The transducer includes a supply inlet configured to provide a gas supply to the high pressure transducer at a supply pressure and a pressure divider section coupled to the supply inlet. The pressure divider section is configured to reduce the supply pressure to a reduced pressure as a function of a first predetermined ratio. The transducer also includes a low pressure control section coupled to the pressure divider section and configured to receiving the gas supply at the reduced pressure and an amplifying section coupled to the low pressure control section. The low pressure control section varies the reduced pressure to produce a variable control pressure to actuate the amplifying section in response thereto. The amplifying section is also configured to multiply the variable control pressure as a function of a second ratio to obtain an output pressure. Further, the transducer includes a main supply valve coupled to the amplifying section, wherein the amplifying section controls the main supply valve.

Owner:FIDUS MEZZANINE CAPITAL

Flapper assemblies for torque motors of electrohydraulic valves

Flapper assemblies for torque motors of electrohydraulic valves are provided. The flapper assembly comprises a flapper having an upper end portion configured for coupling to an armature and armature-flapper support of the torque motor and a lower end portion having a socket therein. A hemispherical closure member having a flat diametrical face configured to seal against a nozzle outlet is disposed for oscillatory movement in the socket. A retaining clip is slidably mounted about the lower end portion and has a retention opening exposing the flat diametrical face and sized to retain the hemispherical closure member in the socket. The torque motor comprises the armature coupled to the armature-flapper support, the flapper assembly, and a plurality of coils. The electrohydraulic valve comprises the torque motor and a nozzle configured to be in fluid communication with the flapper assembly when the electrohydraulic valve is in an open position.

Owner:HONEYWELL INT INC

Vent assembly and method for a digital valve positioner

ActiveUS20150316158A1Reduce the soundAvoid checkingOperating means/releasing devices for valvesCheck valvesEngineeringActuator

A digital valve positioner for use with an actuator. The digital valve positioner includes a housing, at least one exhaust port opening formed in the housing, and a vent assembly operatively coupled to the at least one exhaust port opening. The vent assembly includes a body having a bore, a valve seat surrounding the bore, and a check valve disposed within the bore. The check valve is arranged to shift from a closed position seated against the valve seat to an open position disposed away from the valve seat. A plurality of barriers is disposed around and positioned to enclose the check valve. The plurality of barriers is arranged to prevent an external medium from entering the check valve and to provide a tortuous flow path for the exhaust medium reducing sound through the vent assembly.

Owner:FISHER CONTROLS INT LLC

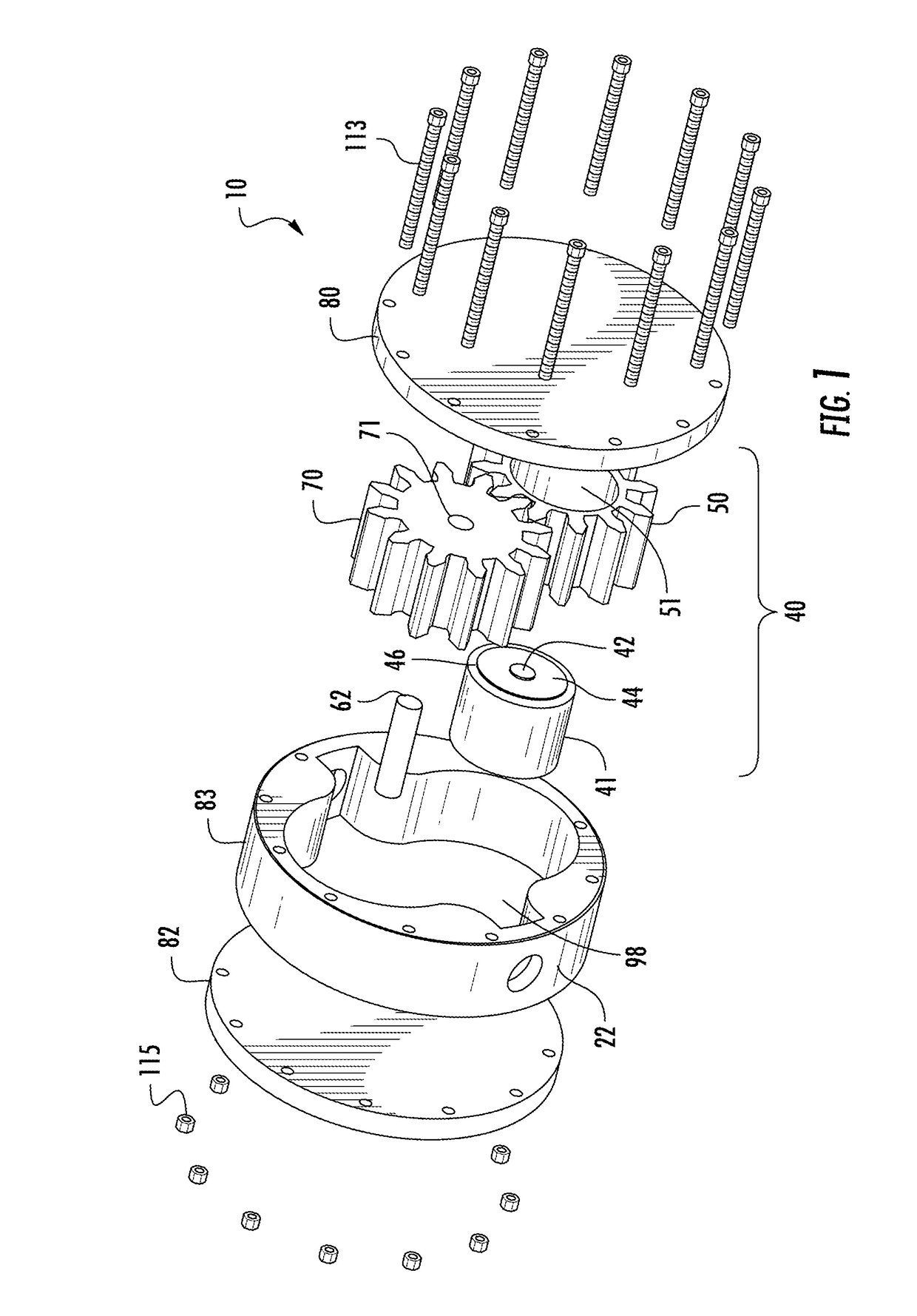

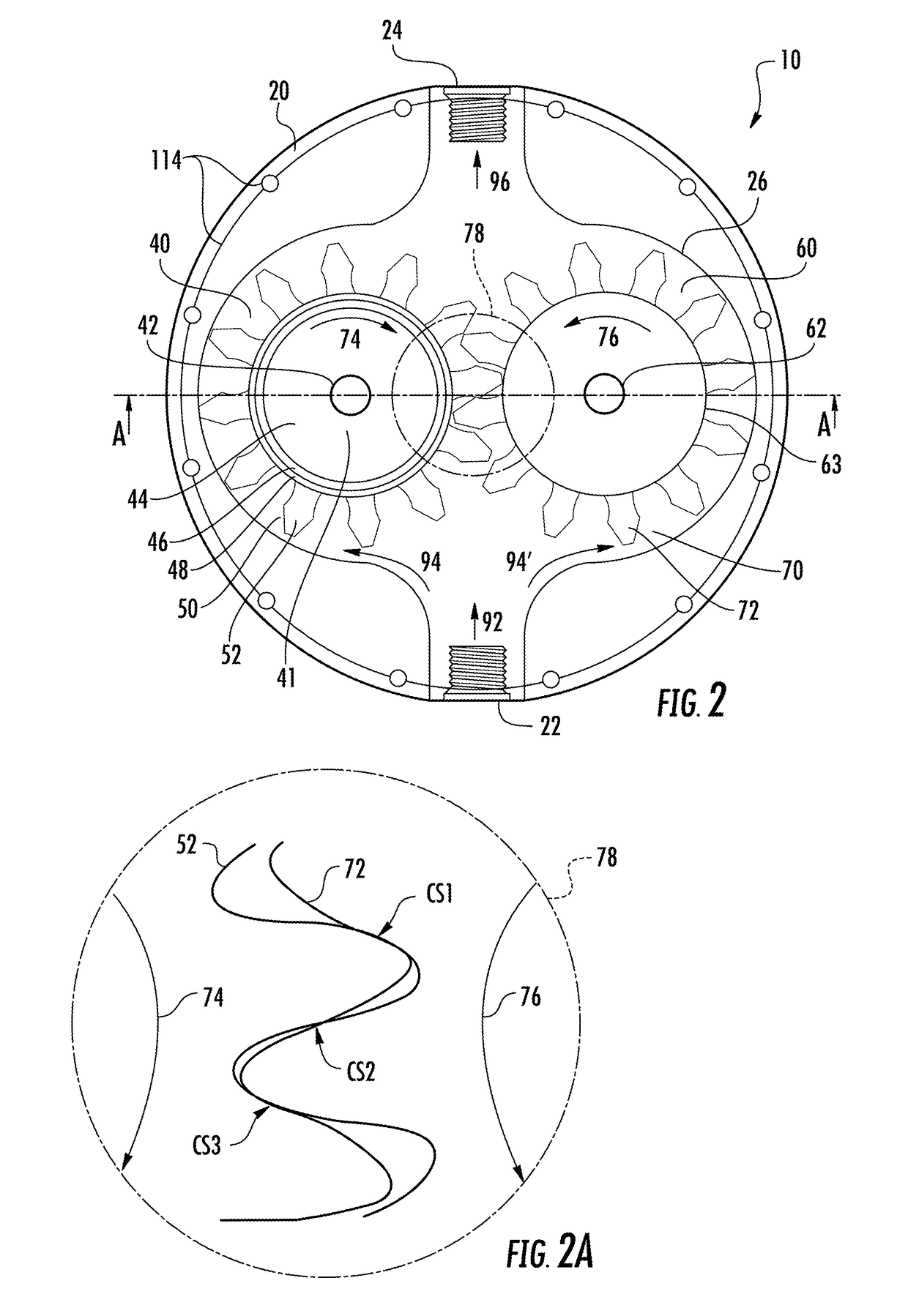

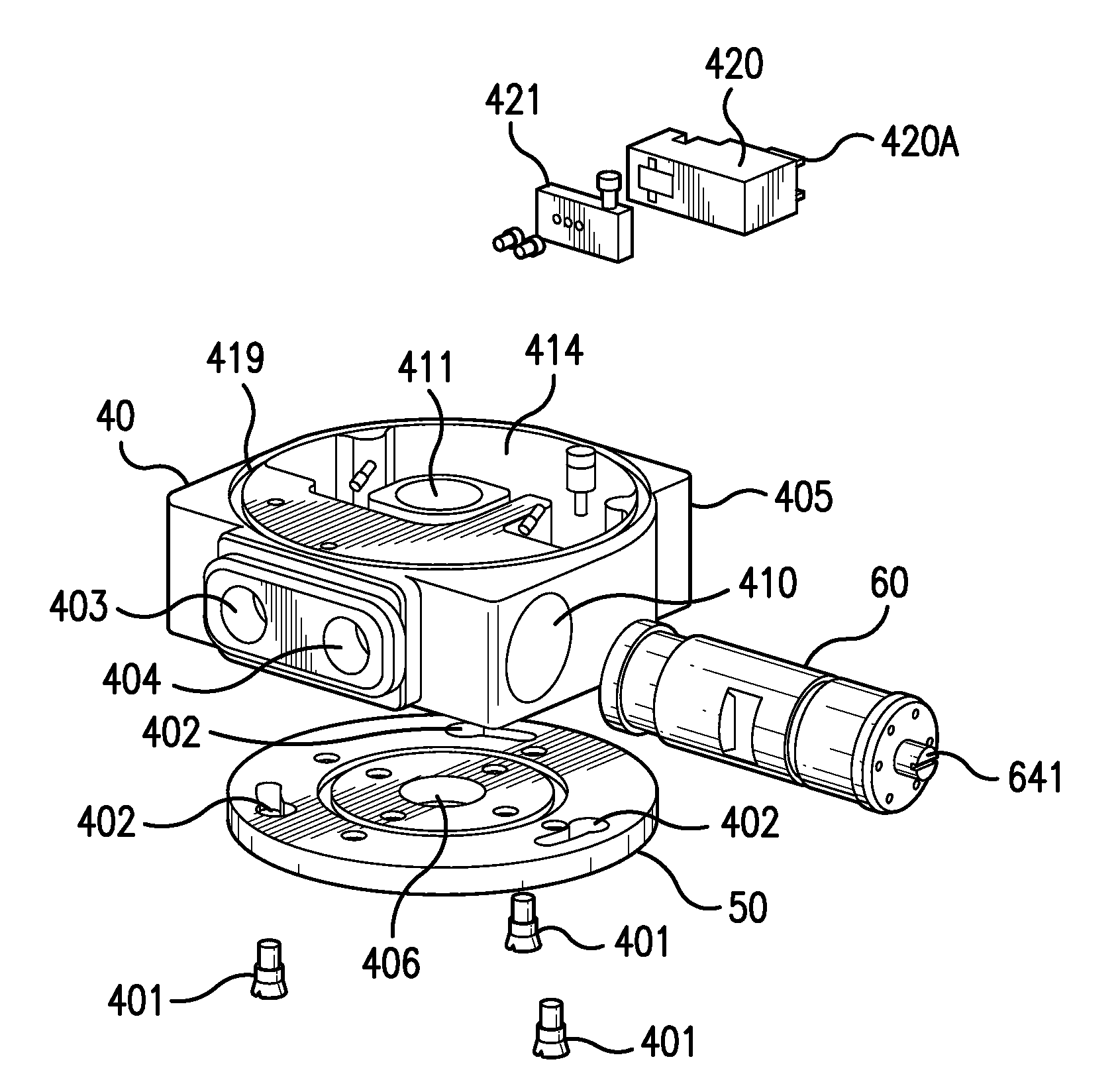

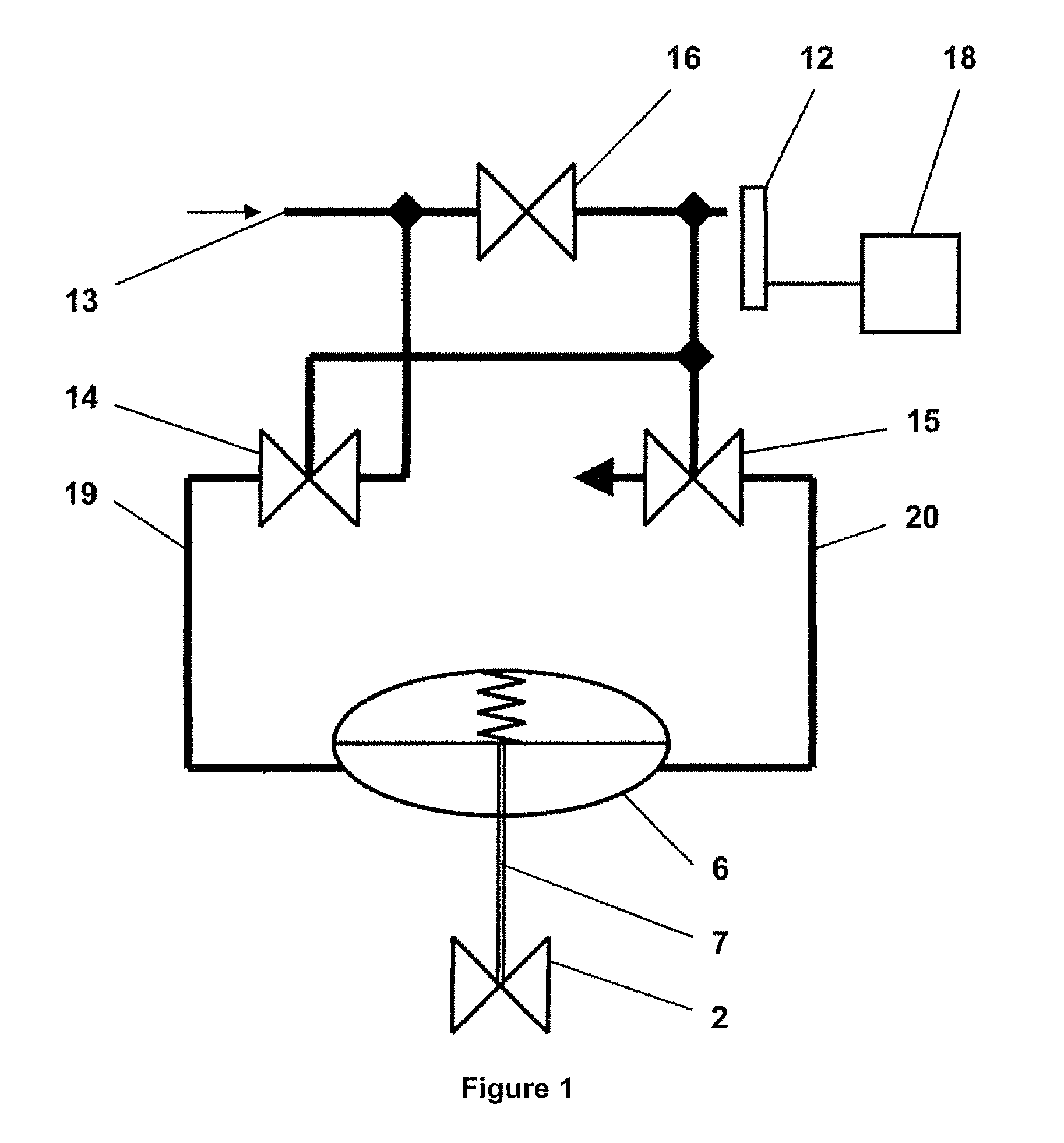

System to pump fluid and control thereof

A pump having a fluid driver disposed within the interior volume of the pump and to a method of delivering fluid from an inlet of the pump to an outlet of the pump using the fluid driver. The fluid driver includes a variable-speed and / or a variable torque prime mover and a fluid displacement assembly. The pump can be used in a fluid pumping system to provide fluid to an actuator that is operated by the fluid. At least one of a speed and a torque of the pump is controlled so as to adjust at least one of a flow and a pressure in the fluid pumping system to a desired set point, without the aid of another flow control device.

Owner:PROJECT PHOENIX

Proportional solenoid valve and control method therefor

InactiveUS6957656B2Reduced vibration rangeImprove seismic performanceOperating means/releasing devices for valvesProportioning devicesSolenoid valveValve seat

In a proportional solenoid valve, a cylindrical valve seat member includes an input / output-side passage provided between an input port and a drain port and between an output port and the drain port, a seat portion provided in an end portion of the input / output-side passage, and a drain-side passage provided between the seat portion and the drain port. The drain-side passage is formed by exhaust passage holes whose number is an even number equal to four or more and which are arranged at regular intervals in the circumferential direction of the valve seat member.

