Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about "Stopper feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

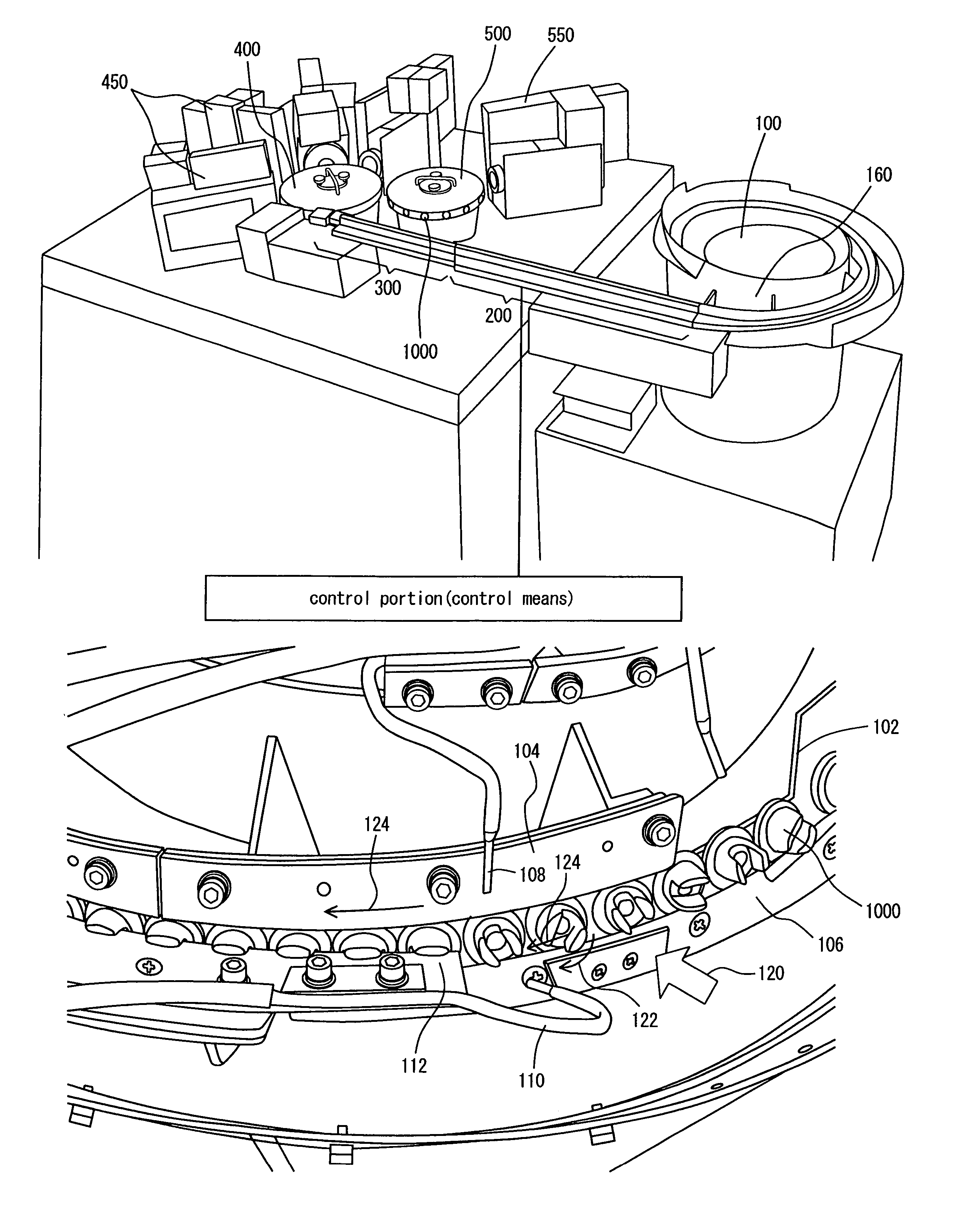

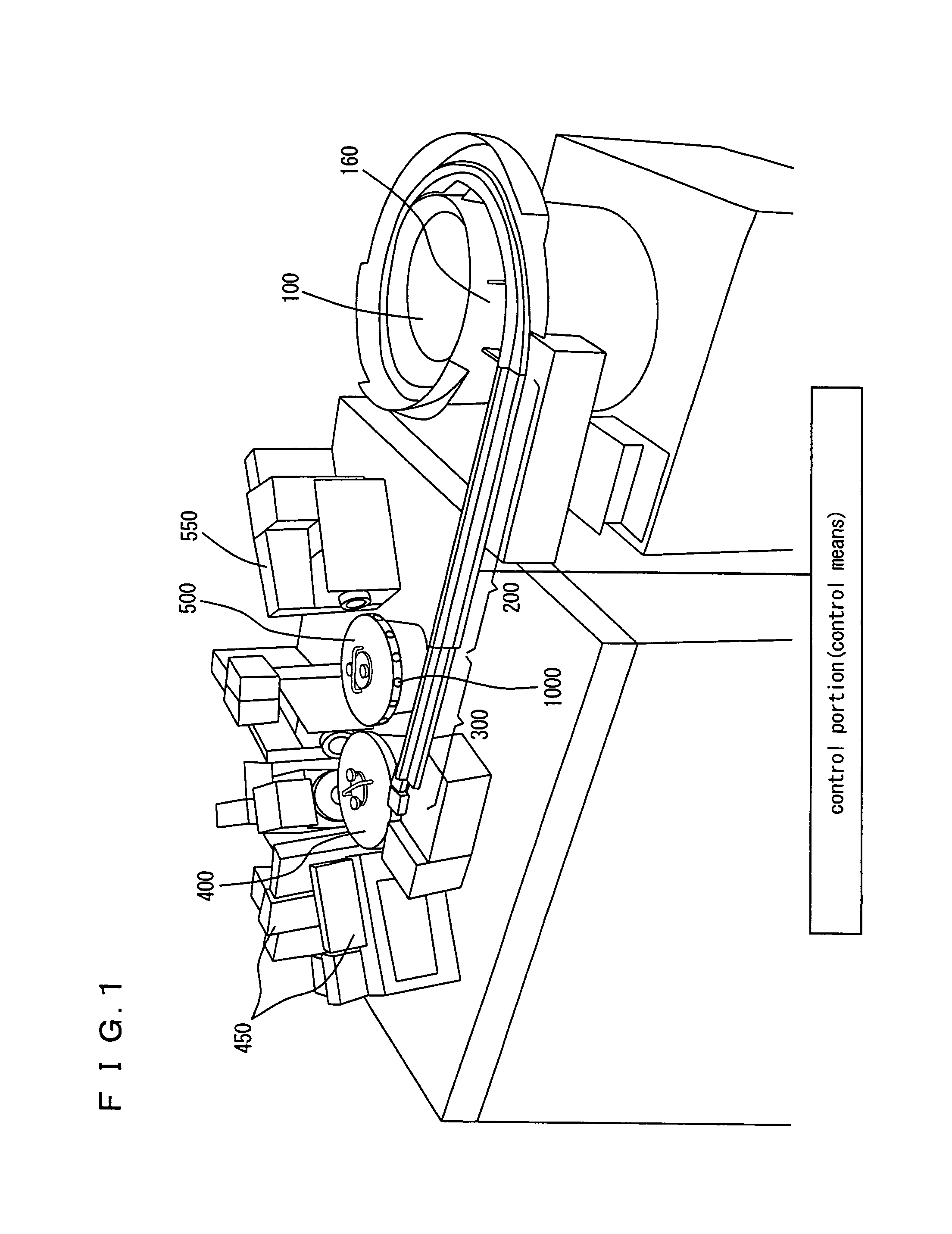

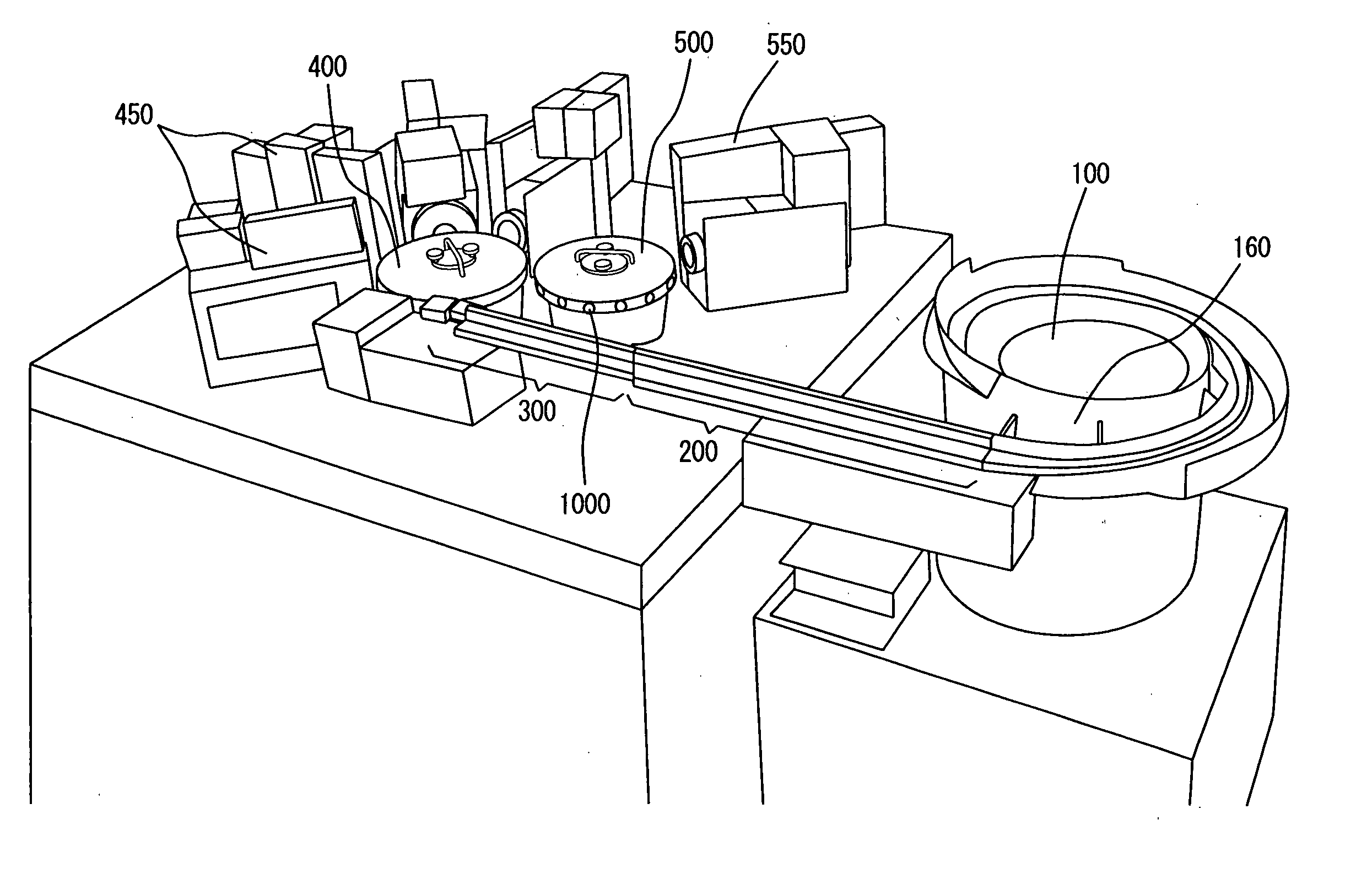

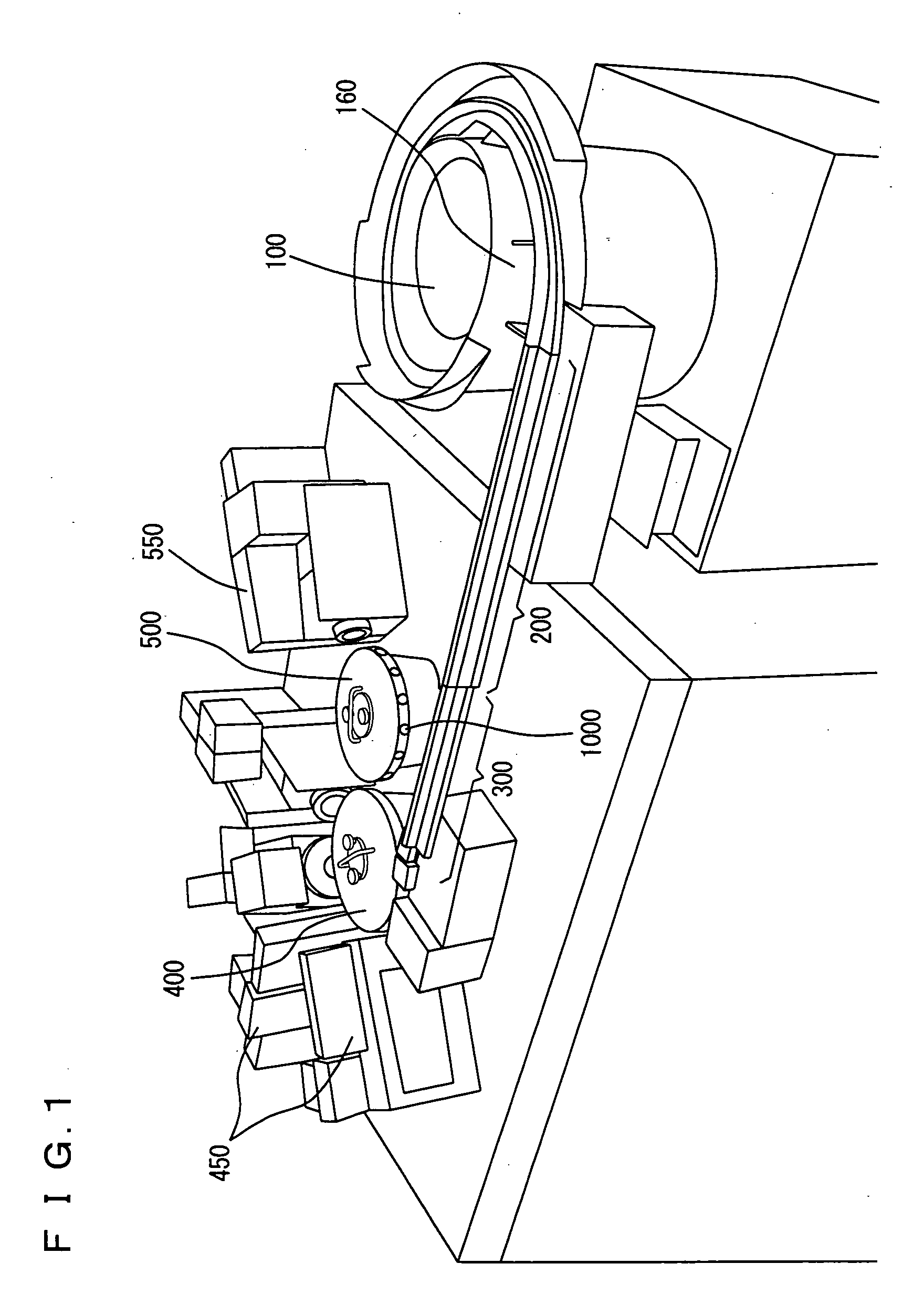

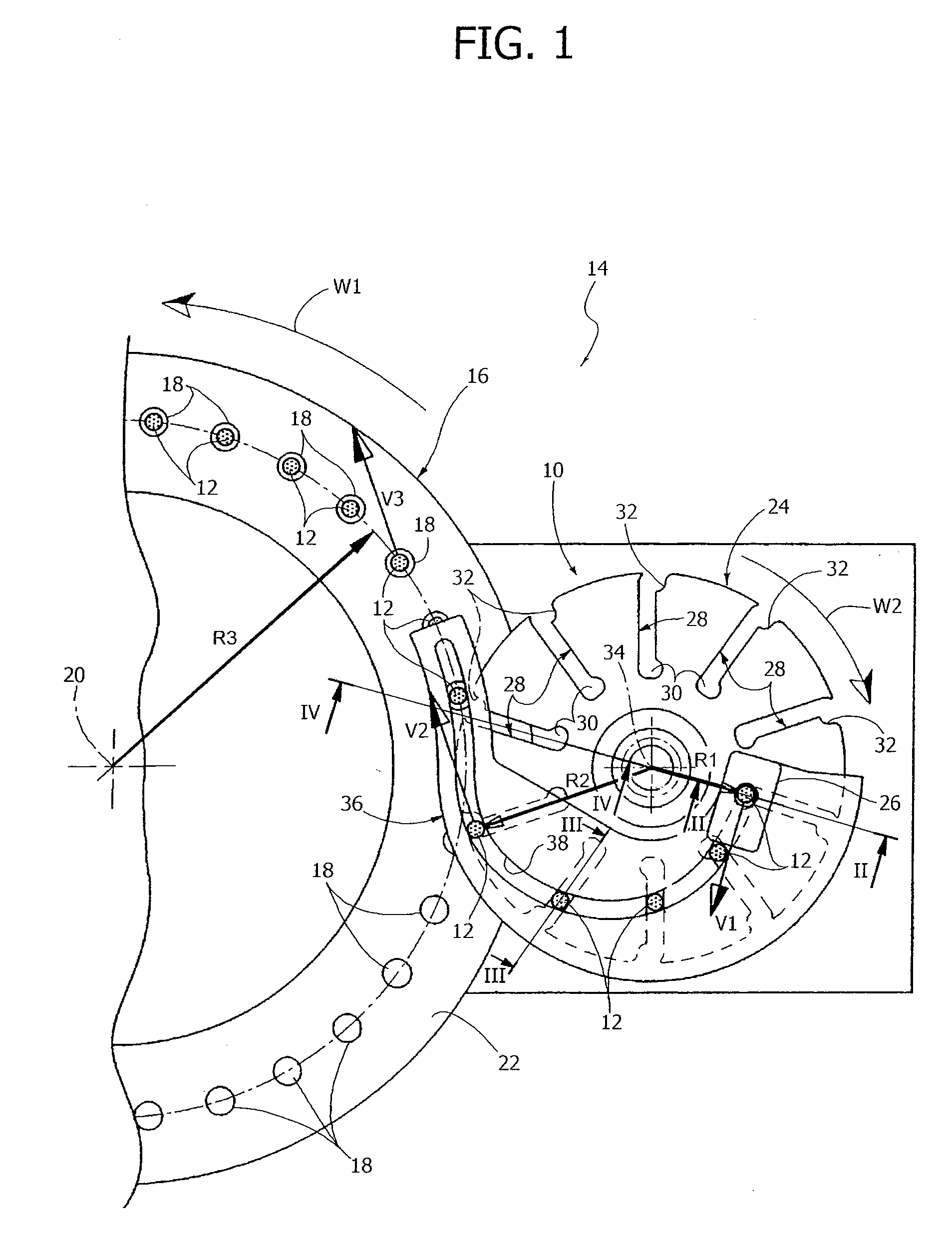

Conveying equipment and inspection device

InactiveUS7553110B2Inspection is accurateAvoid failureFeeding apparatusBulk conveyorsEngineeringCompressed air

An appearance inspecting apparatus includes a parts feeder aligning rubber stoppers in tandem by torsionally vibrating a bowl having a spiral track formed therein, an air conveying portion conveying the rubber stoppers aligned in tandem by blowing compressed air thereto, first and second conveying tables conveying rubber stoppers by suction-holding a surface not to be inspected of the rubber stoppers, an inspecting portion inspecting a surface to be inspected of the rubber stoppers conveyed by the first and second conveying tables, and a selecting portion sorting out rubber stoppers that are determined to be defective, in accordance with the result of inspection by the inspecting portion. Objects to be inspected having a complicated shape are aligned preliminarily by using a vibration parts feeder, while highly accurate appearance inspection is conducted.

