Transport system for container closures

A technology for conveying systems and closures, applied in the field of conveying systems, can solve the problems of time-consuming guide rails, guide rail deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

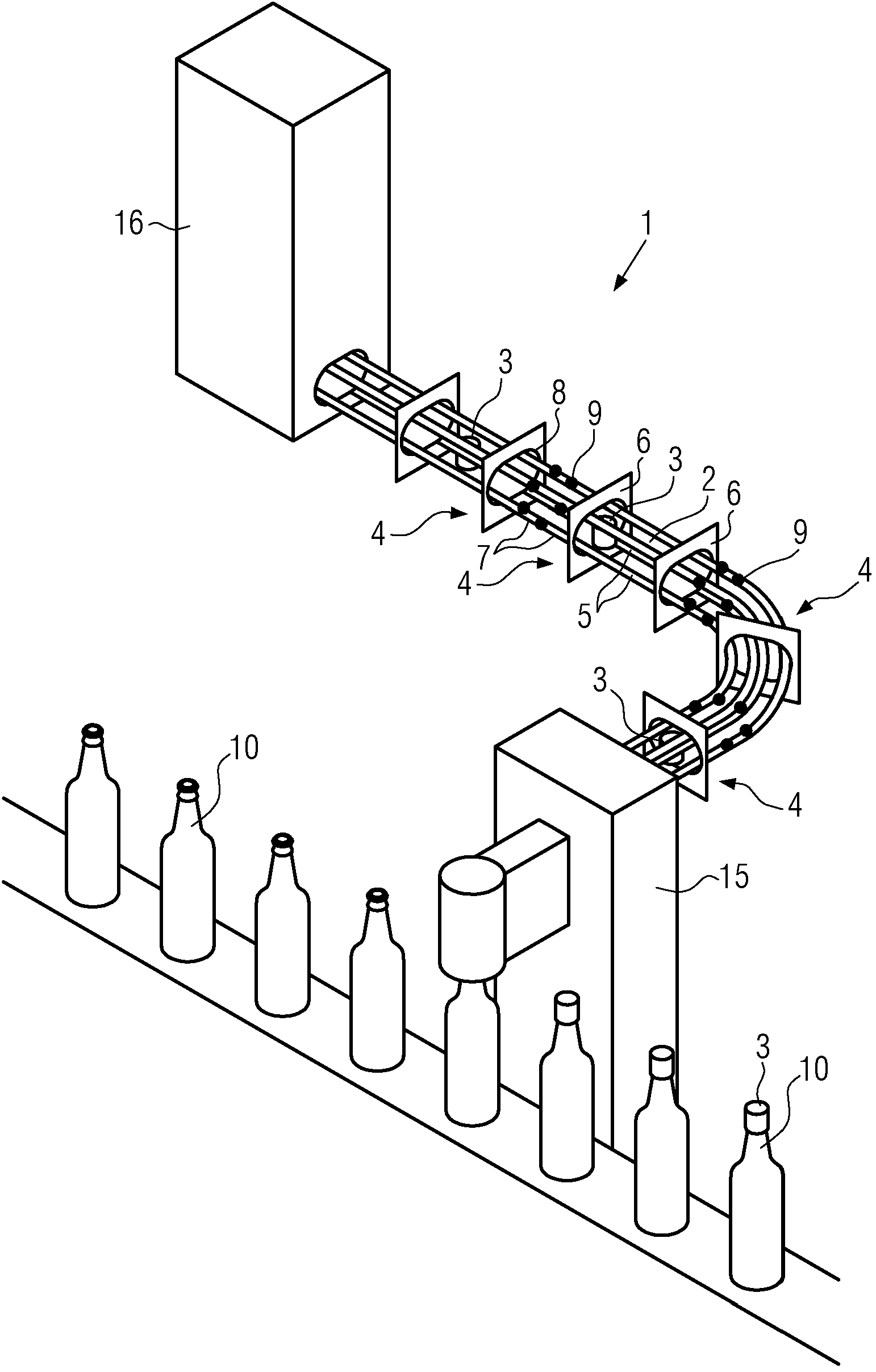

[0020] figure 1 A schematic illustration of a delivery system 1 for container closures 3 is shown in a perspective view. A closure storage device 16 can be seen, from which the container closures 3 are conveyed via the conveyor system 1 to the closure device 15 . figure 1 The closing device 15 in is implemented here as a single closing station. Particularly preferably, however, the closing device 15 is a continuously operating closing device carousel with a plurality of closing stations arranged at a uniform distance from one another on the circumference of the closing device carousel. The uninterrupted supply of the container closures 3 expediently results in a high capacity of the delivery system 1 for continuous supply. The container 10 is closed with the closure 3 by means of the closure device 15 . In this case, the container 10 is designed as a bottle and the container closure 3 as a screw closure. In this case, the conveyor system 1 forms a channel 2 in which the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com