Owner:MITSUBISHI ELECTRIC CORP

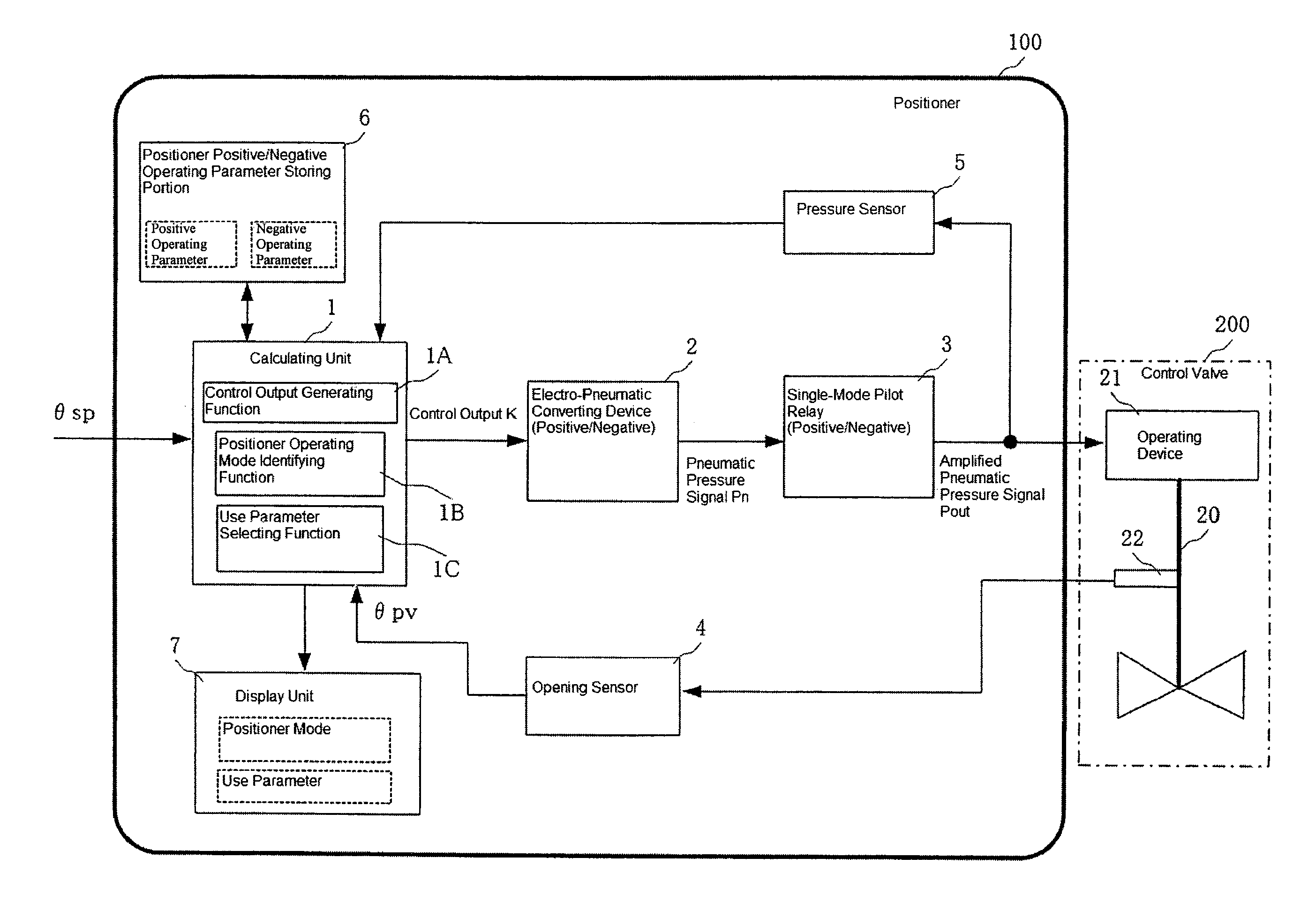

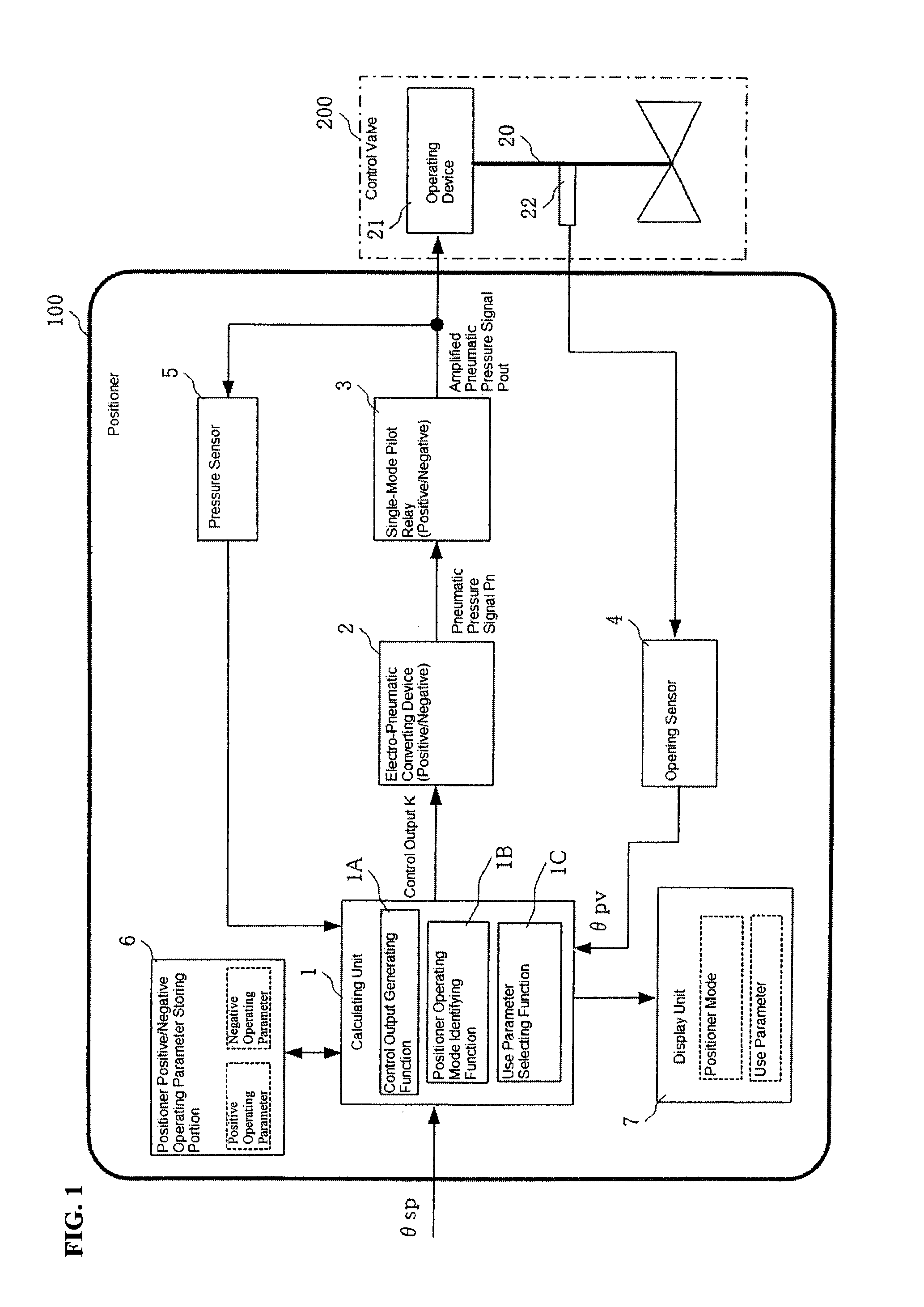

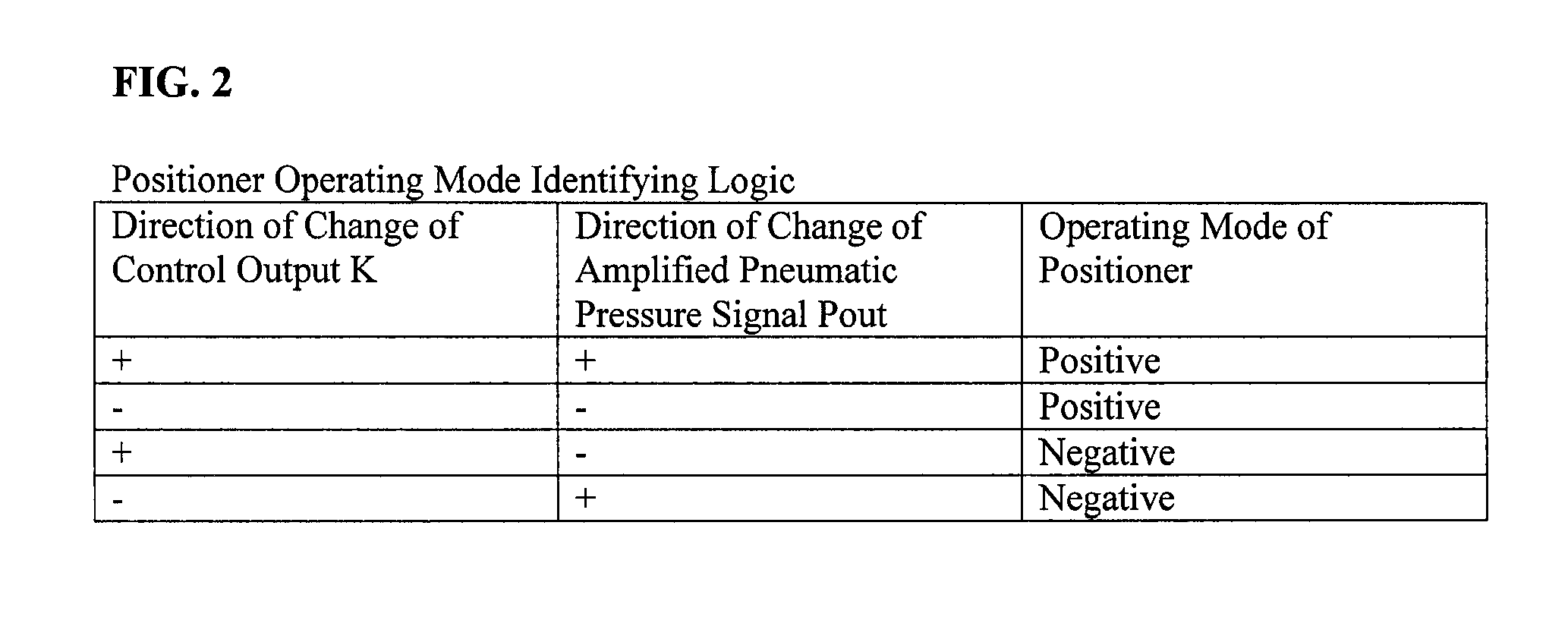

Positioner

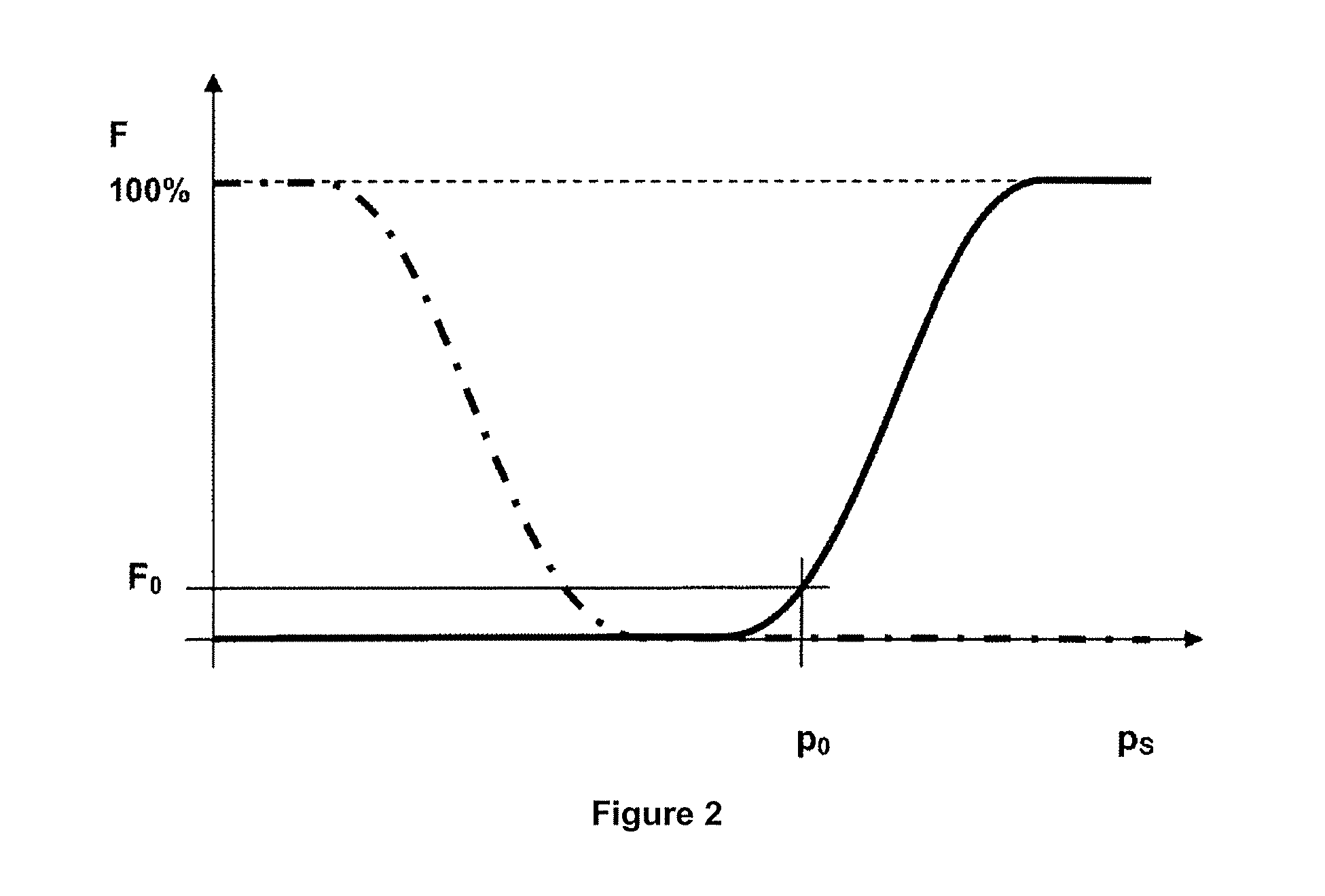

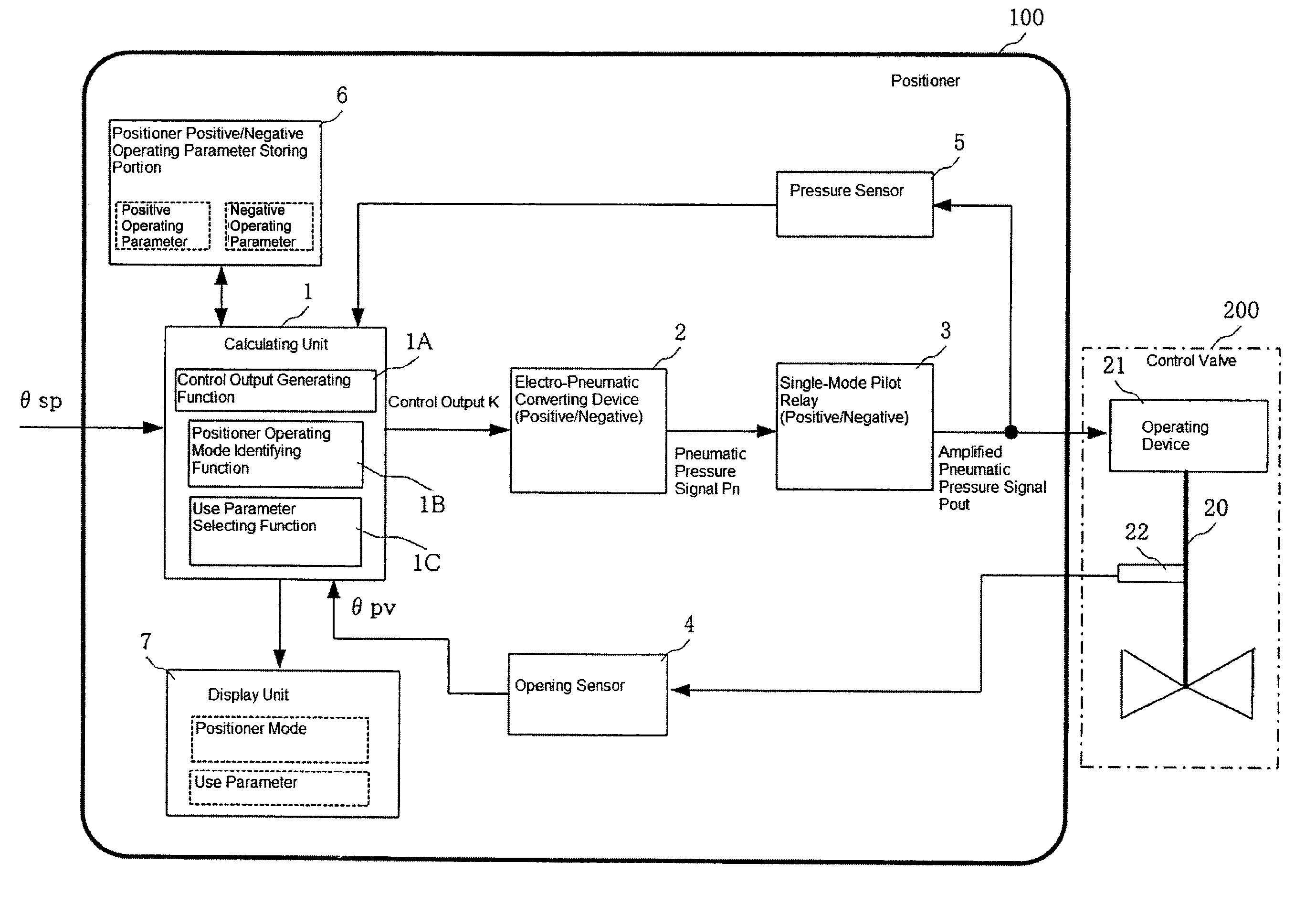

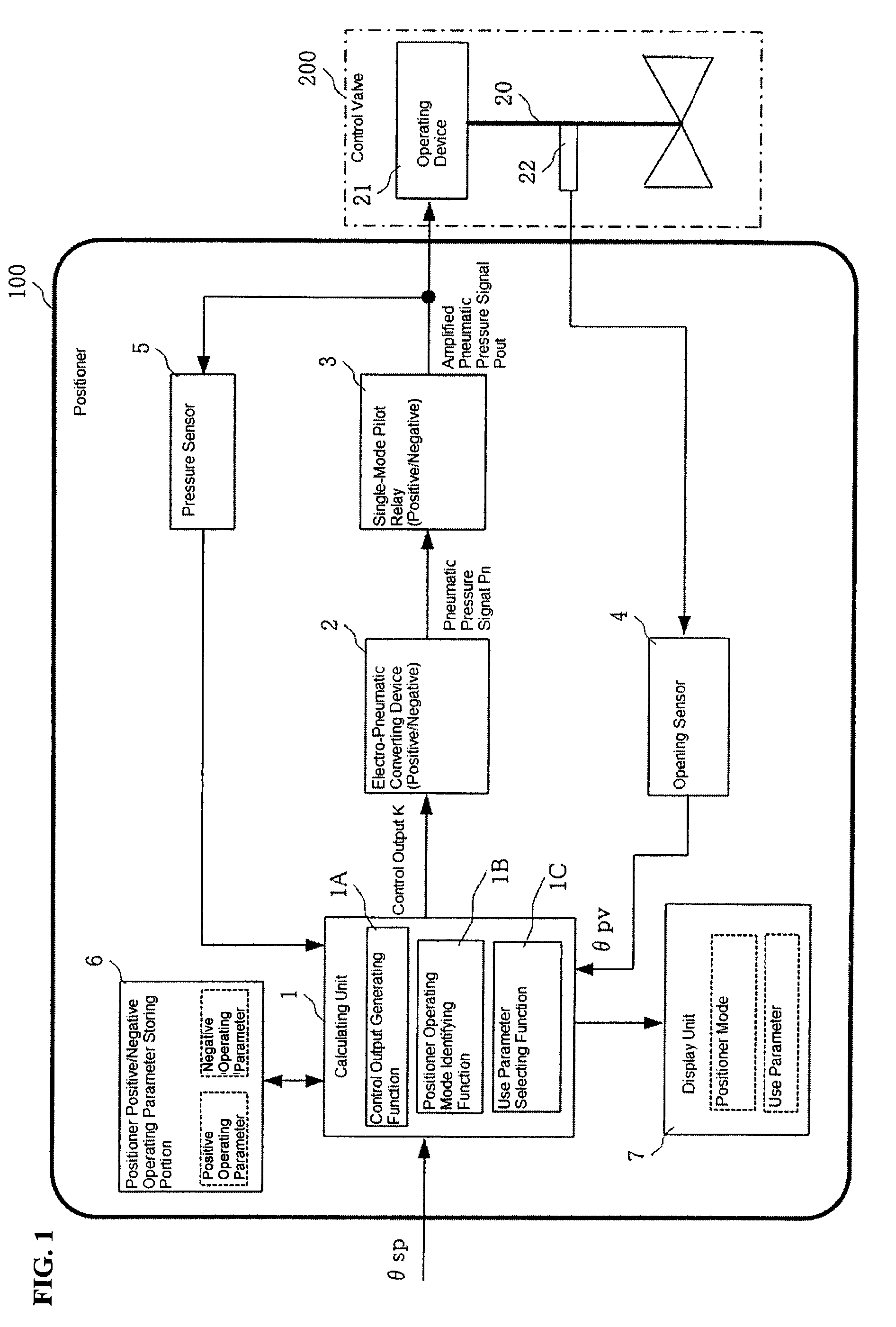

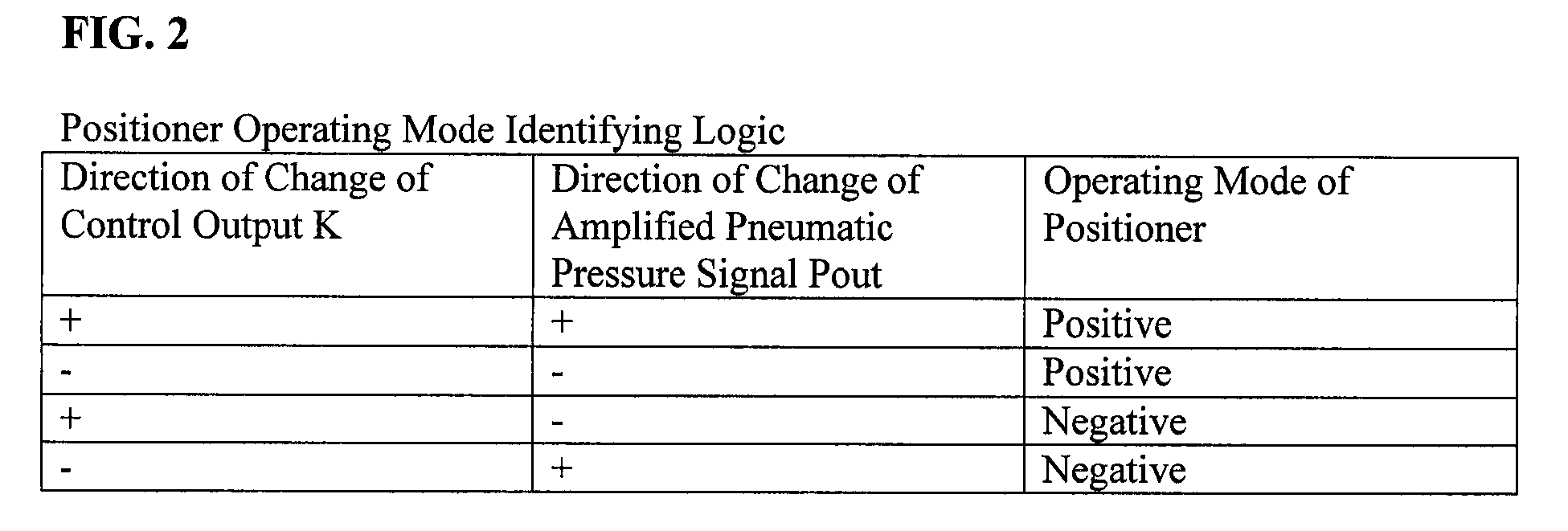

InactiveUS20110240891A1Operating means/releasing devices for valvesTransducersAtmospheric pressurePneumatic pressure

A positioner operating mode identifying function and an use parameter selecting function are provided in a calculating unit. A positive operating parameter and a negative operating parameter are stored in a storing portion. The positioner operating mode identifying function identifies the operating mode of a positioner or from the direction of change of a control output and the direction of change of an amplified pneumatic pressure signal Pout, and the identification result is set automatically as the current operating mode of the positioner. In accordance with the current operating mode identified for the positioner, the use parameter selecting function selects, as the use parameter from the storing portion, the positive operating parameter if the positive operating mode, and the negative operating parameter if the negative operating mode, and sets the selected use parameter automatically.

Owner:YAMATAKE HONEYWELL CO LTD

Three-way bleed type proportional electromagnetic valve

InactiveUS7036525B2Stable flowStable pressureOperating means/releasing devices for valvesServomotor componentsSolenoid valveEngineering

A bleed-type proportional electromagnetic valve having an input port, output port, and ejection port is disclosed. Fluid force and pressing force, proportionate to an output pressure and a current flowing in a solenoid coil respectively, act on a bleed valve for controlling the output pressure, whereby the valve can obtain an output pressure commensurate to the flowing current by displacing the valve to a position that those forces counterbalance, wherein the valve is provided with a stop valve disposed so as to be in sliding contact with a passage between the input and output port, and in contact with or separated from a valve seat. This enable the stop valve to contact with the valve seat so as to close the input port and communicate the output port with the ejection port when controlling the output pressure to be minimum.

Owner:MITSUBISHI ELECTRIC CORP

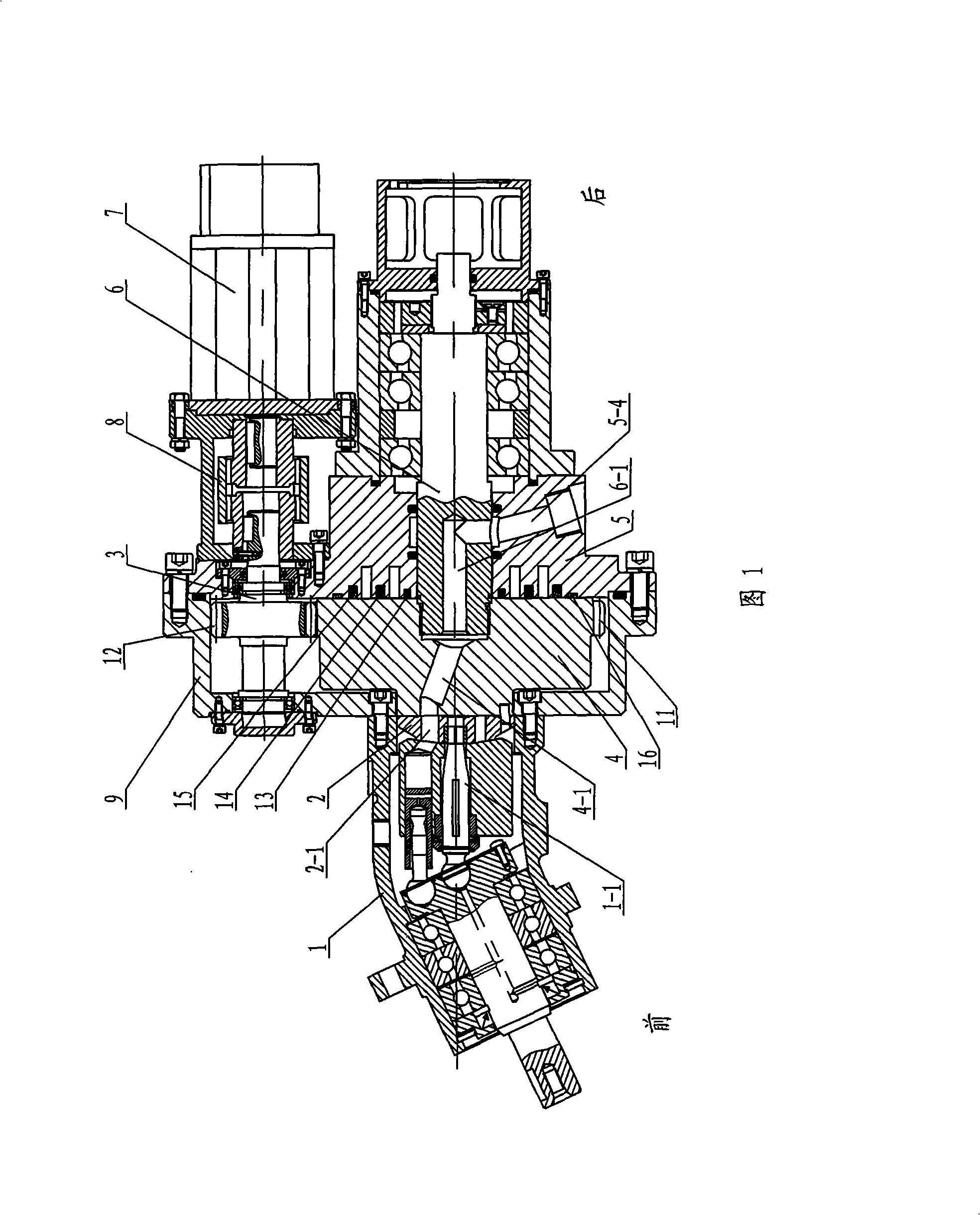

Electric control inclined shaft plunger type hydraulic transformer

InactiveCN101354051ASimple designEasy to operateServomotor componentsTransducersCouplingElectric machine

The invention relates to a hydraulic transformer, in particular to an electrically controlled clino-axis piston hydraulic transformer. The hydraulic transformer of the invention aims at solving the problems that the current hydraulic transformer is mainly controlled by hands and is inconvenient for operation and difficult for ensuring precision. The front end of a transitional plate (4) of the invention is arranged in the lower part of a shell body (9) and connected with a port plate (2); the rear end of the transitional plate (4) is connected with a main shaft (6) of the port plate; a rear end cover (5) is arranged on the main shaft (6) of the port plate and fixedly connected with the shell body (9); the front end surface of the rear end cover (5) mutually contacts the rear end surface of the transitional plate (4); a driven gear (11) on the transitional plate (4) is meshed with a driving gear (12) on a gear shaft (3); the gear shaft (3) is connected with the outputting end of an servo motor (7) by a coupler (8). The servo motor is adopted in the invention to control the rotating angle of the driven gear by the gear shaft; servo control is introduced, thus not only having convenient operation, but also being capable of realizing precise control and improving the controlling performance of a system.