Owner:DAIICHI JITSUGYO VISWILL

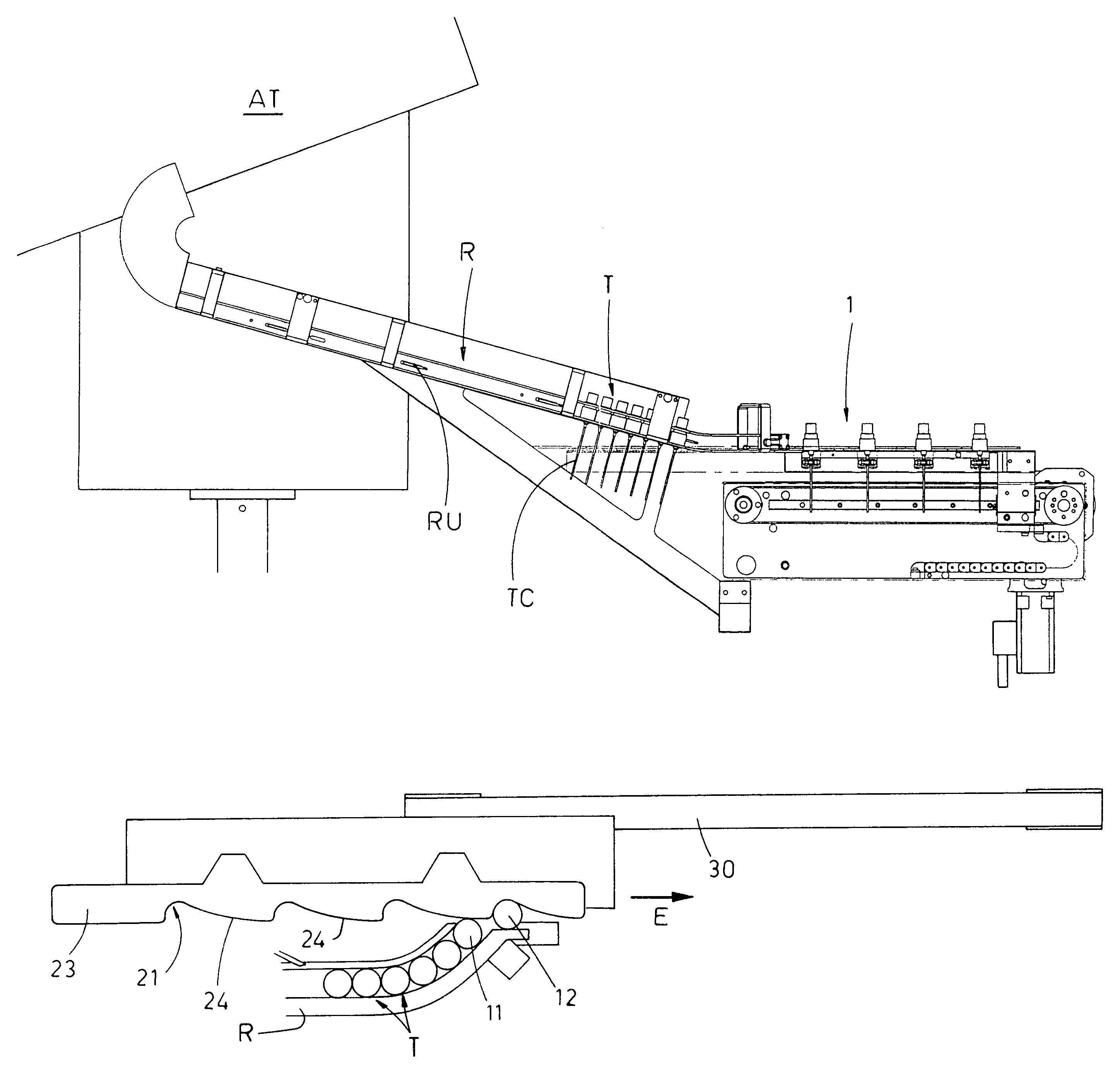

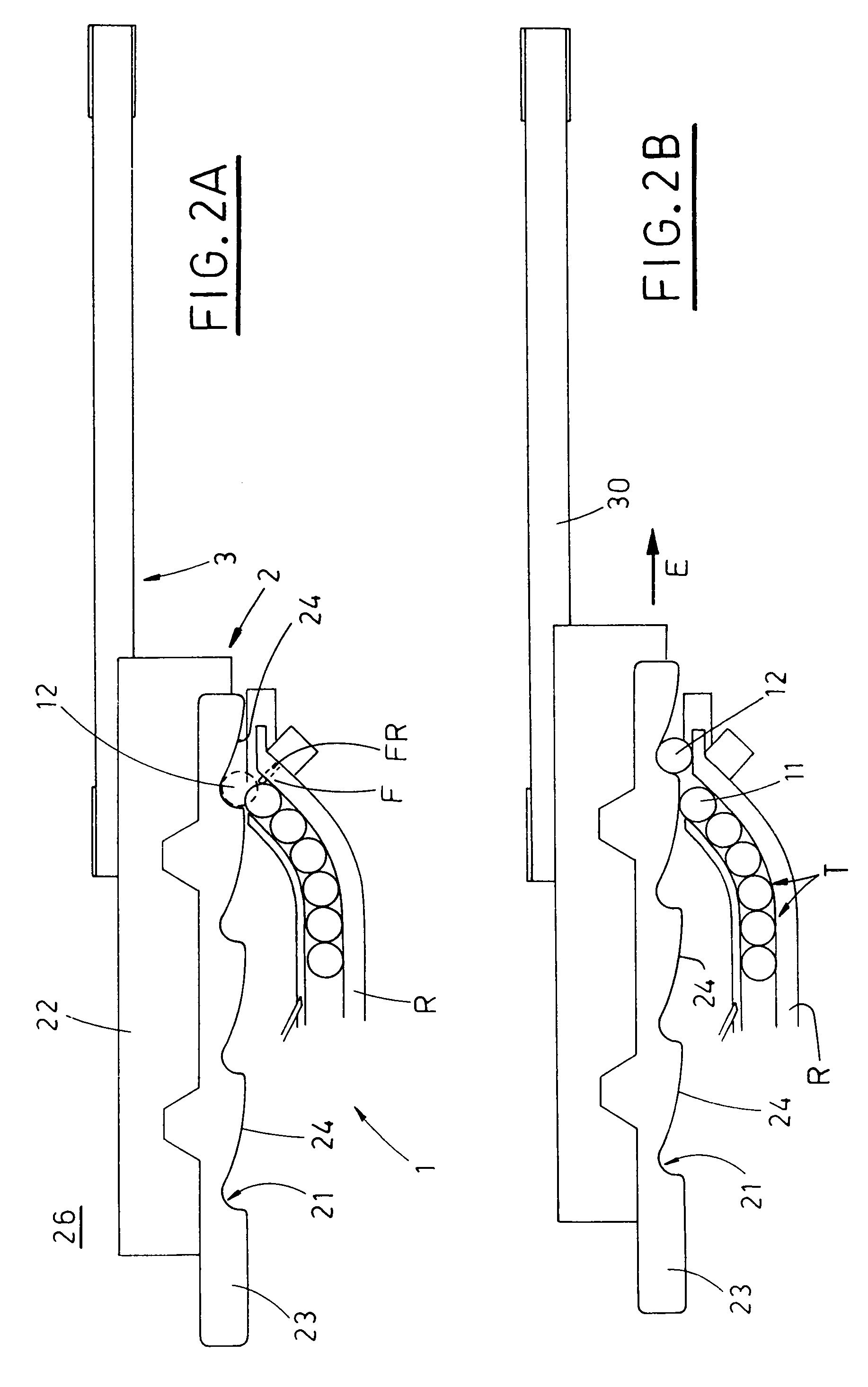

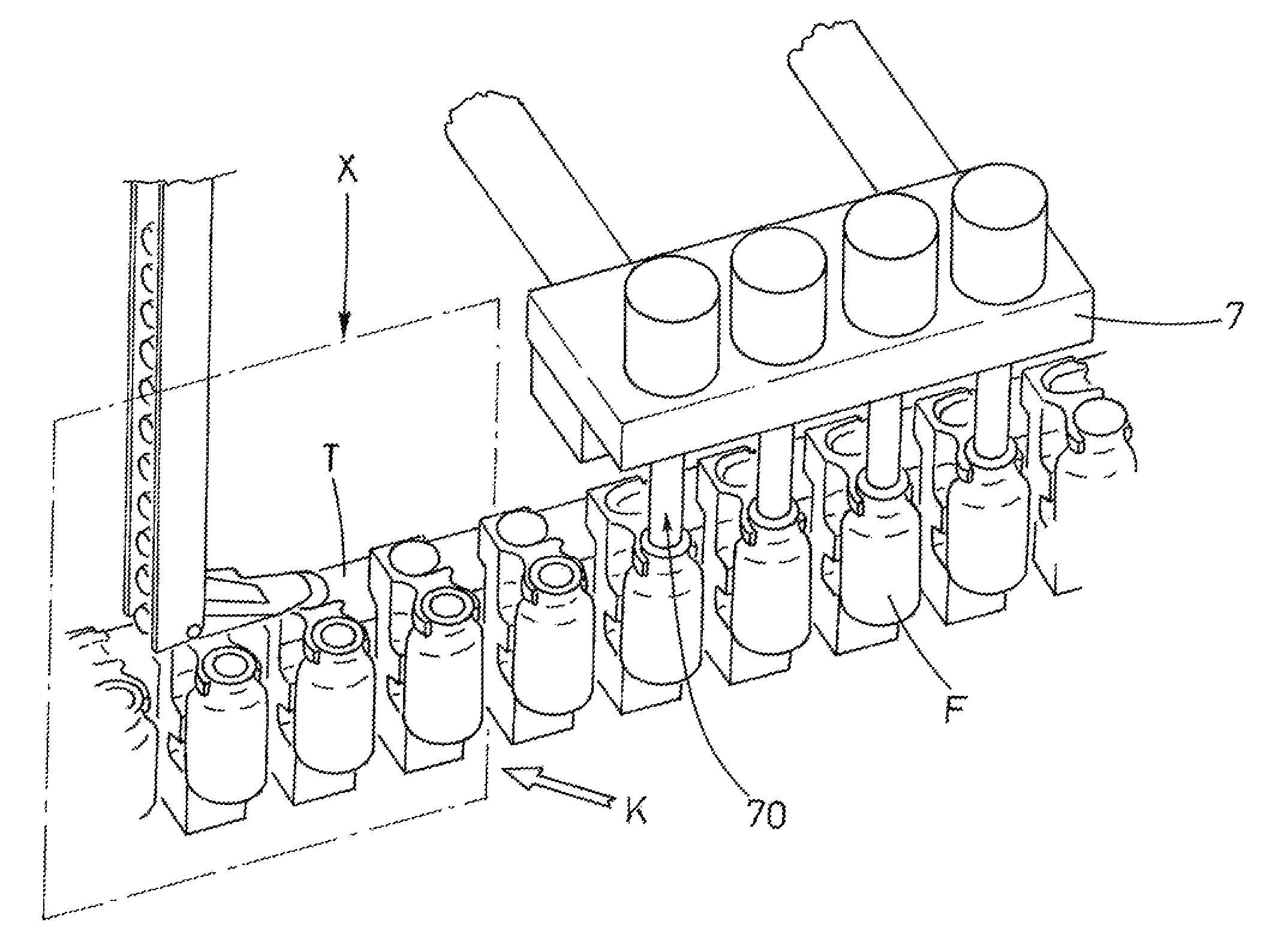

Device for singling out items coming from a feeder

In a device for singling out items coming from a feeder, with the feeder comprising an outlet channel for conveying the items an end section, compacting air jets are placed along the outlet channel for gathering the items one behind the other according to a continuous row, at the end section. The device is equipped with and abutment and catching comb for singling out a series of single and successive leading items of the row of items at the end section, and a driving belt moves the abutment and catching comb according to a direction of extraction at the end section, for abutting and catching a series of single and successive leading items and for transferring and placing the series of singled out items at a handling station.

Owner:MARCHESINI GROUP SPA

Conveying equipment and inspection device

InactiveUS20050236255A1Avoid failureInspection is accurateFeeding apparatusBulk conveyorsEngineeringCompressed air

An appearance inspecting apparatus includes a parts feeder aligning rubber stoppers in tandem by torsionally vibrating a bowl having a spiral track formed therein, an air conveying portion conveying the rubber stoppers aligned in tandem by blowing compressed air thereto, first and second conveying tables conveying rubber stoppers by suction-holding a surface not to be inspected of the rubber stoppers, an inspecting portion inspecting a surface to be inspected of the rubber stoppers conveyed by the first and second conveying tables, and a selecting portion sorting out rubber stoppers that are determined to be defective, in accordance with the result of inspection by the inspecting portion. Objects to be inspected having a complicated shape are aligned preliminarily by using a vibration parts feeder, while highly accurate appearance inspection is conducted.

Owner:DAIICHI JITSUGYO VISWILL

Apparatus for capping bottles and a method for realising the cap

An apparatus for capping bottles, comprising: gripping devices for bottles containing products, constrained to a transporter, each of which gripping devices exhibits on a side thereof a gripping means of a corresponding bottle, and on an opposite side thereof hooking-receiving-stabilizing organ of a cap; at least a channel for supplying caps, arranged superiorly of the transporter upstream of a capping zone overlying the hooking-receiving-stabilizing organs transiting below the channel, into which a row of caps is conveyed, a head cap of the row of caps being held elastically by a lower end of the supply channel in order to position an internal surface of a relative head such as to intercept a front head (96a) of an underlying hooking-receiving-stabilizing organ in order to enable the head cap, in combination with the advancing of the transporter and with the striking and guiding action exerted by the supply channel, to disengage from the supply channel in order to locate in the corresponding hooking-receiving-stabilizing organ, with the relative body facing downwards; at least a pick-up organ, located in the capping zone, operating in phase relation with a corresponding hooking-receiving-stabilizing organ, with the body thereof facing downwards; at least a pick-up organ destined to hook and extract the cap present therein, and to position the cap axially in an inlet mouth of the corresponding bottle supported by the gripping device flanking the hooking-receiving-stabilizing organ, in order to perform insertion of the body of the cap in the mouth of the bottle in order to close the bottle.

