Subpackaging machine

A packaging machine and machine technology, applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of affecting the packaging environment, unable to guarantee the product environment, high pollution risks, etc., and achieve the effect of eliminating the turbulent layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

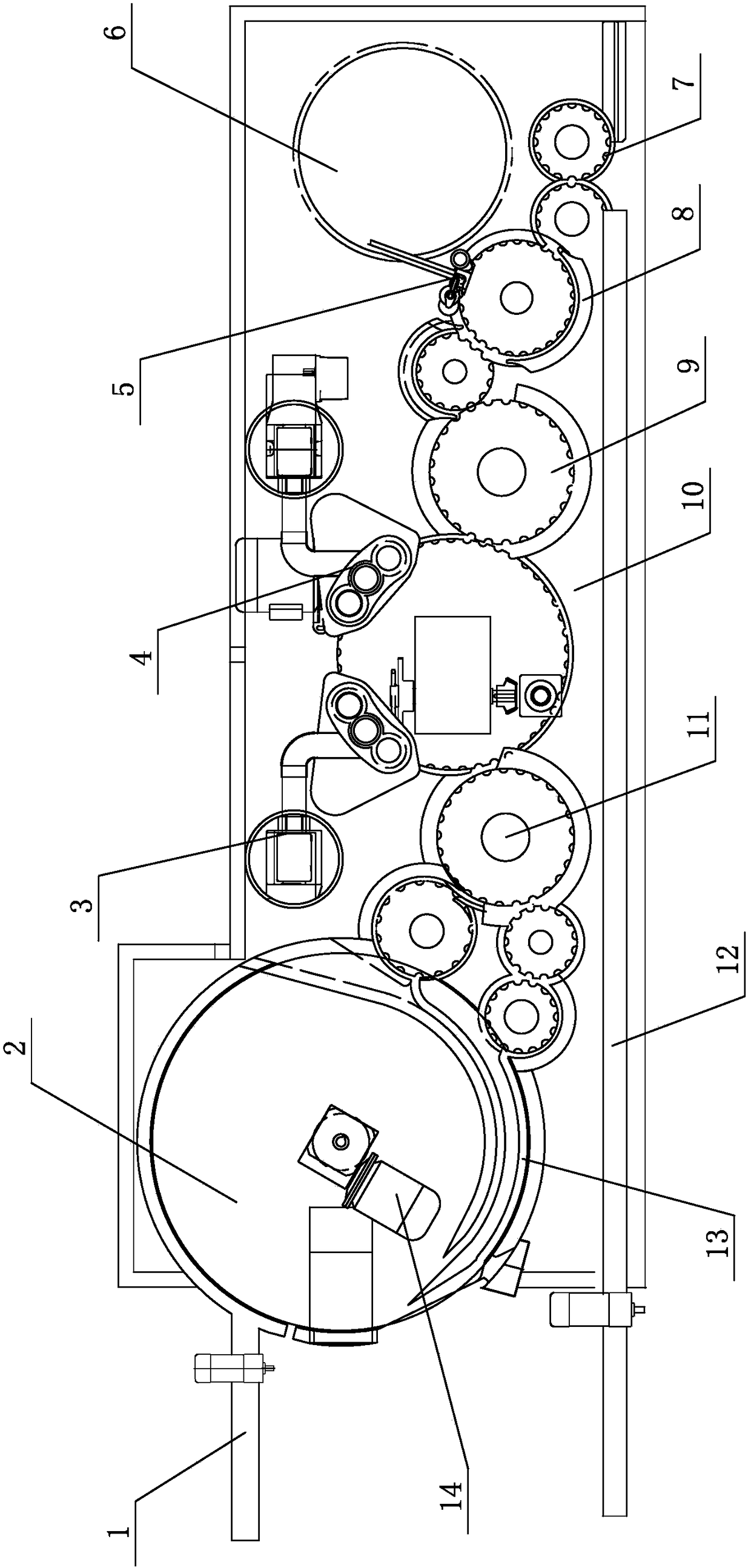

[0019] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0020] Such as Figure 1-3 As shown, the dispensing machine of the present invention comprises a machine table 10, and the upper end of the machine table 10 is respectively provided with a bottle-in and out mechanism, a screw packing mechanism 4, a powder adding mechanism 3, a vial transmission mechanism, a stopper mechanism 5 and a controller, It also includes a closed air return device, which includes a return air duct 23 arranged at the lower end of the machine table 10, the return air duct 23 is externally connected to the air conditioner through the air conditioner connecting pipe 24, and the panel of the machine table 10 has a plurality of through holes , the diameter of the through hole is 2 mm, and the through hole communicates with the return air duct 23 through the connecting piece 22, and the dust on the machine table 10 and close to the machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com