Owner:HARBIN INST OF TECH

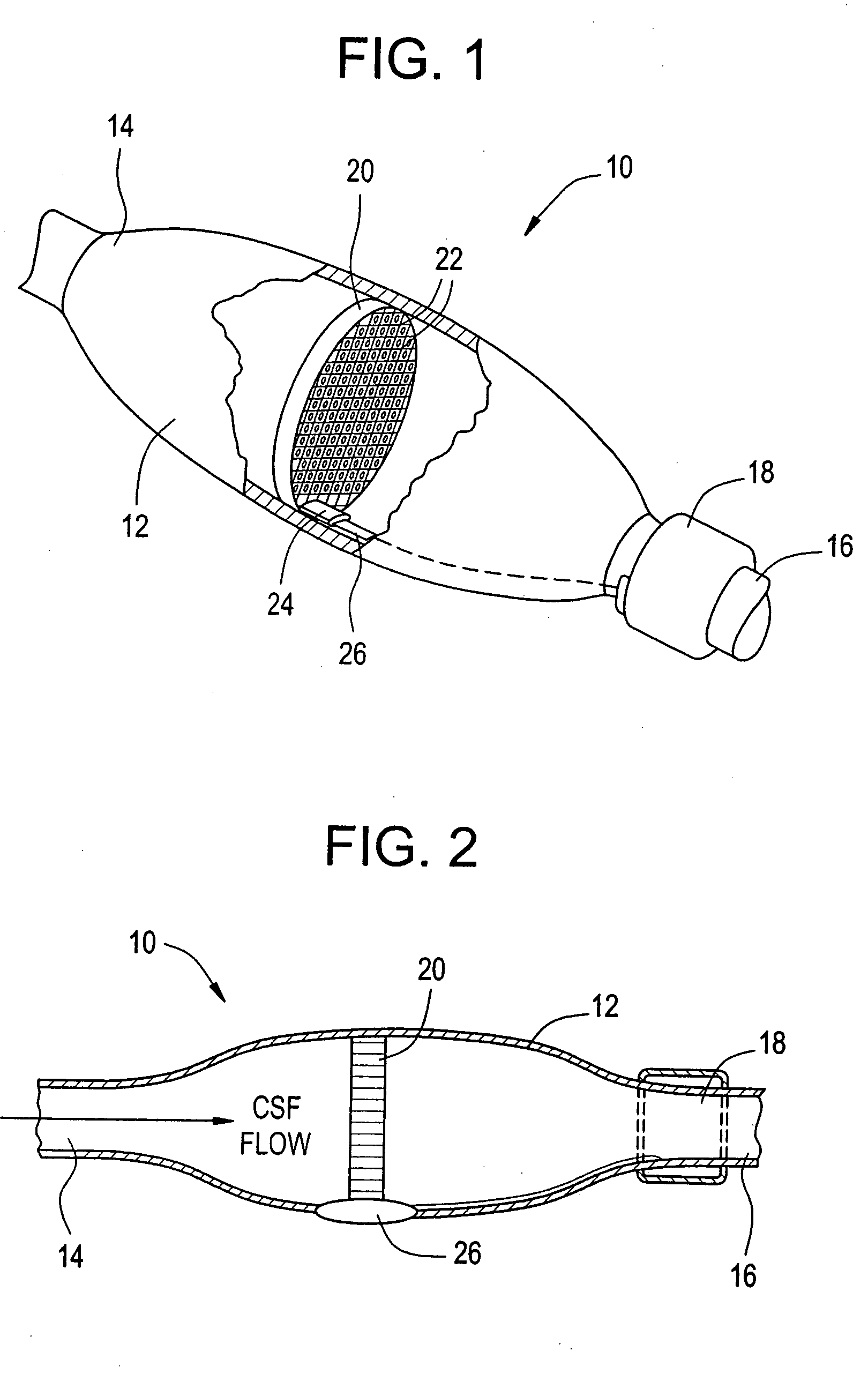

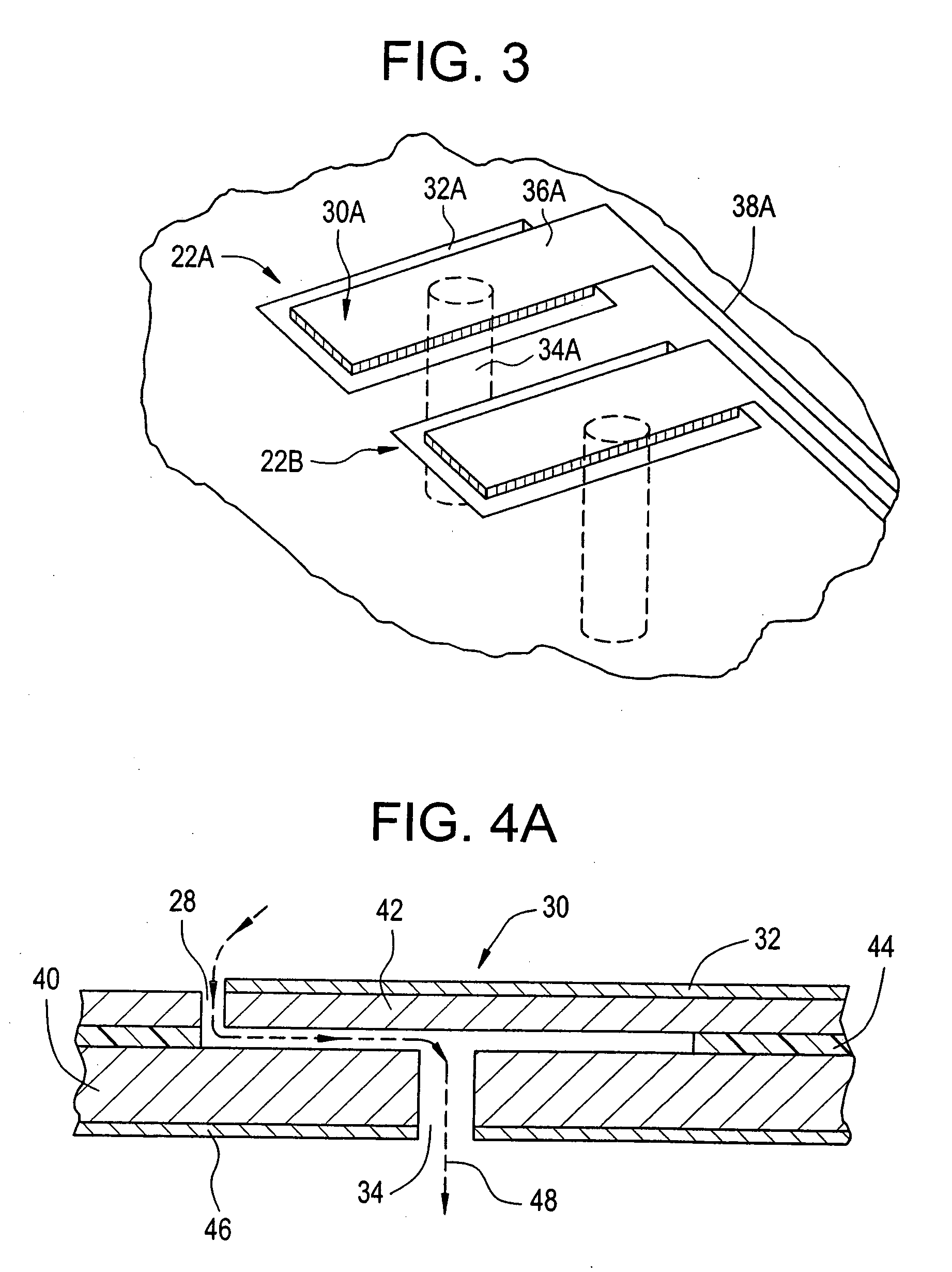

Waveform sensing and regulating fluid flow valve

InactiveUS20060241545A1Rapid responseEasy to controlPiezoelectric/electrostriction/magnetostriction machinesServomotor componentsEngineeringVALVE PORT

Microfluidic shunt valves are disclosed having a deflectable element capable of being held in a closed position to occlude the passage of fluid between an inlet and outlet and, when not held in the closed position, the deflectable element is adapted to oscillate in response to fluid pressure pulses and thereby facilitate fluid passage through the valve. Controls for activating the deflectable element to permit fluid passage are also included.

Owner:CHILDRENS MEDICAL CENT CORP +1

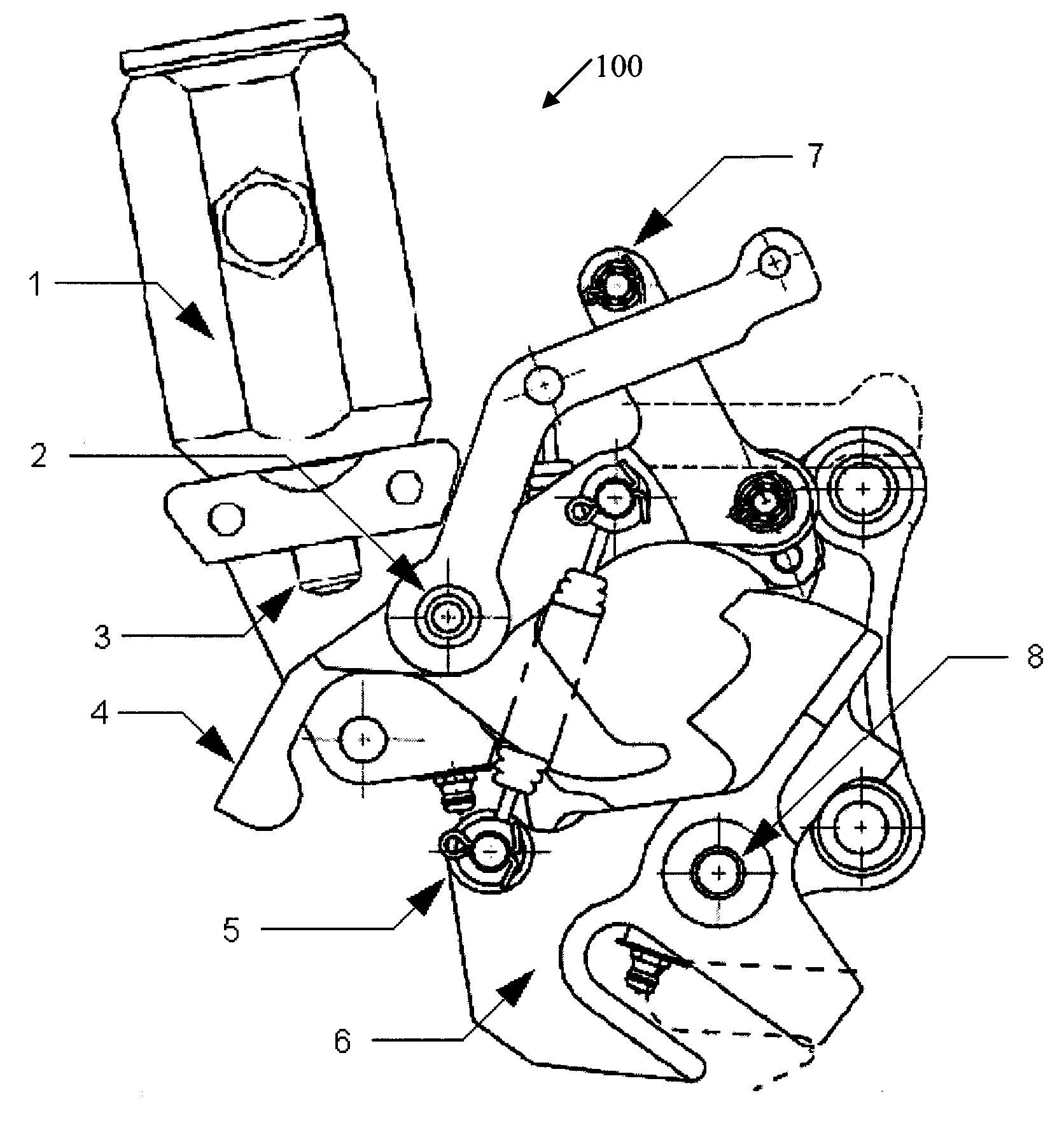

Valve controller

InactiveUS20080078462A1Avoid the needOperating means/releasing devices for valvesServomotor componentsSolenoid valveUnit operation

A controller for controlling a valve is disclosed including a manifold assembly, a valve position indicator and a trigger assembly. An operating media distribution system is disposed in the manifold assembly and an electronic control unit is disposed in the controller. The electronic control unit operates at least one electromagnetic valve to control operating media flow via the operating media distribution system to activate an actuator which opens or closes the valve. The trigger assembly includes a cylinder adapted to receive an actuator shaft and provide a self setting mechanism corresponding to the stroke length of the actuator shaft.

Owner:WESTLOCK CONTROLS

Landing gear uplock mechanism employing thermal phase-change actuation

An uplock assembly for retaining and releasing landing gear systems, said uplock assembly comprising: a thermal actuator comprising: a chamber configured to contain expansible material therein; a heating mechanism coupled to said chamber for heating said expansible material and causing volumetric expansion thereof; a piston slidably coupled to said chamber and adapted to extend in response to said volumetric expansion; and an uplock release mechanism releasably engaged by said piston when extended such that said engaged uplock release mechanism causes the release of said landing gear.

Owner:SAFRAN LANDING SYST CANADA INC

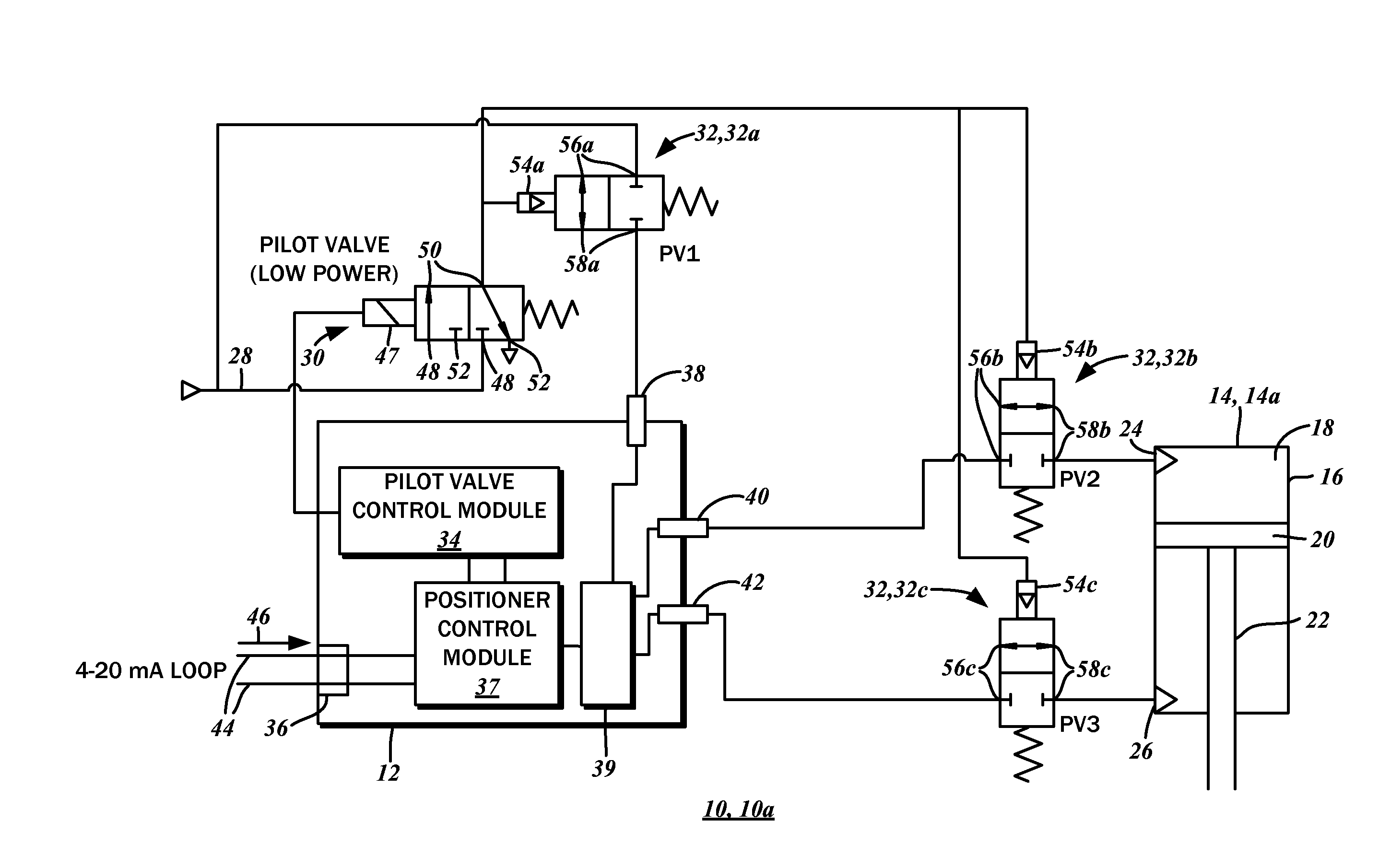

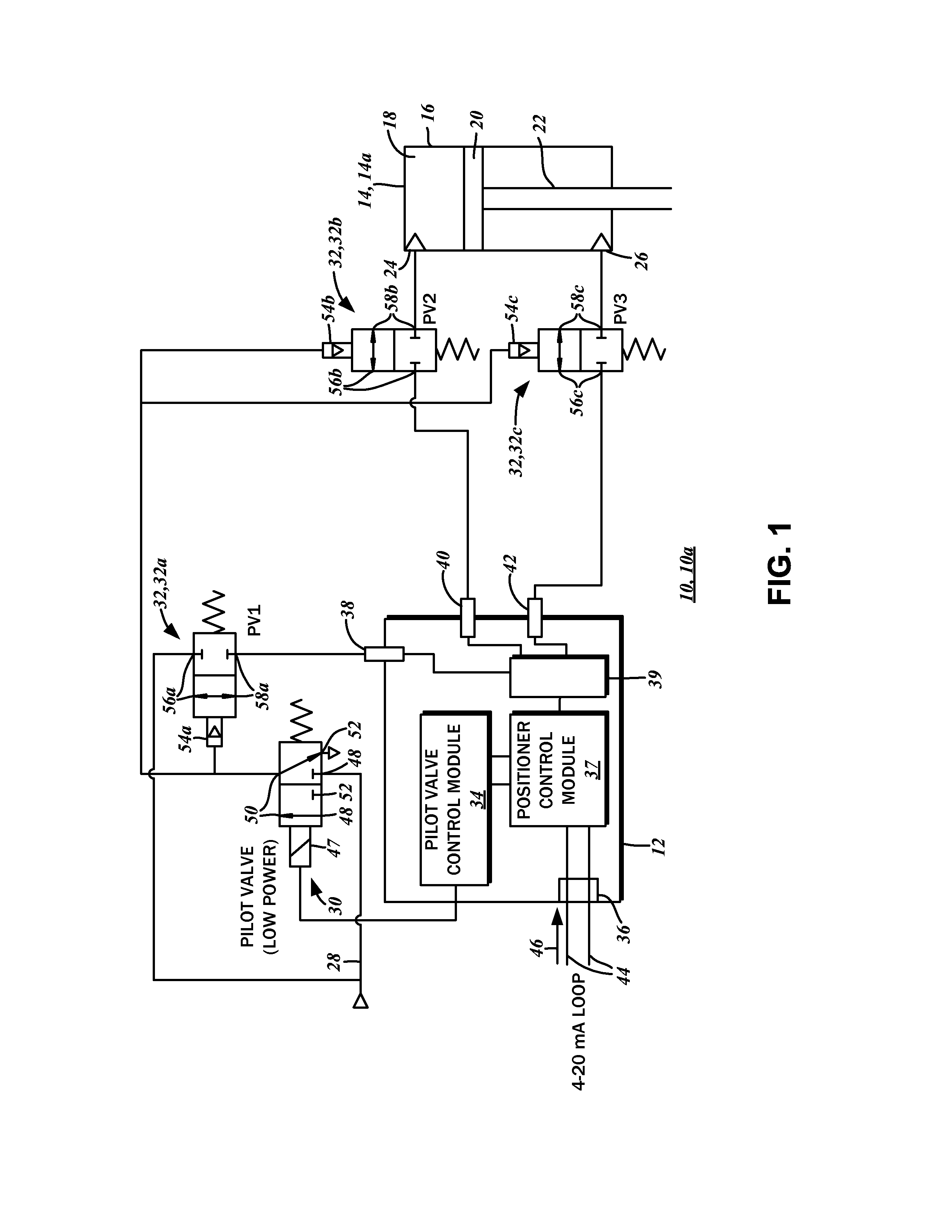

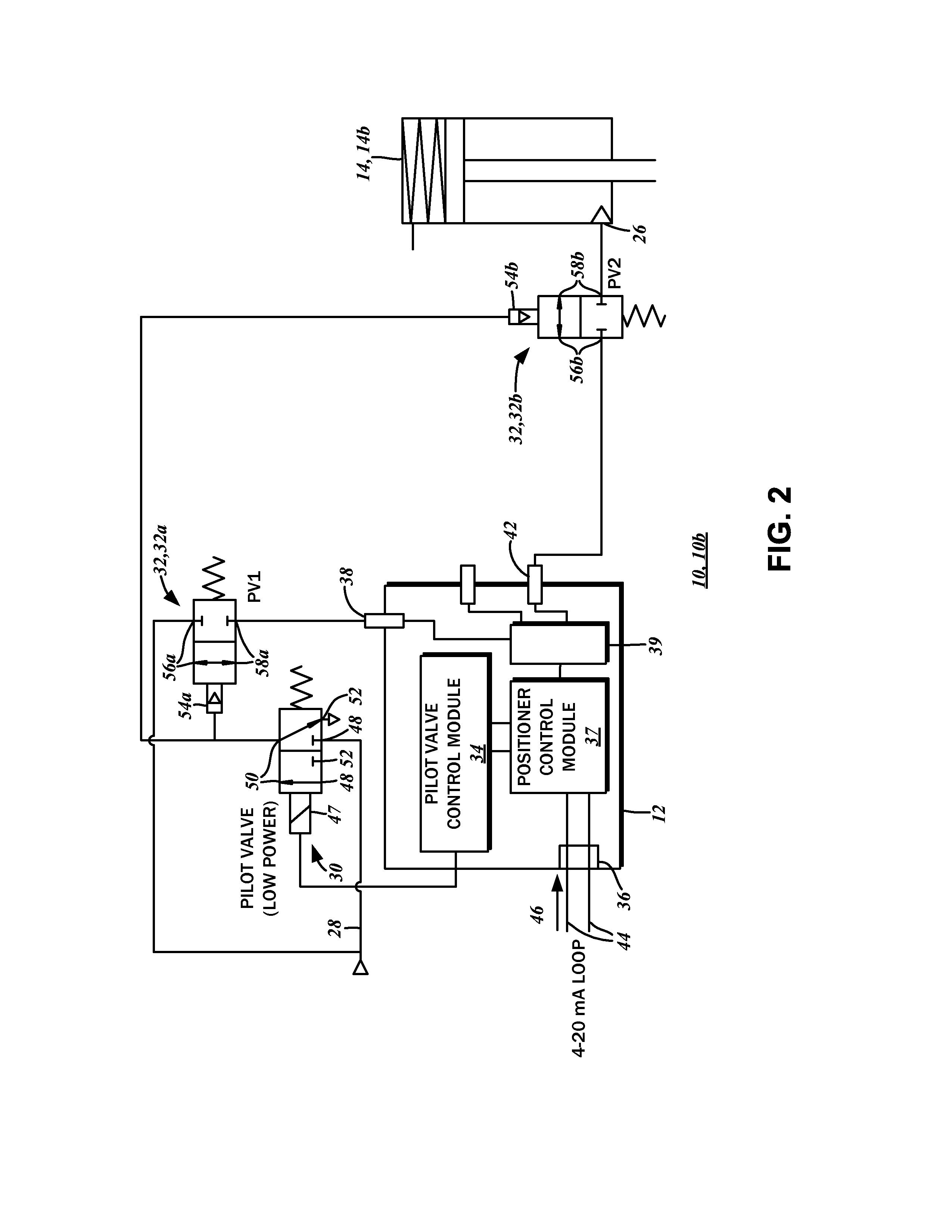

Valve positioning system with bleed prevention

ActiveUS20130174915A1Fluid-pressure actuator safetyFluid-pressure actuator testingStable stateValve actuator

A valve positioner system with zero bleed at steady state is disclosed. The system has a pilot valve, the operation of which is controlled by an electronic circuit powered from a signaling and power connection of a positioner device. A plurality of pneumatic valves are activated and deactivated by the pilot valve to control a valve actuator. With varying configurations and arrangements of normally open or normally closed pilot valves and pneumatic valves, fail freeze and fail safe operations are contemplated. The activation and deactivation of the pilot valve is controlled by an electronic circuit that monitors a valve position signal.