Owner:MARCHESINI GROUP SPA

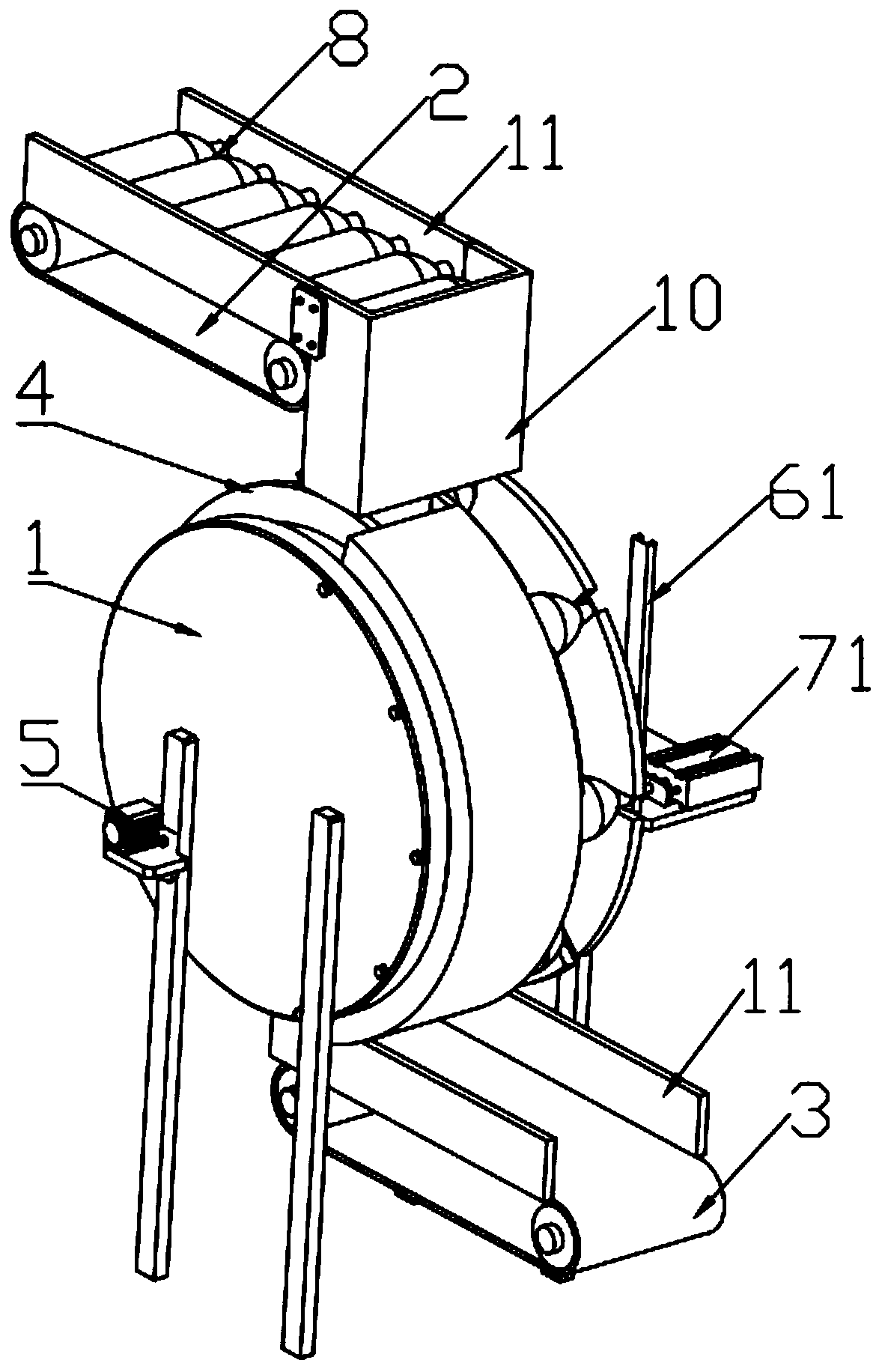

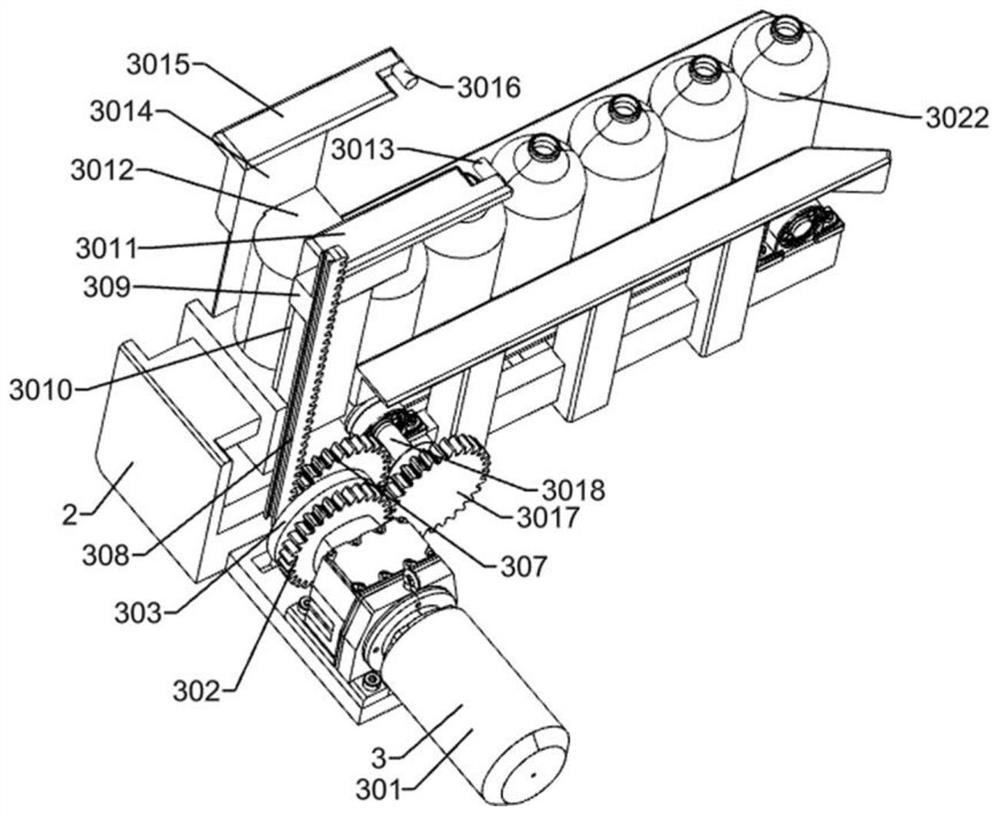

Plastic bottle stopper production equipment

The invention discloses plastic bottle stopper production equipment, and relates to the technical field of bottle stopper production and processing. The plastic bottle stopper production equipment includes a mounting frame and a plastic bottle feeding component; a placing frame is arranged over the plastic bottle feeding component, the mounting frame is provided with a motor, and the side, close to bottle openings of plastic bottles, of the mounting frame is provided with a bottle stopper feeding component and a press fit component. The plastic bottle stopper production equipment is simple instructure and convenient to operate. By arranging a ratchet and pawl structure in the plastic bottle feeding component, intermittent rotation of a support plate and a limit plate can be achieved, theplastic bottles are conveyed to the position right ahead the press fit component one by one meanwhile, the support plate drives an annular block to rotate in the rotating process, a tension spring pulls a connection block to slide along a wedge-shaped chute, an inserting plate is inserted into an inserting slot again after leaving the inserting slot, and bottle stoppers can drop one by one. Simultaneous feeding of the plastic bottles and the bottle stoppers can be achieved through one driving element, the cost is reduced, and the feeding accuracy is also high.

Owner:李克文

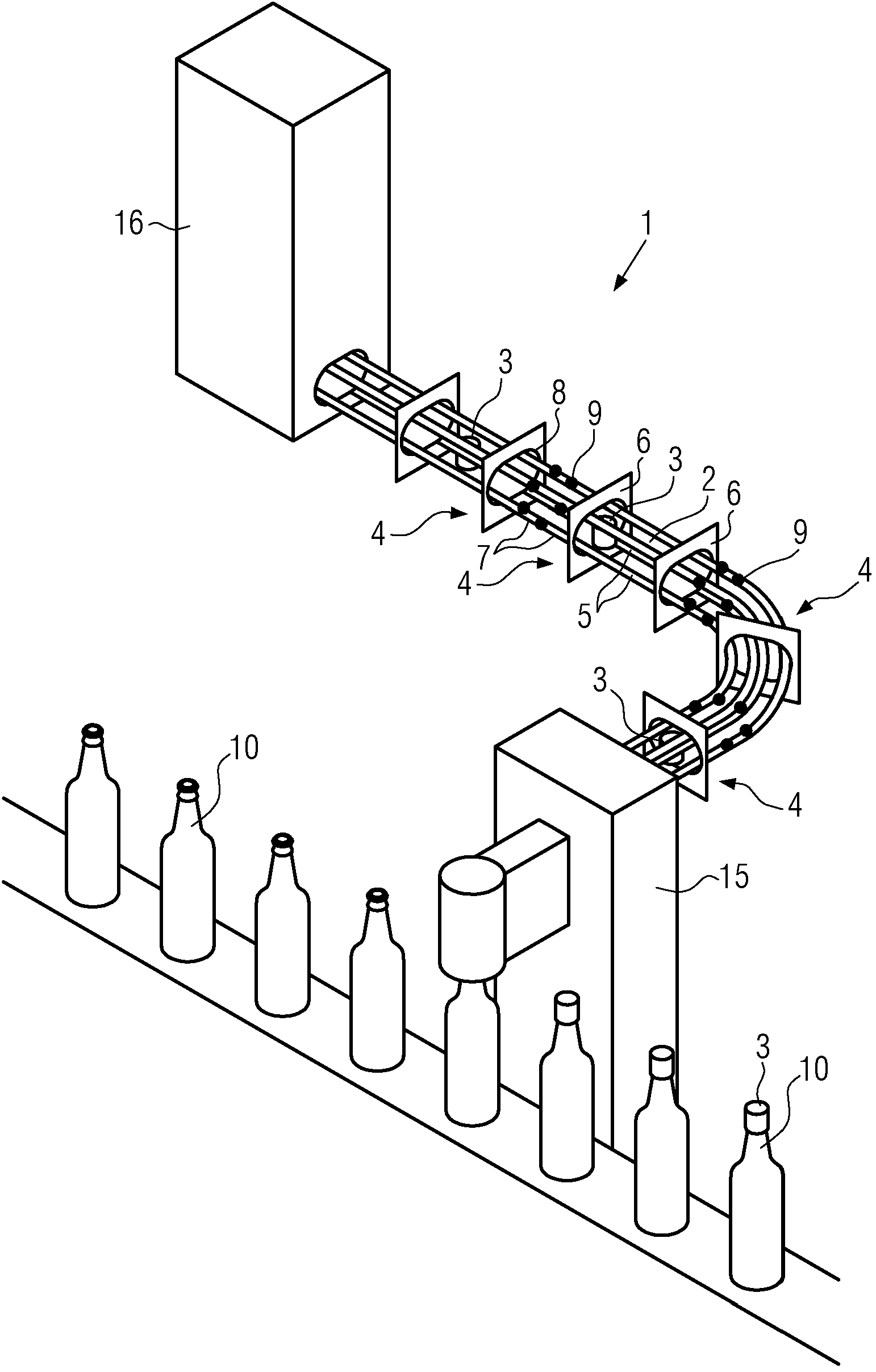

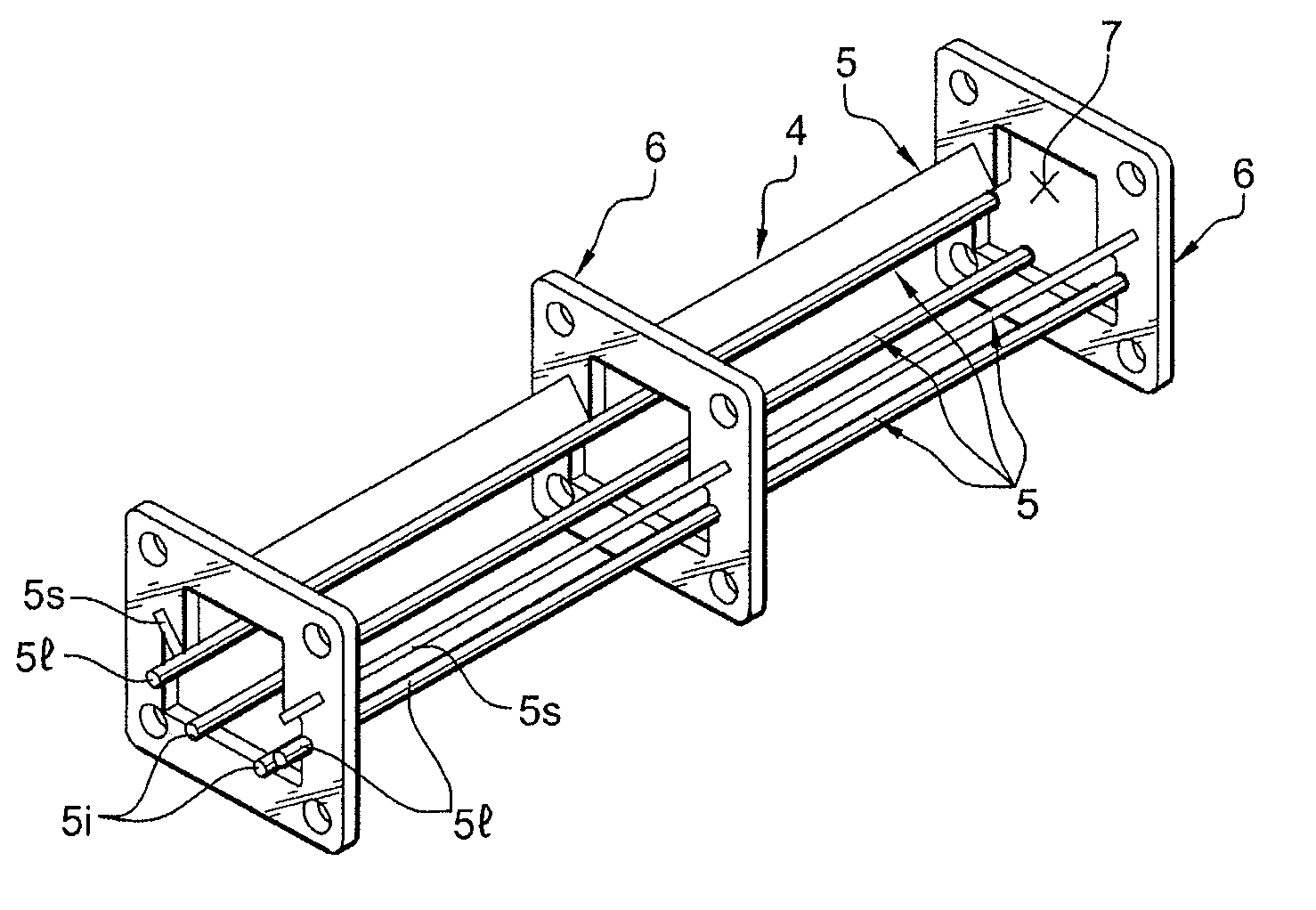

Transport system for container closures

ActiveCN103086114AReduce sealContact surface sealFlanged caps applicationStopper feedingTransport systemEngineering

The transport system (1) has one or multiple channels (2) in which container closures (3) are transported. The channels are formed by channel segments (4) with guide rails (5). The guide rails (5) are fixed to each other via retaining elements (6) arranged from ends of the guide rails in a spaced-apart manner. The transport system for the container closures is characterized in that: the end portions of the retaining elements (6) and the guide rails (7) are separately arranged; and furthermore the end segments (7) of the guide rails (5) are connected with each other.

Owner:KRONES AG

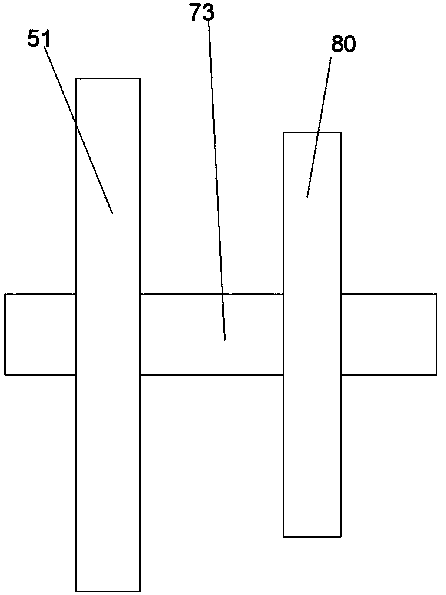

Plug pressing device

The invention relates to a plug pressing device. The plug pressing device comprises a cam indexer I, a cam indexer II, a rotary disk I and a rotary disk II, wherein the cam indexer I is connected with the rotary disk I through a flange I; semi-circular holes are formed in the periphery of the rotary disk I and used for mounting cap holding plates, and the cap holding plates are used for transferring caps; the cam indexer II is connected with the rotary disk II through a flange II; holes are formed in the periphery of the rotary disk II and used for mounting plug seats, and inner cavities of the plug seats are used for transferring plugs; a cap feeding mechanism is mounted on one side of the rotary disk I and used for feeding the caps; a positioning cylinder is mounted on the upper portion of the rotary disk I and used for correcting the positions of through holes of the caps; a plug falling mechanism is mounted on the upper portion of the rotary disk II and used for enabling the plugs to fall off; the rotary disk I is located below the rotary disk II; the center of a through hole of each cap holding plate of the rotary disk I is externally tangent to the center of an inner hole of the corresponding plug seat of the rotary disk II; a pressing cylinder is mounted over the external tangent position and used for pressing the plugs into through holes of the corresponding caps to complete the plug pressing process. Through motion of the two cam indexers, the plug pressing process can be rapidly completed, the automation degree is high, and the plug pressing success rate is high.

