Electric control inclined shaft plunger type hydraulic transformer

A technology of hydraulic transformer and inclined shaft column is applied in the field of hydraulic transformer, which can solve the problems of inconvenient operation and difficult to guarantee accuracy, and achieve the effects of convenient operation, simplified design and simplified structure form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

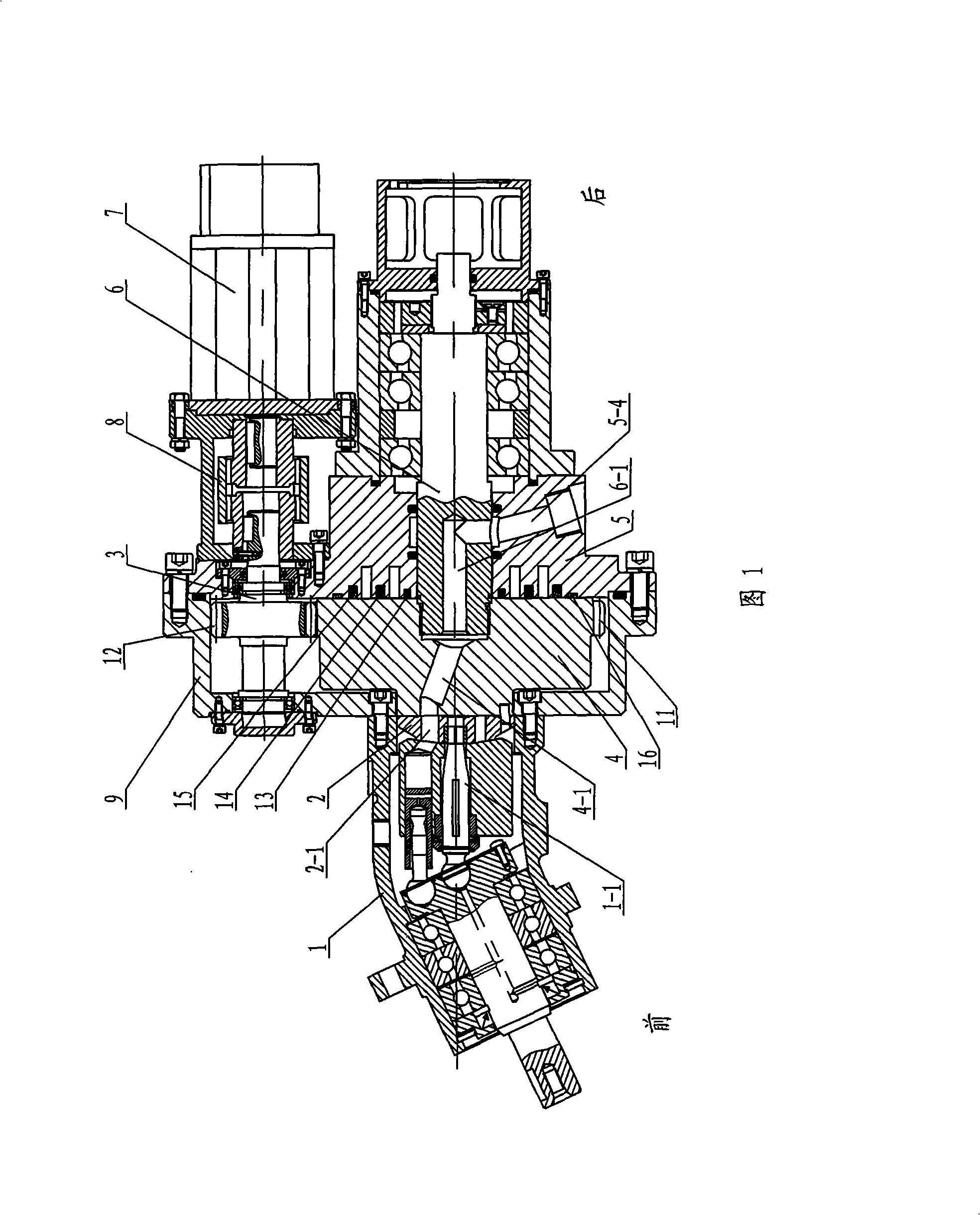

[0007] Specific embodiment one: in conjunction with Fig. 1 and figure 2 Describe this embodiment. This embodiment includes a plunger pump 1, a flow distribution plate 2, a gear shaft 3, a rear end cover 5, a flow distribution plate main shaft 6, a coupling 8 and a housing 9. The plunger pump 1 is fixed on the housing 9 One side of the distribution plate 2 is connected with the central rod 1-1 in the plunger pump 1, and the same circle on the distribution plate 2 is provided with a first distribution hole 2-1 and a second distribution hole 2-2 of the same shape. and the third distribution hole 2-3, the hydraulic transformer also includes a transition plate 4 and a servo motor 7, the front end of the transition plate 4 is arranged at the bottom of the housing 9 and connected with the flow distribution plate 2, the rear end of the transition plate 4 is connected to the The distribution plate main shaft 6 is connected, the rear end cover 5 is arranged on the distribution plate mai...

specific Embodiment approach 2

[0008] Specific embodiment two: in conjunction with Fig. 1 and figure 2 The present embodiment will be described. In this embodiment, the transition plate 4 and the driven gear 11 are integrally formed.

specific Embodiment approach 3

[0009] Specific Embodiment Three: This embodiment is described with reference to FIG. 1 . The gear shaft 3 and the driving gear 12 of this embodiment are integrated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com