Owner:SUBARU TECNICA INTERNATIONAL

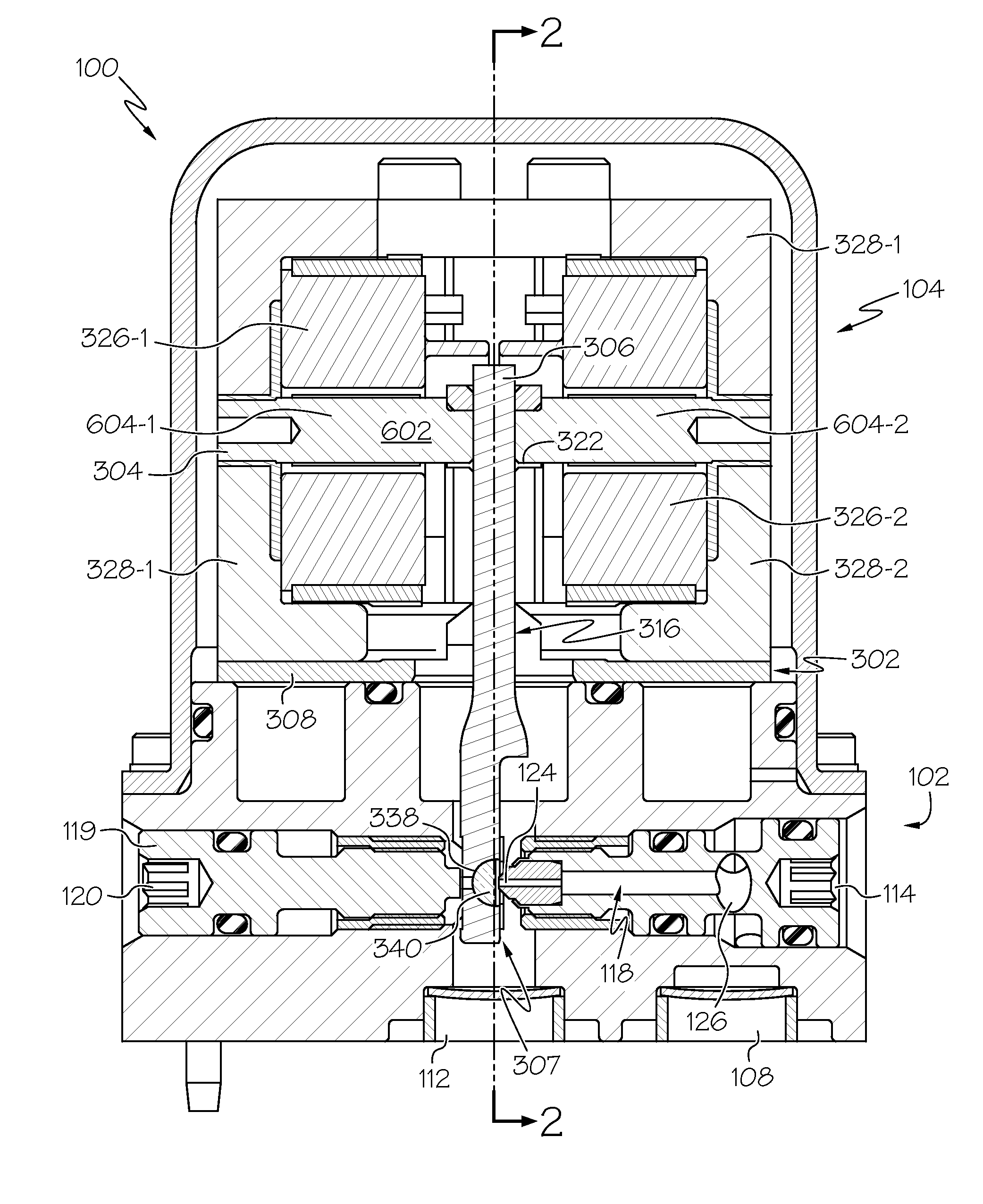

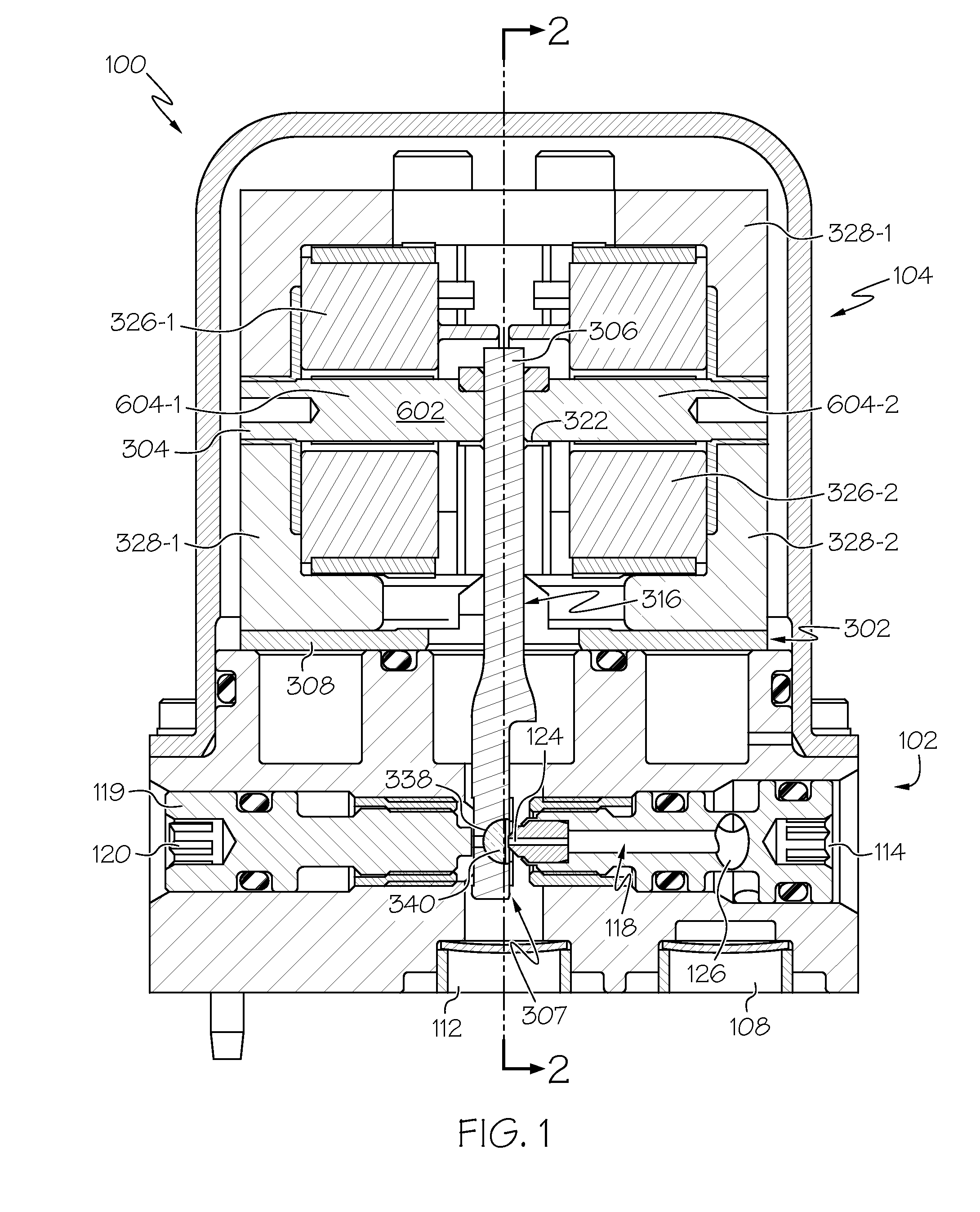

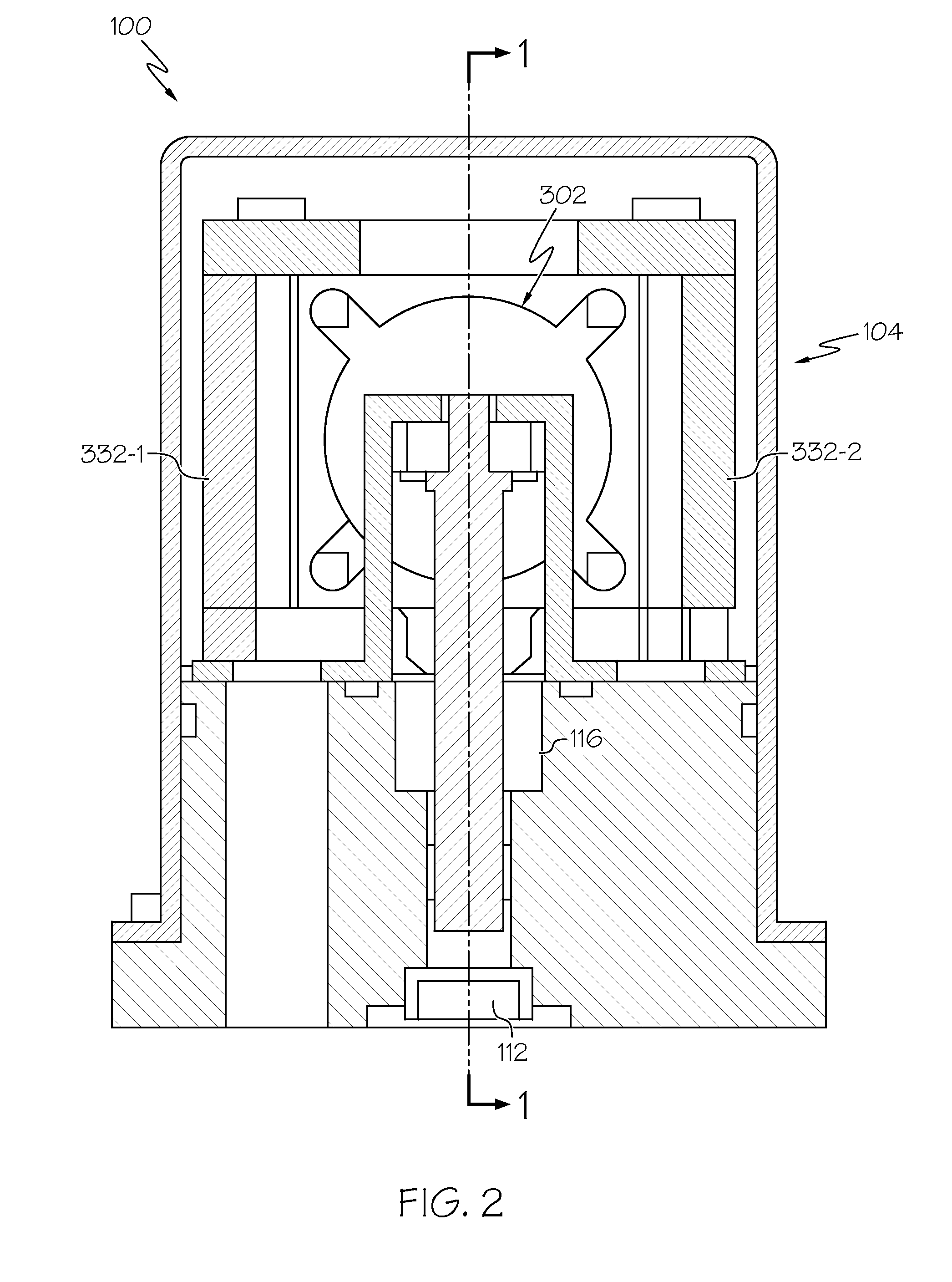

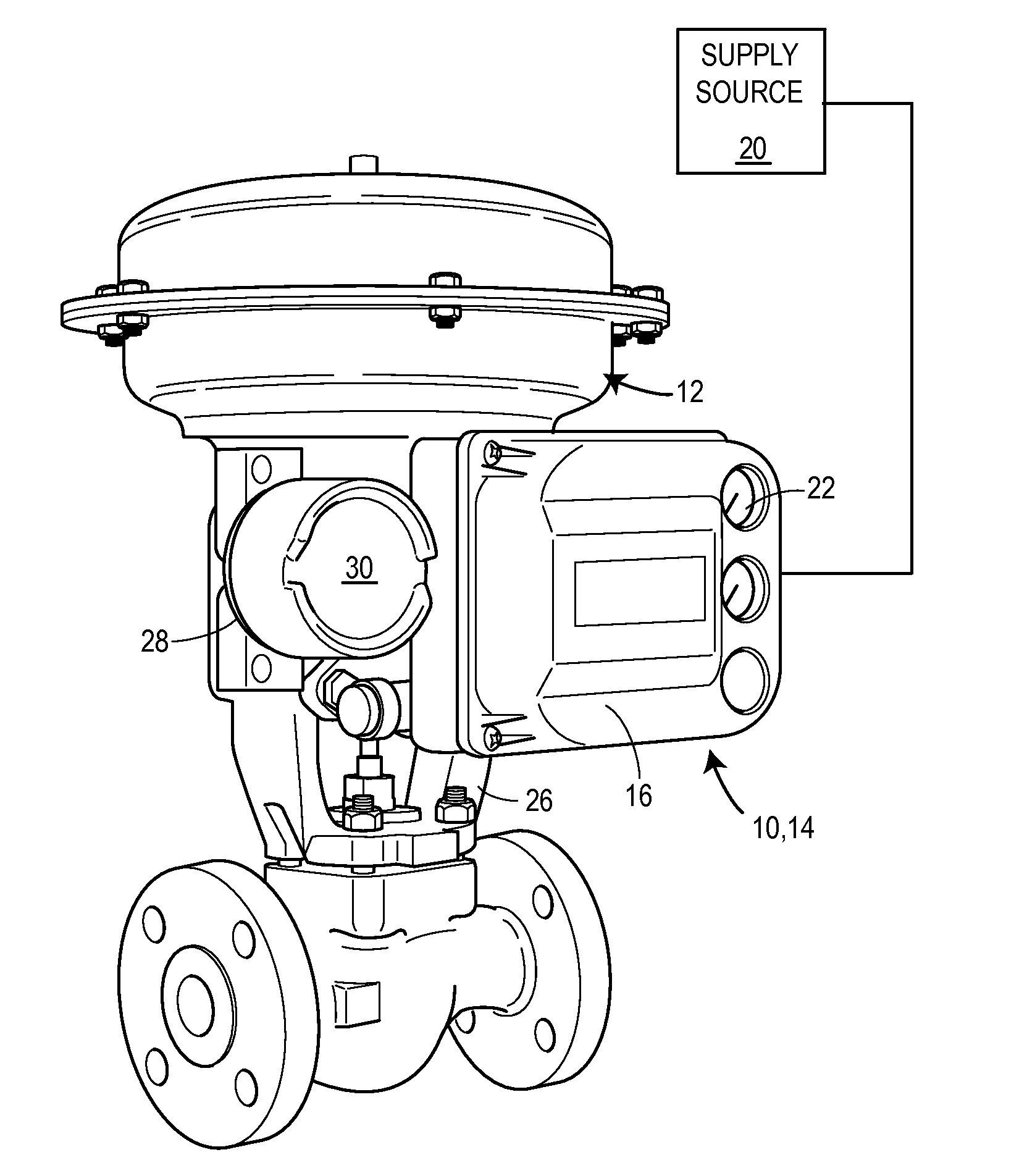

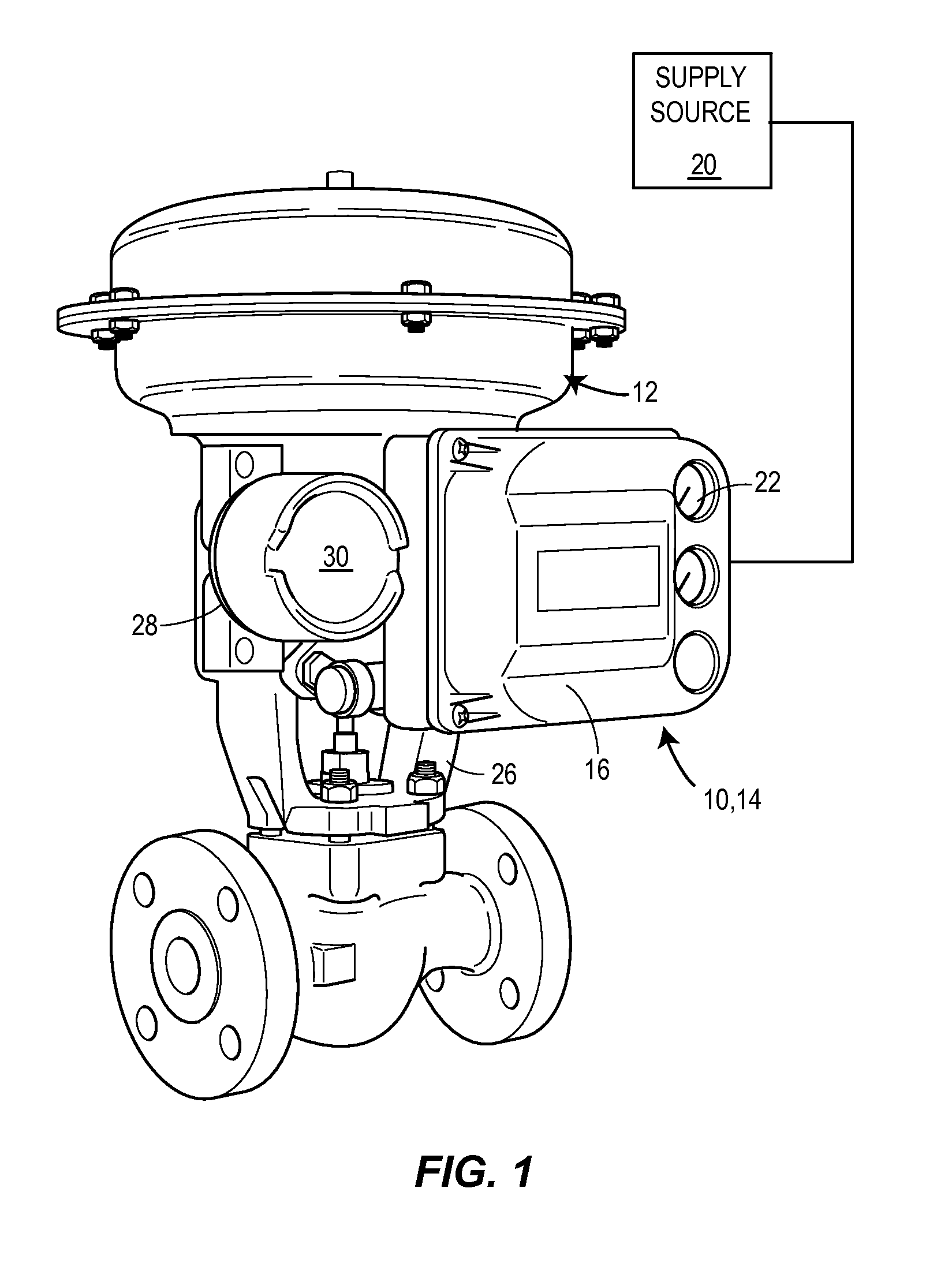

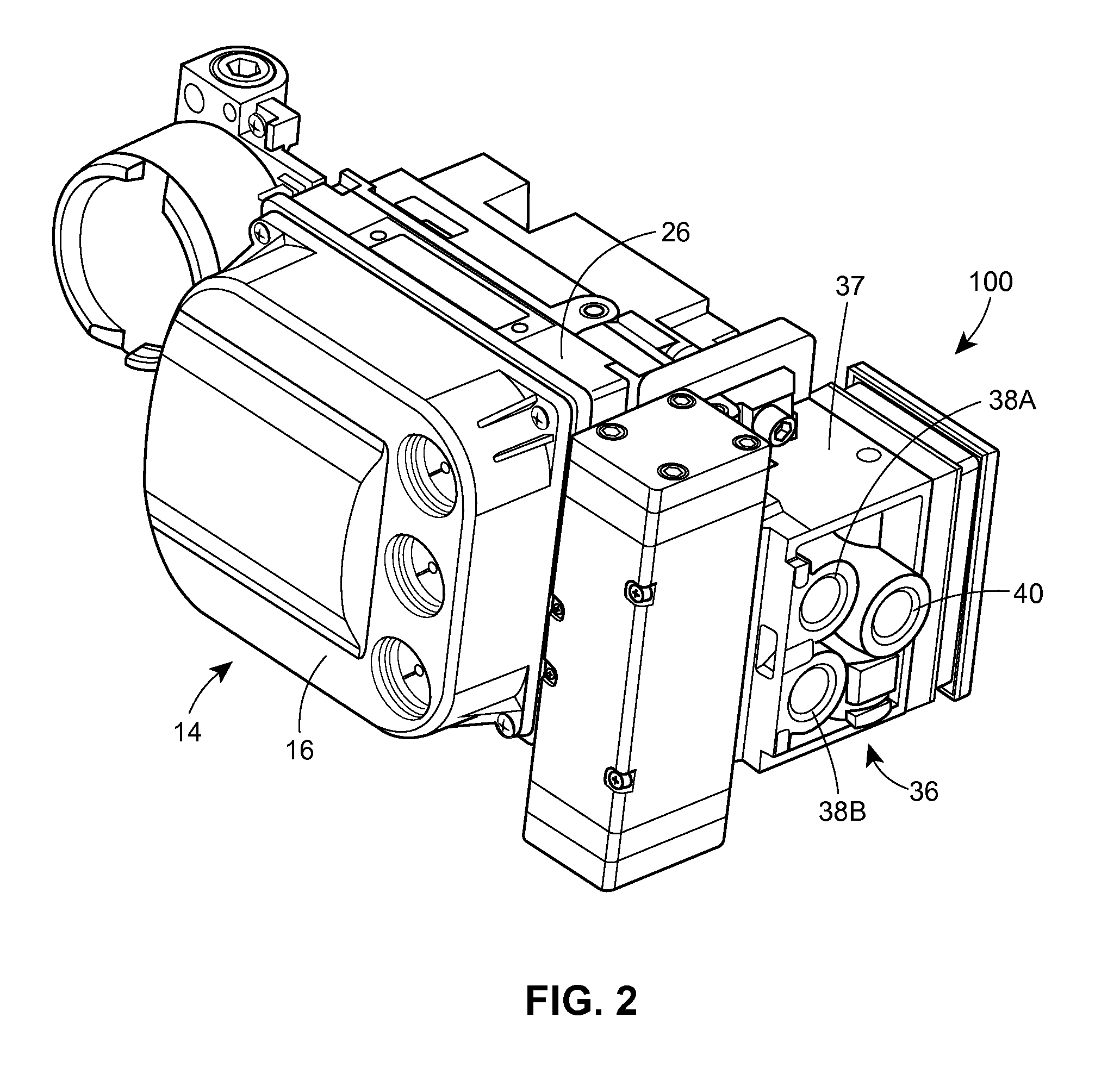

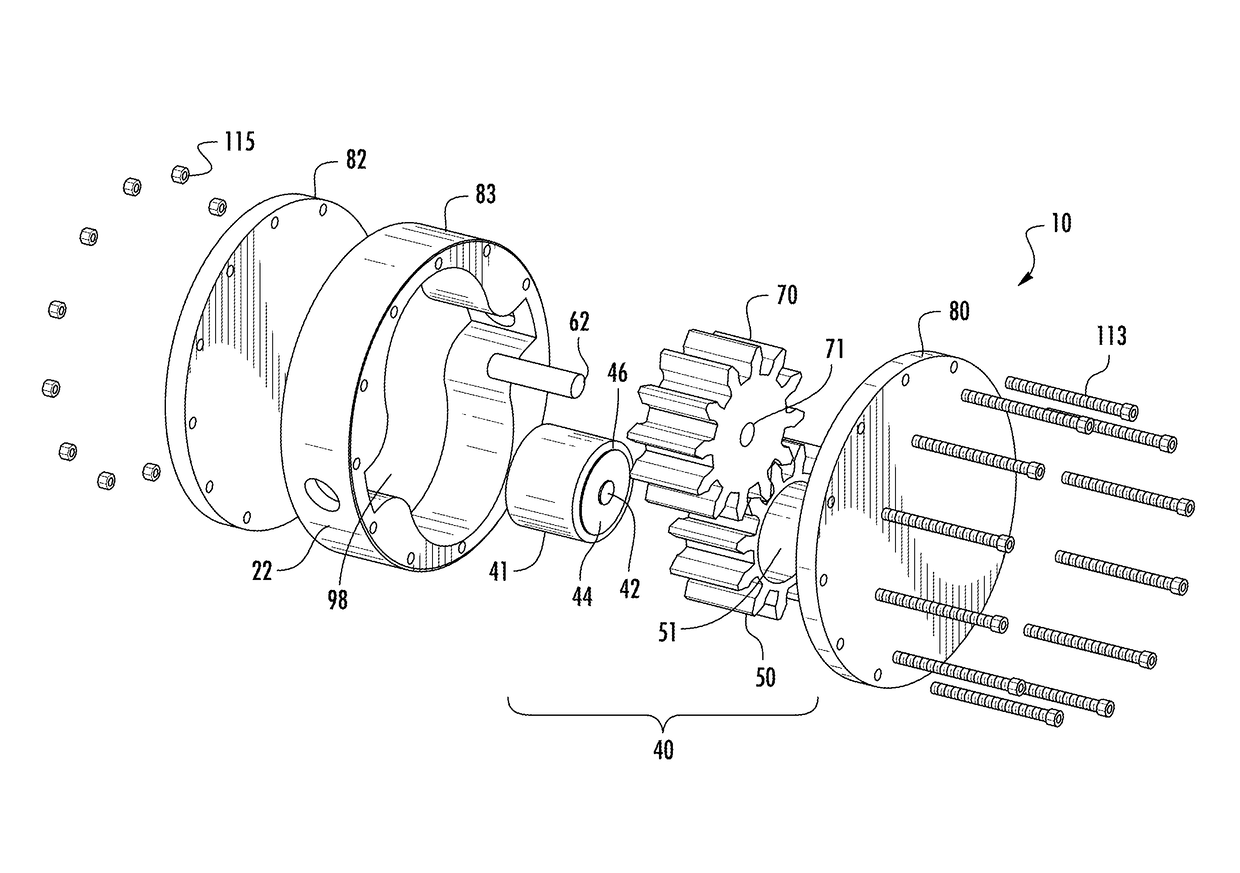

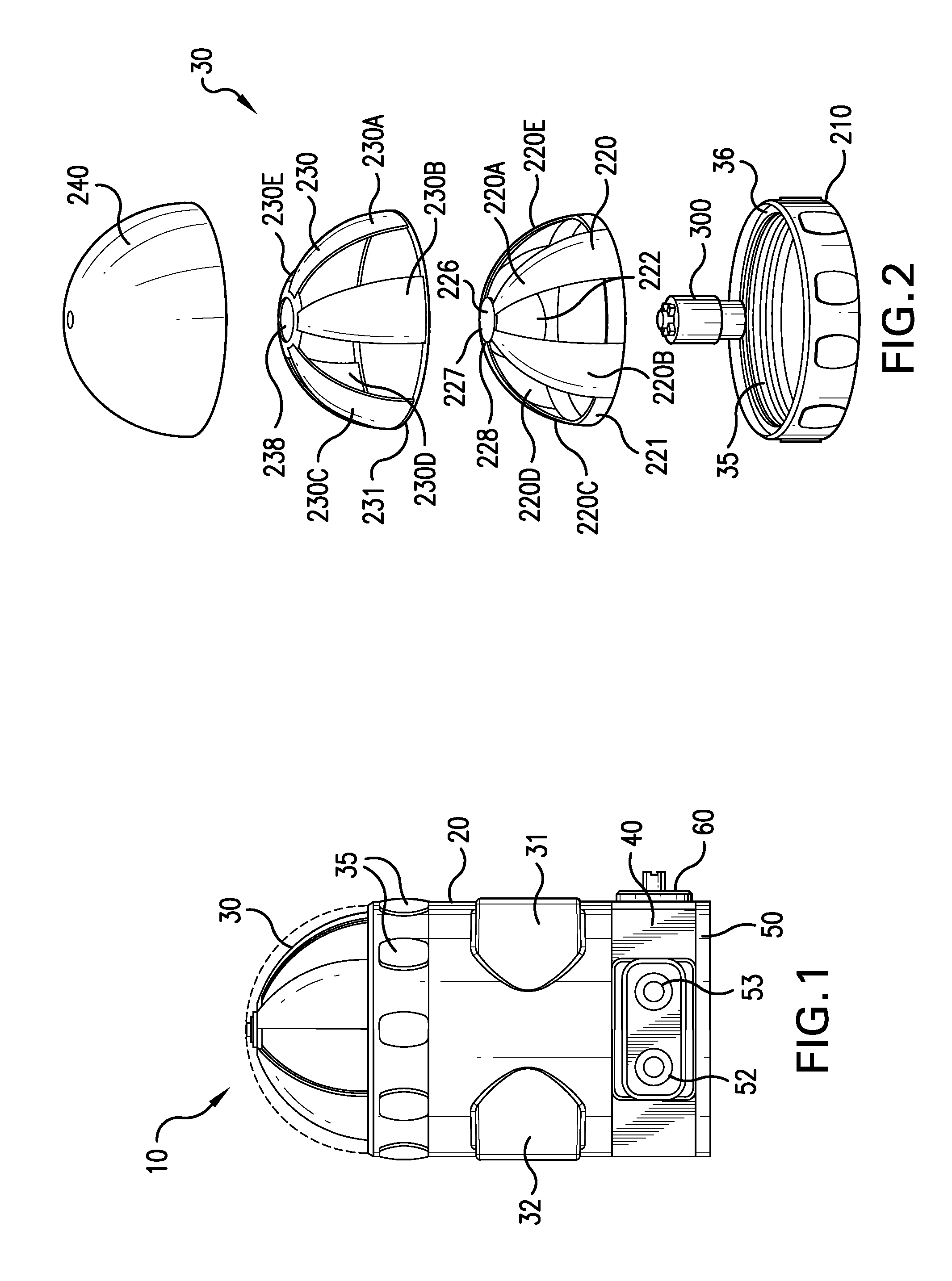

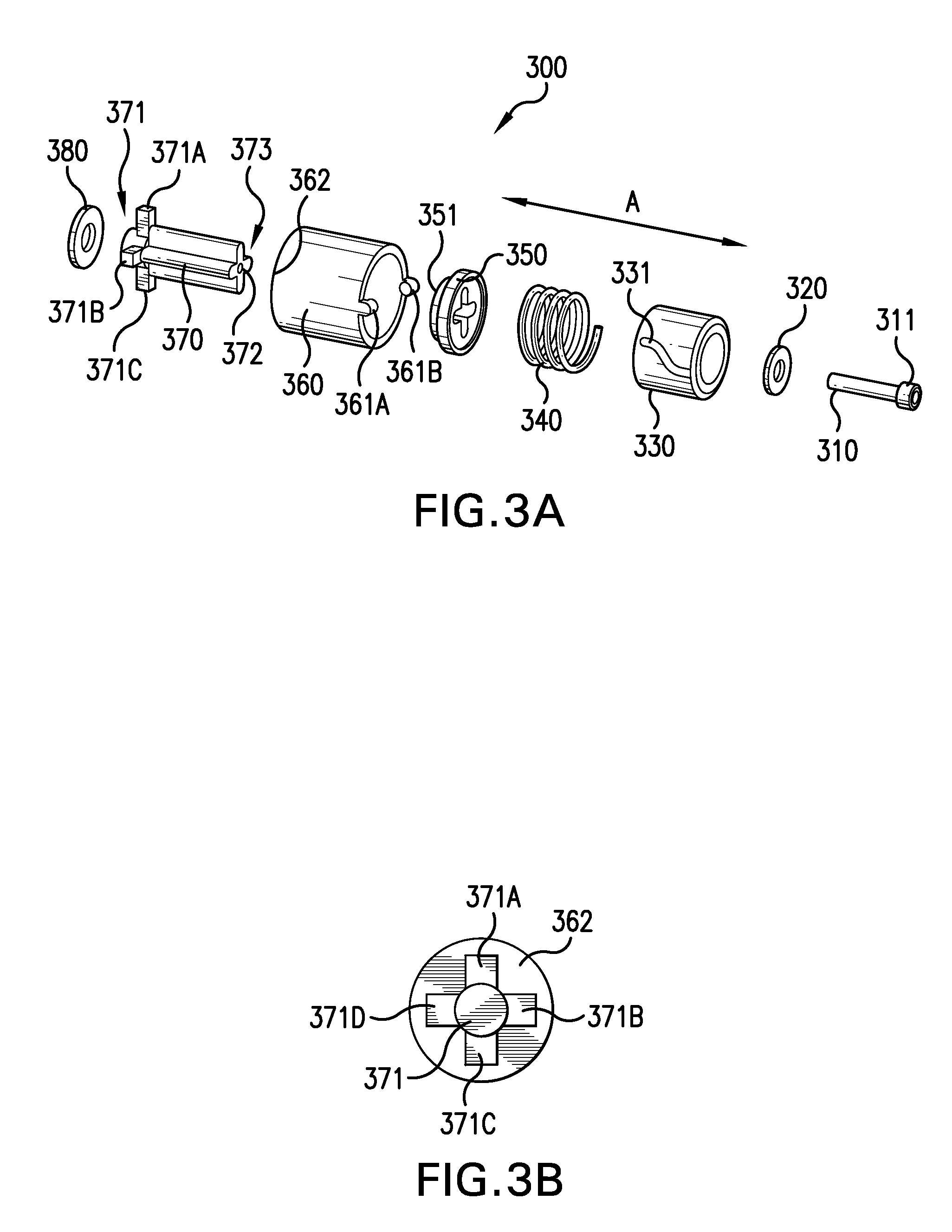

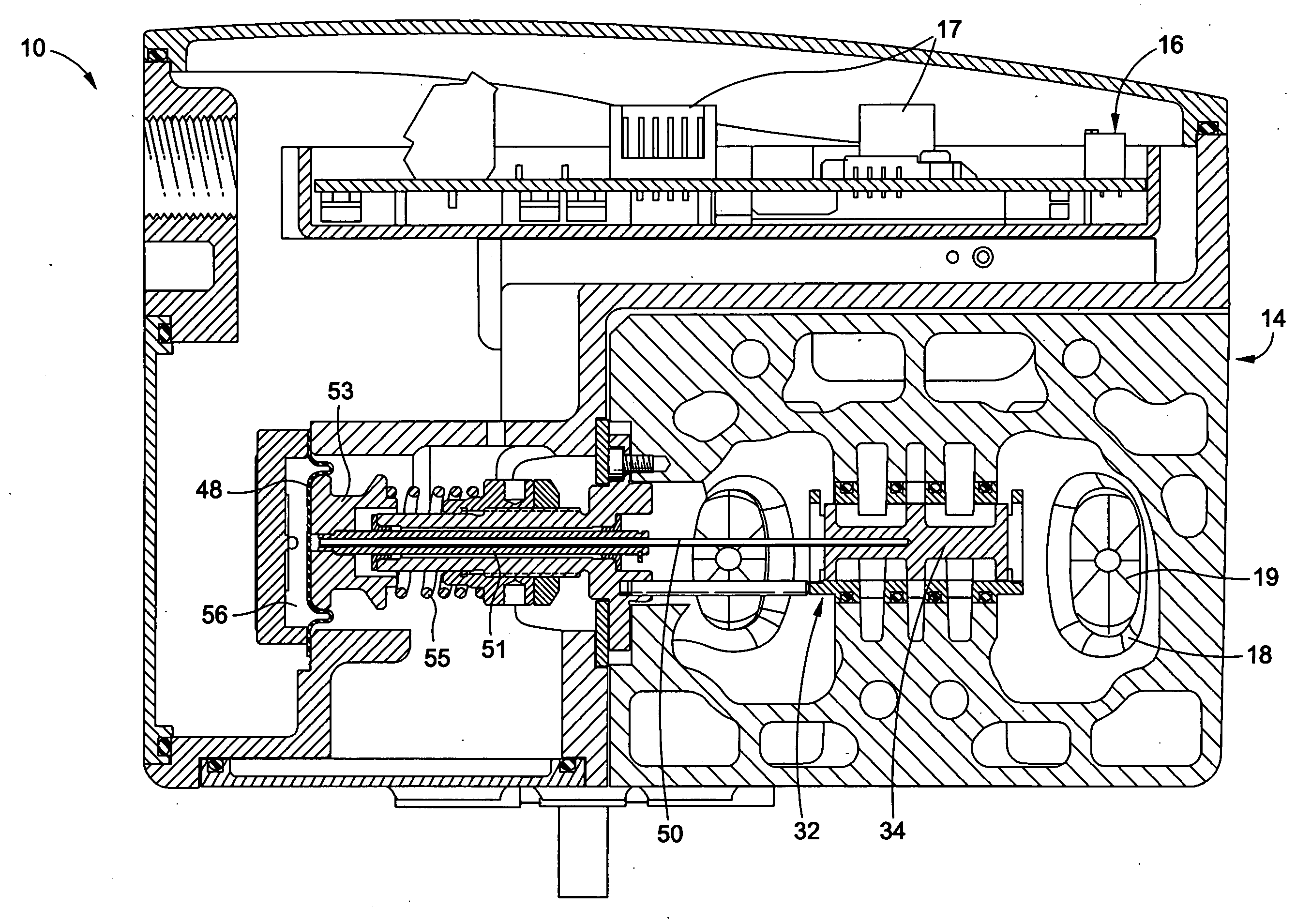

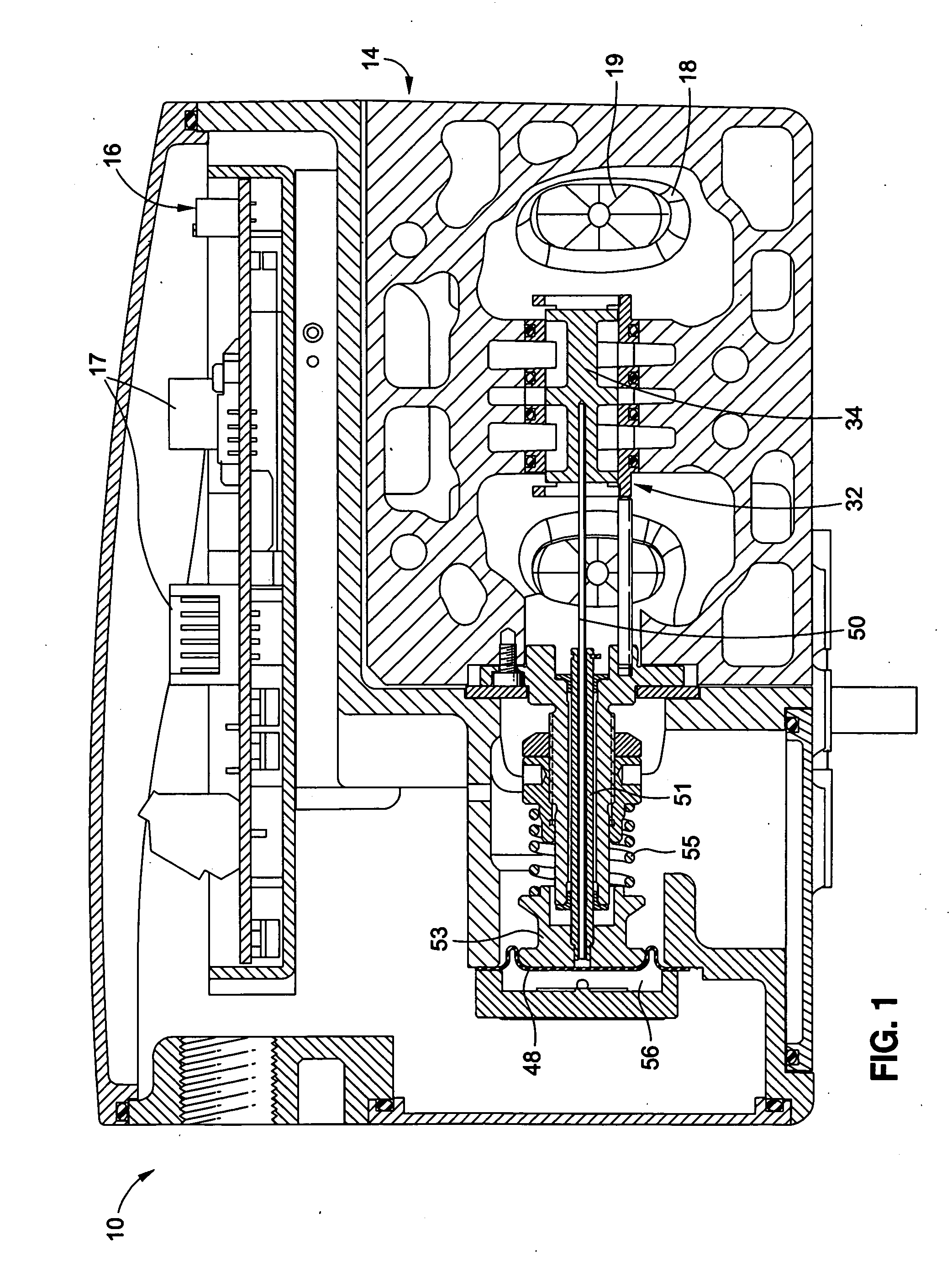

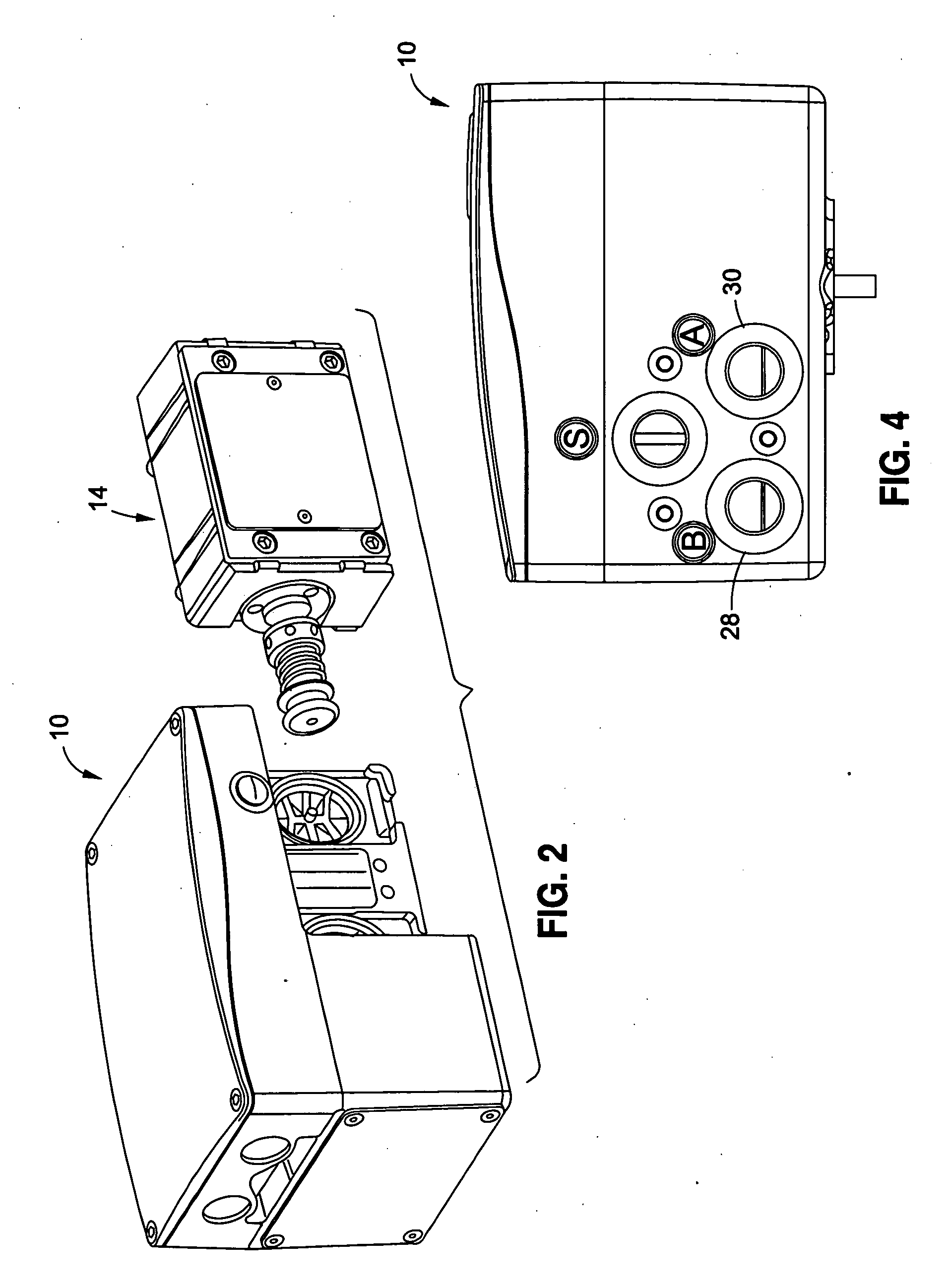

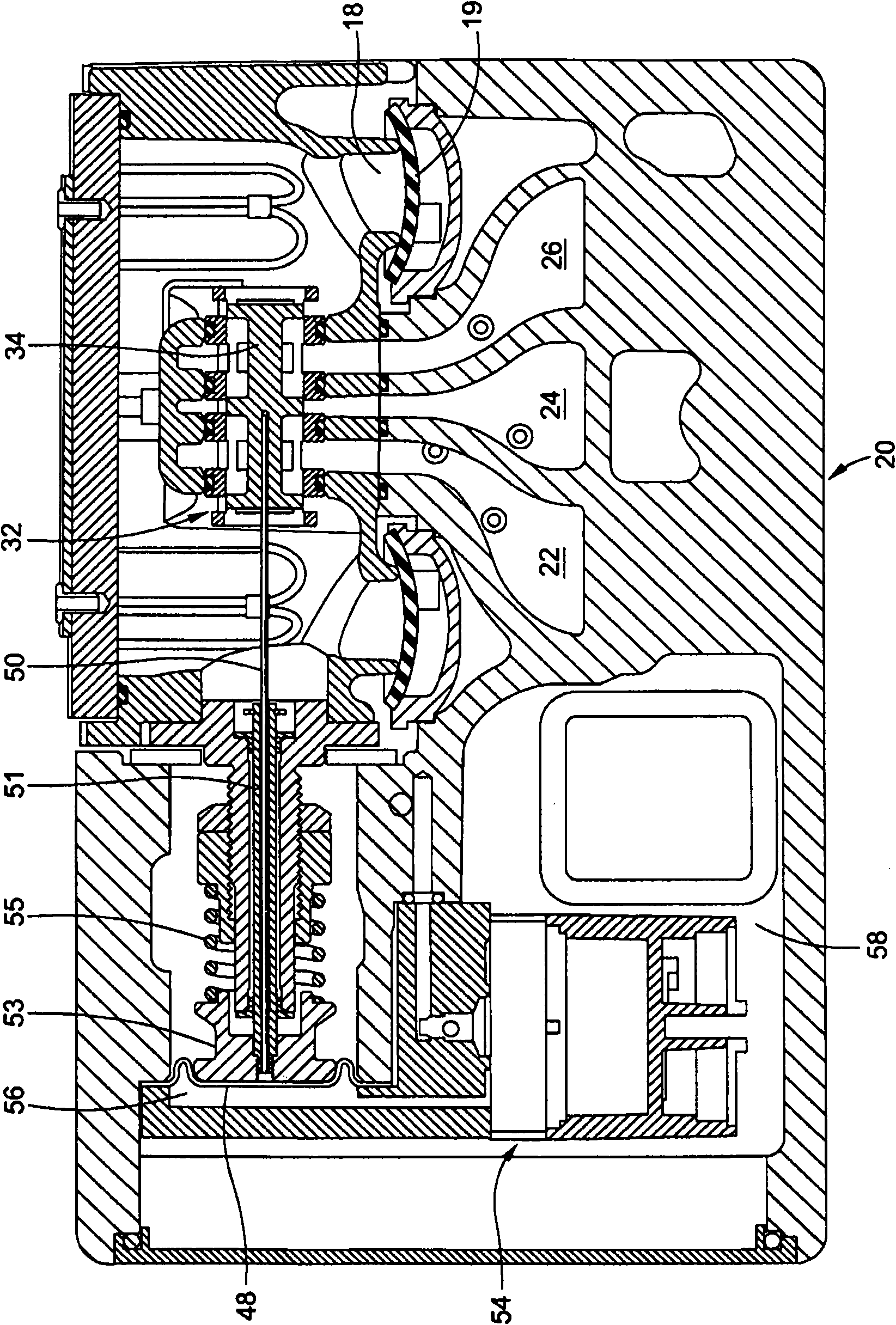

High Flow Capacity Positioner

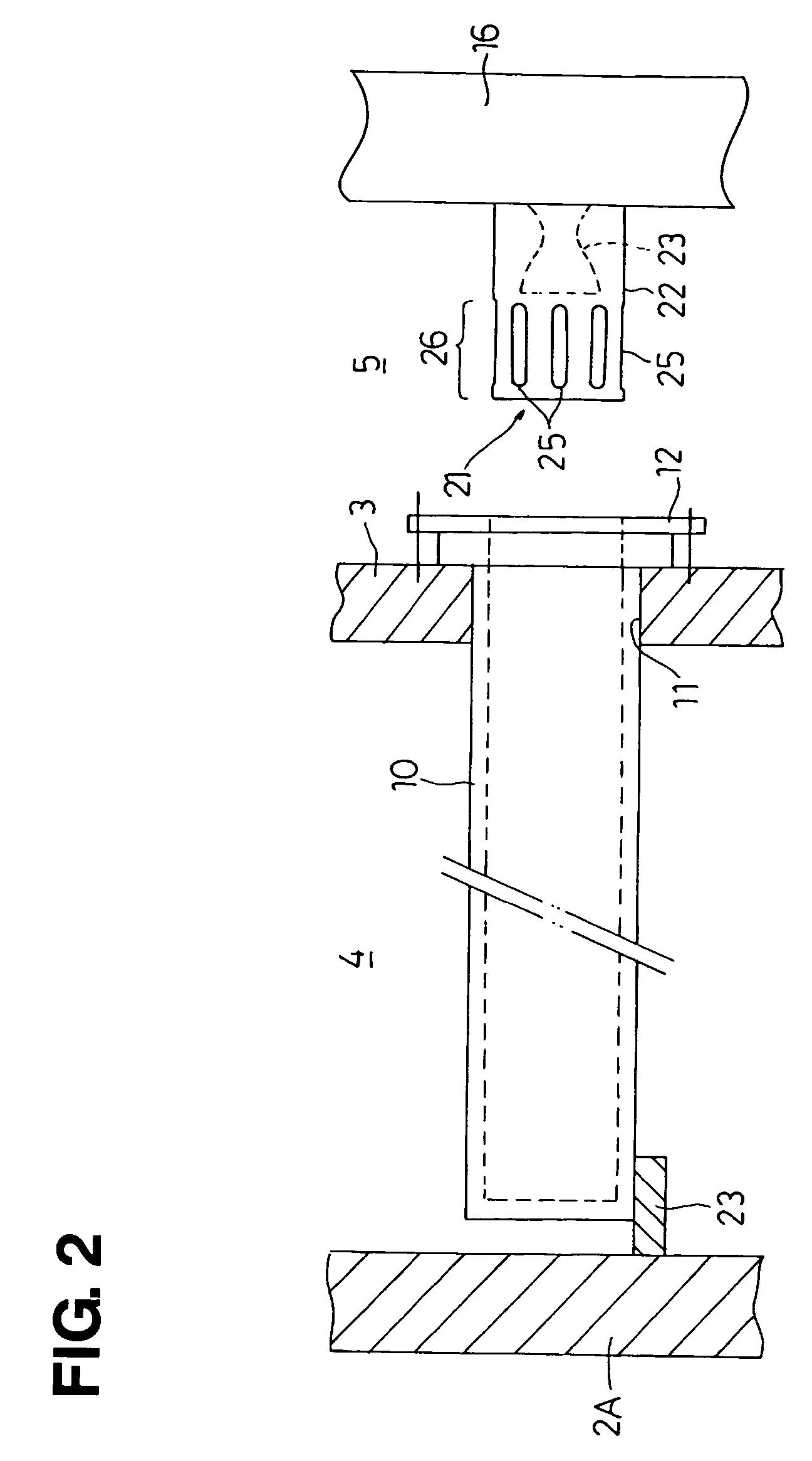

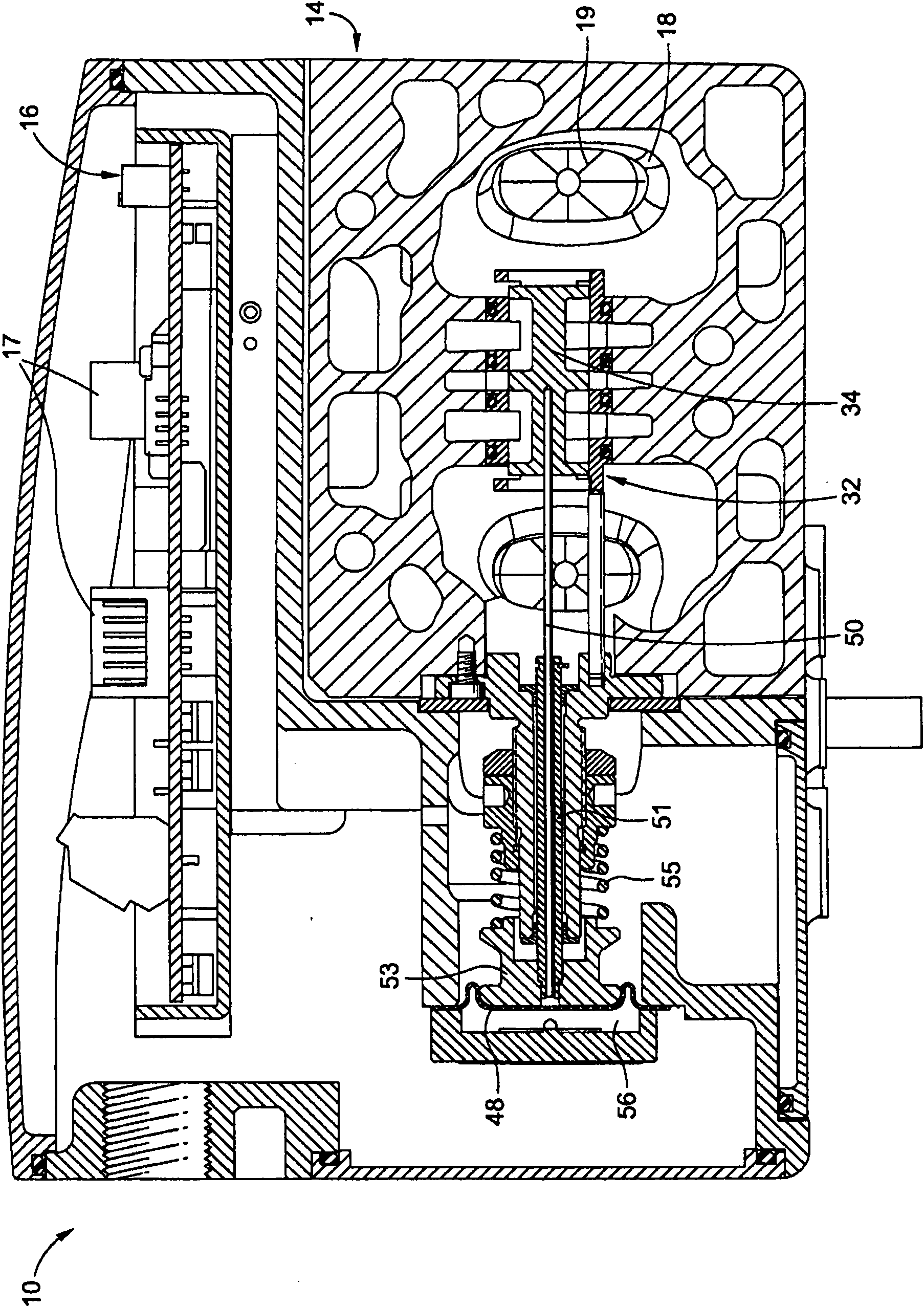

ActiveUS20090178713A1Minimize spool displacementAvoid fatigueEngine diaphragmsServomotor componentsTransducerFluid supply

A valve positioner for controlling a valve closure element is provided. The positioner includes a positioner housing with a plurality of fluid flow passageways in fluid communication with a fluid supply source and the valve closure element. The positioner housing is configured to receive a detachable spool manifold assembly. The spool manifold assembly is positioned adjacent the plurality of fluid flow passageways. The spool manifold assembly includes a reciprocally moveable spool configured to selectively port fluid flow from the plurality of fluid flow passageways. The spool manifold assembly includes a diaphragm connected to the spool via a flexible shaft. The diaphragm is in fluid communication with a transducer for receiving a fluid causing the diaphragm to expand or contract and thereby displacing the spool. The flexible shaft is radially elastic in order to minimize axial backlash between the diaphragm and the spool. The flexible shaft configuration minimizes the spool stroke.