Owner:舟山市宏基工业产品设计研究所

High-precision automatic split charging equipment for radioactive medical liquid

ActiveCN107364822AHigh micro-dispensing accuracyHigh degree of automationFilling using suctionSafety device in filling machineryControl systemEngineering

The invention discloses and describes high-precision automatic split charging equipment for radioactive medical liquid. The equipment comprises a filling and plugging system, a split charging system and a control system. The split charging equipment is arranged between a penicillin bottle sample inlet railing and a penicillin bottle sample outlet railing and located above a station transfer device; and by means of the station transfer device, a penicillin bottle arrangement base and penicillin bottles arranged in the penicillin bottle arrangement base are linearly transferred to the penicillin bottle sample outlet railing from an entrance station of the penicillin bottle sample inlet railing. The equipment has the characteristics of irradiation resistance, high trace split charging precision, high split charging speed, high automation degree and the like, and provides a technological base for split charging of the various radioactive medical liquid.

Owner:HTA CO LTD

Glass tube sealing device for medical glass tube sealing assembly machine

ActiveCN111717859AAvoid affecting the sealing qualityStopper securingStopper feedingEngineeringSlide plate

Owner:山东鑫诺新玻璃工程有限公司

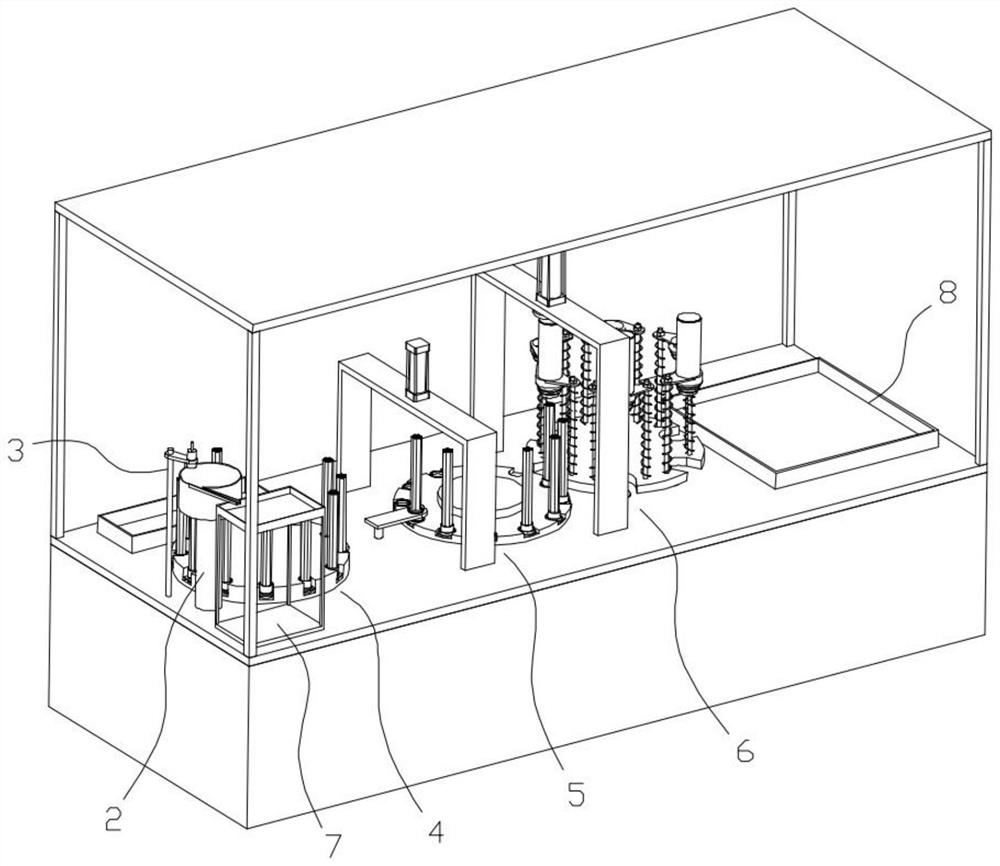

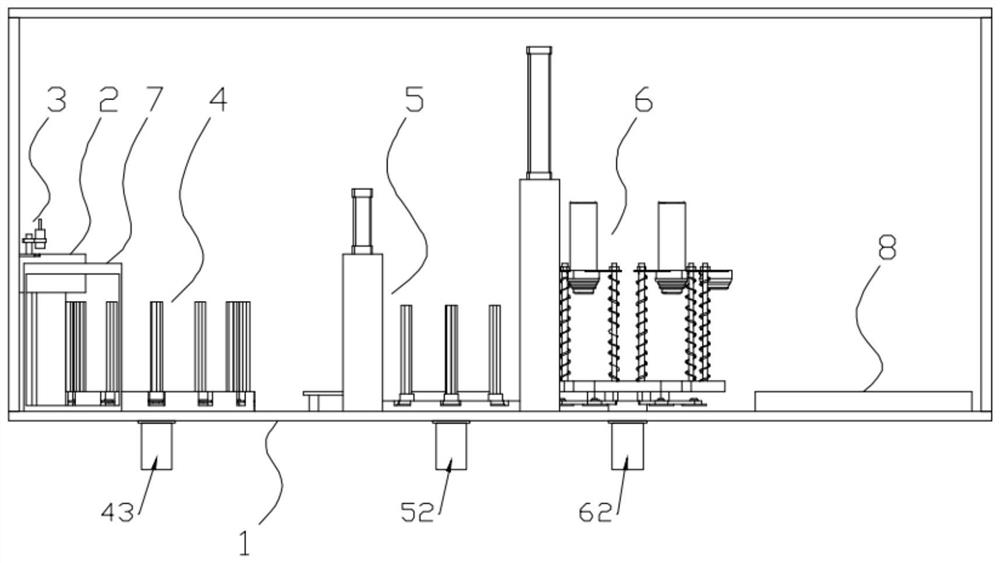

Subpackaging machine

InactiveCN108190060AEliminate generationTest coherenceSolid materialStopper feedingEngineeringBottle

The invention relates to the technical field of medical industry clean room powder-injection subpackaging, in particular to a subpackaging machine. The subpackaging machine comprises a machine table face. A bottle feeding and discharging mechanism, a screw subpackaging mechanism, a powder adding mechanism, a penicillin bottle transmission mechanism, a plug pressing mechanism and a controller are arranged at the upper end of the machine table face. A closed air return device is further included and comprises an air return air pipe arranged at the lower end of the machine table face. The air return air pipe is externally connected with an air conditioner through an air conditioner connecting pipe. Multiple through holes are formed in a face plate of the machine table face and communicate with the air return air pipe through connecting parts. Through additional mounting of the closed air return device at the bottom of the machine table face of the subpackaging machine, airflow in the whole subpackaging machine isolation space is from top to bottom and from inside to outside, a turbulent flow layer in the whole subpackaging machine area is eliminated, dust and other particles generatedin the subpackaging process are eliminated in time, smoke module testing is smooth, and the GMP requirement is met.

Owner:REYOUNG PHARMA

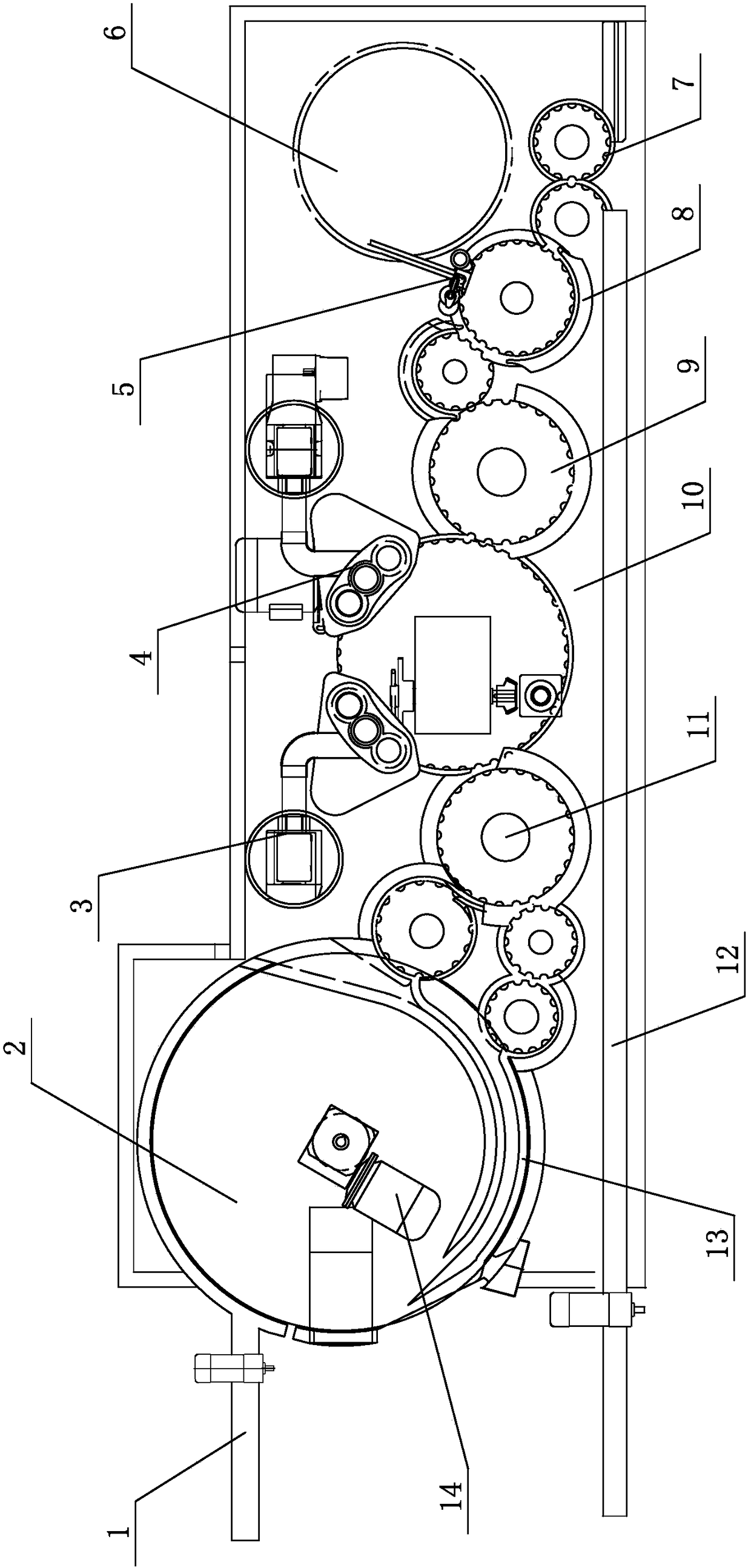

Nephropathy detection reagent collecting device

The invention relates to a medical apparatus, in particular to a nephropathy detection reagent collecting device. The nephropathy detection reagent collecting device comprises a test tube storage mechanism, a test tube conveying mechanism, a test tube plug automatic mounting mechanism, a test tube box mechanism, a test tube box lifting mechanism, a reagent cooling treatment mechanism and a test tube body. The nephropathy detection reagent collecting device can store the test tubes for patients to use; the nephropathy detection reagent collecting device can transport the test boxes, facilitatescollection and sealing of the reagents, is rapid in operation and convenient to use and improves the working efficiency; the nephropathy detection reagent collecting device can seal the test tubes, prevent the reagents from being polluted and guarantees the accuracy of the detection result; the nephropathy detection reagent collecting device is provided with the test tube box mechanism, can clampand position the test tubes and can prevent the test tubes from waggling; the nephropathy detection reagent collecting device can separate the test tube box mechanism from the test tube box conveyingmechanism, so that a doctor can transfer the test tube box mechanism to a library conveniently and operation of the doctor is facilitates; and the nephropathy detection reagent collecting device canperform cooling treatment on the detection reagent so as to avoid sample deterioration caused by too high room temperature and guarantee the accuracy of the detection result.

Owner:刘孝琴

Automatic sealing device for chemical alkaline solution

InactiveCN112479118APhenomenon of not tiltingPrevent outflowStopper feedingThreadless stopper insertionThermodynamicsProcess engineering

The invention relates to the field of chemical engineering, in particular to an automatic sealing device for a chemical alkaline solution. According to the technical scheme, the automatic sealing device for the chemical alkaline solution comprises a bottom plate, a rack, a conveying mechanism, a covering mechanism and an auxiliary mechanism; and the side bottom of the covering mechanism is connected to the auxiliary mechanism, and the auxiliary mechanism is connected to the conveying mechanism. According to the automatic sealing device, the effect that a glass bottle filled with the alkaline solution can be covered instead of manual work, so that the alkaline solution is prevented from contaminating the body of a worker and causing damage to the worker is achieved; and meanwhile, when a rubber plug is plugged into the glass bottle, the glass bottle can be limited and fixed, so that the glass bottle cannot be inclined, the alkaline solution in the glass bottle is prevented from flowingout, the circumstance that the glass bottle falls off from the device during covering is avoided, and loss of the alkaline solution due to the fact that glass is broken is also avoided.

Owner:孙浩

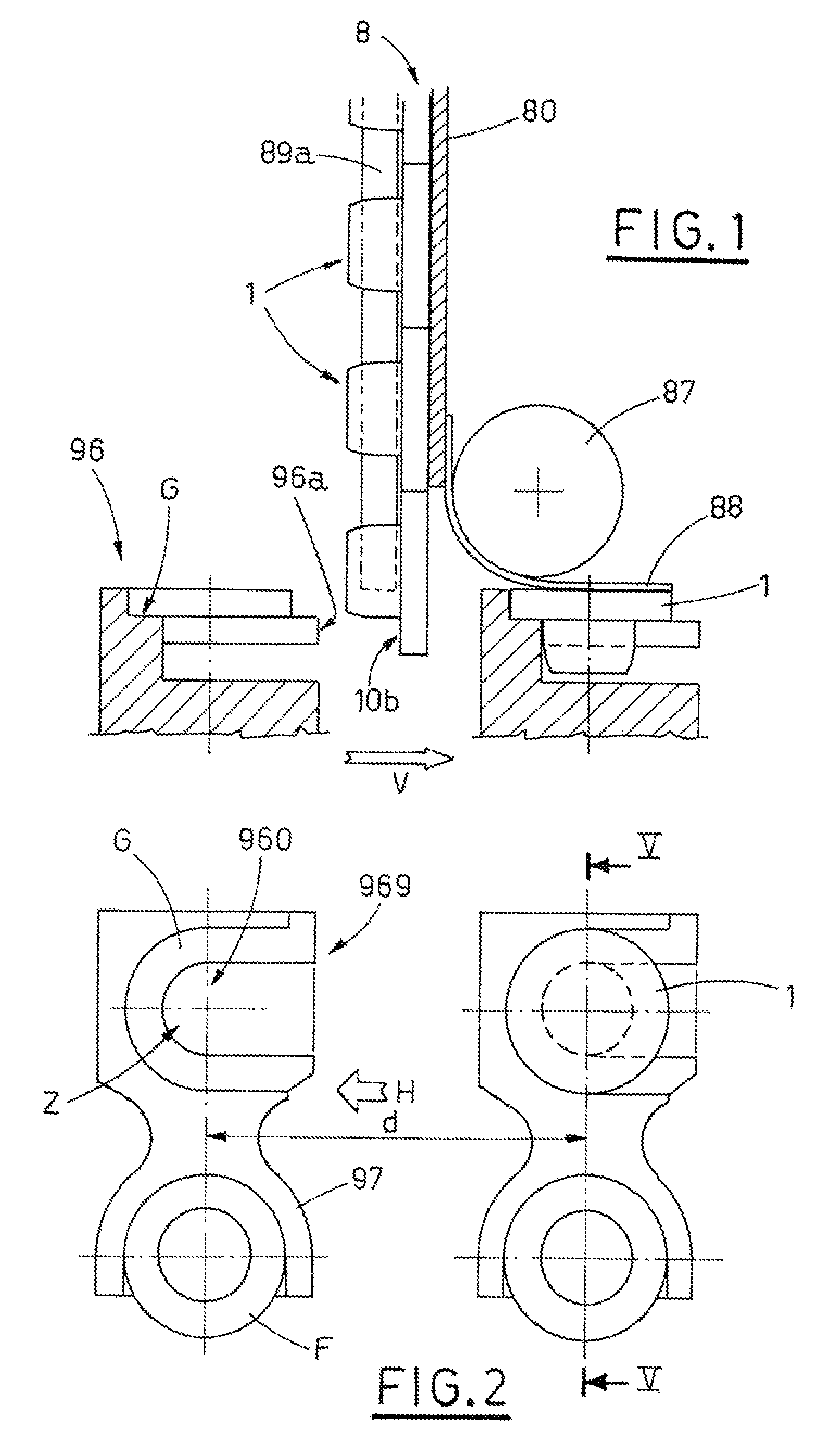

Guide structure for stoppers

InactiveUS20110017568A1Avoid collectingEasy to cleanConveyorsStopper feedingElectrical and Electronics engineeringC shaped

The guide structure for stoppers takes the form of a tunnel with a C-shaped section for trapping and guiding the cylindrical part of the stoppers (1c, 1t), which tunnel has opposing edges spaced out at a distance such as to allow the passage of the bulge (3) of the nipple-type stoppers (1t). This structure consists of filamentary rails (5) and of plates (6) with a hole through their central part shaped according to the profile of the stoppers that are to be transferred.

