Automatic conveying press-fitting mechanism for bottle plugs

An automatic conveying and stopper technology, applied in the direction of stopper feeding, non-threaded stoppers, etc., can solve the problems of low production efficiency, waste of production cost, poor consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

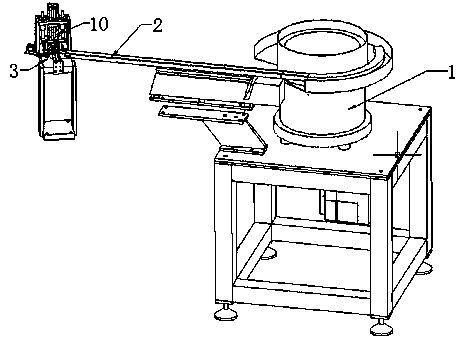

[0021] The bottle stopper automatic conveying and pressing mechanism of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] As shown in the figure, the cork automatic conveying and pressing mechanism of the present invention includes a pressing platform 3 connected to the cork conveying channel 2 of the vibrating feeding device 1. As can be seen from the figure, the cork conveying channel 2 has a The corks in the vibrating feeding device 1 can enter the cork conveying channel 2 after being vibrated. The size of the cork conveying channel 2 can be adjusted, so it can be applied to corks of different specifications. , the bottle stoppers 4 to be pressed are vibrated from the vibrating feeding device and are arranged sequentially through the bottle stopper conveying channel to enter the pressing platform 3. The pressing platform 3 is provided with a No. 1 working position 5 and a No. 2 wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com