Owner:SUBARU TECNICA INTERNATIONAL

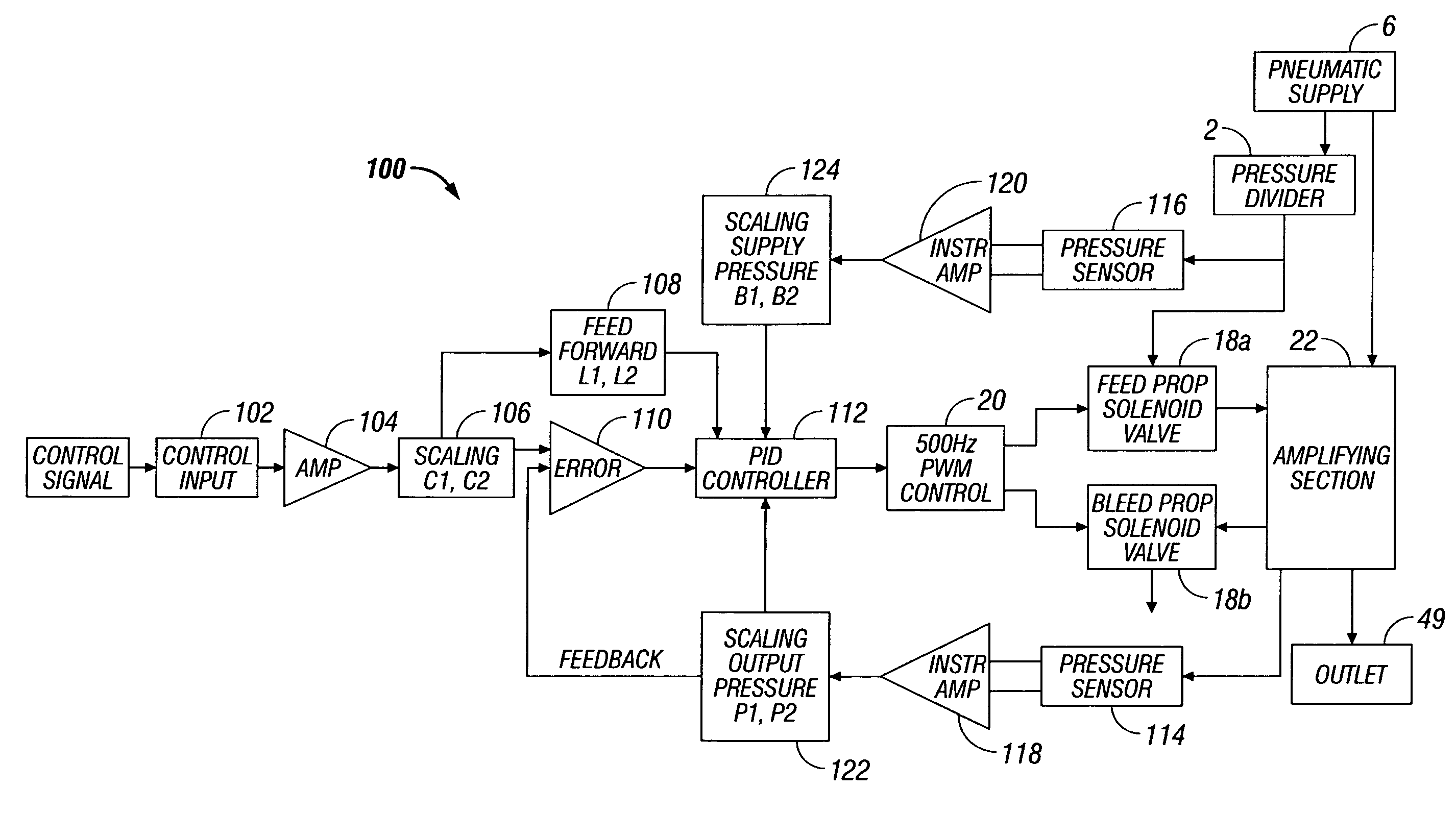

Digital Closed Loop Proportional Hydraulic Pressure Controller

ActiveUS20090194169A1Improve robustnessMinimize potentialOperating means/releasing devices for valvesHollow article cleaningTransducerRotary valve

A digitally controlled current to pressure converter (CPC) is provided. A digital CPC utilizes a digital controller and an onboard pressure transducer to accurately control the output pressure based upon an input analog control signal. The digital controller includes an anti-silting algorithm that provides an impulse movement of the three-way rotary valve of the CPC to loosen and flush away silt contamination from the valve. A redundant seal stack including an intermediate passage to the hydraulic drain ensures a low pressure drop across the outboard seal minimizing the potential for leakage and improving reliability of the CPC. The digital controller also includes redundancy and fault management algorithms that enable the use of multiple inputs and feedback signals for control of the CPC. Master / slave operation and transitioning is also provided by the digital controller.

Owner:WOODWARD GOVERNOR CO

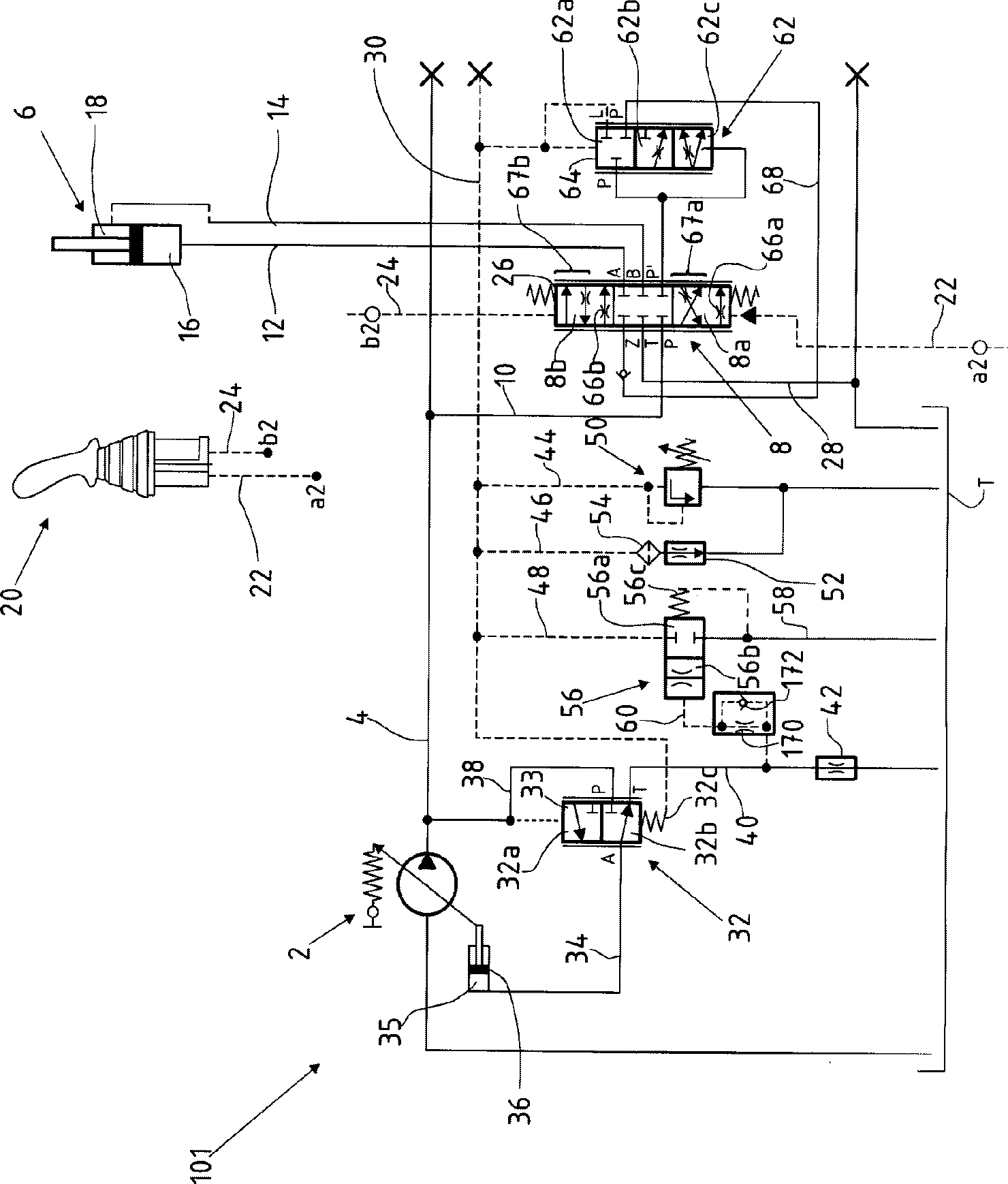

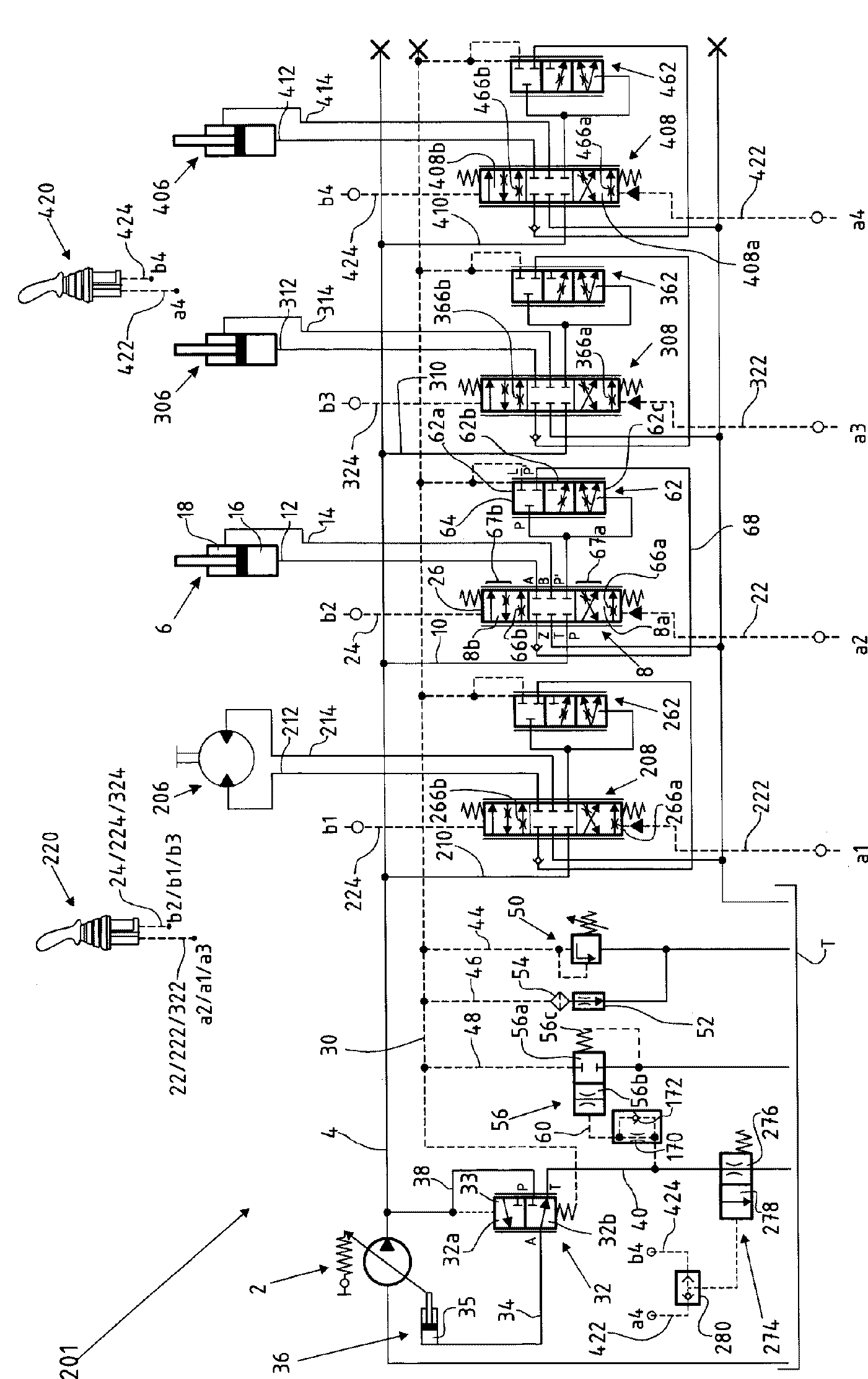

Hydraulic control system with load pressure reduction device and hydraulic valve set therefor