Owner:SIDEL PARTICIPATIONS SAS

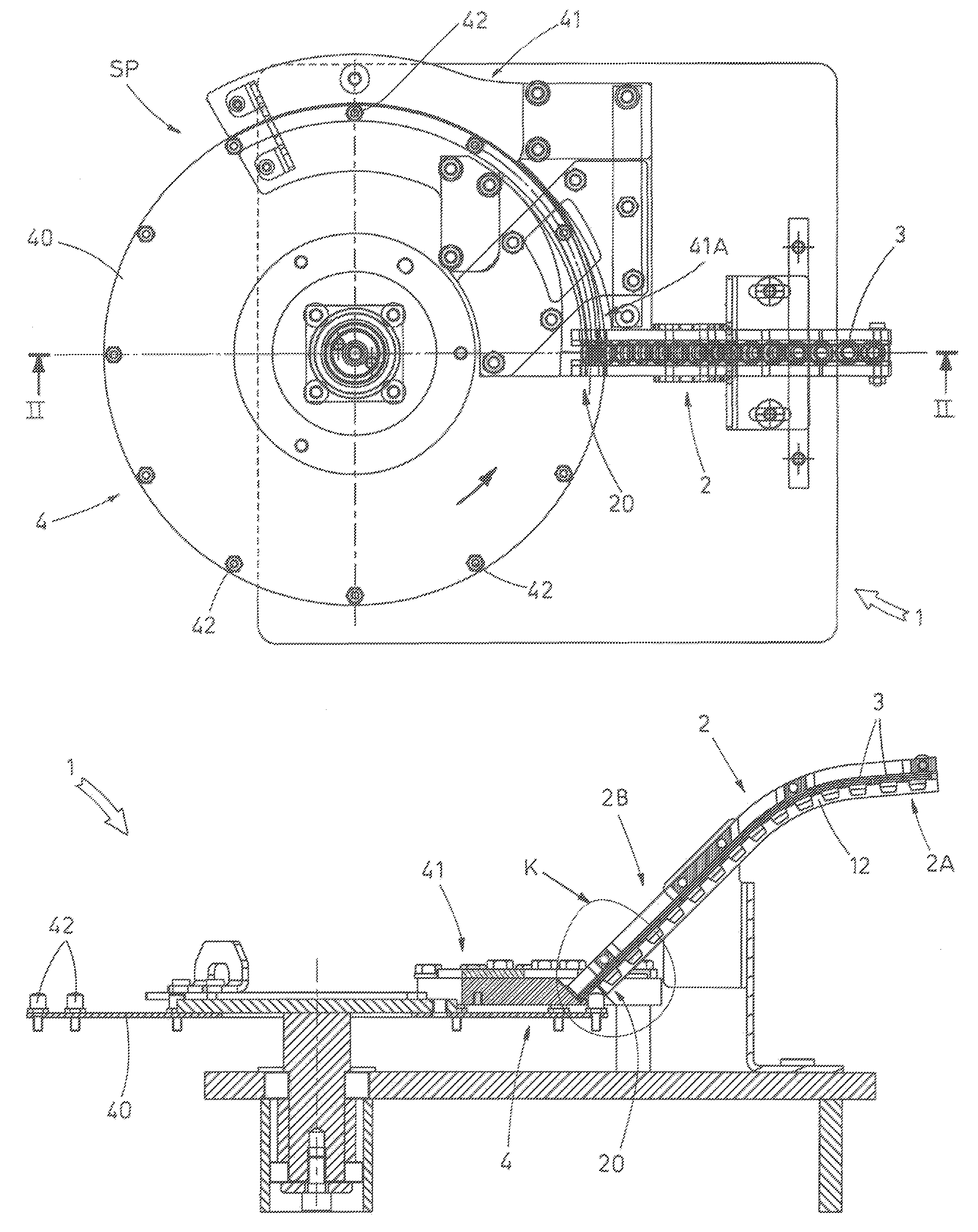

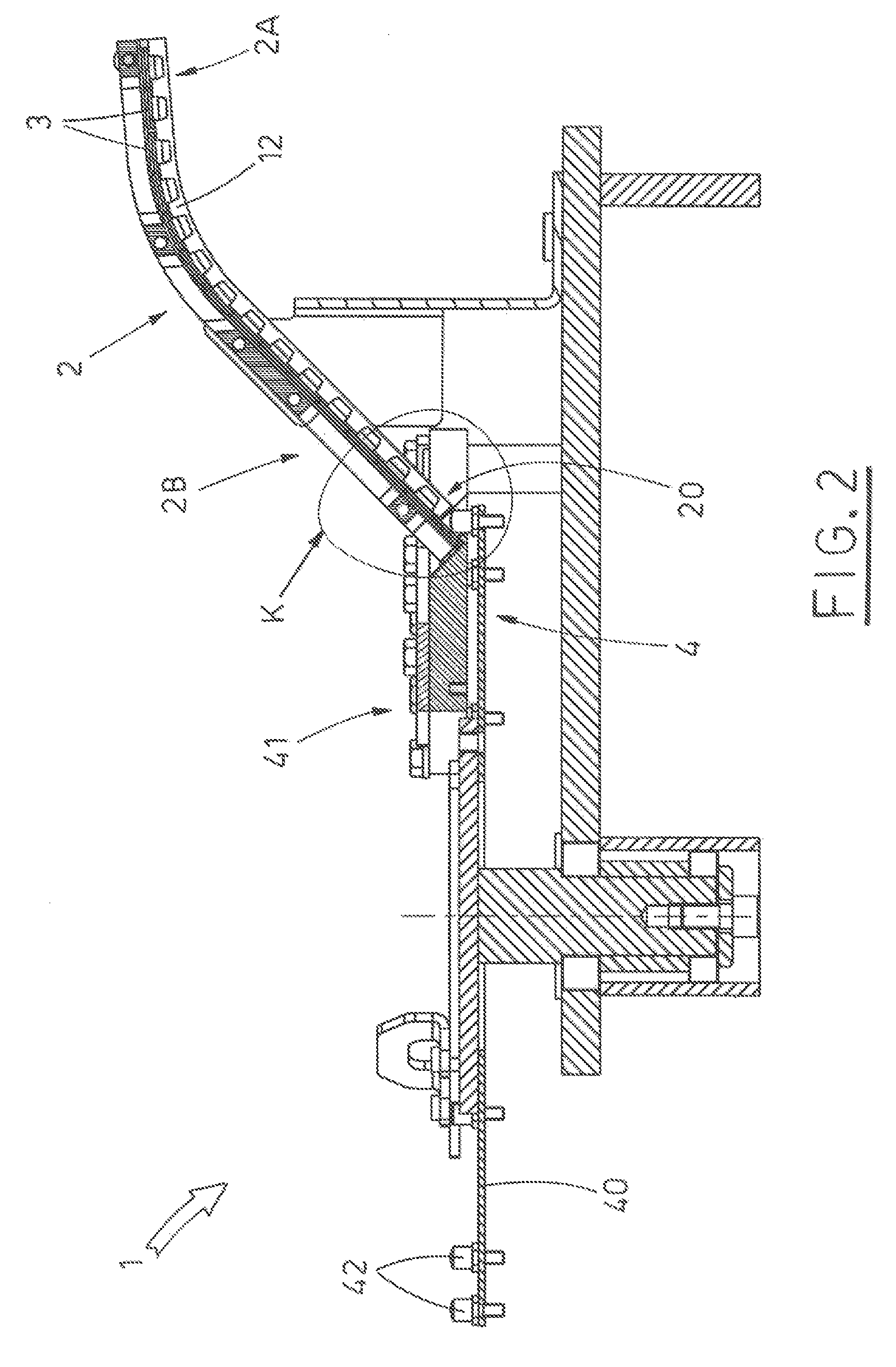

Device for feeding articles, in particular corks, to a pick-up station

ActiveUS20070234682A1Easily and efficiently sanitizedCapsFlanged caps applicationEngineeringMechanical engineering

In a feeding device, a feeding channel receives articles, or corks, supplied, with a selected orientation, by a selector situated upstream of the device. The feeding channel has, downstream of an initial section, a descending track, in which the articles, or corks are made to slide, due to gravity, toward an outlet section. A first stop, situated in the outlet section, causes an accumulation of articles, or corks, arranged in row, one after another. An extractor is situated at the outlet section to move, with a selected pace, a foremost article, or cork, situated each time ahead of other articles, along a guide toward the discontinuous picking up station for supplying a gripper working at said station.

Owner:MARCHESINI GROUP SPA

Gas filling device

PendingCN112340369AReduce labor intensityIncrease productivityFluid handledStopper feedingEngineeringBottle

Owner:上海众巍化学有限公司

Device for feeding corks to an automatic corking machine

Device for feeding corks to an automatic corking machine comprising a cork transfer wheel rotating around a vertical axis and provided with a plurality of seats distanced one from another in the circumferential direction, the transfer wheel being capable of receiving in said seats successive corks arriving from a stationary loading station. Each of the seats of the transfer wheel has a cork reception zone and a cork release zone distanced one from the other in the radial direction.

Owner:AROL

Wine bottle mouth corking equipment

ActiveCN110451443AAvoid breakingGuaranteed qualityStopper feedingThreadless stopper insertionBungEngineering

The invention discloses wine bottle mouth corking equipment. The wine bottle mouth corking equipment comprises an equipment body, wherein a moving cavity is formed in the equipment body; a communication cavity is formed in the top wall of the moving cavity; an arranging device for arranging corks in order is arranged in the moving cavity; the corks are firstly placed in a concave block cavity, andthen a power motor is started to drive a crankshaft, a rotating block and a hinged rod to rotate so as to drive an extending block and a concave block to move left and right. Compared with manual corking, wine bottles filled with wine can be automatically corked by means of the equipment, and a mechanical structure can ensure that the corks are not prone to breaking in the corking process; and meanwhile, the corking depth consistency of the corks is ensured, so that the product quality is uniform.

Owner:SHAANXI PUTIANYUAN AGRI DEV

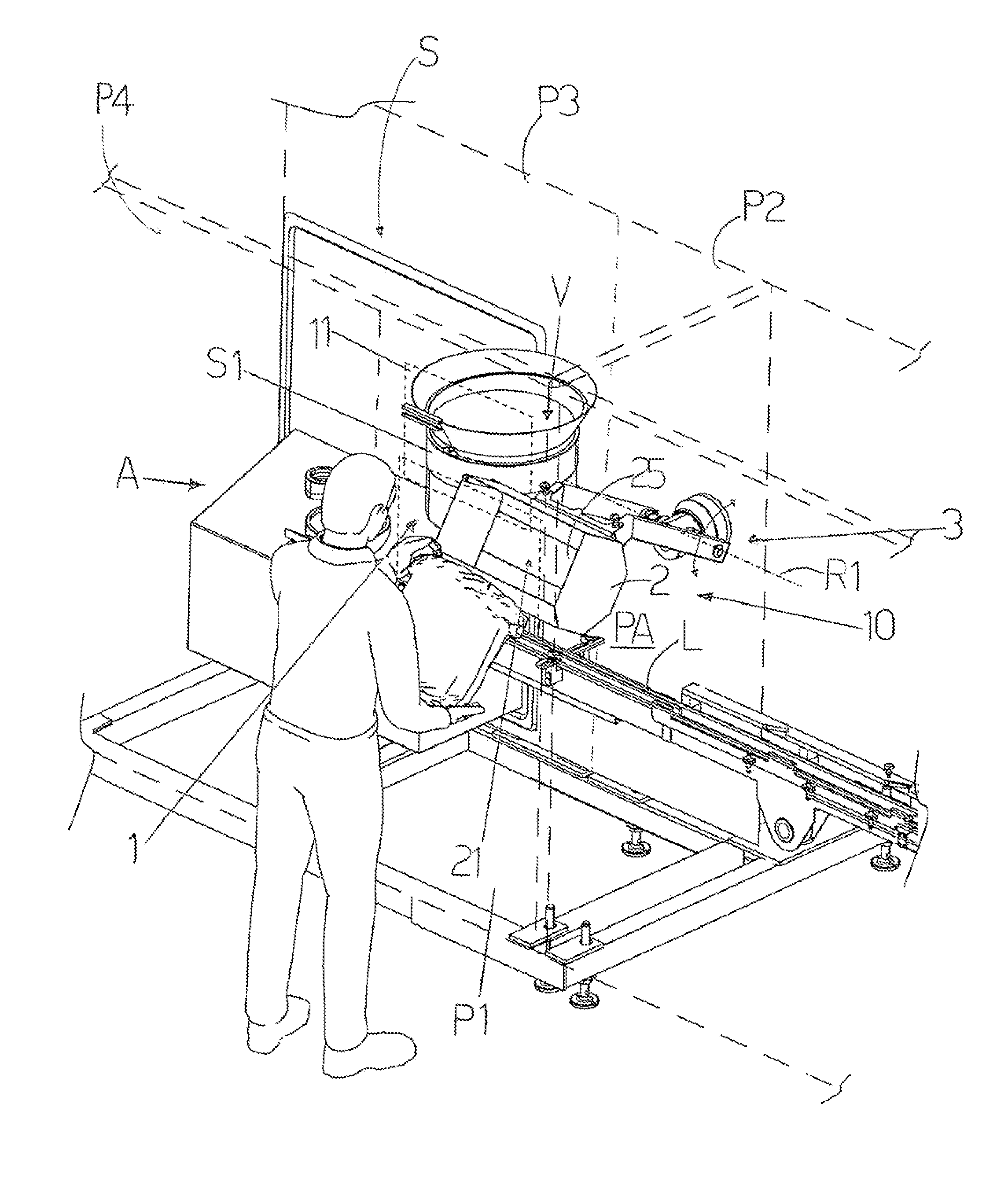

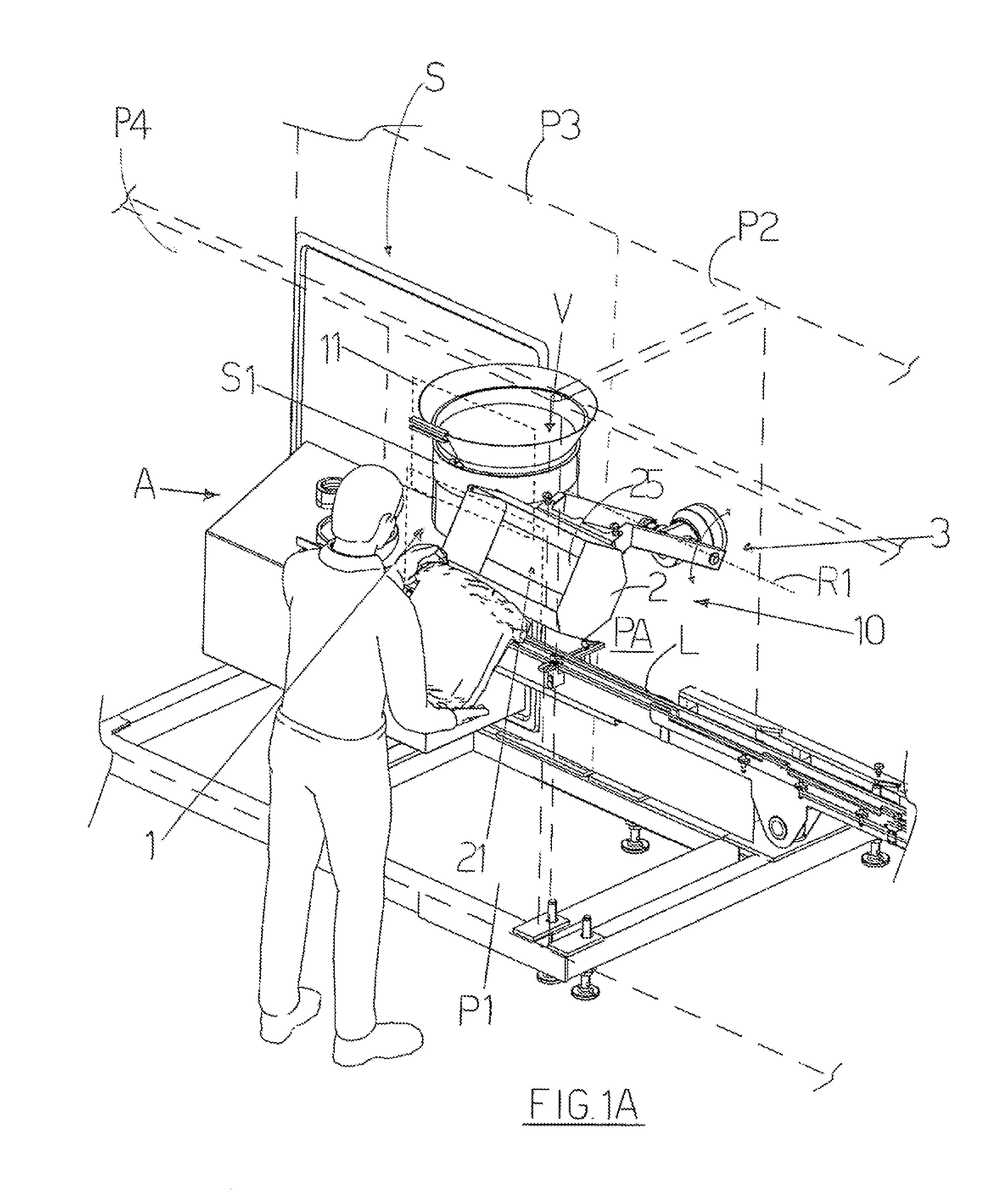

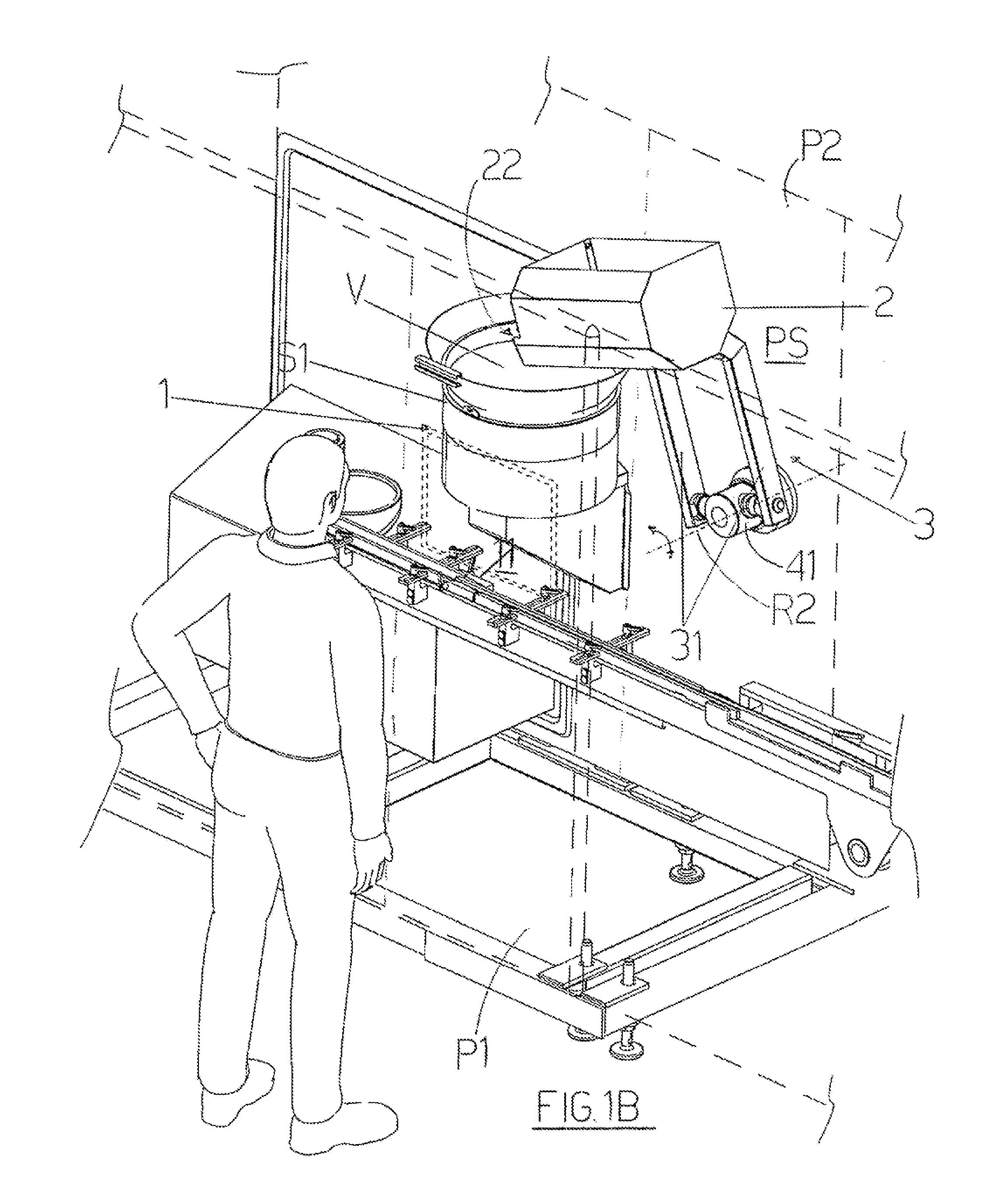

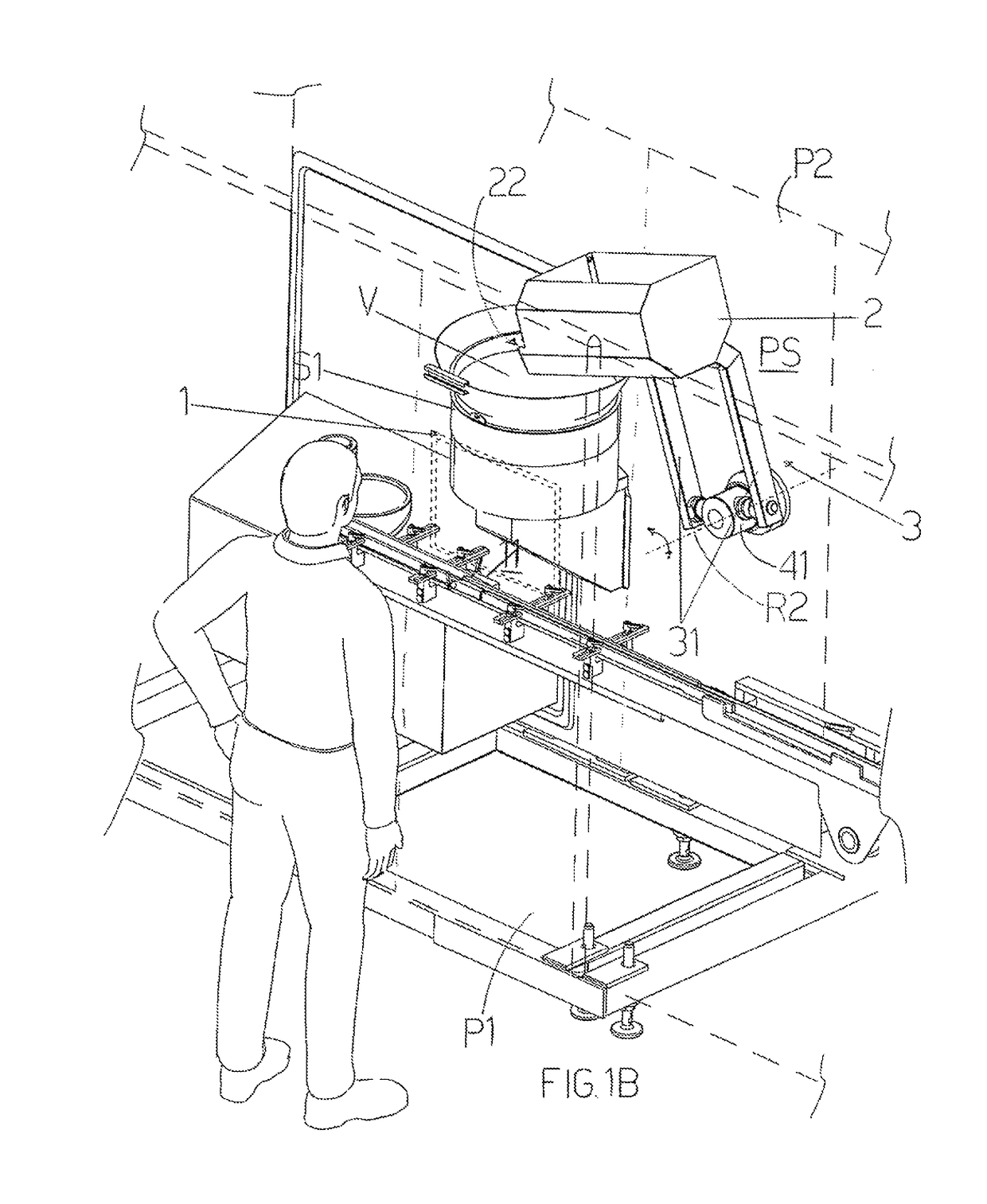

Packing Apparatus In A Sterile Environment With A Loading And Supply System Of Articles

ActiveUS20140165500A1Easy to operateAvoid seizuresCaps pretreatmentPackage sterilisationSterile environmentMechanical engineering

A packing apparatus for use in a sterile environment has an article loading and supply system. The loading system has a hatch in a first wall (P1) positioned at a height corresponding to a normal and ergonomic working height for an operator. The hatch faces an operating station which is to be supplied with the articles. A container element (2) has an internal volume (25) for containing articles, with a first article loading opening (21) and a second article unloading opening (22). The container element (2) is positioned in the sterile environment and is movable so that it can be positioned in a lowered position (PA) which corresponds to the hatch position for loading articles through the first loading opening, and then positionable in a raised position (PS) in which the second loading opening (22) is above the operating station (51) for unloading the articles to be supplied thereto.

Owner:MARCHESINI GROUP SPA

Device for feeding articles, in particular corks, to a pick-up station

ActiveUS7503154B2Easily and efficiently sanitizedCapsFlanged caps applicationEngineeringMechanical engineering

Owner:MARCHESINI GROUP SPA

Pre-filling equipment for sterile solid medicine granules

ActiveCN112407429AIncrease contactImprove filling efficiencyPackaging automatic controlStopper feedingProcess engineeringAssembly line

The invention discloses pre-filling equipment for sterile solid medicine granules, and relates to the field of automatic equipment. The pre-filling equipment comprises a workbench, a feeding vibrationdisc, a medicine granule dispersing mechanism, a weighing mechanism, a rubber plug press-fitting mechanism and a bottle body press-fitting mechanism. The pre-filling equipment achieves automation inthe whole process based on assembly line type filling and automatic weighing; compared with traditional manual filling, the filling efficiency and the weighing precision are remarkably improved, and operation errors are reduced; and in the whole filling process, solid medicine granules can be in good contact with a pre-filling needle tube and are not prone to scattering.

Owner:WUHU SIMCERE ZHONGREN PHARM

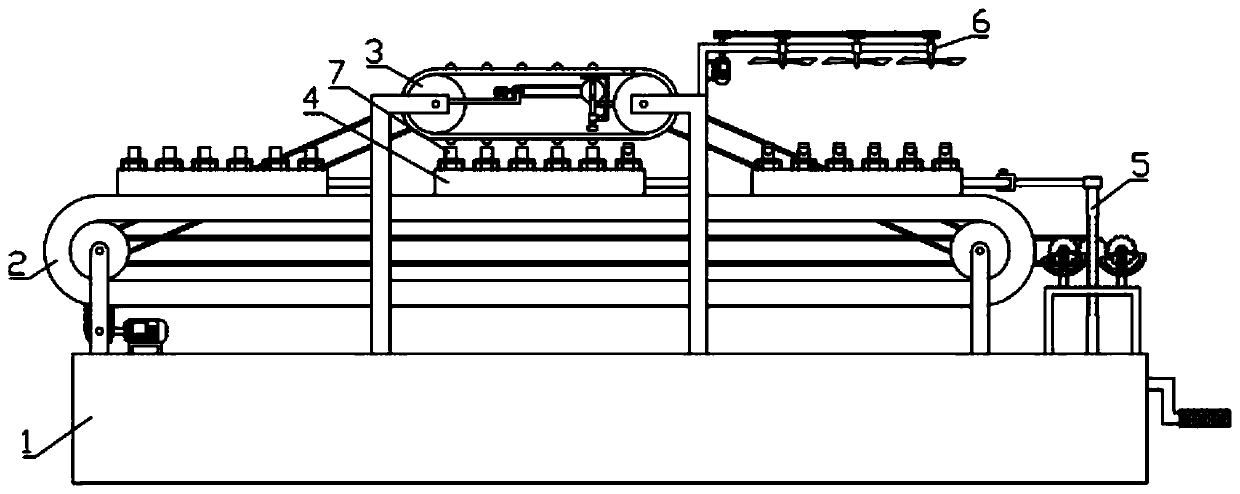

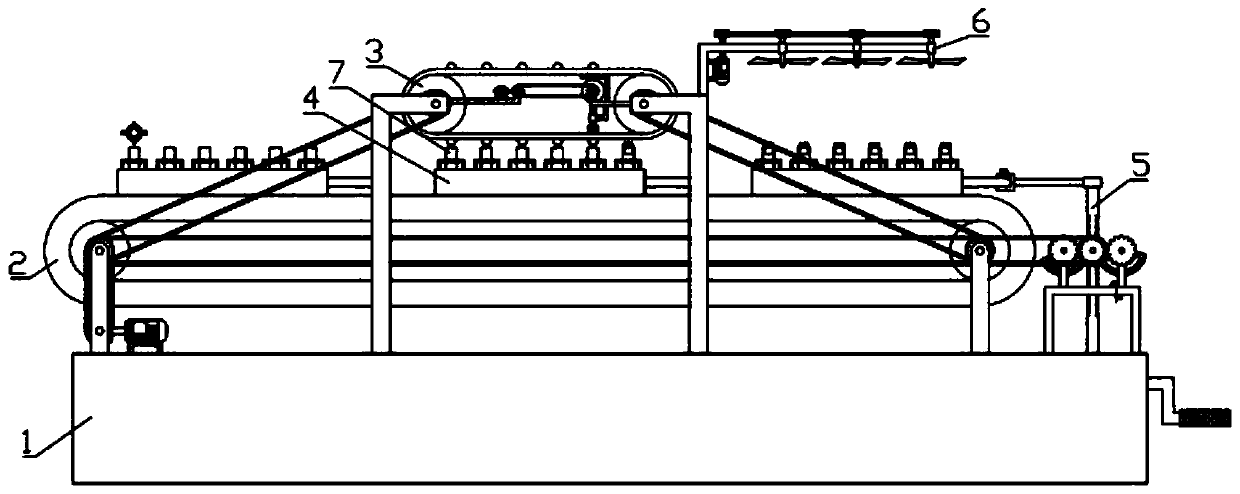

Injector filling machine

InactiveCN112174078AReduce filling cycleSimple filling and stoppering processFilling using suctionSynchronising machinesPhysicsInjector

The invention relates to an injector filling machine. The injector filling machine comprises a nest plate, a conveying mechanism, a moving platform, a feeding mechanism, a filling and plugging mechanism and a discharging mechanism. The nest plate is placed on the conveying mechanism and can move based on moving of the conveying mechanism. The moving platform is parallel to the conveying mechanism.The moving direction of the moving platform is consistent with the moving direction of the conveying mechanism. The feeding mechanism is arranged between the conveying mechanism and the moving platform, and can transfer the nest plate from the upstream position of the conveying mechanism to the moving platform. The filling and plugging mechanism is arranged corresponding to the moving platform and used for carrying out filling and plugging on injectors on the nest plate. The discharging mechanism is arranged between the conveying mechanism and the moving platform, and can transfer the nest plate from the moving platform to the downstream position to the conveying mechanism. The discharging mechanism and the feeding mechanism are located on the two sides of the filling and plugging mechanism correspondingly. The injector filling machine is simple in structure, small in occupied space, short in filling period and high in production capacity.

Owner:帕克奇科技(杭州)有限公司

Test tube flipping device

ActiveCN111847342AImprove efficiencyQuality improvementStopper feedingThreadless stopper insertionProduction lineEngineering

The invention relates to the technical field of test tube assembly, in particular to a test tube flipping device comprising a base and a rotary driving part arranged on the base. A flipping table is arranged at the output end of the rotary driving part; the flipping table is provided with a clamping mechanism; after the clamping mechanism clamps the outer lateral wall of a plug head, the flippingtable drives the clamping mechanism to rotate by a preset angle, so that a connecting part is bent, the bottom end of the plug head is aligned with a test tube opening; the test tube flipping device also comprises a plug pressing mechanism, and the plug pressing mechanism drives the flipped plug head to be inserted into the test tube opening. The mechanism has reasonable design and compact linkageand matching, the test tube opening can be automatically sealed with a plug lid, the test tube flipping device is suitable for production line type assembly, and the efficiency and quality of test tube sealing are effectively improved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Powder automatic filling system

PendingCN108146667AShorten the timeReduce pollutionThreaded caps applicationSolid materialEngineeringBottle

The invention discloses a powder automatic filling system. The powder automatic filling system includes a rack, an automatic bottle handling device, a conveying device, a filling device, and a bottlesealing pipeline with a bottle inlet and a bottle outlet. The filling device is positioned above the conveying device and is positioned downstream of the automatic bottle handling device, so that thefilling powder is transferred from the automatic bottle handling device on the conveying device to fill the bottle. The bottle inlet of the bottle sealing pipeline is connected with the bottle outletof the automatic bottle handling device and communicates with the interior of the automatic bottle handling device. The bottle outlet of the bottle sealing pipeline is directly above the conveying device and faces the conveying device, so that the filling bottle sent out from the outlet of the bottle sealing pipeline can be placed vertically on the conveying device. The powder automatic filling system shortens the opening time of the filling bottle before powder filling, and reduces the dust pollution of the filling bottle.