ActiveCN103382952AMaximum load pressure does not decreaseRelieve pressureFluid-pressure actuator testingServomotor componentsHydraulic pumpHigh load

The hydraulic control system has an adjustable hydraulic pump (2) via which the pressure medium is supplied to hydraulic load. A pumping controller (32) is provided for controlling the volumetric flow of an adjuster (36) of the hydraulic pump in dependence of supply pressure or highest load pressure of the hydraulic load. A pressure reduction device (56) for high load pressure is more adjusted in dependence of controlled volumetric flow.

Owner:ROBERT BOSCH GMBH

Method for operation of a position regulator

InactiveUS20090146088A1Operating means/releasing devices for valvesServomotor componentsElectricityAudio power amplifier

The disclosure relates to a method for operation of a position regulator for control of a pneumatic drive for an actuating member in a process installation. The position regulator has a pneumatic system with at least one nozzle / bounce-plate system, in which the bounce plates are in the form of piezo bending bars. For damped ventilation and venting of the pneumatic drive in the event of failure of the electrical power, it is proposed that the level of the electrical power supply be monitored and that, if a predeterminable limit value is undershot, the piezo bending bars of the pneumatics are adjusted via the input signals of the pneumatics such that the pneumatically controlled valves, which are subject to a characteristic, of the amplifier are open precisely just so far that a damped movement of the pneumatic actuating drive takes place to a predeterminable limit position at the desired movement speed.