Owner:上海上药神象健康药业有限公司

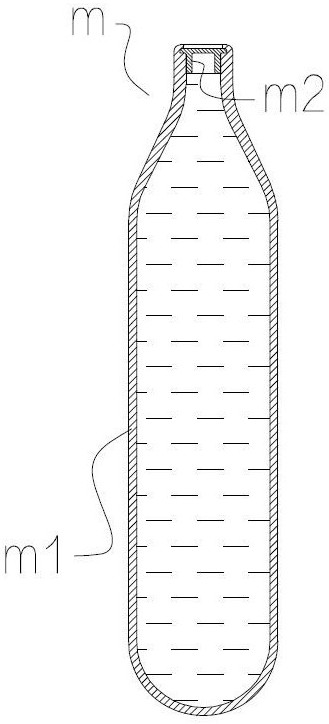

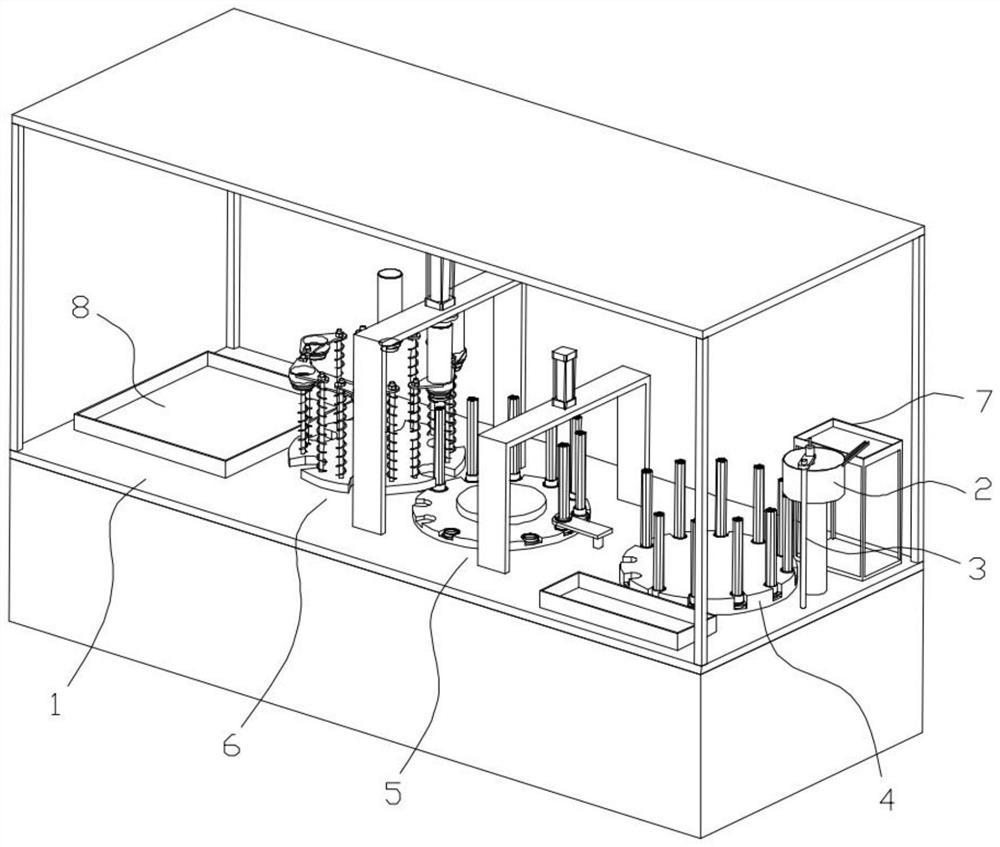

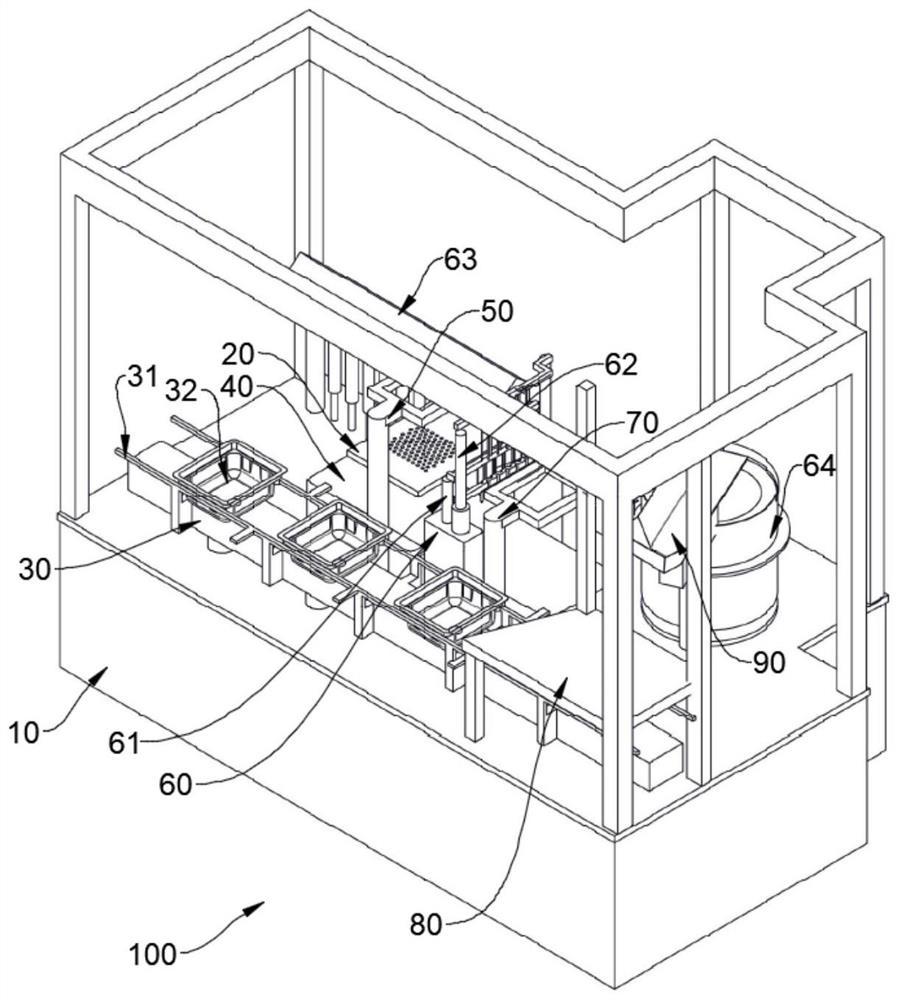

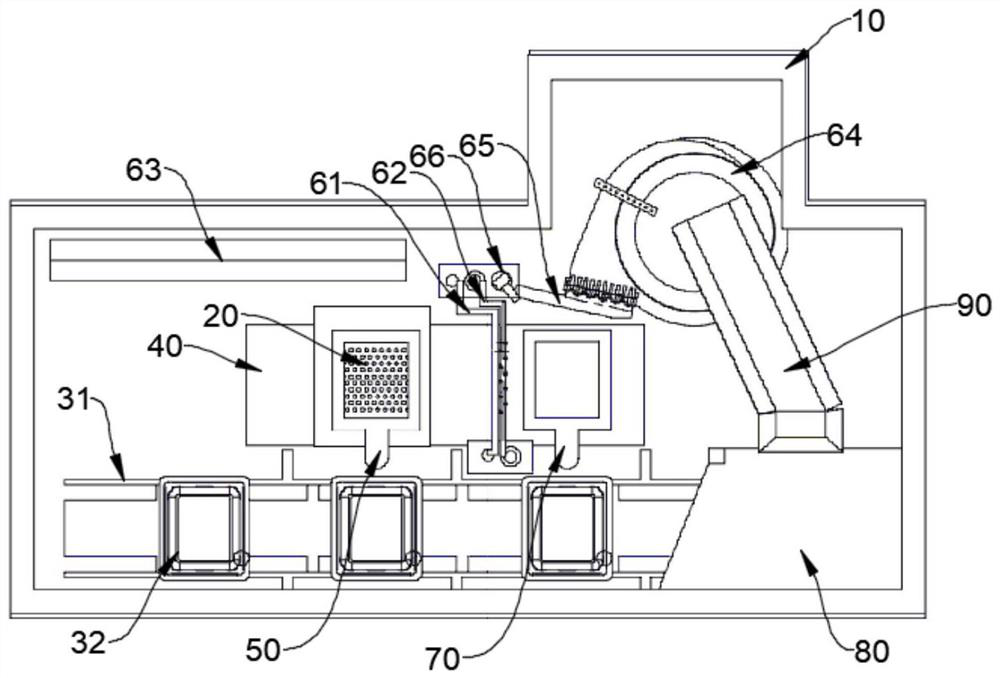

Nuclear medicine subpackaging equipment and subpackaging method thereof

PendingCN114803996ARealize batch automationReduce instabilityFlanged caps applicationFilling device cleaningPenicillinEngineering

The invention discloses nuclear medicine subpackaging equipment and a subpackaging method thereof.The nuclear medicine subpackaging equipment comprises a rack, and a mechanical arm device, an activity detection device, a penicillin bottle liquid injection device, an automatic capping device, a vacuum adsorption device and a tray device are arranged on the rack; the tray device, the activity detection device, the penicillin bottle liquid injection device, the automatic capping device and the vacuum adsorption device are arranged around the manipulator device. According to the nuclear medicine subpackaging equipment, batch automatic subpackaging of the nuclear medicine can be achieved, manpower is saved, instability caused by manual participation in the nuclear medicine subpackaging process is reduced, and the nuclear medicine subpackaging efficiency and quality are improved.

Owner:CELLAUTO BIOLOGICAL AUTOMATION CO LTD

System for high-speed filling and plug adding and method

PendingCN112794256AFast transferAccurate transferLiquid fillingPackaging foodstuffsProcess engineeringMechanical engineering

The invention discloses a system for high-speed filling and plug adding. The system involves a conveying device, a plug conveying device, a filling device, a first plug adding device, a second plug adding device and a rubber plug transferring device used for transferring rubber plugs to the first plug adding device and the second plug adding device, wherein the filling device, the first plug adding device, the second plug adding device, the rubber plug transferring device and the plug conveying device are sequentially arranged along the conveying device, the rubber plug transferring device comprises a first plug adding plate provided with a first rubber plug positioning channel, a second plug adding plate provided with a second rubber plug positioning channel, and an eccentric shaft assembly used for driving the first plug adding plate and the second plug adding plate to rotate so as to adjust the distance between the first rubber plug positioning channel and the second rubber plug positioning channel, and a plug ejecting part is arranged below the plug conveying device. The method comprises the steps that the conveying device conveys containers; the filling device is used for filling the containers; and after the two rows or above of containers are filled, the first plug adding device and the second plug adding device add plugs of the front row of containers and the rear row of containers. The system has the advantages of being high in production efficiency and good in operation stability.

Owner:TRUKING TECH LTD

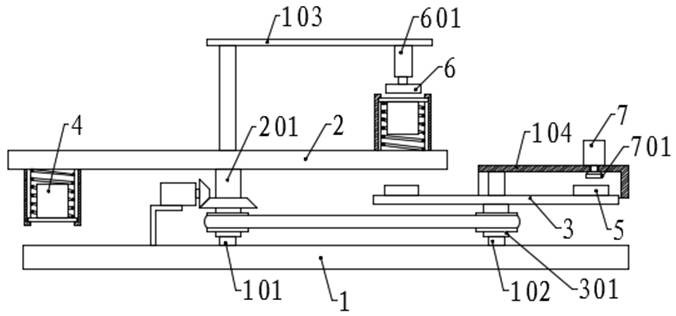

Automatic conveying press-fitting mechanism for bottle plugs

PendingCN108751086AProduct quality consistency is goodWithout human interventionStopper feedingThreadless stopper insertionEngineeringBottle

The invention discloses an automatic conveying press-fitting mechanism for bottle plugs. The automatic conveying press-fitting mechanism for the bottle plugs comprises a press-fitting platform which is provided with a number one work station and a number two work station; a swinging stopping block is hinged to the press-fitting platform, and can prevent bottle plugs waiting for press fitting fromdirectly entering the number two work station; a photoelectric detection sensor is further arranged on the press-fitting platform; a pair of V-shaped clamping blocks are hinged to the press-fitting platform; and a lifting device is arranged above the number two work station, and can be used for pressing bottle plugs clamped and positioned through the V-shaped clamping blocks into bottle openings of bottle bodies below the number two work station. After the above structure is adopted, the whole process achieves full-automatic operation, manual interference is not needed, the labor intensity islow, the operation efficiency is greatly improved, the product quality consistency is very good due to mechanical operation, the product qualification rate is high, and the production cost is saved; and in addition, due to the fact that a bottle plug conveying channel is variable in size, the automatic conveying press-fitting mechanism for the bottle plugs is currently applicable to bottle plug press fitting of all cosmetics on the market, and is high in adaptability.