Owner:ABB (SCHWEIZ) AG

Positioner

Owner:YAMATAKE HONEYWELL CO LTD

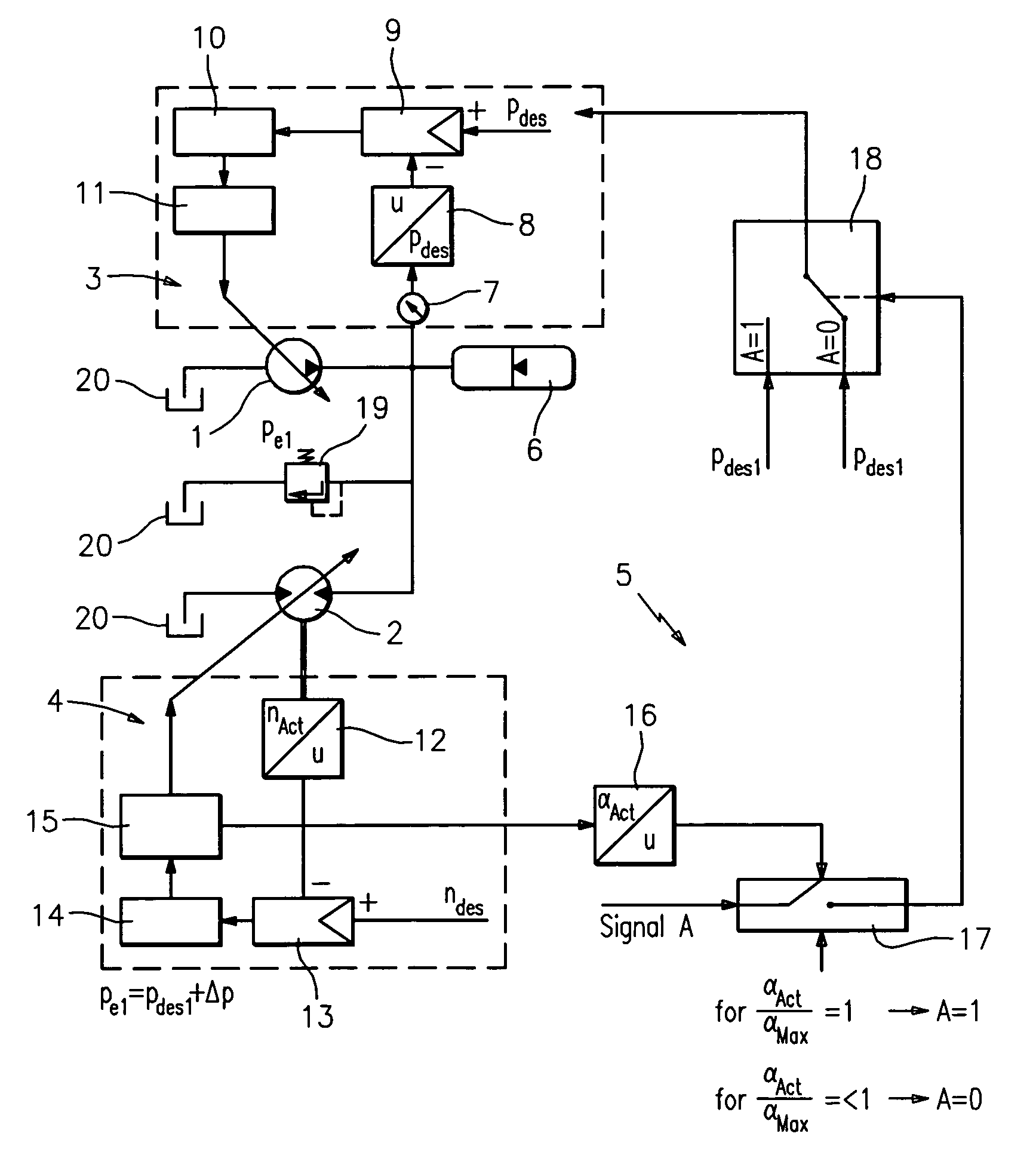

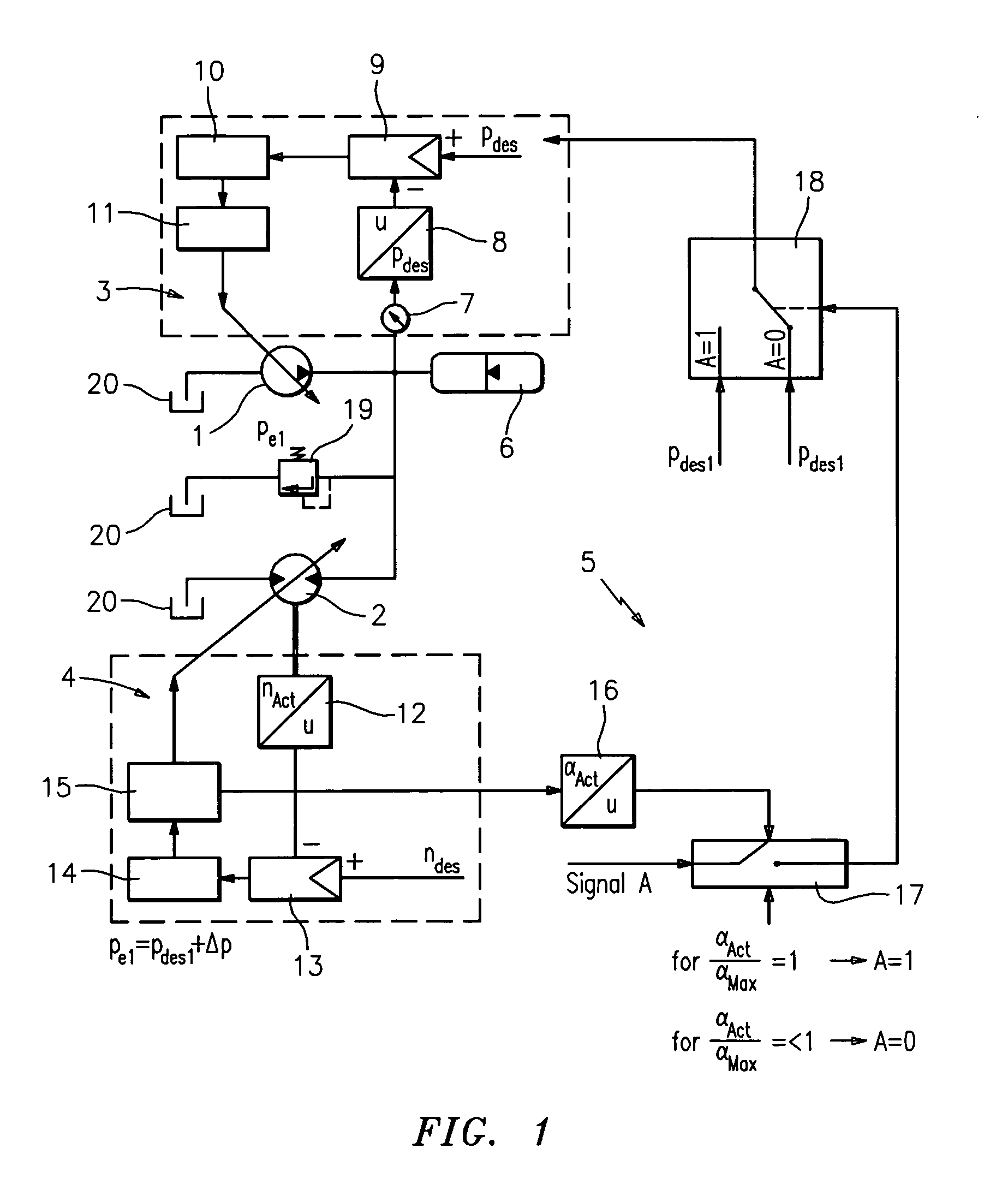

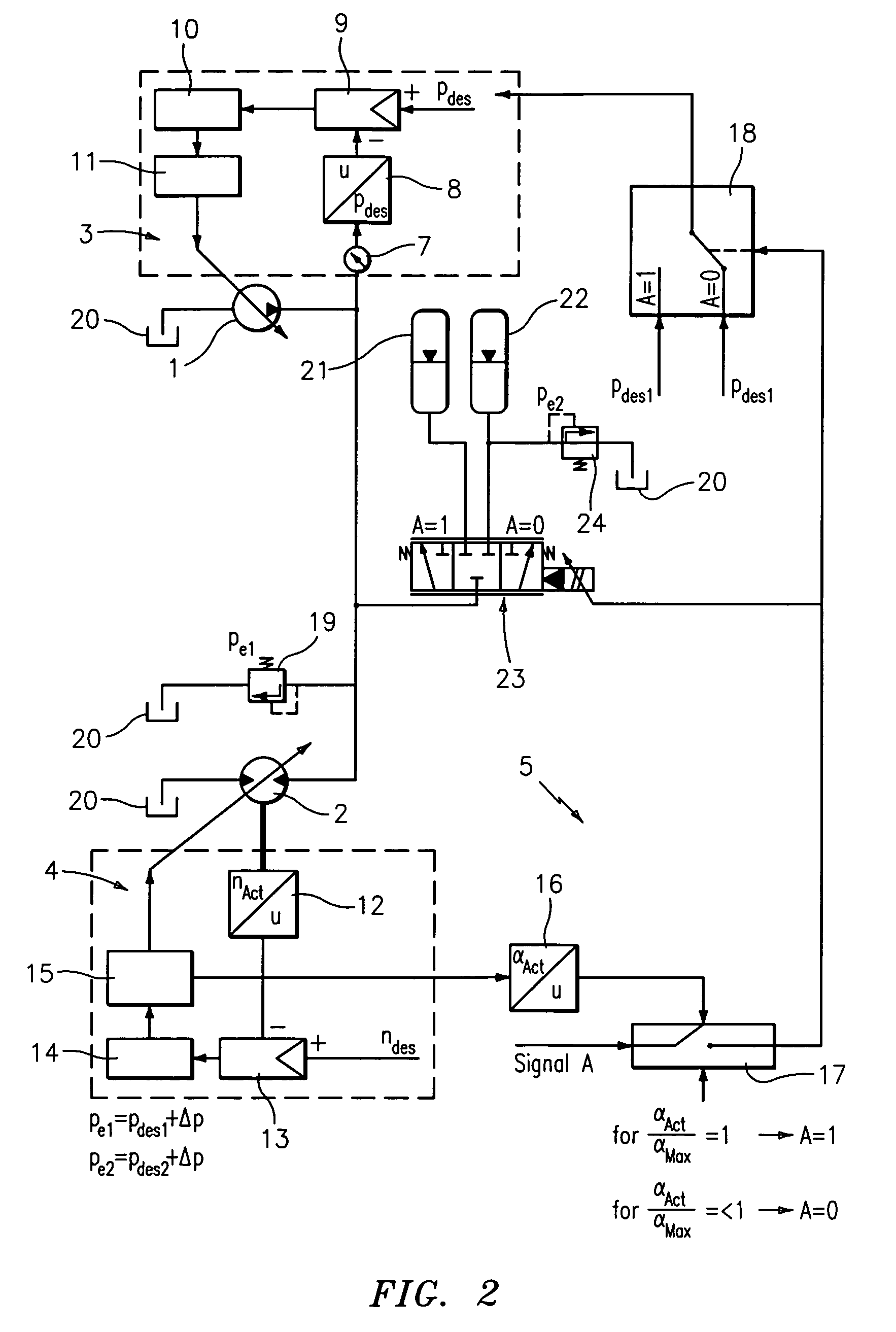

Hydraulic drive system

ActiveUS20090145122A1Reduce fuel consumptionImprove performanceFluid parameterFluid couplingsHydraulic pumpSystem pressure

The present invention relates to a hydraulic drive system having a pressure-regulated hydraulic pump for the provision of a system pressure and having a secondarily regulated hydraulic motor. In accordance with the invention, a control is provided which sets the desired system pressure during operation in dependence on an operating parameter of the hydraulic motor.

Owner:LIEBHERR MACHINES BULLE

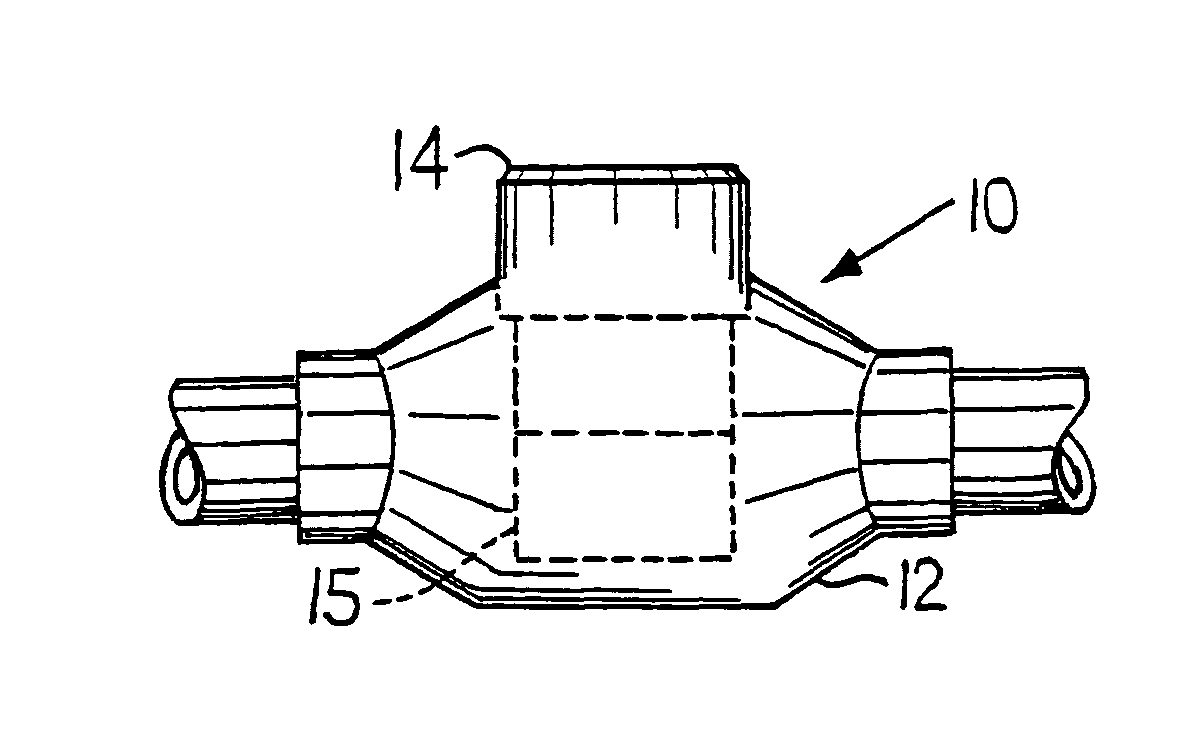

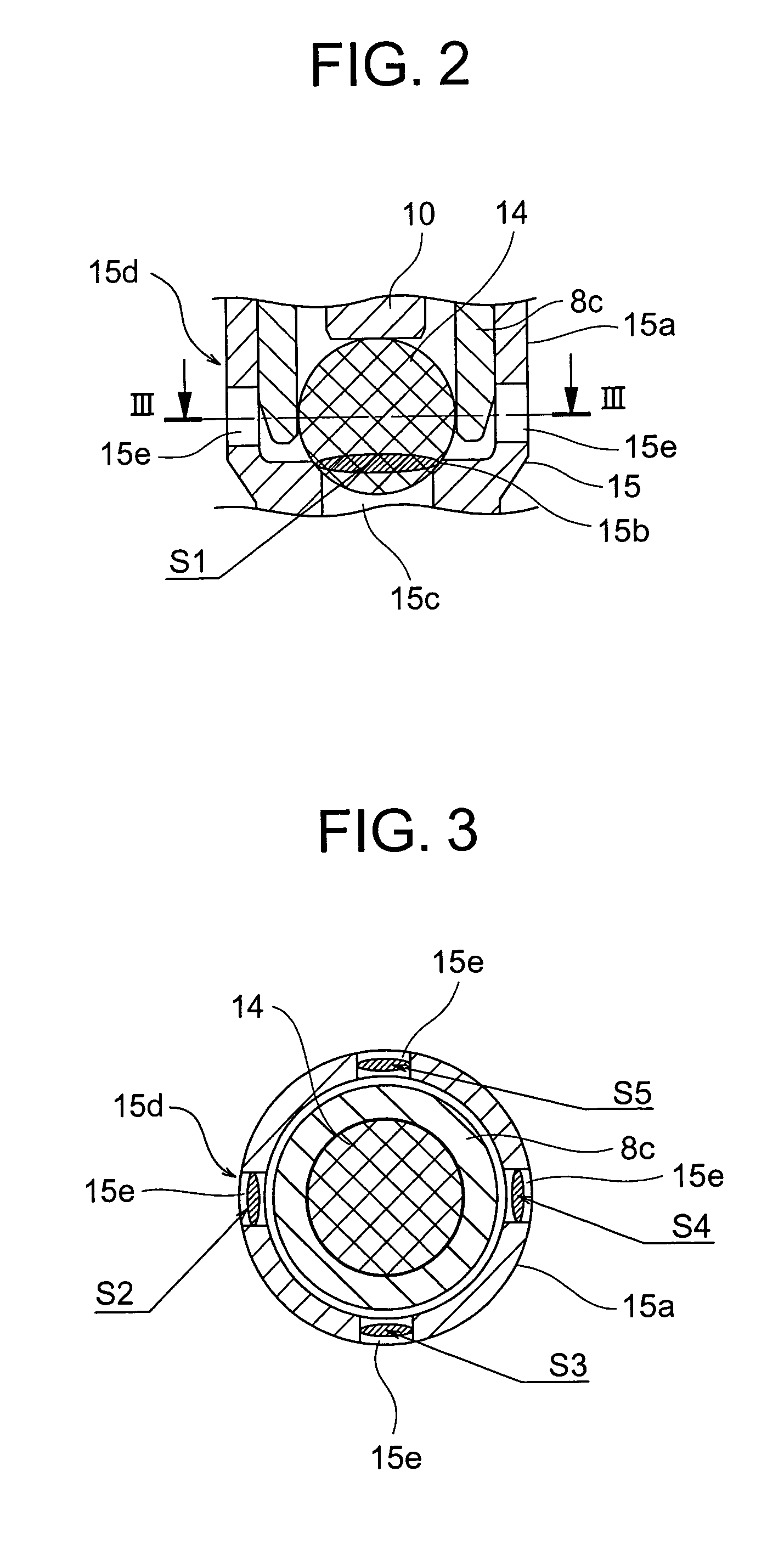

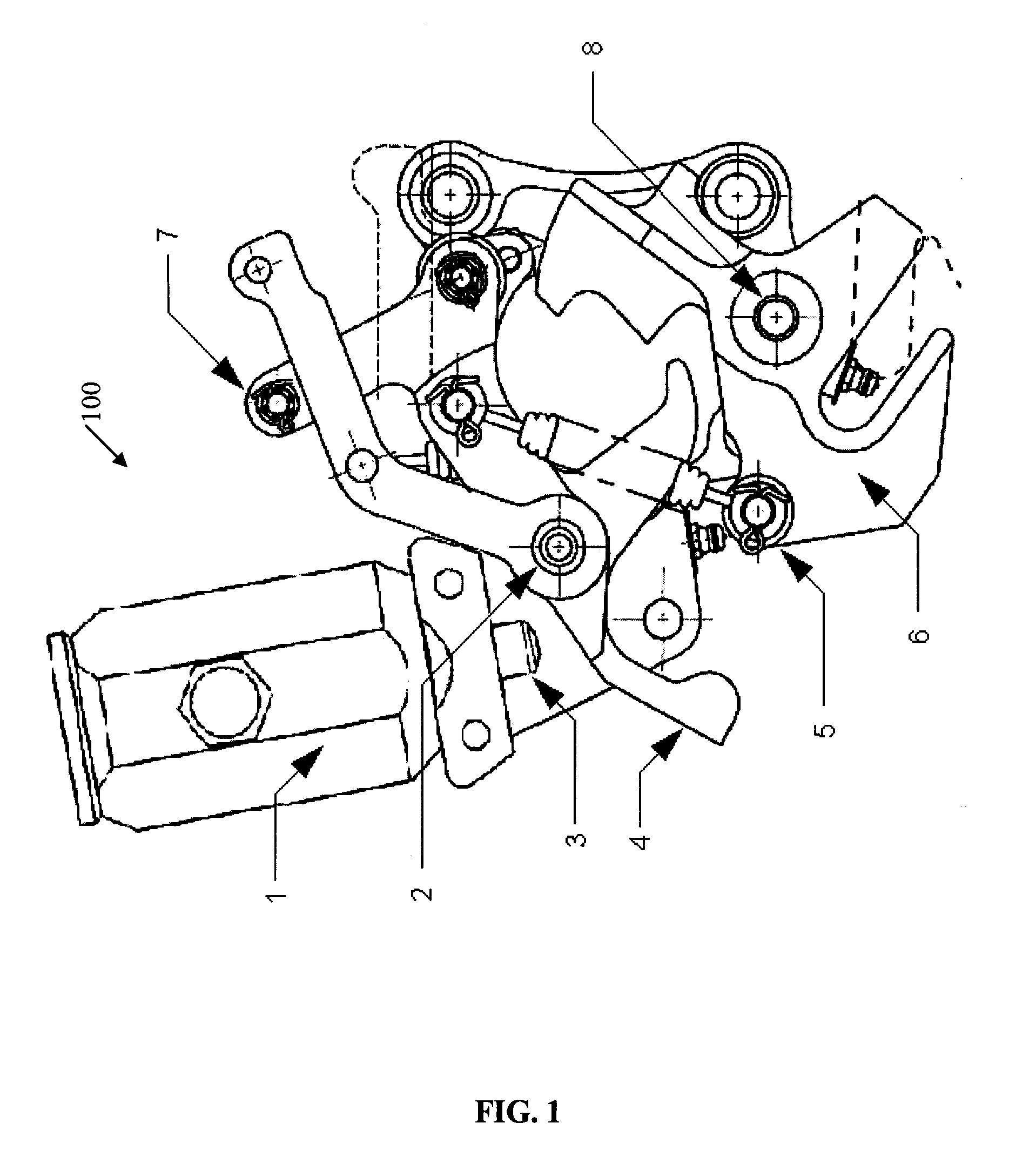

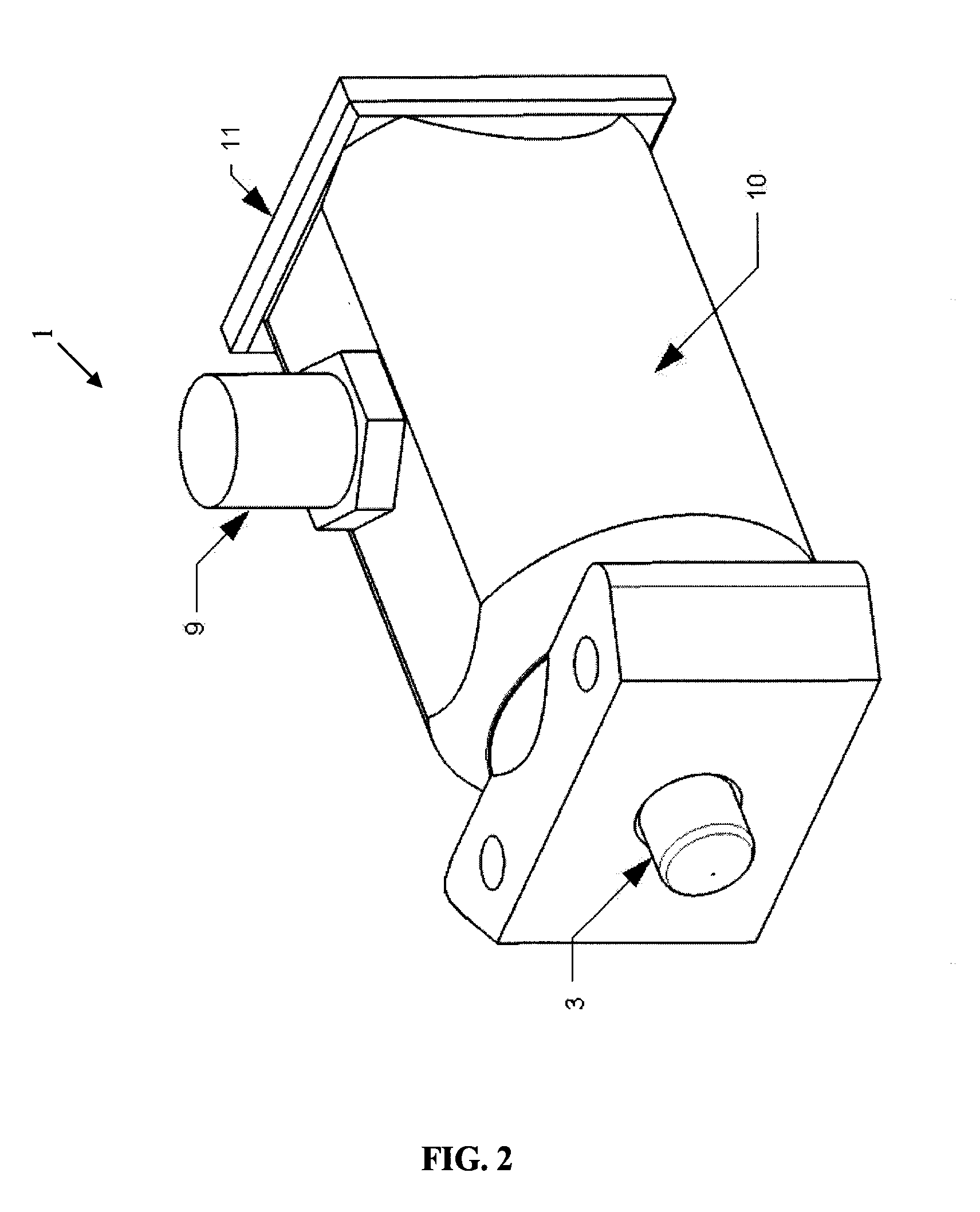

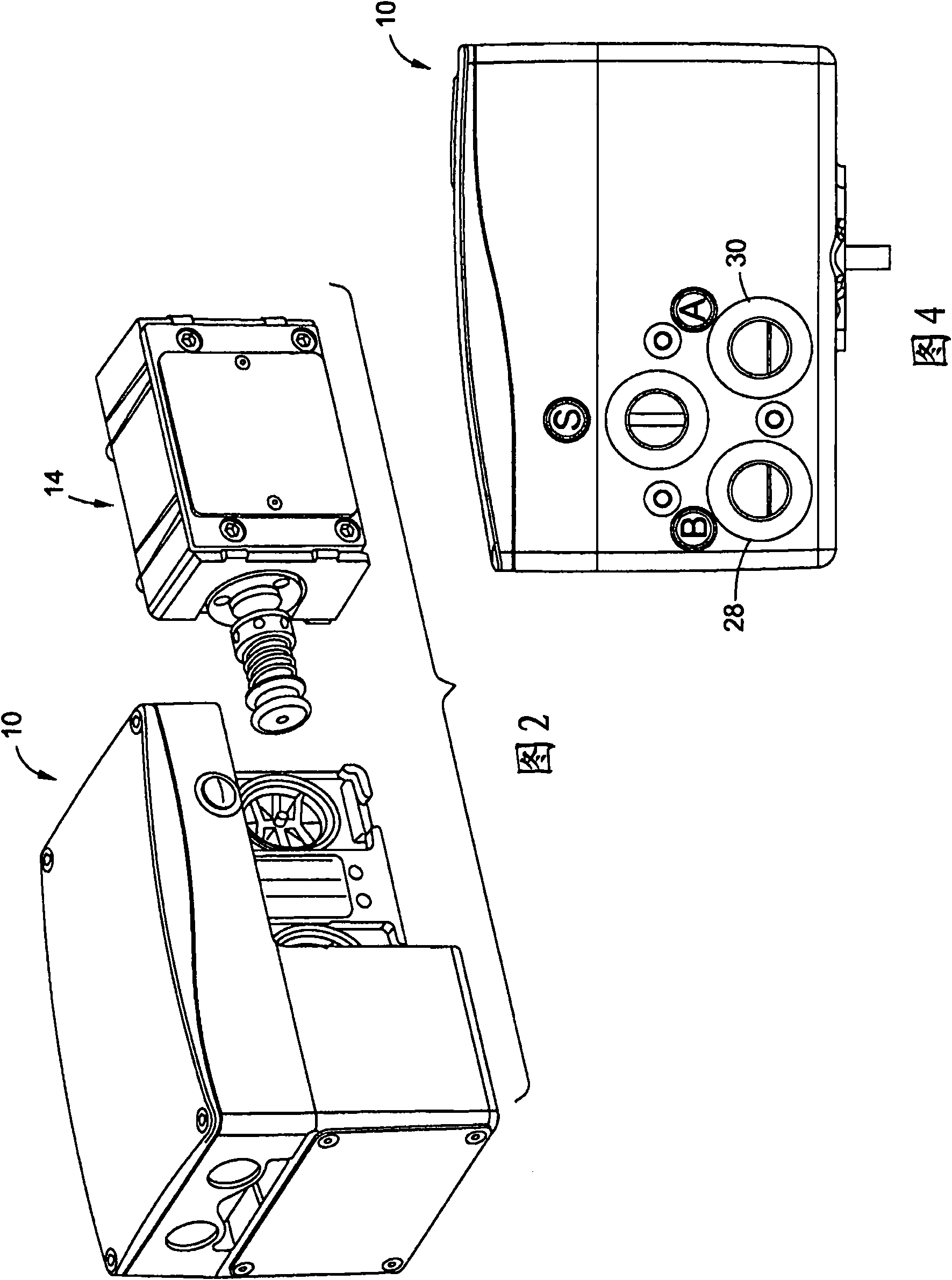

Actuator for a spool valve

ActiveCN101939577AOperating means/releasing devices for valvesServomotor componentsSpool valveReciprocating motion

A valve positioner (10) for controlling a valve closure element is provided. The positioner includes a positioner housing with a plurality of fluid flow passageways in fluid communication with a fluid supply source and the valve closure element. The positioner housing is configured to receive a detachable spool manifold assembly (14). The spool manifold assembly is positioned adjacent the plurality of fluid flow passageways. The spool manifold assembly includes a reciprocally moveable spool (34) configured to selectively port fluid flow from the plurality of fluid flow passageways. The spool manifold assembly includes a diaphragm (48) connected to the spool via a flexible shaft (50). The diaphragm is in fluid communication with a transducer for receiving a fluid causing the diaphragm to expand or contract and thereby displacing the spool. The flexible shaft is radially elastic in order to minimize axial backlash between the diaphragm and the spool. The flexible shaft configuration minimizes the spool stroke.