Owner:宏一包装技术(丹阳)有限公司

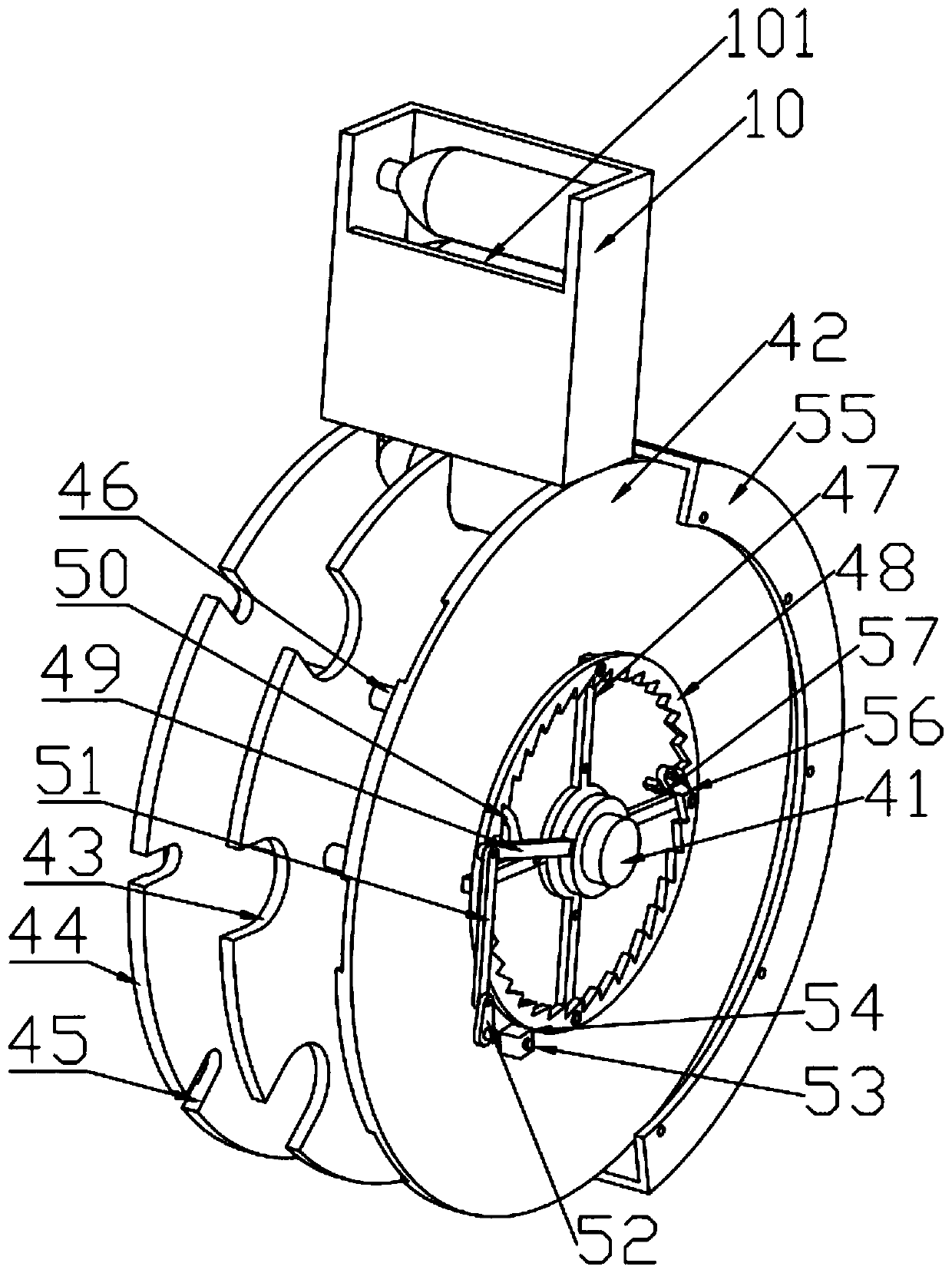

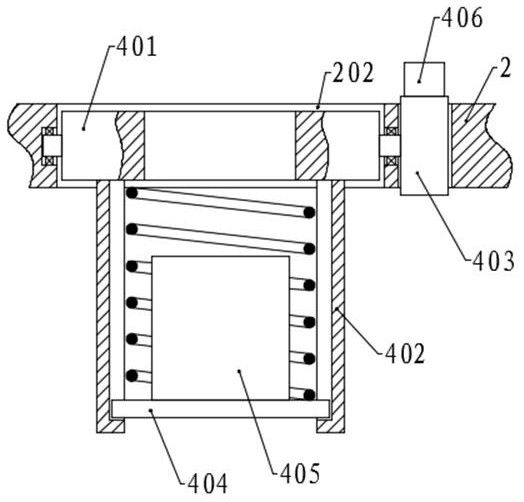

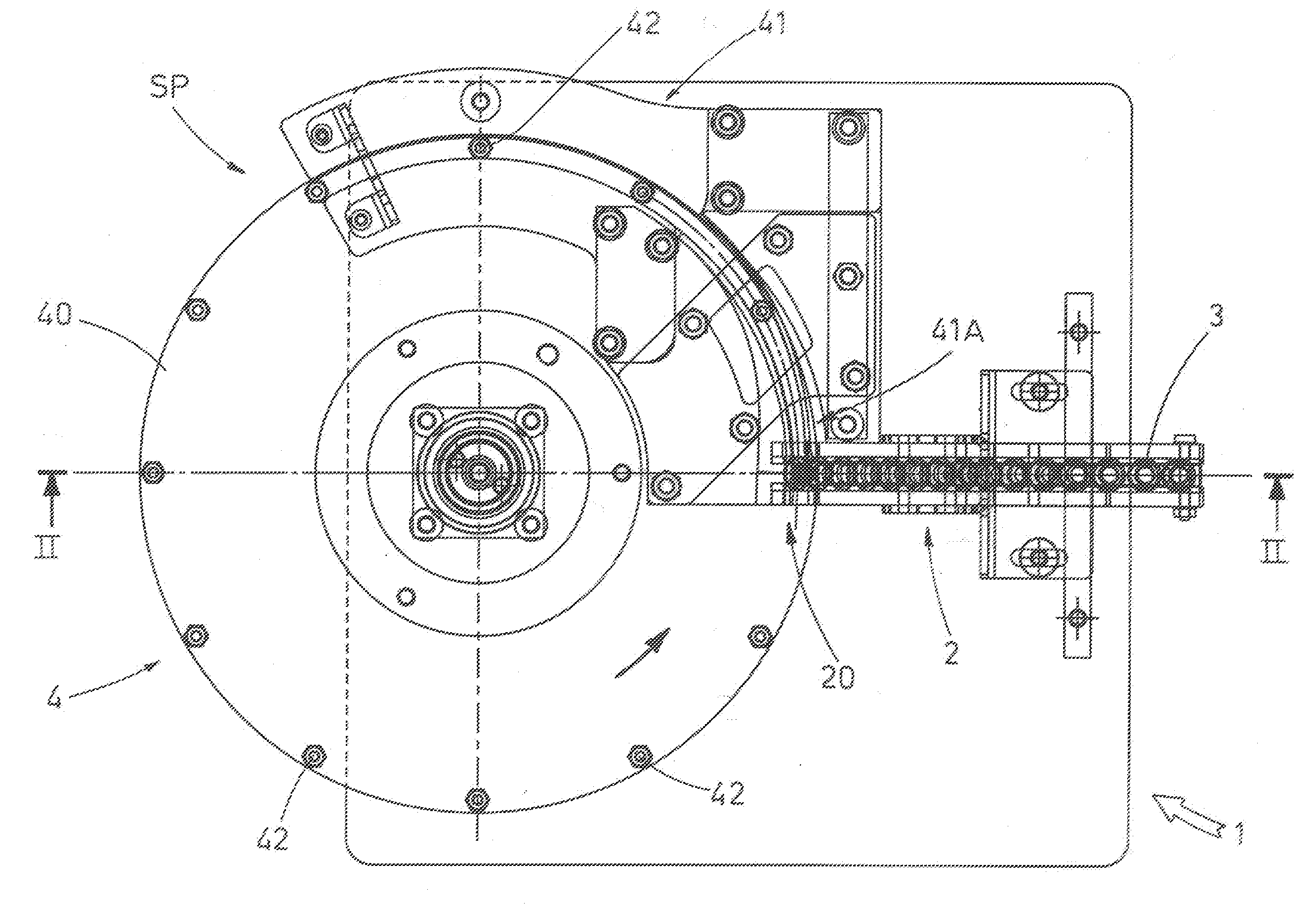

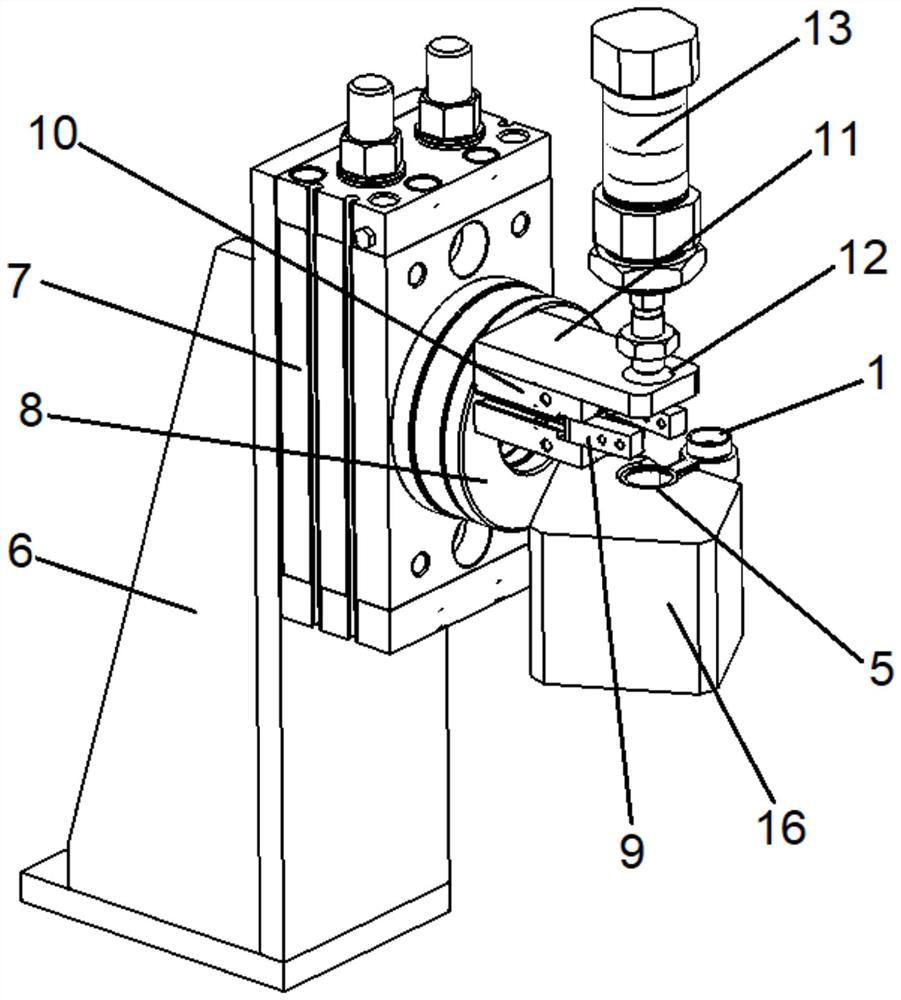

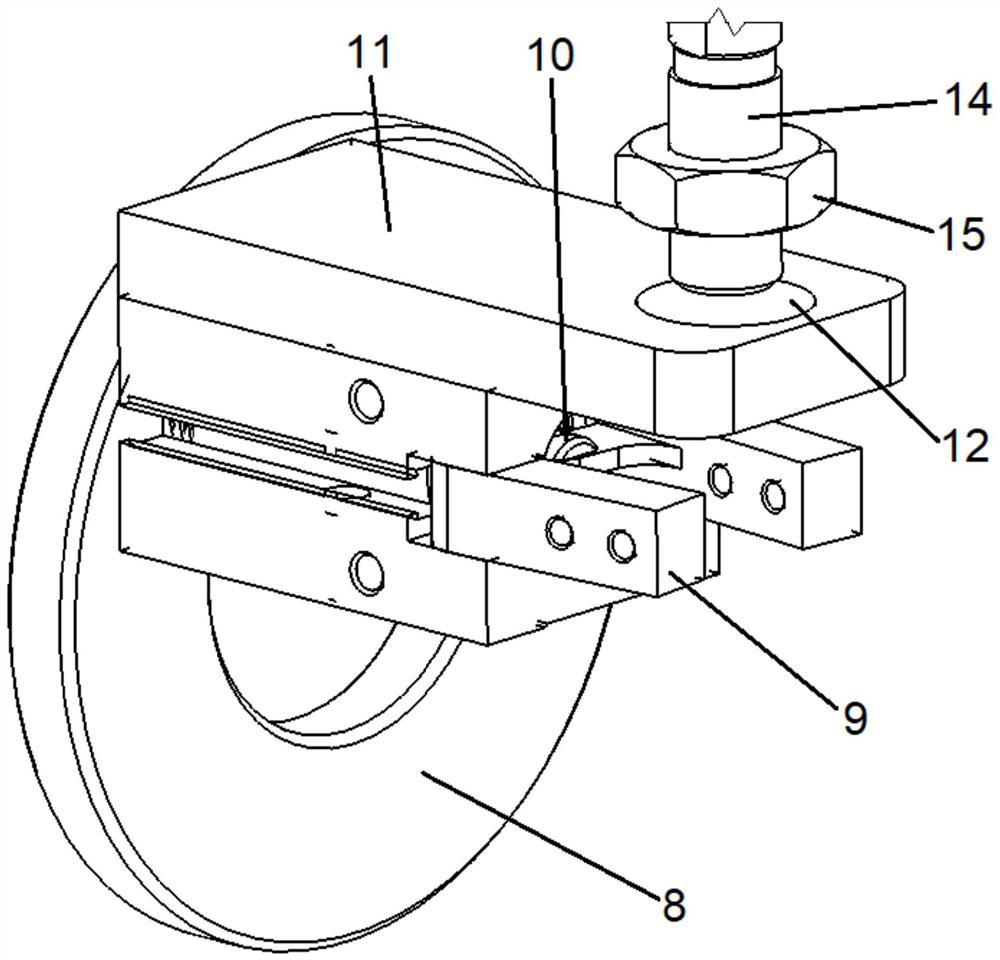

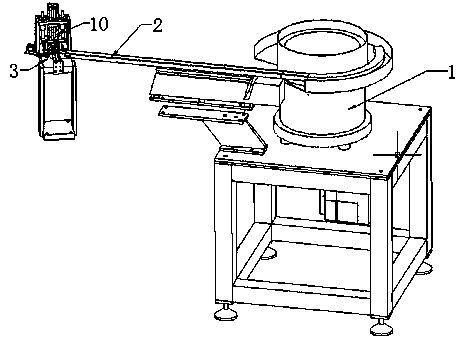

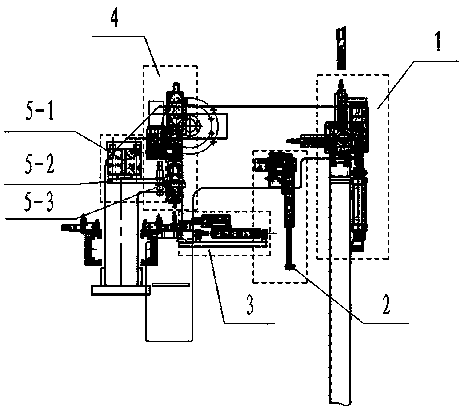

Prelubricated rotary plug-feeding mechanism

InactiveCN108033416AReduce scratchesReduce the risk of having plastic debrisStopper pretreatmentStopper feedingEngineeringLubrication

The invention provides a prelubricated rotary plug-feeding mechanism, and relates to the field of infusion bag production. The prelubricated rotary plug-feeding mechanism comprises a rack; a plug-conveying overturning assembly, a dipping lubrication assembly, a hose positioning assembly and a rotary plug-feeding assembly are mounted on the rack; the plug-conveying overturning assembly is providedwith a plug receiving station and a plug conveying station, the dipping lubrication assembly is provided with a dipping station and a lubrication station, the hose positioning assembly is provided with a positioning station, and the rotary plug-feeding assembly is provided with a lubrication station and a plug feeding station; the lubrication station of the rotary plug-feeding assembly is matchedwith the plug conveying station of the plug-conveying overturning assembly in position; the lubrication station of the dipping lubrication assembly is matched with the lubrication station of the rotary plug-feeding assembly in position; and the plug feeding station of the rotary plug-feeding assembly is matched with the positioning station of the hose positioning assembly in position. During working, sealing plugs are conveyed to the rotary plug-feeding assembly through the plug-conveying overturning assembly, lubricated through the dipping lubrication assembly and then rotatably stuffed intohoses located by the hose positioning assembly through the rotary plug-feeding assembly.

Owner:SHINVA MEDICAL INSTR CO LTD

Packing apparatus in a sterile environment with a loading and supply system of articles

A packing apparatus for use in a sterile environment has an article loading and supply system. The loading system has a hatch in a first wall (P1) positioned at a height corresponding to a normal and ergonomic working height for an operator. The hatch faces an operating station which is to be supplied with the articles. A container element (2) has an internal volume (25) for containing articles, with a first article loading opening (21) and a second article unloading opening (22). The container element (2) is positioned in the sterile environment and is movable so that it can be positioned in a lowered position (PA) which corresponds to the hatch position for loading articles through the first loading opening, and then positionable in a raised position (PS) in which the second loading opening (22) is above the operating station (S1) for unloading the articles to be supplied thereto.

Owner:MARCHESINI GROUP SPA

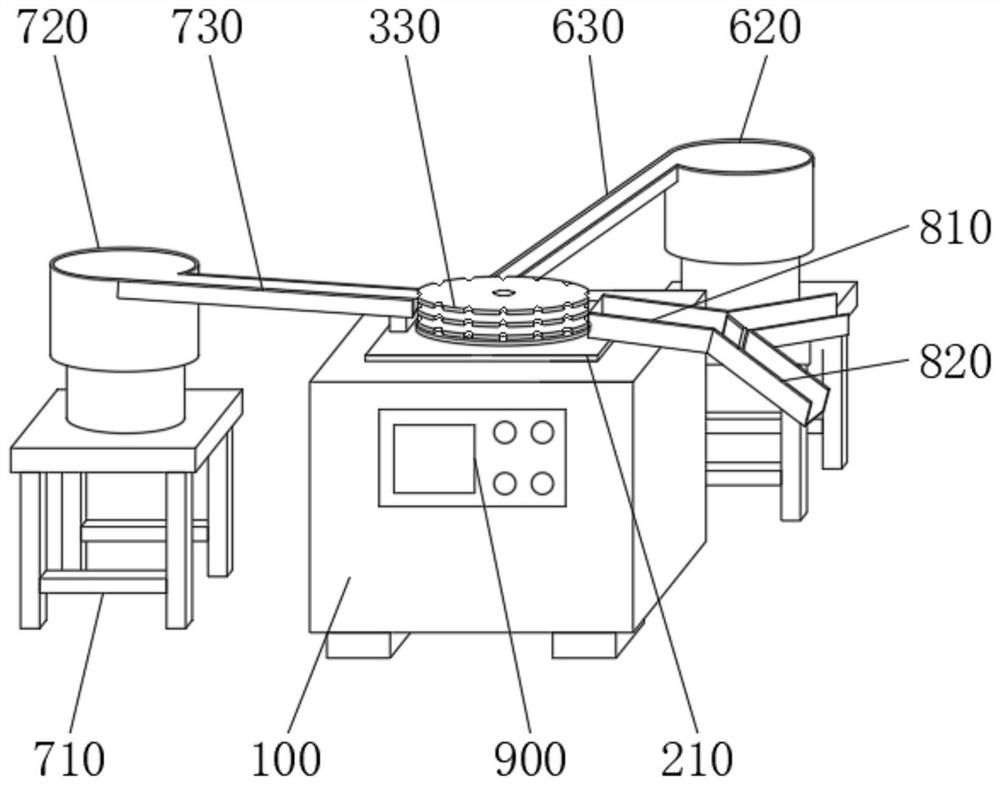

Bottle cap inner plug press-fit device

ActiveCN112938858ARealize automatic feeding processLabor savingPlastic recyclingStopper feedingBottle capMachining

The invention discloses a bottle cap inner plug press-fit device, and belongs to the technical field of bottle cap machining. The bottle cap inner plug press-fit device comprises an operation table, a rotating mechanism, a limiting mechanism, a press-fit mechanism, a height measuring mechanism, a first feeding mechanism, a second feeding mechanism, a screening mechanism and a control face plate; the rotating mechanism is fixedly connected to the top of the operation table through bolts, the limiting mechanism is fixedly connected to the top of the rotating mechanism through bolts, and the press-fit mechanism is fixedly connected to the front side of the top of the rotating mechanism through bolts; and the height measuring mechanism is fixedly connected to the right side of the top of the press-fit mechanism through bolts, and the first feeding mechanism is placed on the rear side of the operation table. According to the bottle cap inner plug press-fit device, automatic feeding of outer caps and inner plugs of bottle caps can be achieved, and manual operation is not needed, so that the feeding efficiency is improved while labor is saved; continuous press-fit is carried out on the bottle caps so that the production and machining yield of the bottle caps can be increased; and defective products are screened out, so that economic losses are avoided.

Owner:ANHUI HENGZHENG PACKAGE TECH

Cosmetic automatic filling production line

InactiveCN113911992AReduce laborIncrease productivityThreaded caps applicationWrapper twisting/gatheringCartoning machineProduction line

The invention provides a cosmetic automatic filling production line. The cosmetic automatic filling production line comprises a clean area and a general production area, and a separation wall is arranged between the clean area and the general production area. The clean area is provided with a filling unit, the general production area is provided with a case taking and opening device, a case filling mechanism, a case sealing mechanism, a box opening machine, a box filling machine, a box sealing machine and a stacking device, the filling unit is used for producing bottled cosmetics and is connected with the case filling mechanism through a first conveying mechanism, the case sealing mechanism is used for sealing and capping material cases containing the bottled cosmetics, the box opening machine is used for opening packaging paper boxes and sealing glue on bottom caps of the packaging paper boxes, the box filling machine is used for placing the material cases containing the bottled cosmetics into the opened packaging paper boxes, the box sealing machine is used for sealing glue on top caps of the packaging paper boxes, and the stacking device is used for stacking and storing the packaging paper boxes. The production line achieves full-automatic production, the production progress can be accurately controlled, stable and efficient production is achieved, and the product quality is guaranteed.

Owner:拜斯特药业(广州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com