Owner:STI LLC

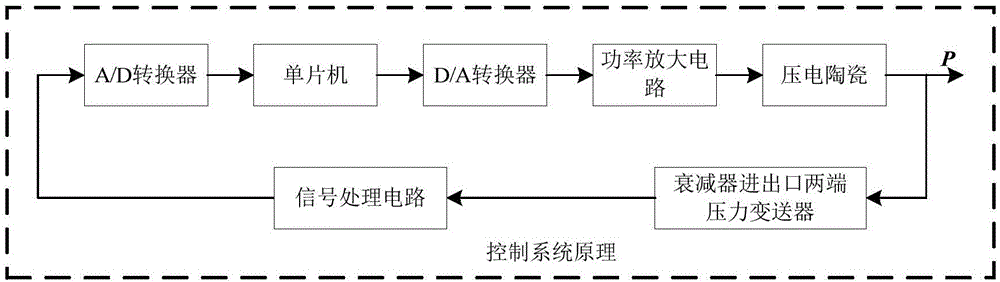

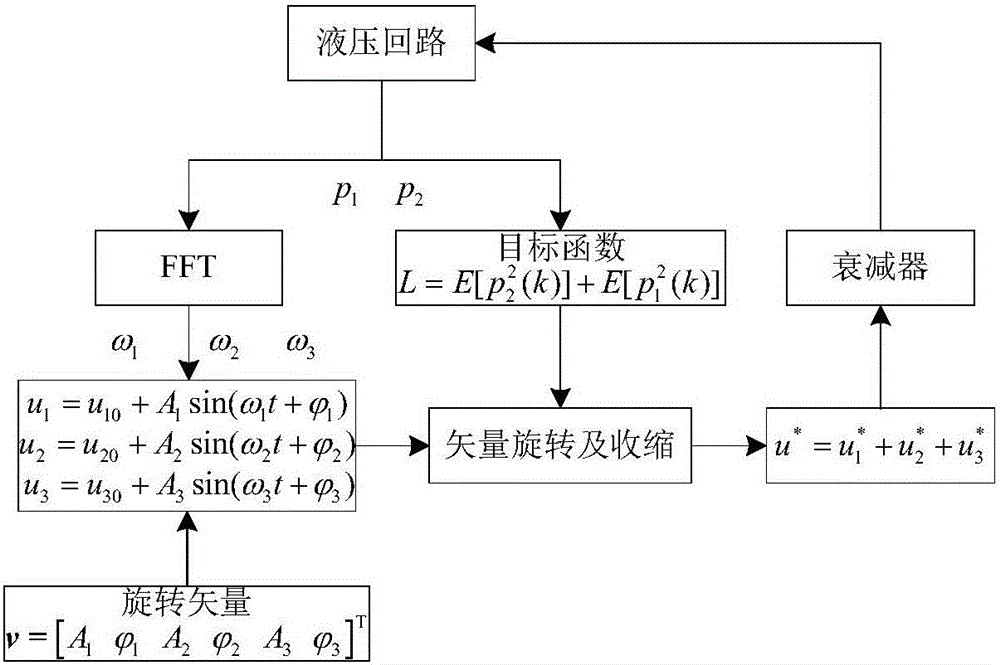

Series hydraulic pressure pulsation attenuator and attenuation method

ActiveCN106090524AEliminate lossReduce lossesPipe elementsTransducersElectricityUltrasound attenuation

The invention discloses a series hydraulic pressure pulsation attenuator and an attenuation method. The series hydraulic pressure pulsation attenuator comprises a piston rod, a piston and an attenuator shell body; the piston rod is fixed to the attenuator shell body, one end of the piston rod is located in the attenuator shell body, and the other end of the piston rod penetrates out of the attenuator shell body; a through hole is formed in the piston rod in the axis direction and communicates with a follow-up oil line; the piston is located in the attenuator shell body, and a piezoelectric ceramic is arranged between the piston and the attenuator shell body and makes contact with the piston; the rigidity of the piezoelectric ceramic is changed by changing voltage applied to the two ends of the piezoelectric ceramic according to the magnitude of the pressure pulsation, and accordingly piston displacement is changed; and high-frequency change of the volume of the attenuator shell body and attenuation of the hydraulic pressure pulsation are achieved. According to the novel series hydraulic pressure pulsation attenuator, compared with a traditional hydraulic pressure pulsation attenuator, the oil line energy loss caused by the series hydraulic pressure pulsation attenuator is small, the bandwidth of the pressure pulsation playing an inhibition effect is increased, and the pressure pulsation in a high-pressure oil line can be inhibited.

Owner:XI AN JIAOTONG UNIV

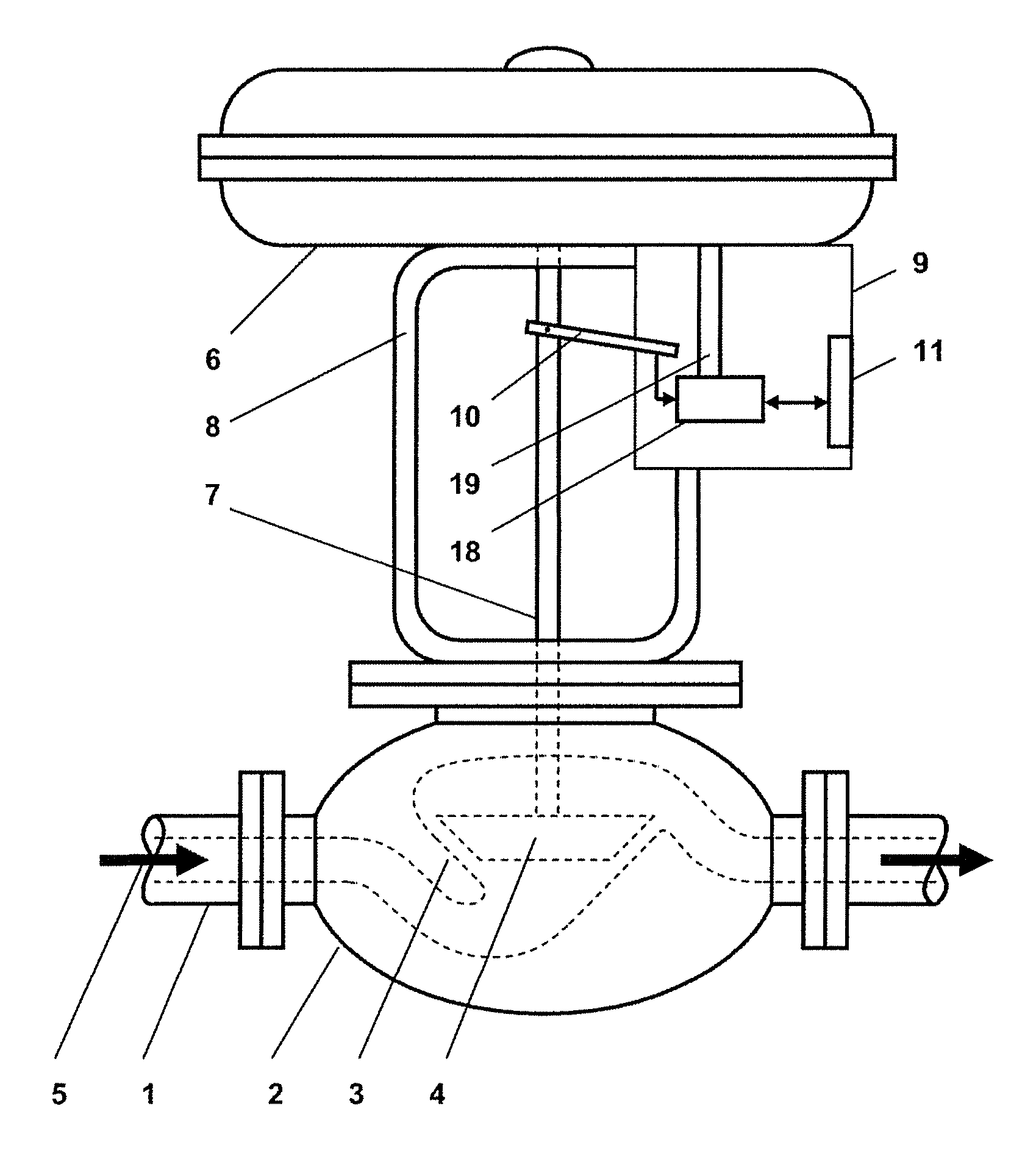

Inclined shaft type hydraulic transformer and voltage transformation method

The invention relates to an oblique axle type hydraulic transformer. A hydraulic transformer reconstructed according to the prior oblique axle type hydraulic pump / motor is different to realize continuous voltage transformation of between 0 and 120 degrees under the condition of unchanging a structure of a shell. A transition plate is arranged between a rear cover and the shell; the rear end of a rotating rod is connected with an actuating mechanism or an angle is adjusted manually so as to achieve the aim of changing pressure. The invention puts forward a concept of using the transformation ratio of the hydraulic transformer by stages so as to fully utilize the function of voltage transformation which can be realized by the prior hydraulic transformer and utilize parts of mature elements of the hydraulic pump / motor.

Owner:BAOTOU SAIBEI MECHANICAL EQUIP CO LTD

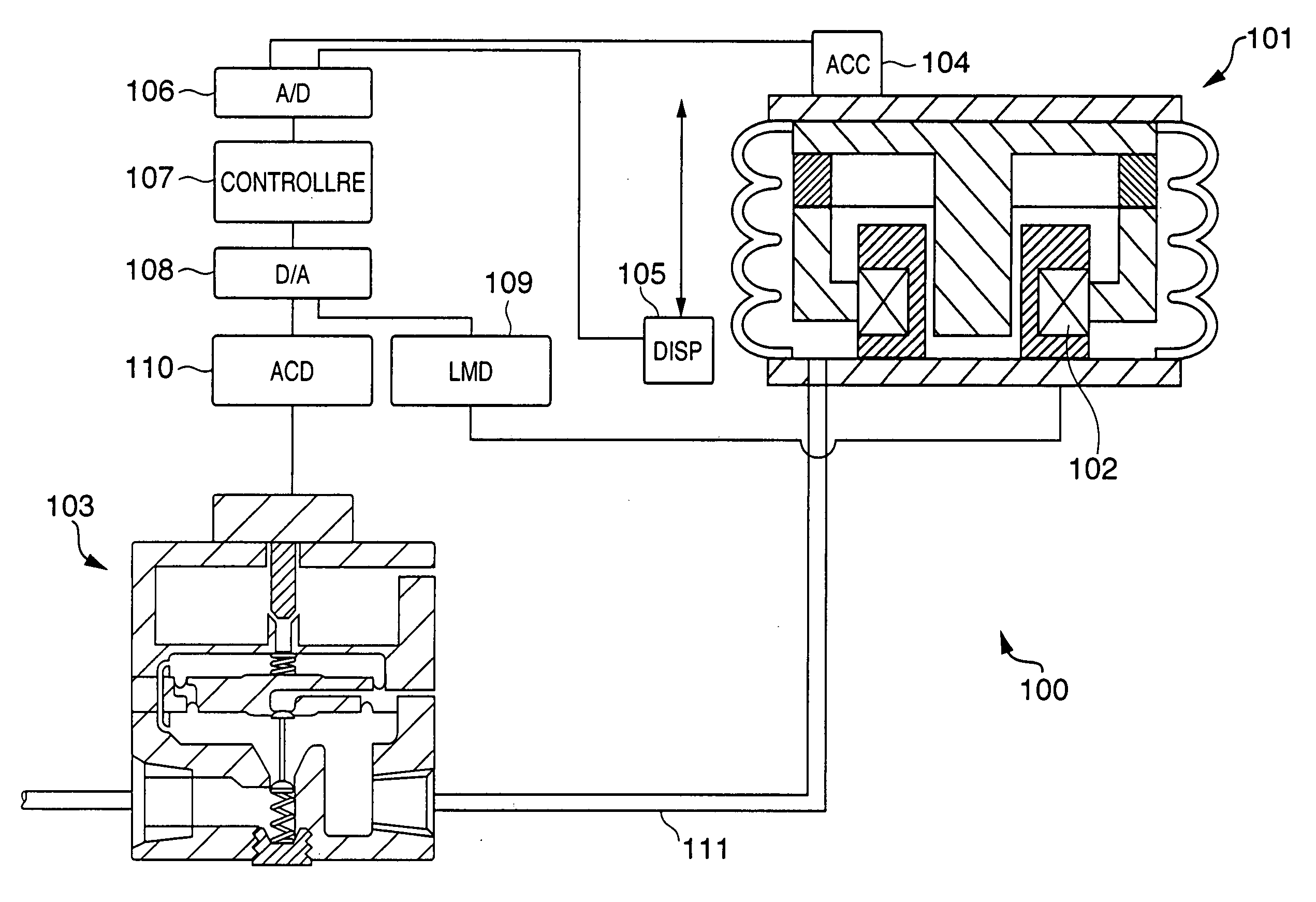

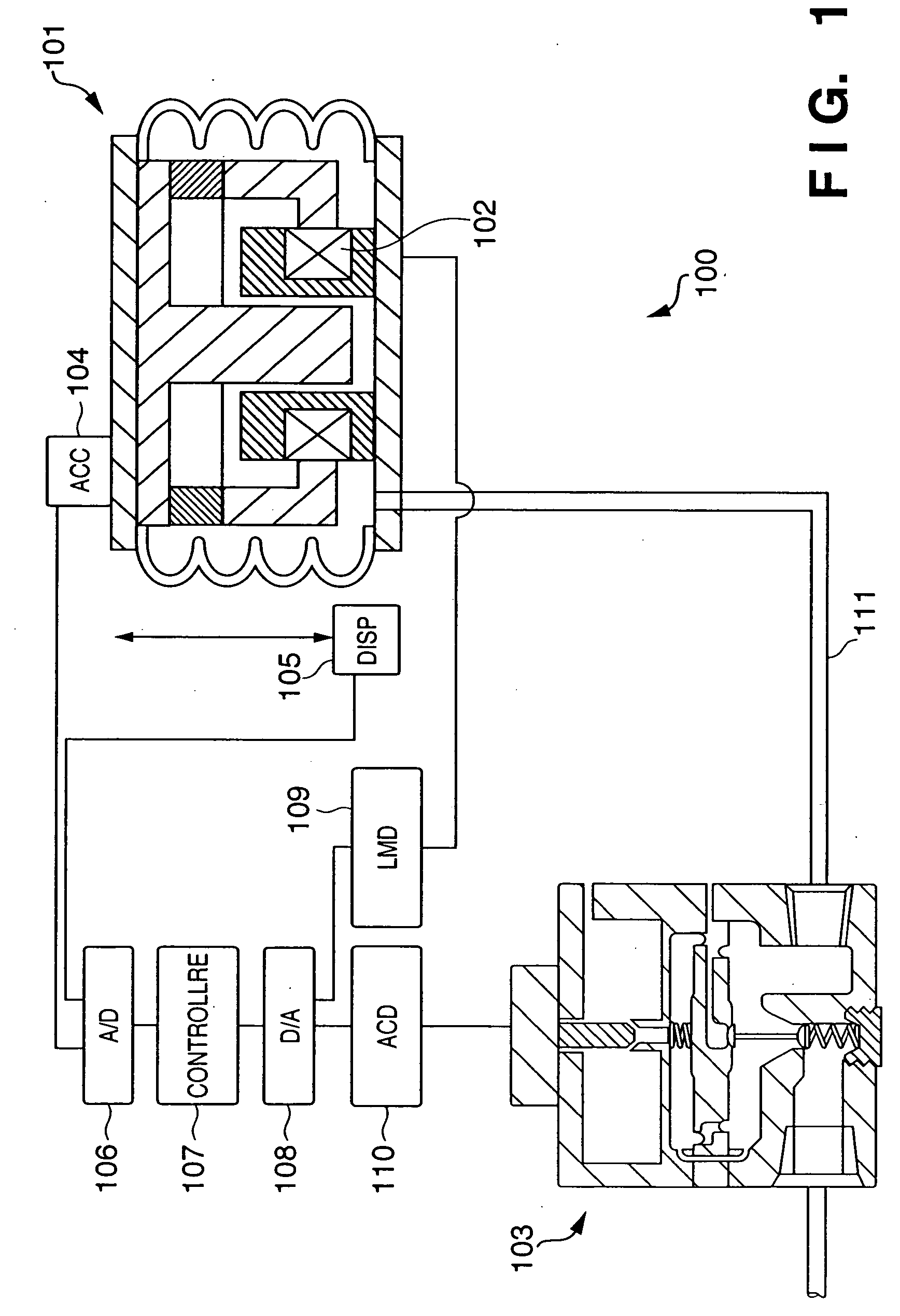

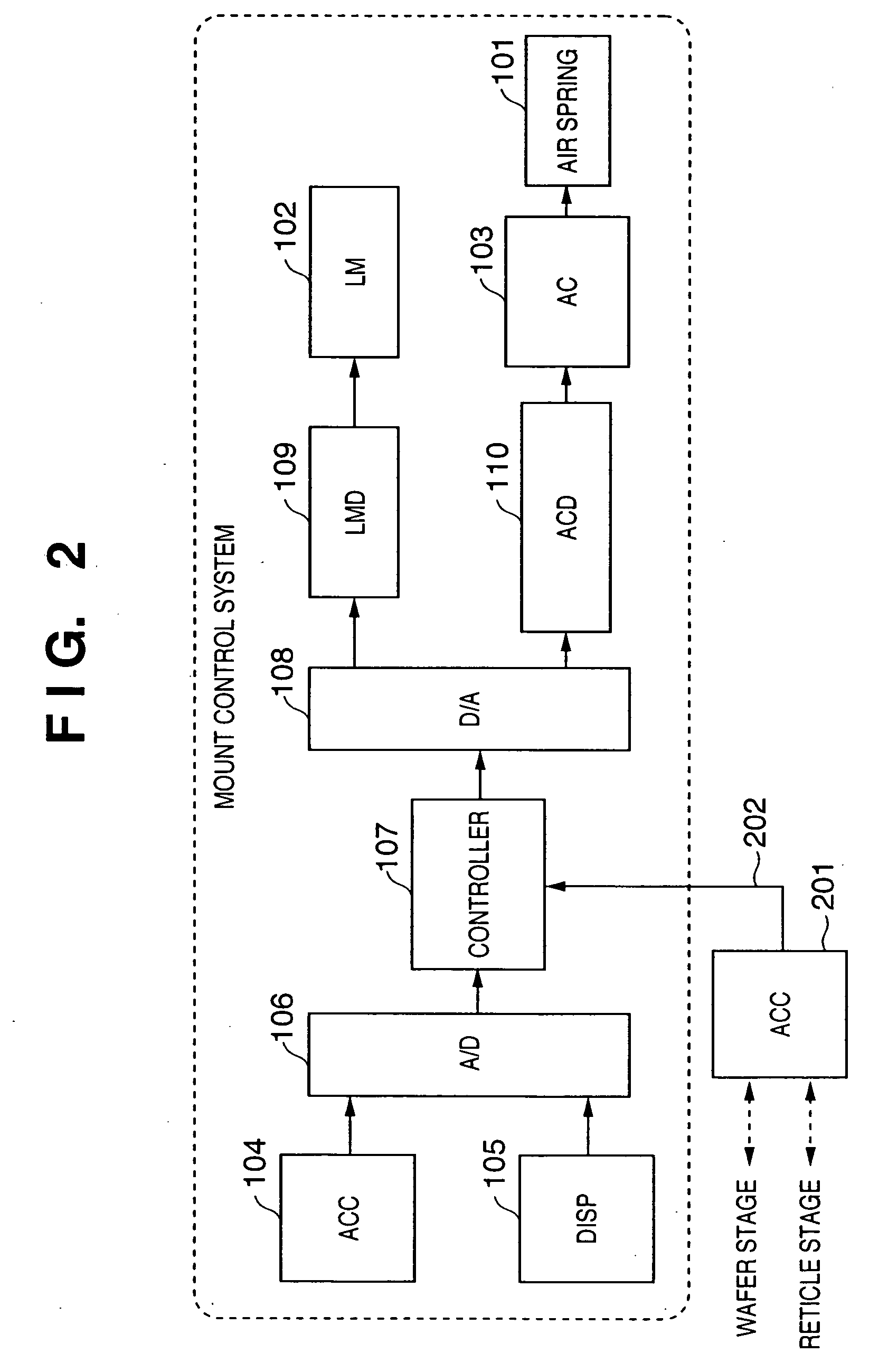

Anti-vibration mount apparatus, exposure apparatus, and device manufacturing method

An anti-vibration mount apparatus which suppresses vibration of a structure is disclosed. The apparatus comprises a gas spring which supports the structure, and a controller which controls an internal pressure of the gas spring. The controller comprises a primary chamber which communicates with a pressure source, a secondary chamber which communicates with the gas spring, a back-pressure chamber which communicates with the secondary chamber, a back-pressure control mechanism which has a nozzle communicating with the back-pressure chamber and a flapper facing the nozzle and controls a pressure in the back-pressure chamber via control of exhaust from the back-pressure chamber by changing a gap between the nozzle and the flapper, and a pressure control mechanism which controls a pressure in the secondary chamber via one of gas supply from the primary chamber to the secondary chamber and gas exhaust from the secondary chamber to outside caused in accordance with a pressure difference between the back-pressure chamber and the secondary chamber. The flapper has a tapered portion facing the nozzle, and the nozzle has a bore widened toward an outlet of the nozzle.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com